Silicon micro-powder with surface chemical modification, preparation method and application of same

A surface chemical and surface modification technology, which is applied in the field of surface modification of non-metallic materials, can solve the problems of high rigidity and easy delamination of epoxy adhesive, and achieve the effect of improving toughness and good dispersibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

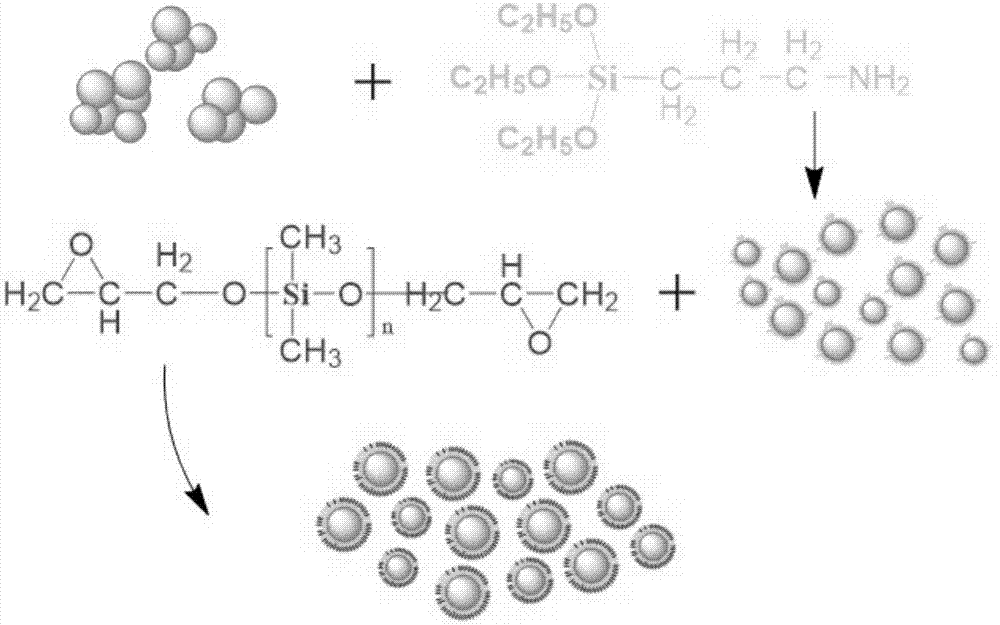

[0034] see figure 1 , the embodiment of the present invention provides a method for preparing surface chemically modified silicon micropowder, comprising the following steps:

[0035] Step (1), carrying out hydroxylation treatment on the surface of silicon micropowder;

[0036] Step (2), mixing and reacting the surface hydroxylated silicon micropowder with a coupling agent to obtain coupling agent modified silicon micropowder;

[0037] Step (3), adding organosilane to the coupling agent-modified silicon micropowder obtained in step (2) for reaction to obtain surface-modified silicon micropowder.

[0038] Specifically, the hydroxylation treatment described in step (1) includes:

[0039] Add silicon micropowder into dilute sodium hydroxide solution, reflux reaction under stirring condition for 1-5 hours, separate solid phase components, and then wash separated solid phase components with acidic alcohol solution to obtain surface hydroxylated silicon micropowder. In the embodi...

Embodiment 1

[0055] 1. The embodiment of the present invention provides a surface chemically modified silica powder, the specific preparation method is as follows:

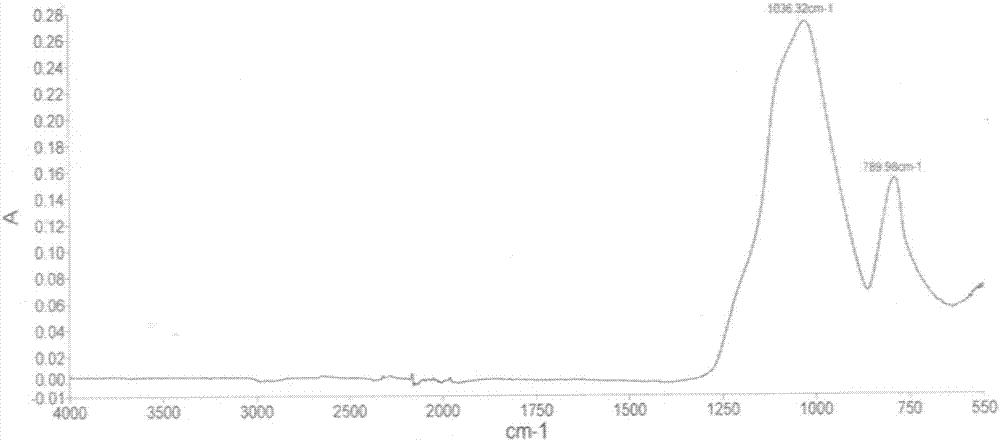

[0056]10.0 g of microsilica filler was immersed in 50 ml of dilute sodium hydroxide solution with a mass fraction of 5%, and reflux reaction was carried out at 90° C. for 3 h under constant temperature and stirring. After the reaction is completed, centrifuge to obtain the solid phase components, and use an ethanol solution with a mass fraction of 3% and a pH value of 4 to wash the solid phase components. The number of times of washing is twice, and the consumption of each ethanol solution is 30ml to obtain a surface Hydroxylated silica powder.

[0057] Add 1.0 g of KH-550 silane coupling agent to 19.2 ml of ethanol aqueous solution (ethanol: water = 9:1, mass ratio), and adjust the pH of the system to 8. Add the surface-hydroxylated silicon micropowder into the coupling agent solution, stir evenly, and then reflux at 80° C. ...

Embodiment 2

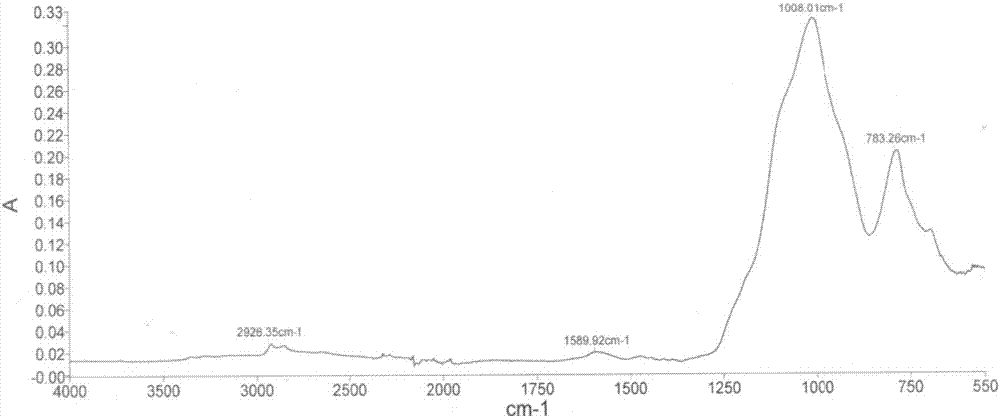

[0069] 1. The embodiment of the present invention provides a surface chemically modified silica powder, the specific preparation method is as follows:

[0070] 10.0 g of microsilica filler was immersed in 50 ml of dilute sodium hydroxide solution with a mass fraction of 5%, and reflux reaction was carried out at 90° C. for 3 h under constant temperature and stirring. After the reaction is completed, centrifuge to obtain the solid phase components, use a mass fraction of 3%, and use an ethanol solution with a pH value of 4 to wash the solid phase components. The number of times of washing is twice, and the consumption of each ethanol solution is 30ml to obtain a surface Hydroxylated silica powder.

[0071] Add 5.0g KH-550 silane coupling agent to 96ml ethanol aqueous solution (ethanol:water=9:1, mass ratio), adjust the pH of the system to 8. Add the surface-hydroxylated silicon micropowder into the coupling agent solution, stir evenly, and then reflux at 80° C. for 3 hours. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com