Mold quenching method

A mold and oil cooling technology, applied in the direction of quenching agent, manufacturing tool, furnace type, etc., can solve the problems of long time, poor productivity, unstable metal structure, etc., and achieve the effect of improving surface toughness and improving life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0078] The present invention is described in more detail using the following examples.

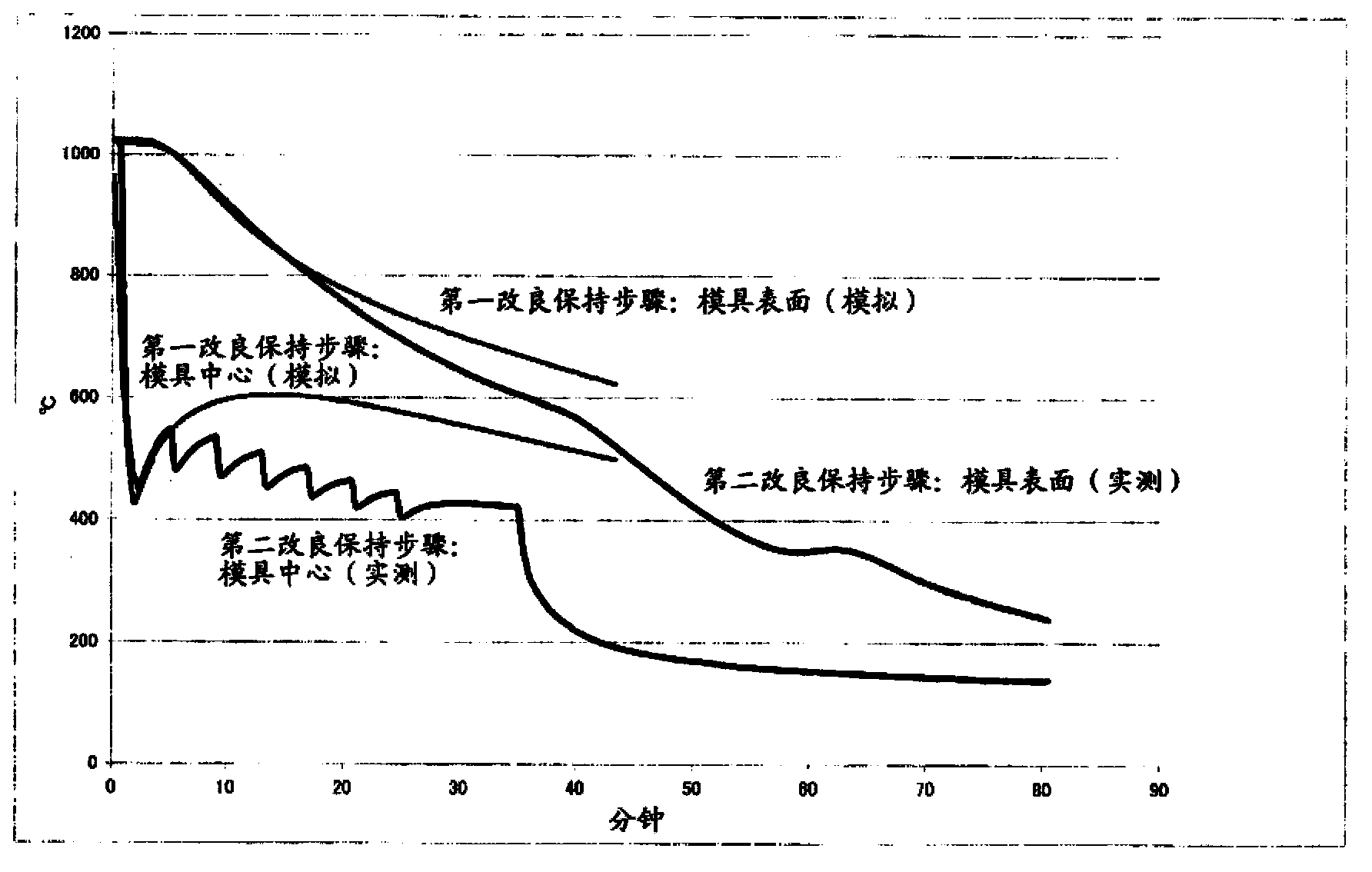

[0079] Cut out a block of 300 mm (w) x 300 mm (l) x 300 mm (t) from the mold material for a hot mold with the composition shown in Table 1, and make the first sample for the first improvement holding step and the second improvement Hold the second sample of the step. The prepared alloys are all materials equivalent to Japan Industrial Standard (JIS)-SKD61.

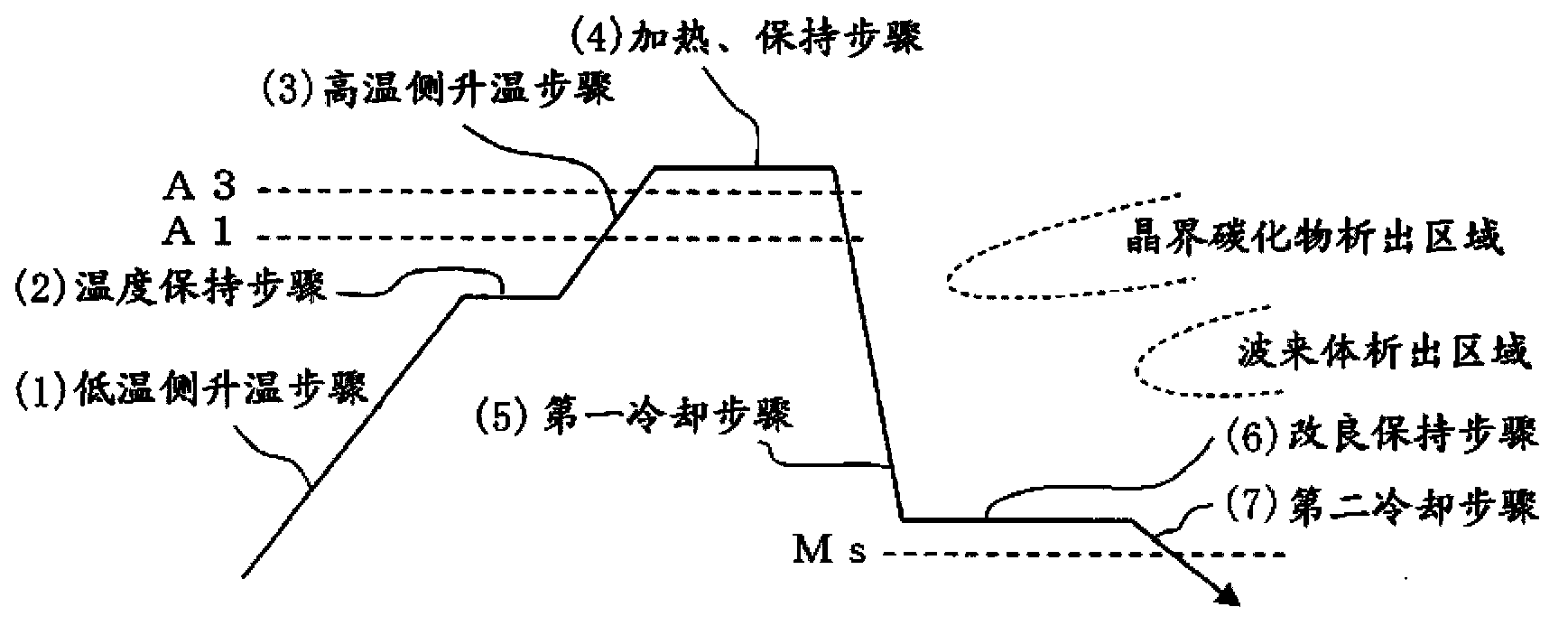

[0080] The A1 transformation point of the alloy is 850°C, the A3 transformation point is 895°C, the Ms point is 300°C, and the nose (nose) of the grain boundary carbide precipitation region is 700°C-20 minutes.

[0081] [Table 1]

[0082] (wt% (weight percentage))

[0083] C Si mn Cr Mo V The remaining part 0.37 0.95 0.40 5.10 1.36 0.95 Fe and impurities

[0084] Quenching treatment was performed using the above-mentioned samples. The temperature conditions up to the heating and holding steps are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com