Concrete base wet-curing anticorrosive adhesive material and preparation method thereof

A moisture-curing, adhesive technology, applied in the direction of adhesive types, polymer adhesive additives, non-polymer adhesive additives, etc., can solve the problems of prolonged construction time, large environmental pollution, and low curing content. , to achieve the effect of high surface toughness, good leveling performance and strong adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

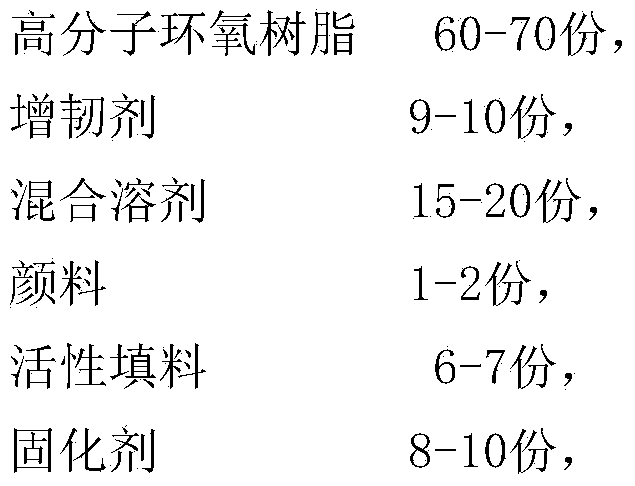

[0038] A concrete foundation moisture-curing anti-corrosion adhesive material, the composition of which is as follows in parts by weight of raw materials:

[0039]

[0040] The mixed solvent is a mixture of butanol, xylene and KH-559, and the mass ratio of butanol:xylene:KH-559 is 1:2:7. KH-559 is a mixture of butyl ester, styrene, methyl ester and ethyl ester in a mass ratio of 1.5:1.5:1.8:1.2.

Embodiment 2

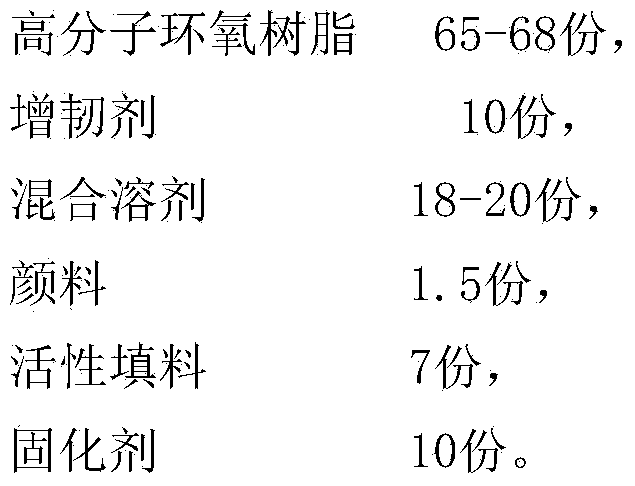

[0071] A concrete foundation moisture-curing anti-corrosion adhesive material, the composition of which is as follows in parts by weight of raw materials:

[0072]

[0073] The mixed solvent is a mixture of butanol, xylene and KH-559, and the mass ratio of butanol:xylene:KH-559 is 1:1.6:6. KH-559 is a mixture of butyl ester, styrene, methyl ester and ethyl ester in a mass ratio of 1.5:1.5:1.8:1.2.

Embodiment 3

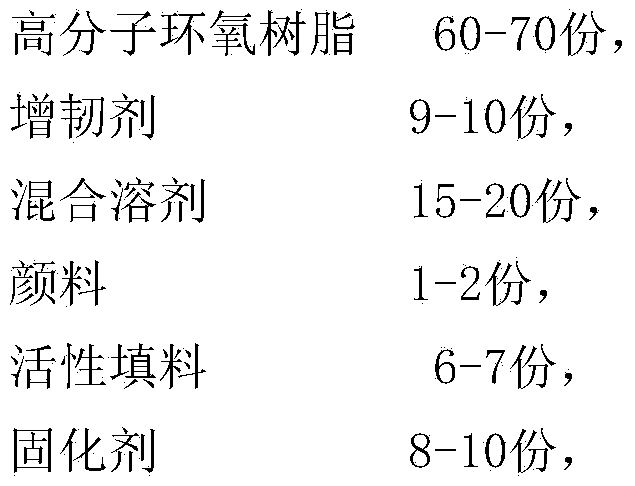

[0075] A concrete foundation moisture-curing anti-corrosion adhesive material, the composition of which is as follows in parts by weight of raw materials:

[0076]

[0077] The mixed solvent is a mixture of butanol, xylene and KH-559, and the mass ratio of butanol:xylene:KH-559 is 1:2.5:.57. KH-559 is a mixture of butyl ester, styrene, methyl ester and ethyl ester in a mass ratio of 1.5:1.5:1.8:1.2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com