Preparation method of toughened and anti-aging unsaturated polyester resin

A polyester resin, unsaturated technology, applied in the field of preparation of toughened anti-aging unsaturated polyester resin, can solve the problems of poor toughness, easy aging, low bond strength, etc., to achieve curing crosslinking promotion, strong anti-oxidation Performance, the effect of excellent adhesive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

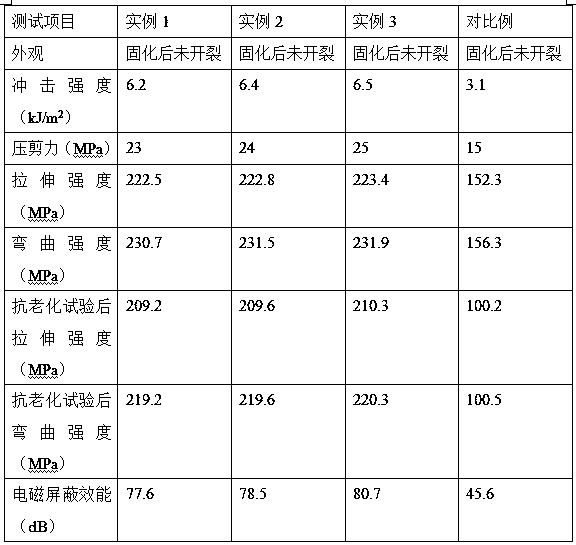

Examples

Embodiment Construction

[0023]In parts by weight, add 50-60 parts of distilled water, 10-15 parts of sodium dodecylsulfonate, 4-5 parts of carbonic acid Sodium hydrogen, start the stirrer to stir at a speed of 200-220r / min, raise the temperature in the water bath to 70-85°C, add 40-45 parts of acrylic acid and 20-30 parts of methacrylic acid into the three-necked flask, and continue the reaction for 10-15 minutes to obtain Seed emulsion; in parts by weight, add 20 to 30 parts of epoxidized soybean oil to the above-mentioned three-necked flask, and then use a dropping funnel to drop 1 to 3 parts of over- Potassium sulfate, after the dropwise addition, keep the temperature for 30-40 minutes, continue to heat up to 90-100 °C, keep the temperature for 45-55 minutes, cool down to 55-60 °C, adjust the pH to 6.0-7.0 with 20% ammonia water by mass fraction, Discharge to obtain acrylate emulsion; add 40-50mL of absolute ethanol and 2-3g of carbon nanotubes to the ultrasonic disperser, control the ultrasonic f...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com