PVC foamed fold-proof plate and preparation method thereof

A PVC resin powder and folding-resistant technology, applied in the field of PVC foamed folding-resistant board and its preparation, can solve the problems of increasing the use effect of joint surface gaps, affecting popularization and use, and being unable to directly bend, so as to reduce the combined interface and joint Surface, cost-effective, uniform performance and folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] The PVC foamed fold-resistant board described in Example 1 is composed of a core layer, an upper skin layer and a lower skin layer, and the raw materials of each layer are composed as follows:

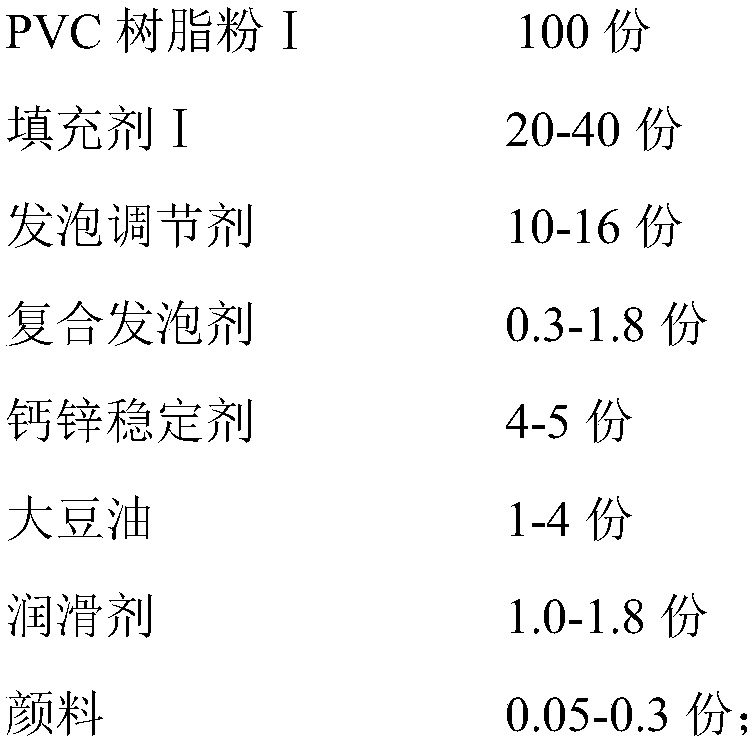

[0047] The core layer is a foamed polyvinyl chloride material, which consists of the following raw materials in parts by weight:

[0048]

[0049]

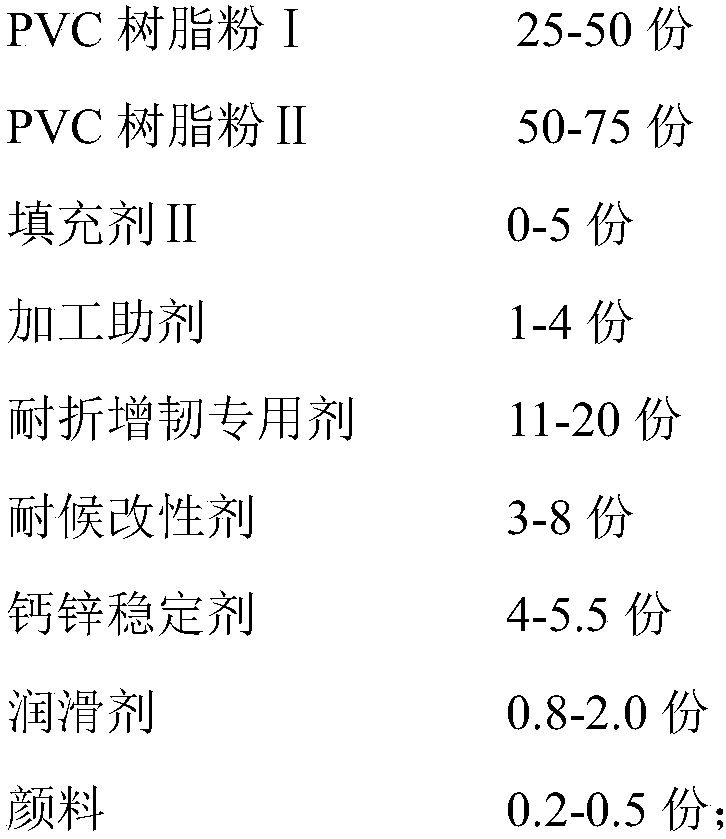

[0050] The upper skin layer and the lower skin layer have the same raw materials, and the skin layer material is composed of the following raw materials in parts by weight:

[0051]

[0052] in:

[0053] The special anti-folding and toughening agent is a high molecular weight acrylate chlorinated polyethylene graft polymer. The manufacturer is Shandong Rike Chemical Co., Ltd., model: ACM-PY-2G.

[0054] PVC resin powder Ⅰ is polyvinyl chloride resin SG-8, the degree of polymerization is 600-800.

[0055] PVC resin powder II is polyvinyl chloride resin SG-5, the degree of polymerization is 1000-1300.

[0056] Filler Ⅰ is li...

Embodiment 2

[0076] The PVC foamed fold-resistant board described in Example 2 is composed of a core layer, an upper skin layer and a lower skin layer, and the raw materials of each layer are composed as follows:

[0077] The core layer is a foamed polyvinyl chloride material, which consists of the following raw materials in parts by weight:

[0078]

[0079]

[0080] The upper skin layer and the lower skin layer have the same raw materials, and the skin layer material is composed of the following raw materials in parts by weight:

[0081]

[0082] in:

[0083] The special anti-folding and toughening agent is a high molecular weight acrylate chlorinated polyethylene graft polymer. The manufacturer is Shandong Rike Chemical Co., Ltd., model: ACM-PY-2G.

[0084] PVC resin powder Ⅰ is polyvinyl chloride resin SG-8, the degree of polymerization is 600-800.

[0085] PVC resin powder II is polyvinyl chloride resin SG-5, the degree of polymerization is 1000-1300.

[0086] Filler Ⅰ is ...

Embodiment 3

[0097] The PVC foamed fold-resistant board described in this embodiment is composed of a core layer, an upper skin layer and a lower skin layer, and the raw materials of each layer are composed as follows:

[0098] The core layer is a foamed polyvinyl chloride material, which consists of the following raw materials in parts by weight:

[0099]

[0100] The upper skin layer and the lower skin layer have the same raw materials, and the skin layer material is composed of the following raw materials in parts by weight:

[0101]

[0102] in:

[0103] The special anti-folding and toughening agent is a high molecular weight acrylate chlorinated polyethylene graft polymer. The manufacturer is Shandong Rike Chemical Co., Ltd., model: ACM-PY-2G.

[0104] PVC resin powder Ⅰ is polyvinyl chloride resin SG-8, the degree of polymerization is 600-800.

[0105] PVC resin powder II is polyvinyl chloride resin SG-5, the degree of polymerization is 1000-1300.

[0106] Filler Ⅰ is light ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Ash content | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com