Patents

Literature

97results about How to "Anti-scratch" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polyurethane transparent matt topcoat, preparation method and use method thereof

ActiveCN101381581AFeel smoothGood flexibilityLiquid surface applicatorsPolyurea/polyurethane coatingsWaxLow speed

Owner:SHENZHEN GRANDLAND ENVIRONMENTAL COATING CO LTD

Continuous adjustment screen printing process of water-based gloss oil

The invention belongs to the technical field of printing and particularly relates to a continuous adjustment screen printing process of water-based gloss oil. The continuous adjustment screen printing process comprises the following steps of: 1) manufacture of continuous adjustment image files; 2) manufacture of films; 3) cleaning of the films; 4) stretching of a screen; 5) gluing; 6) positioning of the films; 7) exposure; 8) development; 9) drying; and 10) screen printing. The continuous adjustment screen printing process has the advantages that 1) the wear resistance is strong, the scratching is resisted, the screen-printed surface is wear-resistant, water-repellent and oil-repellent, and no color-fading phenomenon occurs on the surface of a printed product; 2) the film forming speed is fast, and the drying is rapid; 3) the high temperature resistance and the hot-sealing performance are good; 4) the degree of planeness is good, and the winding force resistance is strong; 5) the used water-based gloss oil has better leveling property, can realize fast leveling before a coating layer is dried to form a smooth surface, so that the coating layer can have high glossiness; and 6) the water-based gloss oil adopts water as a solvent without toxicity and smell. Compared with the water-based gloss oil used for local glossing, the continuous adjustment screen printing has the advantage that the image layering can be reproduced.

Owner:浙江华人数码科技有限公司

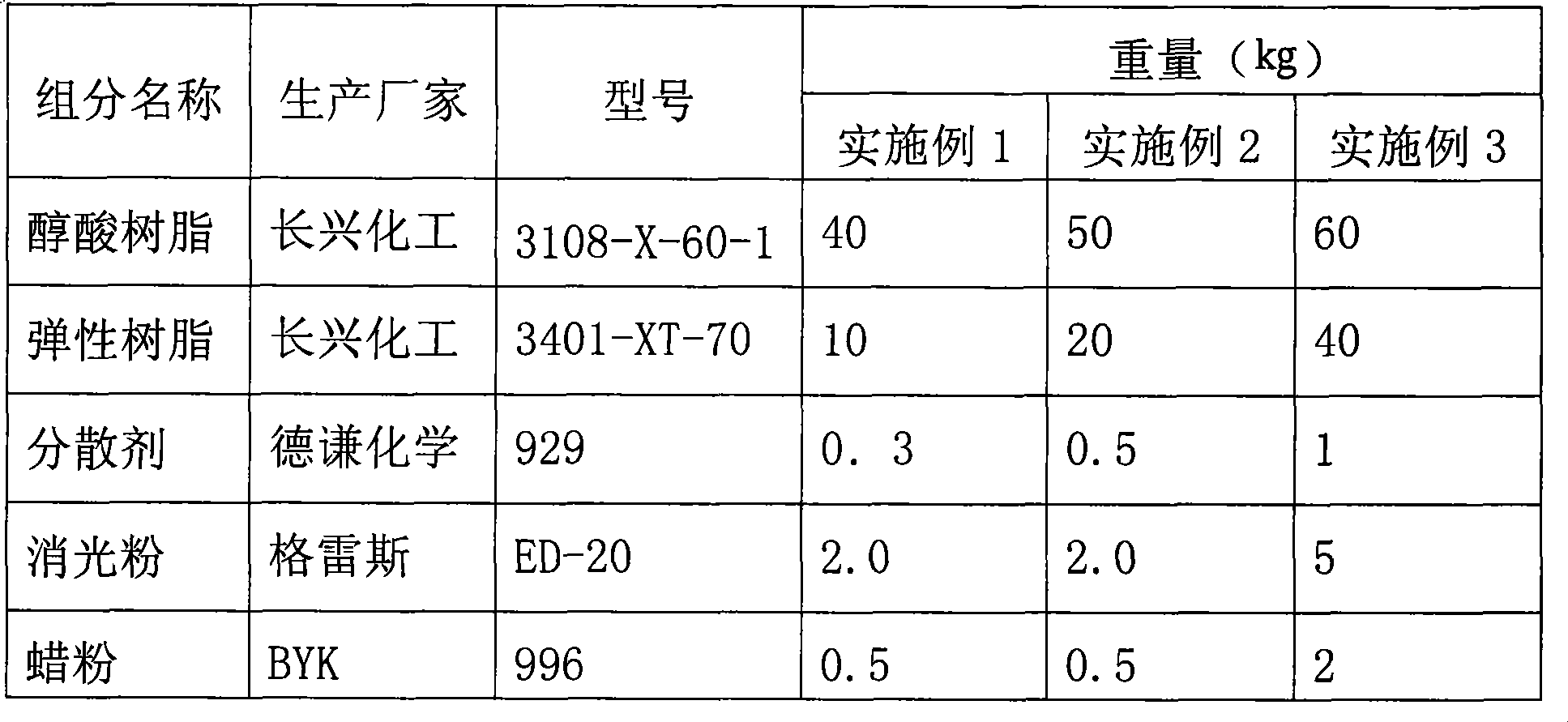

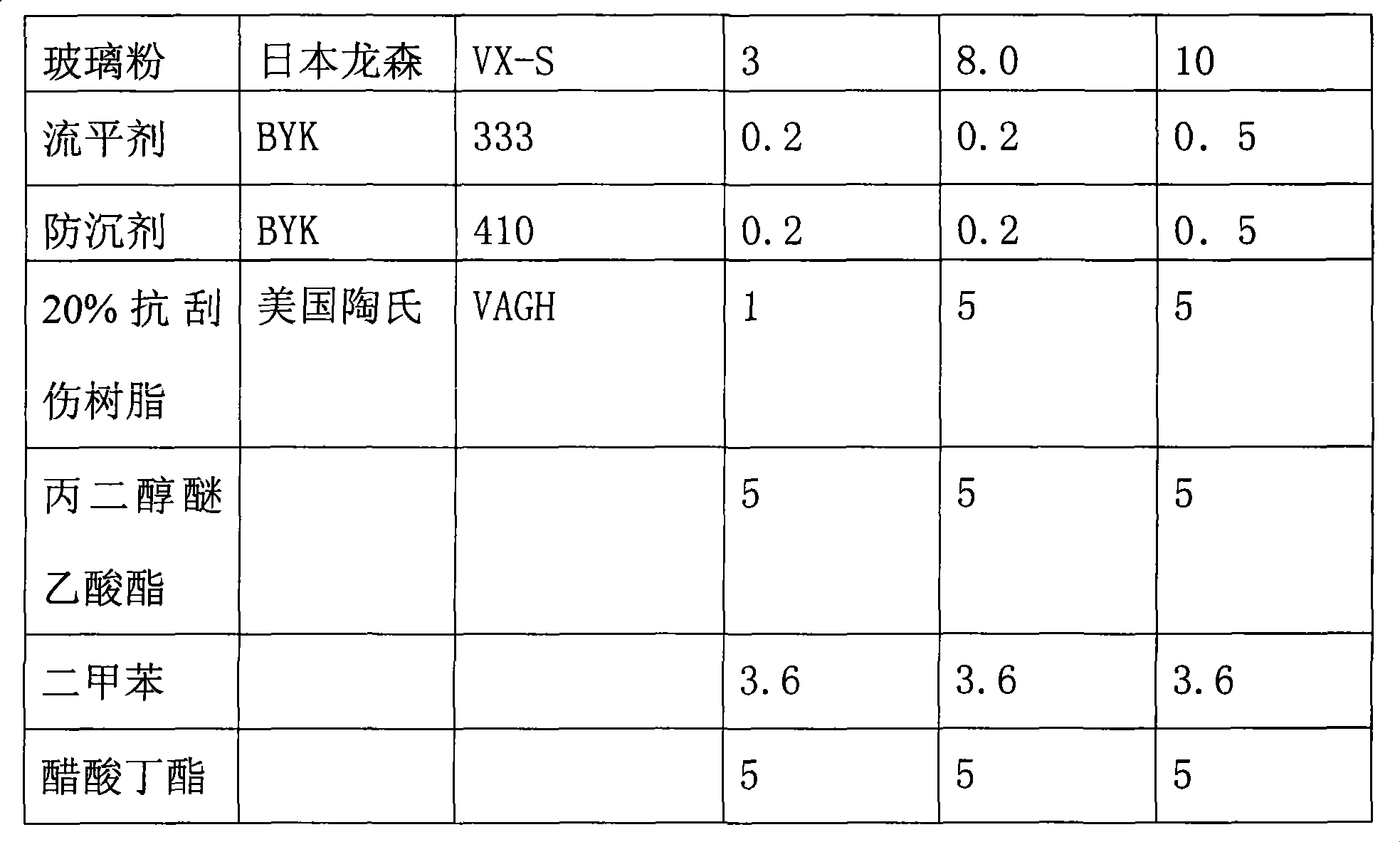

Self-cleaning superhard polysilazane hydrophobic coating and preparation and use method thereof

The invention discloses a self-cleaning superhard polysilazane hydrophobic coating and a preparation and use method thereof, and belongs to the technical field of super-hydrophobic coatings. The self-cleaning superhard polysilazane hydrophobic coating is prepared from the following components in parts by weight: 5 to 25 parts of organic-inorganic hybridized polysilazane, 15 to 30 parts of hydrophobic acrylate resin, 5 to 15 parts of nanometer silicon dixoide and 40 to 250 parts of organic solvent. The self-cleaning superhard polysilazane hydrophobic coating has the advantages that the excellent superhard, super-hydrophobic, scratch-resistant, abrasion-resistant and high-adhesion properties of a coating are realized; the defects of easiness in cracks, voids and the like in the inorganic polysilazane coating along with the increase of coating thickness are overcome; the problem of low hardness of the organic polysilazane is solved; the coating has the advantages that the hardness is high, the adhesion force is high, the easiness in falling and cracking of the coating is avoided, and the abrasion-resistant and scratch-resistant properties of the coating are ensured; the preparation technology is simple, the implementing is easy, and the preparation technology is suitable for widely popularized and applied.

Owner:BEIJING NEATRITION TECH CO LTD

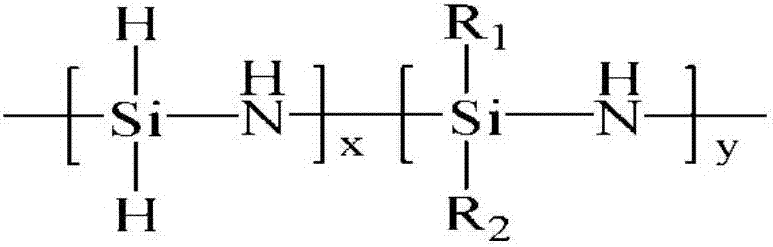

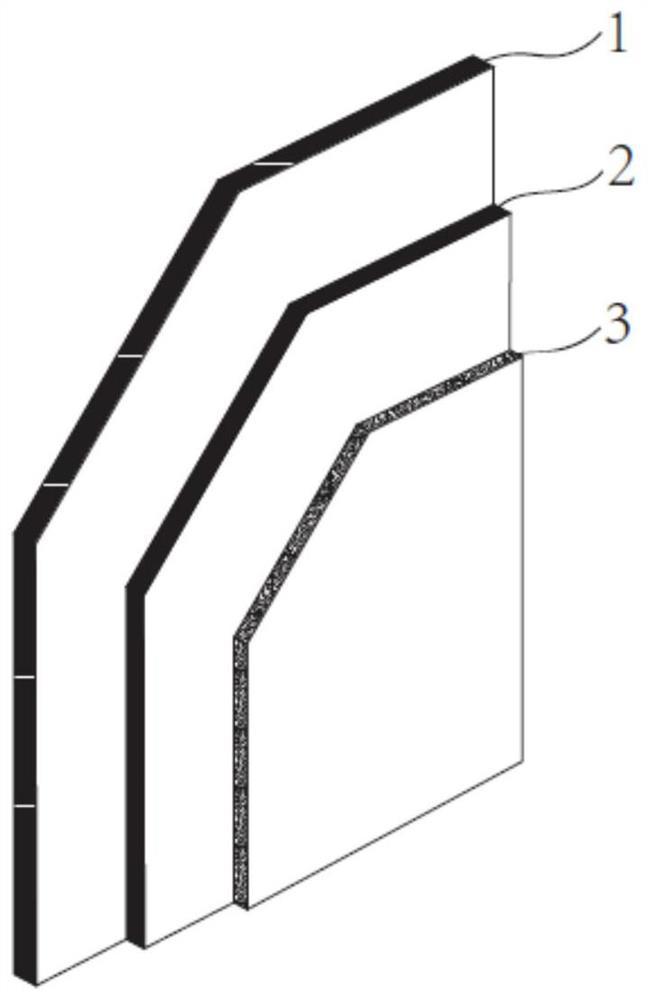

Composite board and preparation method thereof

PendingCN107571577AStrong impact resistanceHigh mechanical strengthLamination ancillary operationsSynthetic resin layered productsSurface layerAdhesive

The invention discloses a composite board, comprising a composite layer, an upper adhesive layer and a lower adhesive layer respectively bonded with the upper and lower surfaces of the composite layerto form an integral body with the composite layer, and a functional surface layer bonded with the upper surface of the upper adhesive layer to form an integral body with the upper adhesive layer. According to the invention, the upper adhesive layer and the lower adhesive layer respectively cover the upper and lower surfaces of the composite layer, and the functional surface layer is laminated with the upper surface of the upper adhesive layer via a film spraying method, so the prepared composite board has excellent impact resistance and the advantages of high mechanical strength, ageing resistance, scratch resistance, etc.; meanwhile, the functional surface layer endows the composite board with unique appearance and functionality; moreover, since one part of the upper adhesive layer is embedded into the upper surface of the composite layer and another part of the upper adhesive layer is embedded into the lower surface of the functional surface layer, such mechanical bonding can improve peeling strength between the functional surface layer and the composite layer; and the lower adhesive layer may be embedded into the lower surface of the composite layer so as to realize bonding between the composite board and other materials.

Owner:GUANGZHOU KINGFA CARBON FIBER NEW MATERIALS DEV

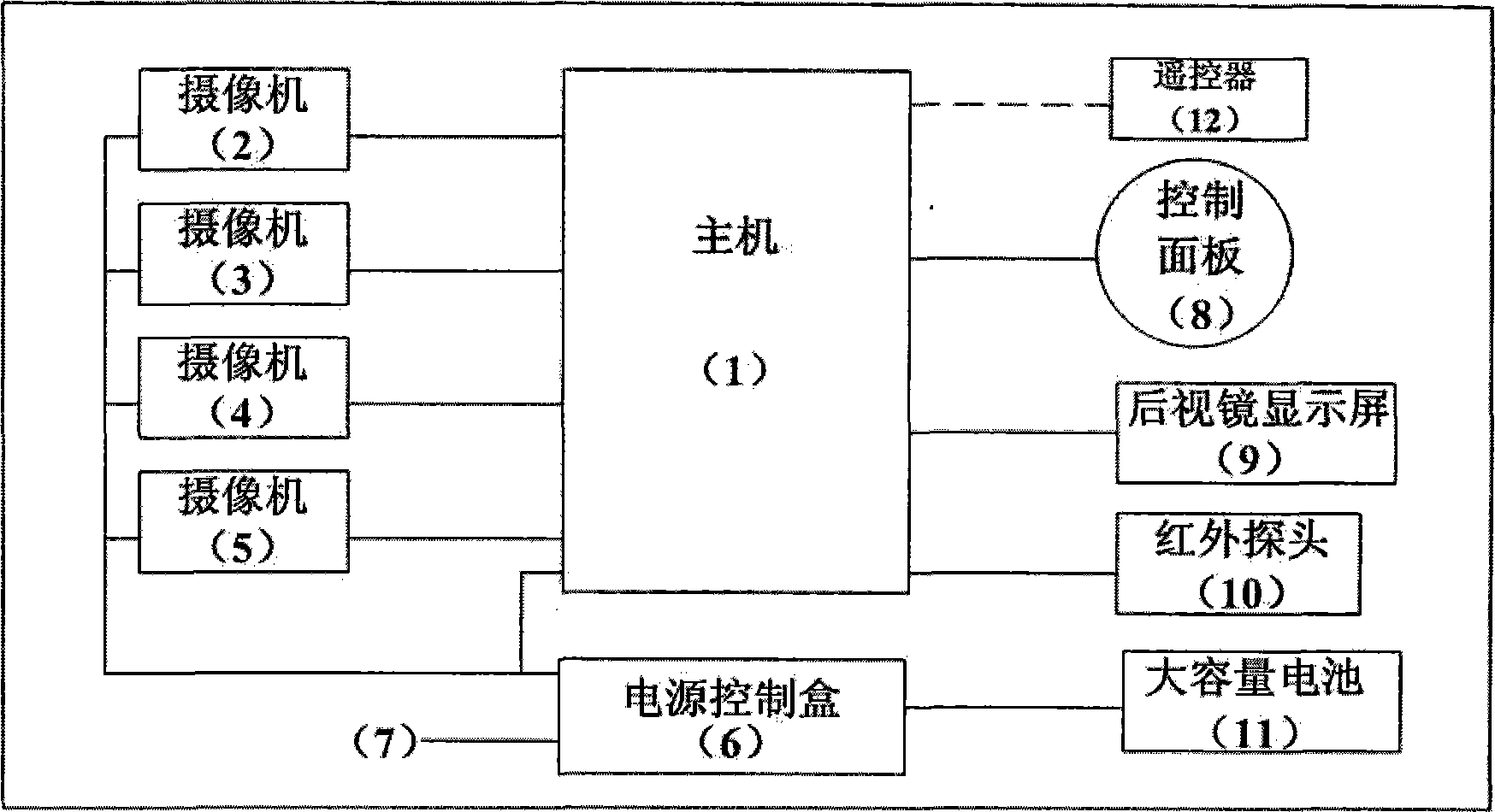

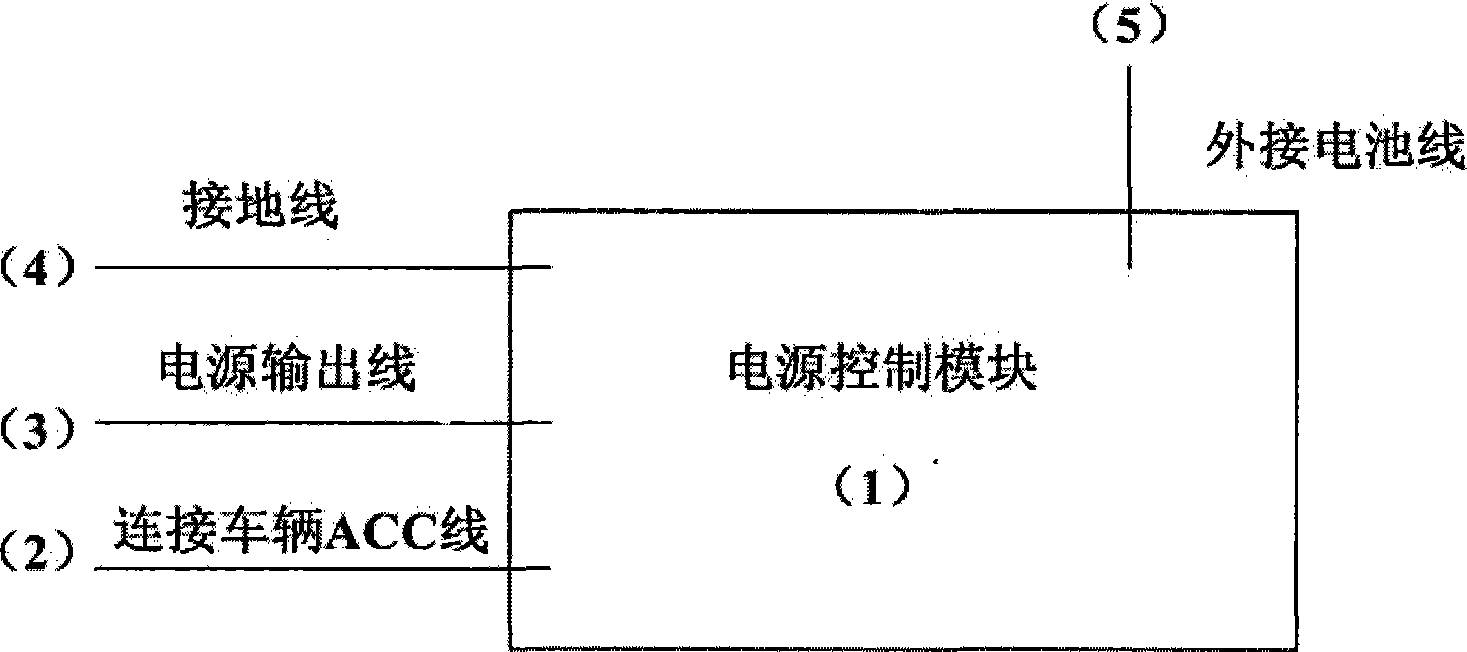

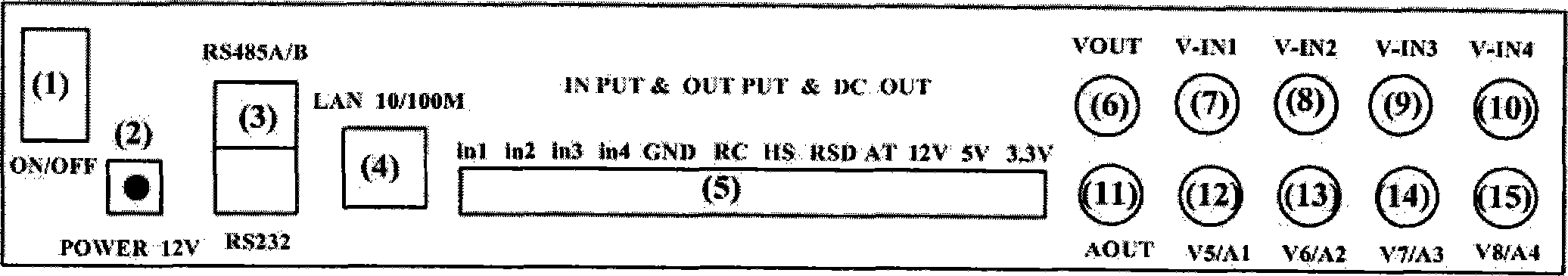

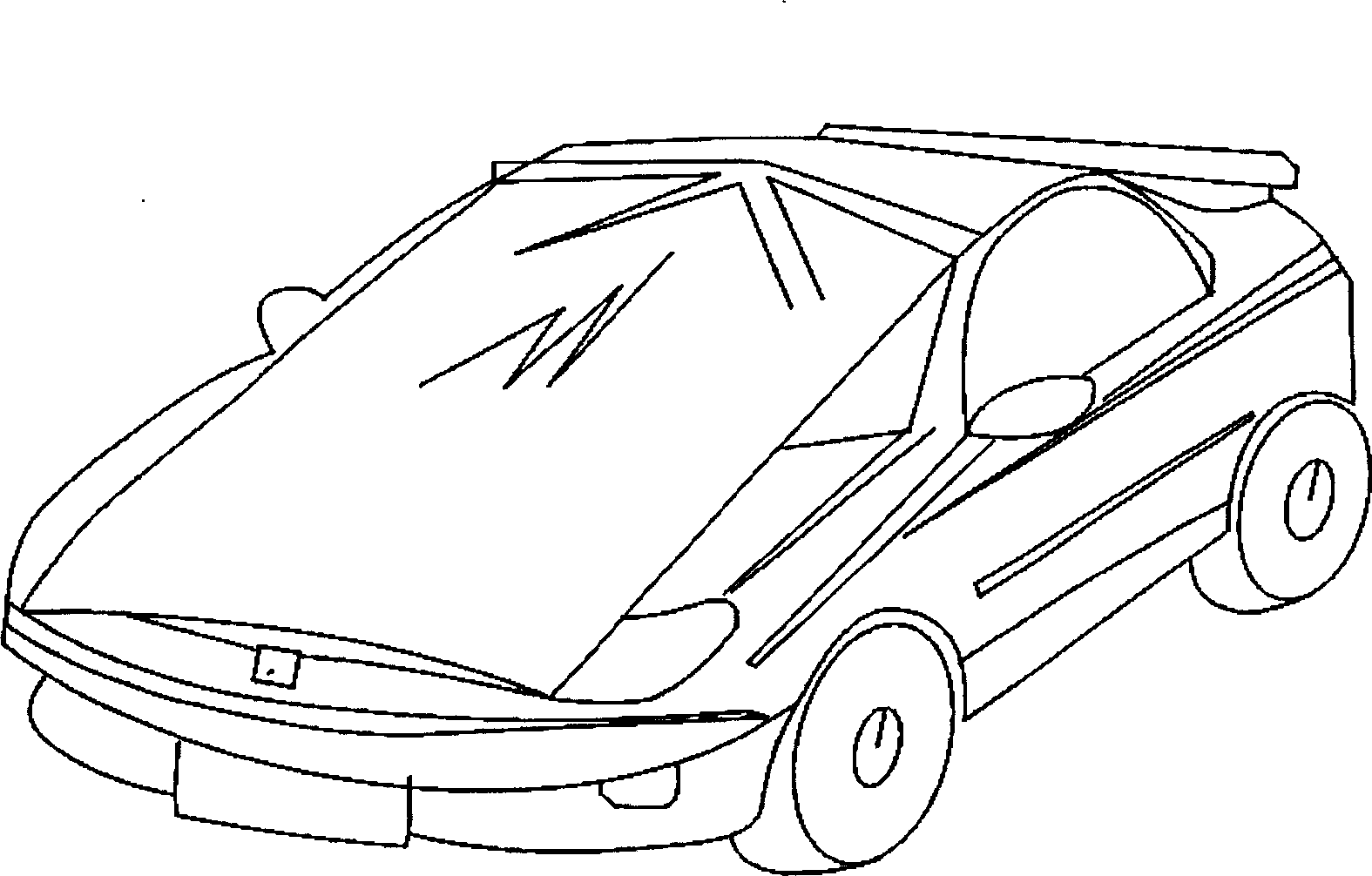

Car panoramic intelligent safeguard system

A car panoramic intelligent safeguard system relates to the field of communication technology, particularly to the audio / video encoding and decoding and network transmission technologies. The car panoramic intelligent safeguard system aims at providing a guard means for problems happening to the owners of cars such as malicious scratch, burglaries, robberies, kidnapping and traffic disputes. The car panoramic intelligent safeguard system is composed of a host, vehicle-mounted wide-angle cameras, a power control box, a control panel, a rearview mirror display, an infrared probe, a high-capacity battery and a remote control. Four or six vehicle-mounted wide-angle cameras are mounted on a car to achieve wide-angle shooting of surroundings of the car; the power control box achieves seamless switching of power supplies of the system; the control panel achieves multiple control functions of the system. When anyone approaches or enters the car, the car panoramic intelligent safeguard system can issue alarm to a mobile phone immediately, accordingly the function of one-key remote control video help calling can be achieved. Besides, the car panoramic intelligent safeguard system supports remote video checking through a 3G (third-generation) smartphone.

Owner:BEIJING COOL COMUNICATION TECH

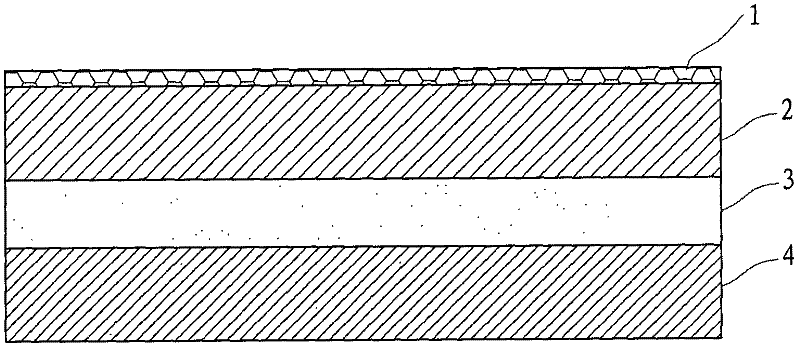

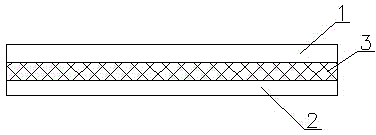

A kind of flexible screen protective film and preparation method thereof

ActiveCN102294862AIncreased flexibilityAnti-scratchSynthetic resin layered productsSputteringCopper oxide

The invention discloses a flexible screen protection film, which is characterized by comprising a base material, a sterilizing and hardening layer, a gluing layer and a release film, wherein the sterilizing and hardening layer is arranged on the first surface of the base material; the gluing layer is arranged on the second surface of the base material; the release film is stuck on the gluing layer; and in addition, the base material is a PU (Poly Urethane) film, a TPU (thermoplastic urethanes) film, a PO (Propylene Oxide) film or a PVC (Poly Vinyl Chloride) film; the sterilizing and hardening layer is plated on the base material by vacuum evaporation, vacuum ion plating or vacuum sputtering; and the sterilizing and hardening layer is pure copper, copper alloy or copper oxide. The invention also discloses a preparation method of the flexible screen protection film. Compared with the prior art, the flexible screen protection film has the advantages that the surface of the protection film has the functions of preventing from starching and sterilizing. The flexibility of the whole protection film is greatly increased, and no creases are generated in the folding or bending process.

Owner:NINGBO SOKEN CHEM

Deep punching stewing-resistant transparent aluminum lid gloss oil and preparation method thereof

The invention relates to light industry aluminum and iron printing coating, in particular to deep punching stewing-resistant transparent aluminum lid gloss oil which is prepared by following steps: polyester resins is taken as basal materials, right amount of methyl etherified tripolycyanamide and butyl etherified benzoguanamine is taken as a cross linking agent, also right amount of closed type polymeric isocyanate and epoxide resins is taken as an additive in an auxiliary way, an auxiliary agent,is added, right amount of acid catalyst is induced, and reserved carboxyl of the basal materials and a small quantity of hydroxide radical are carried out cross linking solidifying reaction under set temperature and time with activated functional groups of epoxide resin carboxyl, a cross linking resin and the acid catalyst. The invention adopts the maximum basal materials-polyester resins, adopts the butyl etherified benzoguanamine, the closed type polymeric isocyanate and the polyester resins to be matched with the polyester resins to be used and has optimized mixture ratio among the composites, thereby reaching the reasonable cross linking density, reducing the internal stress and enhancing the stretchability resistance, the flexible property and the water and stewing resistant property.

Owner:无锡市太湖防腐材料有限公司

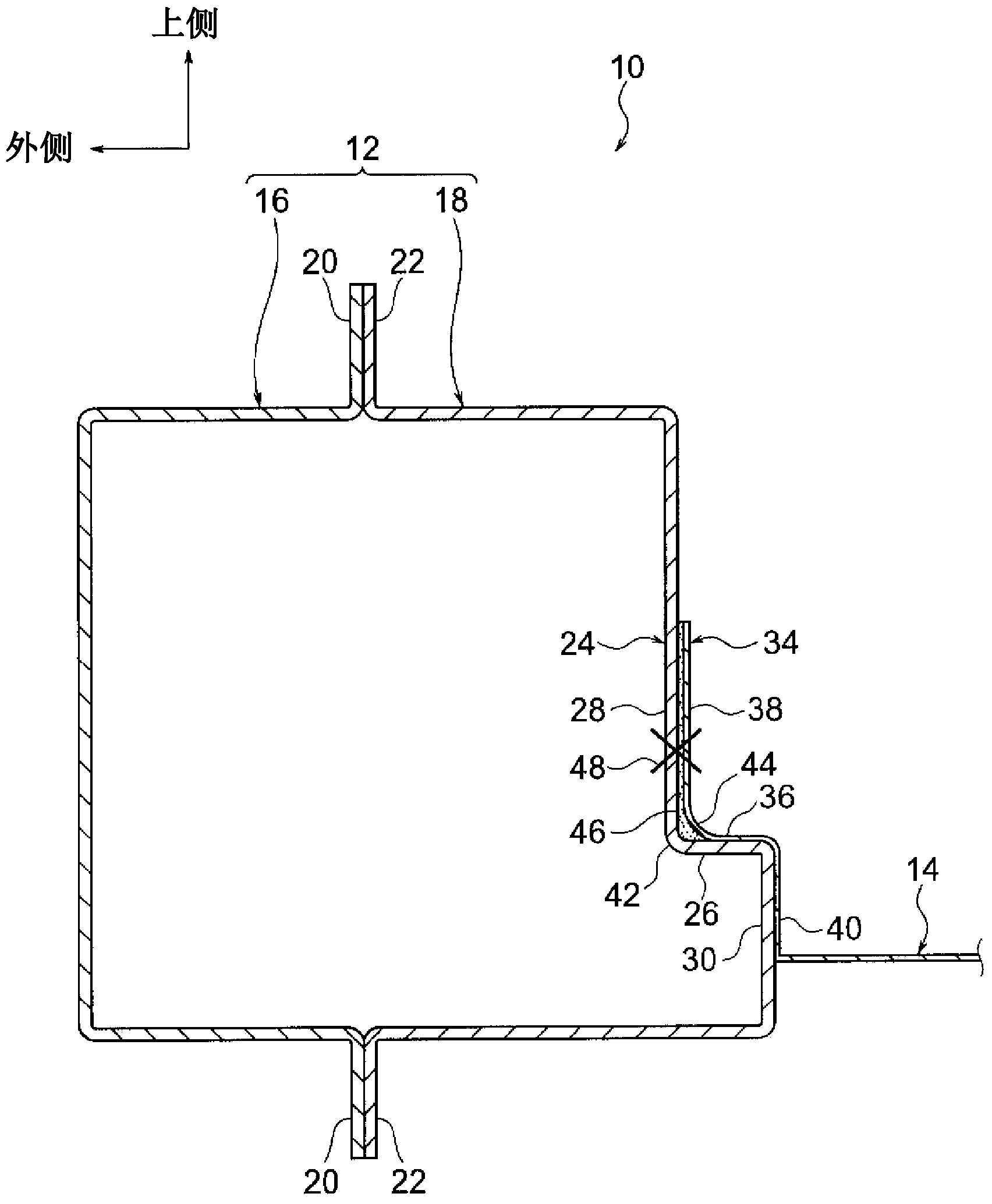

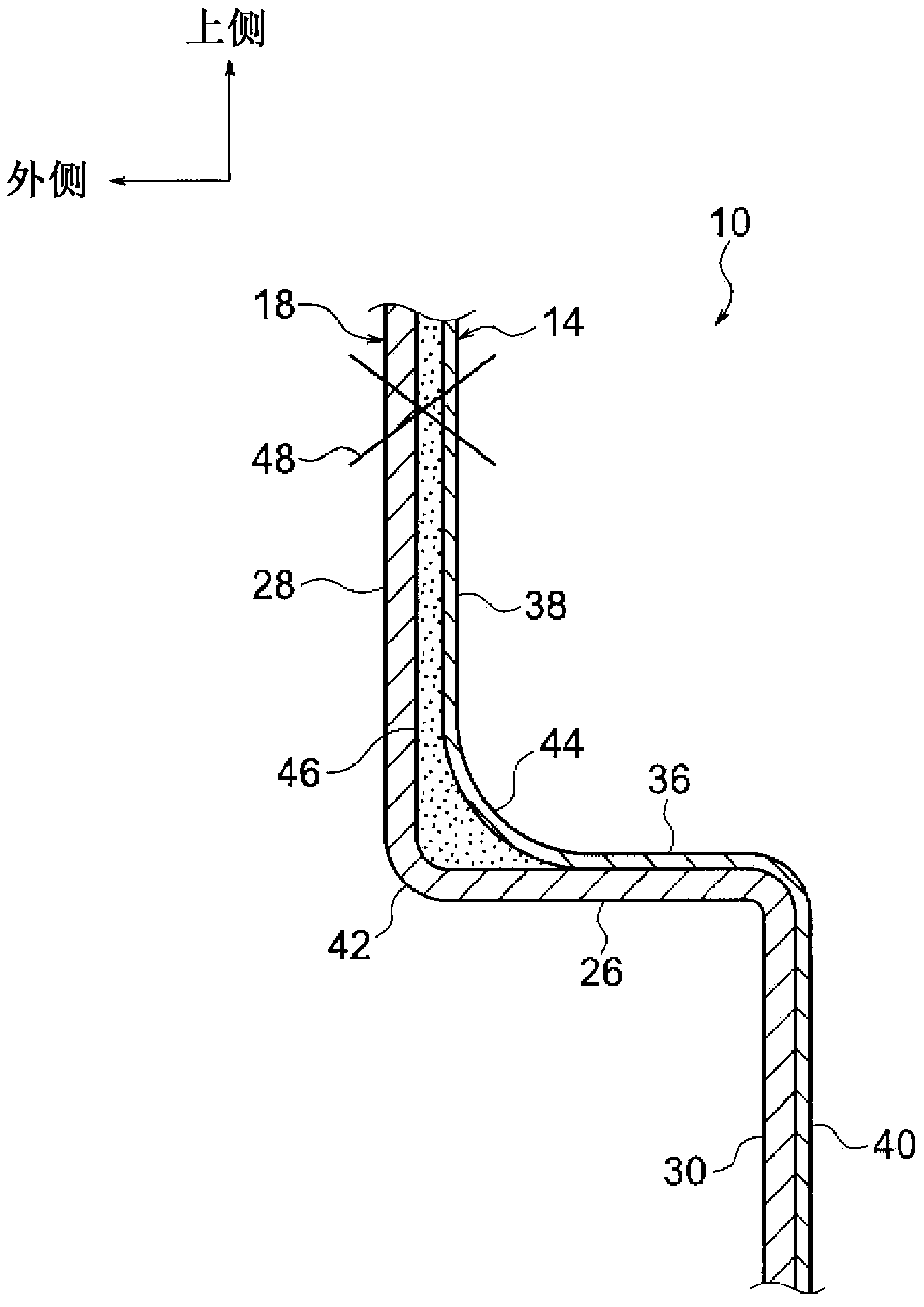

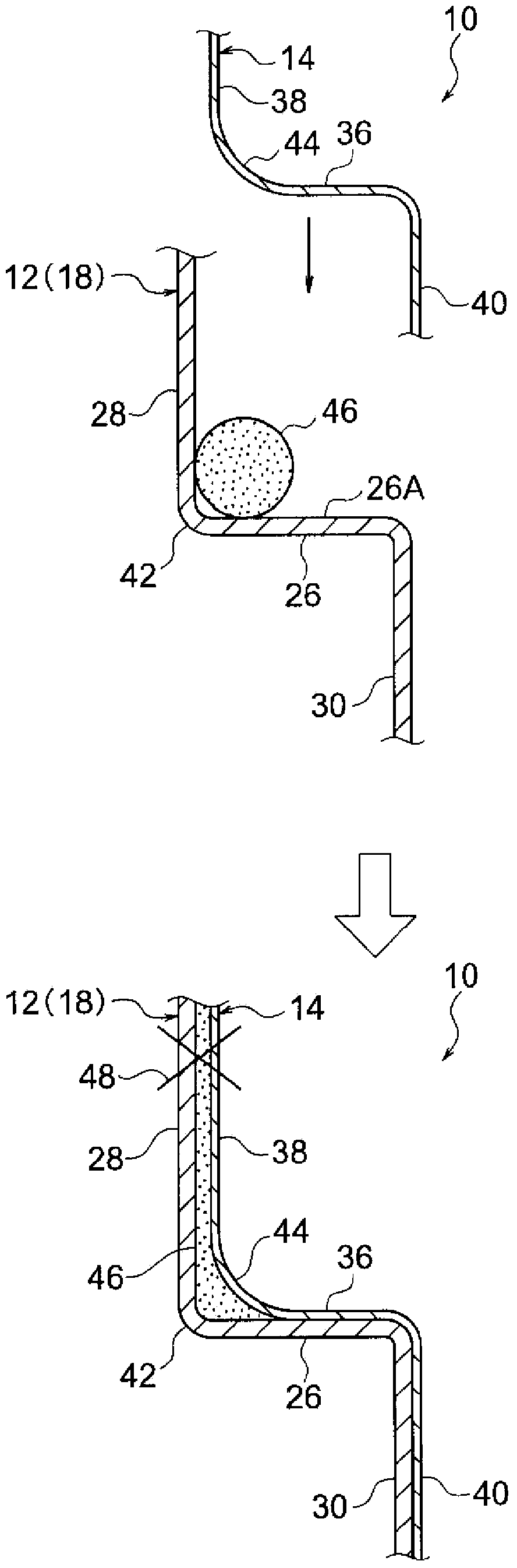

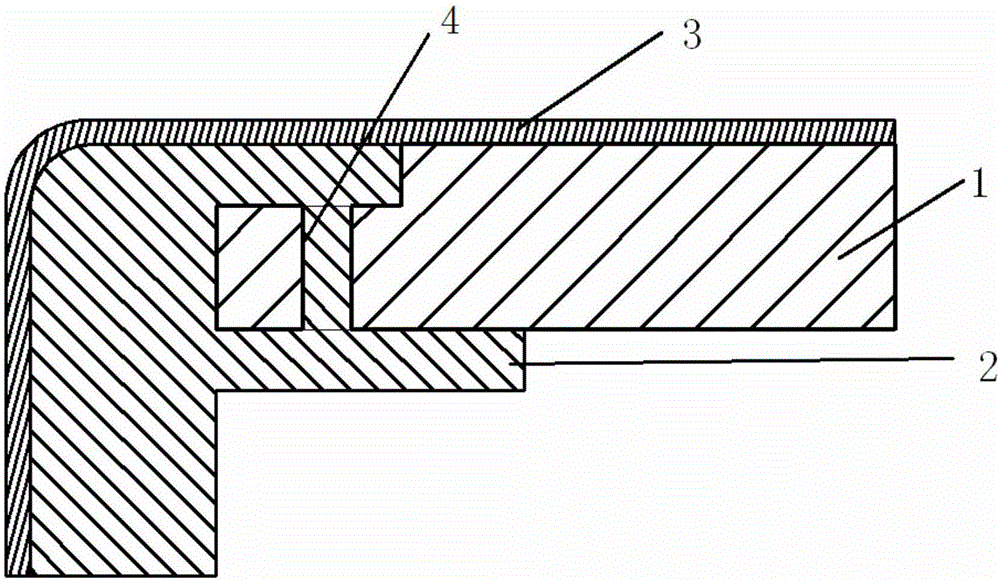

Panel joining structure and panel joining method

ActiveCN104024093ADrip suppressionAnti-scratchMaterial gluingSuperstructure subunitsAdhesiveEngineering

The problem addressed by the present invention is inhibiting the dripping down or scraping off of adhesive when a part to be joined and a part to be joined with are bonded. This panel joining structure (10) is provided with a first panel (18) having a step part (26) extending in a direction that crosses a vertical direction and a joining part (28) extending upward in the vertical direction from one end part of the step part (26) in that crossing direction, and a second panel (14) having a facing part (36) that extends in that crossing direction and also is made to overlap the step part (26) on the upward vertical direction side, a part (38) to be joined that extends in the upward vertical direction from one end part of the facing part (36) in that crossing direction and is joined to the joining part (28) by adhesion and welding, and a downward part (40); that extends downward in the vertical direction from the other end of the facing part (36) in that crossing direction.

Owner:TOYOTA JIDOSHA KK

Two-way separating zip

Owner:DEQILE INNOVATION BEIJING TECH & TRADE CO LTD

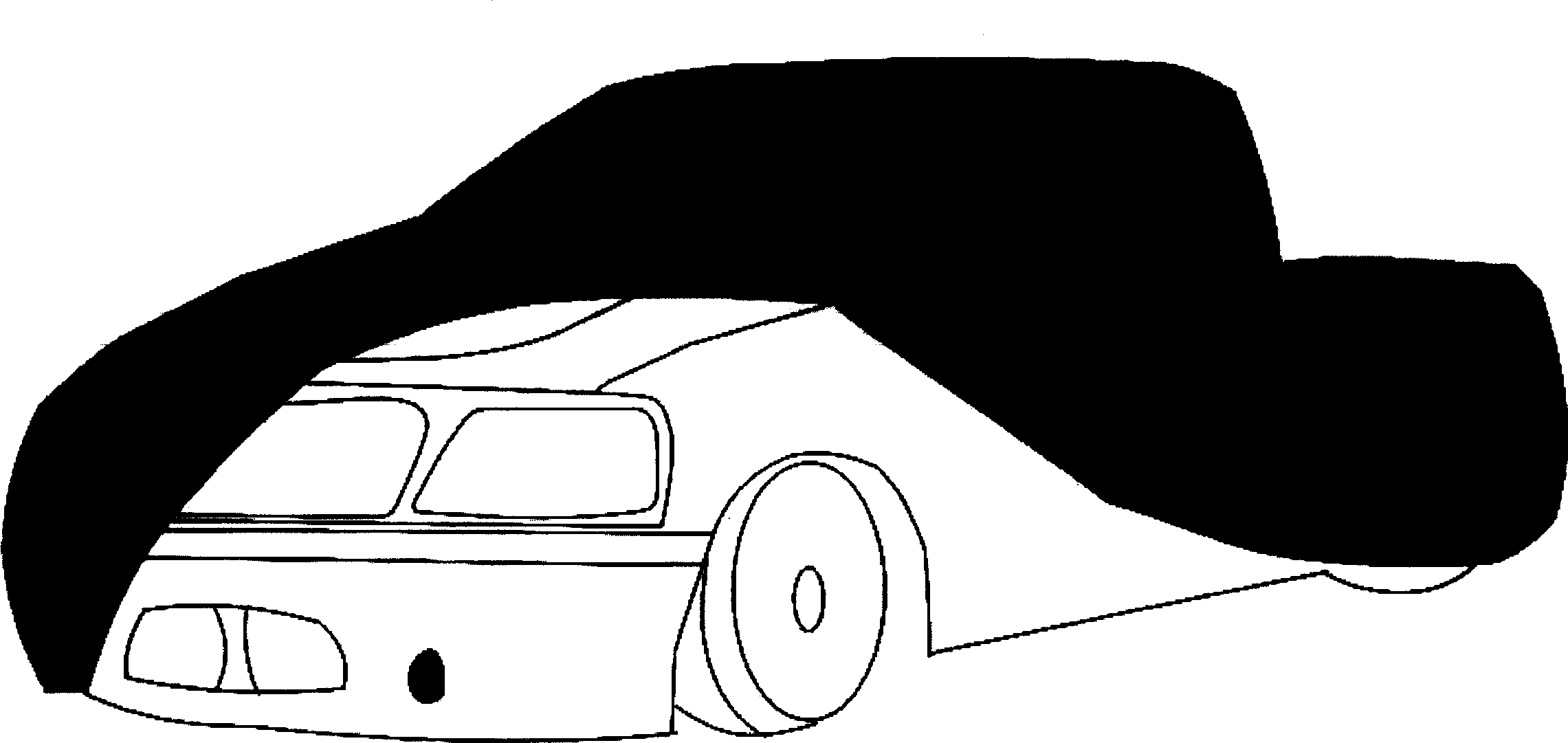

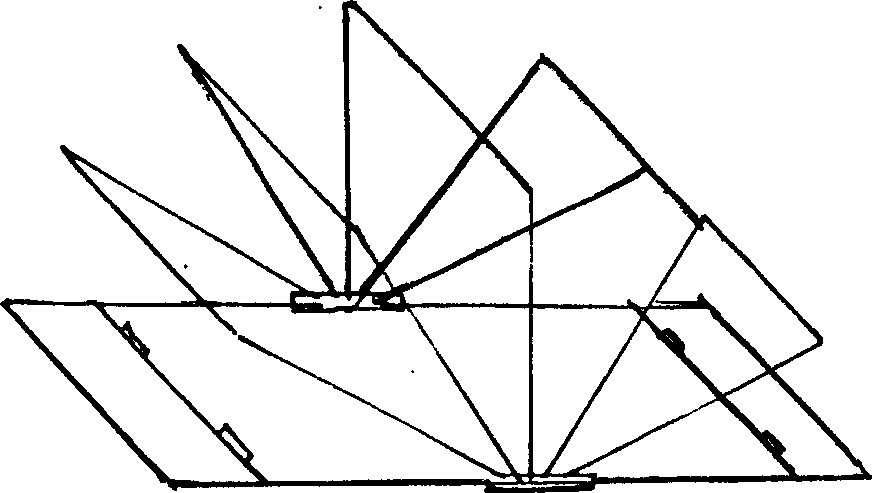

Portable and quickly retracting automobile hood

InactiveCN1663828AExtended service lifeDust-proofRemovable external protective coveringsEngineeringCantilever

The invention discloses a portable and fast retraction cover of automobiles, which comprise the face shield and the framework. The framework includes two base sets, two bearing devices, two cantilever booms and a cantilever overarm. The two base sets, the two bearing devices and the two cantilever booms are separately set at two sides of the automobile and are integrated by the cantilever overarm. The lower end of the bearing devices and the base sets are rotary connected; the cantilever devices and the upper end of the bearing devices are rotary connected and distribute extendedly along the length direction of automobiles. The base sets, the bearing devices and the cantilever devices separately contractively fold. The invention can extend the life of automobiles and is not limited by the place and the time.

Owner:SHANGHAI QINMAN TECH DEV CO LTD

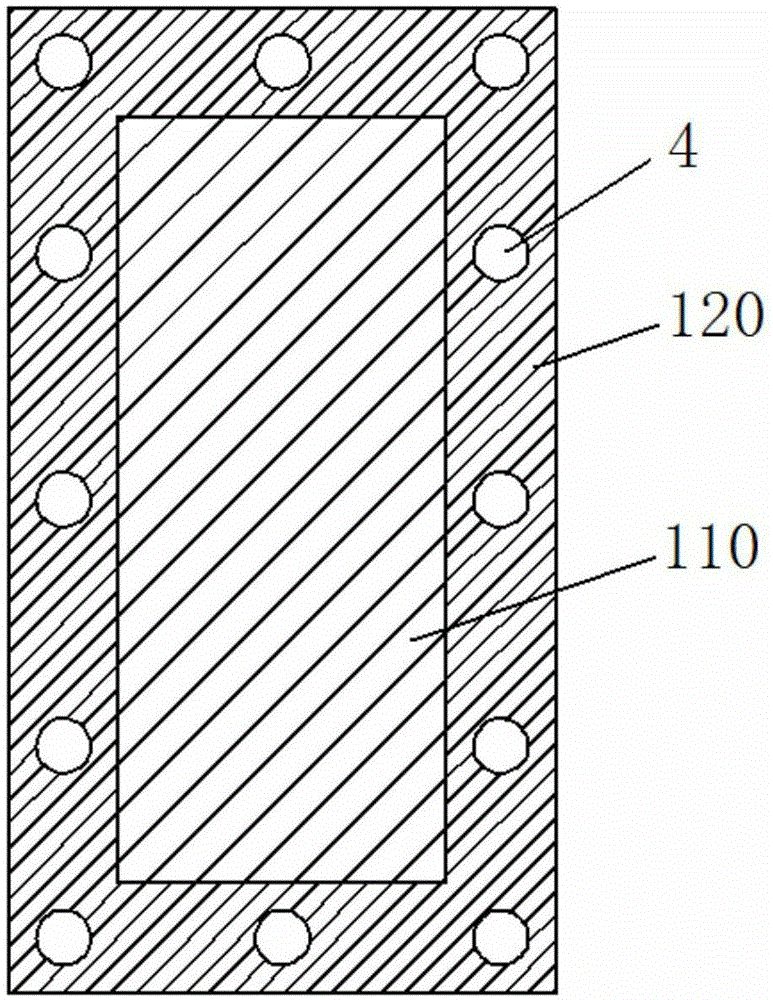

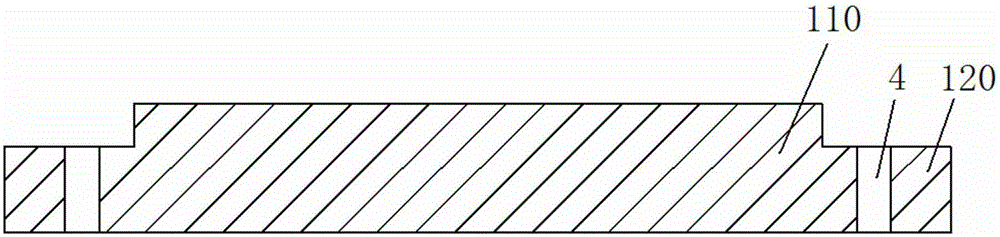

Electronic product shell with carbon fiber and plastic integrated structure and manufacturing method thereof

InactiveCN105172029AImprove bindingNot easy to fall offCoatingsElectrical apparatus casings/cabinets/drawersFiberCarbon fibers

An electronic product shell with a carbon fiber and plastic integrated structure comprises a carbon fiber sheet structure and a plastic structure formed on the carbon fiber sheet structure through injection molding, wherein a pore is formed in the carbon fiber sheet structure, and part of the plastic structure is formed in the pore so as to be buckled and fixed together with the carbon fiber sheet structure through the pore. A method for manufacturing the electronic product shell with the carbon fiber and plastic integrated structure comprises the step of injection molding of the plastic structure. During injection molding of the plastic structure, injection is conducted on the carbon fiber sheet structure provided with the pore to enable part of the plastic structure formed through injection molding to be formed in the pore, and then the plastic structure and the carbon fiber sheet structure are buckled and fixed together through the pore. By the adoption of the electronic product shell with the carbon fiber and plastic integrated structure and the manufacturing method thereof, the plastic part and the carbon fiber part of the shell can be combined seamlessly, and the structure is firmer and more reliable.

Owner:GUANGDONG JANUS SMART GRP CO LTD +1

Double-joint zip

Owner:DEQILE INNOVATION BEIJING TECH & TRADE CO LTD

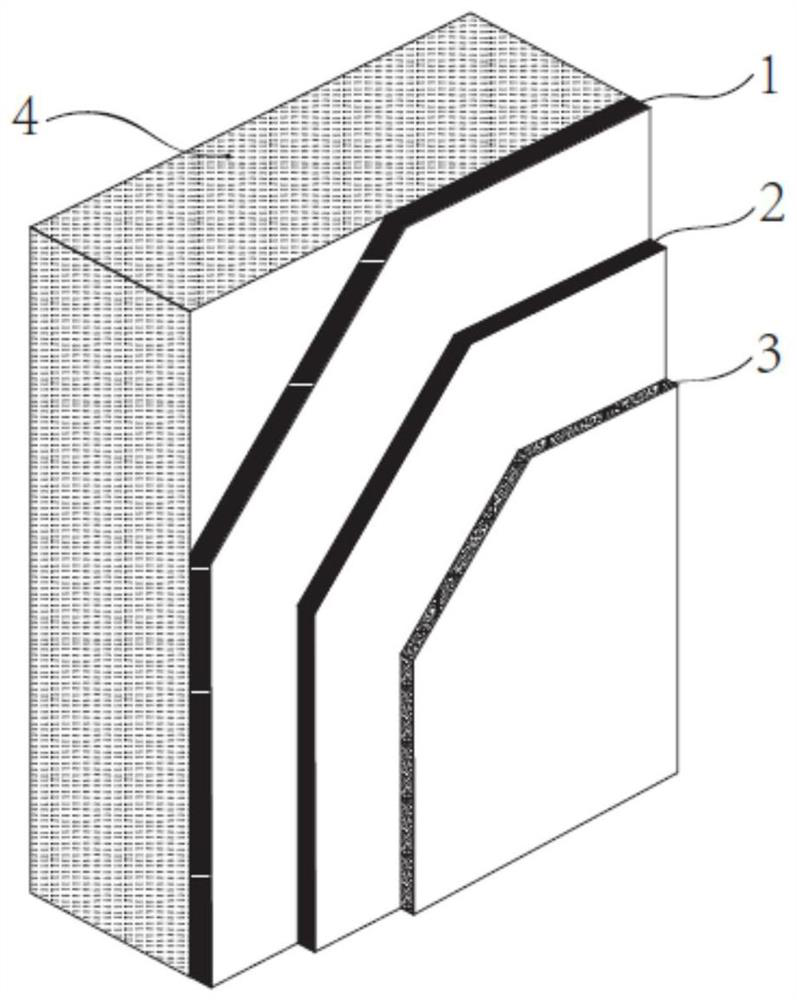

Nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete

The invention relates to a nano inorganic anti-corrosion, anti-seepage and anti-fouling coating structure for hydraulic concrete, which is characterized by comprising a bi-component high-molecular polymer mortar bonding bottom coating, a bi-component high-strength polymer mortar middle coating and a nano anti-corrosion and anti-fouling protective surface coating, wherein the bi-component high-molecular polymer mortar bonding bottom coating, the bi-component high-strength polymer mortar middle coating and the nano anti-corrosion and anti-pollution protective surface coating are sequentially stacked together. The coating structure has the advantages of corrosion prevention, seepage prevention and pollution resistance, good effect, good stability, easiness in cleaning, lasting effect, good applicability and the like.

Owner:韦尔狄(广州)生物工程科技有限公司

Ecological shell powder coating substrate

The invention relates to an ecological shell powder coating substrate, and belongs to the technical field of building materials. The ecological shell powder coating substrate is prepared from the following raw materials in parts by weight: 40-50 parts of shell powder, 20-28 parts of talcum powder, 3.2-5.5 parts of sodium bentonite, 8.5-9.8 parts of a pure acrylic emulsion, 0.2-0.4 part of an antifoaming agent, 0.5-0.6 part of a dispersing agent, 0.26-0.4 part of HPMC (hydroxypropyl methyl cellulose), 0.2-0.35 part of a bactericide, 20-35 parts of water and 0.25-0.45 part of a mildew preventive; a preparation method comprises the following steps: step 1, preparing the shell powder; step 2, preparing the ecological shell powder coating substrate. According to the ecological shell powder coating substrate, provided by the invention, the production cost is extremely low, the cost of the ecological coating is greatly reduced, and a greater price advantage and quality guarantee are achieved; besides, the prepared exterior wall coating has the characteristics of ultraviolet radiation protection, air purification, corrosion resistance, scratch resistance, temperature regulation and control, good stain resistance and the like, and the preparation method is simple in preparation processes, environment-friendly and low-carbon.

Owner:周春莲

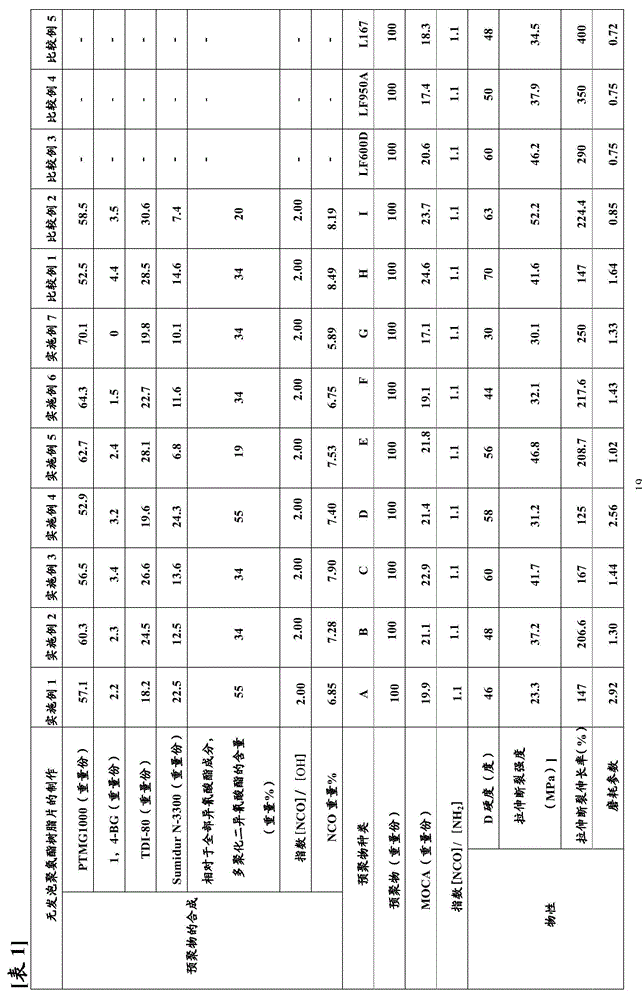

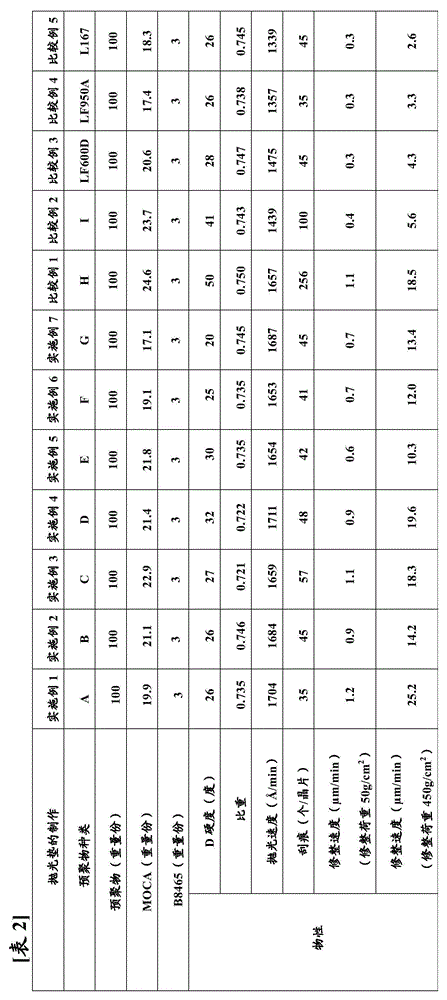

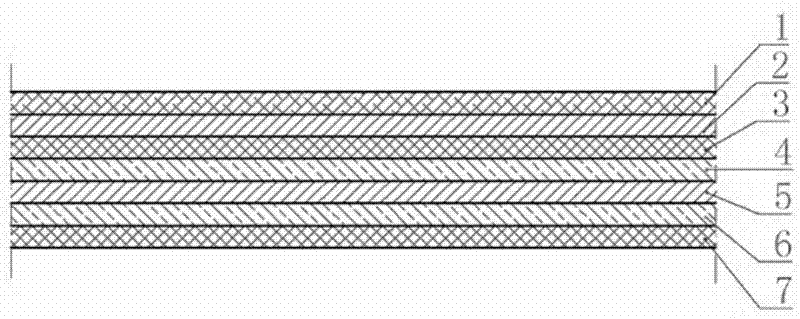

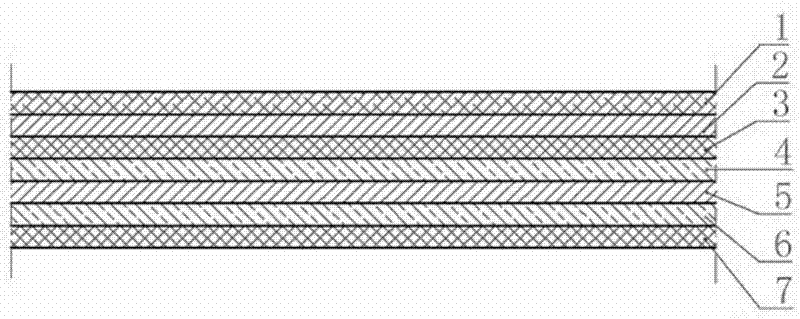

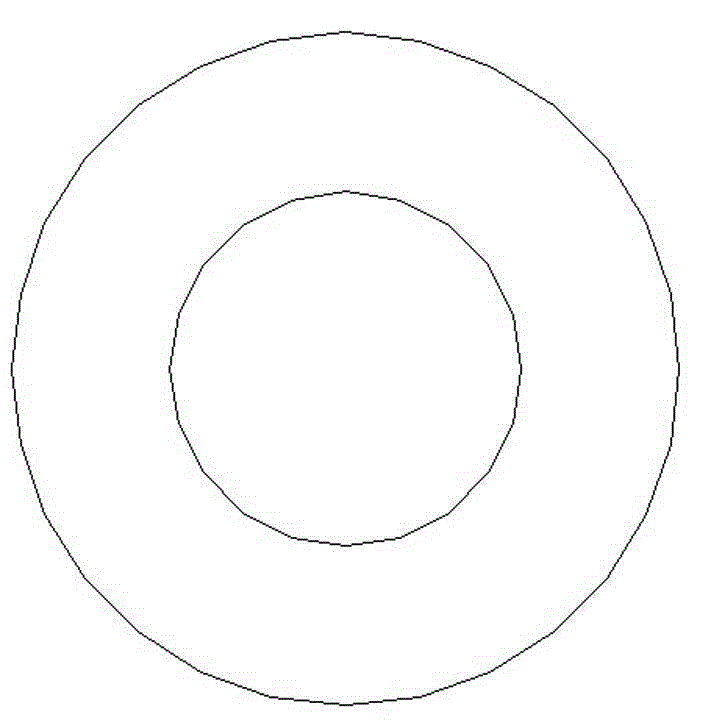

Polishing pad

InactiveCN103958125ALow hardness and softLarge wear parametersAbrasion apparatusSemiconductor/solid-state device manufacturingBreaking strengthHardness

An aim of the present invention is to provide a polishing pad which generates almost no scratches on the surface of an object to be polished, and has improved dressability. Another aim of the present invention is to provide a semiconductor device manufacturing method using the polishing pad. The polishing pad according to the present invention comprises a polishing layer formed of a microbubble-containing polyurethane resin foam. The polyurethane resin foam contains a polyurethane resin whose asker D hardness is between 20 degrees and 60 degrees, and whose wear parameter, which is expressed by the following formula, is between 1 and 3. Wear parameter = {1 / (tensile breaking strength [MPa] tensile breaking elongation [%] / 100)} 100

Owner:ROHM & HAAS ELECTRONICS MATERIALS CMP HLDG INC

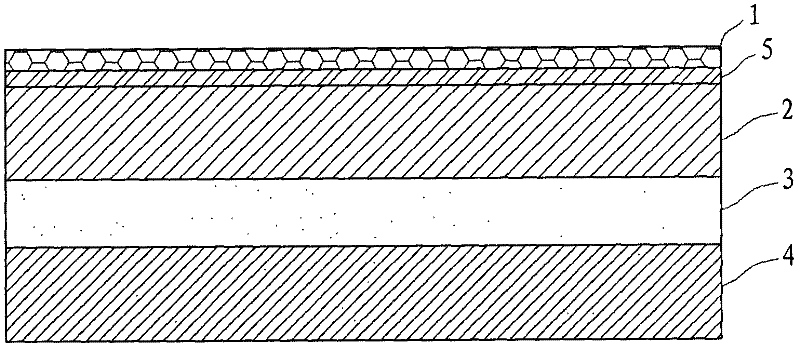

Envelope fabric of an insulation board and a preparation process for the same

ActiveCN102501473AImprove air tightnessGuaranteed service lifeLamination ancillary operationsSynthetic resin layered productsPolyethylene terephthalatePolyethylene terephthalate glycol

An envelope fabric of an insulation board and a preparation process for the same are disclosed, wherein the envelope fabric of an insulation board comprises a glass fibre cloth layer, a first aluminium foil layer, a PET (polyethylene terephthalate) layer, a first nylon layer, a second aluminium foil layer, a second nylon layer and a PE (polyethylene) layer which are orderly compounded from outside to inside. The insulation board and the preparation process for the same disclosed by the invention have the following advantages that: the outmost side of the insulation board uses glass fibre cloth for acting important flame-retardant performance as well as scratch-resistant and puncture-resistant performances; and the insulation board is greatly enhanced in alkali resistance and ageing-resistant performance due to the utilization of the glass fibre cloth on the outmost side. The envelope fabric of an insulation board disclosed by the invention uses double-layer aluminium foil and double-layer nylon, thereby enhancing the air impermeability of the envelope fabric of an insulation board and ensuring the duration time of the vacuum degree of vacuum thermal insulation board. Thus, the service life of the vacuum thermal insulation board is ensured.

Owner:QINGDAO CREEK NEW ENVIRONMENTAL PROTECTION MATERIAL

Impact-resistance-modified organic glass

The invention discloses an impact-resistance-modified organic glass, which is composed of organic glass, an impact-resistance modifier, a toughener, a molecular weight regulator, a heat-resistant agent, an initiator and an anti-wear agent, wherein the impact-resistance modifier is a methacrylate-butadiene-styrene copolymer, the toughener is ethylene propylene diene monomer rubber, the molecular weight regulator is tert-dodecylmercaptan, the heat-resistant agent is mica powder, the initiator is di-cyclohexylperoxy dicarbonate, and the anti-wear agent is calcined kaolin. By adding the impact-resistance modifier, toughener, molecular weight regulator, heat-resistant agent, initiator and anti-wear agent into the organic glass, the impact-resistance-modified organic glass has the advantages of high shock strength, favorable toughness, favorable product quality and high heat resistance. The impact-resistance-modified organic glass has the characteristics of high production efficiency, scratch resistance and long service life.

Owner:ZHANGJIAGANG DELITE NEW MATERIAL

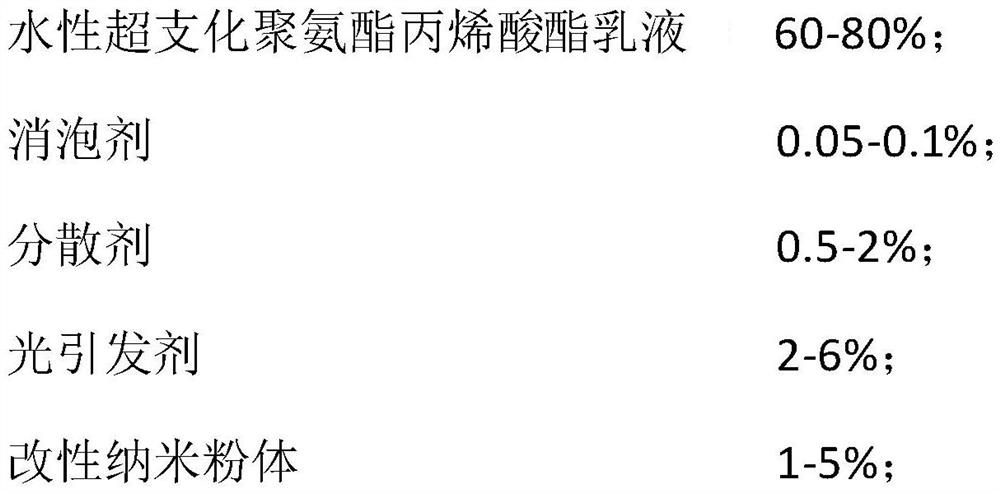

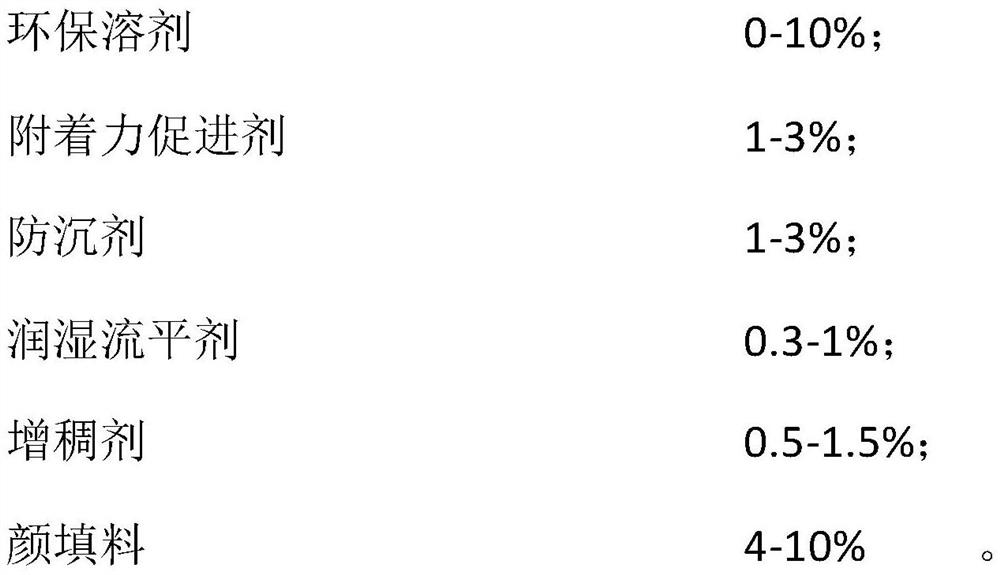

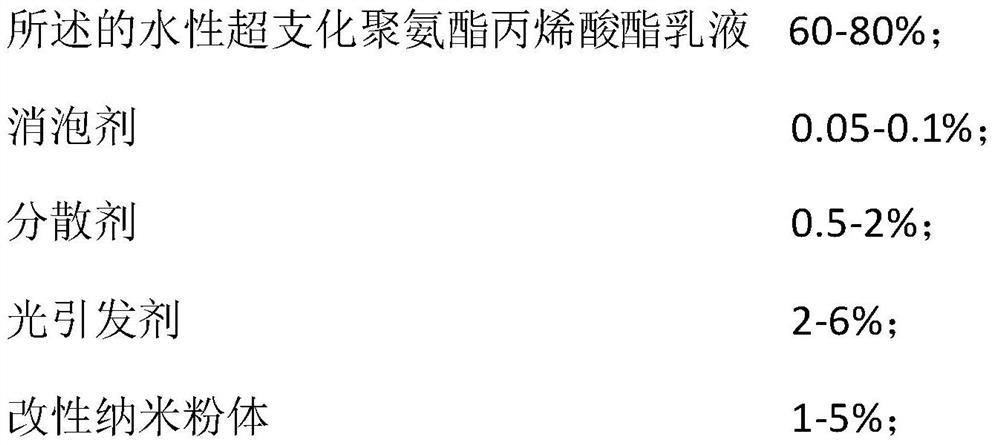

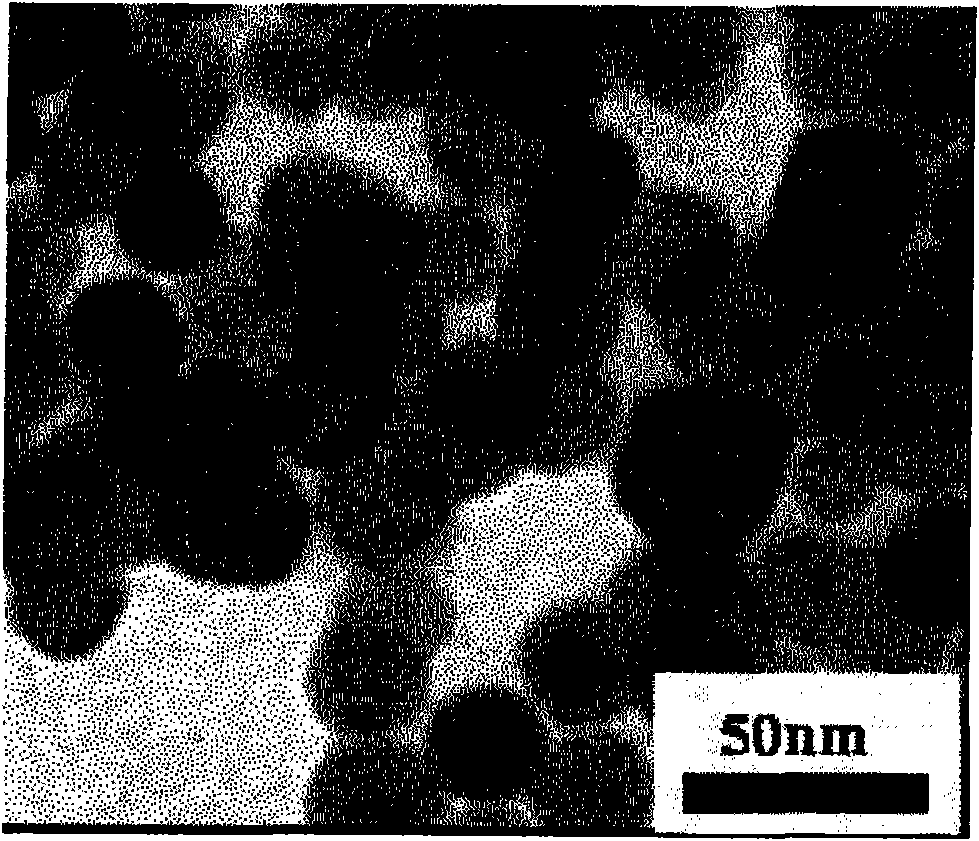

Preparation method of waterborne hyperbranched polyurethane acrylate emulsion, UV curing coating and preparation method and application of UV curing coating

ActiveCN111978506AHigh yieldHigh catalytic activityAntifouling/underwater paintsPaints with biocidesPolymer scienceUV curing

The invention belongs to the technical field of UV curing coatings, and particularly relates to a preparation method of a waterborne hyperbranched polyurethane acrylate emulsion, a UV curing coating and a preparation method and application of the UV curing coating. The UV-curable coating is prepared from the following raw materials in percentage by weight: 60 to 80 percent of waterborne hyperbranched polyurethane acrylate emulsion, 0.05 to 0.1 percent of a defoaming agent, 0.5 to 2 percent of a dispersing agent, 2 to 6 percent of a photoinitiator, 1 to 5 percent of modified nano powder, 0 to 10 percent of an environment-friendly solvent, 1 to 3 percent of an adhesion promoter, 1 to 3 percent of an anti-settling agent and 0.3 to 1 percent of a wetting leveling agent. 0.5-1.5% of a thickening agent and 4-10% of a pigment filler; the invention further provides a preparation method of the UV curing coating for a polypropylene packaging barrel. The UV curing coating for the polypropylene packaging barrel, prepared by the invention, has excellent wear resistance and relatively high adhesive force on the polypropylene packaging barrel, and has excellent weather resistance.

Owner:珠海瑞杰包装制品有限公司

Camouflage cooling coating material

ActiveCN103183994AAnti-scratchDoes not break the invisibility effectEpoxy resin coatingsMulticolor effect coatingsMetallurgyCooling effect

The invention discloses a camouflage cooling coating material which is characterized by comprising camel, army green and blackish green cooling coating materials, wherein the army green cooling coating material also comprises a surface coating and a bottom coating. The camouflage cooling coating material can achieve a cooling effect and is good in mechanical and physicochemical performances of scratch resistance, impact resistance and the like, and the hiding effect cannot be destroyed due to reflection or radiation.

Owner:青岛乐化科技有限公司 +3

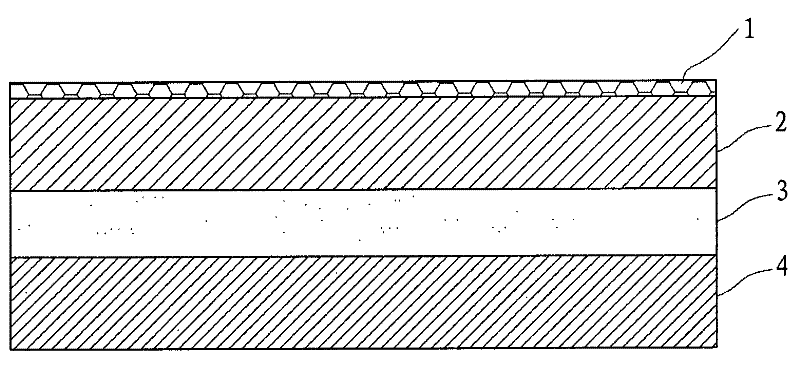

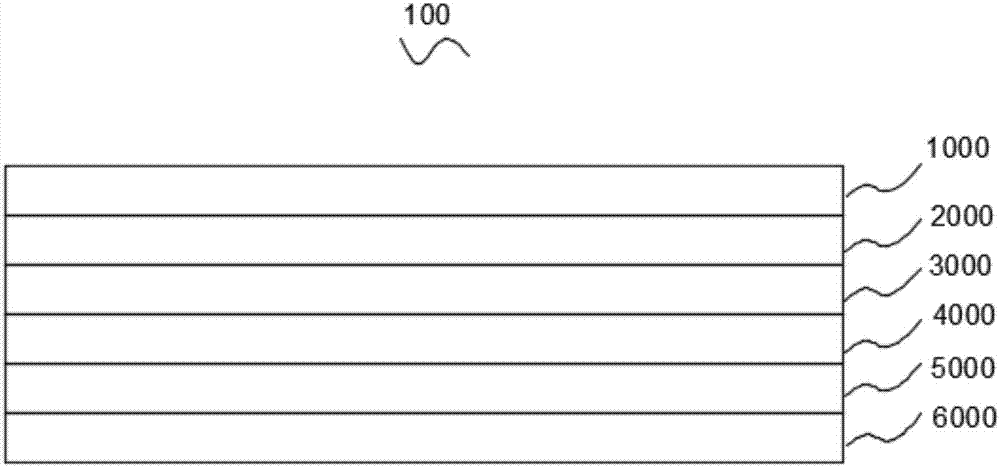

Scratch-resistant wallpaper and production method thereof

InactiveCN103952946AReduce external forceAnti-scratchCovering/liningsSpecial paperScreen printingPolymer science

The invention discloses scratch-resistant wallpaper and a preparation method thereof. The scratch-resistant wallpaper has a layered structure and consists of a bottom wallpaper layer, a middle adhesive layer and a top scratch-resistant layer in sequence from bottom to top, wherein the wallpaper layer is made of pure wallpaper, non-woven wallpaper or PVC (polyvinyl chloride) wallpaper; the adhesive layer is formed by coating the bottom wallpaper layer with transparent slurry consisting of a plasticizer, polyvinyl chloride resin, a viscosity reducer, an external lubricating agent and a stabilizing agent, and then drying at 180-200 DEG C; the top scratch-resistant layer is formed by coating the adhesive layer with homogenate consisting of 25 percent of plasticizer, 60 percent of polyvinyl chloride, 7 percent of viscosity reducer, 7 percent of external lubricating agent and 1 percent of stabilizing agent through a photogravure roller or a rotary screen printing roller, and drying at 180-200 DEG C. Under the action of outer force, the scratch-resistant wallpaper disclosed by the invention can effectively buffer the outer force to achieve a scratch resisting effect; furthermore, under outer force friction, the scratch-resistant wallpaper still can keep the original attractiveness.

Owner:SHANGHAI SUWALPER WALLPAPER CO LTD

Method for producing oxide crystal fine particle

InactiveCN101784486ASmall particle sizeImprove uniformityMaterial nanotechnologyOxide/hydroxide preparationRare-earth elementMicroparticle

Owner:ASAHI GLASS CO LTD

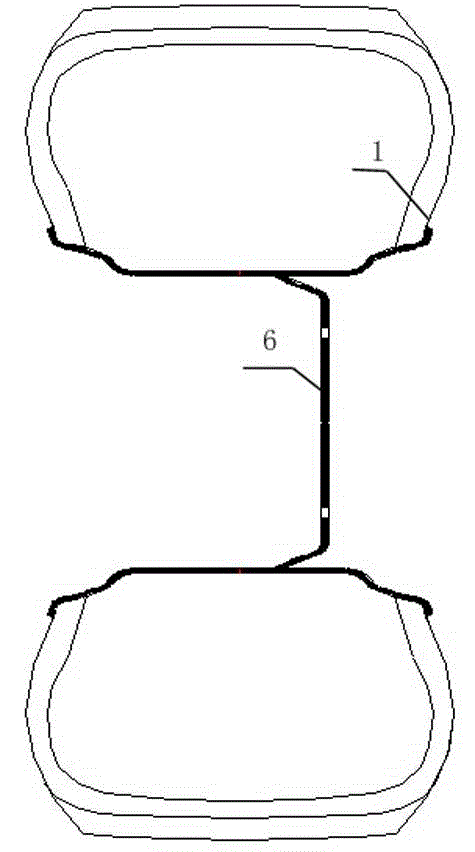

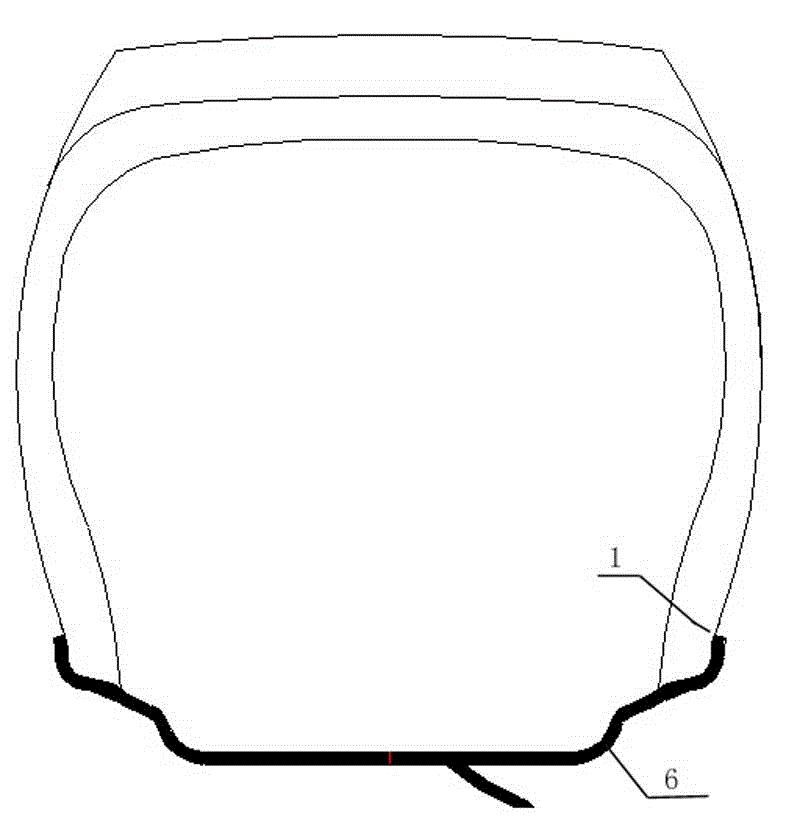

Tire capable of protecting sides

InactiveCN104149554ABlock and slow down scratchesBlock and relieve stressTyre sidewallsPolyesterRubber material

The invention provides a tire capable of protecting the sides. The tire capable of protecting the sides comprises a tire rim and a tire rim installation surface which is a tire side rubber surface, wherein the circumference of the tire side rubber surface is uniformly provided with a plurality of protective caps which are integrally compounded with the tire side rubber surface; the protective caps are wear-resistant rubber columns, and take the shapes of columnar pipes or conical pipes; the bottom surfaces of the wear-resistant rubber columns extend toward the circumference of the tire side rubber surface so as to cover the tire side rubber surface and are integrally compounded with the tire side rubber surface; the tire side rubber surface is integrally compounded with the wear-resistant rubber columns by flexible rubber; the pipes of the wear-resistant rubber columns are internally provided with flexible rubber frameworks which are integrally compounded with the flexible rubber; polyester rubber dipping cord fabrics are compounded outside the flexible rubber frameworks and the flexible rubber and among the wear-resistant rubber columns; the flexible rubber frameworks are internally provided with heat radiation holes. According to the invention, the protective performance of the protective caps is intensified by the combination of different rubber materials, framework materials and the polyester rubber dipping cord fabrics; the protective caps provided with heat radiation devices, so that the temperature of the protective caps is lowered, and the anti-scraping, anti-collision and heat-radiation effects of the tire are realized easily via structure change.

Owner:双星东风轮胎有限公司

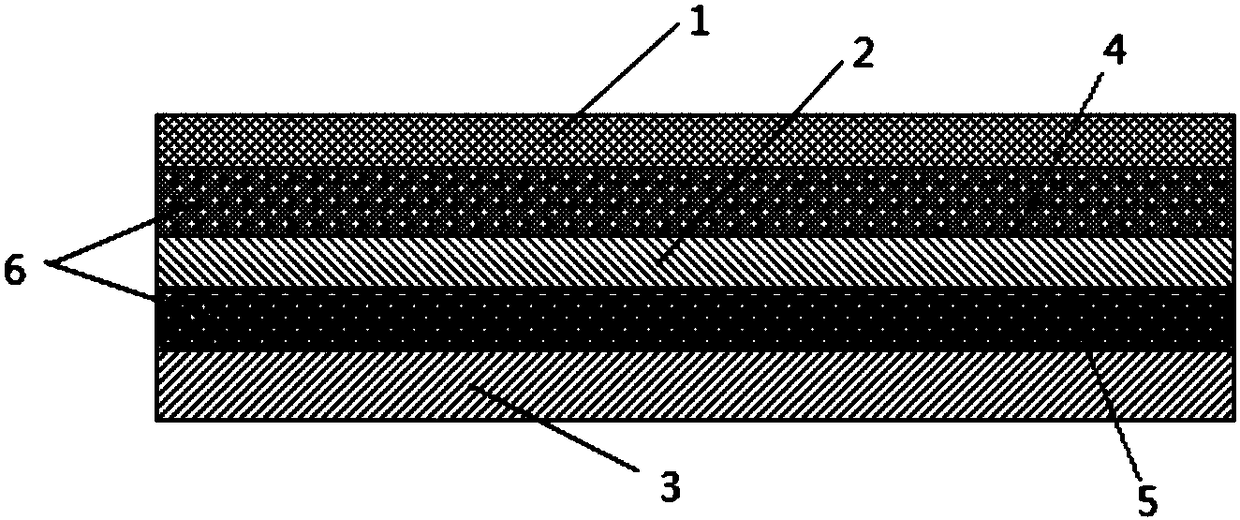

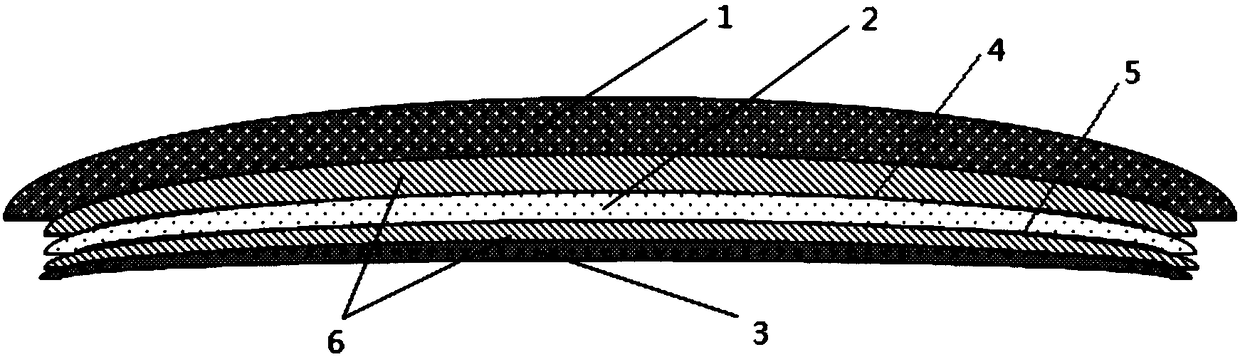

Polaroid with water-proof nano-coating and liquid crystal display

InactiveCN107247301AAnti-scratchAnti-reflectionPolarising elementsNon-linear opticsLiquid-crystal displayWater vapor

The invention provides a polaroid with a water-proof nano-coating and a liquid crystal display provided with the same. The polaroid with the water-proof nano-coating comprises the water-proof nano-coating, a first TAC film, a PVA film, a second TAC film, a PSA adhesive layer, and a release film in sequence. The water-proof nano-coating, the first TAC film, the PVA film, the second TAC film, the PSA adhesive layer, and the release film are attached to one another. The water-proof nano-coatings is used for resisting water vapor and providing structural strength, the first TAC film is used for providing protection, the PVA film is used as a polarizer layer, the second TAC film is used for providing protection, the PSA adhesive layer is used for providing cohesive property, and the release film is used for providing isolation, padding, and protection. Because the water-proof nano-coating is arranged on the outside of the polaroid, the polaroid with the water-proof nano-coating and the liquid crystal display are not only water-proof, but also have advantages of resistance to scratching, anti-reflection, fingerprint-proofness and the like.

Owner:深圳市鑫友道科技有限公司

Reinforced waterproof insulating electrical adhesive tape

The present invention relates to a reinforced waterproof insulating electrical adhesive tape, which comprises an ethylene propylene rubber base layer and a butyl rubber layer, wherein a reinforced layer is arranged between the ethylene propylene rubber base layer and the butyl rubber layer, and is mesh-like. According to the present invention, the structure is simple, and the mesh-like reinforced layer is arranged between the ethylene propylene rubber base layer and the butyl rubber layer, such that the puncture and the scratching of hard objects can be effectively resisted, and the fusion of the ethylene propylene rubber base layer and the butyl rubber layer can be promoted so as to further improve the waterproof and insulating effect of the adhesive tape.

Owner:谭欣

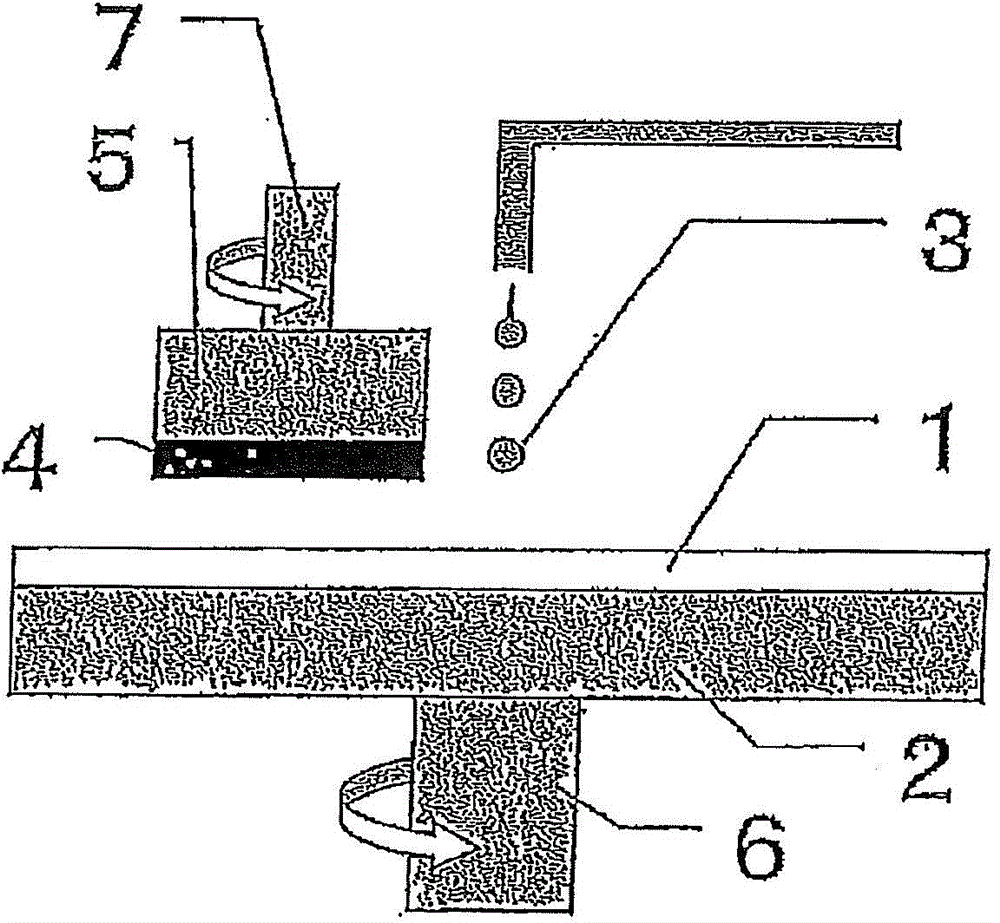

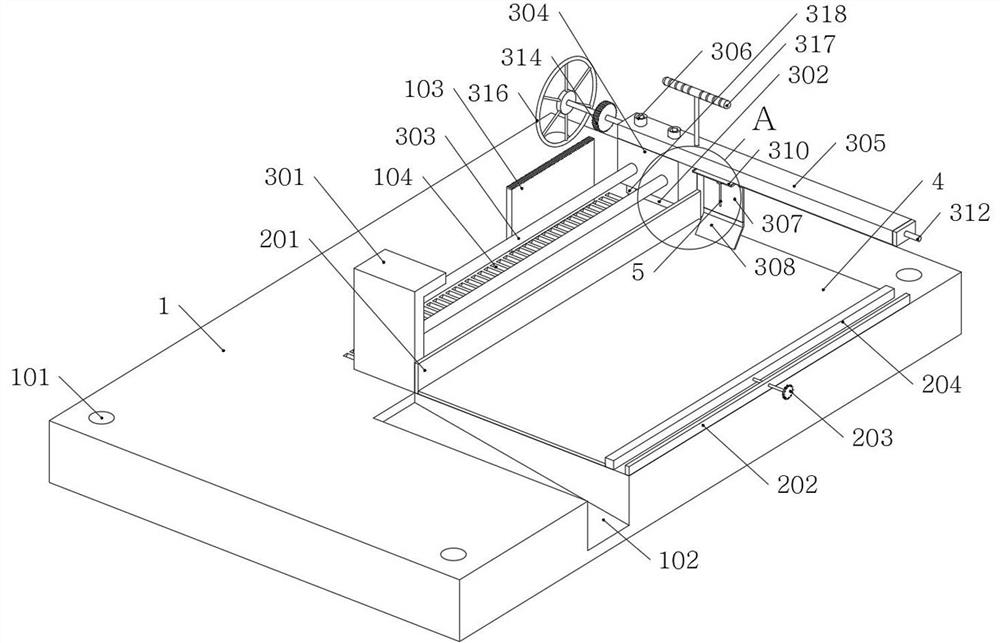

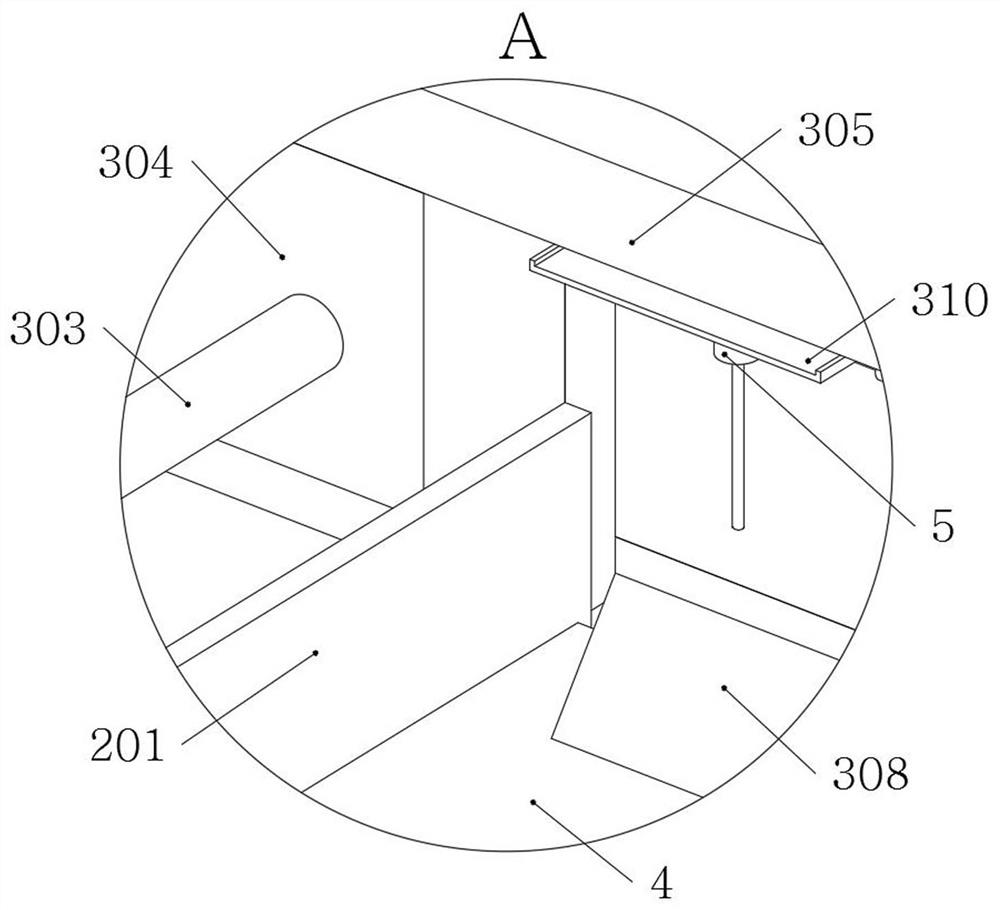

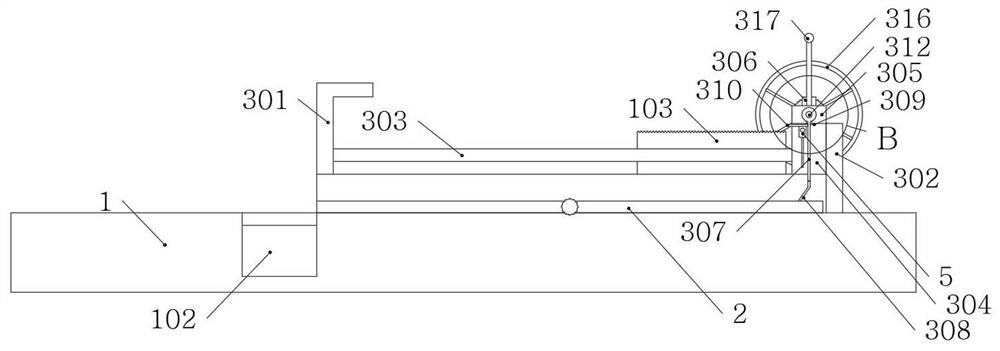

Scraping and planing device for matching surface machining during intelligent production of fitness equipment

ActiveCN113385746AAchieve wind coolingRealize drip coolingLarge fixed membersPositioning apparatusExercise machineMachining

The invention provides a scraping and planing device for matching surface machining during intelligent production of fitness equipment, and relates to the technical field of fitness equipment machining. The scraping and planing device solves the problems that although an existing device can also realize scraping of a matching surface through reciprocating scraping and planing, a scraper of the existing device is prone to wear; and the scraper of the existing device is generally small, scraping and planing of the whole matching face cannot be achieved at a time, and the position of the scraper needs to be manually adjusted multiple times in the scraping and planing process. The scraping and planing device for matching surface machining during intelligent production of the fitness equipment comprises a main body seat and a fixing structure, wherein the main body seat is of a rectangular platy structure; and the fixing structure is mounted on the main body seat, and a plate is clamped on the fixing structure. According to the scraping and planing device, a mounting seat A is welded on the top end face of the main body seat, and the mounting seat A is of an L-shaped structure; and an adjusting seat is fixedly connected to a sliding block through fixing bolts, and when the sliding block moves forwards by 50cm, the top end face of each fixing bolt makes contact with the bottom end face of the inner wall of the mounting seat A, so that looseness detection of the fixing bolts can be achieved through the mounting seat A.

Owner:南通莱鑫运动用品有限公司

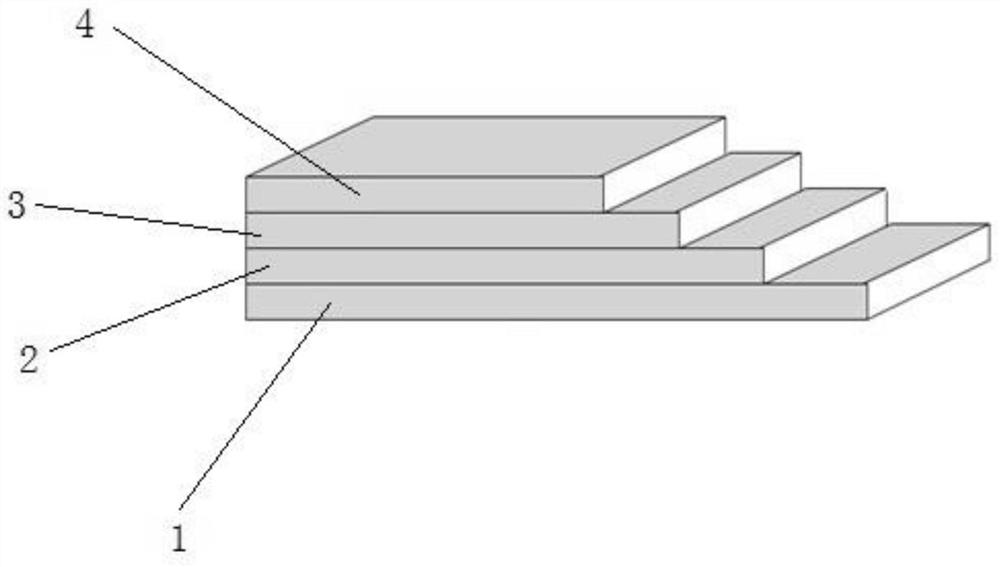

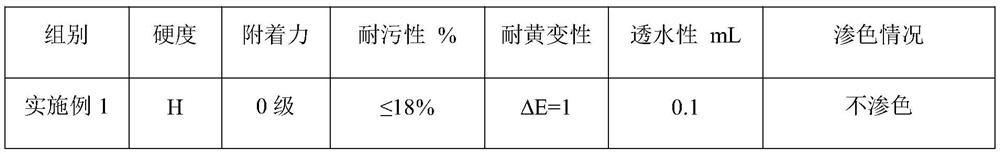

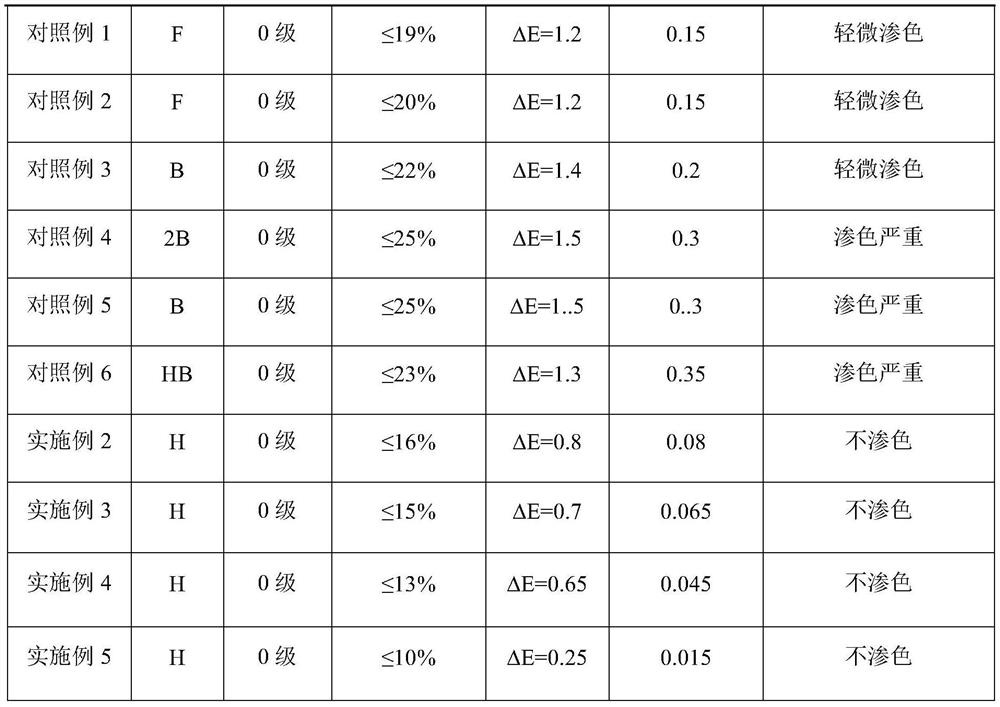

Anti-bleeding water-borne wood coating structure and application thereof

InactiveCN112724754AImprove permeabilityEasy to polishLiquid surface applicatorsCoatingsPolymer scienceFirming agent

The invention relates to the technical field of woodware coating structures, and discloses an anti-bleeding water-based woodware coating structure. The structure comprises a closed coating, a polishing coating and a finish paint coating; raw materials of the sealing coating comprise a main agent I and a curing agent; the main agent I comprises a high-hydroxyl-value acrylic acid dispersion, a coalescing agent, a wetting agent, a defoaming agent, a thickening agent and deionized water; the polishing coating is prepared from the following raw materials: a main agent II and a curing agent; the main agent II comprises a water-based acrylic emulsion, an antifoaming agent, a coalescing agent, a dispersing agent, a leveling agent, a mildew preventive, a thickener and deionized water; the finish paint coating is prepared from the following raw materials: a main agent III and a curing agent; and the main agent III comprises a water-based acrylic emulsion, an antifoaming agent, a coalescing agent, a dispersing agent, a leveling agent, a mildew preventive, a thickener and deionized water. The invention further discloses application of the water-based woodware coating structure. The water-based woodware coating structure has the advantages of color seepage prevention, high adhesive force, high hardness, high stain resistance, low water permeability and the like.

Owner:CHENGDU ZHANCHEN PAINT

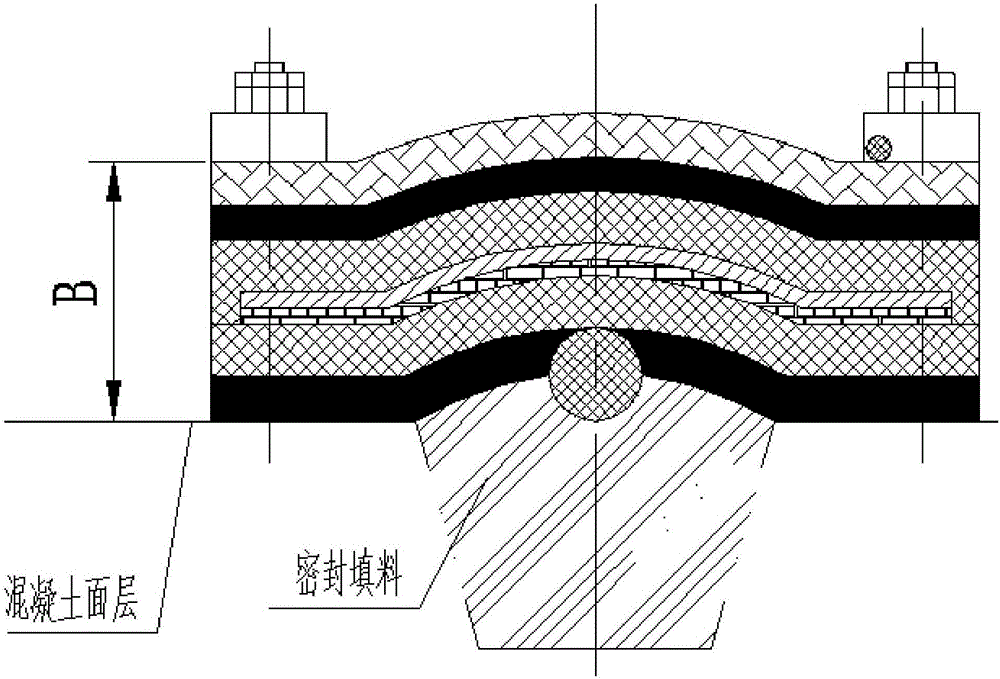

Cover plate for dam concrete water-stopping surface

InactiveCN106638477AExcellent anti-aging performanceHigh tensile strengthBarrages/weirsEngineeringExpansion joint

A cover plate for a dam concrete water-stopping surface is an anti-freezing cover plate for a dam concrete water-stopping surface ice layer expansion joint. The cover plate includes a waterproof seal self-gluing layer; an EPDM layer I is arranged on the waterproof seal self-gluing layer; a reinforcing rib is arranged on the EPDM layer I; an electrical heating layer is arranged on the reinforcing rib; an EPDM layer II is arranged on the electrical heating layer; a waterproof seal gluing layer is arranged on the EPDM layer II; an anti-folding wear-resisting protection film is arranged on the waterproof seal gluing layer; a cable for reflecting the temperature and a water level signal is arranged on the anti-folding wear-resisting protection film; and a waterproof heating layer power supplying cable is arranged under the waterproof seal self-gluing layer. The invention provides an anti-scraping cover plate for dam concrete water-stopping surface ice layer expansion joint and an anti-freezing cover plate for dam concrete water-stopping parts, water gate working door pages, and embedded parts. The cover plate is high in tensile strength, is excellent in anti-collision performance, can prevent scraping and freezing, and is long in service life.

Owner:刘煜华

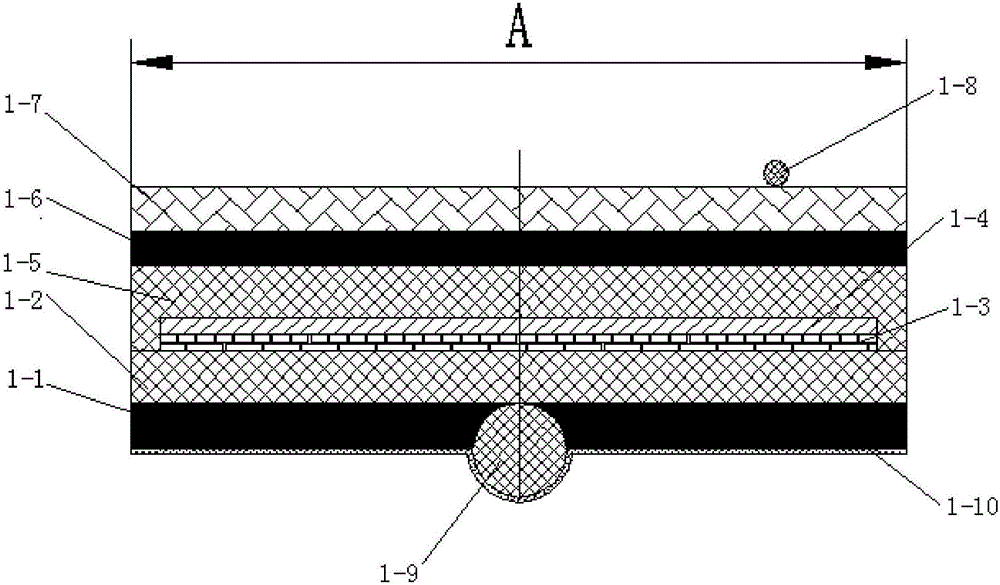

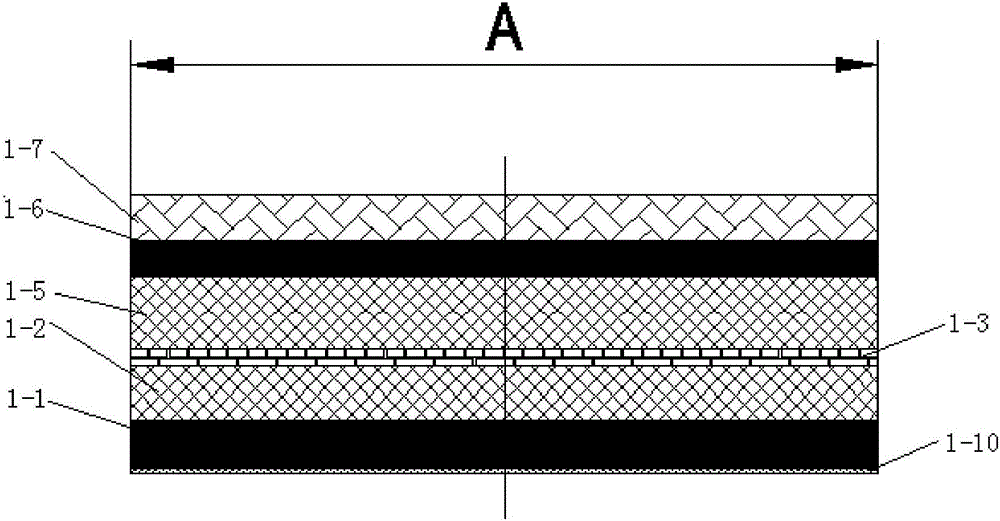

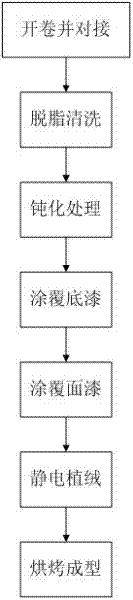

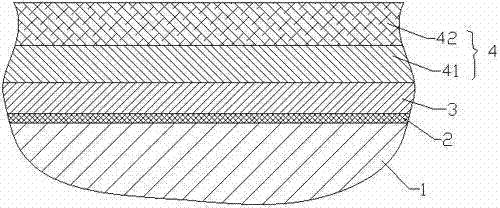

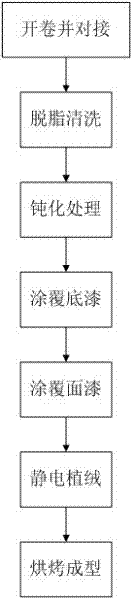

Flocked decorative steel plate and production process thereof

The invention discloses a flocked decorative steel plate. The flocked decorative steel plate comprises a basis material layer, wherein the surface of the basis material layer is in sequence compounded with a surface processing layer, a prime paint layer and a flocking layer from inside to outside; the flocking layer comprises a fluff layer composed of a surface paint layer and fiber fluffs; and the fluff layer is directly arranged on the surface of the surface paint layer and directly forms an integrated structure with the surface paint of the surface paint layer. The invention also discloses a processing technology of the flocked decorative steel plate, which comprises the specific steps of: coiling and butting; surface treatment; prime paint coating; surface paint coating; electrostatic flocking; and roasting and forming. The flocked decorative steel plate and the production process thereof disclosed by the invention have the characteristic of once forming; with respect to the general flocked plate, the flocked decorative steel plate disclosed by the invention has the advantages that: a gluing operation is not required before a flocking process is carried out; the fiber fluffs are directly flocked on the surface paint coating layer by using the adhesiveness of the surface paint before being roasted; and the roasted fiber fluffs are tightly connected with the surface paint coating layer, so that the materials are saved, a working procedure is removed, and the cost is effectively reduced.

Owner:CHANGSHU HUAYE STEEL STRIP

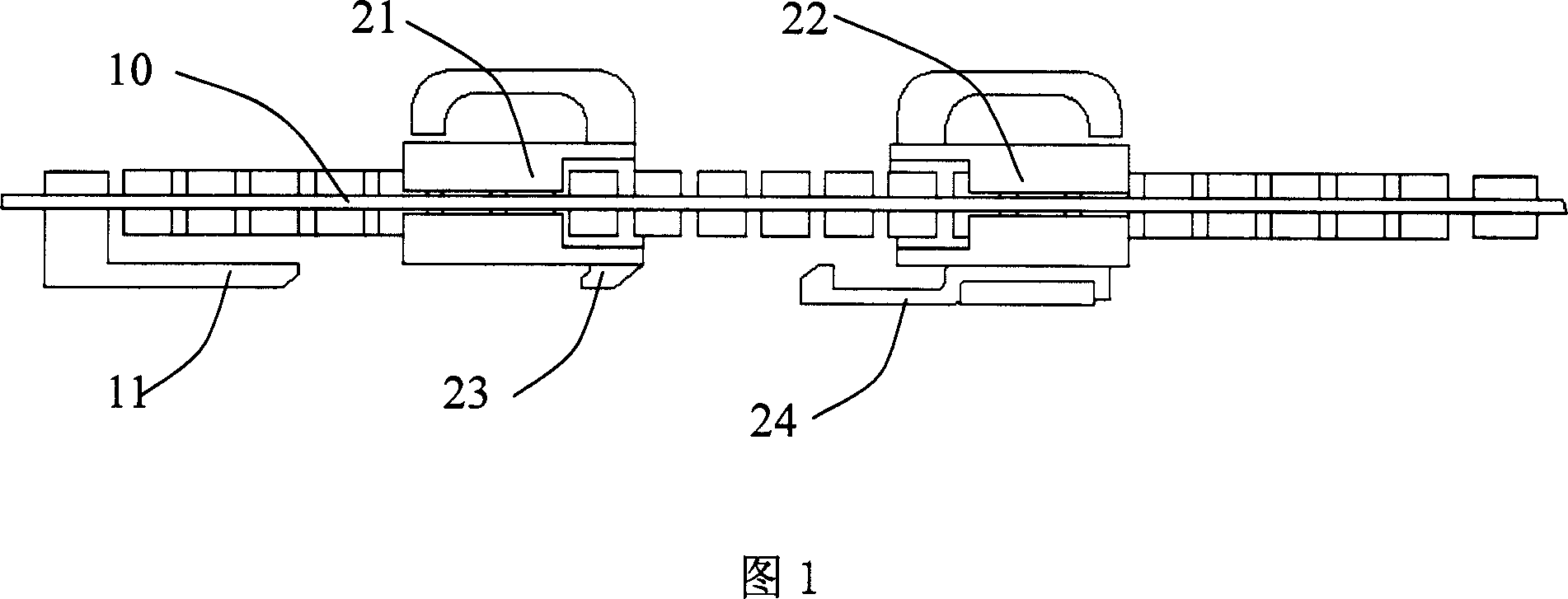

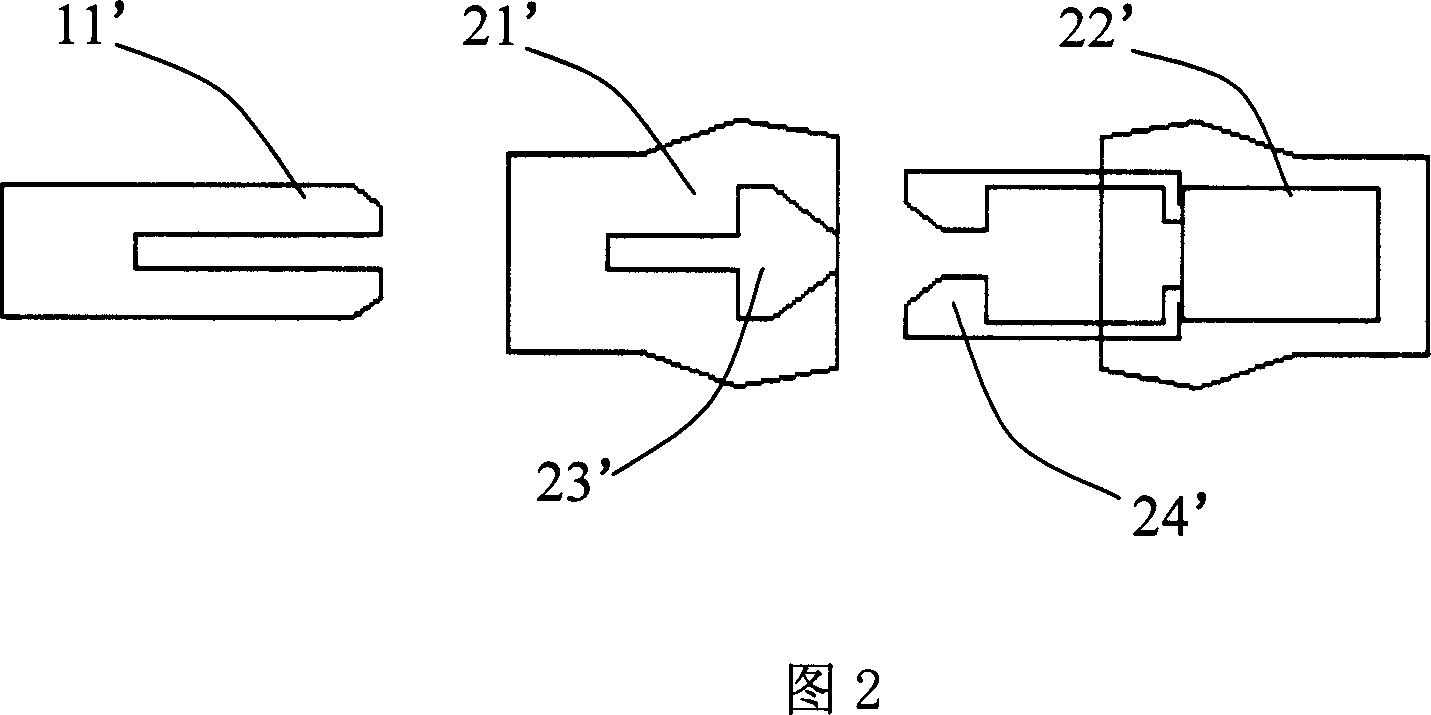

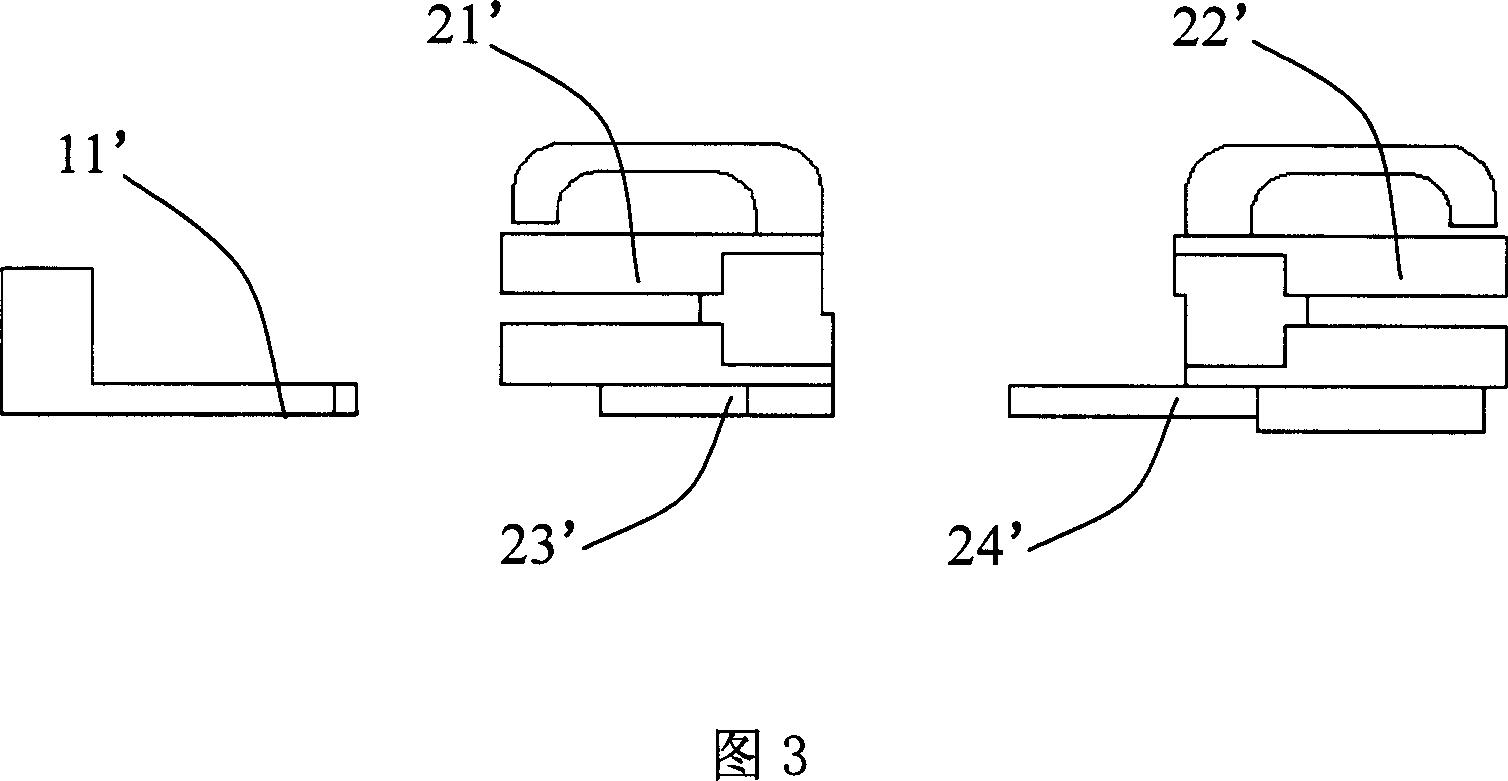

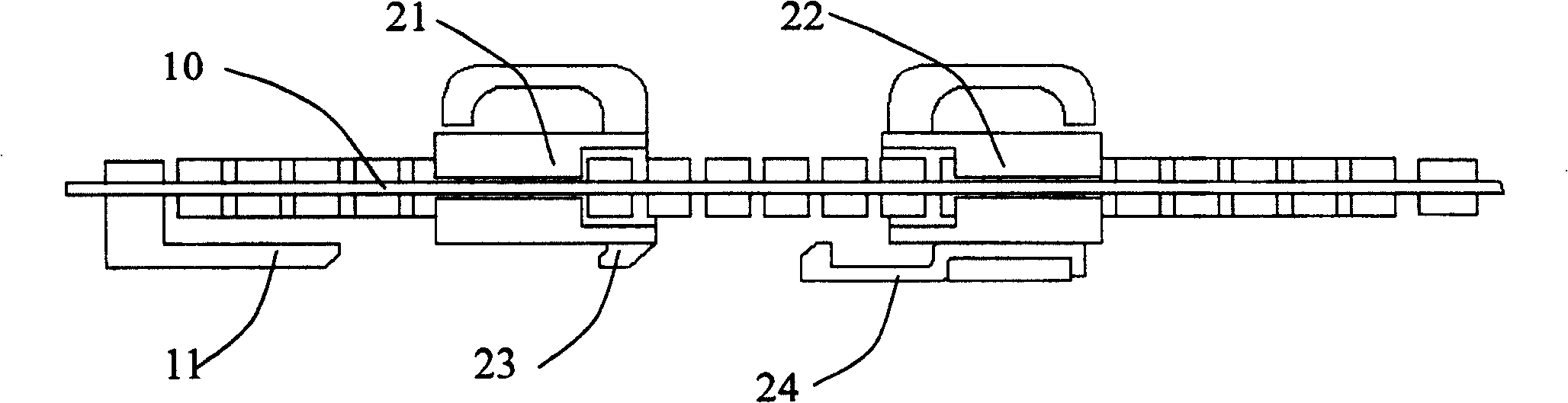

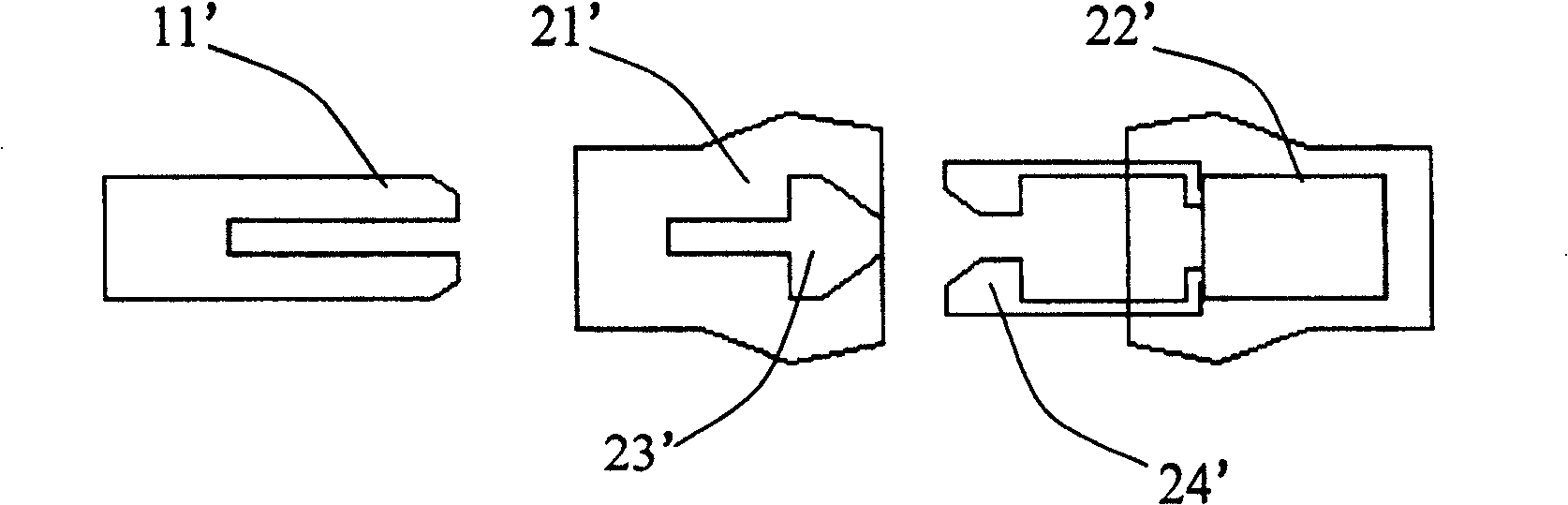

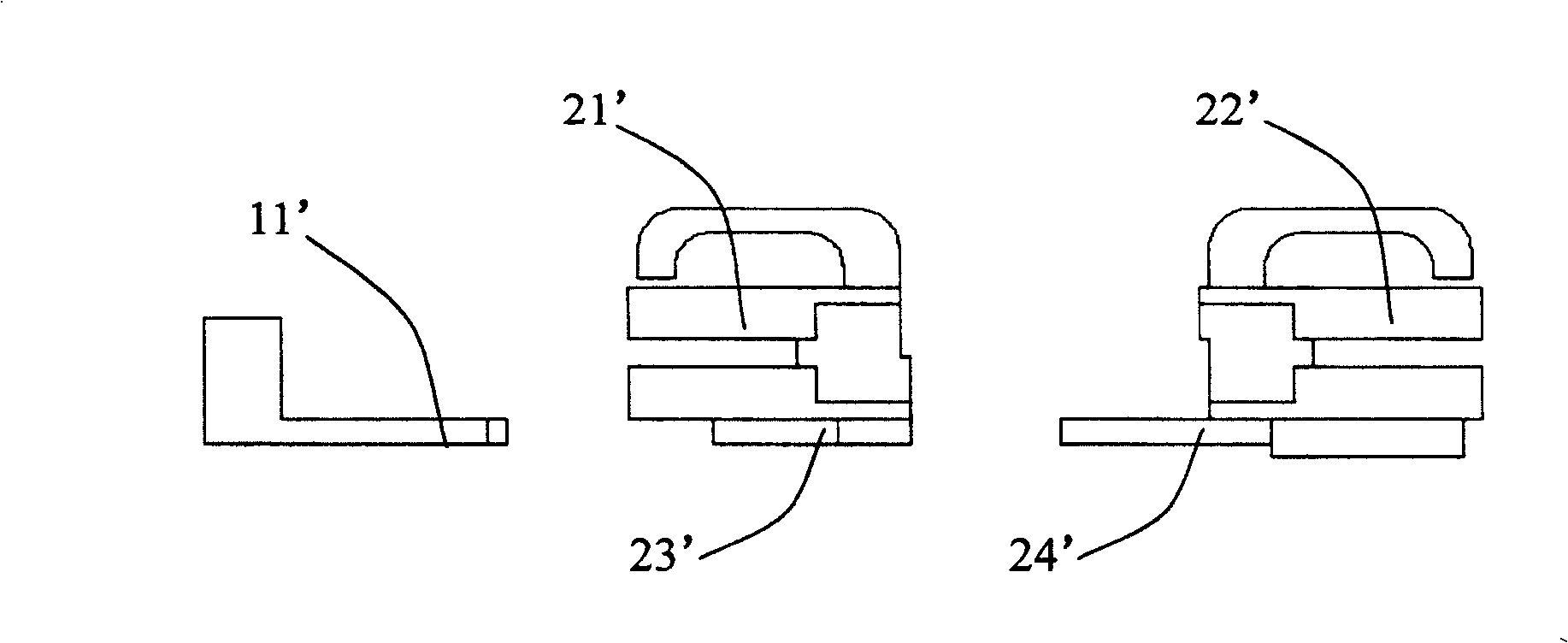

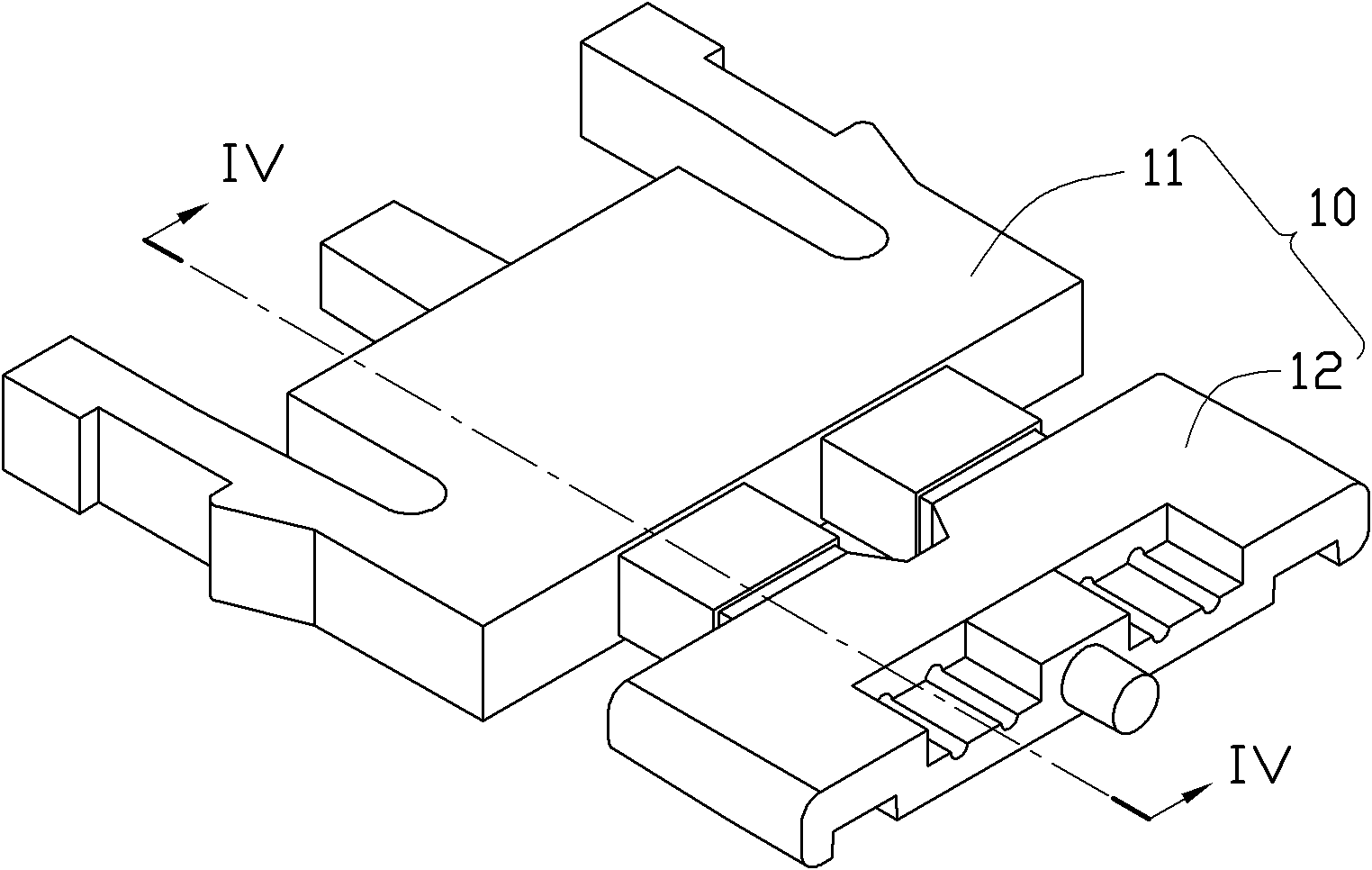

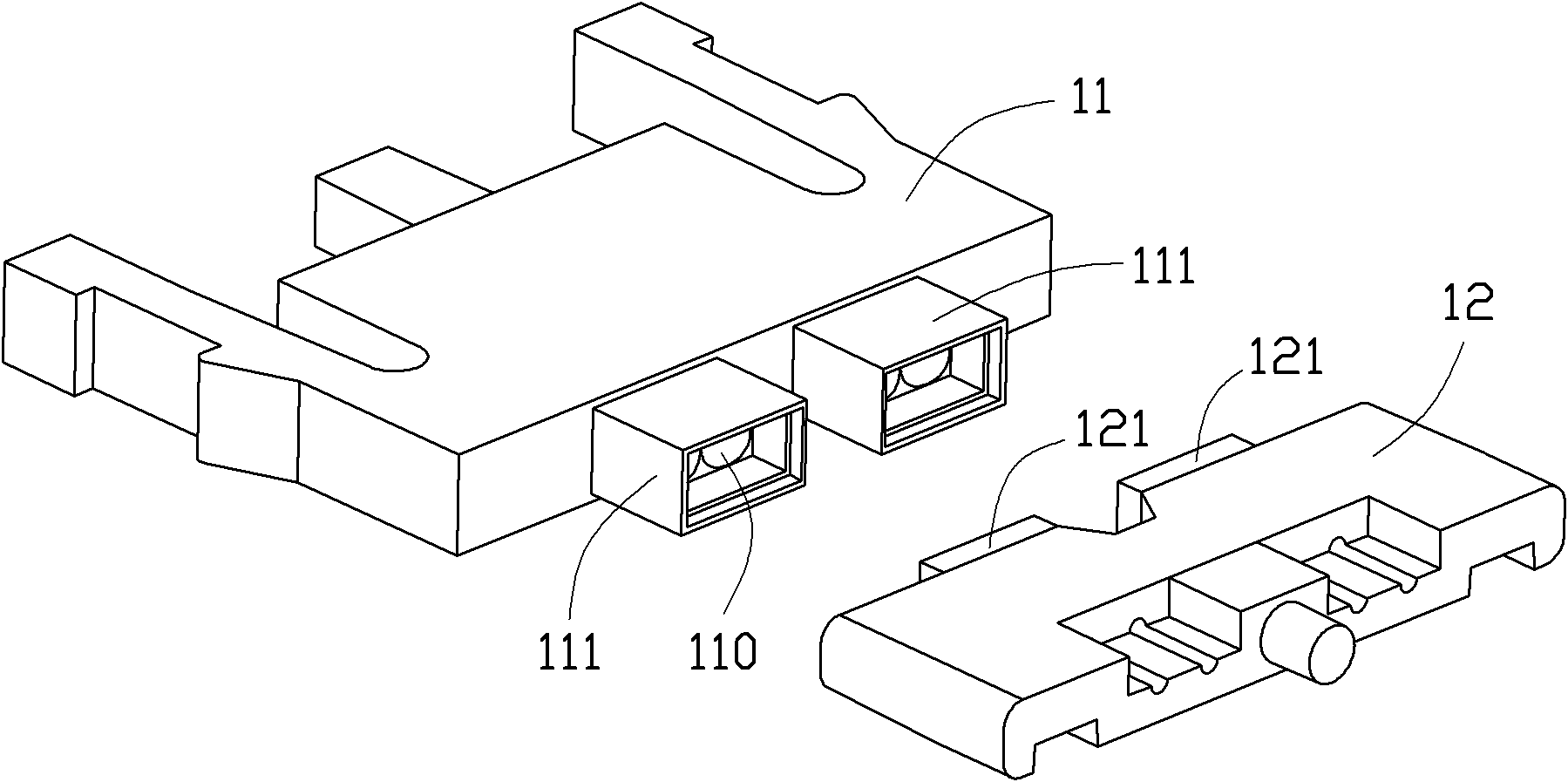

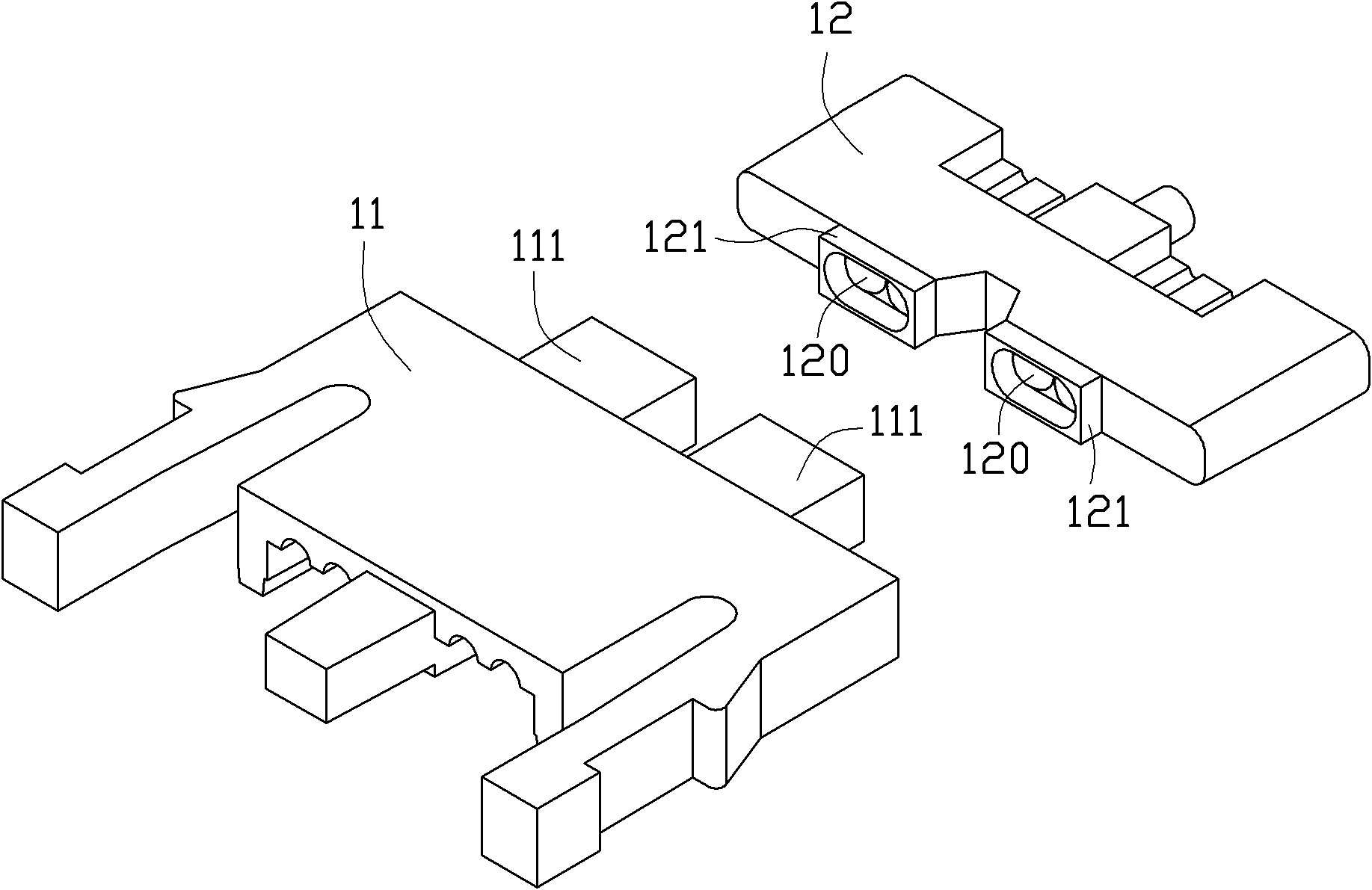

Fiber coupling connector

The invention discloses a fiber coupling connector, which comprises a plug and a socket matched with the plug, wherein the plug is provided with a first optical fiber and a first lens coupled with the first optical fiber; the socket is provided with a second optical fiber and a second lens coupled with the second optical fiber; the plug is provided with a first sleeve surrounding the first lens; the socket is provided with a second sleeve surrounding the second lens; and the first sleeve and the second sleeve are used for clamping with each other and form a sealing space for accommodating the first lens and the second lens.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Curved touch display screen and preparation method thereof

PendingCN108563369ASimple processHigh yield and high stabilityInput/output processes for data processingComposite structureEngineering

The invention provides a curved touch display screen and a preparation method thereof. The curved touch display screen comprises a glass cover plate, wherein a touch film and a display screen are sequentially arranged at one side of the glass cover plate; the glass cover plate, the touch film and the display screen form a multi-layer composite structure, a first conducting circuit layer and a second conducting circuit layer are respectively arranged at two sides of the touch film, the first conducting circuit line is laminated to the glass cover plate, and the second conducting circuit layer is laminated to the display screen. According to the invention, OCA optical cement is adopted as an adhesive to be matched with the process of defoaming with a still kettle, so as to realize complete lamination of an OLED display screen which cannot resist high temperature with other components; then precise slab single-face heating and hot bending forming is performed, the process is simple, the rate of finished products and the stability of finished products are high, the production efficiency is greatly improved, the service life of the product is greatly prolonged, and the prepared curved touch screen has the performances of scratch resistance and full shielding and interference resistance, and has an arc field of view and arc angle of view, a convenient touch function and strong practicability.

Owner:牧东光电科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com