A kind of flexible screen protective film and preparation method thereof

A screen protective film, flexible technology, applied in the direction of chemical instruments and methods, synthetic resin layered products, layered products, etc., can solve the problem of no anti-scratch protective film, etc., and achieve the effect of greatly increasing flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

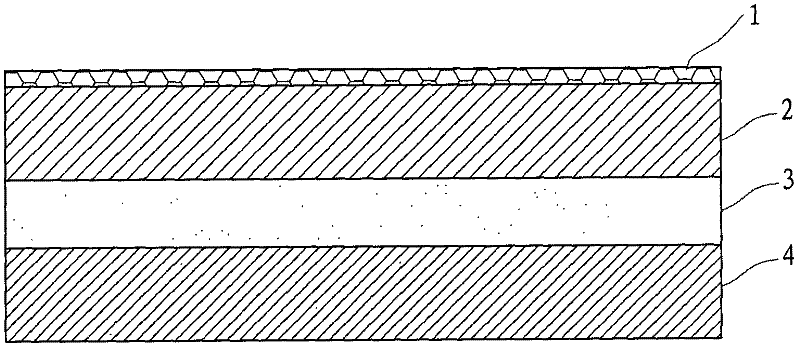

[0018] Example 1, such as figure 1 As shown, the flexible screen protective film includes a substrate 2, a sterilizing and hardening layer 1, an adhesive layer 3 and a release film 4, the sterilizing and hardening layer is arranged on the first surface of the substrate 2, and the adhesive layer 3 is arranged on the base On the second surface of the material 2, the release film 4 is adhered to the adhesive layer 3, and the sterilization and hardening layer is plated on the substrate by vacuum evaporation, vacuum ion plating or vacuum sputtering. In this embodiment, the substrate is PU The film has a thickness of 25 μm, a total light transmittance of 80%, and a haze of 0.9%. The thickness of the adhesive layer is 10μm, the thickness of the release film is 25μm, the sterilization and hardening layer is copper, the thickness is 20nm, and the pencil hardness is 1H.

[0019] The preparation method of the flexible screen protective film comprises the following steps: using the subst...

Embodiment 2

[0020] Embodiment 2, the base material of the flexible screen protective film in this embodiment is TPU film with a thickness of 38 μm, a total light transmittance of 85%, and a haze of 1.0%. The thickness of the adhesive layer is 15 μm, the thickness of the release film is 38 μm, the sterilization and hardening layer is bronze, the thickness is 100 nm, and the pencil hardness is 2H. The preparation method refers to Example 1.

Embodiment 3

[0021] Embodiment 3, the base material of the flexible screen protective film in this embodiment is PVC film with a thickness of 100 μm, a total light transmittance of 90%, and a haze of 0.9%. The thickness of the adhesive layer is 50 μm, the thickness of the release film is 50 μm, the sterilization and hardening layer is brass, the thickness is 1000 nm, and the pencil hardness is 3H. The preparation method refers to Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com