Patents

Literature

67results about How to "No crease" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

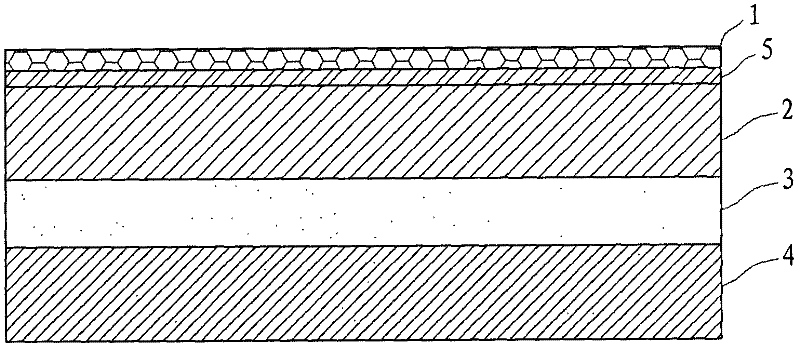

Waterborne shiny leather

InactiveCN103422361AImprove surface brightnessNo creaseLamination ancillary operationsSynthetic resin layered productsPolymer sciencePolymer chemistry

The invention discloses waterborne shiny leather which is made in a dry-method film moving machining method. The method comprises the following steps that waterborne polyurethane resin slurry is arranged on release paper in a coating mode, the waterborne polyurethane resin slurry is divided into three layers, namely the face layer, the middle layer and the bottom adhesive layer, then a leather base cloth is bonded, paper and leather are separated, and the leather is detected and stored in a bin. The waterborne shiny leather has the advantages that besides the waterborne polyurethane resin utilization, the surface of the waterborne shiny leather is transparent, the surface brightness is high, and the surface has no crease line, the hydrolysis resistance of a synthetic leather product can be maintained for 5 years, the content of VOC is zero, no cell and needle eye exists in the surface of produced shiny synthetic leather, the surface is flat and smooth, similar products of other enterprises can not achieve the effect, and the waterborne shiny leather can be widely applied to various fields of sofas, automobile internal decoration, office appliances, and household walls.

Owner:ZHEJIANG WUZHOU IND

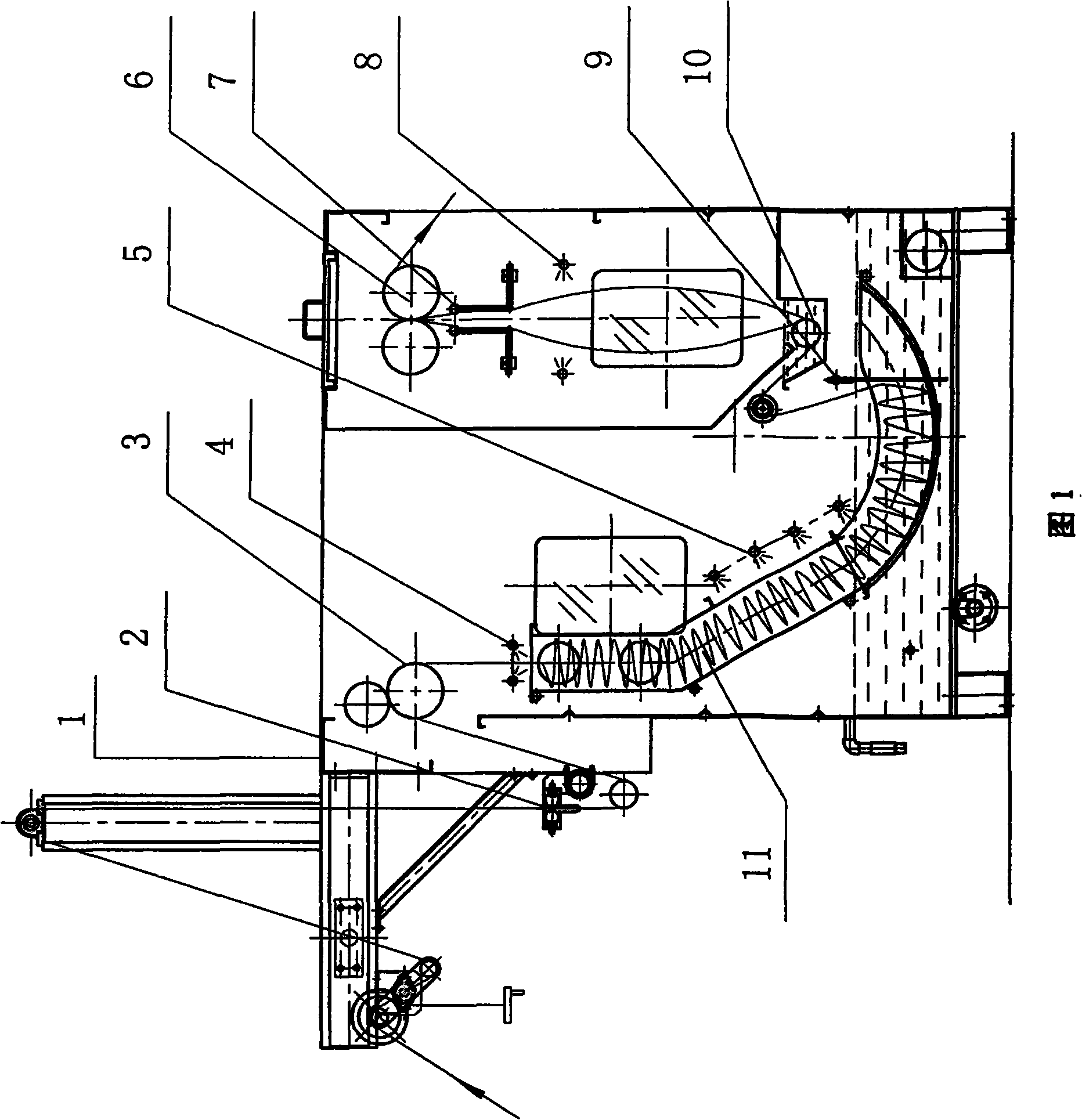

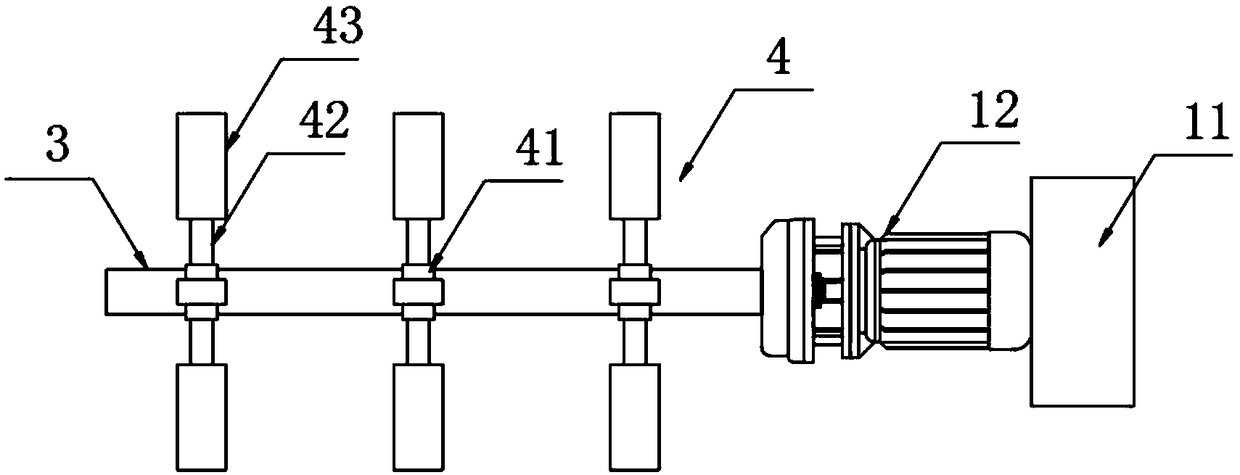

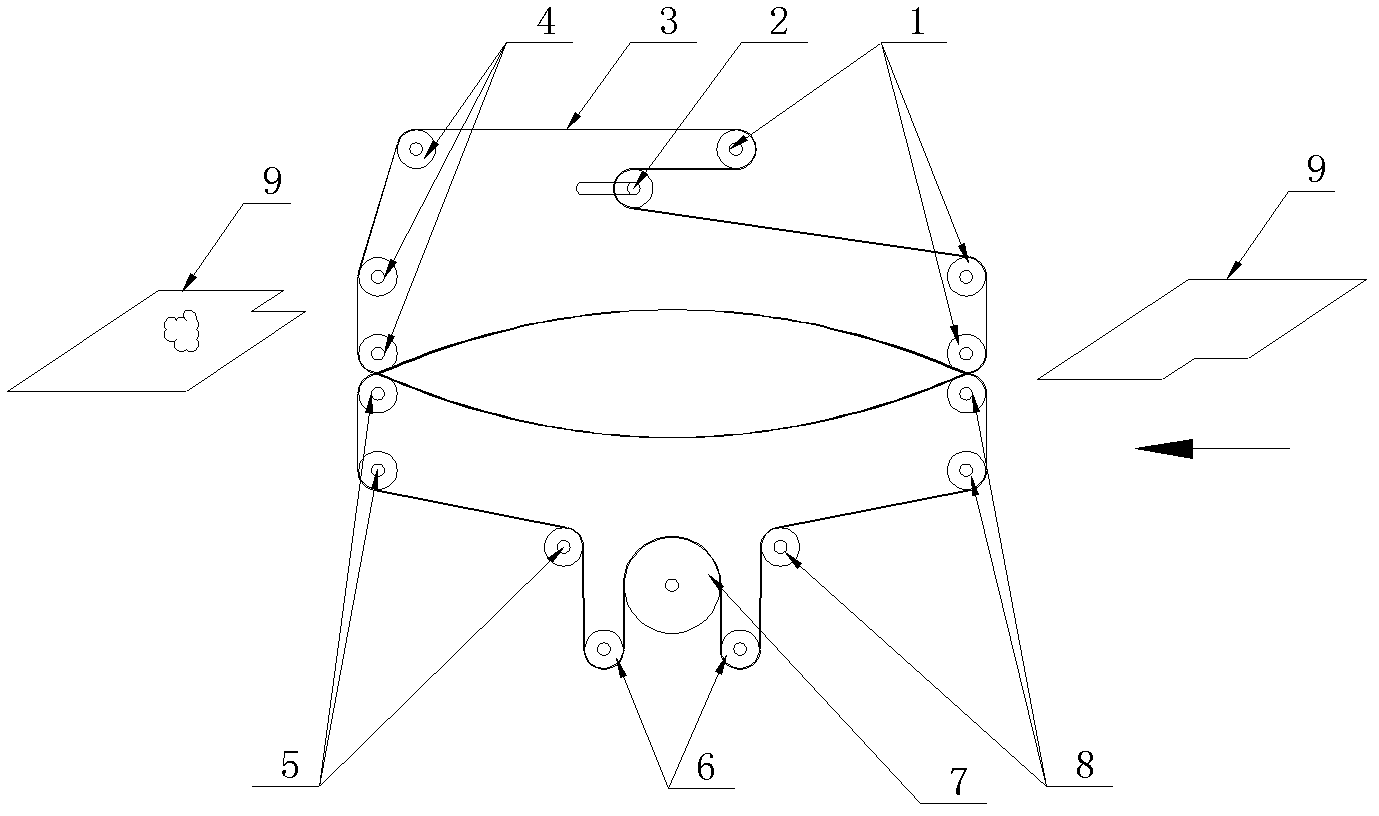

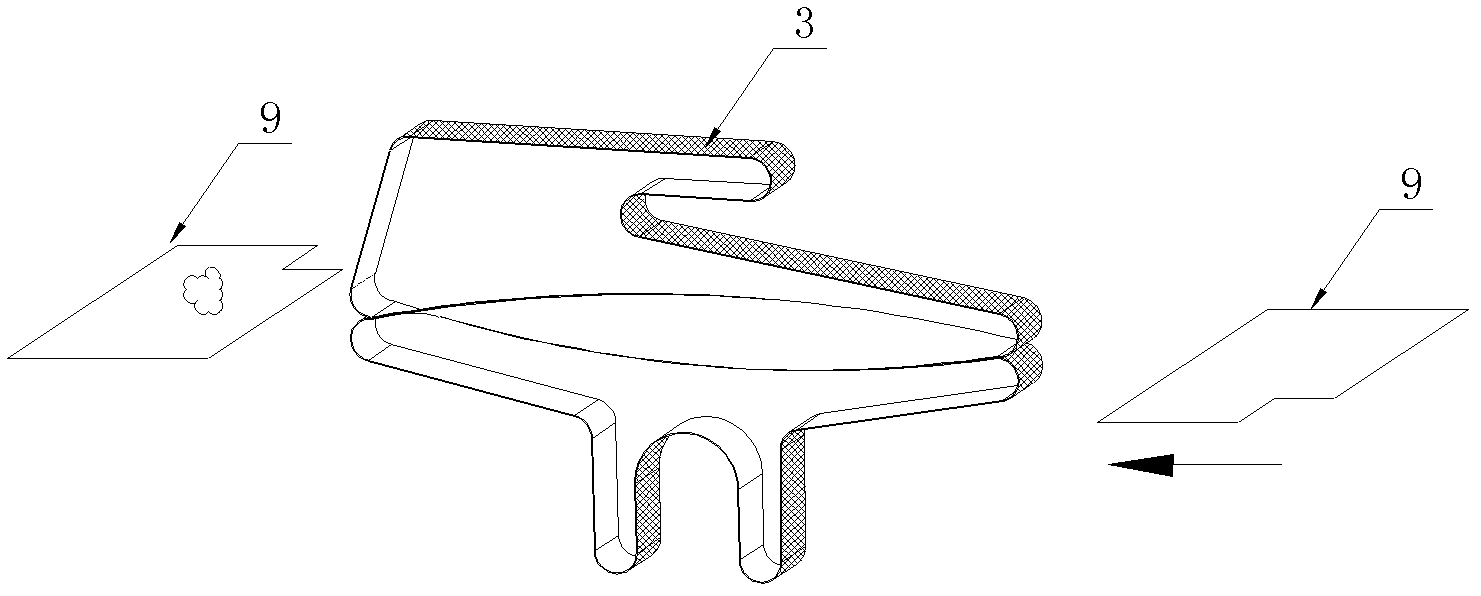

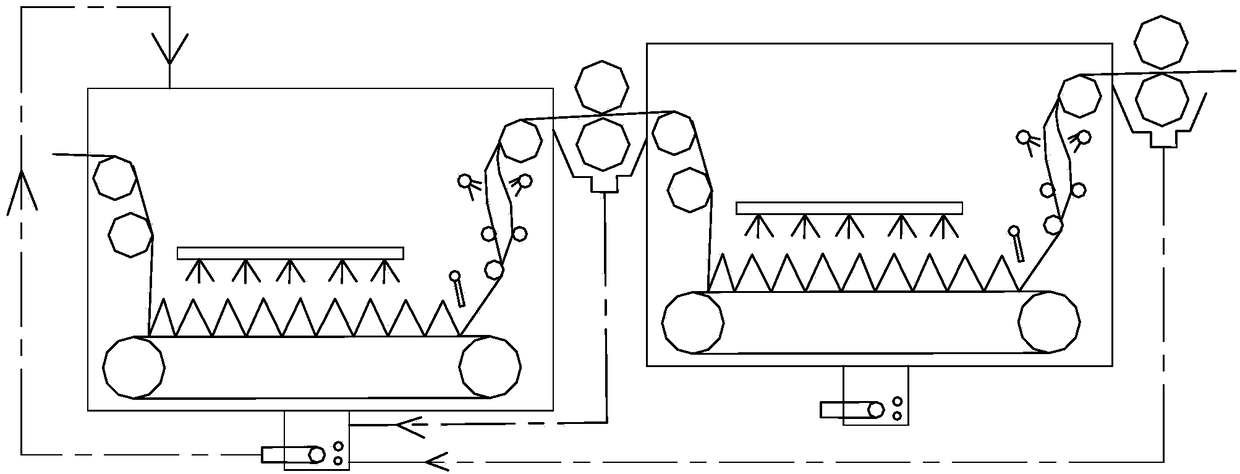

Crosslapper

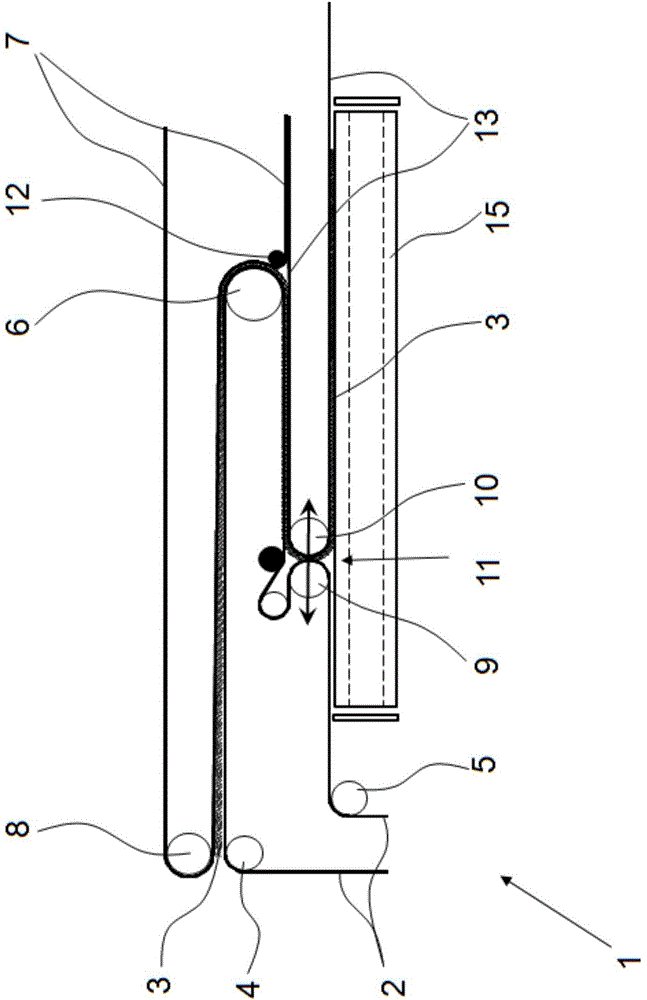

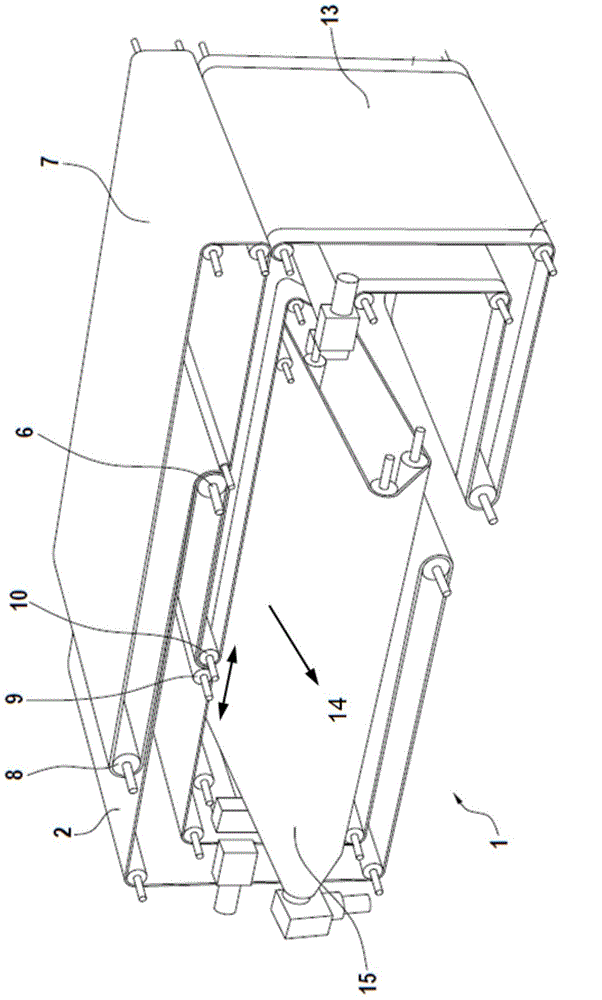

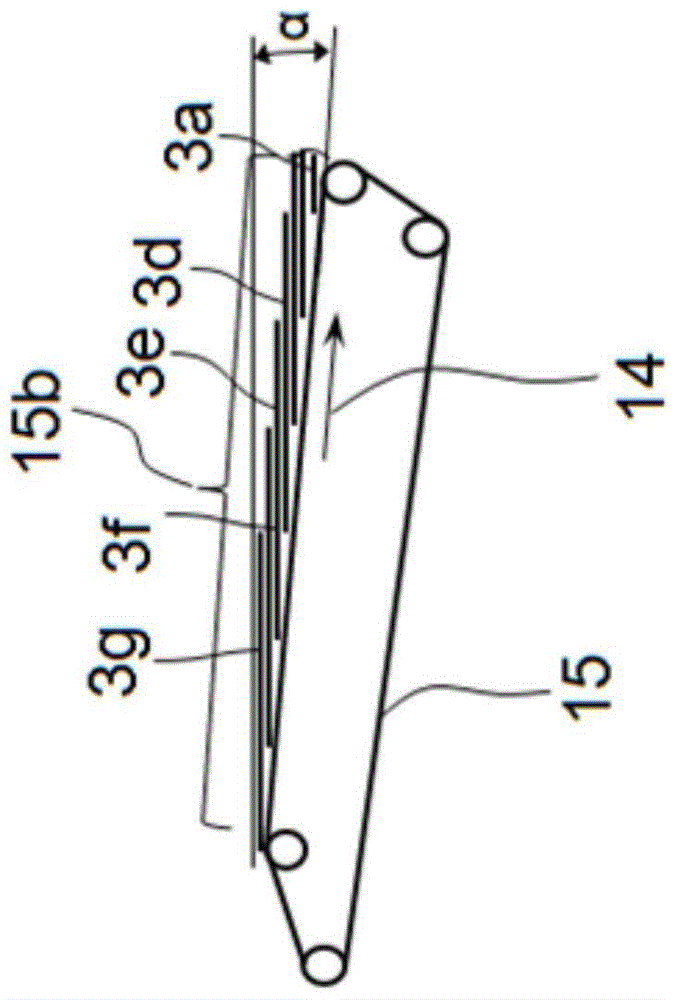

The invention relates to a crosslapper used for a multi-layer fibre web to form non-woven fabrics.The crosslapper comprises at least one belt used for conveying the fibre web (3) from an input area of the crosslapper (1) to a lapping gap (11) of a lapping pulley. During the process, the lapping pulley enables the fibre web to be laid on an output belt (15). The crosslapper is characterized in that the output belt (15) is provided with a mechanism used for forming a horizontal segment (15a) in an area at a laying position of the output belt (15) of the fibre web (3).

Owner:TRUETZSCHLER GMBH & CO KG

Polyurethane resin for solvent-free crease-free microfiber mirror-surface synthetic leather and preparation method and application of polyurethane resin

The invention discloses a polyurethane resin for solvent-free crease-free microfiber mirror-surface synthetic leather. The polyurethane resin is prepared from a component A and a component B in a mass ratio of 2:1-1:2 by means of stirring and mixing, wherein the component A comprises 80-95 parts of polytetrahydrofuran glycol, 5-15 parts of chain extenders, 0.01-0.5 part of catalysts, 0.5-2.0 parts of light / heat stabilizers, 0.01-0.2 part of defoaming agents and 0.1-2.0 parts of solvent-free color paste, and the component B comprises 40-50 parts of polytetrahydrofuran glycol, 50-60 parts of isocyanate, 0.001-0.1 part of phosphoric acid and 0.01-05 part of catalysts. The invention further provides a preparation method and application of the polyurethane resin. The solvent-free crease-free microfiber mirror-surface synthetic leather prepared by the preparation method is capable of resisting normal-temperature flexing for 100 thousand times in terms of physical performance and resistant to the temperature as low as -10 DEG C and remains uncracked for 80 thousand times at -10 DEG C.

Owner:HEFEI ANLI POLYURETHANE NEW MATERIAL

Anti-wrinkle crease-free non-woven fabric polyurethane synthetic leather used for shoes and preparation method thereof

ActiveCN105002748AReduce creasesIncrease softnessLamination ancillary operationsSynthetic resin layered productsFiberWrinkle skin

The invention discloses anti-wrinkle crease-free non-woven fabric polyurethane synthetic leather used for shoes and a preparation method thereof. The preparation method comprises the steps that fiber screen laying and needling are carried out on a spunlaced non-woven fabric surface, and a anti-wrinkle non-woven base is formed; after dipping carried out in a polyurethane dipping sizing agent is finished, condensing and ironing are carried out in a DMF aqueous solution; after coating is carried out by a polyurethane coating, the condensing, washing and drying are sequentially carried out; a post-processing grinding machine is used for carrying out orientated grinding on the surface of a semi-finished product; one layer of a thermoplastic polyurethane resin dry coating sizing agent is coated on release paper, after drying is conducted, one layer of a thermoplastic polyurethane dry bonding layer sizing agent is coated on the release paper, then drying is carried out in a drying oven until the release paper is half-dried, and a dry synthetic leather semi-finished product is obtained; the dry synthetic leather semi-finished product is attached to the wet synthetic leather semi-finished product, and after drying and ripening are conducted, the non-woven fabric polyurethane synthetic leather is obtained. The non-woven fabric polyurethane synthetic leather has the advantages that wrinkles cannot be generated, the physical mechanical strength is high, meanwhile sizing of shoemaking is good, and the durability is good; processing and performance requirements for children shoes, sport leisure shoes and the like are completely met.

Owner:ANHUI ANLI MATERIAL TECH

High-elastic and high-fluffy ultra-cotton-imitated fabric and production technology of same

InactiveCN104988633AFully degreasingShrink evenlyHeating/cooling textile fabricsWoven fabricsDyeingEngineering

A high-elastic and high-fluffy ultra-cotton-imitated fabric is formed by weaving ultra-cotton-imitated filaments and spandex filaments into a gray fabric with a single-face organization structure, and produced successively through weaving, open-width washing, initial shaping, dyeing, a post-treatment, drying, sanding and a shaping technology. The high-elastic and high-fluffy ultra-cotton-imitated fabric adopts a new technological process of conducting gray fabric shaping after the open-width washing, a rationally designed initial shaping technology and an improved dyeing technology, and solves problems in the prior art that a hand feeling, fluffiness and elasticity of the fabric are obviously weakened after the ultra-cotton-imitated elastic fabric is shaped by high-temperature heating. The fabric has good stretching resilience, can be stretched freely, is free of compression or tension, has the high fluffiness and a good texture, is equipped with functions of moisture absorption and sweat release, and has very excellent wearing comfort like cotton. Meanwhile, raw materials are cheap and no additional investments are added, but performances of the product far exceed the performances of common cotton-imitated elastic cloth. The high-elastic and high-fluffy ultra-cotton-imitated fabric has very high additional product values, promises a good market prospect and can generate good economic and social benefits.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

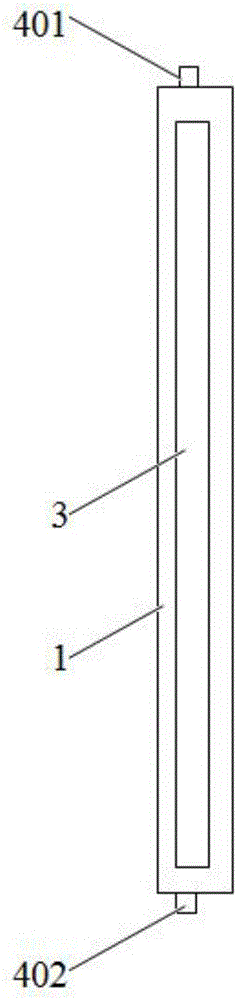

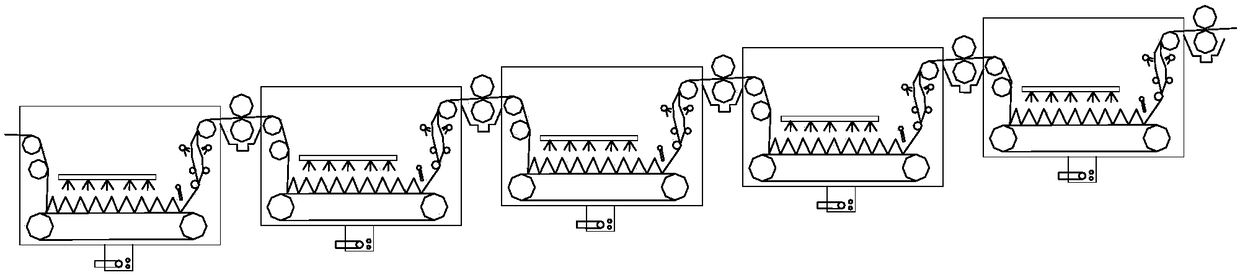

Flexible pole piece, preparation method of flexible pole piece, flexible battery and flexible mobile phone

InactiveCN106356505AHigh mechanical strengthImprove bendabilityFinal product manufactureElectrode carriers/collectorsFiberCellulose

The invention relates to a flexible pole piece, a preparation method of the flexible pole piece, a flexible battery using the flexible pole piece and a flexible mobile phone using the flexible battery. The preparation method of the flexible pole piece comprises the following steps: (1) mixing and stirring an active material, a conductive agent, an adhesive and a solvent to form a uniformly-dispersed suspension; (2) adding cellulose into the suspension, and stirring to obtain a viscous slurry; and (3) laying the viscous slurry on a metal net via a film rolling process, drying and then obtaining the flexible pole piece. According to the embodiment of the invention, the battery pole piece is prepared from the active material, the conductive agent, the adhesive, the solvent and cellulose; the cellulose can achieve a support effect and can ensure that the pole piece is high in flexibility and mechanical strength; the metal net can achieve an effect of a current collector, so that the mechanical strength of the pole piece can be further improved; a structure of combining the metal net and the slurry with support fiber can ensure that the pole piece still has high flexibility, the bending part is free of bending marks, and the material cannot fall off in the bending process.

Owner:武汉艾特米克超能新材料科技有限公司

A kind of flexible screen protective film and preparation method thereof

ActiveCN102294862AIncreased flexibilityAnti-scratchSynthetic resin layered productsSputteringCopper oxide

The invention discloses a flexible screen protection film, which is characterized by comprising a base material, a sterilizing and hardening layer, a gluing layer and a release film, wherein the sterilizing and hardening layer is arranged on the first surface of the base material; the gluing layer is arranged on the second surface of the base material; the release film is stuck on the gluing layer; and in addition, the base material is a PU (Poly Urethane) film, a TPU (thermoplastic urethanes) film, a PO (Propylene Oxide) film or a PVC (Poly Vinyl Chloride) film; the sterilizing and hardening layer is plated on the base material by vacuum evaporation, vacuum ion plating or vacuum sputtering; and the sterilizing and hardening layer is pure copper, copper alloy or copper oxide. The invention also discloses a preparation method of the flexible screen protection film. Compared with the prior art, the flexible screen protection film has the advantages that the surface of the protection film has the functions of preventing from starching and sterilizing. The flexibility of the whole protection film is greatly increased, and no creases are generated in the folding or bending process.

Owner:NINGBO SOKEN CHEM

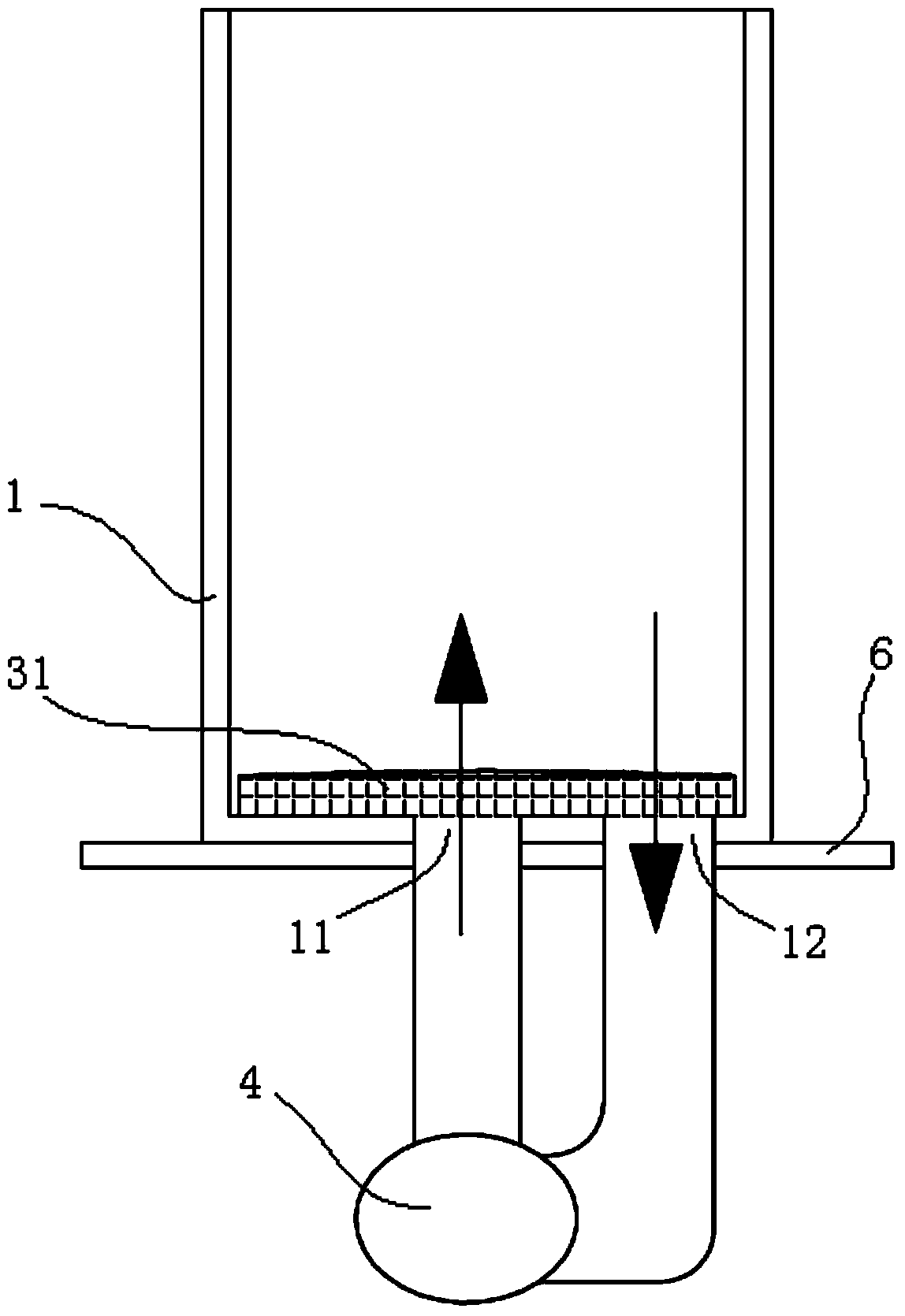

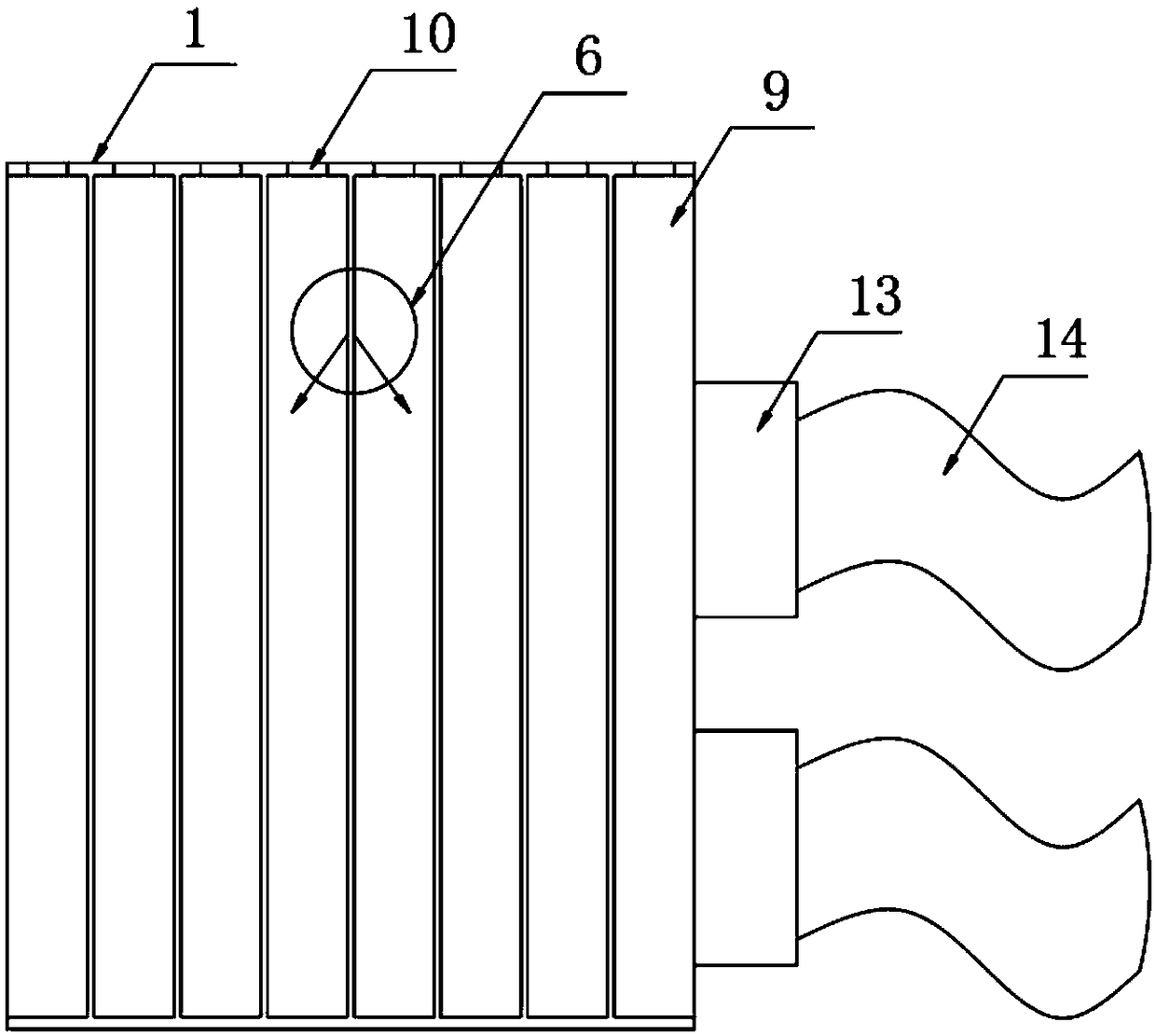

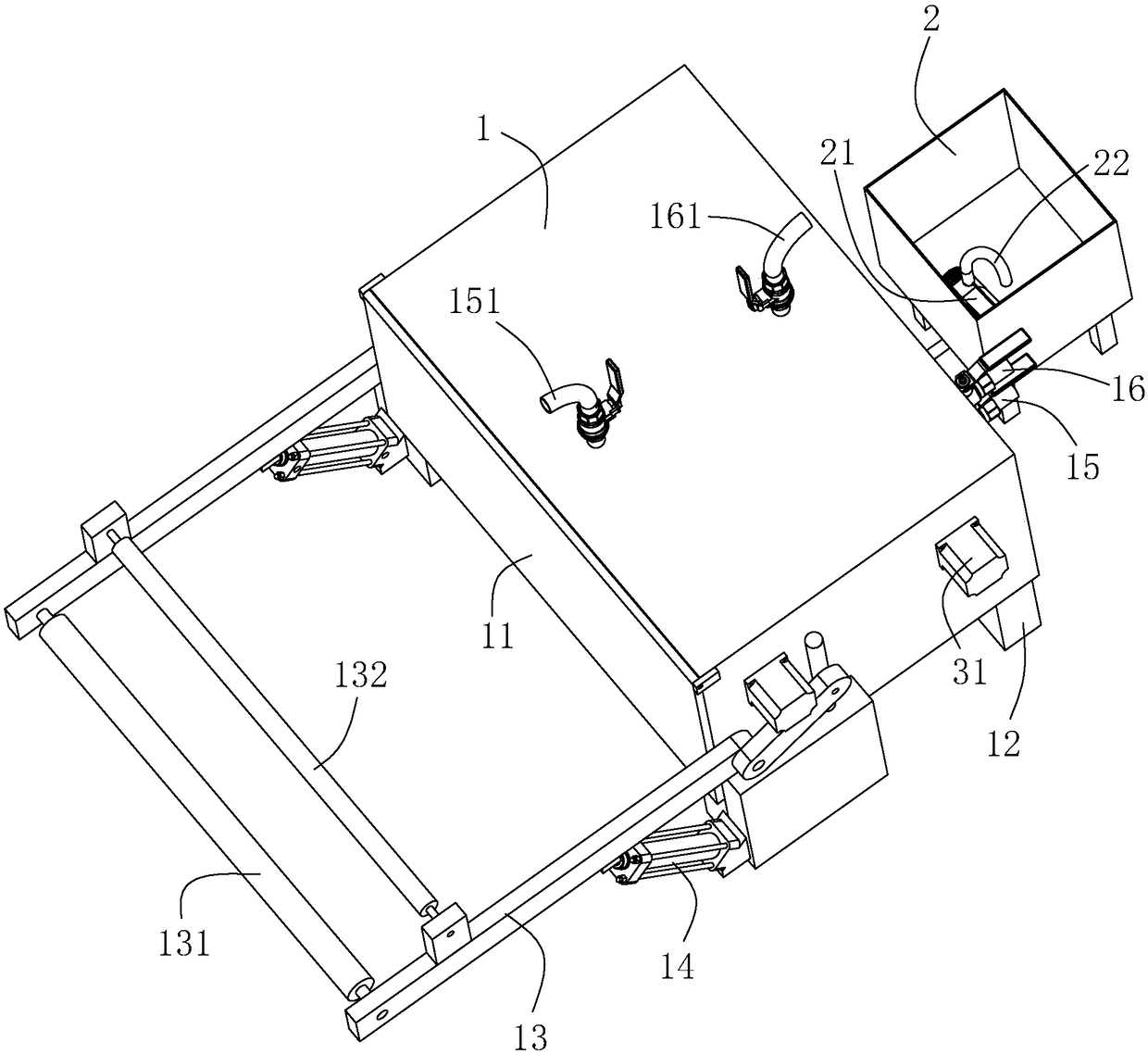

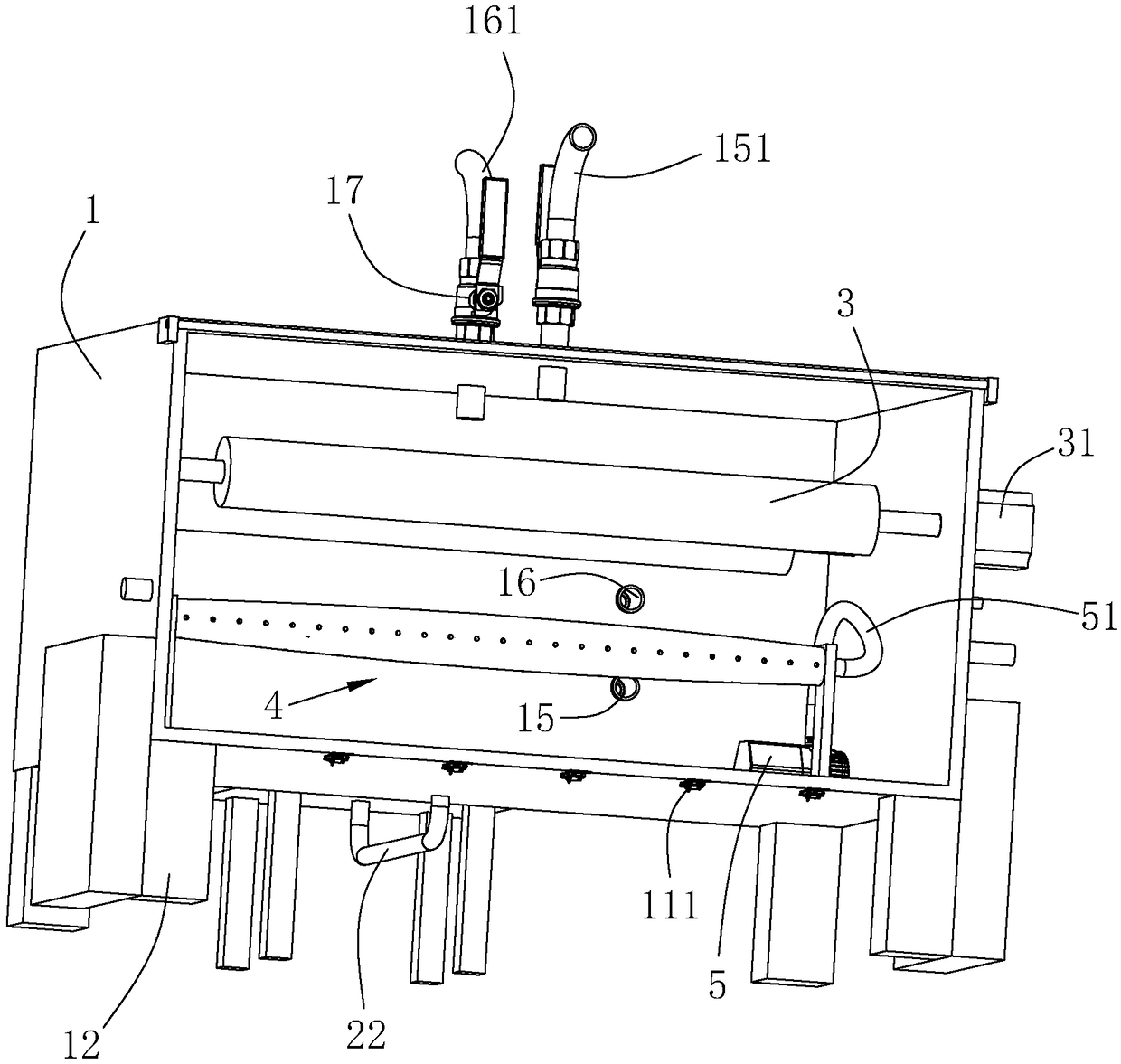

J-shape stacked pickling tank for knitting tubular open width refining rinsing combination machine

InactiveCN101289791ANo creaseNo blemishesLiquid/gas/vapor removal by squeezing rollersTextile treatment by spraying/projectingMechanical engineeringSmelting

The invention relates to a J-shaped stacking and steeping box for a knitted cylinder type open-width smelting and bleaching machine, comprising a steeping box body (1), a J-shaped stacking box (11), a cloth feeding spray device (4), a stacking spray device (5), an isochronous controller (9), a cloth discharge spray device (8), a blowing and bubbling device (7), water seals (10), a cloth feeding roller (3) and a cloth discharge roller (6), wherein, the cloth feeding spray device (4) is arranged above a grey cloth inlet of the J-shaped stacking box (11); the stacking spray device (5) is arranged on the side of the J-shaped stacking box (11); the isochronous controller (9) is arranged near a circular outlet of the J-shaped stacking box (11); the cloth discharge spray device (8) and the blowing and bubbling device (7) are arranged above the circular outlet of the J-shaped stacking box (11); and the water seals (10) are arranged under the cloth discharge spray device (8); the cloth feeding roller (3) is arranged on the upper front of the the cloth feeding spray device (4); and the cloth discharge roller (6) is arranged above the cloth discharge spray device (8) and the blowing and bubbling device (7). The J-shaped stacking and steeping box has the characteristics that: the surface of grey cloth can not be damaged and fuzzed and has no fold and grinding flaw; the water and the energy are saved; the efficiency is high; the production cost is low; the bleaching technique is stable; etc.

Owner:张琦

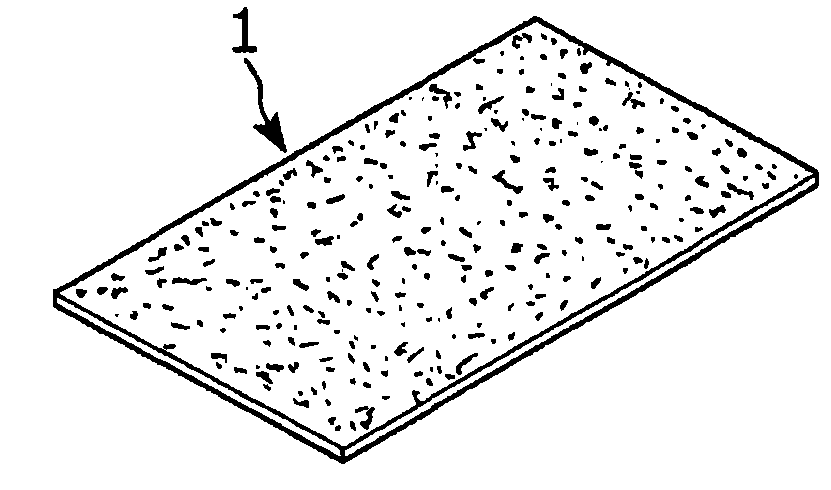

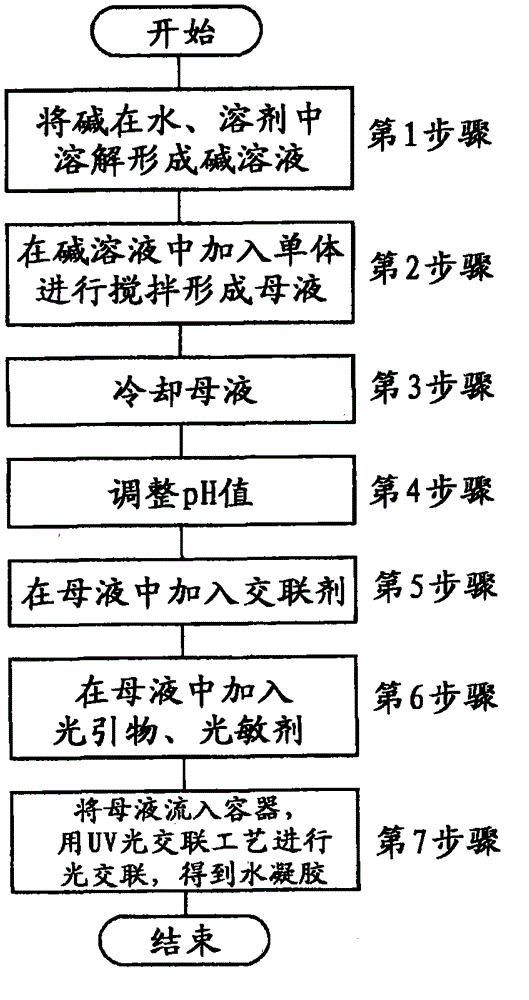

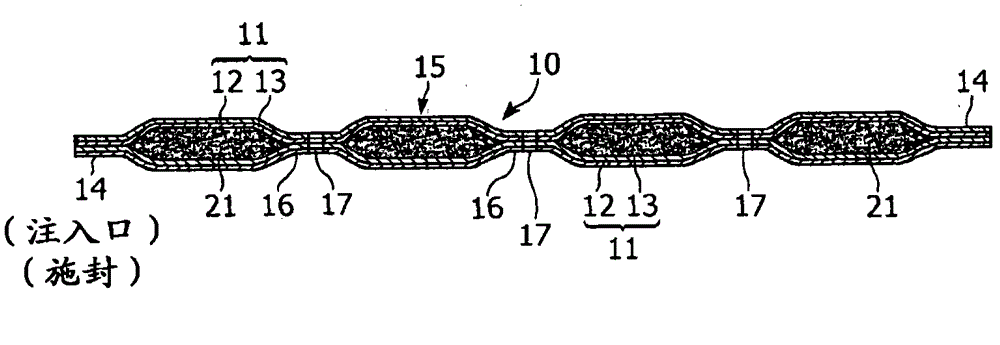

Water gel and method for manufacturing the same, as well as water retaining gel mat and method for manufacturing the same

InactiveCN102746518AIncrease elasticityNo creaseStuffed mattressesSpring mattressesPhotosensitizerLength wave

The present invention provides a water gel in the form of, for example, flakes with which the defects, such as malodor, discoloration, and hydration, associated with conventional water gels have been eliminated. The water gel 1 according to the present invention is provided by using, as raw materials, an alkaline solution, and a monomer, such as acrylic acid, acrylate, or acrylamide, which is added to the alkaline solution, the content of the monomer being approx. 10% to 20%; making a pH-value adjustment; adding a crosslinking agent, a photoprimer and a photosensitizer; and making a UV photo-curing treatment at a wavelength of 320 nm to 400 nm for photocrosslinking the monomer to produce a water gel in the form of, for example, flakes.

Owner:HIRAKAWA CORP

Thermoplastic polyimide (TPI) adhesive film, double-sided base material containing same and preparation method thereof

InactiveCN103232818AImprove adhesionIncrease freedomFilm/foil adhesivesMetal layered productsMetal foilThermal expansion

The invention provides a thermoplastic polyimide (TPI) adhesive film, a double-sided base material containing the same and a preparation method thereof. Through the combination of dianhydrides and diamines which are different in number of benzene rings and replacement position, the inlaid TPI adhesive film is prepared by inlaying a thermosetting material in a thermoplastic material; in the crystal imidization process, the glass transition temperature is 255 DEG C, the melting point is 380 DEG C, and the storage modulus is 2*10<6>Pa; the double-sided base material is synthesized by taking the TPI adhesive film as a medium carrier and coating the TPI adhesive film with a copper base, an aluminum base or other metal foils; the peel strength of the double-sided base material is ultra high (2.5KN / CM or above), the dielectric strength is more than 190KV / mm, and the thermal expansion coefficient is 21ppm DEG C; and the double-sided base material has a roughness of less than 2mu m, and does not warp or curl.

Owner:SHENZHEN DANBOND TECH

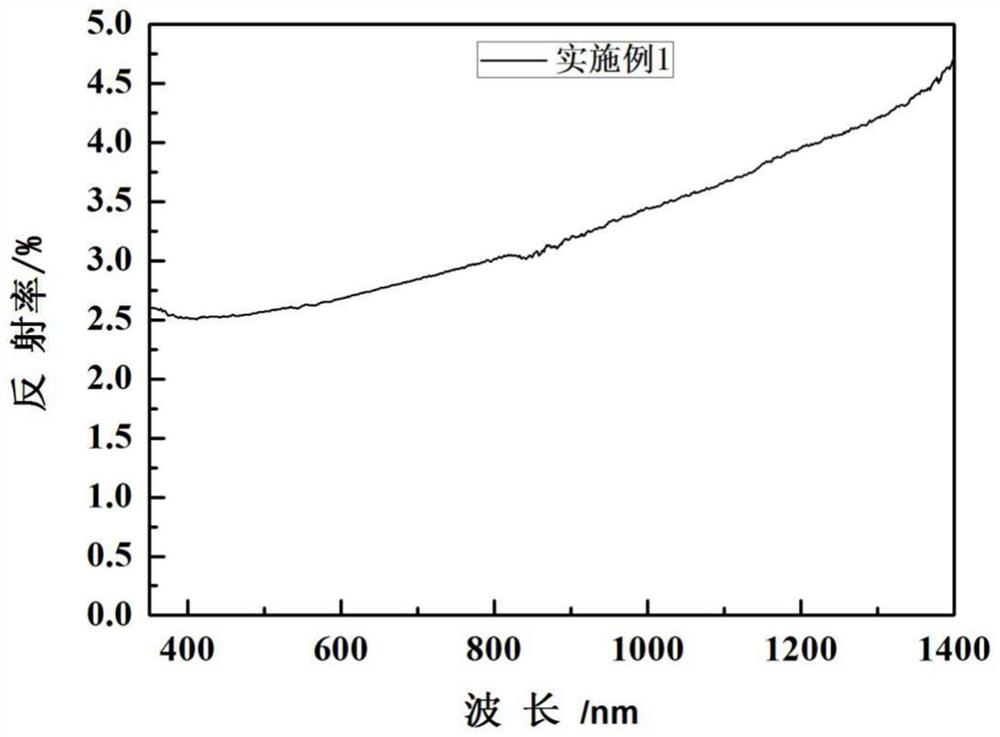

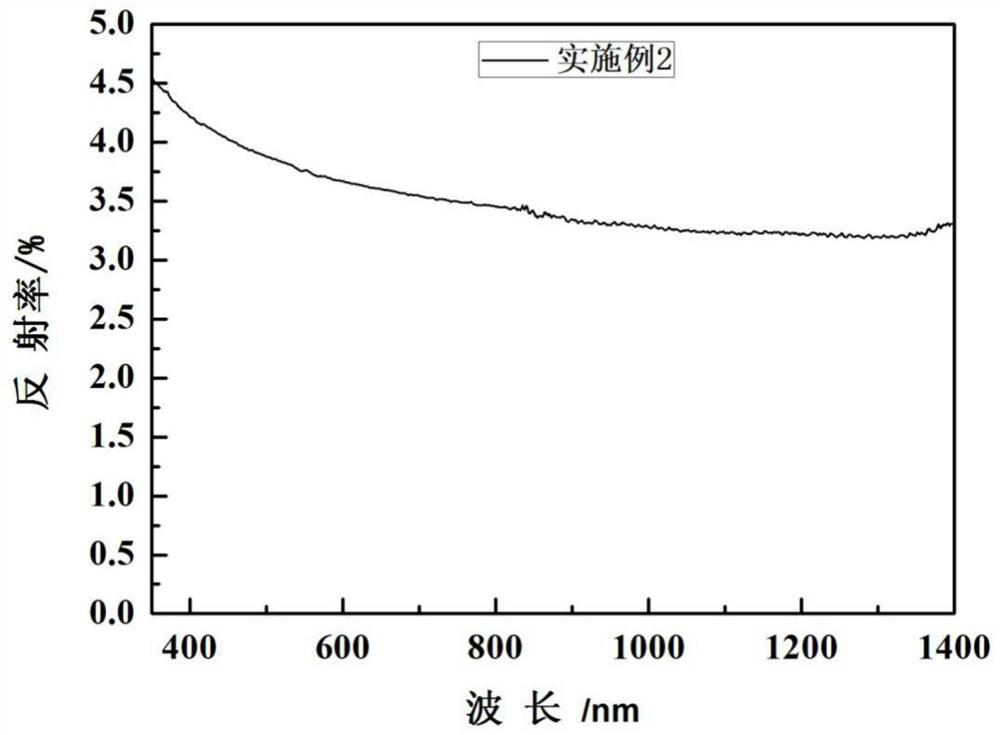

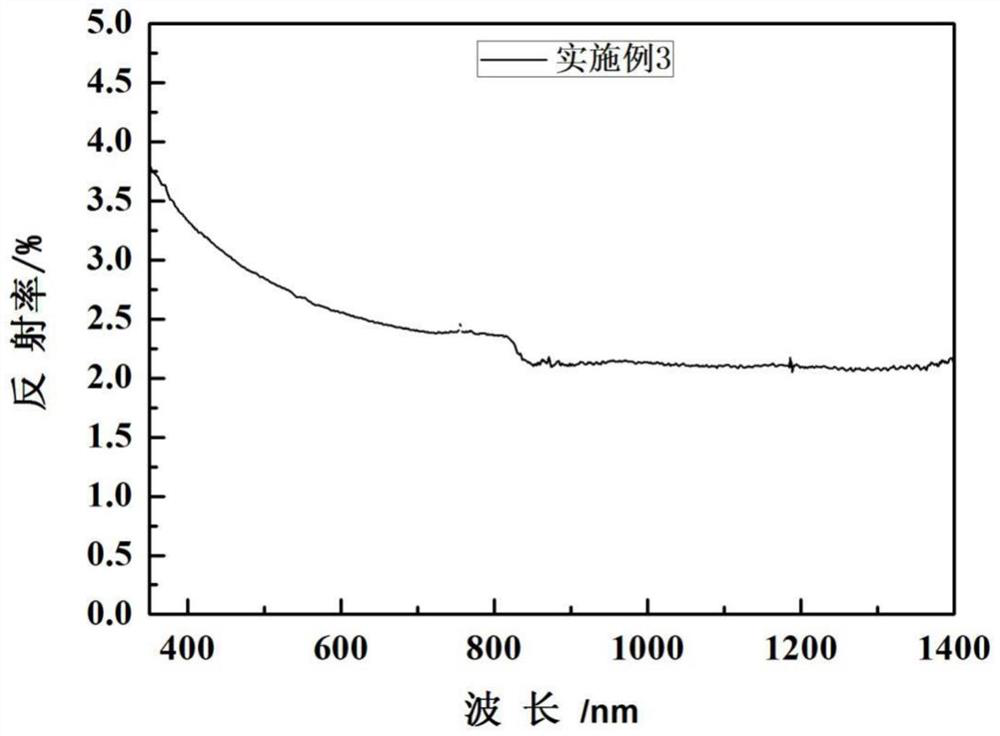

Black shading conductive coating and preparation method thereof

PendingCN113337198AImprove conductivityExcellent light-shielding and light-absorbing propertiesPolyurea/polyurethane coatingsRadiation-absorbing paintsPolymer scienceUltraviolet

The invention discloses a black shading conductive coating and a preparation method thereof. The coating comprises a component A and a component B in a mass ratio of 100:(1-20), wherein the component A comprises the following components in percentage by mass: 40-60% of a film-forming substance, 20-30% of a solvent, 10-20% of pigment filler and 5-15% of an auxiliary agent; the component B is a curing agent; the auxiliary agents comprise a dispersing agent, a defoaming agent, a flatting agent, a delustering agent, an adhesion promoter, a softening agent, a grinding aid, an ultraviolet aging auxiliary agent, a light stabilizer and an antioxidant. The shading conductive coating can be coated on the surface of plain cloth, various films, wall bodies or glass with flat surfaces to obtain a shading, light-absorbing and low-reflection material with the coating resistance as low as 305 m[ohm], and the preparation method provided by the invention is simple, is suitable for mass production, and can be applied to the fields of electromagnetic shielding, darkroom shading, military thunder camouflage protection and the like.

Owner:上海戎科特种装备有限公司

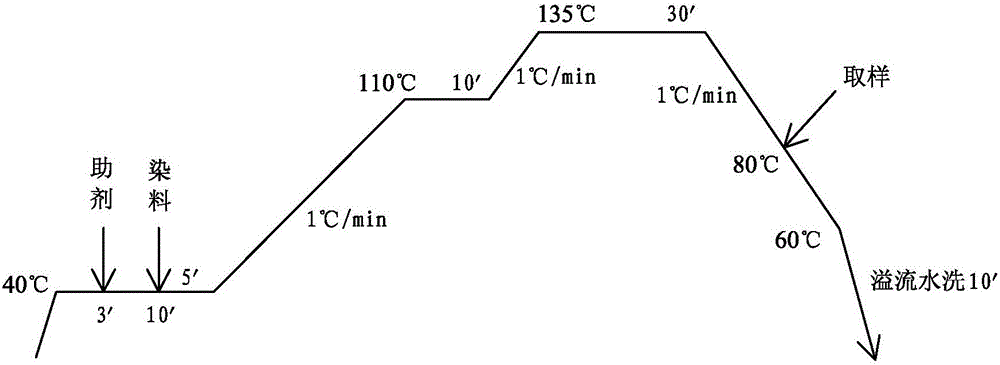

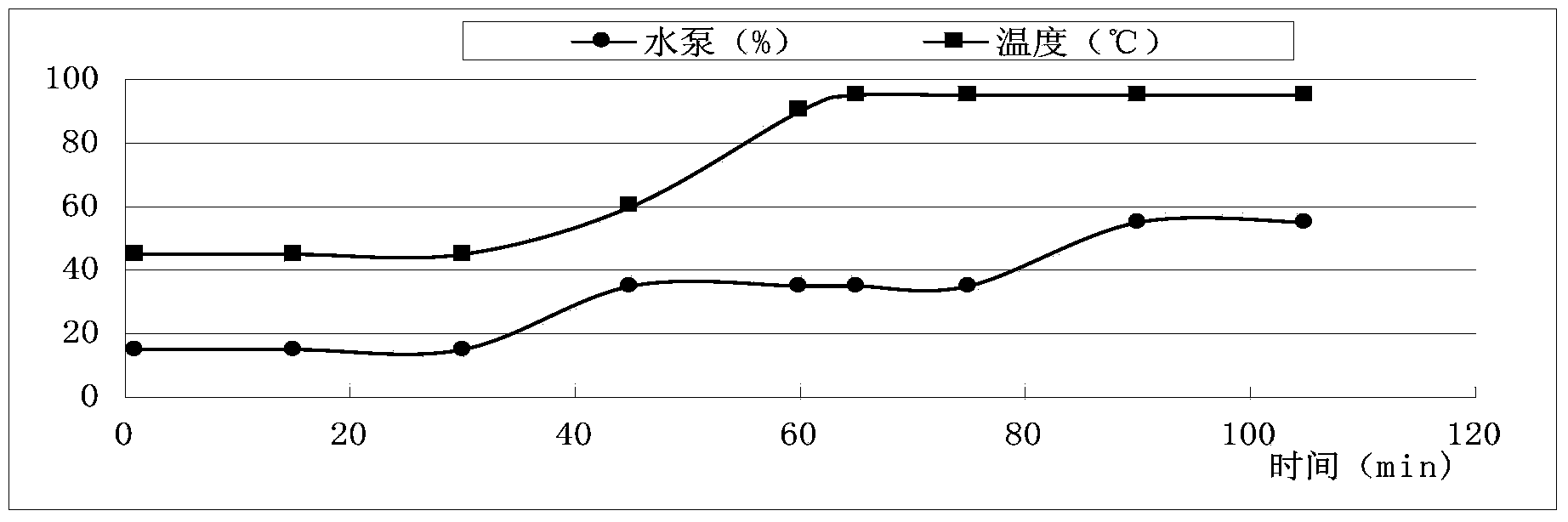

Colored wide and dense cotton belt and dyeing method thereof

ActiveCN104294503ASolve the problem of uneven dyeingUniform colorBleaching apparatusBiochemical treatment with enzymes/microorganismsPulp and paper industryThermal water

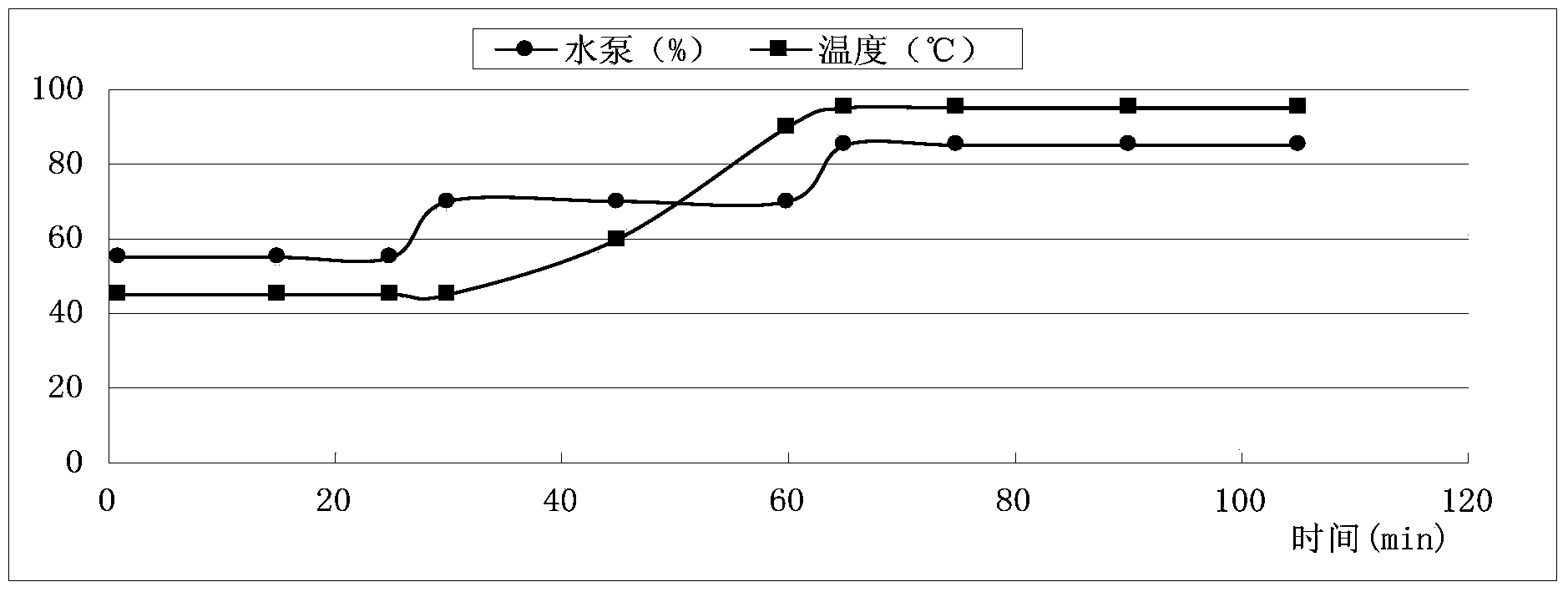

The invention discloses a colored wide and dense cotton belt and a dyeing method of the colored wide and dense cotton belt and belongs to the technical field of textile dyeing. The dyeing method comprises the following steps of (1) preshrinking the wide and dense cotton belt, wherein the wide and dense cotton belt is immersed in hot water with the temperature ranging from 50 DEG C to 90 DEG C for 15 to 50 minutes, and then dehydration is carried out, wherein the bath ratio is 1:5-20; (2) winding the belt, wherein the preshrunk wide and dense cotton belt is evenly wound around a dyeing shaft; (3) conducting pretreatment, wherein the dyeing shaft with the wound wide and dense cotton belt is placed in a dyeing device for pretreatment, specifically, the start pump speed of a water pump of the dyeing device is 10 percent to 15 percent of the maximum pump speed, the pump speed of the water pump is increased by 15 to 25 percent every 20 to 40 minutes, the pump speed is increased to 80 to 90 percent of the maximum pump speed finally, and pretreatment is carried out for 40 to 60 minutes at the final pump speed; (4) conducting dyeing, wherein the pretreated wide and dense cotton belt is dyed. By the adoption of the dyeing method, the obtained colored wide and dense cotton belt has the advantages of being even in color, free of wrinkles and folds. The dyeing method can be widely applied to dyeing production of wide and dense cotton belts.

Owner:广东康派环创科技有限公司

Preparation method of micro-fiber color-altered cow suede leather

The invention relates to a preparation method of microfiber color-altered cow suede leather, and belongs to the technical field of microfiber leather preparation. According to the preparation method,a pre-solidification and main solidification combined step-type foaming technology is firstly adopted in the foaming stage of the bass, so as to prepare a bottom leather bass which has large inner layer pores and dense outer layer pores; half-dry pasting is carried out by adoption of plain-grain release paper so as to prepare a semi-finished product; colored yangba resins are coated on the semi-finished product on a processor for twice; the semi-finished product is placed in an oven for high-temperature foaming and then embellished on the processor; and finally, the semi-finished product undergoes vein rubbing in a vein rubbing machine to obtain the color-altered cow suede micro-fiber leather. The preparation method is simple; the steps are easy to operate; and through the control of the foaming step and the color of the slurry or the type of the foaming powder, color-altered microfiber cow suede leathers with different styles and colors can be prepared, thereby significantly improvingthe leather surface feeling and playing role of inverting smooth hair and altering color.

Owner:WUXI DOUBLE ELEPHANT MICRO FIBER MATERIAL

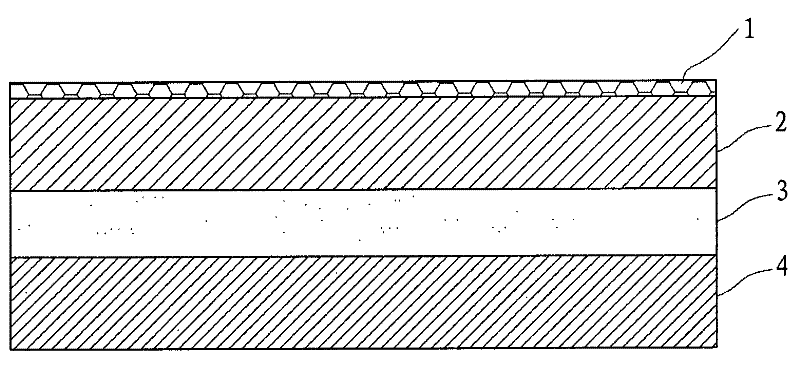

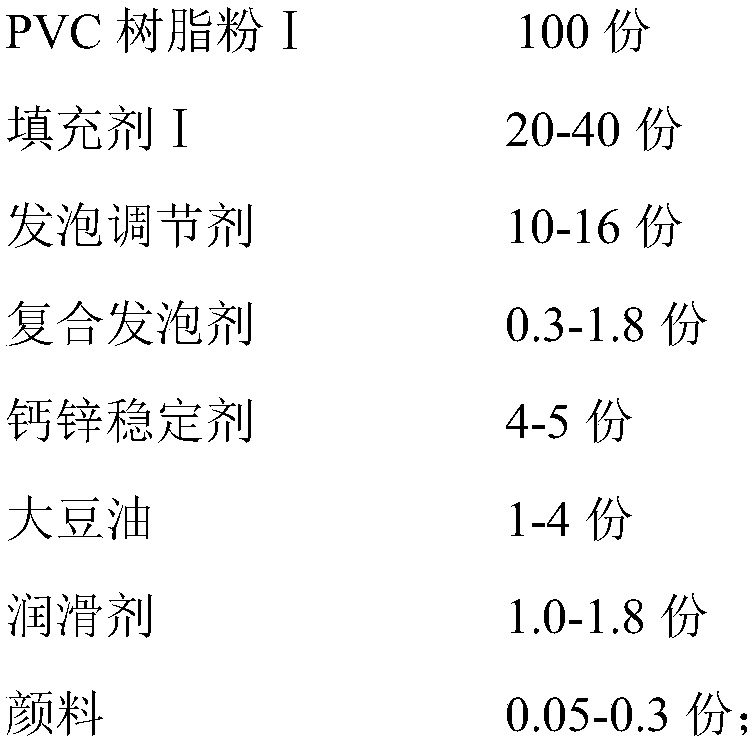

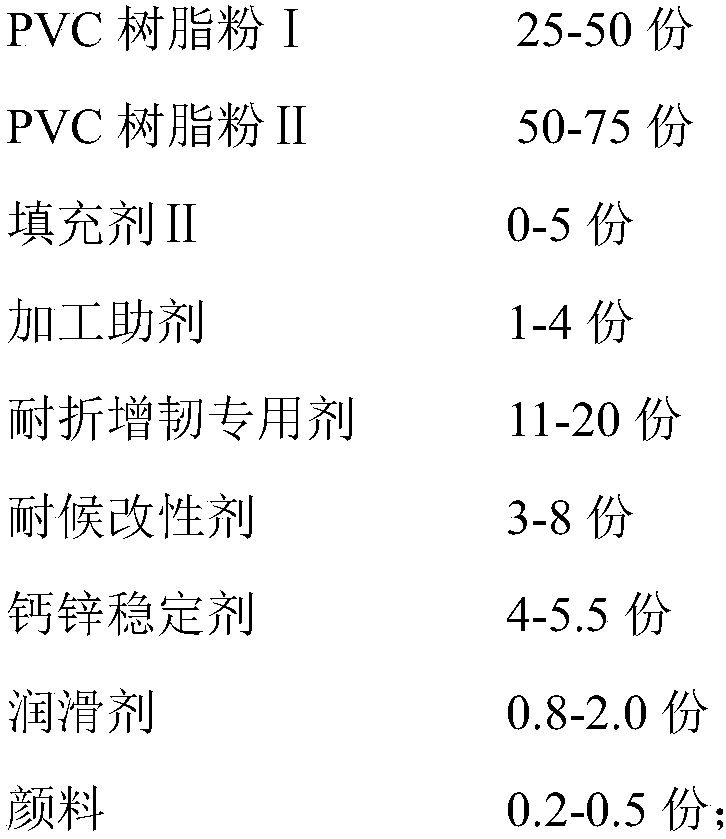

PVC foamed fold-proof plate and preparation method thereof

ActiveCN109591419AImprove liquidityFine foamSynthetic resin layered productsPolymer sciencePolyvinyl chloride

The invention belongs to the technical field of polyvinyl chloride plates, and particularly relates to a PVC foamed fold-proof plate and a preparation method thereof. The PVC foamed fold-proof plate comprises a core layer and surface layers, wherein the core layer is made from a foamed PVC material, and is prepared from PVC resin powder I, filler I, foaming regulator, compound foaming agent, calcium-zinc stabilizer, soybean oil, a lubricating agent and pigment; the upper surface layer and the lower surface layer are made of same raw materials; the surface layer is prepared from PVC resin powder I, PVC resin powder II, filler II, a processing aid, a fold-proof toughening specific agent, a weather-resistant modifying agent, calium-zinc stabilizer, a lubricating agent and pigment; and the fold-proof toughening specific agent is high-molecular-weight chlorinated polyethylene acrylate grafted polymer. The PVC foamed fold-proof plate has the advantages of high strength, pulling and folding resistance, surface cracking prevention, large-angle fold use availability and no mark, few combined joint and joint surface of the composition, environmental friendliness, sanitation, convenience in cleaning, high cost performance and wide application range.

Owner:SHANDONG BODO PLASTICS CO LTD

RPUC high-performance die-pressed sole material

InactiveCN106916366AUniform foamingImprove structural stabilitySolesDomestic footwearRubber materialMaterials science

The invention discloses a RPUC high-performance die-pressed sole material, wherein a formula comprises the following components: 100 parts of a rubber material, 0.6-1 part of a bridging agent, 6.2-17.8 parts of an auxiliary gent, and 2-5 parts of a color material. A specific use method is improved. A sole produced by the RPUC high-performance sole formula with the specifically selected materials and proportion meets the requirements of slip stopping, abrasion resistance, light weight, high elasticity and the like, the sole comfort degree and practical degree are improved, and the development tendency of the sole is met.

Owner:DONGGUAN XINGTENG FOOTWARE MATERIAL

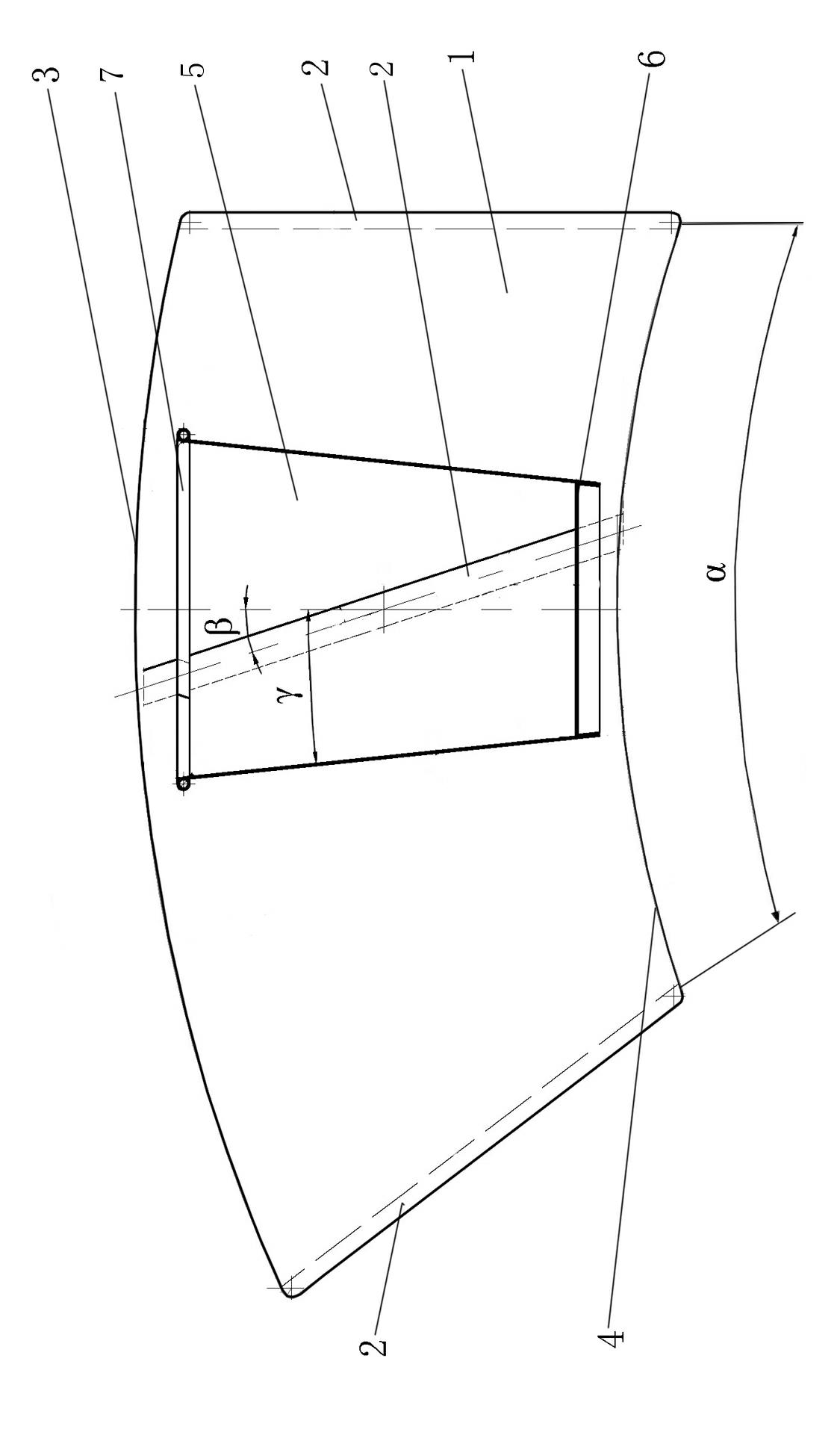

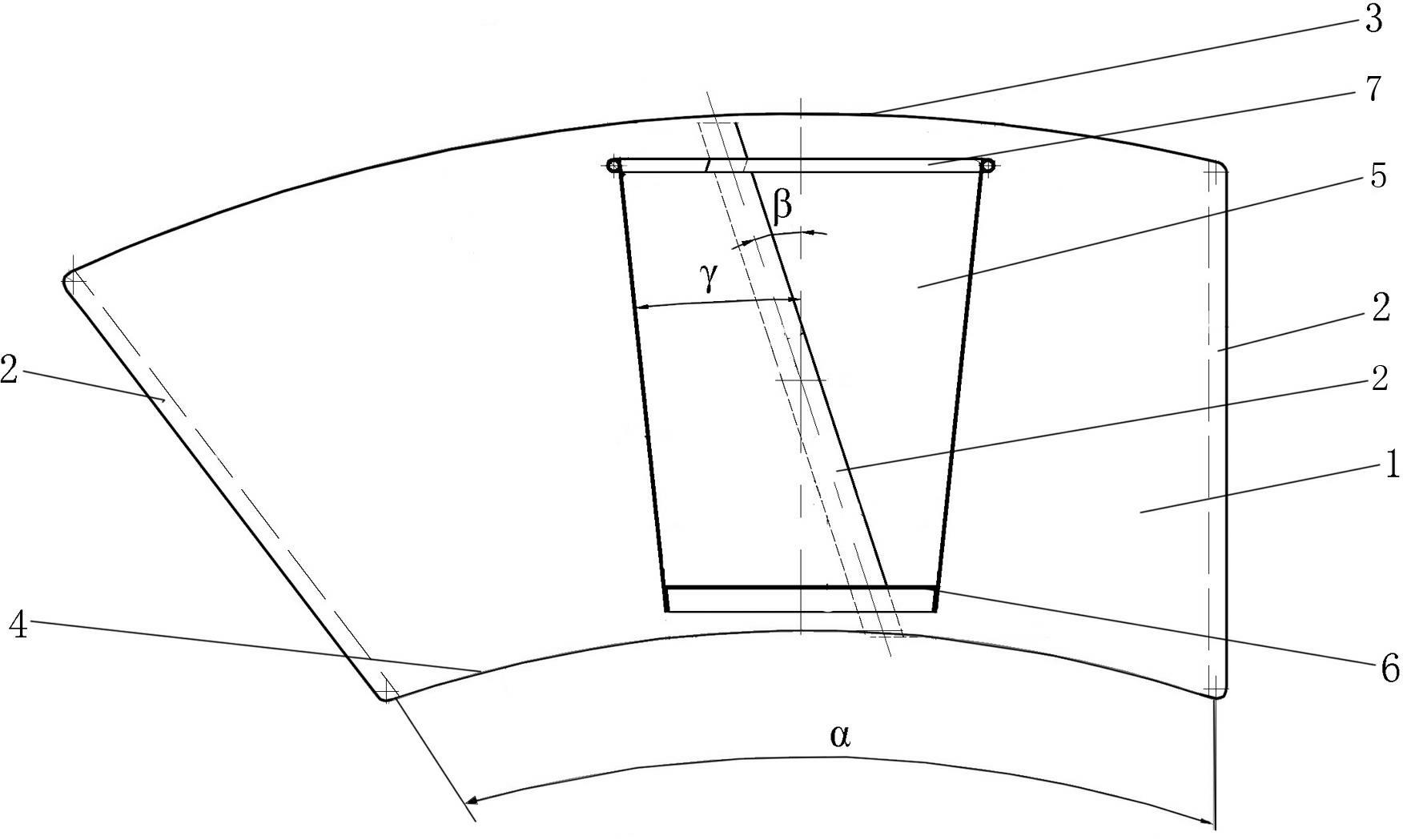

Obliquely overlapped paper cup and manufacturing method thereof

InactiveCN102379602ALow costImprovement of technical parametersPaper/cardboard wound articlesDrinking vesselsRolling paperPaper tape

The invention relates to a method for manufacturing a paper cup, especially relates to an obliquely overlapped paper cup and a manufacturing method thereof. The invention mainly solves the technical problems that in the prior art, paper cups are all prepared by winding up fan-shaped sheet paper, because the overlap edges of the prepared paper cups are arranged vertically, when the paper cups are unfolded and arranged on roll paper, a gap between every two paper cups is large, and more paper is wasted after cutting, thereby causing a high production cost. The paper cup provided by the invention comprises a paper tape body, the two ends of the unfolded paper tape are respectively provided with an overlap edge, an included angle is formed between the two overlap edges, the upper and lower edges of the paper tape body are respectively an upper arc edge and a lower arc edge, the left and right ends of the paper tape body are wound inwards so as to form a truncated-cone shaped cup body, the two overlap edges are fixed together and then obliquely arranged on the cup body, and a cup bottom is fixed at the lower arc edge. The manufacturing method provided by the invention comprises the steps of carrying out roll paper intaglio preprinting; laminating; carrying out die cutting on paper blanks; forming paper cups by using a disposable paper-cup forming machine, and outputting finished products.

Owner:赵建芳

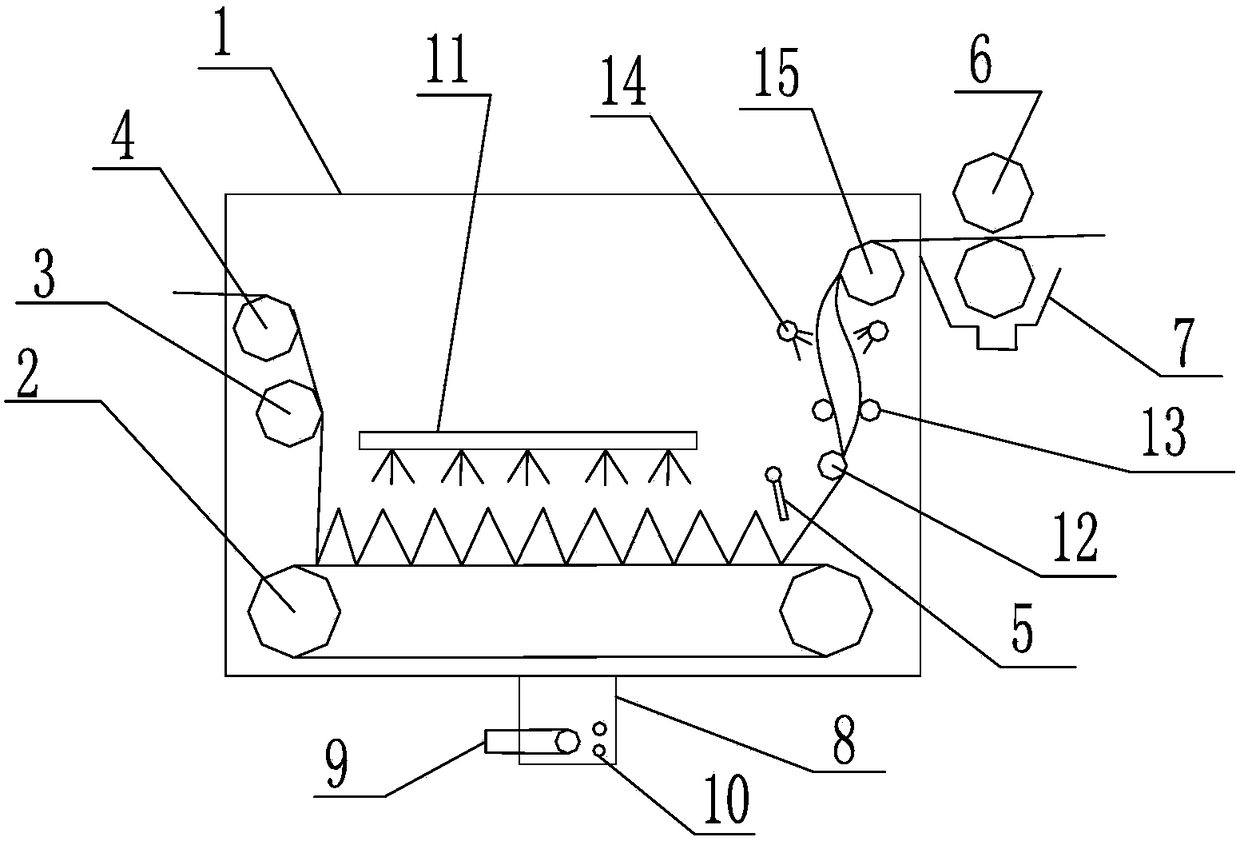

Knitwear dust removing and ironing device

InactiveCN108842419ASlap fullGood for ironingMechanical cleaningPressure cleaningArchitectural engineeringClothes hanger

The invention discloses a knitwear dust removing and ironing device, which comprises a device body, and two sets of upper and lower guide rails are arranged on two sides of the inner wall of the device body; a rotating shaft is arranged between the upper and the lower guide rails on both sides, and a plurality of dust removing devices are sleeved on the rotating shaft; one side of each dust removing device is provided with two sets of electric irons, the top of each dust removing device is provided with a left guide rail and a right guide rail, and two ends of the left and the right guide rails penetrate through the two side walls of the device body and extend to the side of the outer wall of the body; the bottom of the left and the right guide rails are movably connected with a pluralitysets of first stepping motors, clothes hangers are fixedly arranged at the bottom of each set of first stepping motor, and dustproof doors are arranged at both sides of the upper and the lower guide rails. The rotating shaft of the dust removing device drives the dust removing device to rotate, so that the knitwear is tapped, and the rotating shaft can move up and down to make the knitwear more comprehensively beaten, thereby removing the dust on the knitwear.

Owner:FOSHAN SANCHUANG KNITTING CO LTD

Heat conduction adhesive tape and production method thereof

InactiveCN108102568ANo creaseFilm/foil adhesive primer layersPressure sensitive film/foil adhesivesResin matrixMetal

The invention provides a heat conduction adhesive tape and a production method thereof. The heat conduction adhesive tape comprises a heat conduction layer and a pressure-sensitive adhesive layer disposed on one side surface of the heat conduction layer, the heat conduction layer comprises a resin-base layer and a first heat conduction metal layer, the resin-base layer comprises a resin matrix andheat conduction packing dispersed in the resin matrix; and the first heat conduction metal layer is arranged on the surface of one side, close to the pressure-sensitive adhesive layer, of the resin-base layer. The heat conduction layer comprises a resin-base layer and a first heat conduction metal layer, and the resin-base layer comprises a resin matrix and heat conduction packing dispersed in the resin matrix. The bending resistance of the heat conduction layer and the heat conduction adhesive tape can be improved by utilizing the resin-base layer, the heat conduction packing dispersed in the resin matrix can enable the resin-base layer to have high heat conduction performance, so that the first heat conduction metal layer can be thinned, the heat dissipation performance can be compensated, and the heat conduction adhesive tape has good bending resistance and heat conduction performance by combining the first heat conduction metal layer with good heat conduction performance.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Overturning mechanism of single-sheet printing product and working method of overturning mechanism

InactiveCN102501584ANo creaseProtect the creasePrinting press partsEngineeringMechanical engineering

Owner:MASTERWORK GROUP CO LTD

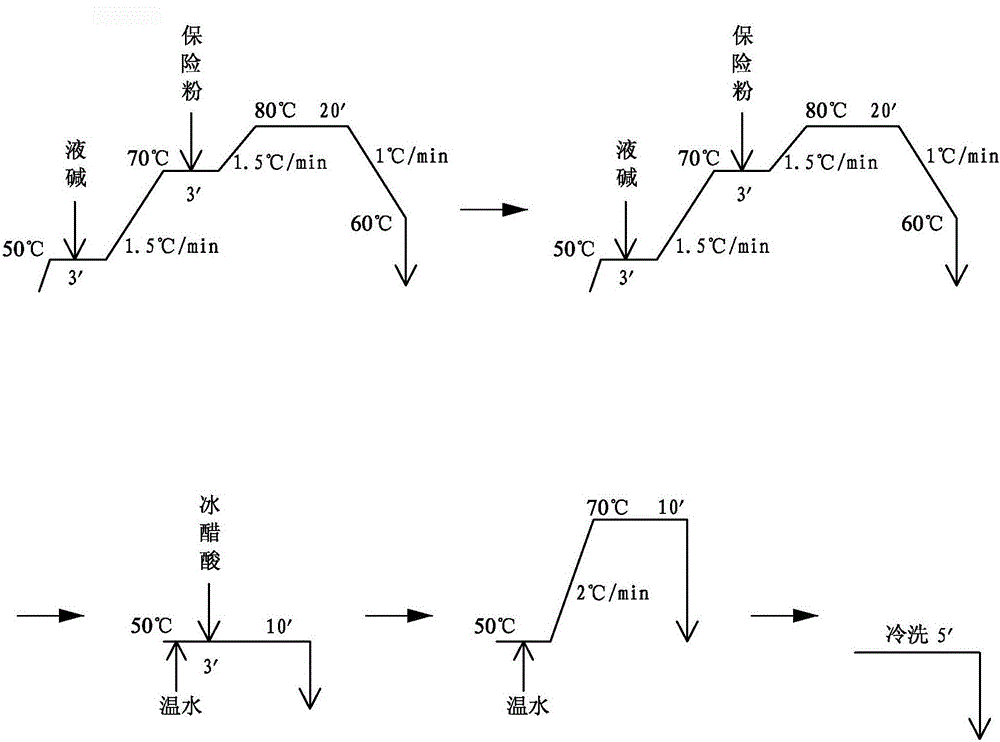

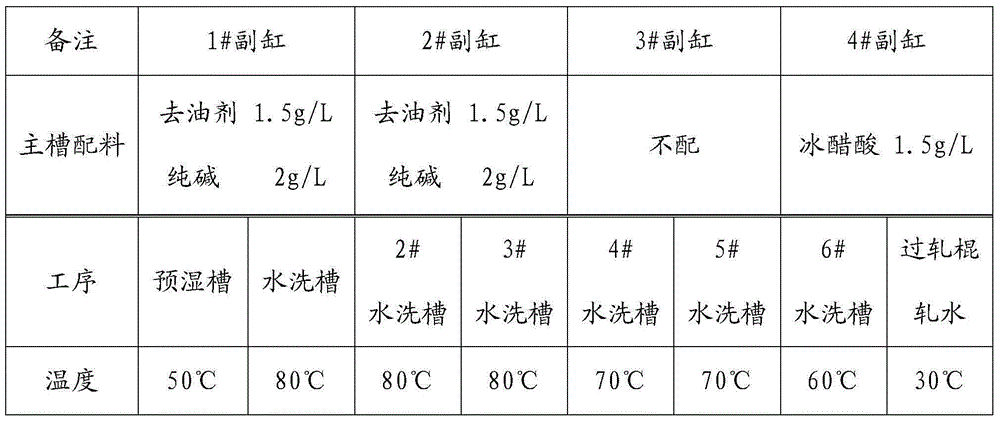

An afterfinish method allowing a wool knitted single-face-felted fabric to be free of creases

InactiveCN108823889ANot easy to expandEasy to unfoldShrinkingSucessive textile treatmentsEngineeringWool

The invention relates to the fields of textile designing and dyeing and finishing, and particularly relates to an afterfinish method allowing a wool knitted single-face-felted fabric to be free of creases. The method includes following steps in order: subjecting a gray fabric to crabbing and setting in an overflow dyeing vat; washing with an MAT air washing machine; washing with a roller type water washing machine; fulling, dehydrating, slitting, drying, softening with a softening agent, continuously decatising, shrinking and inspecting a finished product. Compared with the prior art, main technical effects of the method are that: the cylinder-shaped gray fabric is subjected to crabbing and setting with the overflow dyeing vat firstly, thus overcoming a problem that gray fabrics of wool knitted single-face-felted fabrics curl up towards one side, and are not liable to expand, difficult in folding position changing, and prone to crease generation in steps of washing, fulling and the like; then steps of air washing, washing and shrinking with a large bath ratio are adopted to achieve step-by-step shrinking and slow fulling of the grey fabric; the grey fabric can be easily expanded and a folding position can be changed easily, thus achieving an objective of no crease, and overcoming an afterfinish crease quality problem of wool knitted single-face-felted fabrics; and a finished-product fabric is free of a curling edge.

Owner:JIANGSU DANMAO TEXTILE

Multi-purpose high-modulus polyurethane resin and application thereof

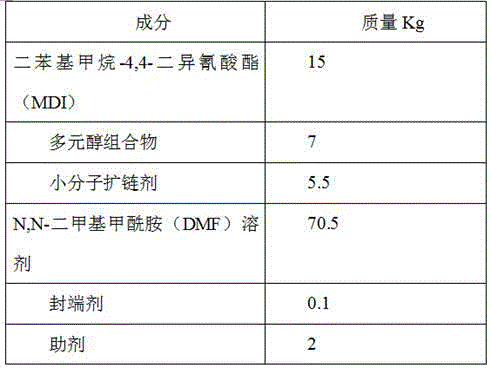

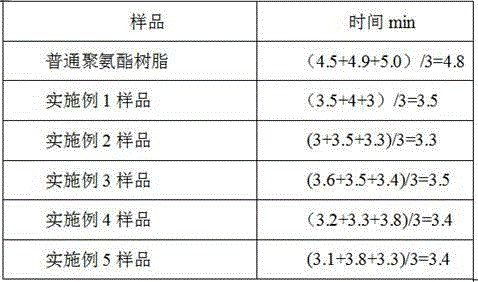

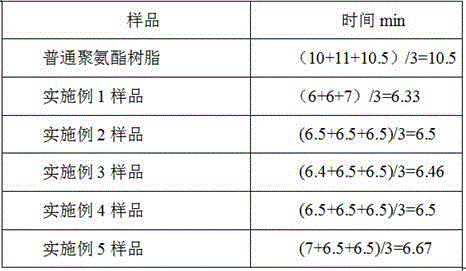

ActiveCN105732950AGood breathability and water absorptionBright colorsDimethyl formamideColor contrast

The invention discloses a multi-purpose high-modulus polyurethane resin and its application. Its components are calculated according to the total mass percentage of the reaction system: including 14%-16% of diphenylmethane-4,4-diisocyanate; polyol composition 6%-8%; small molecule chain extender 5%-5.5%; N,N-dimethylformamide solvent 68%-72%; end-capping agent 0.03%-0.1% and auxiliary agent 1%-2%. The present invention uses mixed polyols and mixed chain extenders to reduce the crystallinity of the system, uses different proportions of polyol compositions and chain extenders to adjust the slender and upright cell structure and superior color development, and is modified by adding polyether Additives make the cell structure more uniform, slender and upright, and feel more comfortable. The polyurethane resin prepared by the invention has the characteristics of high modulus, excellent color development, uniform, slender and upright cells, good anti-curling performance, fast solidification, fast water washing, etc., and has wide application range.

Owner:TAIZHOU HEXIN HIGH MOLECULAR NEW MATERIAL

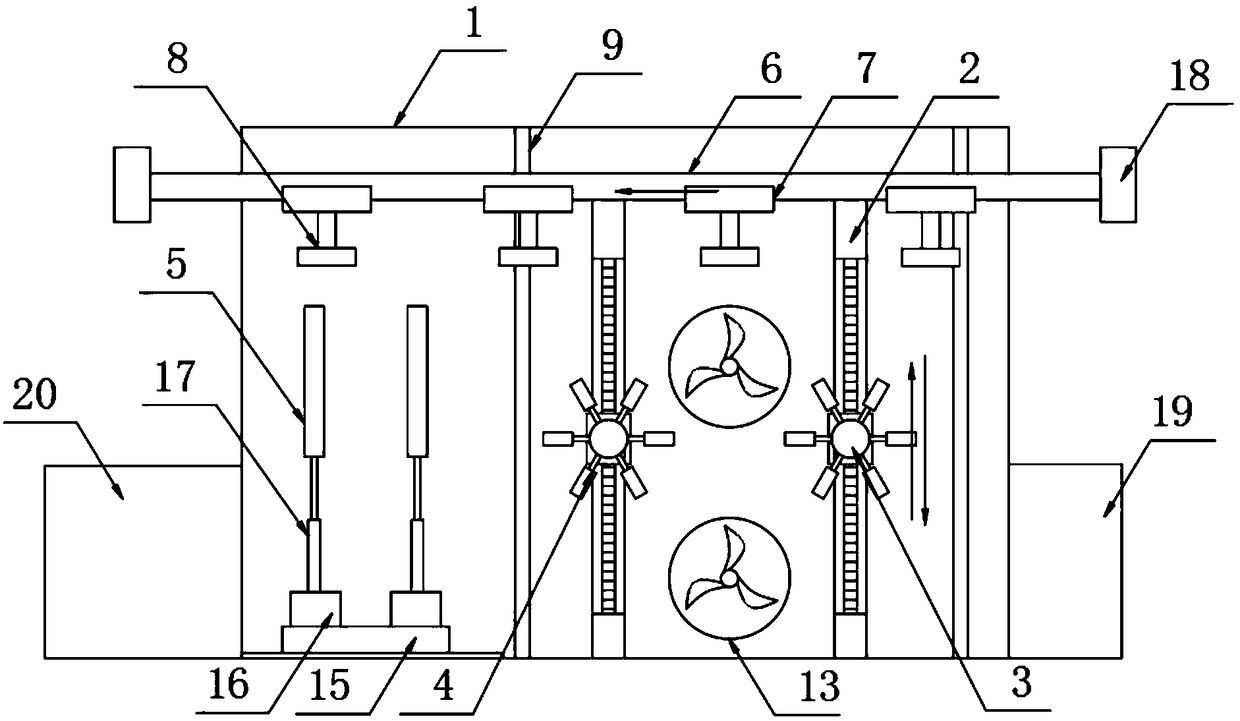

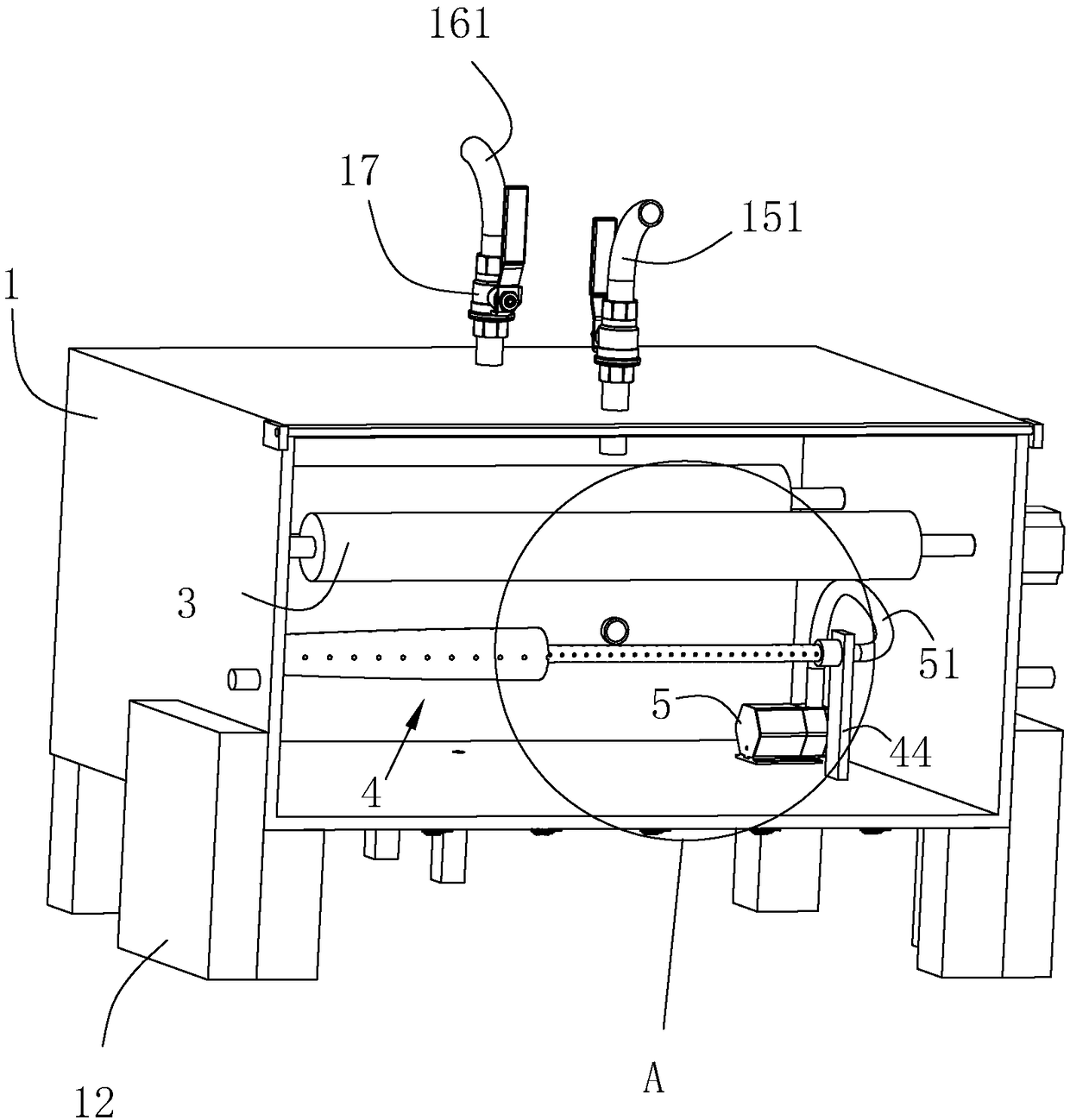

Cloth dyeing device and cloth dyeing method utilizing device

ActiveCN108642753ANo creaseGuaranteed to soak into the fabricTextile treatment containersTextile treatment machine arrangementsDyeingEngineering

The invention relates to the technical field of printing and dyeing and aims to solve the problem that the cloth dyeing quality is reduced due to fabric folding and provide a cloth dyeing device. According to the technical scheme, the cloth dyeing device comprises a main dyeing vat, an auxiliary dyeing vat, a cloth roller and a vat cover and also comprises a tensioning roller, wherein a pluralityof jet holes are formed in the side wall of the tensioning roller and are distributed in two sides of a middle axial point of the tensioning roller, the axial direction of the jet holes obliquely extends towards the axial end of the tensioning roller in the direction deviating from the axis of the tensioning roller, the mouth portions, away from the axis of the tensioning roller, of the jet holesface the end, closest to the jet holes, of the tensioning roller, and a water supply device communicated with the tensioning roller is arranged in the main dyeing vat. The invention also provides a cloth dyeing method. The cloth dyeing method comprises the steps of cloth feeding, drying, cloth dyeing, heat preservation and cloth discharging. Dyeing liquid is jet towards two sides of cloth throughthe jet holes, the power of jetting the dyeing liquid drives the cloth to stretch so as to ensure that the cloth is not folded when being put into the dyeing liquid, the cloth immersion effect of thedyeing liquid is ensured, and the dyeing quality is improved.

Owner:浙江求寔新材料股份有限公司

Preparation method and application of PBAT modified material

The invention discloses a preparation method of a PBAT modified material. The PBAT modified material is prepared by the following steps: proportionally and uniformly mixing 94-97% of PBAT, 0.5-1% of polyhydroxy ligand transition metal compound, 0.5-2% of flow modifier, 0.1-0.5% of modifying aid, 0.2-0.5% of antioxidant, 0.5-1% of heat stabilizer and 0.5-1% of lubricant all by weight; and performing extrusion granulation through parallel twin screws. The PBAT modified material is biodegradable, and the product is safe and nontoxic and easy to clean; the abandoned product does not influence the environment; the product has soft texture and bright surface gloss; quick and large-scale production of the flexible injection moulding products of PBAT is realized; and therefore, the PBAT material is not limited to film bag products, and the application range of the PBAT material is expanded. The PBAT modified material is particularly suitable for the forks, spoons and teethers of infants, various soft injection moulding products and some silica gel substitutes.

Owner:江西禾尔斯环保科技有限公司

Automatic winding and roll changing system for wet-process lithium battery diaphragm

PendingCN114212584AImprove flatnessRealize automatic roll changeCell component detailsWebs handlingDrive wheelEngineering

The invention discloses a wet-process lithium battery diaphragm automatic winding and roll changing system which comprises a guide roller and a tension roller which are vertically arranged at an interval, a tension bearing is installed at the end of the tension roller, a pair of shearing rollers which are vertically arranged at an interval are arranged behind the guide roller and the tension roller in the advancing direction of a diaphragm, and the upper side and the lower side of the diaphragm are attached to the two shearing rollers respectively. A moving roller is arranged behind the shearing roller, a winding and reel changing mechanism is arranged behind the moving roller and comprises a driving wheel and a driven wheel driven by the driving wheel to rotate, two winding rollers with the same height position are arranged on the two sides of the axis of the driven wheel respectively, and a film scratching mechanism is arranged below the winding roller close to the driven wheel. The membrane scratching mechanism comprises a support and a driving mechanism for driving the support to move up and down, an electrostatic generator, a rotating brush, a cutter and a pressing roller are installed on the support, the driven wheel rotates during roll changing, the positions of the two winding rollers are exchanged, and a membrane sequentially bypasses the positions below the two winding rollers; when the diaphragm is scratched, the driving mechanism drives the support to move upwards, and the cutter cuts off the diaphragm.

Owner:SINOMA LITHIUM BATTERY SEPARATOR CO LTD

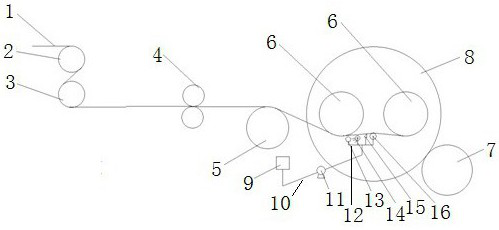

Loose type continuous washing device and continuous washing equipment for cylindrical knitted fabric

PendingCN108085897AImprove flatnessNo creaseTextile treatment machine arrangementsTextile treatment by spraying/projectingElectricityProcess engineering

The invention discloses a loose type continuous washing device and continuous washing equipment for a cylindrical knitted fabric. A fabric quantity control swing roller is arranged over the other endof a caterpillar band, a cylindrical knitted fabric guiding mechanism is arranged on one side of the fabric quantity control swing roller, a fabric outlet is formed in the portion, at the fabric discharging end of the cylindrical knitted fabric guiding mechanism, of a shell, a padder is arranged at the position, corresponding to the fabric outlet, of the outer side of the shell, and a liquid collecting cover is arranged below the padder; a containing pond for containing corresponding liquid is arranged at the lower portion of the shell, a corresponding pipeline is arranged on the liquid collecting cover, and the corresponding pipeline is communicated with the corresponding containing pond; a circulation pump is arranged inside the containing pond, and a heating pipe is arranged inside theportion, on one side of the circulation pump, of the containing pond; a first spraying mechanism is arranged over the caterpillar band between the fabric quantity control swing roller and a cropping roller. The cylindrical knitted fabric is operated in the scotching open-width state, the flatness is high, no fold or scratch is caused, loose type washing is performed, the cylindrical knitted fabricis high looseness, the cylindrical knitted fabric is high in dimension stability, the cylindrical knitted fabric is good in touch, the washing efficiency is high, and the water, electricity and steamconsumption is low.

Owner:GAOMI FUYUAN PRINTING & DYEING

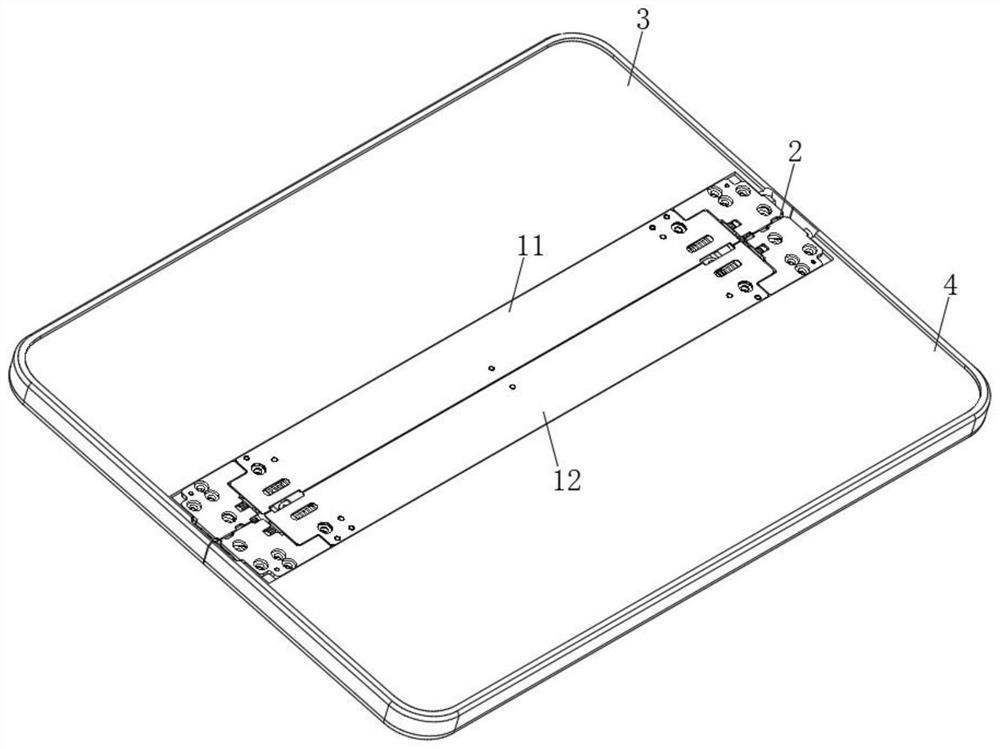

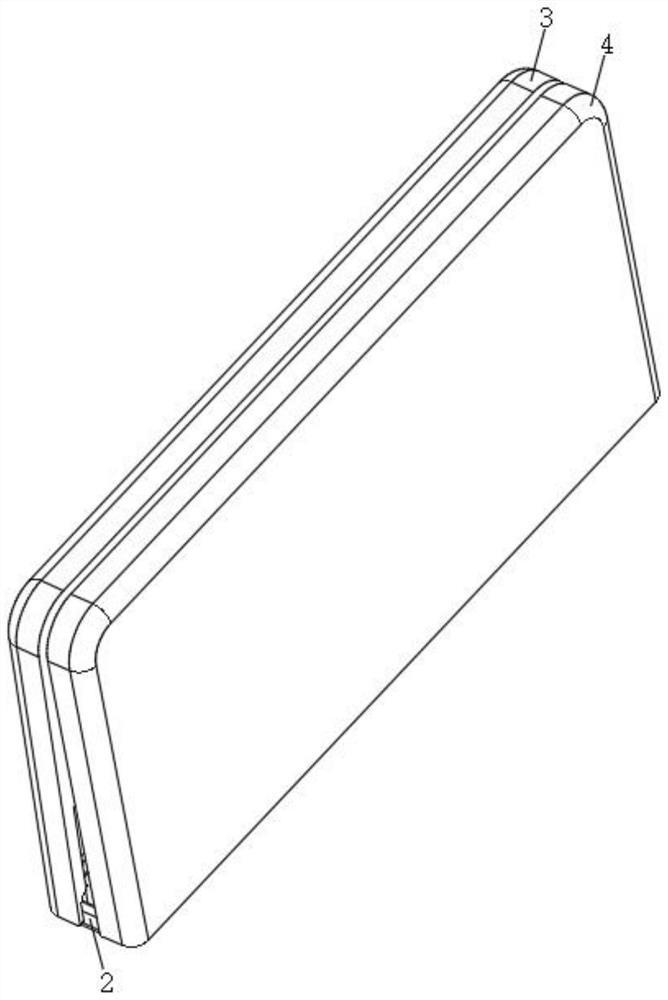

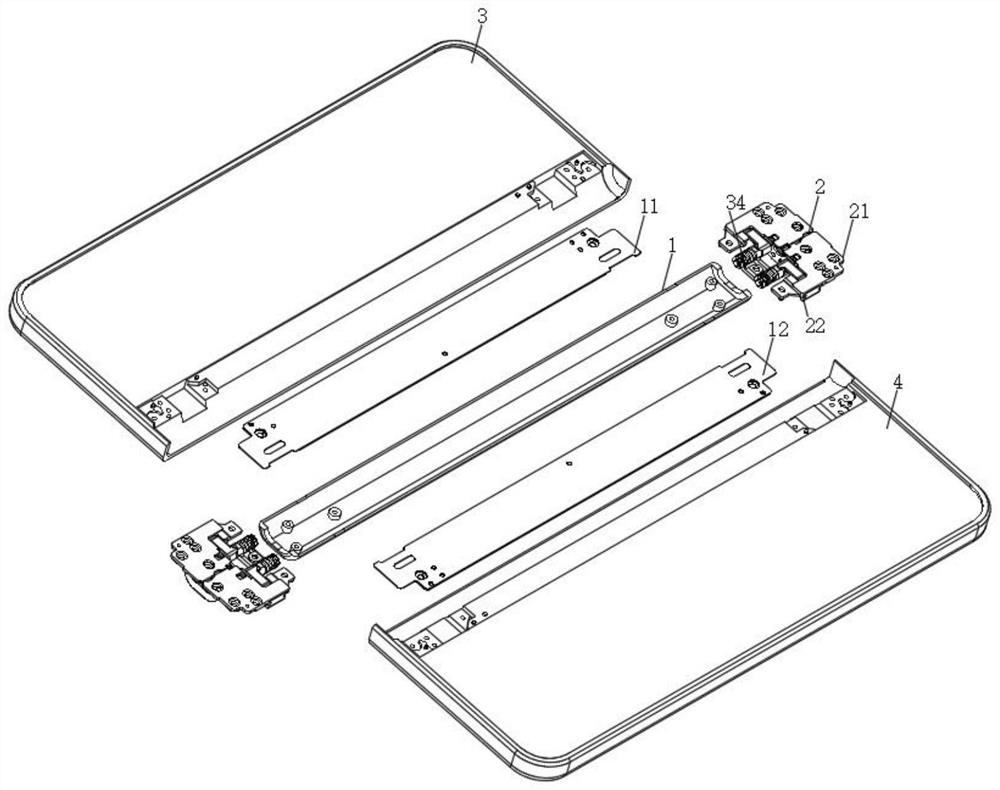

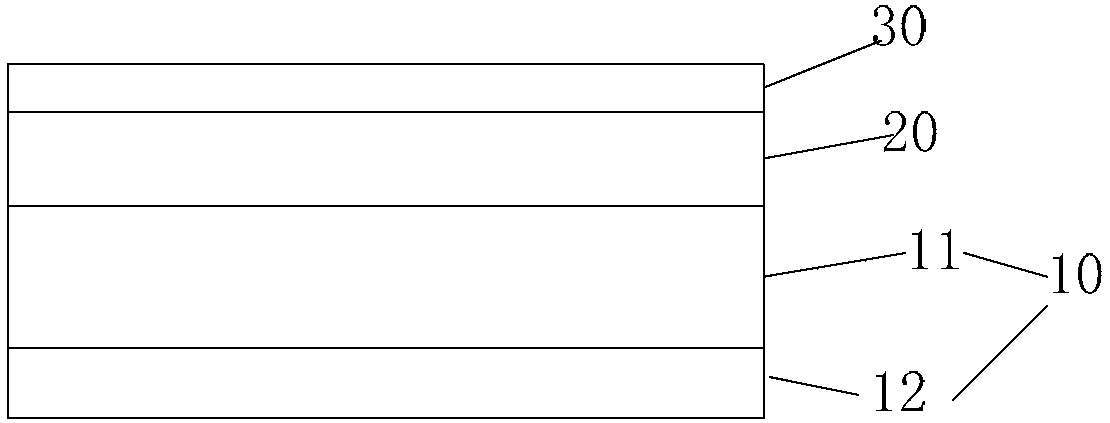

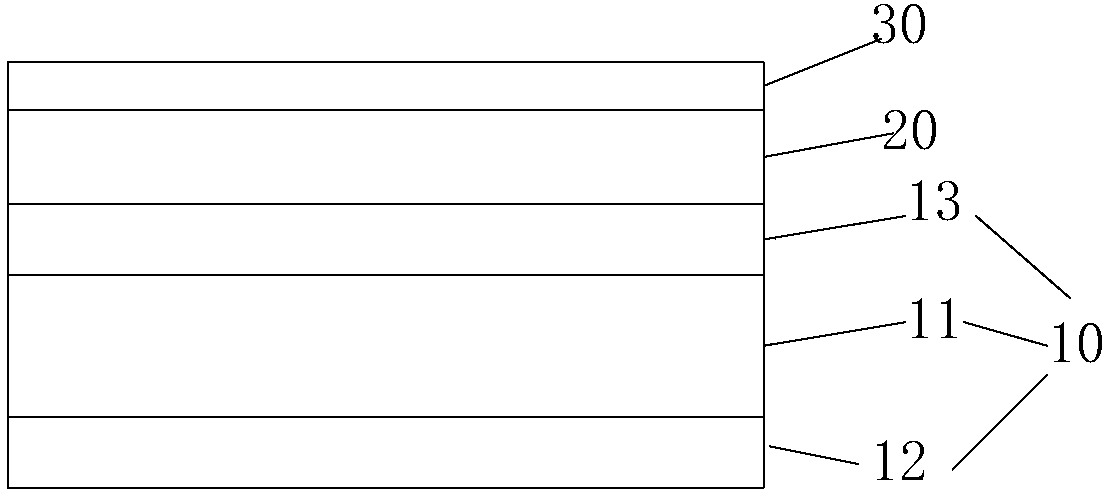

Inner folding hinge applied to mobile terminal and terminal equipment

PendingCN114542588ASimple structureCompact structureDigital data processing detailsCasings/cabinets/drawers detailsLocking mechanismTerminal equipment

The invention provides an inner folding hinge applied to a mobile terminal and terminal equipment, and the inner folding hinge comprises a middle shell, and the two ends of the inner side of the middle shell are each provided with a virtual axis sliding block module; each virtual axis sliding block module is composed of a track mechanism for providing rotation guiding, a sliding block linkage mechanism for supporting the flexible screen to prevent the screen from collapsing, a synchronizing mechanism for driving the terminal shell to rotate synchronously, and a torsion automatic locking mechanism for providing torsion and locking for the hinge. The inner folding hinge has the beneficial effects that the two virtual axis sliding block modules of the same structure are installed at the two ends of the inner side of the middle shell, so that the structure of the inner folding hinge is simpler and more compact, meanwhile, the design and machining cost of the inner folding hinge can be effectively reduced, the structural complexity of the inner folding hinge is simplified, and the inner folding hinge is more convenient to use. And the mobile terminal such as an infolding mobile phone, a notebook computer, a Pad and the like and accessory equipment of the mobile terminal can be better adapted.

Owner:DONGGUAN HUANLI INTELLIGENT TECH CO LTD

Heat-conducting adhesive tape and manufacturing method thereof

The invention provides a heat-conducting adhesive tape and a manufacturing method thereof. The heat-conducting adhesive tape comprises a heat-conducting layer and a pressure-sensitive adhesive layer positioned on the surface of one side of the heat-conducting layer, wherein the heat-conducting layer comprises a graphite layer and a first metal plating layer; the graphite layer is arranged near thepressure-sensitive adhesive layer; and the first metal plating layer is arranged on the surface of the side, far away from the pressure-sensitive adhesive layer, of the graphite layer. By the pressure-sensitive adhesive layer, the heat-conducting layer can be adhered to an OLED screen. The heat-conducting layer comprises the graphite layer and the first metal plating layer, and the first metal plating layer is arranged on the surface of the side, far away from the pressure-sensitive adhesive layer, of the graphite layer. Therefore, the graphite layer can effectively improve the bending resistance of the heat-conducting layer and the heat-conductive adhesive tape. Meanwhile, the metal layer is a first metal plating layer, the plating layer is arranged on the surface of the graphite layer by film plating modes such as metal evaporation and sputtering, and the graphite layer and the metal layer can be combined well by adopting an additional adhesive layer when the graphite layer and themetal layer are not stuck by the traditional adhesive tapes correspondingly, so that the heat-conducting property of the heat-conducting adhesive tape can be further improved.

Owner:ZHANGJIAGANG KANGDE XIN OPTRONICS MATERIAL

Spherical green tea processing technology

ActiveCN103392844BReduce moisture contentKeep it originalPre-extraction tea treatmentShootRoom temperature

The invention relates to a spherical green tea processing technology. The technology comprises the following steps: picking one-bud one-leaf tender bud shoots in early spring and late autumn, carrying out indoor withering at a temperature of 20-22DEG C under a humidity of 65-75% RH for 7h, deactivating enzymes in a roller enzyme deactivating machine at 400DEG C for 2.5-5min, cooling to room temperature, repeating kneading and baking at 60-70DEG C for 6h, baking in a baking machine at 100DEG C for 10-11h, slowly cooling to room temperature, and packaging. The spherical green tea processing technology allows tea leaves to form stable spheres through adopting the repeated kneading and baking, so the tea leaf impression is improved; and water in the tea leaves is gradually lost step by step in the whole technological process, so the tea color is pure, and the mouthfeel is good.

Owner:SHANDONG SHENGFA AGRI SCI & TECH CO LTD +1

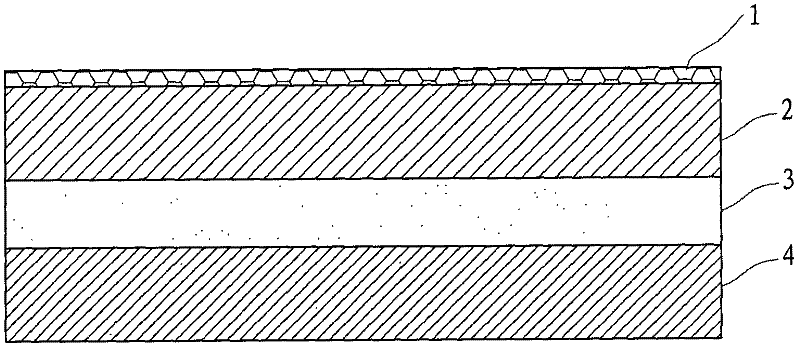

Mirror-surface leather with crystal transferred and attached

InactiveCN104404779ATransparent surfaceImprove surface brightnessLamination ancillary operationsSynthetic resin layered productsTransmittanceWoven fabric

The invention relates to mirror-surface leather with crystal transferred and attached. The mirror-surface leather is manufactured with a dry-process film-transferring machining method. Ultra-fine fiber non-woven fabric is selected to serve as backing fabric, the backing fabric is coated with water-borne polyurethane resin slurry which is divided into two layers of a surface layer and a backing layer adhesion layer respectively, then leather base cloth is attached, paper and leather are separated, the crystal is attached, and finally leather slurry is attached; the temperature of an oven is controlled to range from 120 DEG C to 130 DEG C during first coating, a doubling roller for transfer and attachment of the crystal is controlled to be at a normal temperature, and the flow of water is synchronous with the rotation speed of the doubling roller. The produced crystal mirror-surface leather does not have air bubbles or needle holes, is high in transmittance and good in brightness, has a flat and smooth surface and can be suitable for multiple fields such as sofa, automotive trims, office accommodations, furniture and walls.

Owner:安徽宝博新材料科技有限公司

Finishing process for glued interweaved fabric

ActiveCN107034680ASmooth silk surfaceNo creaseLiquid/gas/vapor open-width material treatmentLiquid/gas/vapor removal by suctionPulp and paper industryMoisture

The invention relates to a finishing process for a glued interweaved fabric and belongs to the technical field of viscose treatment. The finishing process is characterized by comprising the following process steps of: 1) feeding a gray fabric of the fabric into a jig dyeing machine in an open width manner, and operating the fabric in water at 13-18 DEG C till the fabric is flat without folding edges and creases; 2) rolling dyed wet cloth down to an A type rack, and keeping the wet cloth roll to rotate uniformly at a rotating speed of 18-22r / min; 3) after unrolling the wet cloth on the type A rack, absorbing water through a water absorption pipe in front of a rolling groove to control the moisture content of the fabric at 53-60%; and 4) controlling the liquid rate of the fabric after water absorption at 65-70%, preparing a flexible finishing liquid in the rolling groove, and then performing a flexible treatment and drying step. According to the process provided by the invention, the quality of the product is obviously enhanced, consumption of steam and power is saved, and the dosage of an auxiliary agent is greatly reduced.

Owner:ZIBO DARANFANG SILK GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com