RPUC high-performance die-pressed sole material

A shoe sole material and high-performance technology, applied in shoe soles, footwear, footwear, etc., can solve the problems of complex manufacturing process, high energy consumption, and many processes, and achieve good low compression distortion performance, simple production process, and simplified production The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

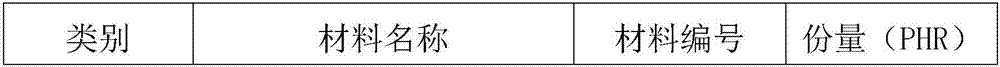

Embodiment 1

[0038]

[0039]

[0040] Its preparation steps are as follows:

[0041] Step 1, weighing raw materials according to the formula;

[0042] Step 2, heat up the machine to 70°C, add rubber particles for kneading, continue to heat up to 90°C, add wear-resistant agent, stearic acid, basic zinc oxide, and coloring material for kneading;

[0043] Step 3, heat up to 115°C, carry out heavy hammer mixing, naturally cool down to 100°C during mixing, put in foaming agent and bridging agent, continue mixing for 3 minutes and unload, while controlling the temperature to 106°C;

[0044] Step 4, put the unloaded material into the granulator for granulation to obtain pellets. The granulation conditions are as follows: set the die head temperature to 65°C; the first stage temperature to 25°C; the second stage temperature to 25°C; the third stage Section temperature 25°C; set host speed 28; mixer speed 19; die head motor speed 10;

[0045] Step 5, put the pellets into a small foaming mol...

Embodiment 2

[0051]

[0052]

[0053] Its preparation steps are as follows:

[0054] Step 1, weighing raw materials according to the formula;

[0055] Step 2, heat up the machine to 80°C, add colloidal particles, continue to heat up to 100°C, add wear-resistant agent, stearic acid, basic zinc oxide, and colorant;

[0056] Step 3, heat up to 120°C, carry out heavy hammer mixing, naturally cool down to 105°C during mixing, add foaming agent and bridging agent, continue mixing for 3 minutes, then unload, while controlling the temperature to 109°C;

[0057] Step 4, put the unloaded material into the granulator for granulation to obtain pellets. The granulation conditions are as follows: set the temperature of the die head to 75°C; the temperature of the first stage is 35°C; the temperature of the second stage is 35°C; Segment temperature 35°C; set host speed 28; mixer speed 19; die head motor speed 12;

[0058] Step 5, put the pellets into a small foaming mold for foaming reaction, the...

Embodiment 3

[0064]

[0065] Its preparation steps are as follows:

[0066] Step 1, weighing raw materials according to the formula;

[0067] Step 2, heat up the machine to 75°C, add colloidal particles, continue to heat up to 95°C, add wear-resistant agent, stearic acid, basic zinc oxide, and colorant;

[0068] Step 3, heat up to 118°C, carry out heavy hammer mixing, naturally cool down to 103°C during mixing, put in foaming agent and bridging agent, continue mixing for 3 minutes and then unload, while controlling the temperature to 100°C;

[0069] Step 4, put the unloaded material into the granulator for granulation to obtain pellets. The granulation conditions are as follows: set the temperature of the die head to 70°C; the temperature of the first stage is 30°C; the temperature of the second stage is 30°C; Section temperature 30°C; set host speed to 28; mixer speed to 19; die head motor speed to 11;

[0070] Step 5, put the pellets into a small foaming mold for foaming reaction, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com