Multi-purpose high-modulus polyurethane resin and application thereof

A technology of polyurethane resin and high modulus, which is applied in the fields of chemical industry and polyurethane synthetic materials. It can solve the problems of being limited to a specific process or a certain type of product, the limitation of the application range of natural leather, and a wide variety of raw materials to achieve excellent ventilation. Water absorption performance, vivid color, fast washing effect

Active Publication Date: 2016-07-06

TAIZHOU HEXIN HIGH MOLECULAR NEW MATERIAL

View PDF3 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0003] Although natural leather has advantages in appearance, air permeability and water absorption, the application range of natural leather is also limited due to factors such as environmental protection and ecological balance, as well as the limitations of its physical properties.

The polyurethane resins currently on the market have certain limitations in the scope of application, and are limited to a specific process or a certain type of product in the process of leather making, resulting in a wide variety of raw materials and easy to confuse

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

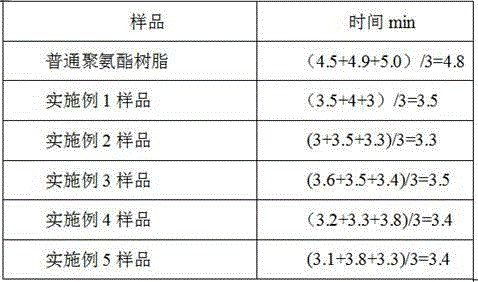

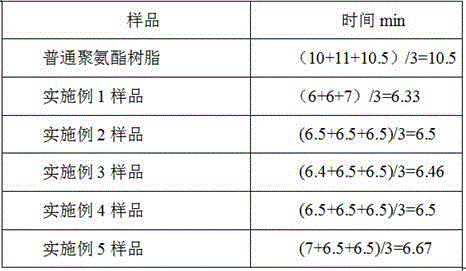

Embodiment 1

[0018]

Embodiment 2

[0020]

Embodiment 3

[0022]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

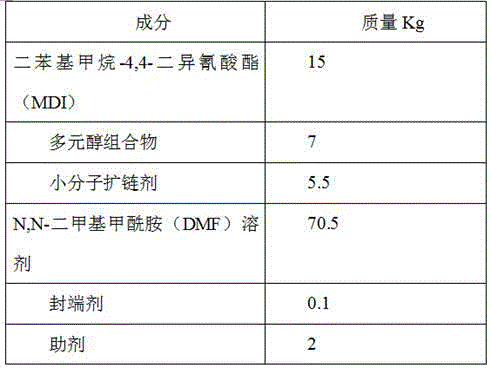

The invention discloses a multi-purpose high-modulus polyurethane resin and its application. Its components are calculated according to the total mass percentage of the reaction system: including 14%-16% of diphenylmethane-4,4-diisocyanate; polyol composition 6%-8%; small molecule chain extender 5%-5.5%; N,N-dimethylformamide solvent 68%-72%; end-capping agent 0.03%-0.1% and auxiliary agent 1%-2%. The present invention uses mixed polyols and mixed chain extenders to reduce the crystallinity of the system, uses different proportions of polyol compositions and chain extenders to adjust the slender and upright cell structure and superior color development, and is modified by adding polyether Additives make the cell structure more uniform, slender and upright, and feel more comfortable. The polyurethane resin prepared by the invention has the characteristics of high modulus, excellent color development, uniform, slender and upright cells, good anti-curling performance, fast solidification, fast water washing, etc., and has wide application range.

Description

technical field [0001] The invention belongs to the technical field of polyurethane synthetic materials, in particular to a multi-purpose high-modulus polyurethane resin which can be used for air-permeable leather, mirror leather and ordinary super-hard leather, and belongs to the technical field of chemical industry. Background technique [0002] Polyurethane resin is widely used in synthetic leather, mainly in clothing, shoes, bags, furniture, automobiles and other fields. With the increasing market demand, the rapid development of polyurethane resin for leather shows an upward trend, so higher requirements are put forward for the development and update of technology. [0003] Although natural leather has advantages in appearance, air permeability and water absorption, the application range of natural leather is also limited due to the influence of factors such as environmental protection and ecological balance, as well as the limitations of its physical properties. The p...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G18/76C08G18/66C08G18/42C08G18/32C08L75/06

Inventor 张勇韩方平朱沂齐佳圭曾庆伟文远海

Owner TAIZHOU HEXIN HIGH MOLECULAR NEW MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com