a sanitary napkin

A technology for sanitary napkins and expansion layers, applied in the field of sanitary napkins, can solve problems such as easy displacement and side leakage, and achieve the effects of improving comfort, preventing side leakage, and being difficult to displace

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

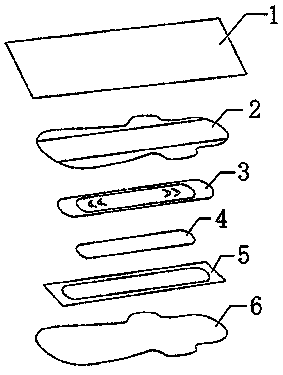

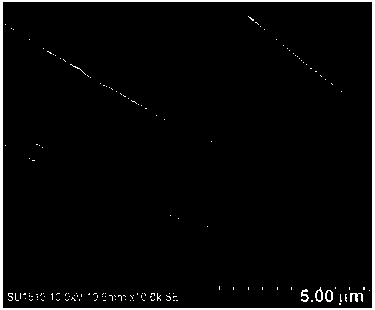

[0043] Such as Figure 1 to Figure 5 As shown, a sanitary napkin has a layered structure, the layered structure from top to bottom is an adsorption layer 1, an absorption layer 2, a first expansion layer 3, a second expansion layer 4, a leak-proof layer 5 and an adhesive layer 6. The layers are fixed and combined by edge pressing. The adsorption layer 1 is woven by modified nano-polyvinyl alcohol electrostatic wire, the weaving aperture is 300nm, the thickness is 0.2mm, and the diameter of the modified nano-polyvinyl alcohol electrostatic wire is 520nm; the surface of the adsorption layer 1 is provided with a number of ventilation holes, which are breathable The aperture size of the holes is 3 cm. Such as image 3 The modified nano polyvinyl alcohol electrostatic wire has a good morphological structure. The absorbing layer 2 is made of hydrophilic material with a thickness of 1 cm. The hydrophilic material includes 18% kapok fiber, 13% polyester filament, 12% cotton filamen...

Embodiment 2

[0045] Such as image 3 As shown, the modified nano-polyvinyl alcohol electrostatic wire is prepared by the following steps,

[0046] Step 1: Weigh 1 part of cellulose, take an appropriate amount of deionized water and stir to dissolve, add tetramethylpiperidine oxide to the solution according to the molar ratio of cellulose: tetramethylpiperidine oxide 1:0.05, according to the cellulose: Add sodium hypochlorite to the solution at a molar ratio of sodium hypochlorite of 1:1 to adjust the pH of the system to 10.3, and stir at room temperature for 24 hours;

[0047] Step 2: disperse the system into a gel form through a homogenizer, undergo ultrasonic treatment for 10 minutes, filter and then freeze-dry to obtain nanocellulose;

[0048] Step 3: Weigh 1 part of polyvinyl alcohol, take an appropriate amount of deionized water, heat to 80°C and maintain a constant temperature, stir for 2 hours until completely dissolved;

[0049] Step 4: Cool naturally to room temperature, dilute th...

Embodiment 3

[0052] Such as Figure 4 to Figure 5 As shown, the flexible absorbent fiber was prepared by the following steps,

[0053] Step 1: Weigh 1 part of xanthan gum, add an appropriate amount of deionized water, stir and dissolve, add acrylic acid with a neutralization degree of 85% to the xanthan gum solution according to the volume ratio of xanthan gum solution:acrylic acid solution=1:2.5 Solution, after stirring, add acrylamide solution to the mixed solution according to the volume ratio of acrylic acid solution: acrylamide solution = 1:1;

[0054] Step 2: Heat the mixed solution to 70°C, mix the solution according to the volume ratio: crosslinking agent = 1:0.05, add the crosslinking agent N,N-methylenebisacrylamide, and keep stirring at a constant temperature of 70°C for 1 hour;

[0055] Step 3: Heating to 85°C, adding the initiator potassium persulfate solution into the solution according to the volume ratio of crosslinking agent:initiator = 1:1, and continuing to stir at a co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com