Knitwear dust removing and ironing device

A technology for knitwear and dust, which is applied in the field of knitwear dust cleaning and ironing devices, and can solve problems affecting the quality of knitwear, knitwear fading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

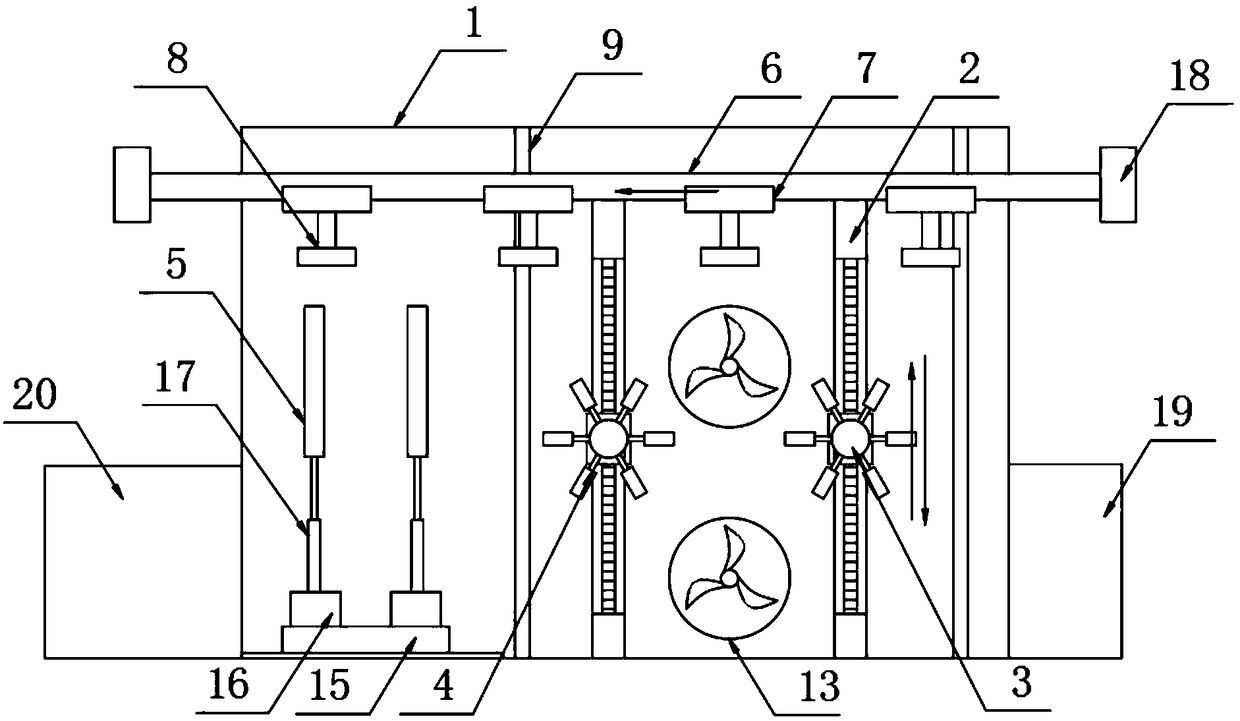

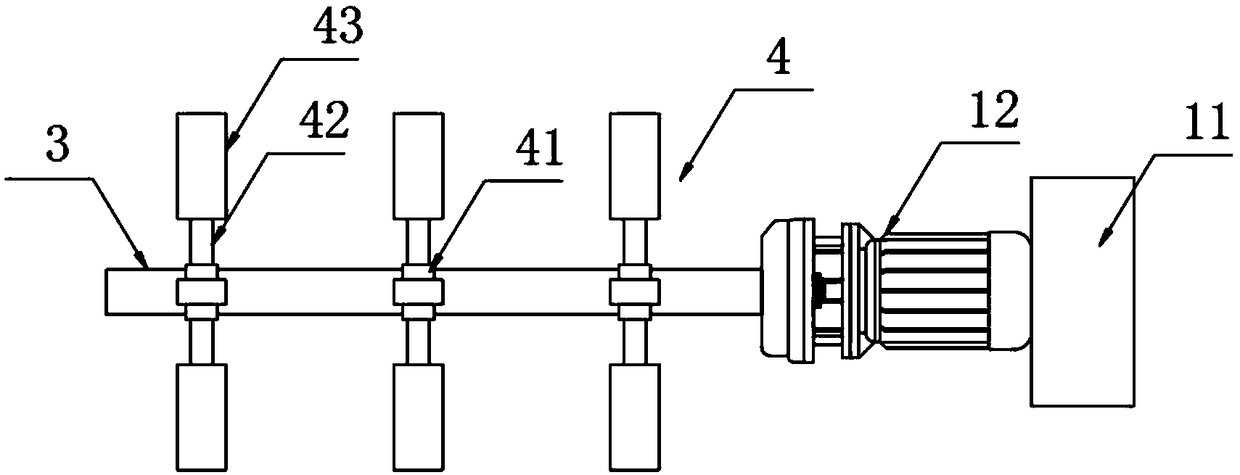

[0021] according to Figure 1-3 The shown dust cleaning and ironing device for knitwear includes a device main body 1, two sets of upper and lower guide rails 2 are arranged on both sides of the inner wall of the device main body 1, and a rotating shaft 3 is arranged between the upper and lower guide rails 2 on both sides. A plurality of ash-beating devices 4 are set on the rotating shaft 3, two groups of irons 5 are arranged on one side of the ash-beating device 4, and left and right guide rails 6 are arranged on the top of the ash-beating device 4, and the two ends of the left and right guide rails 6 respectively pass through The two side walls of the equipment main body 1 extend to one side of the outer wall of the equipment main body 1. The bottom of the left and right guide rails 6 is movably engaged with multiple sets of first stepping motors 7, and the bottom of the first stepping motors 7 is fixedly provided with a clothes hanger 8. Dust-proof doors 9 are arranged on b...

Embodiment 2

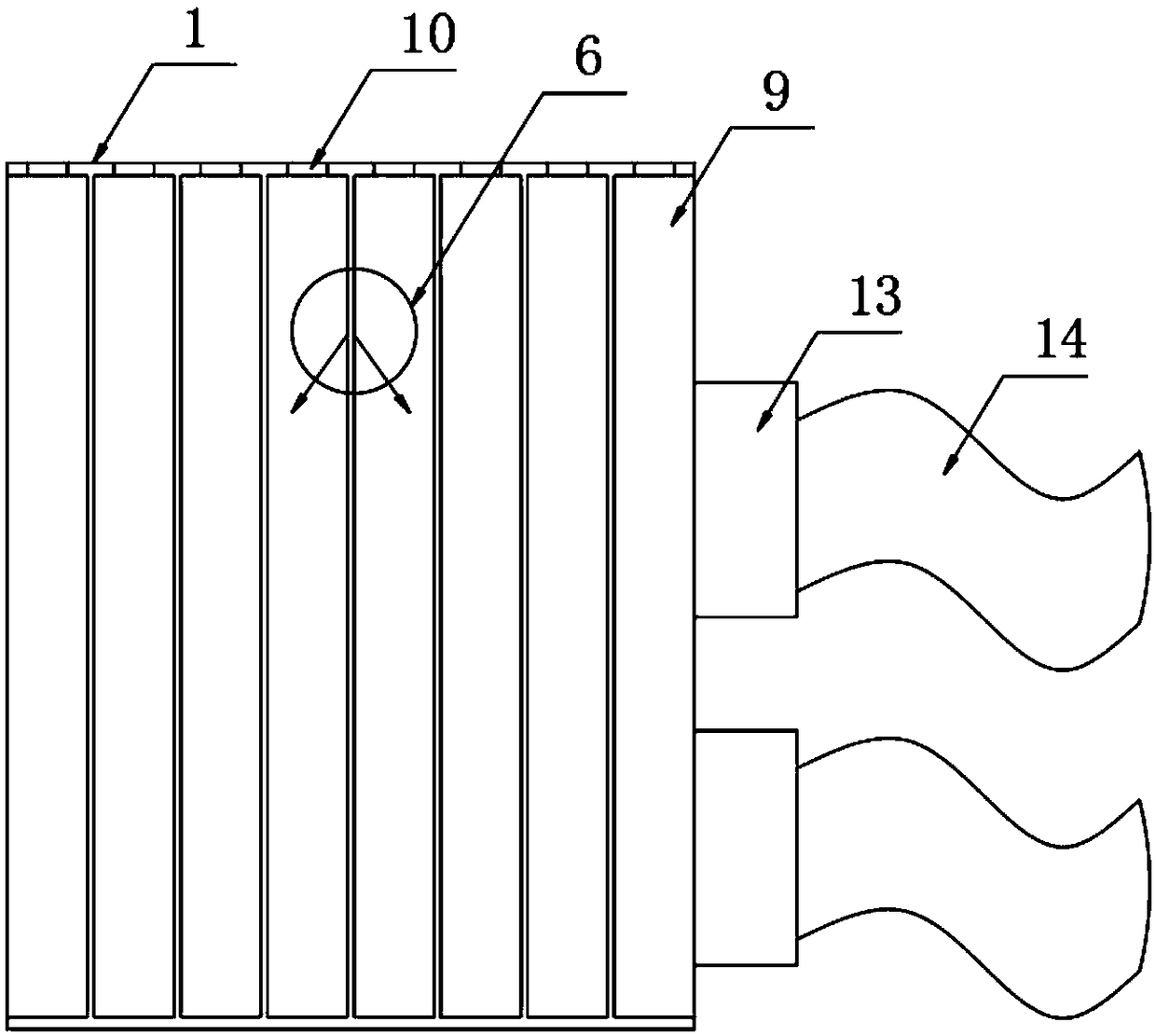

[0024] The difference with embodiment 1 is:

[0025] The dust-proof door 9 is provided with a plurality, and the top of the plurality of dust-proof doors 9 is fixedly provided with a connecting rod 10, and the top of the connecting rod 10 is fixedly connected with the top wall of the equipment main body 1, and the plurality of dust-proof doors 9 They fit each other, and the dust-proof door 9 is made of elastic rubber, which helps to isolate the dust being cleaned and the knitwear that has been dusted, and prevents the clean knitwear from absorbing dust again.

[0026] A rotating motor 11 is movably clamped on the upper and lower guide rails 2 , and a second stepping motor 12 is fixedly arranged on one side of the rotating motor 11 , and the output end of the second stepping motor 12 is connected to the input end of the rotating shaft 3 .

[0027] One side of the device main body 1 is provided with a fan 13 at the upper and lower ends, one end of the fan 13 runs through the sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com