Patents

Literature

194results about How to "Affect cleanliness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-efficiency graded screening and cleaning device for construction sand and gravel

InactiveCN107931124AReduce falling speedAffect cleanlinessSievingGas current separationImpellerArchitectural engineering

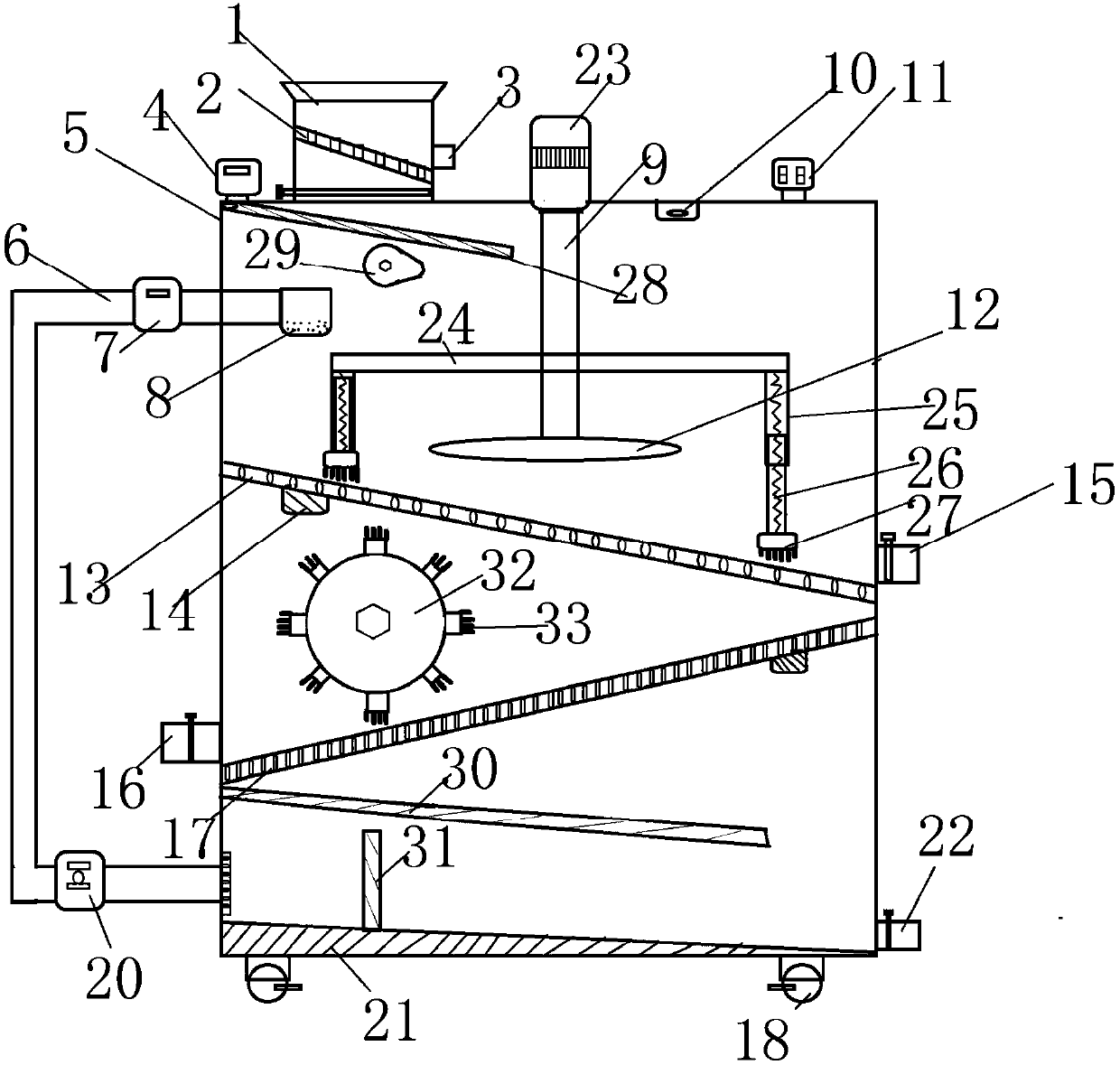

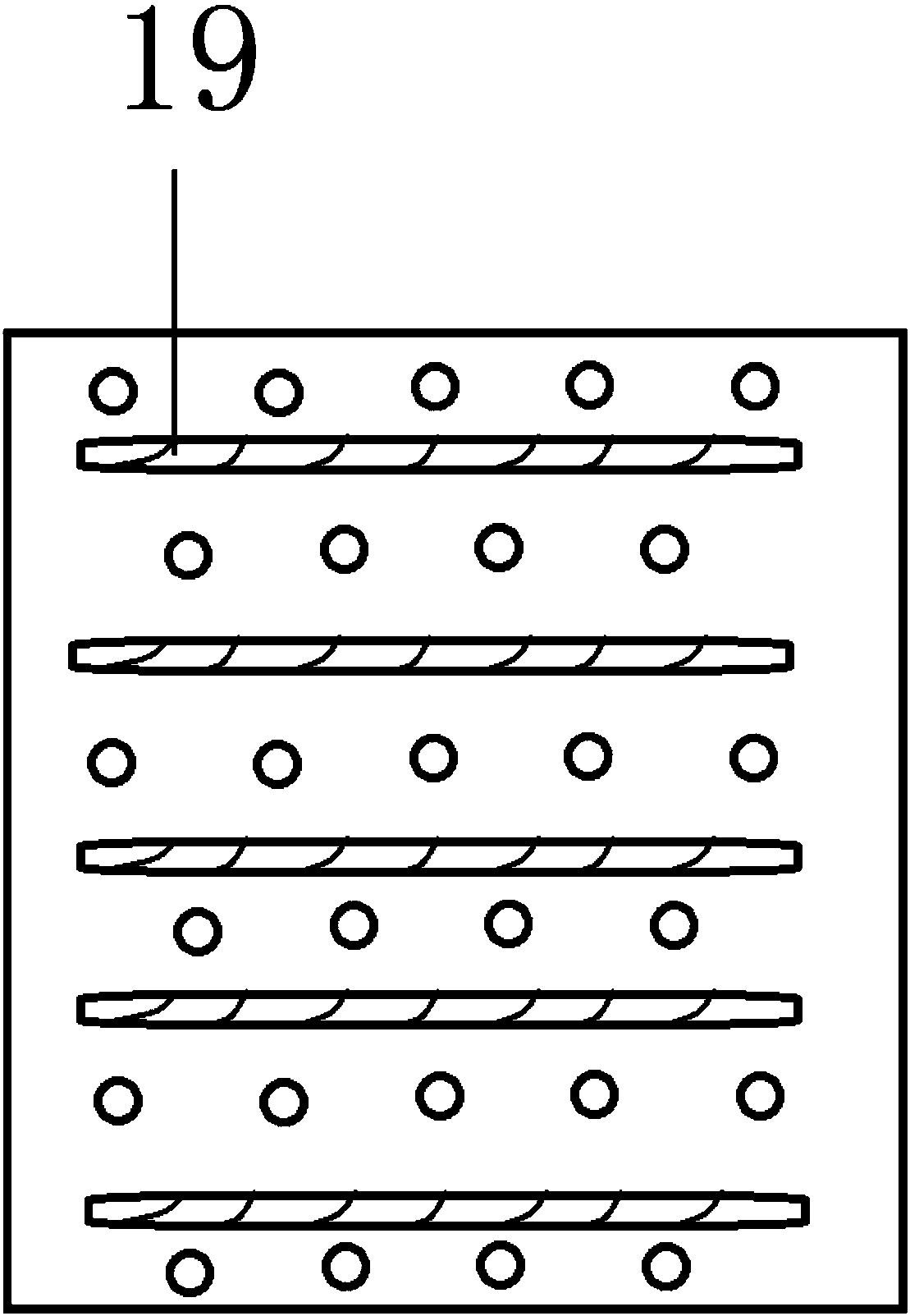

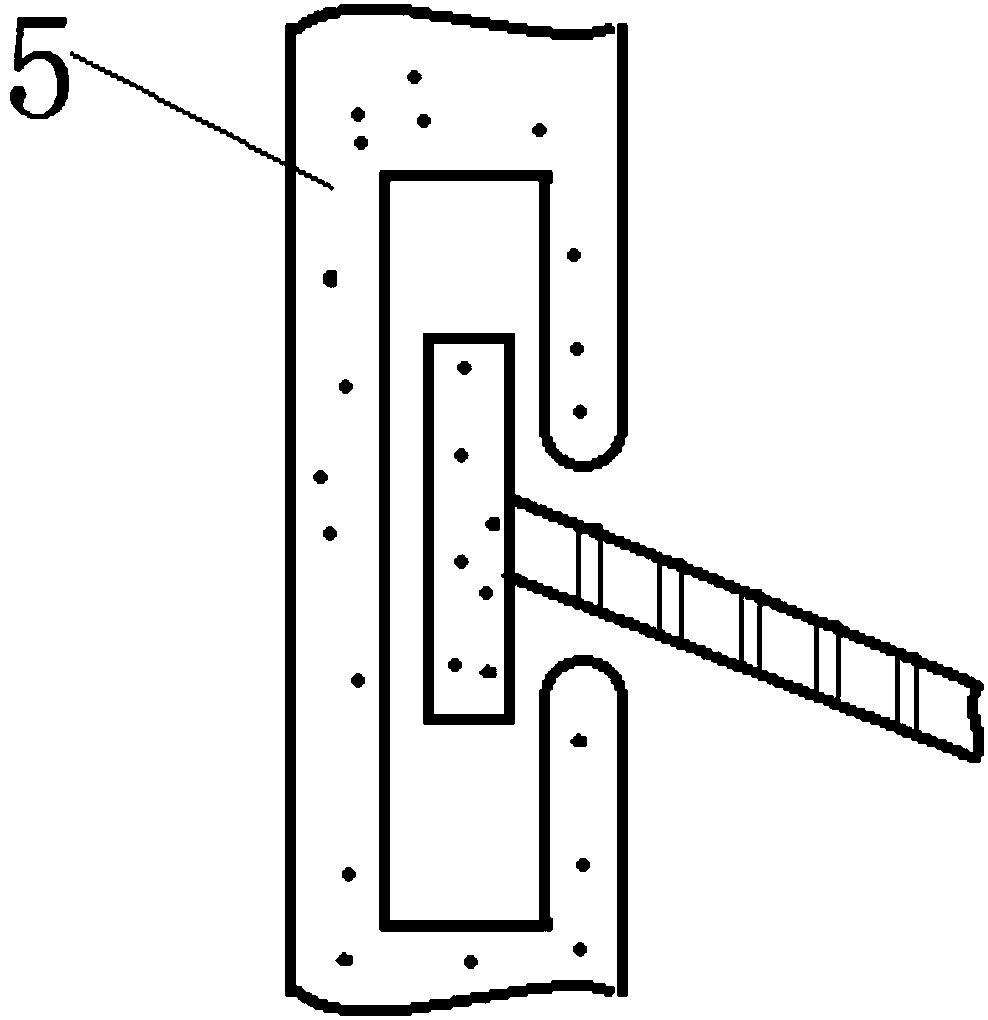

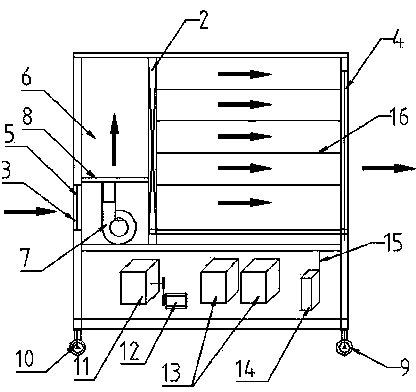

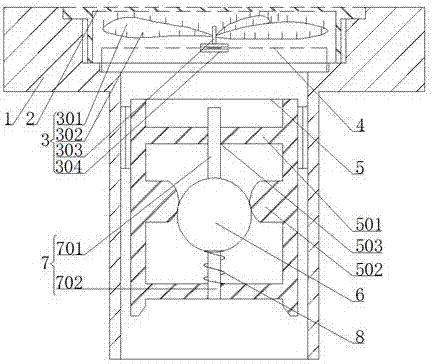

The invention discloses a high-efficiency graded screening and cleaning device for construction sand and gravel. The high-efficiency graded screening and cleaning device for construction sand and gravel comprises a feed pipe, a grid, a liquid level meter, a tank, a water inlet pipe, a flow meter, a sprayer, a rotary shaft, a camera, a timer, an impeller, a screen plate, a vibrator, a coarse sand discharge pipe and a fine sand discharge pipe, wherein the feed pipe is arranged at the top end of the tank; the grid is arranged in the feed pipe obliquely; the lowest end of the grid is provided withan impurity discharge pipe; the tank is provided with the liquid level meter and communicates with the water inlet pipe; the outlet end of the water inlet pipe is provided with the sprayer; the flowmeter is installed on the water inlet pipe; the camera is arranged on the inner wall of the top end of the tank; the rotary shaft is arranged in the tank and provided with the impeller; the screen plate is obliquely arranged in the tank; the vibrator is arranged on the lower surface of the screen plate; and the screen plate comprises a first screen plate body and a second screen plate body. The high-efficiency graded screening and cleaning device for construction sand and gravel is used for screening sand and gravel, improves the working efficiency, saves time and labor, and is simple in structure, convenient to use and beneficial to popularization.

Owner:郑诗永

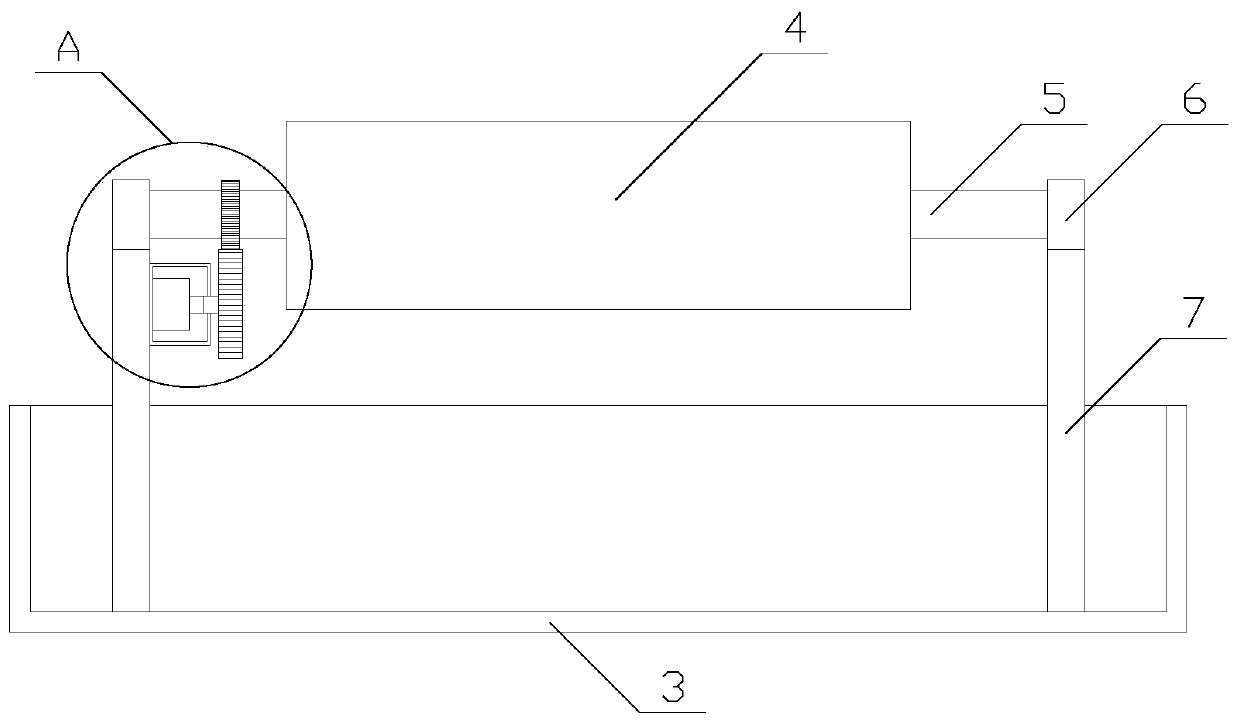

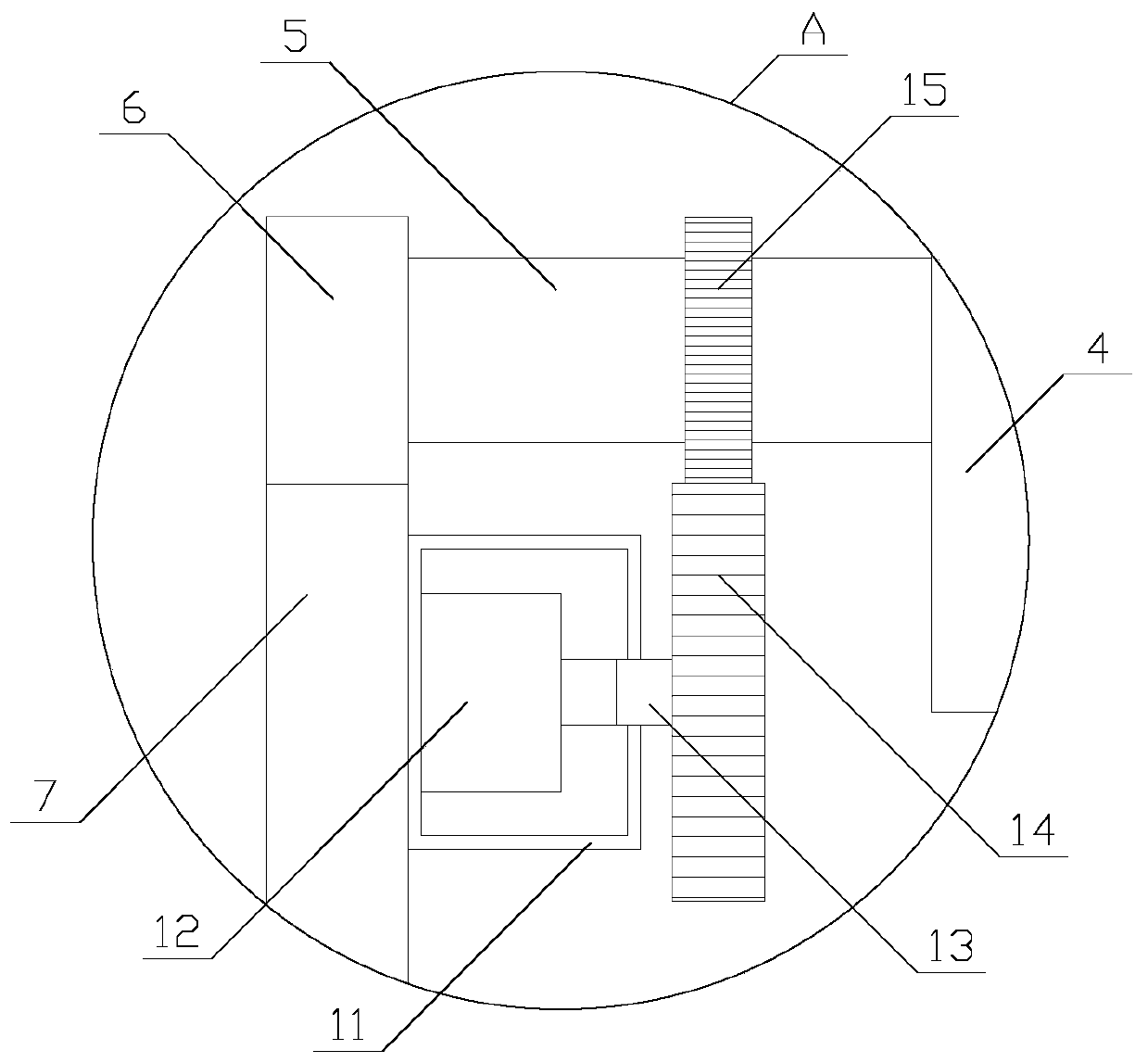

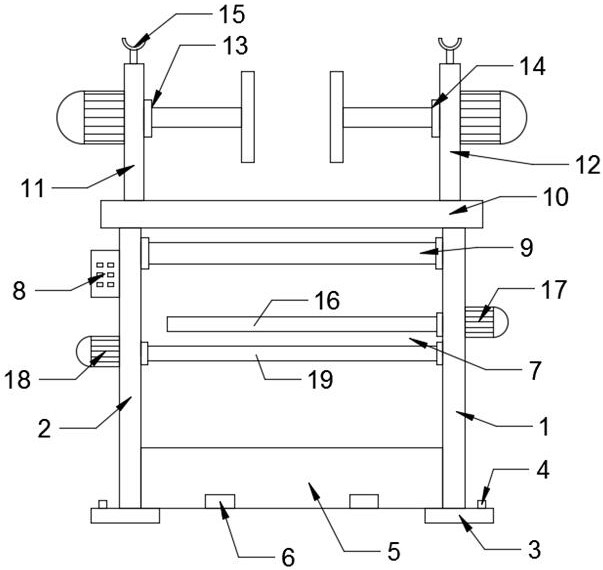

Workbench for mechanical equipment machining

InactiveCN105881037AAffect cleanlinessQuality assuranceLarge fixed membersMaintainance and safety accessoriesReciprocating motionEngineering

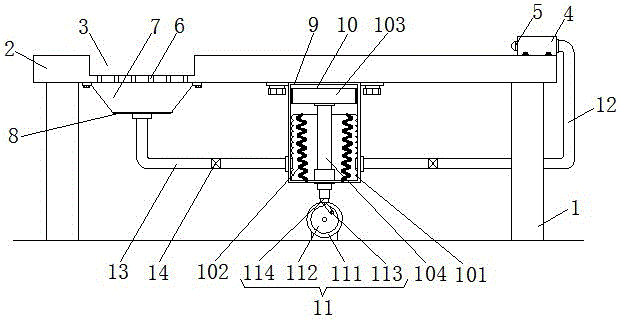

The invention discloses a workbench for mechanical equipment machining. One end of the upper surface of a working table is fixedly provided with a chip storage tank, the portion, at the bottom end of the chip storage tank, of the working table is provided with a chip discharge hole, a chip storage hopper fixedly connected with the lower surface of the working table is fixedly installed under the chip discharge hole, and a separation net is fixedly installed at the bottom of an inner cavity of the chip storage hopper; the other end of the upper surface of the working table is fixedly provided with a fixing seat, and a gas jet head is installed on the fixing seat in a sleeving mode. According to the workbench for mechanical equipment machining, a transmission mechanism is arranged and can drive a sliding rod to do vertically reciprocating motion to enable a pressing plate to extrude a gasbag in a vertically reciprocating mode, so that the gasbag continuously exhausts and sucks gas, cooperates with a gas outlet pipe to jet the exhausted gas from the gas jet head to clean the working table and blow machining chips into the chip storage tank and cooperates with a gas suction pipe to suck the chips into the chip storage hopper through negative pressure generated when the gasbag sucks the gas, and therefore the phenomenon that the chips influence the cleanliness of the working table is prevented.

Owner:WUXI KING MO MACHINERY

Tinning substrate for deep-punching food can and production method thereof

The invention relates to a steel metallurgical material, in particular to a tinning substrate for deep-punching food cans and a production method thereof. The tinning substrate comprises the following chemical element compositions in percentage by weight: less than or equal to 0.04% of C; less than or equal to 0.02% of Si, 0.20-0.25% of Mn, less than or equal to 0.02% of P, less than or equal to 0.018% of S, 0.005-0.040% of Als, and the balance iron and unavoidable inclusion. The production method comprises the following processes: smelting, continuous casting, heating, hot rolling, cooling and reeling, pickling and cold rolling, and annealing and leveling, wherein the heating temperature is 1210 DEG C, the primary rolling temperature is 1100-1150 DEG C, the final rolling temperature is 890+ / -10 DEG C, the reeling temperature is 560+ / -15 DEG C, the annealing temperature is 670-690 DEG C, and others are performed as conventional processes. The invention has small production control difficulty, low cost, stable performance and high can manufacturing percent of pass, and is suitable for manufacturing deep-punching food cans and can covers with more complex transformation.

Owner:TANGSHAN GUOFENG IRON & STEEL

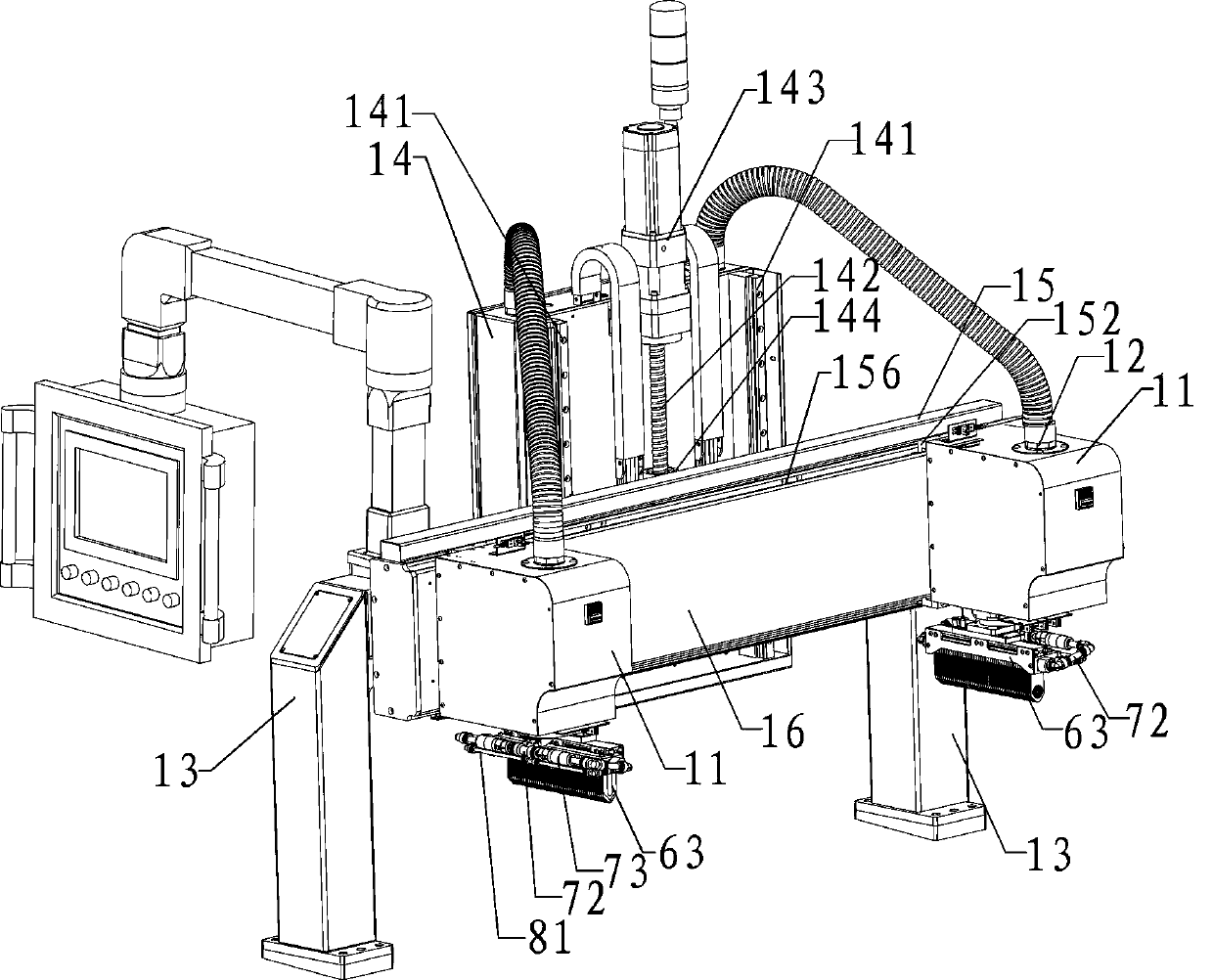

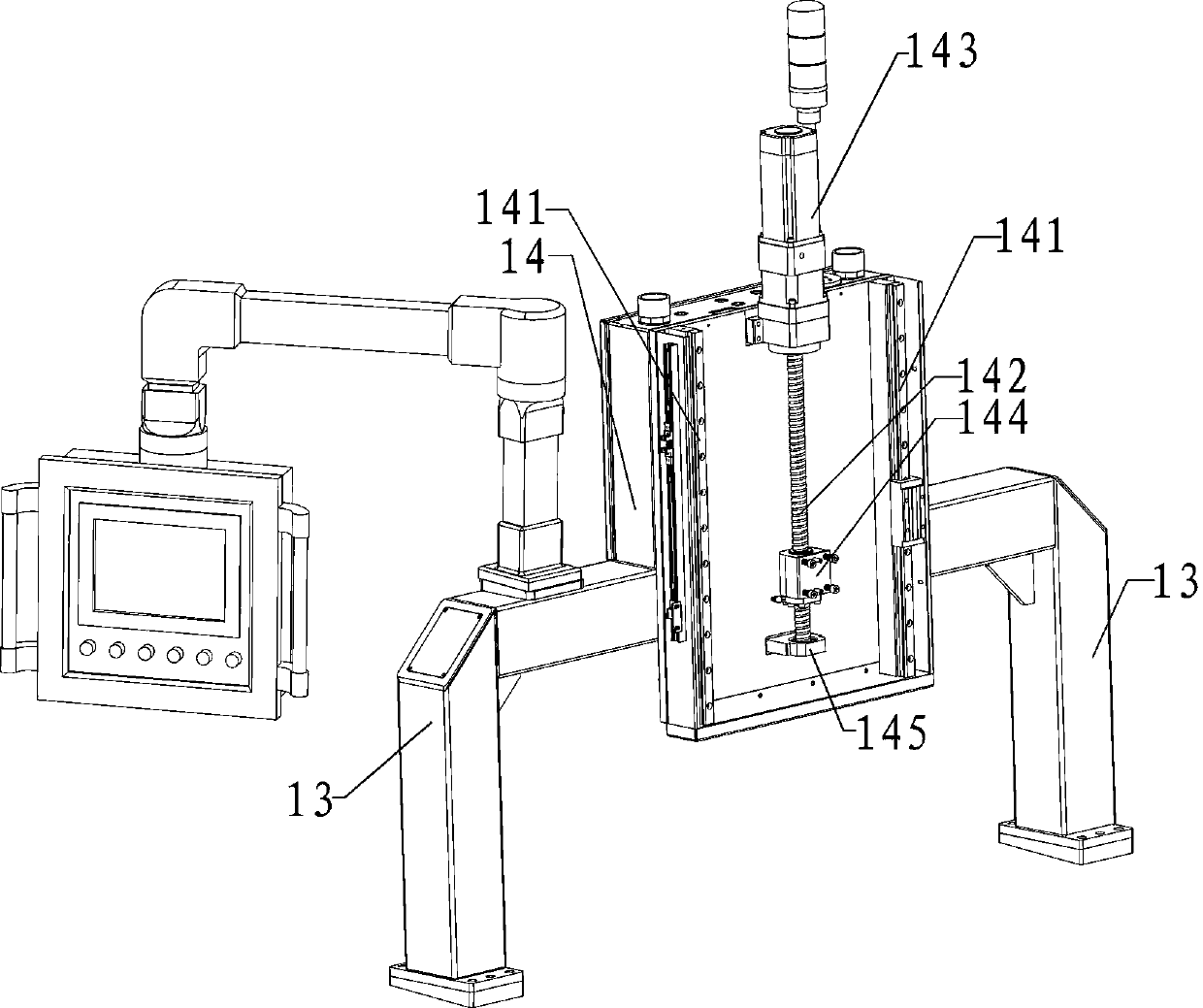

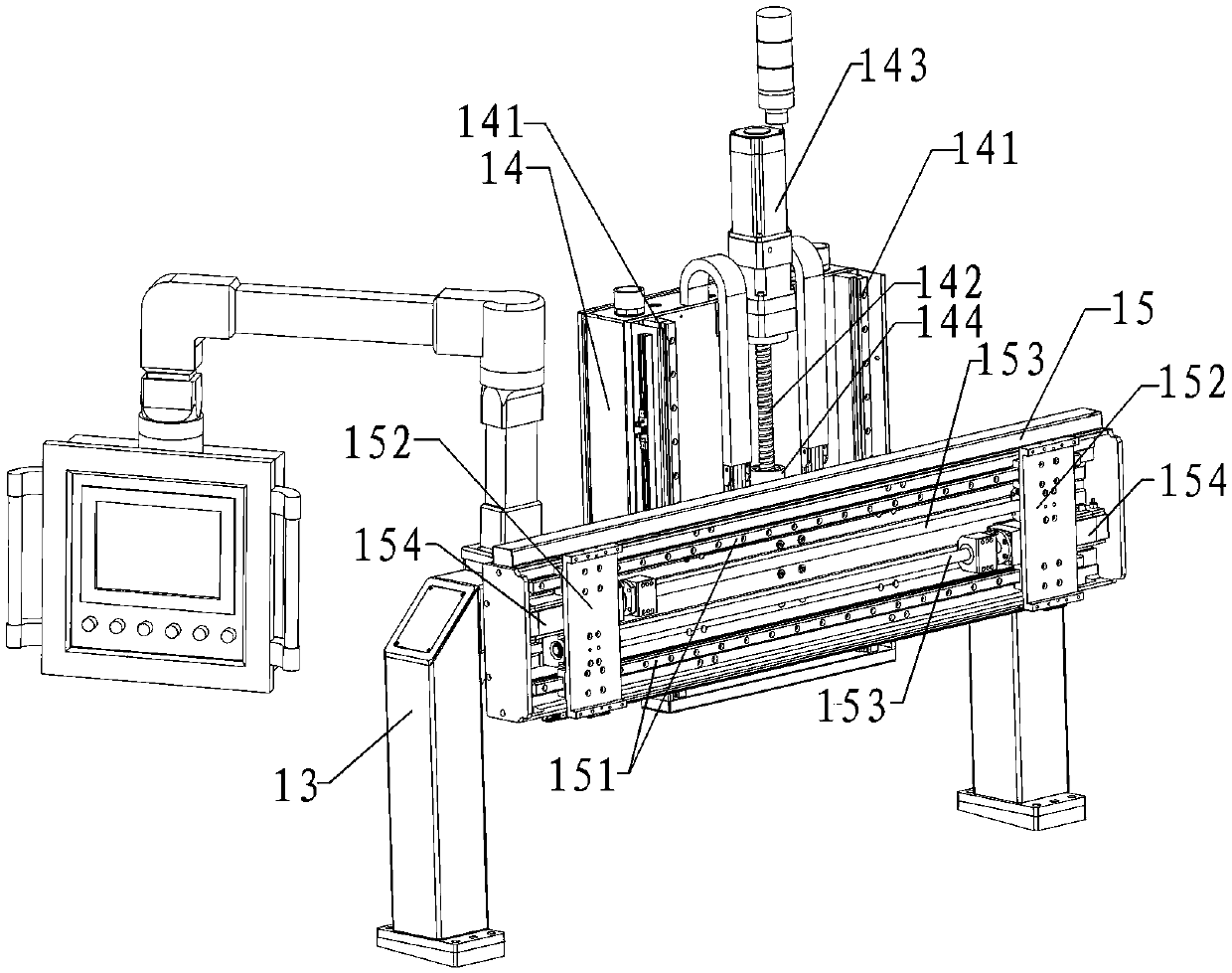

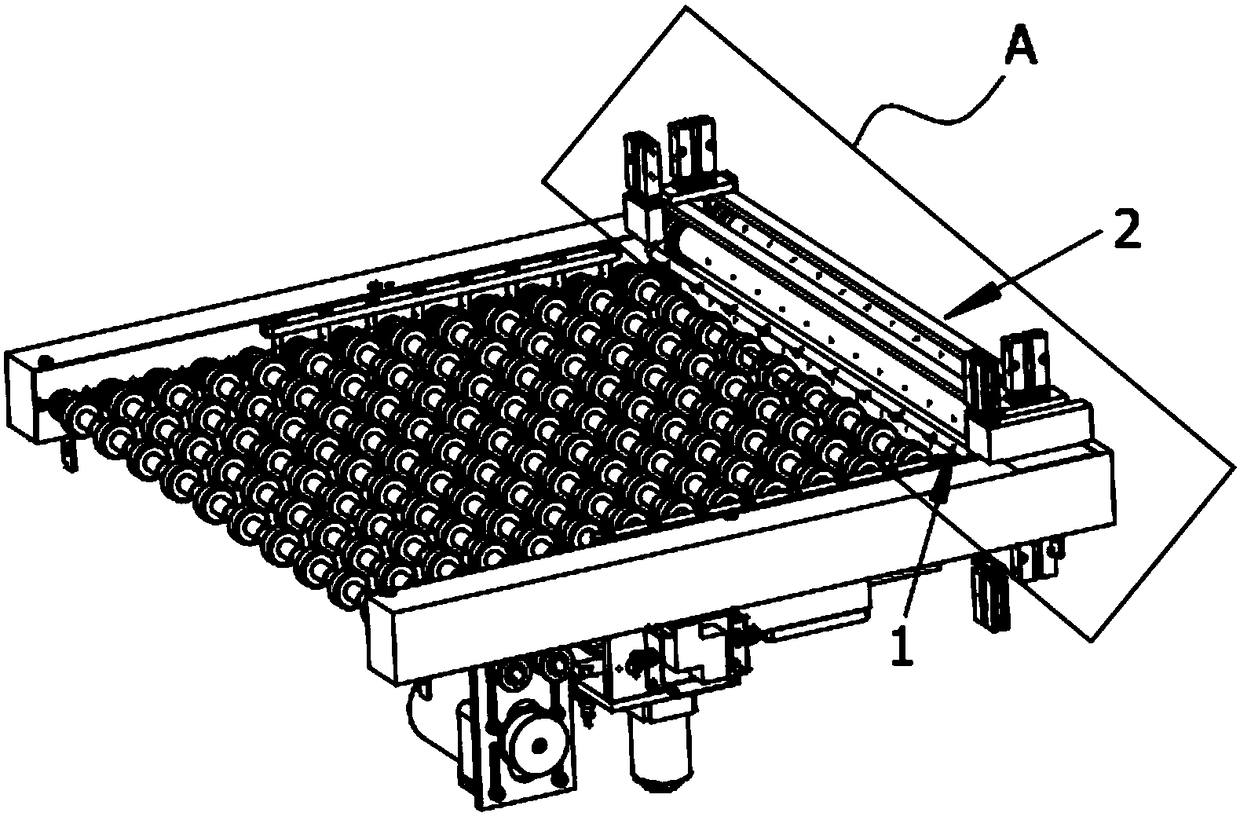

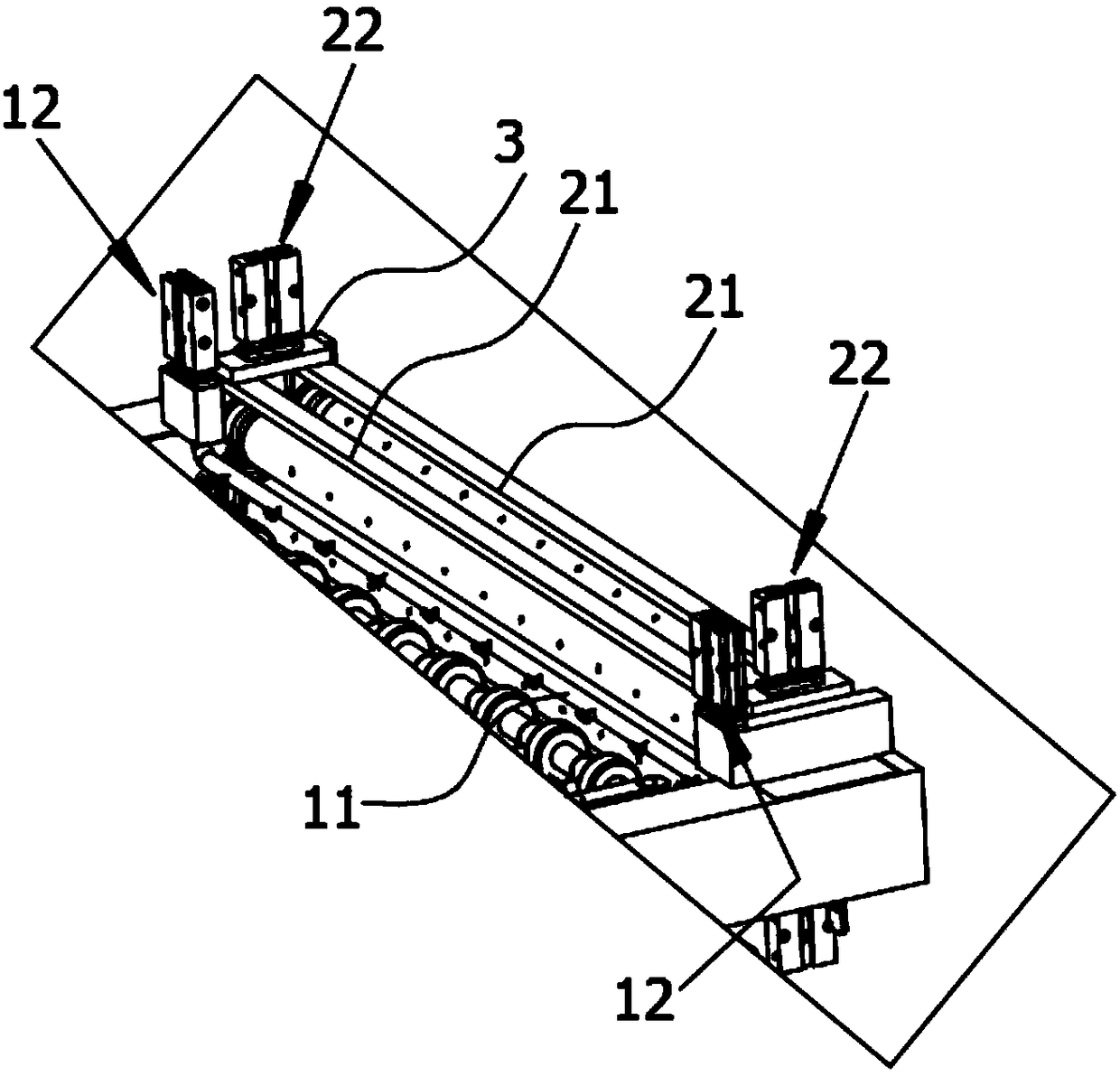

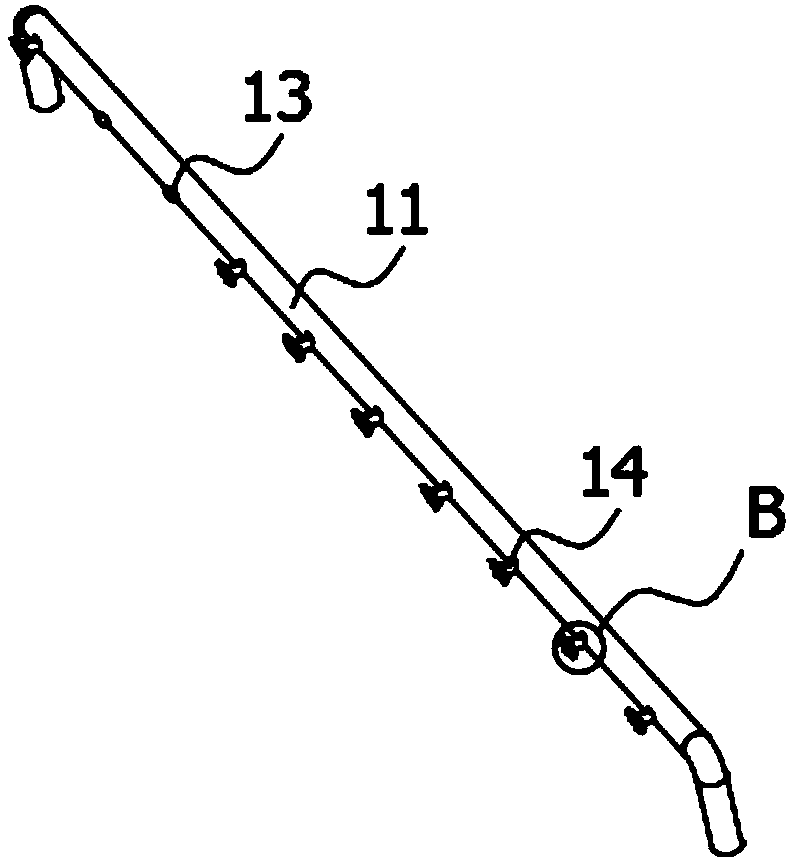

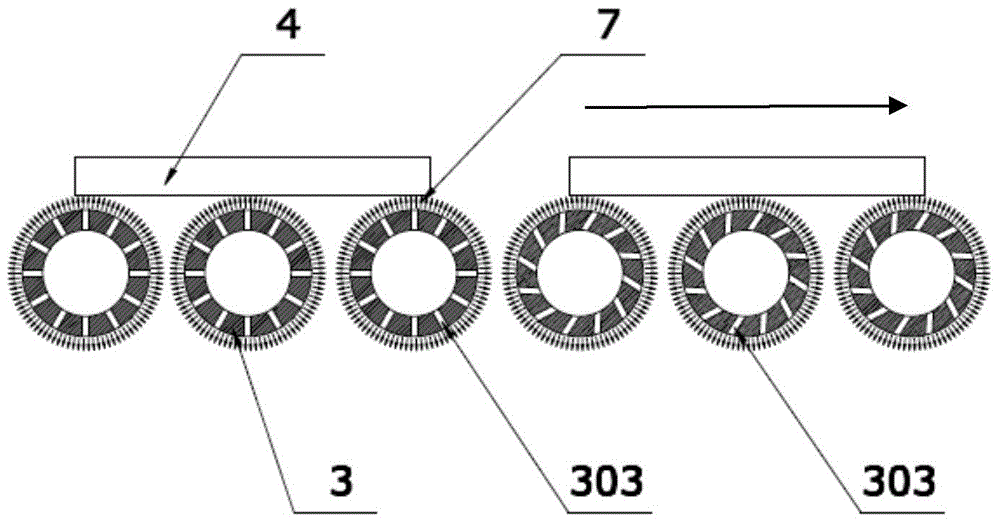

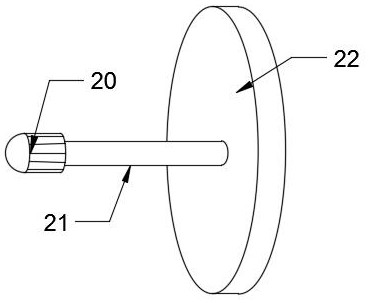

Mechanical arm for transferring solar cell piece basket and double-head transfer device for transferring solar cell piece basket

ActiveCN105374730ASimple working processSimple configurationSemiconductor/solid-state device manufacturingEngineeringSolar cell

The invention relates to a mechanical arm for transferring a solar cell piece basket and a double-head transfer device for transferring the solar cell piece basket. The double-head transfer device comprises mechanical arms, a portal frame, a vertical lifting mechanism fixedly arranged on the portal frame, and a lateral movement mechanism. Each mechanical arm comprises a vertically-arranged installing plate, a top plate fixedly arranged on the installing plate, an installing frame arranged on the top plate through a horizontal slide rail, a rotary table horizontally arranged on the bottom of the installing frame, a micromotion mechanism, a rotating mechanism arranged on the installing frame, and a vacuum system. A negative pressure sucker group adsorbs cell pieces by means of negative pressure provided by a vacuum generator. After the cells are adsorbed, the mechanical arms may start the rotating mechanism as required in a moved process in order to overturn a group of cell pieces by 180 degrees, thereby simplifying downstream work flows. Two baskets directly reach downstream equipment to be processed so that the downstream equipment configuration is simplified.

Owner:HEBEI JING LONG SUN EQUIP

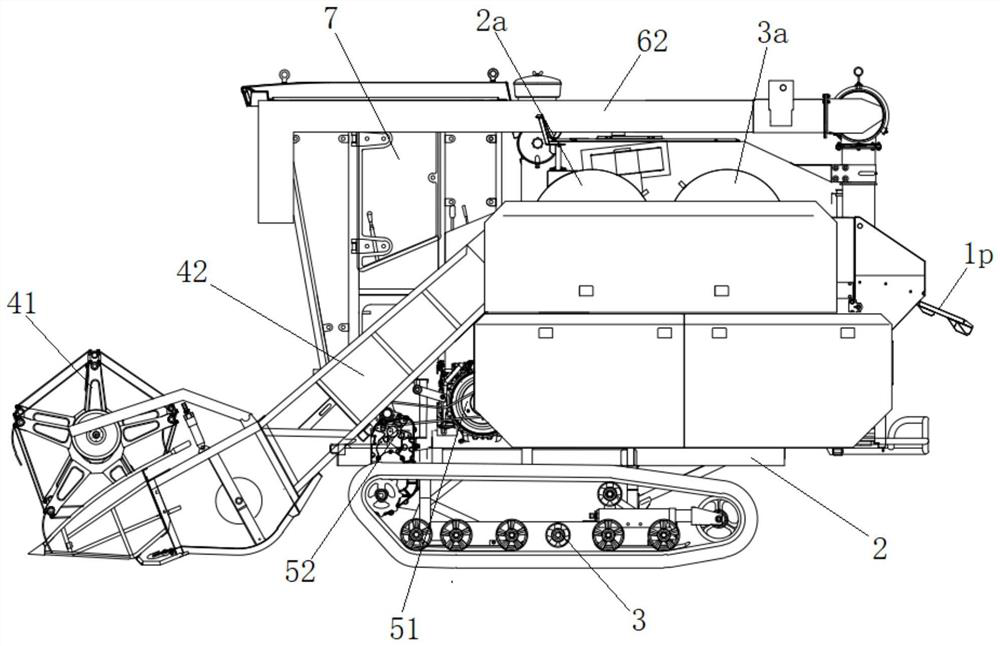

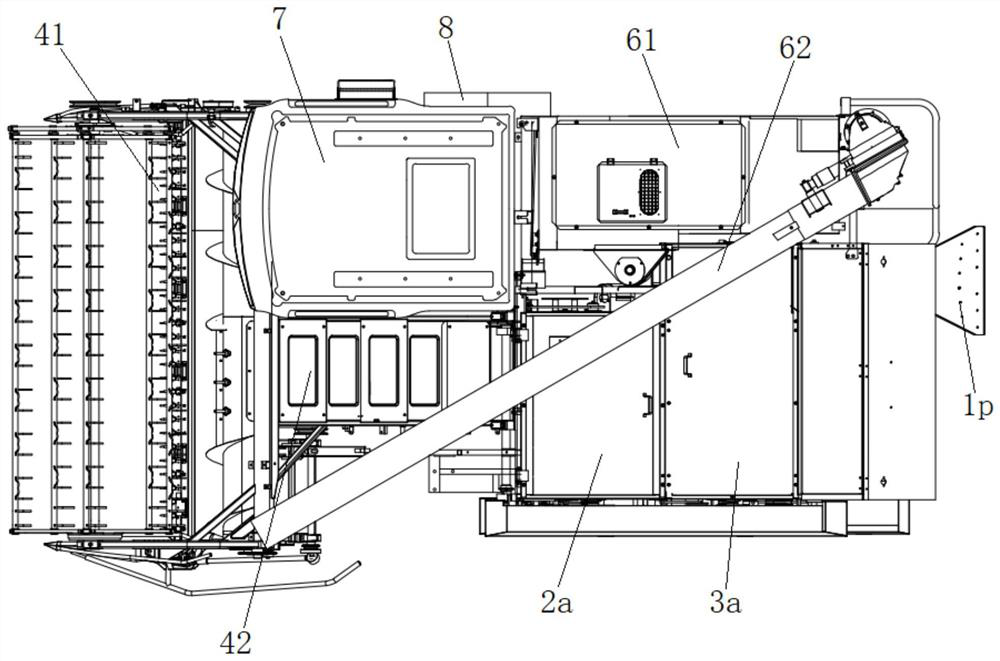

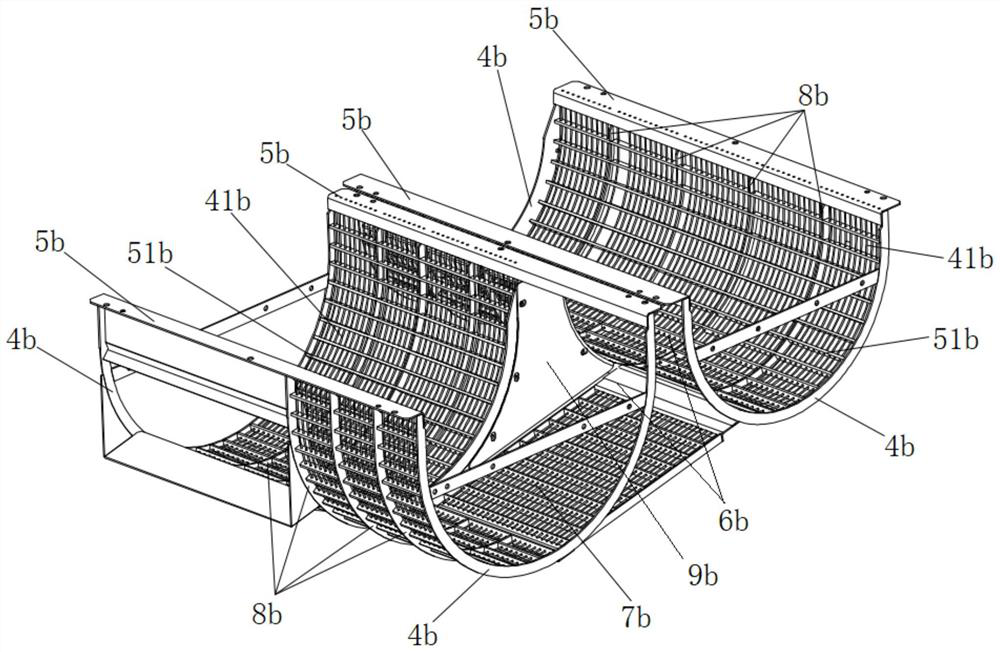

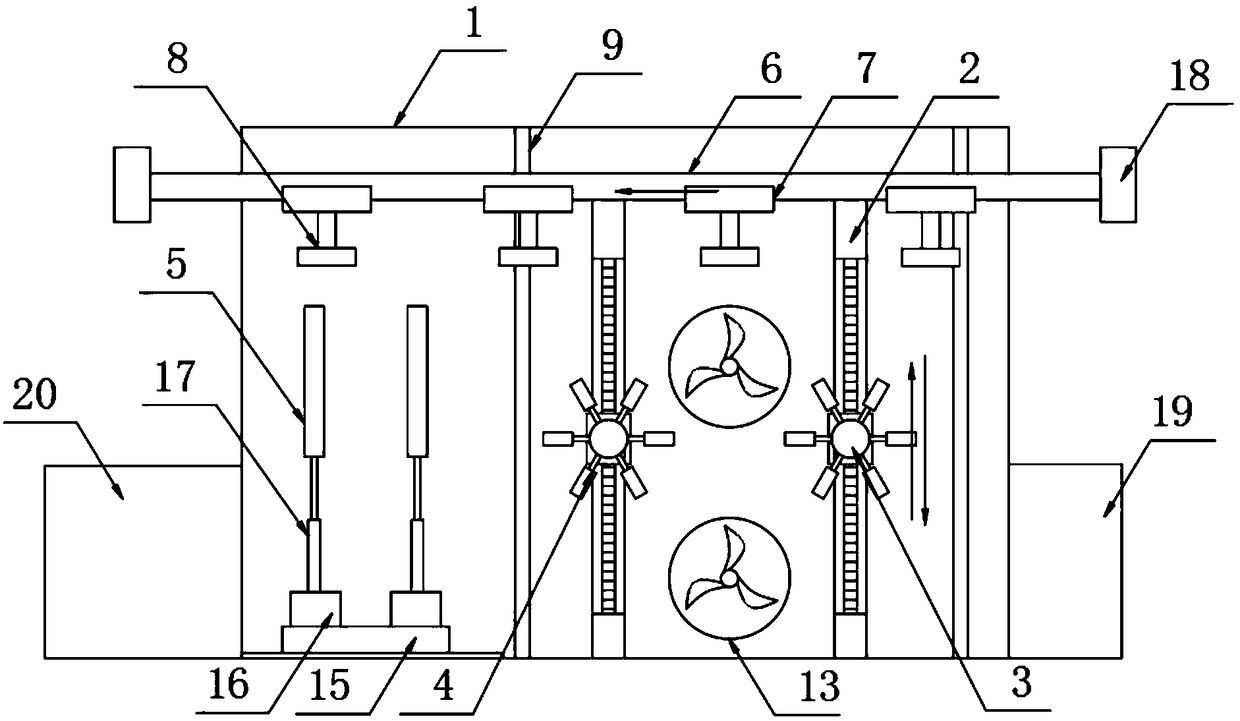

Combine harvester

PendingCN112690086ASmooth feedingGuaranteed stabilityMowersThreshersAgricultural engineeringGrain storage

The invention provides a combine harvester. A feeding port is formed in the middle of a frame, so that a connecting port between a crop conveying structure communicated with the feeding port and a header is located at the position, close to the middle, of the header, and crops are fed into the connecting port from the two sides of the header more evenly; and meanwhile, a scattering structure is arranged close to a grain storage assembly, the crops enter from the middle of the front end of the harvester and are partially scattered out from the middle of the tail end of the harvester through the n-shaped threshing direction of a double-helix threshing conveying system, and the stability of the gravity center of the combine harvester is guaranteed. A cleaning transmission system is arranged at the outer side of a threshing system, centralized transmission is achieved, and installation and debug are convenient. The whole harvester is compact in structure, small in occupied space, high in maneuverability and remarkable in operation efficiency, and the gravity center is always kept stable in the empty operation and harvesting operation process.

Owner:JIANGSU WORLD AGRI MACHINERY

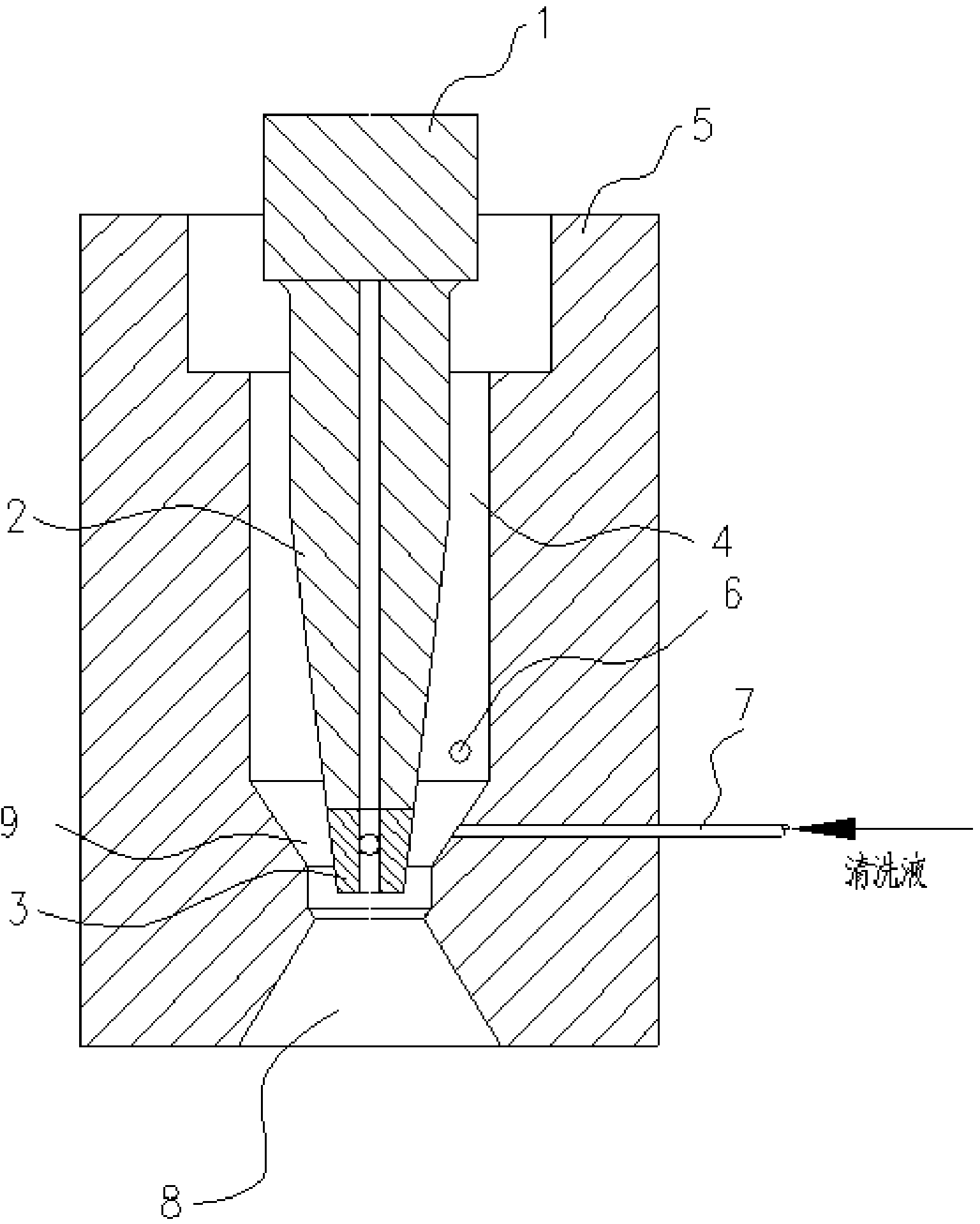

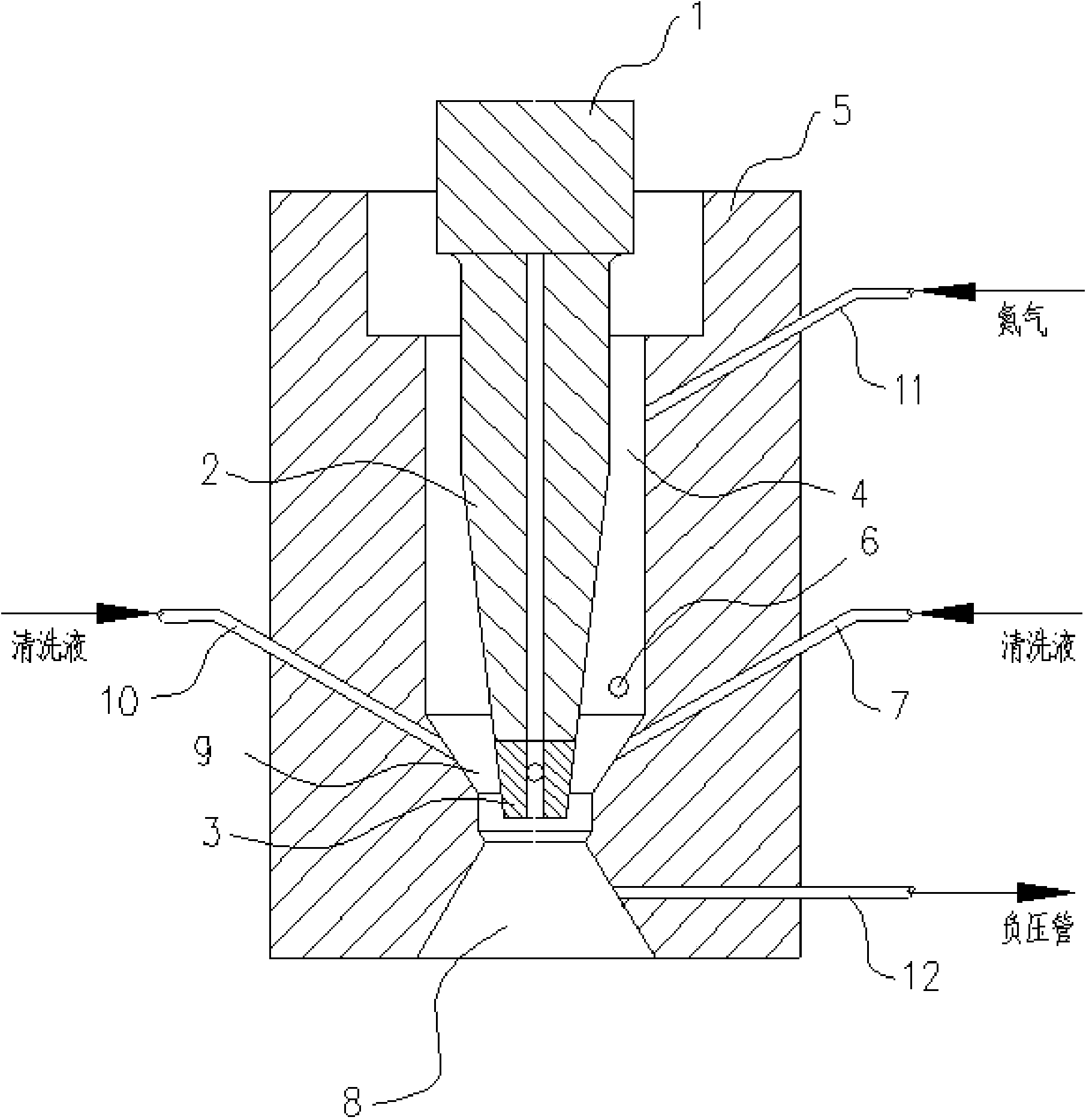

Cleaning trough body structure for photoresist nozzle and application of cleaning trough body structure

The invention relates to a cleaning trough body structure for a photoresist nozzle and application of the cleaning trough body structure. The cleaning trough body structure comprises a cleaning trough shell, a cleaning fluid anti-splattering cavity, a nozzle cleaning cavity, a cleaning fluid discharging opening, a cleaning fluid pipeline, a newly-added cleaning fluid pipeline, a nitrogen purging pipeline and a negative pressure exhaust pipeline, wherein a cleaning fluid flows to the inner lower part of the nozzle cleaning cavity along the cleaning fluid pipeline and the newly-added cleaning fluid pipeline for washing a nozzle head so that the nozzle head is completely cleaned; the nitrogen purging pipeline and the negative pressure exhaust pipeline which are arranged in an inclined manner can be used for reducing frequency of the condition that the cleaning fluid splashes to the cleaning fluid anti-splattering cavity, and can prevent the cleaning fluid or final cleaning fluid from remaining inside the nozzle cleaning cavity. According to the cleaning trough body structure and the application thereof, disclosed by the invention, cleaning effect on the nozzle head can be ensured, residual of pollutants can also be prevented, and the light resistance spraying quality of the photoresist nozzle is not influenced.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

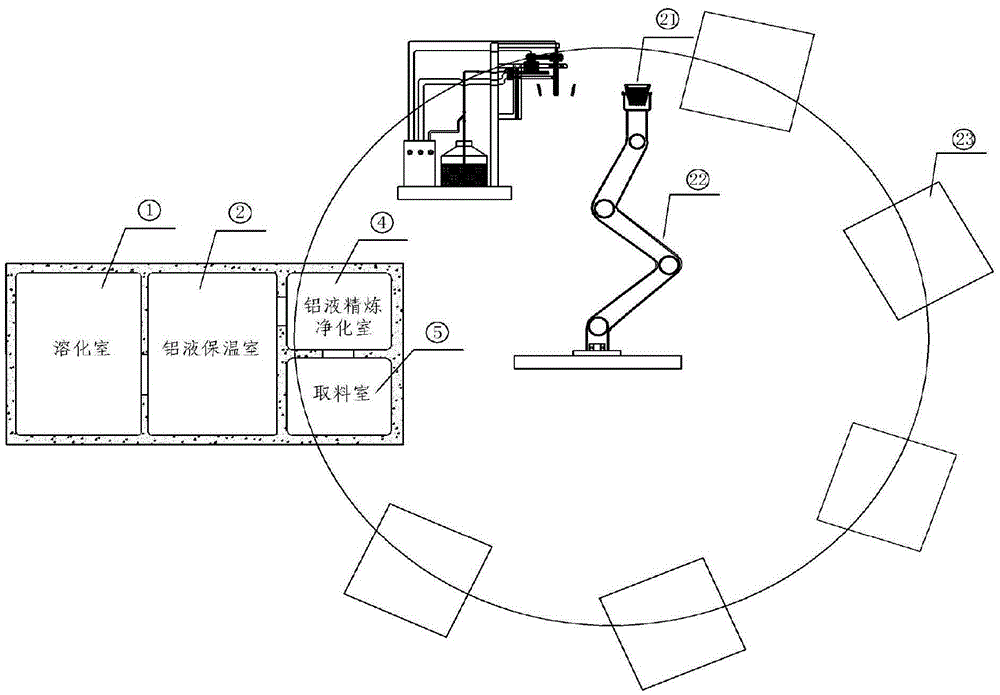

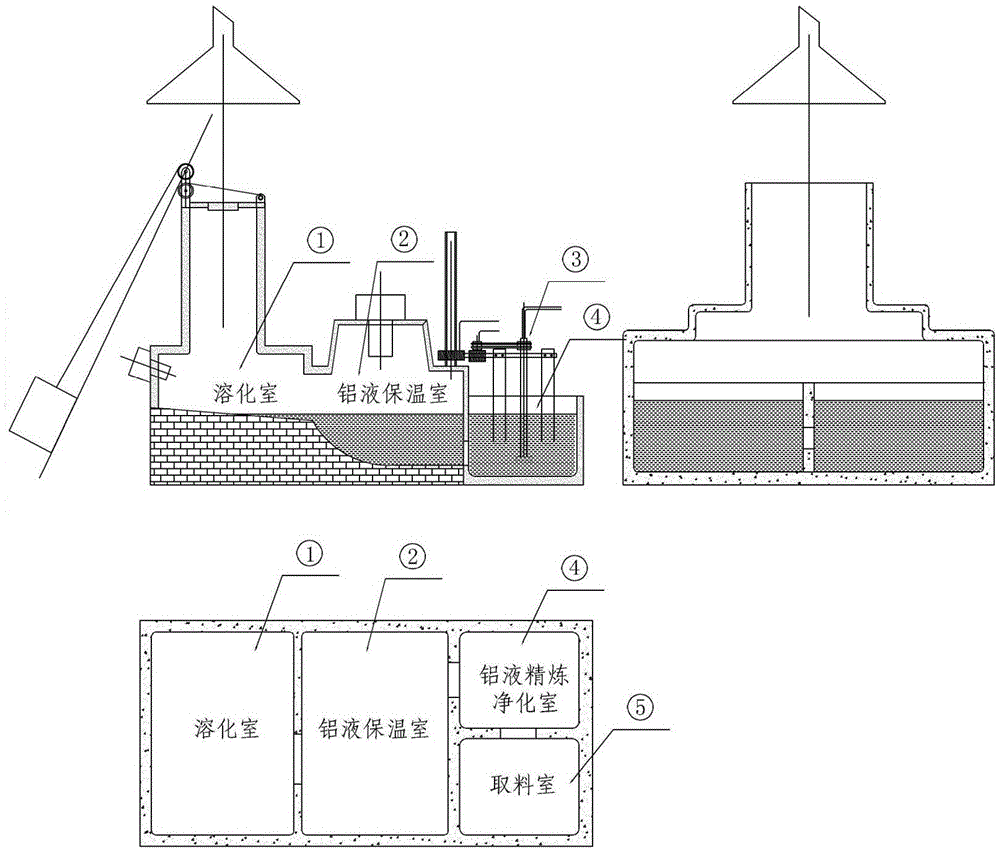

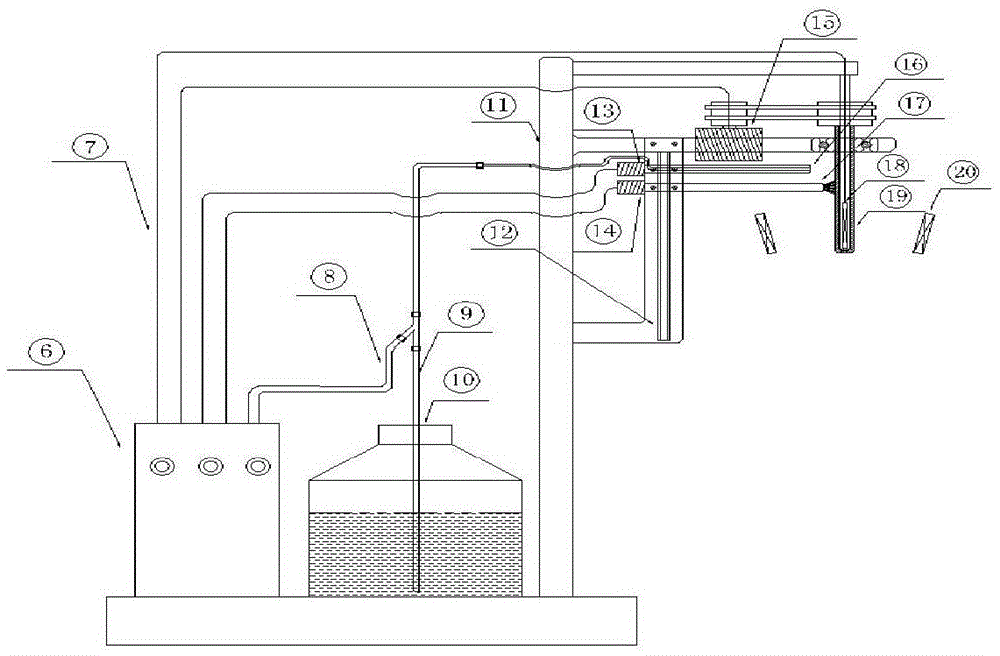

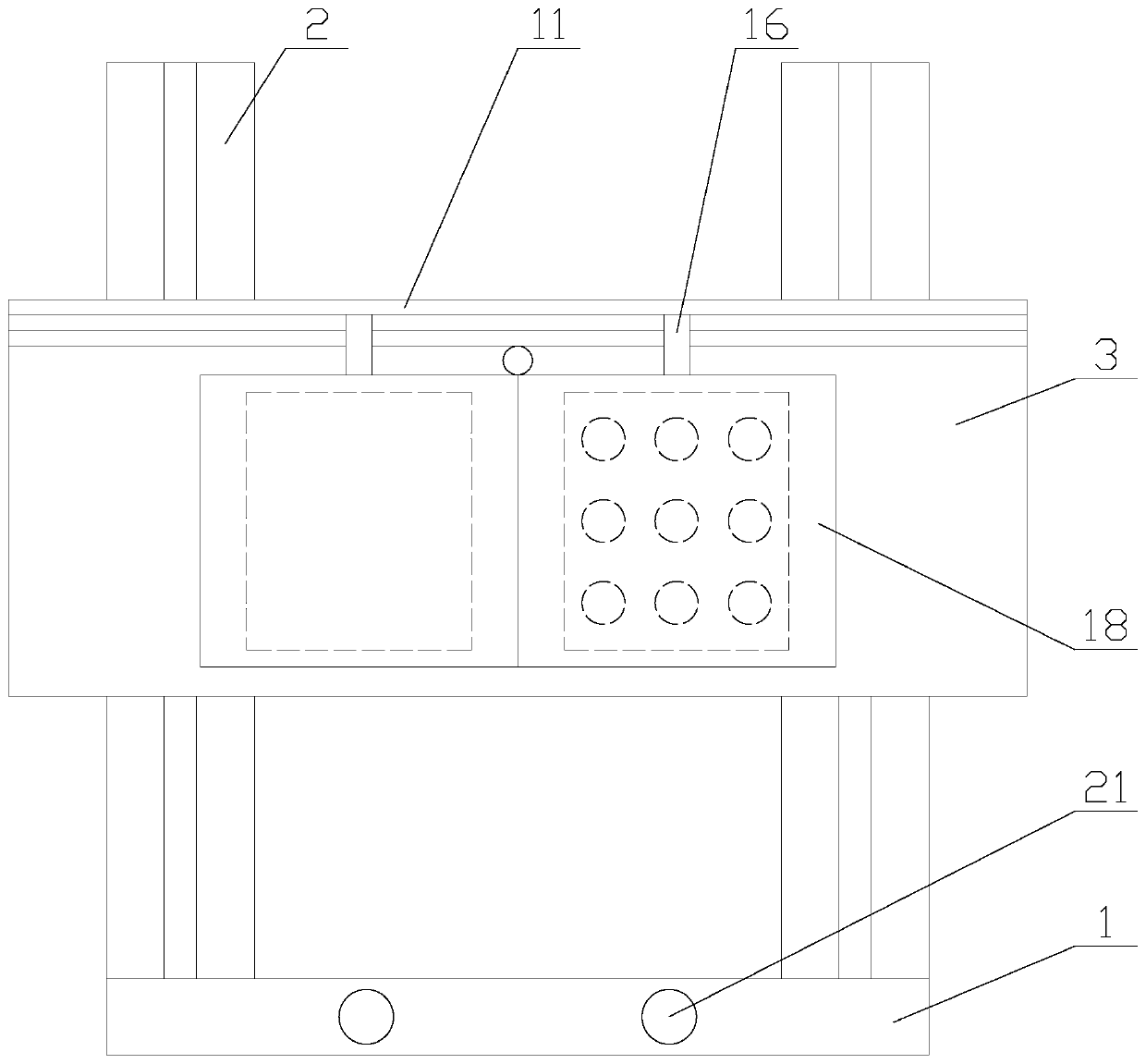

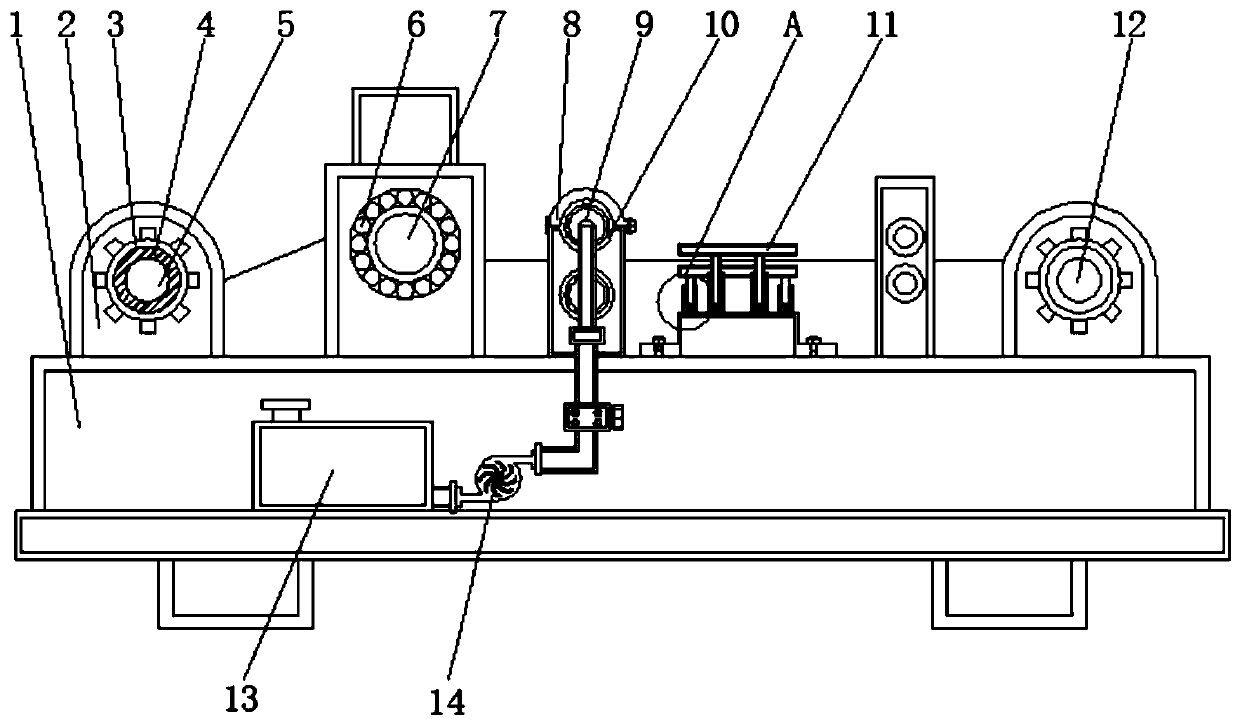

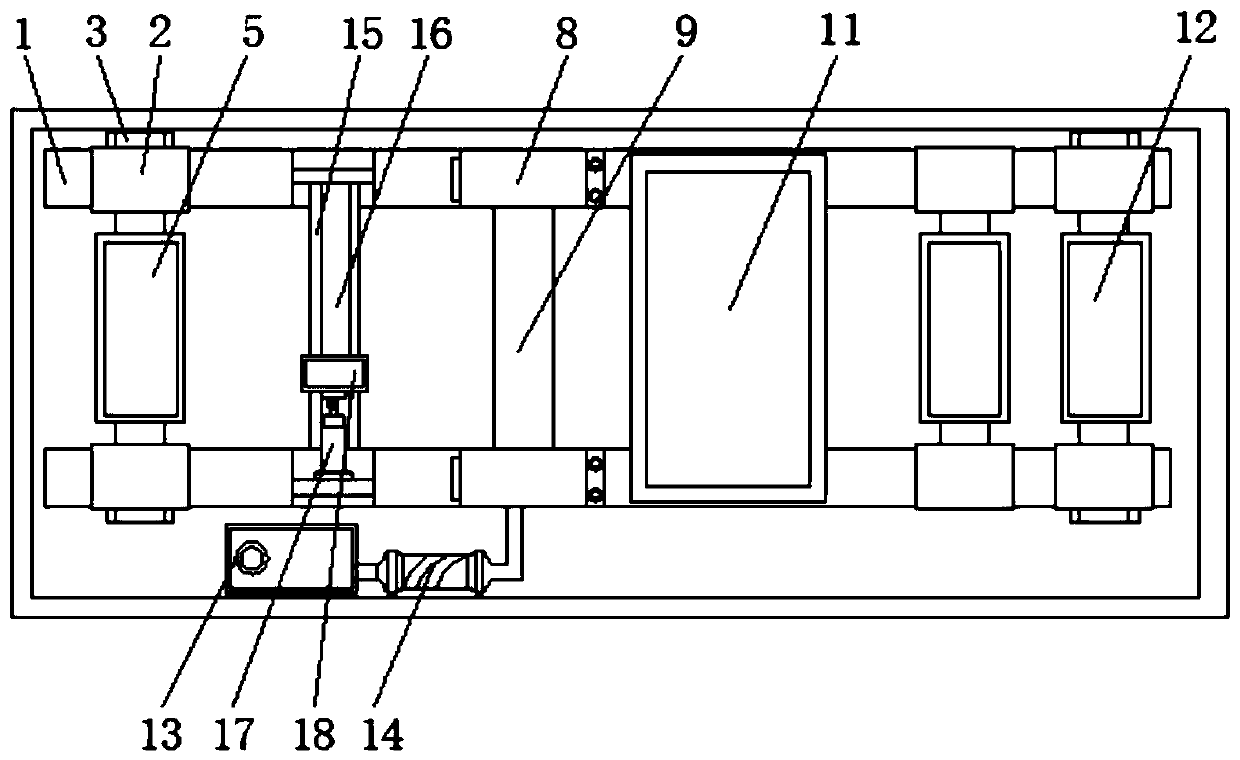

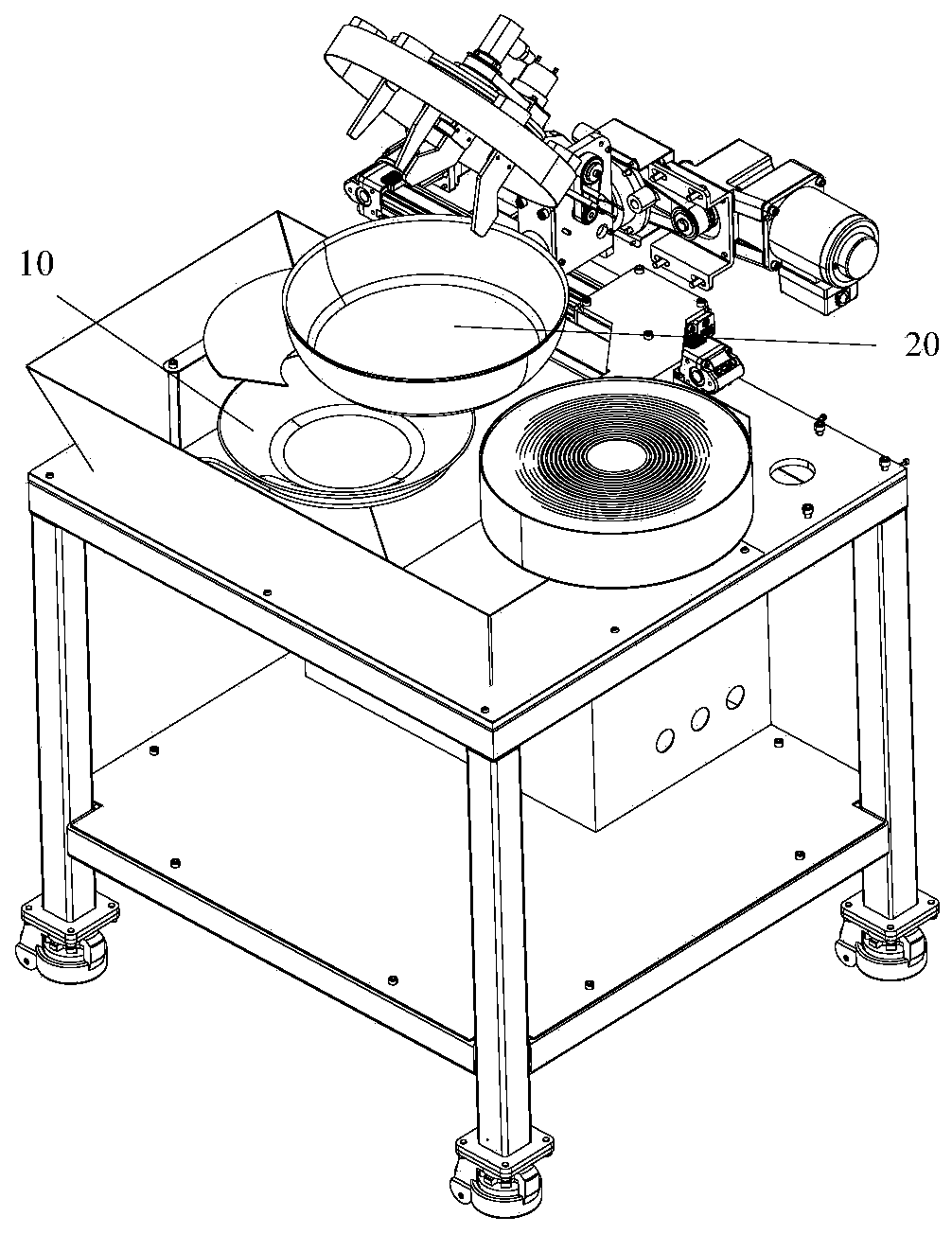

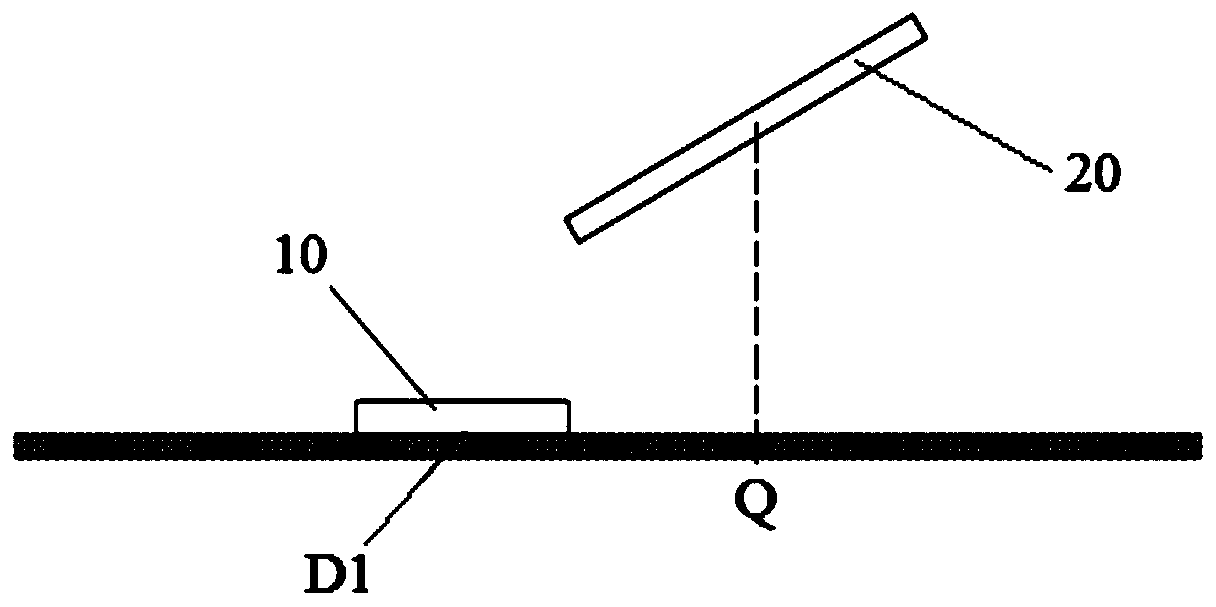

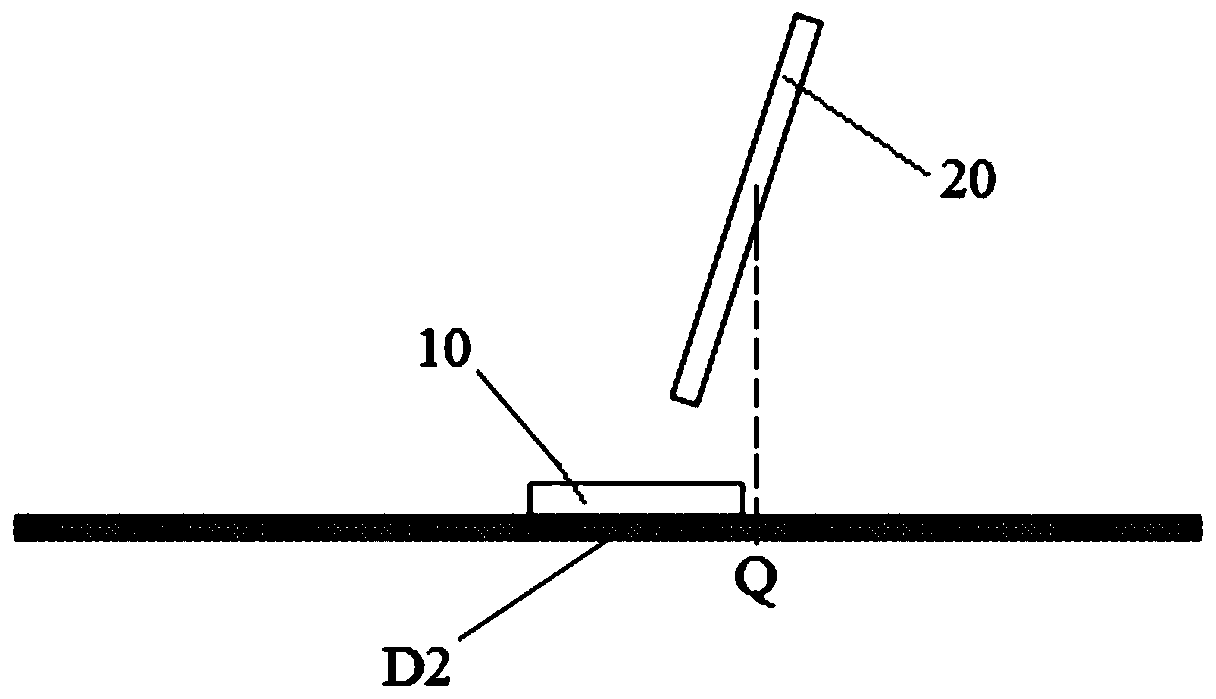

Continuous rapid preparing device of semi-solid slurry of automobile aluminum alloy wheels

The invention discloses a continuous repaid repairing device of semi-solid slurry of automobile aluminum alloy wheels. The device is composed of a continuous melting refining purification furnace, a slurry rapid stirring device, a slurry transfer crucible and an intelligent assistance arm. The material continuous refining purification furnace, the slurry rapid stirring device and die-casting machines (or die forging machines) are distributed on the circumference of the circle with the intelligent assistance arm as the center; the slurry transfer crucible is mounted on the intelligent assistance arm and inputs the motion program of the intelligent assistance arm to a computer; according to the slurry transfer crucible, in a material taking chamber, a liquid face oxide thin film is put aside, a certain amount of molten aluminum is taken, and then is transferred to the position below a graphite pipe of the slurry rapid stirring device, the graphite pipe is inserted into slurry in the center area of the slurry transfer crucible, and an electromagnetic stirrer in the graphite pipe and an electromagnetic stirrer on the periphery of the slurry transfer crucible are started to carry out electromagnetic stirring; the slurry stirred to be qualified is rapidly transferred to the die-casting machines (or die forging machines) for production. According to the technical scheme, semi-solid slurry continuous and rapid preparing and transferring can be achieved, the slurry is stable in quality, and the device is of great significance in semi-solid production of the automobile aluminum alloy wheels.

Owner:JIANGSU KAITE AUTO PARTS

Building interphone with lifting and dustproof functions for security and protection

ActiveCN110166753AImprove convenienceGood dustproof effectClosed circuit television systemsStands/trestlesIntercomStationary case

The invention relates to a building interphone with lifting and dustproof functions for security and protection. The device comprises a main machine, a base and two lifting boxes, the interphone further comprises a dustproof mechanism and two lifting mechanisms. Each lifting mechanism comprises a first motor, a gear, a rack and a connecting rod; the dustproof mechanism comprises a fixing box and two cover plates; a driving assembly, two supporting rods and two springs are arranged in the fixing box. In the building interphone with the lifting and dustproof functions for security and protection, through adopting the lifting mechanisms, the height position of the main machine can be adjusted, users of different heights can operate the main machine conveniently, a display screen and a controlpanel on the main machine can be subjected to dustproof work through the dustproof mechanism, and the situation that the cleanliness of the main machine is affected due to the fact that the display screen and the control panel are covered with dust is avoided.

Owner:北京天安云浩保安服务有限公司

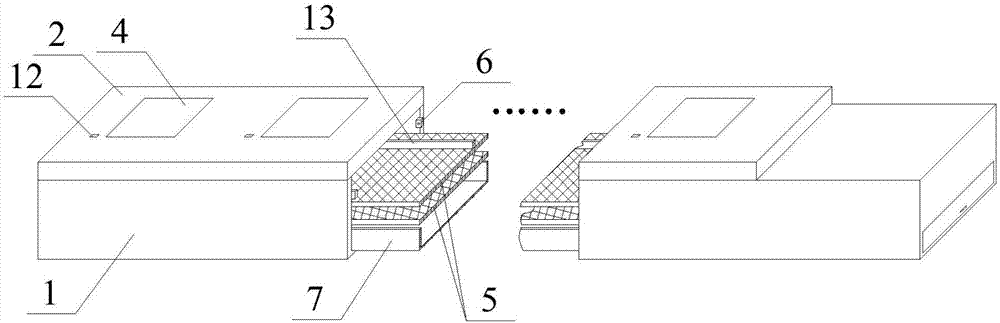

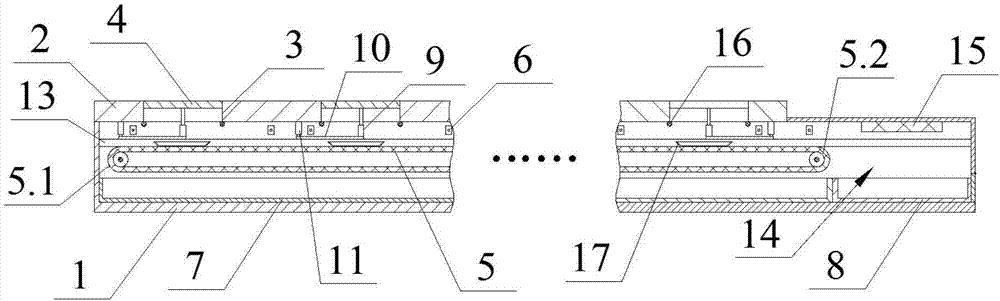

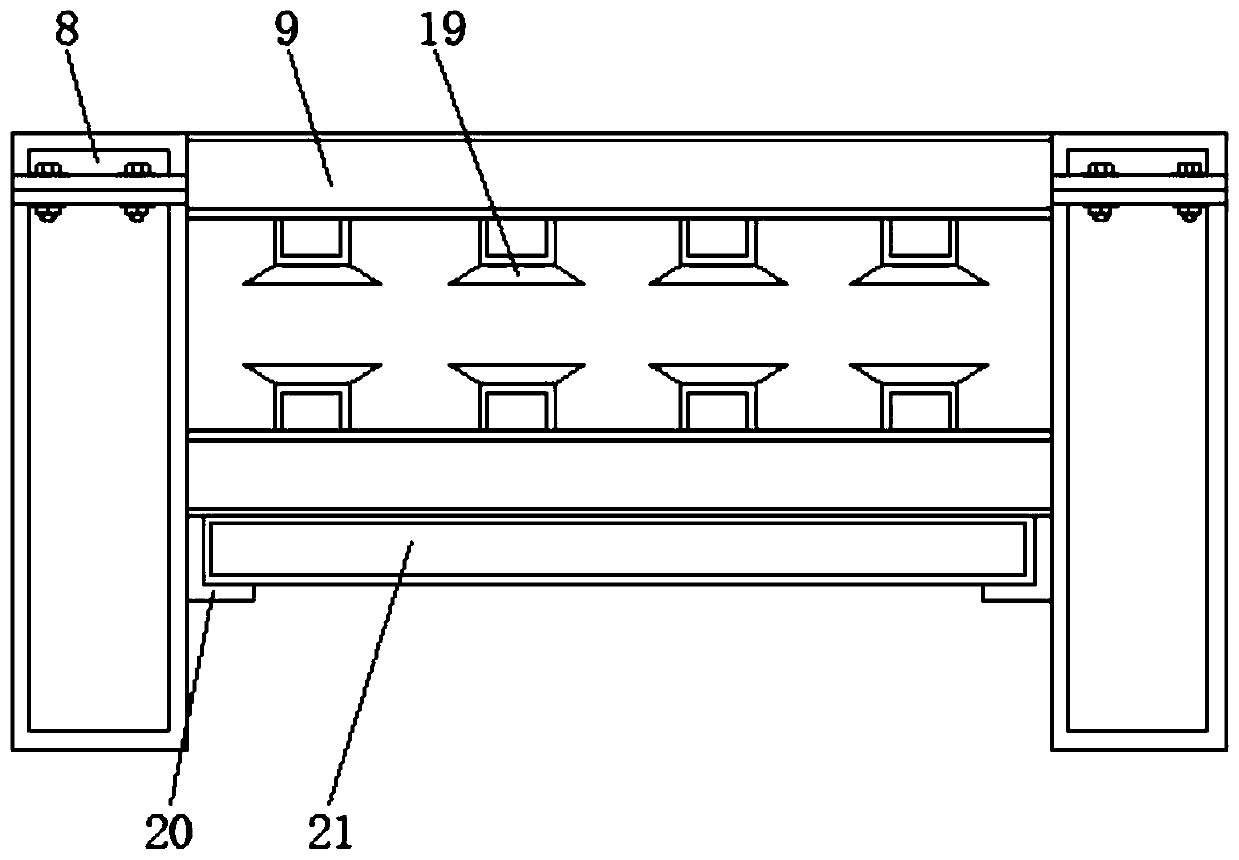

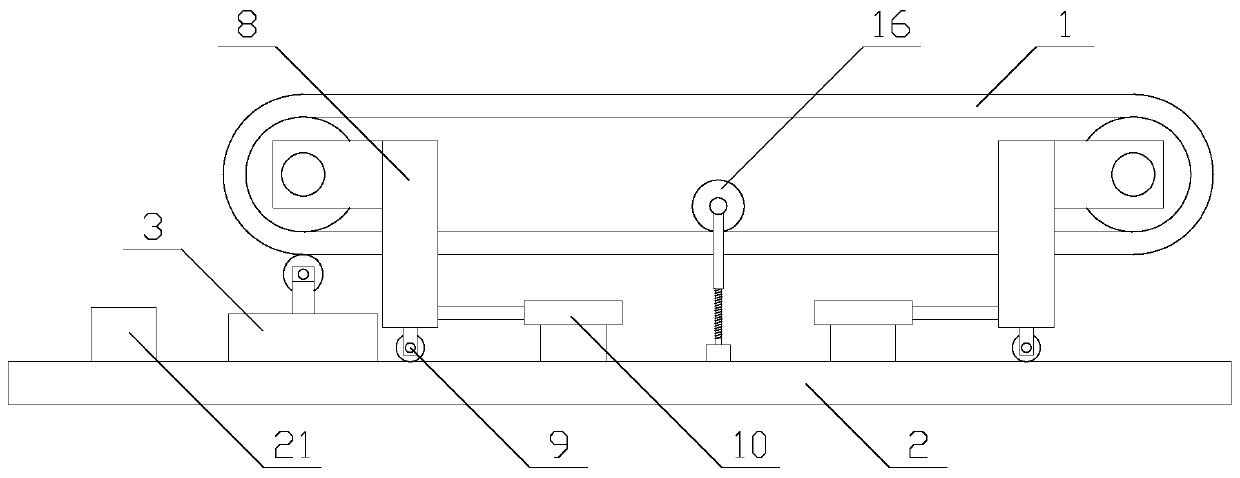

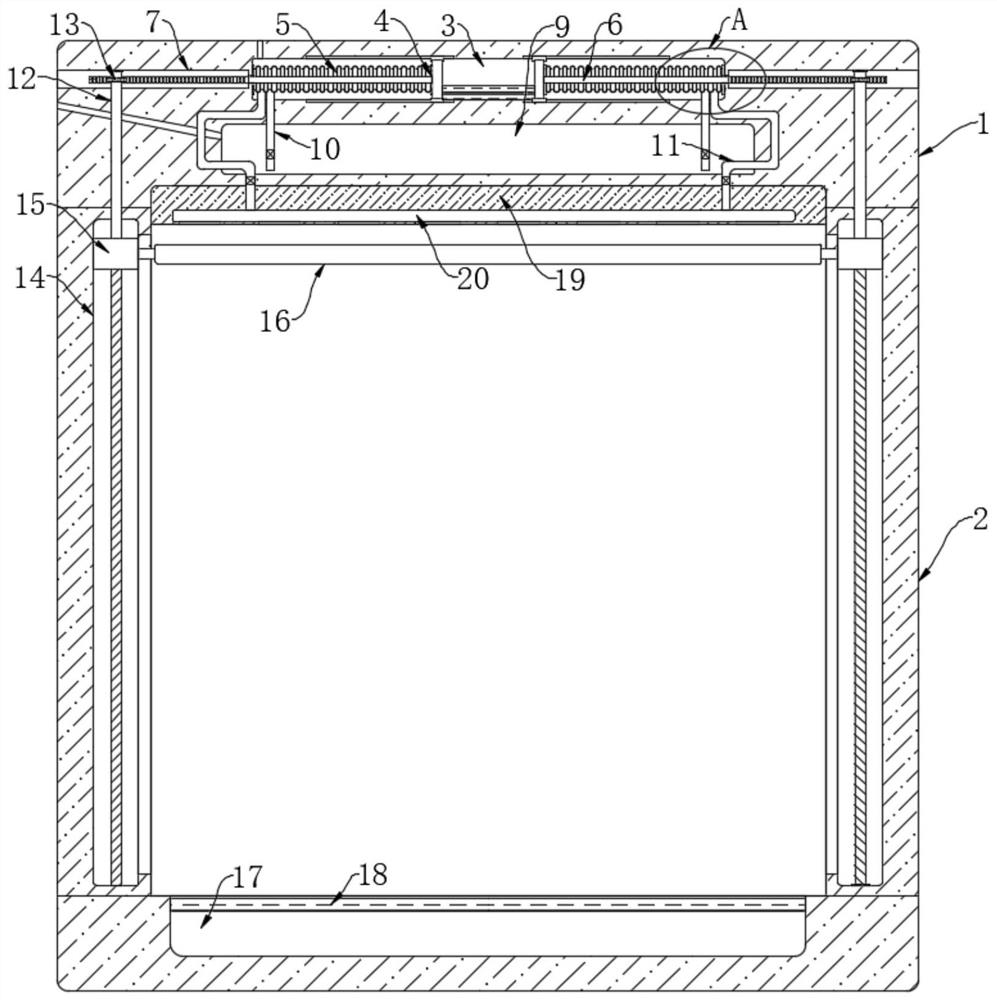

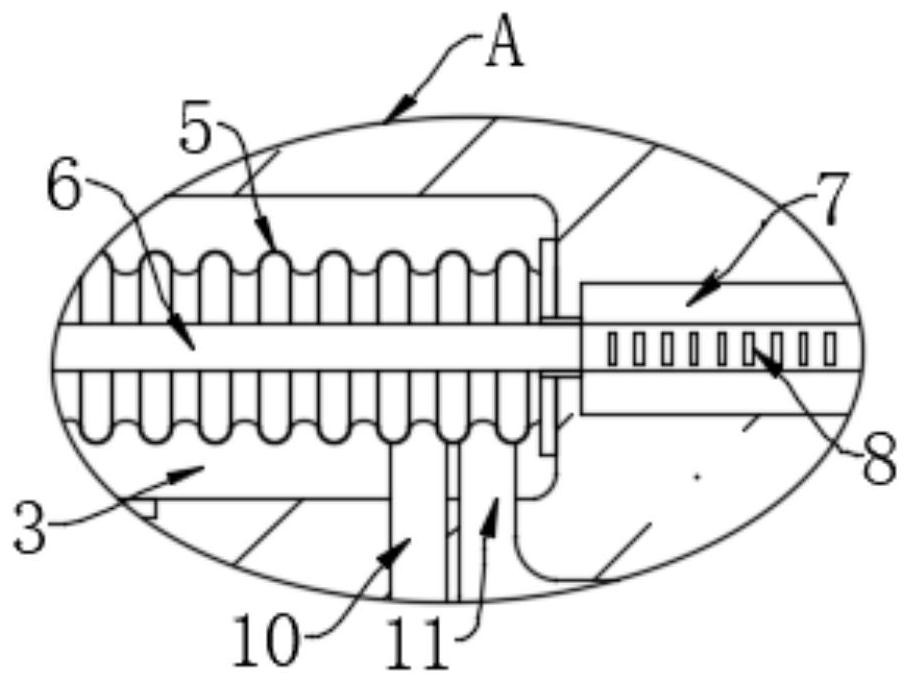

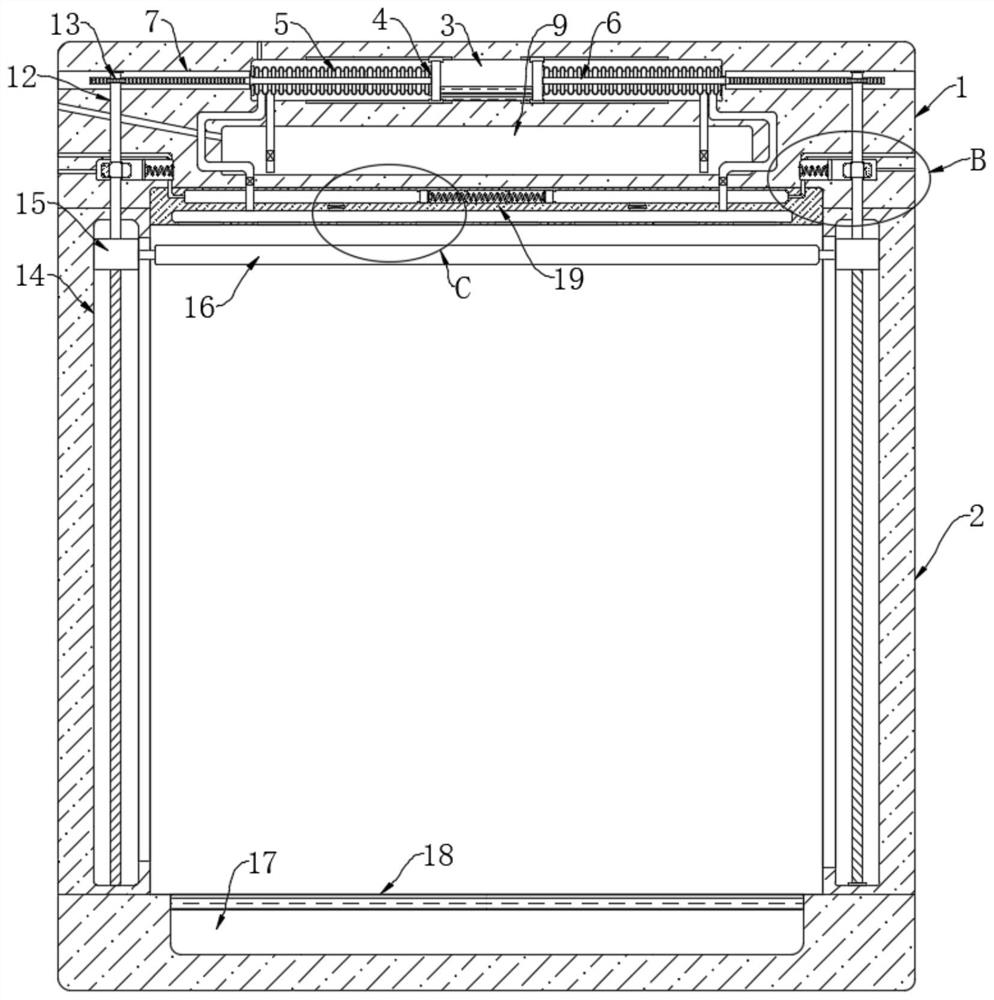

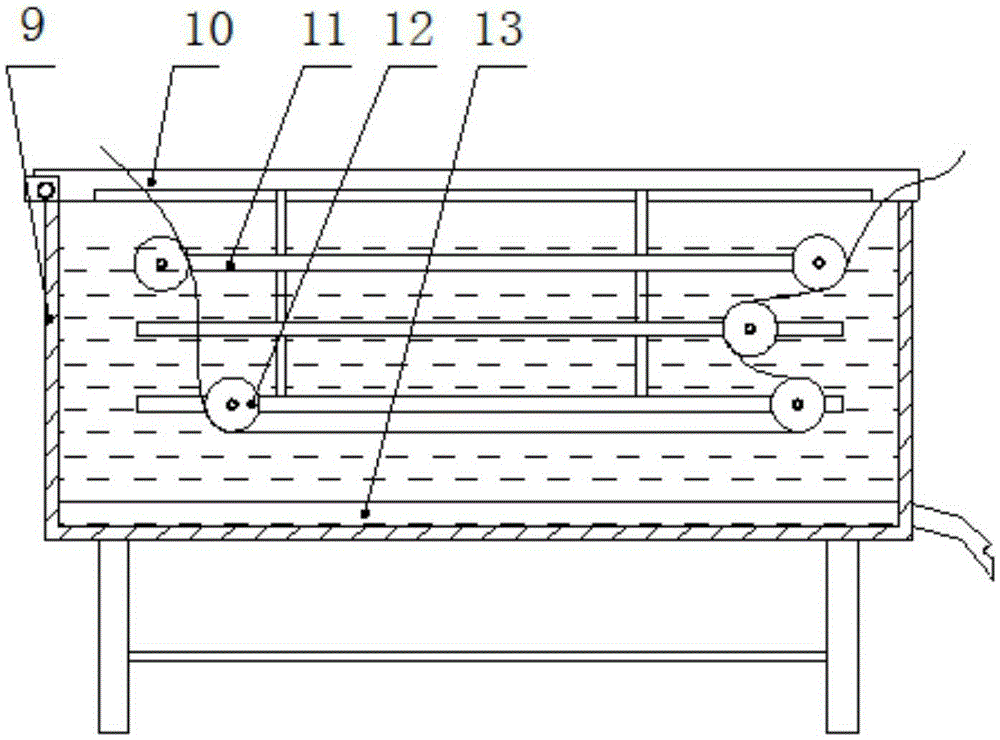

Automatic recovering and cleaning table for standardized tableware for dining rooms and assembling method thereof

InactiveCN106913080ADoes not take up floor spaceWill not affect normal dietKitchen tablesDish-washing tablesEngineeringHigh pressure water

The invention relates to an automatic recovering and cleaning table for standardized tableware for dining rooms and an assembling method thereof. The table comprises a table body and a table cover plate; the table cover plate is provided with multiple recovery openings; the table cover plate is provided with recovery plates for enclosing the recovery openings; the table body is provided with a conveyor belt therein in the arrangement direction of the recovery openings; the conveyor belt is installed under the recovery openings; two sides of the conveyor belt are provided with multiple high pressure water gun nozzles whose water outlets are directed to the conveyor belt; the high pressure water gun nozzles are communicated with an external water pipe; a waste bin is arranged under the conveyor belt; a tableware recovery box is arranged under the end of the conveyor belt. Through the installation of the multiple automatic recovering and cleaning tables for standardized tableware for dining rooms, cleaning and recovering are carried out under tables, which will not occupy the area of dining rooms; automatic cleaning and recovering are realized; dishes can be cleaned; the table is simple and convenient to operate. The whole cleaning and recovering process is carried out inside tables, which will not influence the normal diet for diners.

Owner:左子昂

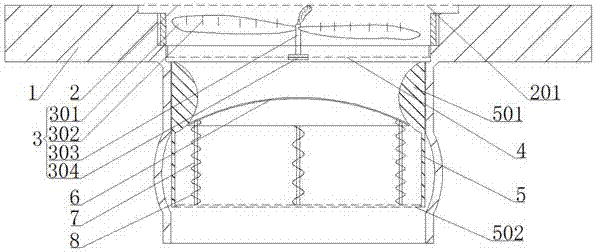

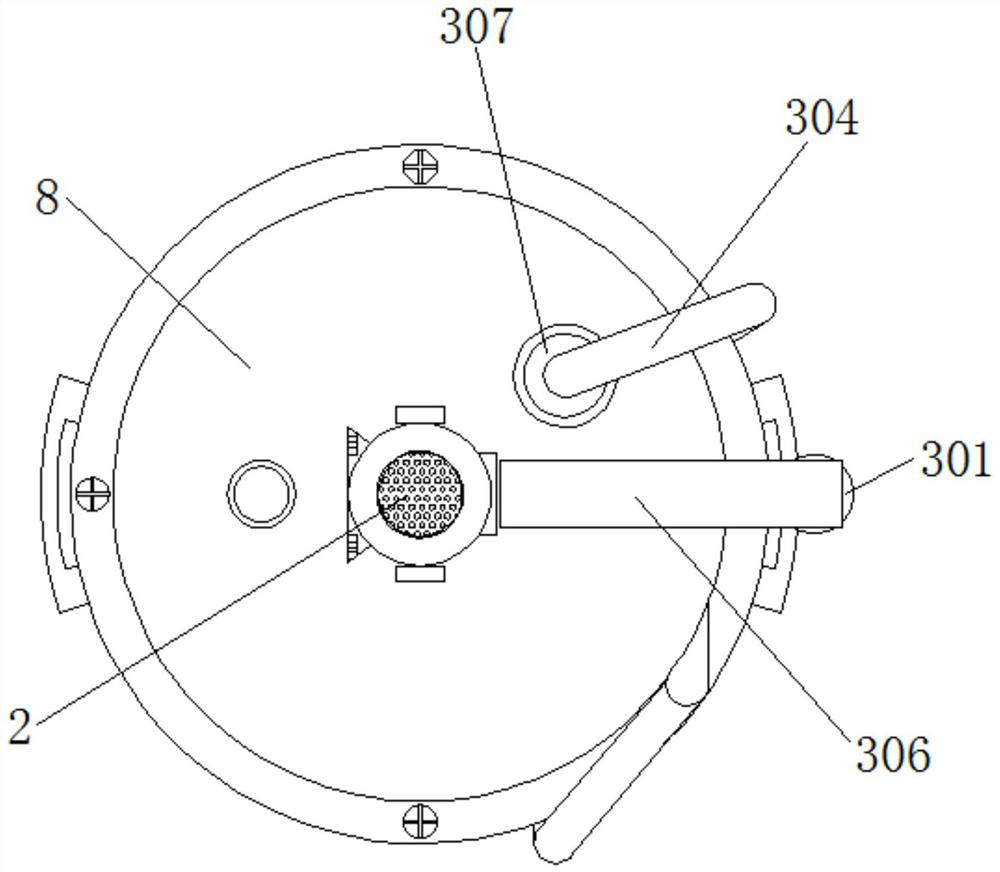

Floor drain for preventing backwater backflow

The invention discloses a floor drain for preventing backflow of water, which comprises a floor drain main body. The floor drain main body is an integral structure with a plurality of steps and internal threads inside. The lower filter is threaded, the lower filter is connected with a number of uprights, the uprights are covered with springs, the upper end of the uprights is connected with a spherical cap, and closely fits with the convex arc surface of the inner wall of the spacer, the upper part of the floor drain body is threaded into the upper cover, and the lower end of the upper cover The inner thread of the inner thread is connected to the outer thread of the mesh ring, and a diversion fan is set on the mesh ring; it has a compact structure, a reasonable design, and fast water discharge, which can prevent debris from clogging the sewer pipe, and at the same time prevent the odor in the sewer pipe from affecting the cleanliness of the indoor air, especially When the pipeline on the next floor is blocked, there will be no water return phenomenon. In addition, after the surface of the local drain is treated with paint, it is resistant to acid and alkaline liquid corrosion and has a long service life.

Owner:赵慧

Fabric fast-carding device for textile production

ActiveCN110318244AEasy to installEasy to disassemble and replaceMechanical cleaningPressure cleaningCorrosionMoisture

The invention discloses a fabric fast-carding device for textile production. The device includes a fixing support, a heating plate and a dust sucking head; the upper ends of the fixing support are provided with a support frame, an unreeling shaft is fixed to the interior of the support frame, the two ends of the unreeling shaft are provided with thread blocks, rotating blocks are fixed to the outer surfaces of the thread blocks, the unreeling shaft is provided with a roll shaft, and the outer surfaces of the two ends of the roll shaft are provided with balls. Compared with an existing common fabric fast-carding device for textile production, the fabric fast-carding device for textile production can remove dust, cotton fibers and other impurities adhering to fabrics, the carding effect of the carding device is improved, water is prevented from overflowing during the use of the device so as to avoid parts from moisture and corrosion, centralized treatment of waste liquid is convenient, waste of water resources is avoided, meanwhile, the fabrics with different thicknesses can be flattened, and the applicability of the device is improved.

Owner:YUHUAN ZITI COSMETICS CO LTD

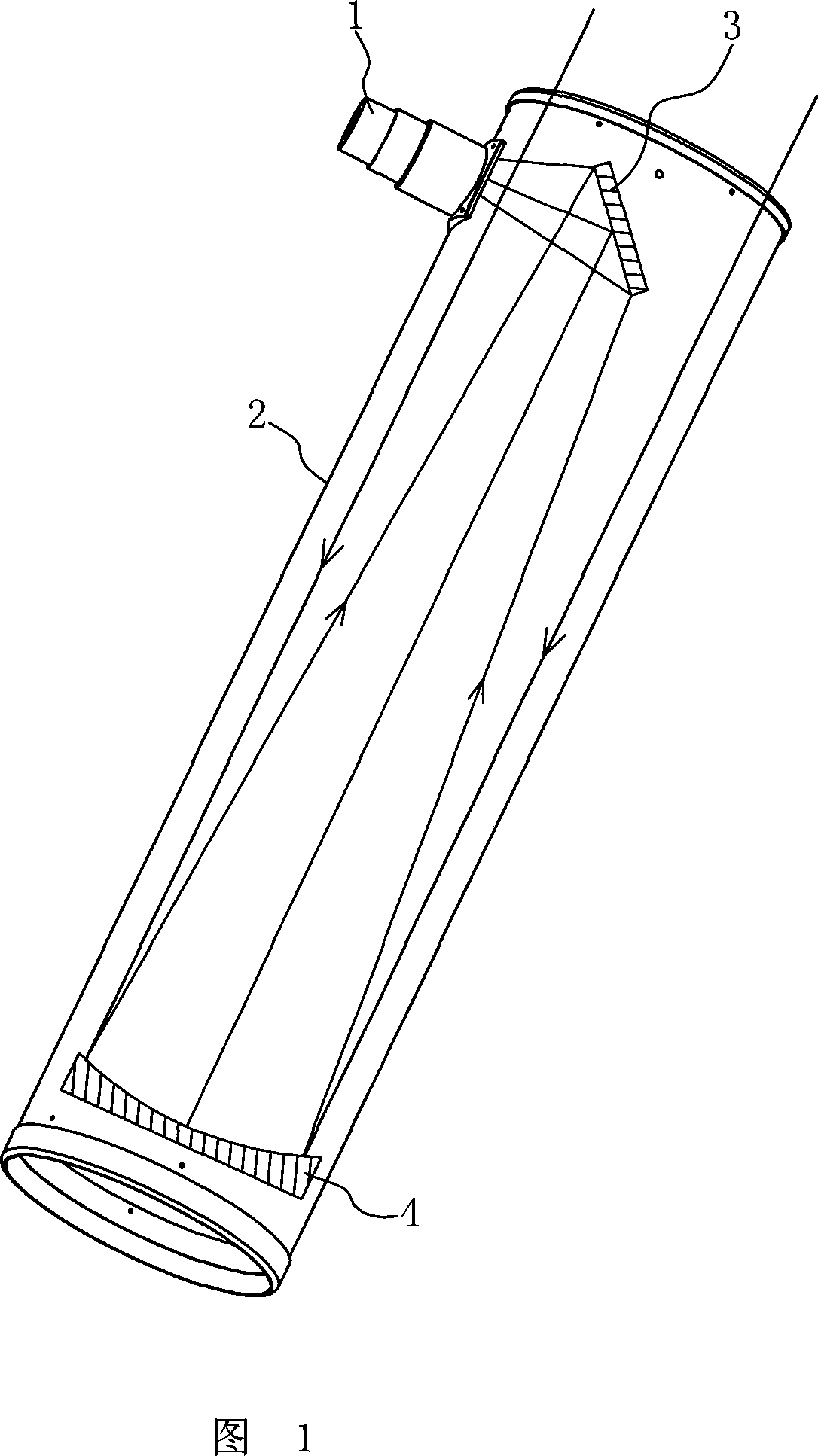

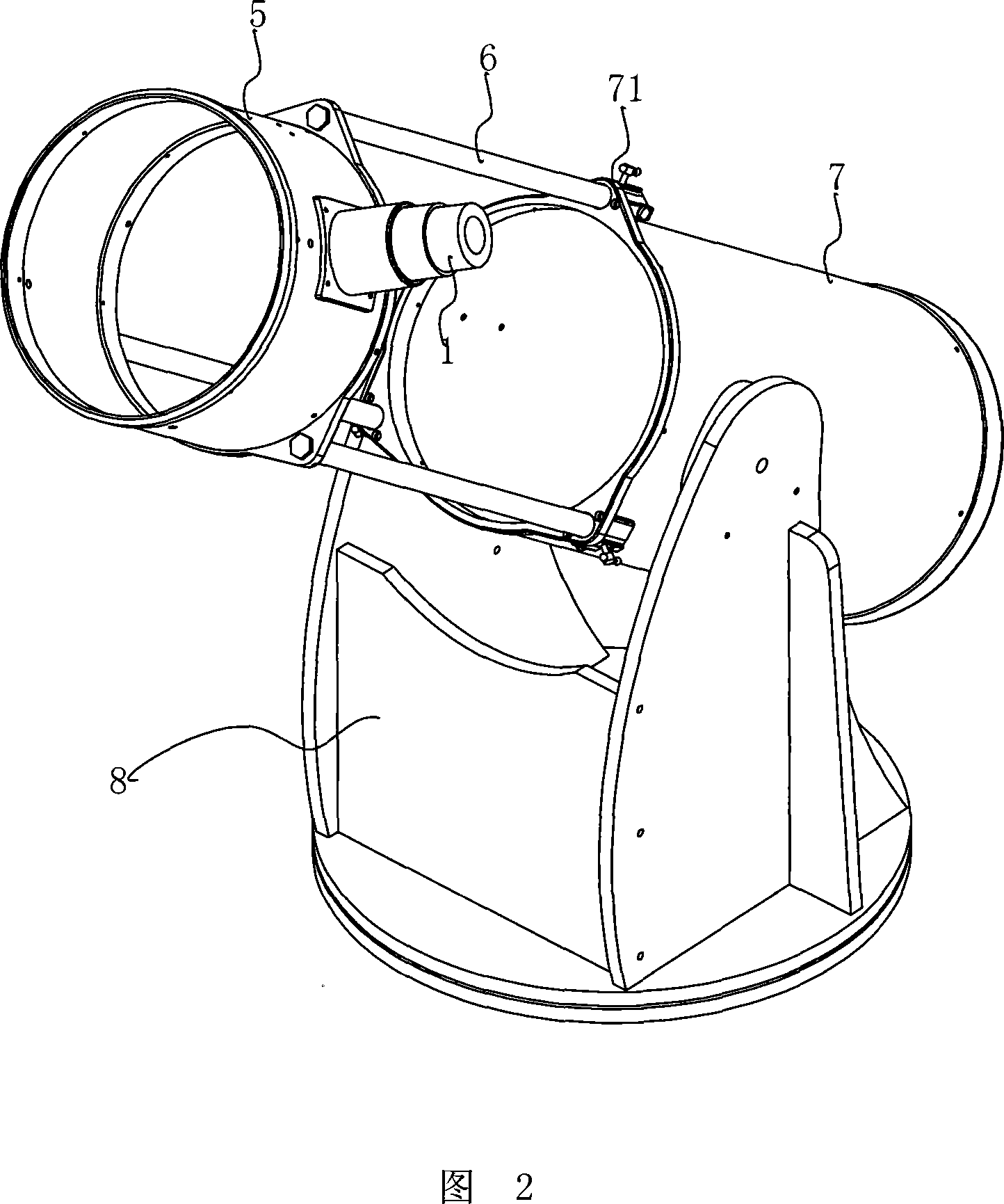

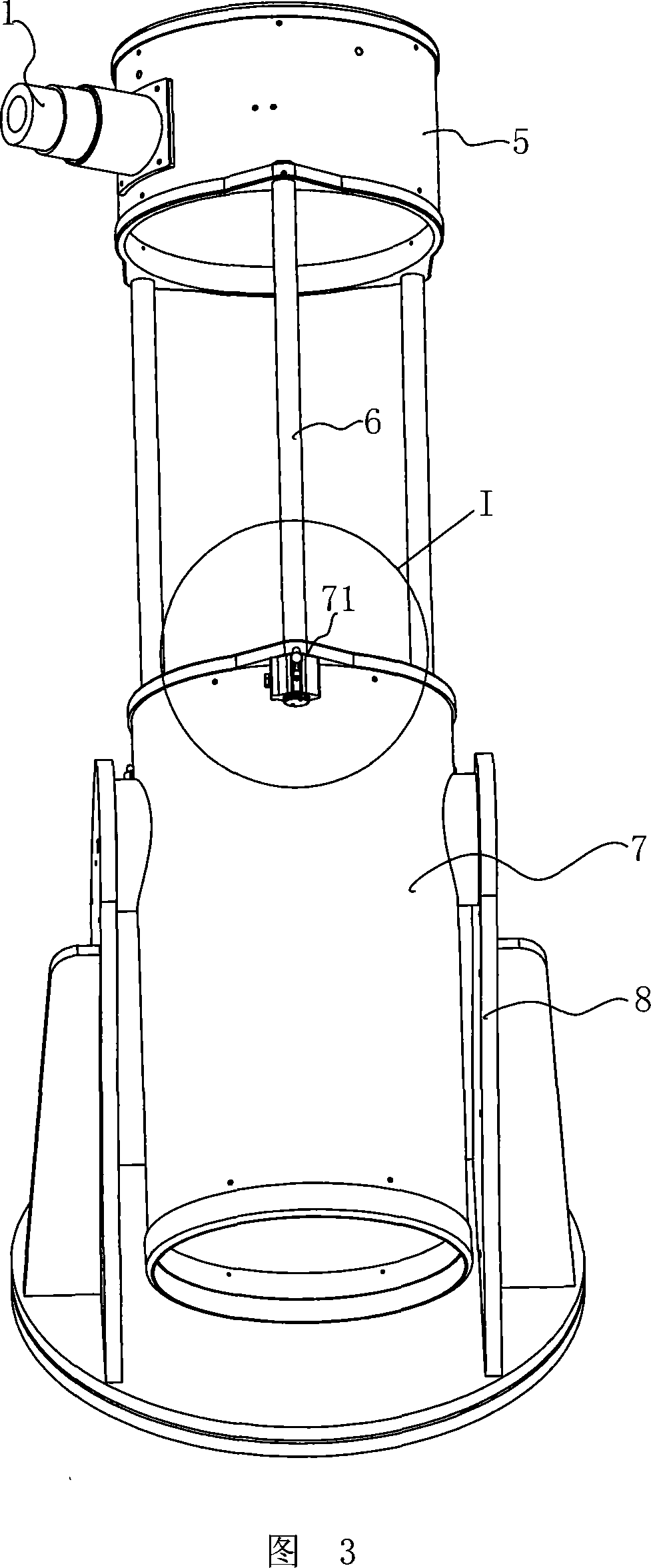

Telescopic lens cone

The retractable lens barrel comprises a front lens barrel and a rear lens barrel both located in same axis; the front lens barrel and the rear lens barrel are connected by using even numbers of linkages parallel with the axial line of the lens barrel; the front lens barrel or the rear lens barrel can be zoomed in or out along with the barrel axial direction. The invention can shorten the length of Newton type reflecting telescope and reduces the weight of it.

Owner:NANTONG SCHMIDT OPTO ELECTRICAL TECH CO LTD

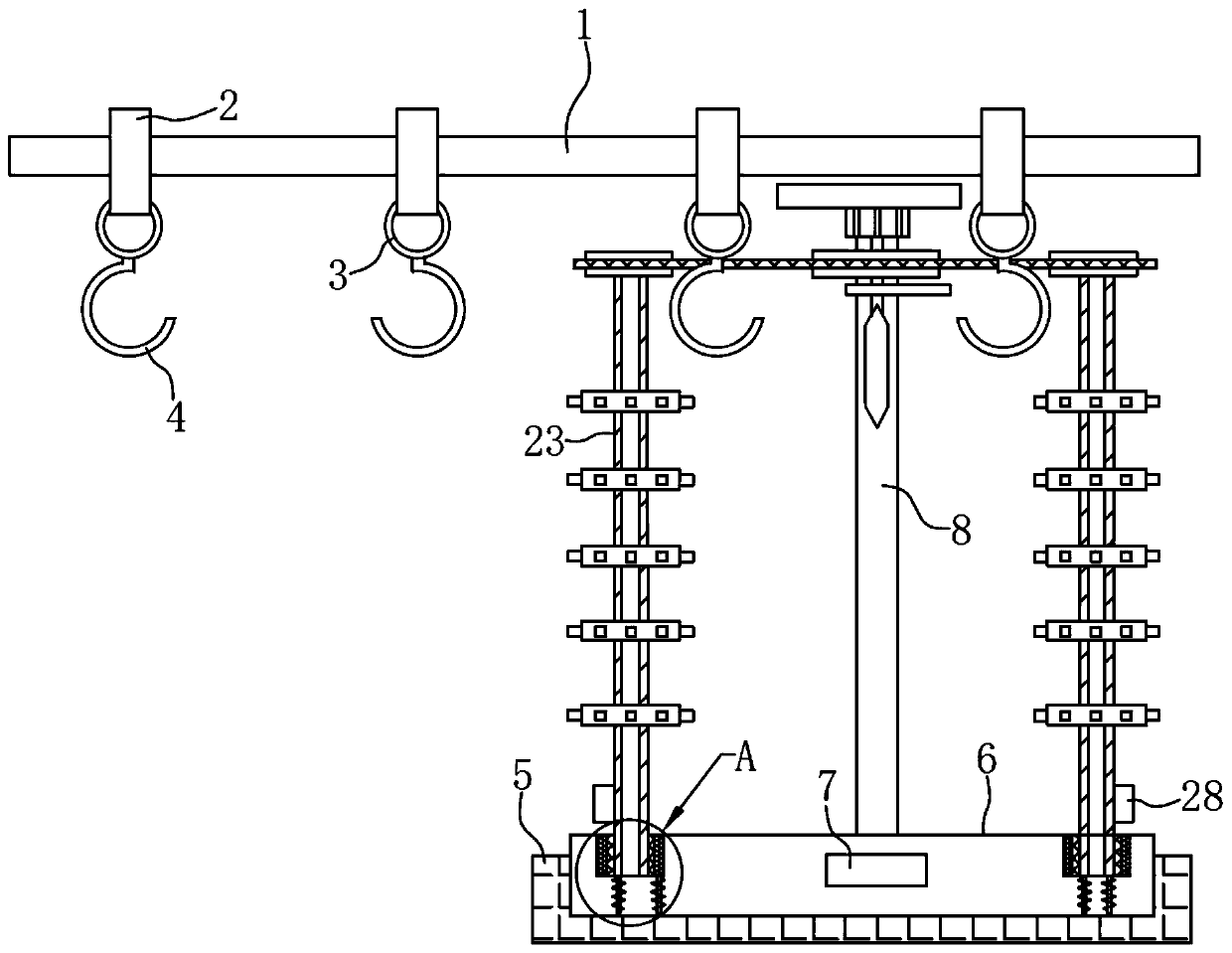

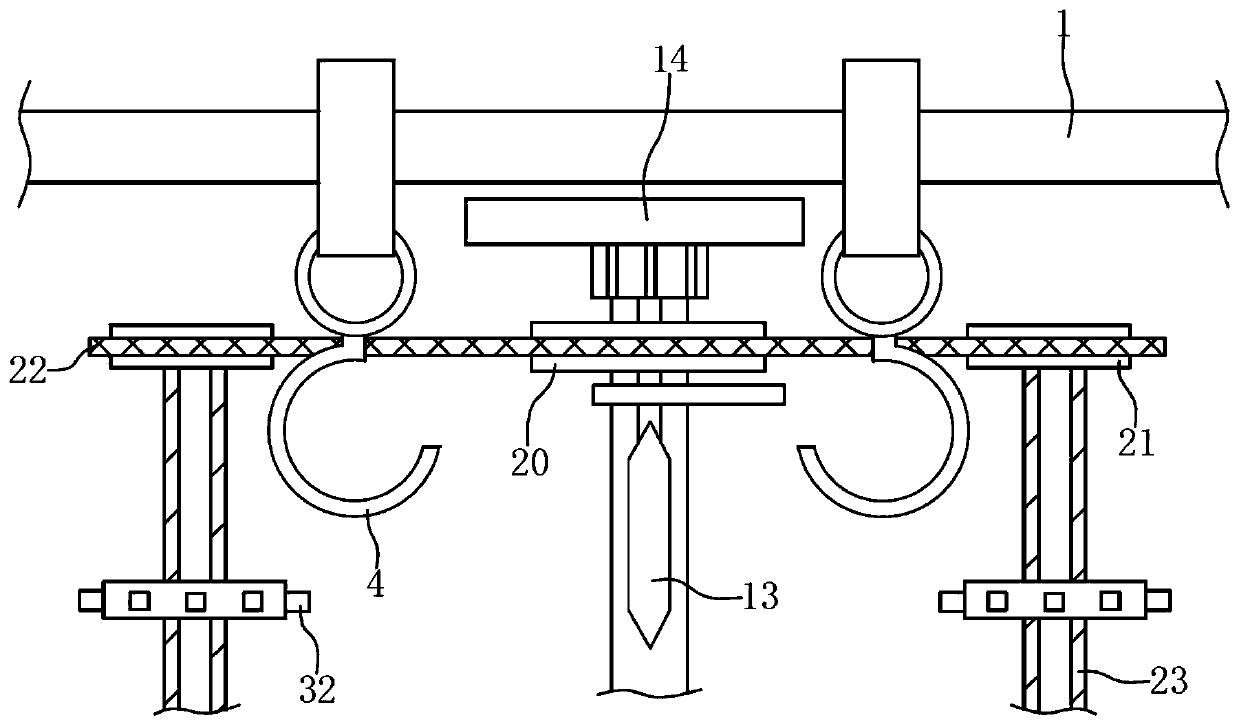

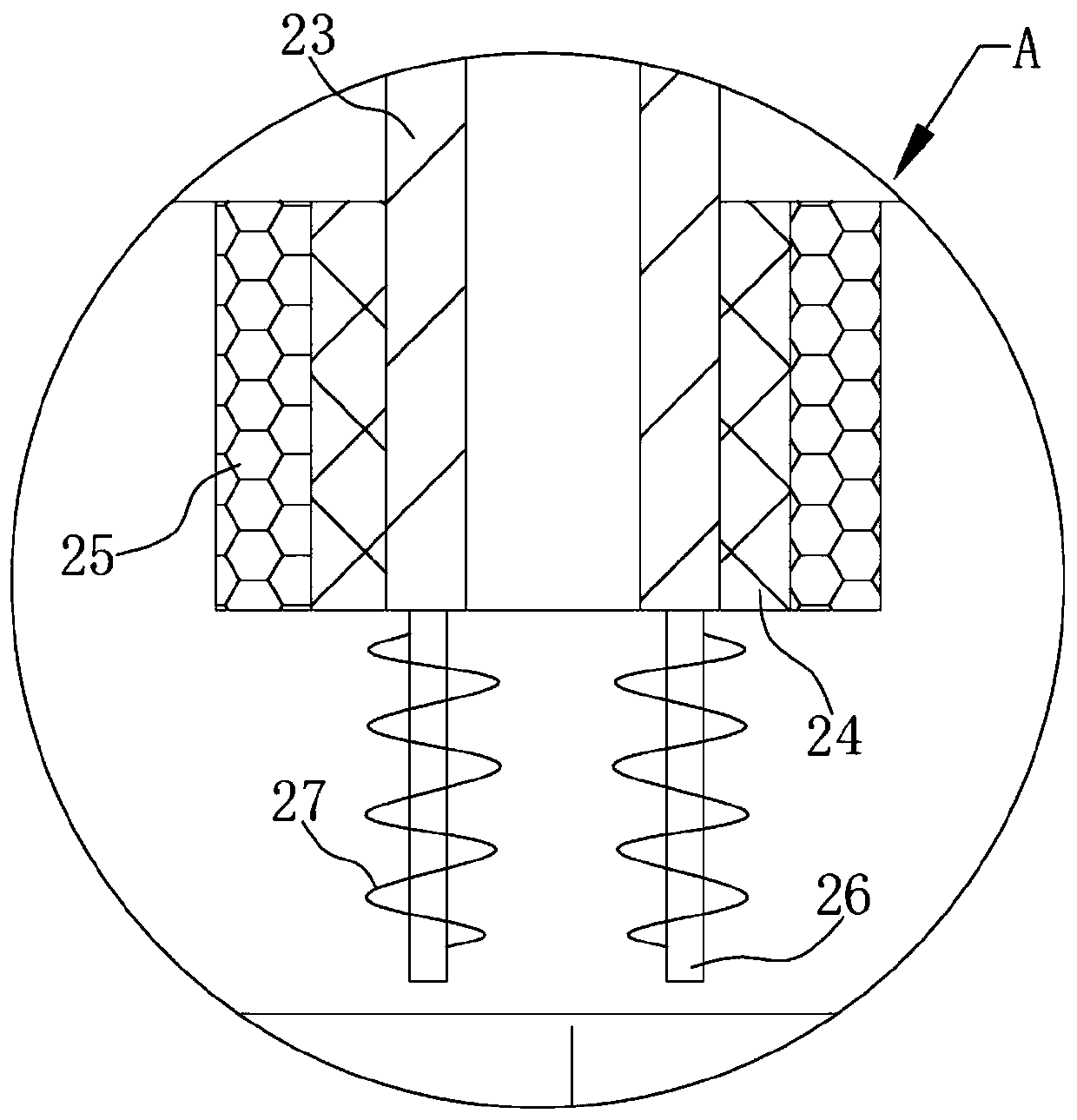

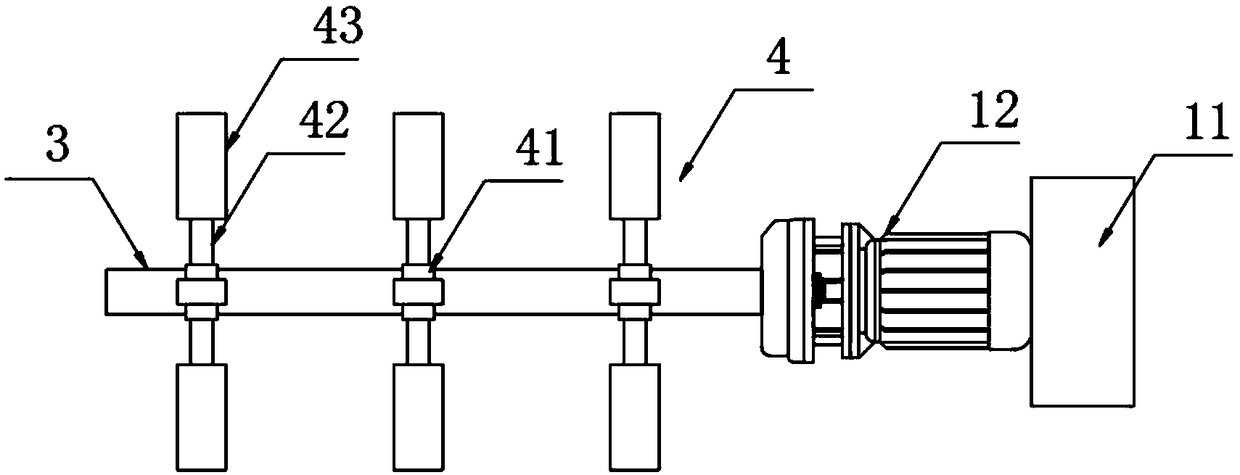

Automatic splitting-in-half device for livestock slaughtering

InactiveCN109699722AEasy to cut in half one by oneNo human assistance requiredSplitting instrumentsMechanical engineeringStain

The invention discloses an automatic splitting-in-half device for livestock slaughtering. The device includes a transfer rod, wherein a plurality of connecting belts are fixedly disposed on the transfer rod, a hook is fixedly disposed on each connecting ring, a sliding block is movably disposed on a sliding rail, one end, far away from the sliding block, of a connecting rod is disposed on a cutting wheel, and one end, far away from a nut seat, of a push rod is fixed on the sliding block; and a driving gear is fixedly arranged on a screw rod in a penetrated mode, and the center of one side, faraway from the transfer rod, of a driven gear is fixedly provided with a cleaning tube. The invention provides the automatic splitting-in-half device for livestock slaughtering. The device can automatically perform splitting-in-half cutting on livestock in turn without manual assistance. During the splitting-in-half cutting, the device, on the one hand, can brush and clean livestock and prevent stain and grimy blood on the skin from affecting the cleanliness of the cutting surface and a cutting knife, and on the other hand, can stir a cleaning liquid. Besides, the above three functions are alldriven by the same rotating motor so as to save energy, to concentrate functions and to be worth promoting.

Owner:BENGBU COLLEGE

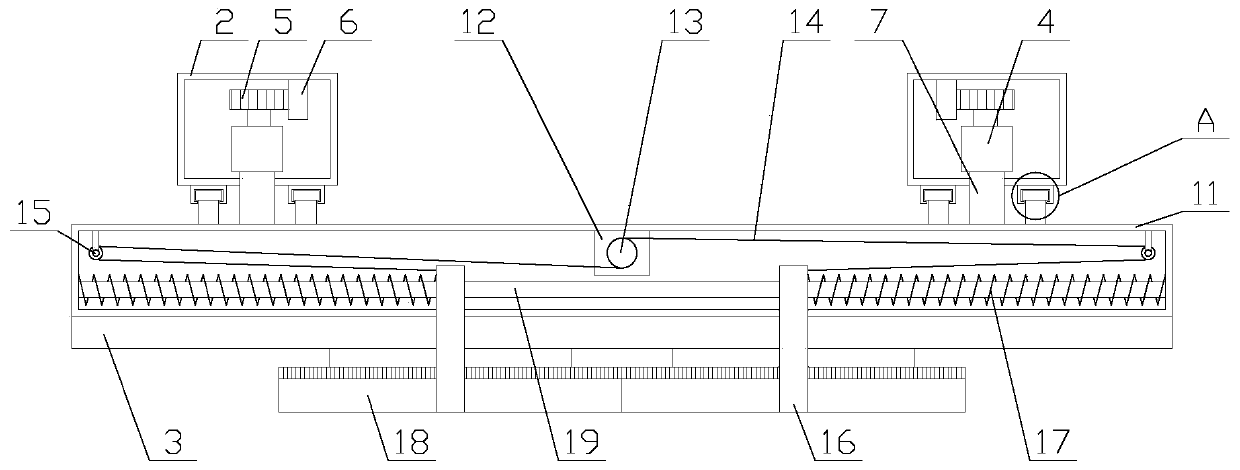

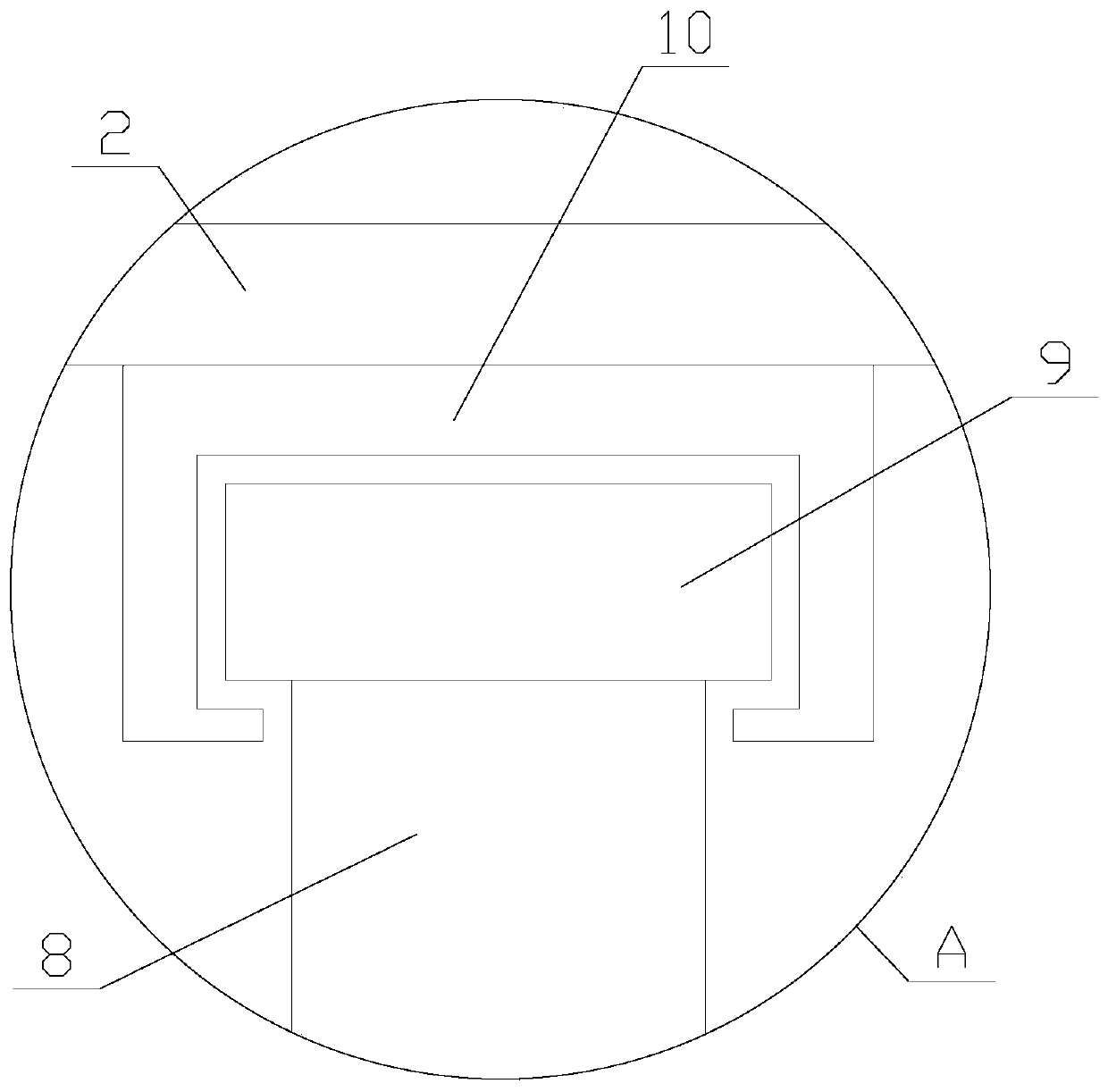

Conveying device which is convenient to clean and wide in application range and used for rare earth exploitation

The invention relates to a conveying device which is convenient to clean and wide in application range and used for rare earth exploitation. The conveying device comprises a conveying belt and a bottom plate. Two driving devices are arranged on the conveying belt and are arranged at the two ends of the inner side of the conveying belt correspondingly. The conveying belt is provided with a cleaningmechanism and an adjusting mechanism, and the conveying belt is arranged on the bottom plate through the adjusting mechanism. The cleaning mechanism is arranged on the side, close to the bottom plate, of the outer side of the conveying belt. The cleaning mechanism comprises a collecting frame, a roller brush, a transmission shaft, a power assembly, two bearing seats and two supporting rods. The adjusting mechanism comprises a stretching assembly and two moving assemblies. By means of the conveying device which is convenient to clean and wide in application range and used for rare earth exploitation, the function of removing dust on the conveying belt is achieved, the phenomenon that cleanliness of the surroundings is affected due to dust falling is avoided, and in addition, the length ofthe conveying belt can also be adjusted through the adjusting mechanism.

Owner:赵秀军

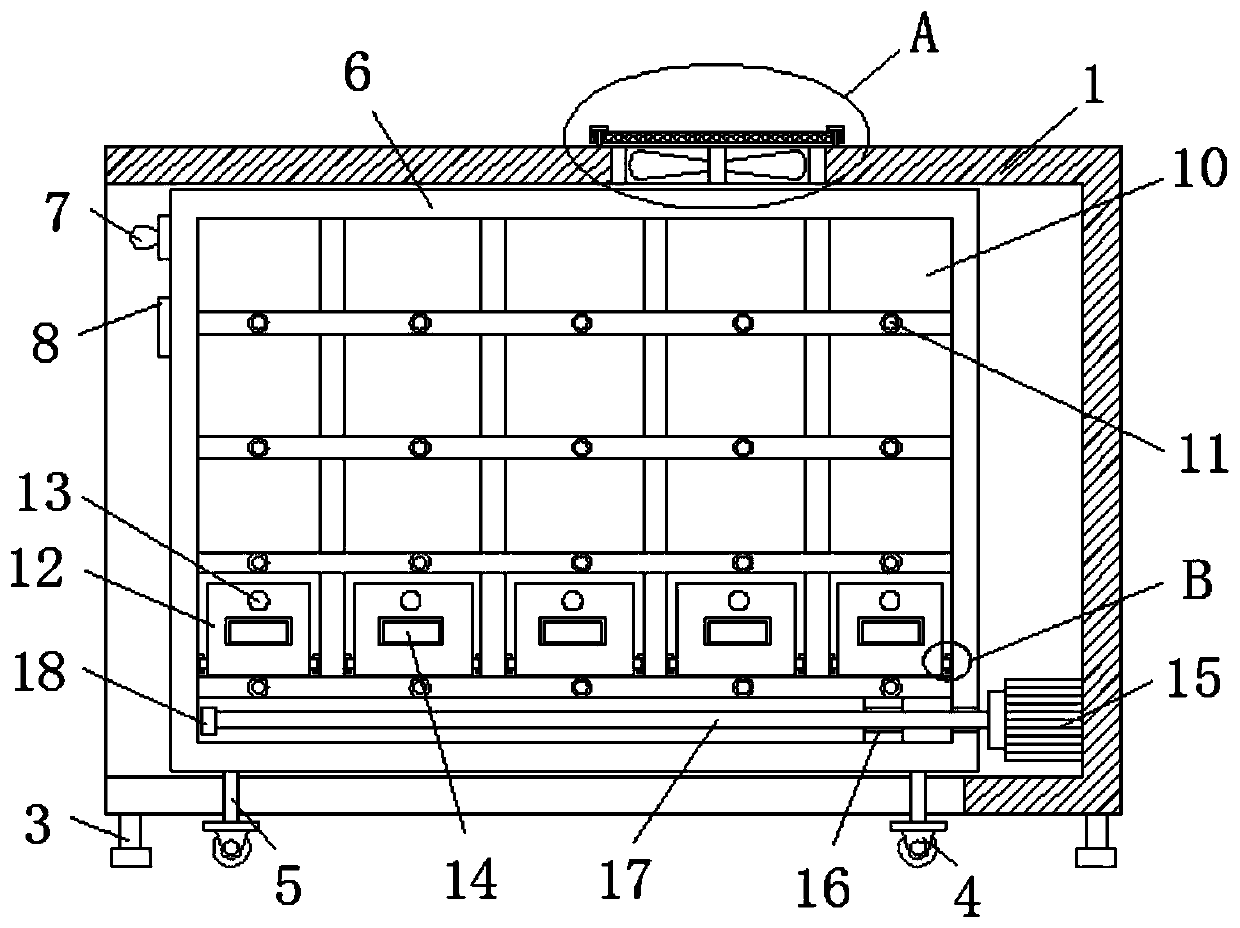

Ideological and political data classification query device

InactiveCN110037455ASmall footprintEasy to findBook cabinetsText database queryingData needsComputer science

The invention discloses an ideological and political data classification query device. The device comprises a storage cabinet and a query machine body, wherein two cabinet doors are installed on the storage cabinet, and a ventilation opening is formed in each cabinet door; a first dustproof net is fixedly connected to the inner side wall of each ventilation opening, a plurality of bookshelves arearranged in the storage cabinet, and the bottom of the query machine body is fixedly connected with the inner bottom of the storage cabinet. The bookshelves for storing ideological data are placed inthe storage cabinet, so that the occupied area of the bookshelves is reduced; meanwhile, the situation that dust in air adheres to the surface of the ideological and political data and accordingly thetidiness of the surface of the ideological and political data is influenced is avoided; the query machine body is used for quickly querying classification of the data needing to be inquired, and thedata can be quickly returned to the original position according to prompt information; discs of some audio and video ideological and political data are stored through a storage box, the discs are prevented from being damaged by external impact, and the service life of the audio and video ideological and political data is prolonged.

Owner:肖志伟

Rotary mobile phone display device

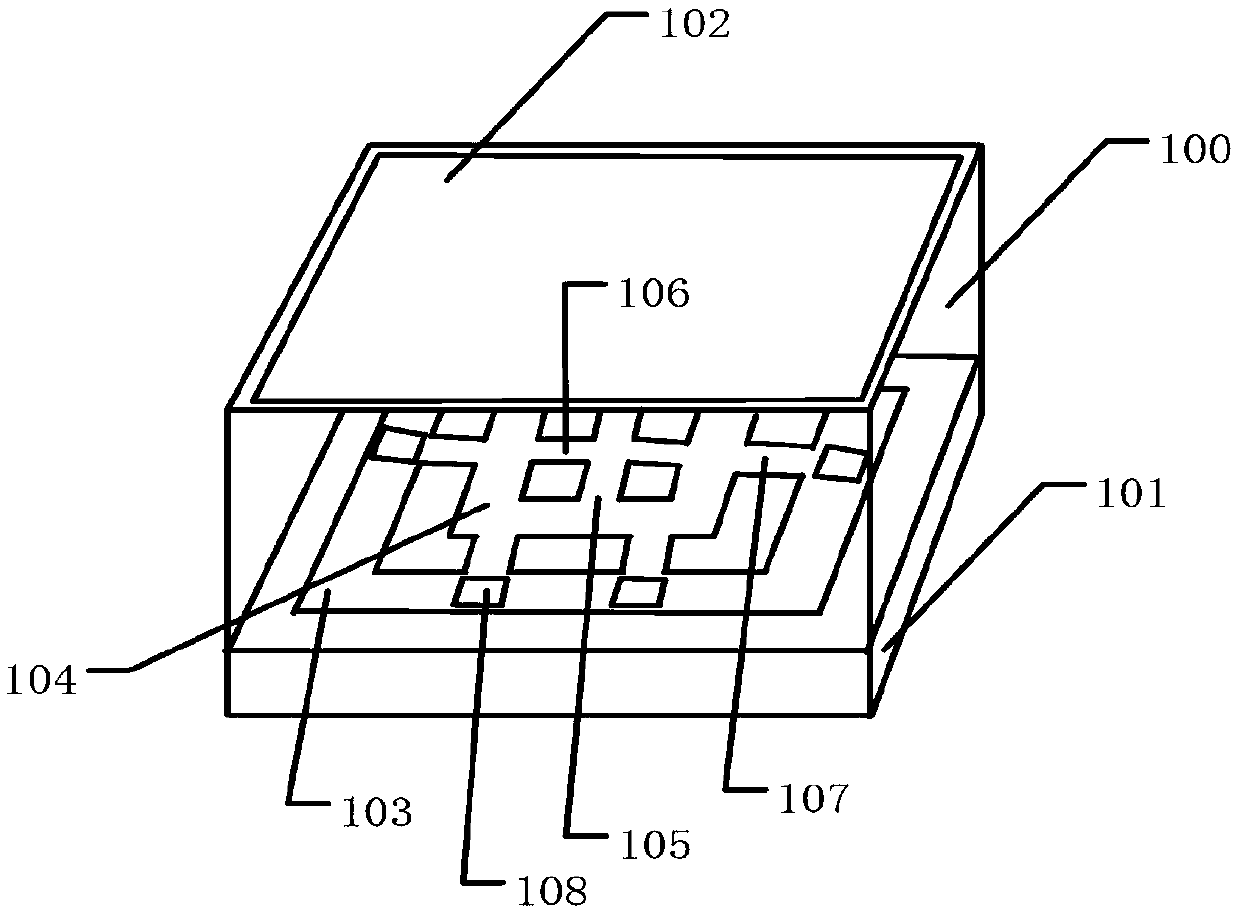

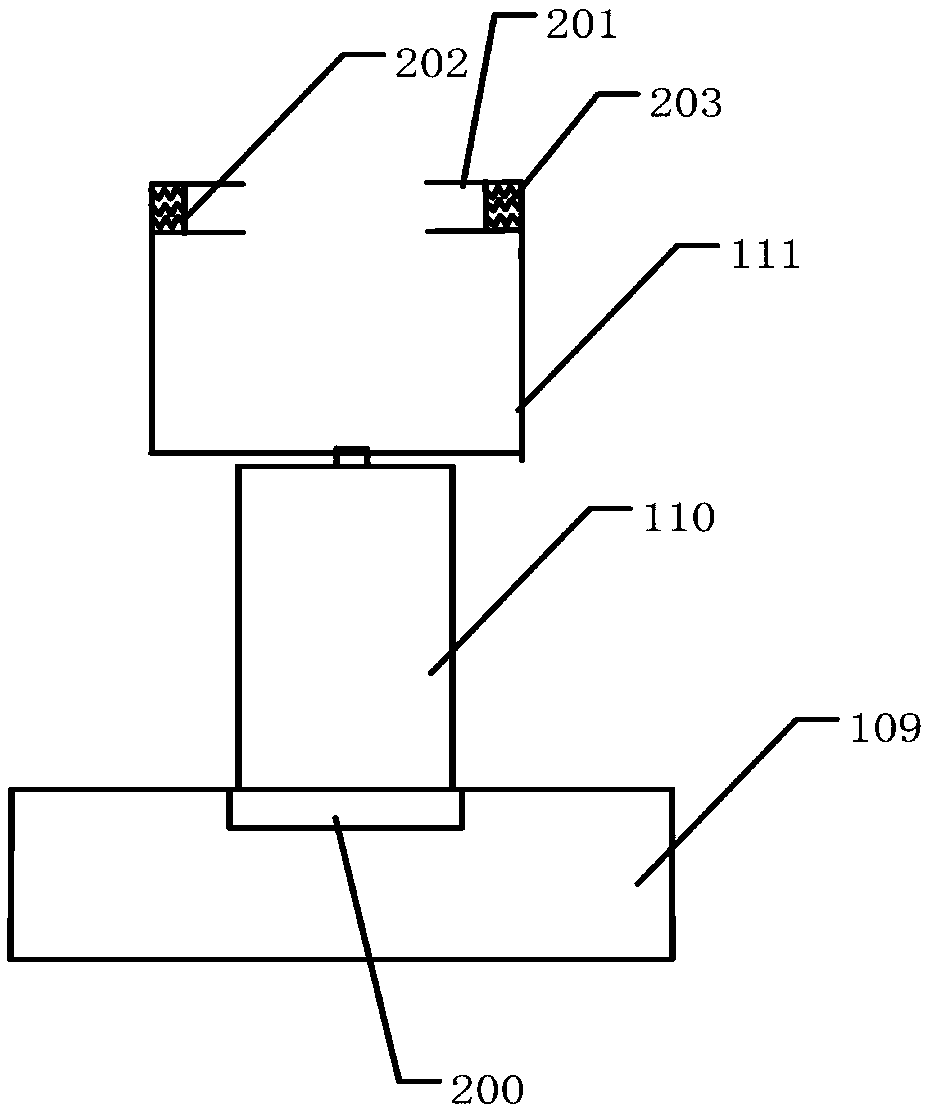

InactiveCN109090909AAffect cleanlinessImprove experienceShow cabinetsShow shelvesDisplay deviceEngineering

The invention discloses a rotary mobile phone display device. The rotary mobile phone display device comprises a shell, a supporting mechanism and a control mechanism. The shell is a hollow box with an upper opening and is internally divided into an upper shell and a lower shell by a partition, an inner rail and an outer rail are arranged around the partition, a cross-shaped rail is arranged on the inner side of the inner rail in a liftable manner and is communicated with the inner rail, the outer rail is provided with a plurality of fitting sliders which are arranged on the outer rail according to numbers, and a vertical rail is arranged at the positions, corresponding to the inner rail, of the sliders and is communicated with the inner rail and the outer rail. The supporting mechanism comprises a base, a connecting shaft and a U-shaped frame, the base is clamped to the sliders, a connecting shaft is rotatably arranged on the upper portion of the base, and the U-shaped frame is arranged above the connecting shaft. The control mechanism comprises a camera, a controller, a display screen and a first motor, the controller can control the camera to turn according to the slider numbers, the first motor to drive the sliders and the display screen to display relative information of a mobile phone. The rotary mobile phone display device is capable of displaying the mobile phone from multiple angles and changing the conventional mobile phone picking and placing mode by bending.

Owner:BEIHAI HUAYUAN ELECTRON CO LTD

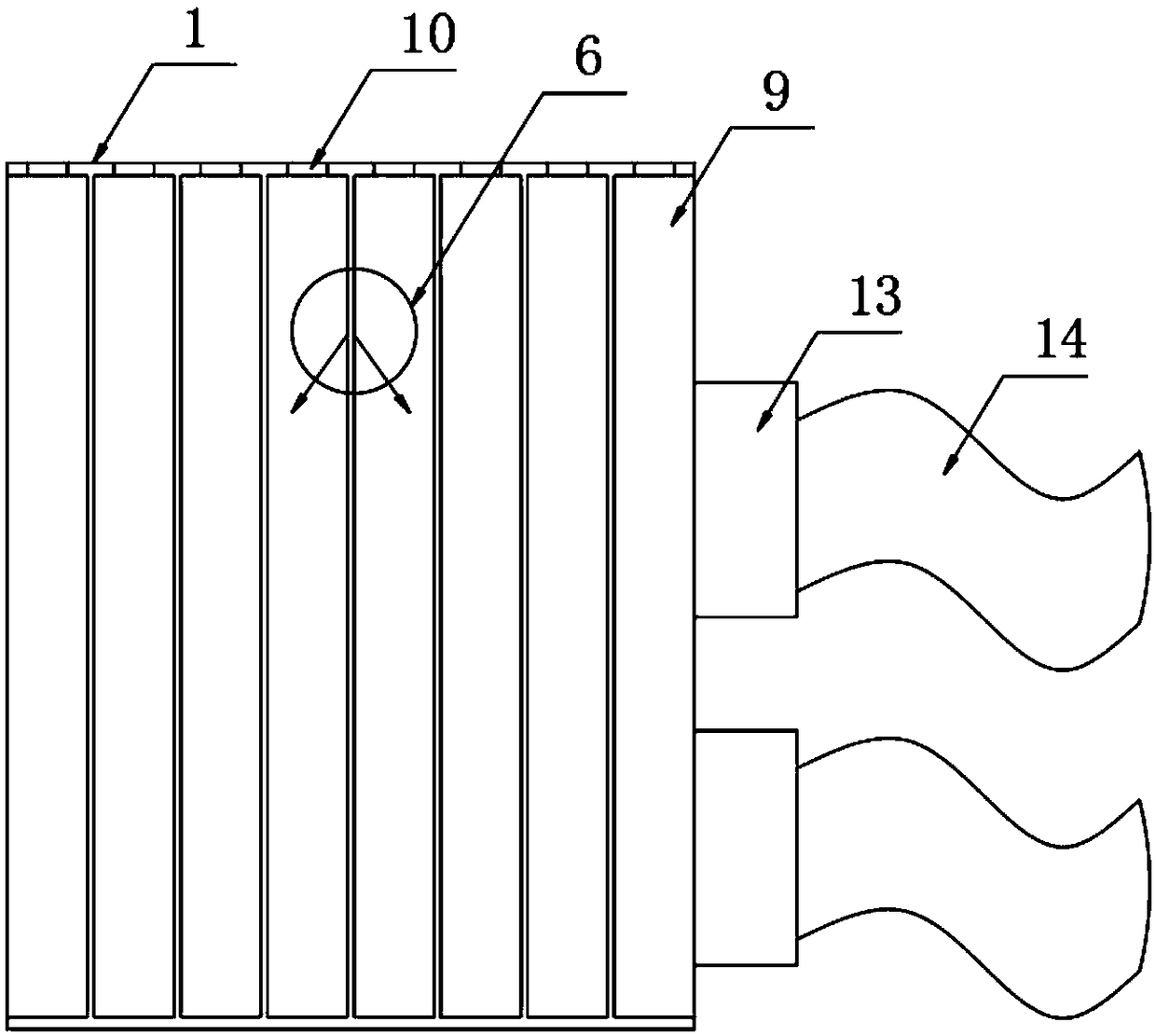

Dust removing mechanism of side wall type plate placing machine

PendingCN109290289AEfficient removalQuality improvementCleaning using gasesForeign matterEngineering

The invention discloses a dust removing mechanism of a side wall type plate placing machine. The dust removing mechanism of the side wall type plate placing machine comprises first-stage dust blowingstructures and second-stage dust sticking structures, wherein the first-stage dust blowing structures and the second-stage dust sticking structures are symmetrically positioned on the downstream of aconveying section; each first-stage dust blowing structure comprises a hollow circular tube and a first lifting structure used for driving the corresponding hollow circular tube to be close to or awayfrom the conveying section; and each two-stage dust sticking structure comprises at least two dust sticking rollers, a second lifting structure used for driving the dust sticking rollers to be closeto / away from the conveying section, and hollow rotating shafts arranged inside the dust sticking rollers in a sleeved mode, wherein one ends of the hollow rotating shafts are provided with air extracting openings, the other ends of the hollow rotating shafts are provided with air back-blowing openings, second gas one-way valves are arranged at the joints between air extracting devices and the hollow rotating shafts, and third gas one-way valves are arranged at the joints between air back-blowing devices and the hollow rotating shafts. According to the dust removing mechanism of the side wall type plate placing machine, on the basis that plates are conveyed to a downstream station, foreign matters on the surfaces of the plates and foreign matters in micro-shaped holes can be effectively removed, so that the overall quality of electronic products is improved.

Owner:大江南电子科技(昆山)有限公司

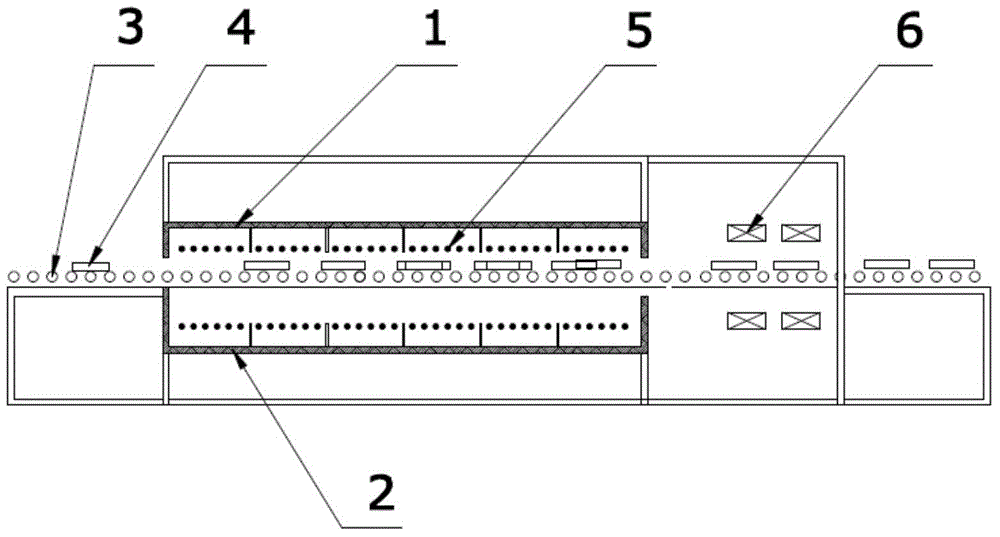

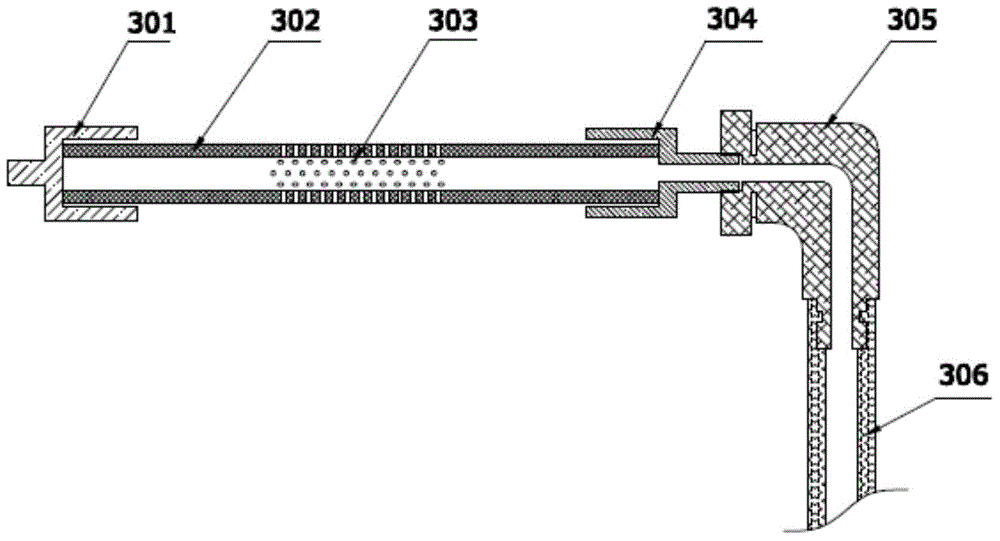

Air-floating roller bed type thermal treatment furnace for semiconductor devices

ActiveCN103557701AConsistent frictionPrevent deviationCharge supportsFurnace typesEngineeringThermal treatment

The invention relates to an air-floating roller bed type thermal treatment furnace for semiconductor devices. The heat-treatment furnace is characterized in that a roller bed for transferring the semiconductor devices comprises a plurality of horizontally-arranged roll shafts capable of reciprocating along self axial lines, at least part of the roll shafts are hollow, a plurality of breathing holes are formed in the parts, where the semiconductor devices pass, of the hollow roll shafts in the radial direction, at least one end of each hollow roll shaft is connected with one air inlet pipe through a rotary joint, and air enters furnace chamber parts where the semiconductor devices pass through the breathing holes in the hollow roll shafts. According to the thermal treatment furnace provided by the invention, the atmosphere and the cleanliness of a center diffusion zone in the furnace are fundamentally ensured, so that the diffusion effect and the quality are improved.

Owner:BEIJING SOLARRAY TECHNOIOGY CO LTD +1

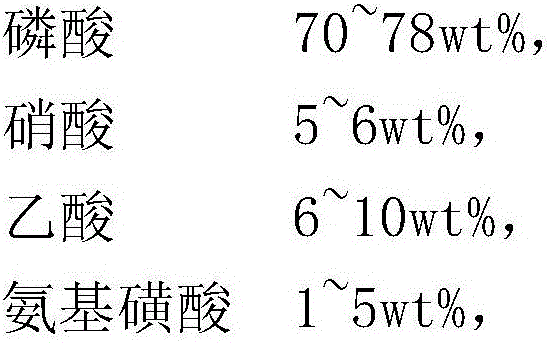

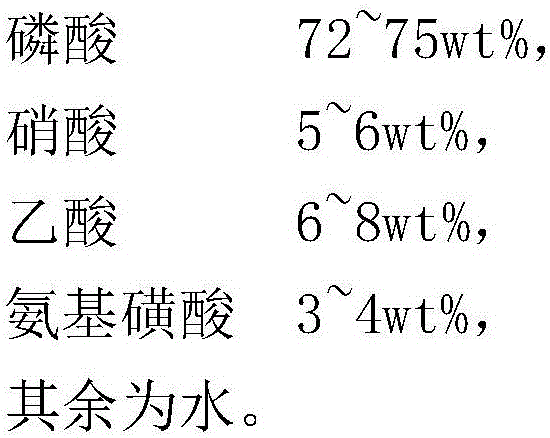

Aluminum etching agent and preparation method thereof

The invention belongs to the technical field of chemical preparations, and relates to an aluminum etching agent and a preparation method thereof. The formula of the aluminum etching agent comprises the following components in percentages by weight: 70-78% of phosphoric acid, 5-6% of nitric acid, 6-10% of acetic acid, 1-5% of sulfamic acid, and the balance of water. The aluminum etching liquid provided by the invention can convert a metal compound into soluble salts which are dissolved in water, speeds of etching to different metals are consistent basically, reaction is stable, the circumstance that etching efficiency and neatness of the surface of a substrate are affected by precipitate attachment is avoided, and surface dirt is removed conveniently.

Owner:SUZHOU BOYANG CHEM

Self-cleaning light-transmitting window for urban high-rise building

InactiveCN112674631AAvoid accidentsClean upWindow cleanersSpecial door/window arrangementsEngineeringStructural engineering

The invention discloses a self-cleaning light-transmitting window for urban high-rise building.The window comprises: a window frame which is composed of two installation blocks and two vertical plates, wherein the two vertical plates are both located between the two installation blocks, glass is installed in the window frame, a trigger cavity is formed in an installation block located on the upper portion, and a low-boiling-point solution is arranged in the trigger cavity; and two triggering mechanisms which are arranged on the left side and the right side of the low-boiling-point solution correspondingly, and comprise pushing plates arranged in the trigger cavity. When in use, the equipment does not need to be started by a worker, only a cleaning agent needs to be added at regular time, labor consumption is reduced, meanwhile, residual water spots on the surface of glass can be treated during cleaning, and the cleaning effect is improved.

Owner:王利

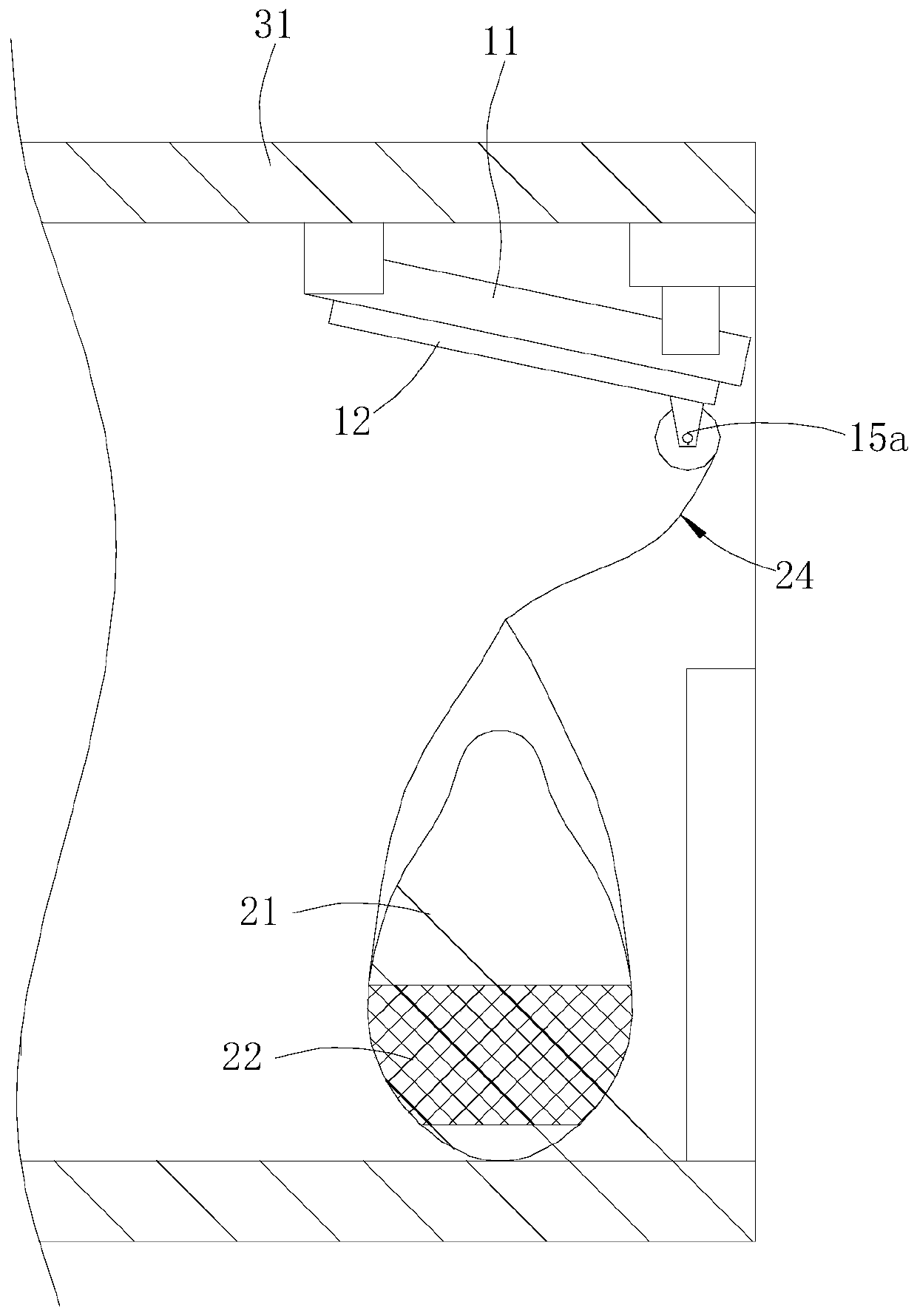

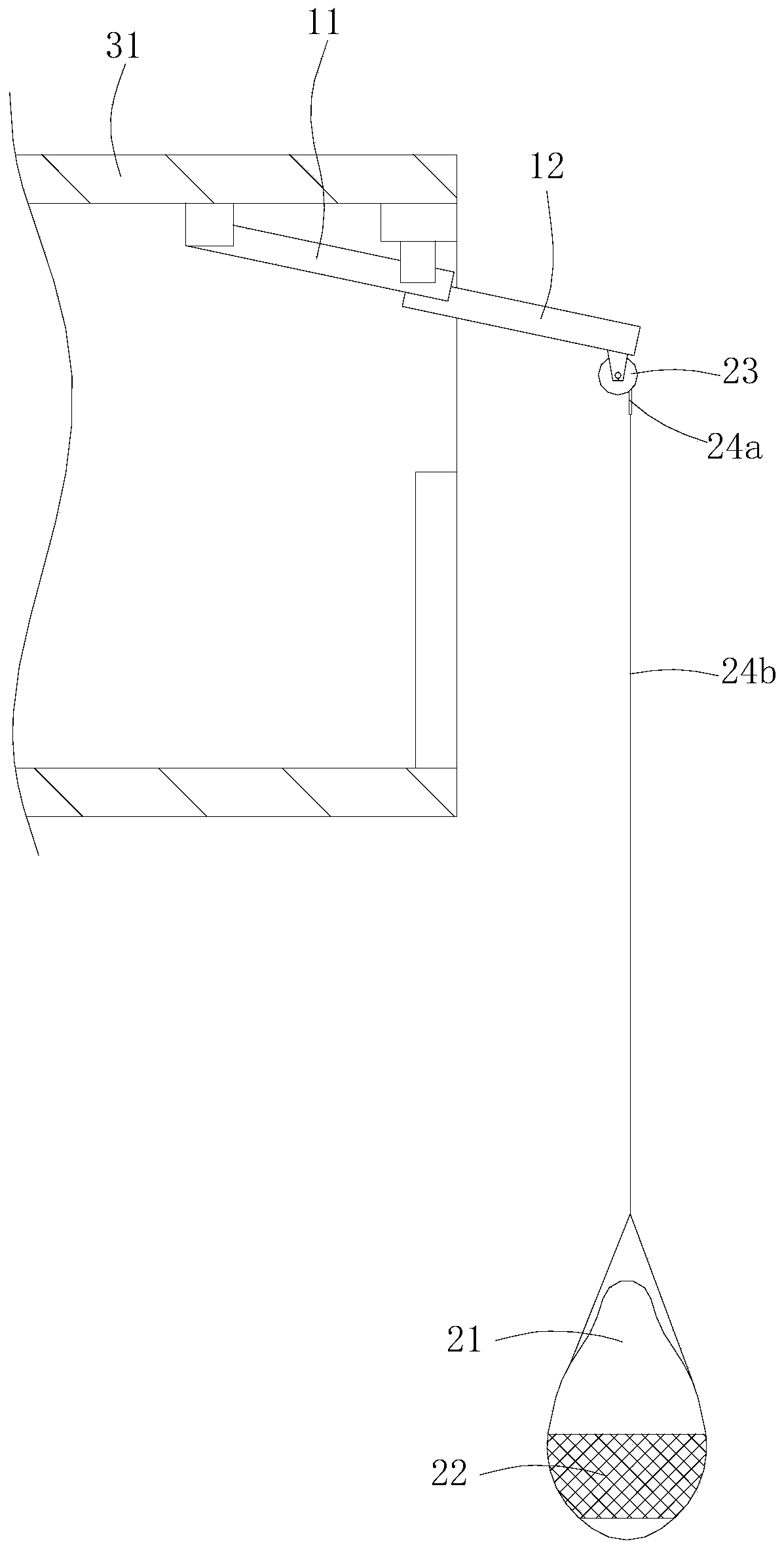

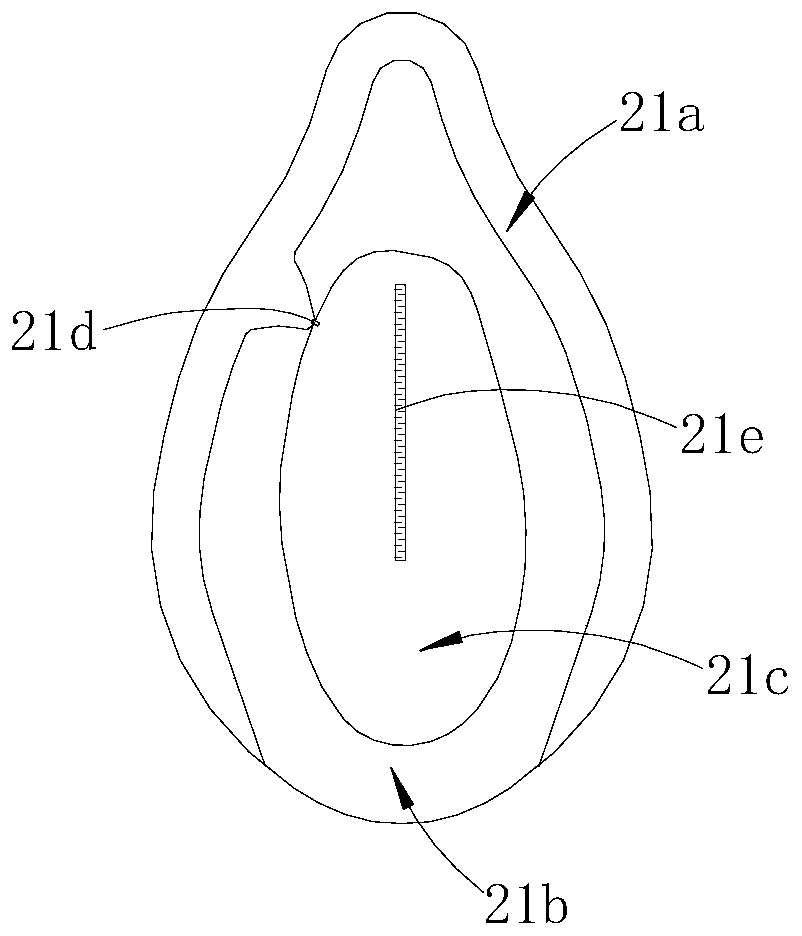

High-altitude escape device

InactiveCN110101980AAffect cleanlinessAvoid affecting constructionBuilding rescueFloor slabFire - disasters

The invention provides a high-altitude escape device. The device comprises a guide rail assembly and a life-saving assembly; the guide rail assembly comprises a sliding block and a sliding rail, wherein the sliding rail is fixedly connected to the lower side of an upper-layer floor slab, the sliding block is matched with the sliding rail, the sliding block extends out of the outer side of the upper-layer floor slab, and a pulley seat is fixedly connected to the lower side of the end part of the sliding block; the life-saving assembly comprises a life-saving air bag, a hanging net, a pulley anda pull rope, at least one layer of air bag cavity is formed in the life-saving air bag, an life-saving cavity allowing people to ride is formed in the air bag cavity, an escape opening communicatingthe life-saving cavity is formed in the outer wall of the life-saving air bag, the hanging net covers the lower side of the life-saving air bag, the upper side of the hanging net is fixed to one end part of the pull rope, the pull rope is wound round the pulley, and the other end of the pull rope is fixed to the pulley. The high-altitude escape device has the beneficial technical effects that thesafety is high, escape personnel can be quickly brought to the position close to the ground, escape of personnel is facilitated, and the survival rate of the high-rise building in the fire disaster isimproved.

Owner:仲恩旭

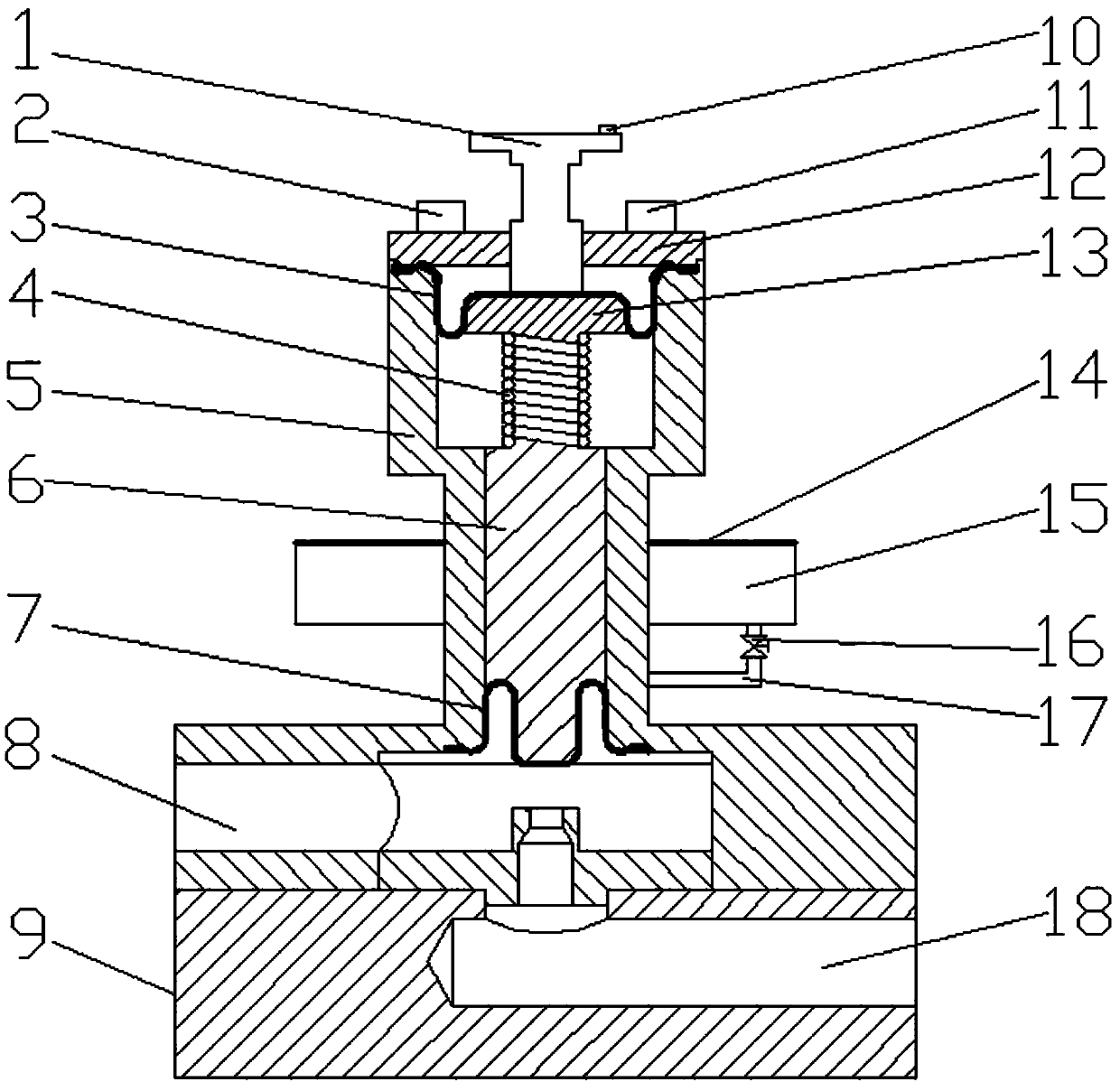

Hydraulic valve

InactiveCN107676320AReduce manufacturing costEasy to installDiaphragm valvesEngine diaphragmsMain channelSelf locking

The invention discloses a hydraulic valve. The hydraulic valve comprises a valve body, a valve core, a valve seat, a valve cover, a timer, a PLC controller, an operating handle, a spring valve seat, apower source switch, a reset spring, an annular oil bearing tank, a sealing cover, a pipeline, an upper membrane, a lower membrane, an upper oil port and a lower oil port. The valve core is arrangedbetween the part, extending into the valve body, of the valve seat and the hydraulic valve cover. The PLC programmable controller is fixedly arranged at the right end of the valve cover, and one end of the PLC programmable controller is connected with the timer. The annular oil bearing tank is fixedly arranged in the middle of the outer side of the valve body. The upper membrane is arranged at thetop of the spring valve seat, the lower membrane is arranged at the bottom of the valve core, and the upper oil port and the lower oil port communicate with a main channel cavity. The hydraulic valveis convenient to install and high in safety, and can achieve automation control. The upper membrane and the lower membrane can conduct isolation sealing on the inner cavity of the valve body and a driving component, and thus impurities in the outside world can be prevented from affecting cleanness of a medium. The PLC controller can effectively control the disconnection and connection time of thehydraulic valve according to the arranged timer, and thus the self-locking function of the hydraulic valve is achieved.

Owner:WUHU ZHONGYI HYDRAULIC TECH

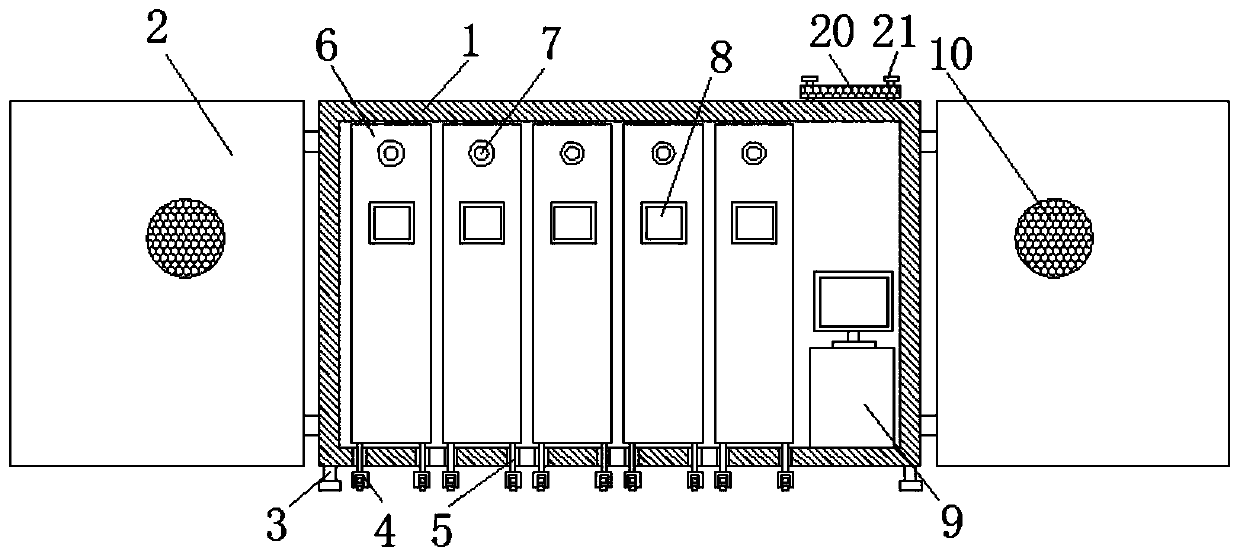

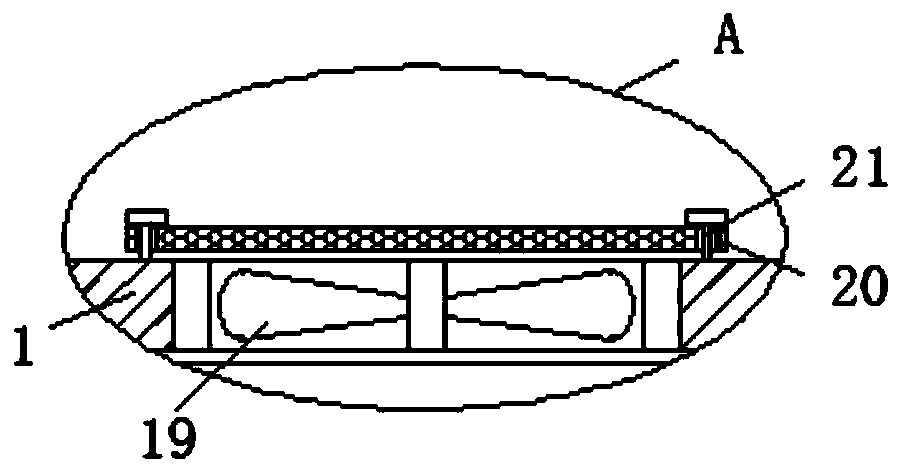

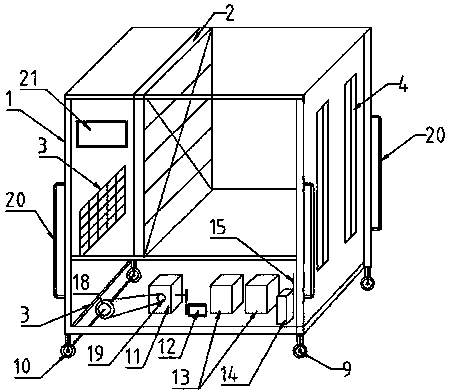

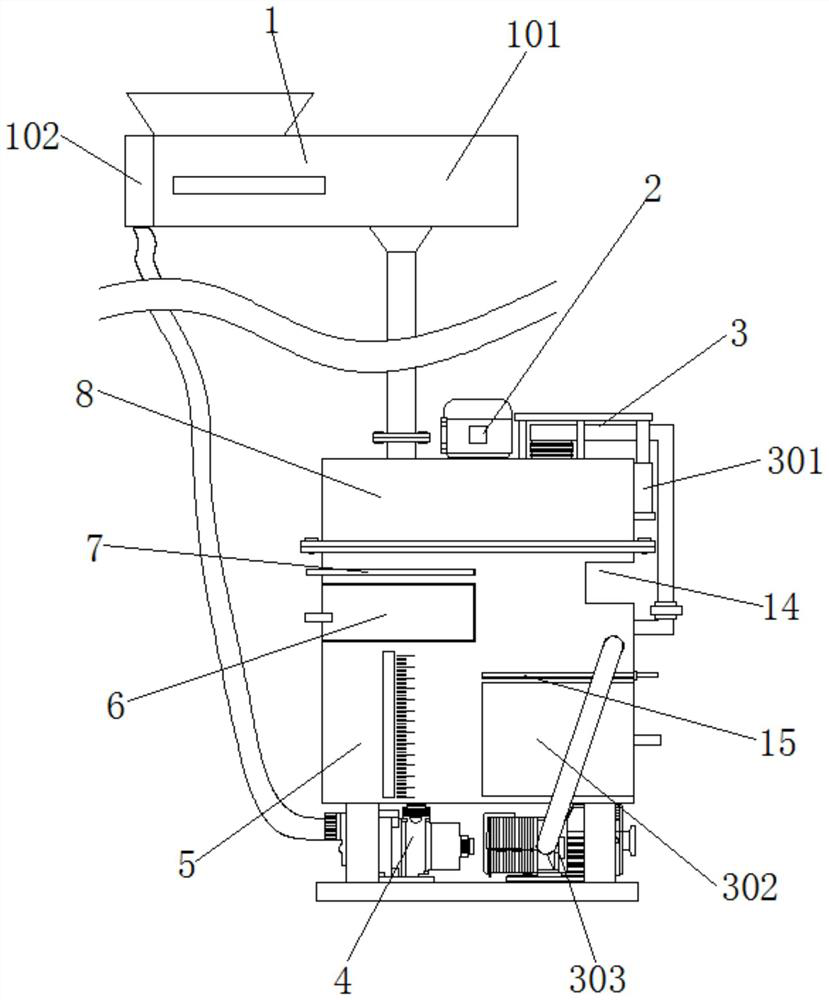

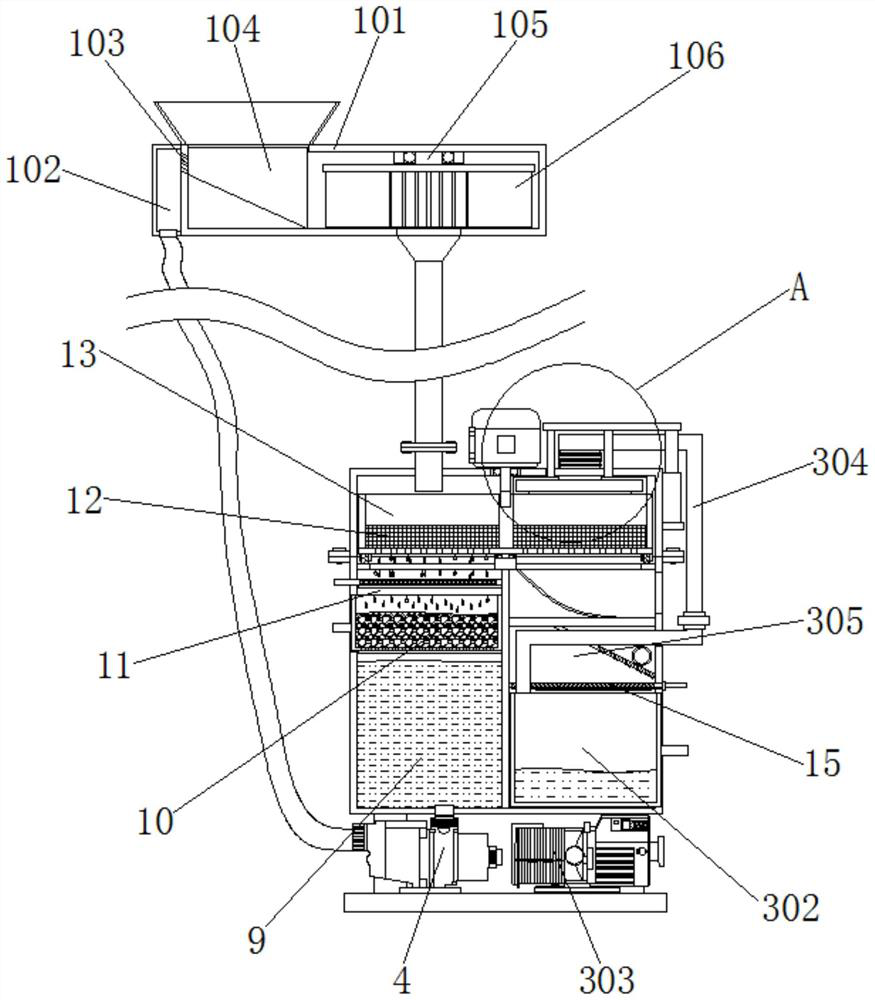

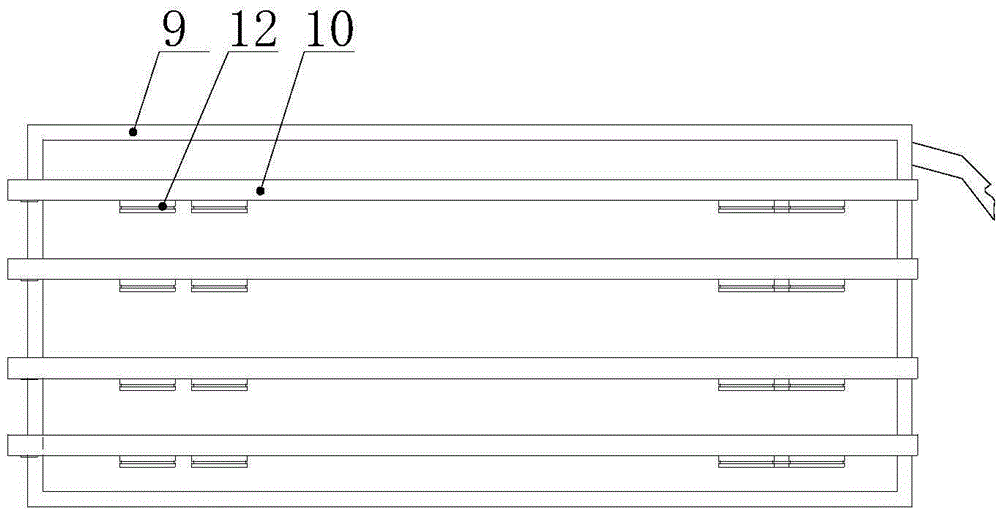

Assist type laminar flow cart

InactiveCN103968463AAffect cleanlinessExtended service lifeLighting and heating apparatusAir conditioning systemsElectricityDrive wheel

The invention discloses an assist type laminar flow cart. The assist type laminar flow cart comprises a tank, wherein the tank is divided into an upper tank body and a lower tank body; a first filter is installed in the upper tank body; the two tank body walls opposite to the first filter are provided with an air inlet and an air outlet respectively; a second filter is installed in the air inlet; a plenum chamber is arranged between the air inlet and the first filter; a speed adjusting centrifugal fan is installed at the lower face of the plenum chamber; two guide wheels and two drive wheels are installed at the bottom of the lower tank body; a power drive device is arranged inside the lower tank body and comprises a gearbox, a motor, a battery, an electricity box and an antenna; the battery and the electricity box are connected in series; the motor and the gearbox are connected; the gearbox and the drive wheels are connected; the antenna is inserted in the electricity box. The assist type laminar flow cart is simple in structure, attractive in appearance and good in purifying effect, can be conveniently and easily moved to the appointed area and saves time and labor, the laminar flow cart is prevented from being interfered manually and affecting the clean degree when moved, process conditions can be improved, product quality is improved, and yield is increased.

Owner:苏州市金燕净化设备工程有限公司

Spring-pushing-ball floor drain capable of preventing water returning

ActiveCN107237391APrevent leakagePrevent odor from risingFatty/oily/floating substances removal devicesSewerage structuresEngineeringSewage

The invention discloses a spring-pushing-ball floor drain capable of preventing water returning. The floor drain body is of an integral structure, the interior of the floor drain body is provided with multiple steps and inner threads, a lower inner thread is connected with an outer thread of a drain plug in a matched mode, and a column rod is arranged in a column hole of the drain plug; a spring is installed on the lower portion of the column rod in a sleeving mode, a ball is arranged in the middle of the column rod, and the upper surface of the ball is in contact with the spherical surfaces of protruding platforms in the drain plug; a filter cover is arranged on a fourth plane of the multiple steps, an impurity removing mechanism is movably connected to the filter cover and located in a lower cylinder of a drain cover, and an upper inner thread of a second vertical surface is connected with an outer thread of the drain cover. According to the floor drain, the structure is compact, the design is reasonable, water draining is fast, impurities in sewage can be removed, and the situation that the impurities block a sewer is avoided; meanwhile, dispersion of an undesirable odor in the sewer can be prevented, influence on cleanness of air in a room can be prevented, and particularly, when a pipeline of the next floor is blocked, a water returning phenomenon is unlikely to occur; besides, the surface of the floor drain is treated with a coating, the floor drain is resistant to corrosion of an acid liquid and an alkaline liquid, and the service life is long.

Owner:王韶华

Intelligent waste weft yarn processing device of water-jet loom

PendingCN113584689AImprove the effect of filter captureEasy to handleLoomsAuxillary apparatusAir pumpControl theory

The invention discloses a waste weft yarn intelligent processing device of a water-jet loom. The device comprises a main body bin, a top cover is installed at the top of the main body bin, a servo motor is installed at the center of the top of the top cover, a rotating bin is arranged in the top cover, and a partition plate is installed in the middle of the interior of the rotating bin. Through holes are evenly formed in the bottom of the partition plate, and the output end of the servo motor is in transmission connection with the middle position of the top of the partition plate. Through cooperative use of a collecting assembly, the top cover, filter cotton and the rotating bin, the servo motor is controlled to drive the whole rotating bin to clockwise rotate by 180 degrees, then an electric lifting rod is controlled to be shortened, then an air pump is controlled to suck air, so that waste weft at the top of the first set of filter cotton sequentially passes through a semicircular bin, a telescopic pipe and a connecting pipe and then enters a collecting bin, only the waste weft in the collecting bin needs to be cleaned regularly, treatment of the waste weft through the device does not need to be stopped, and therefore continuous and normal work of the water-jet loom is guaranteed.

Owner:JIANGSU DEHUA TEXTILES

Dish receiving method and dish receiving device of cooking equipment

InactiveCN111012156AAffect cleanlinessSolve the problem of user experienceCooking vesselsMechanical engineering

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

Special storage device for fire hoses

InactiveCN112774071AExtended service lifeAffect cleanlinessFire rescueWater storage tankWater resources

The invention discloses a special storage device for fire hoses. The special storage device comprises storage device fixing frames, bracket fixing bases, a fire hose squeezing water storage tank, water storage tank water outlets, a fire hose squeezing device, a squeezing control device, a fire hose conveying shaft, a winding device fixing seat and two winding devices. A fire hose is placed in the fire hose squeezing device through a notch in a first squeezing shaft, residual water in the hose is discharged, and the service life is prolonged. The fire hose squeezing water storage tank is arranged between the two fixing frames, water squeezed out of the fire hose by the fire hose squeezing device directly flows into the fire hose squeezing water storage tank, the situation that the water which is squeezed out overflows and affects the environmental cleanliness is avoided, and the water resource is saved. The special storage device is provided with the two fire hose winding devices, so that two fire hoses can be wound at the same time, and the time for firefighters to tidy equipment is shortened. After the fire hoses are wound, fire hose heads are placed on fire hose head placement racks, so that the water hoses can be conveniently taken down in order when used next time.

Owner:南通亚龙消防器材有限公司

Ultra-deep stamped steel sheet

Owner:无锡市森信精密机械厂

Knitwear dust removing and ironing device

InactiveCN108842419ASlap fullGood for ironingMechanical cleaningPressure cleaningArchitectural engineeringClothes hanger

The invention discloses a knitwear dust removing and ironing device, which comprises a device body, and two sets of upper and lower guide rails are arranged on two sides of the inner wall of the device body; a rotating shaft is arranged between the upper and the lower guide rails on both sides, and a plurality of dust removing devices are sleeved on the rotating shaft; one side of each dust removing device is provided with two sets of electric irons, the top of each dust removing device is provided with a left guide rail and a right guide rail, and two ends of the left and the right guide rails penetrate through the two side walls of the device body and extend to the side of the outer wall of the body; the bottom of the left and the right guide rails are movably connected with a pluralitysets of first stepping motors, clothes hangers are fixedly arranged at the bottom of each set of first stepping motor, and dustproof doors are arranged at both sides of the upper and the lower guide rails. The rotating shaft of the dust removing device drives the dust removing device to rotate, so that the knitwear is tapped, and the rotating shaft can move up and down to make the knitwear more comprehensively beaten, thereby removing the dust on the knitwear.

Owner:FOSHAN SANCHUANG KNITTING CO LTD

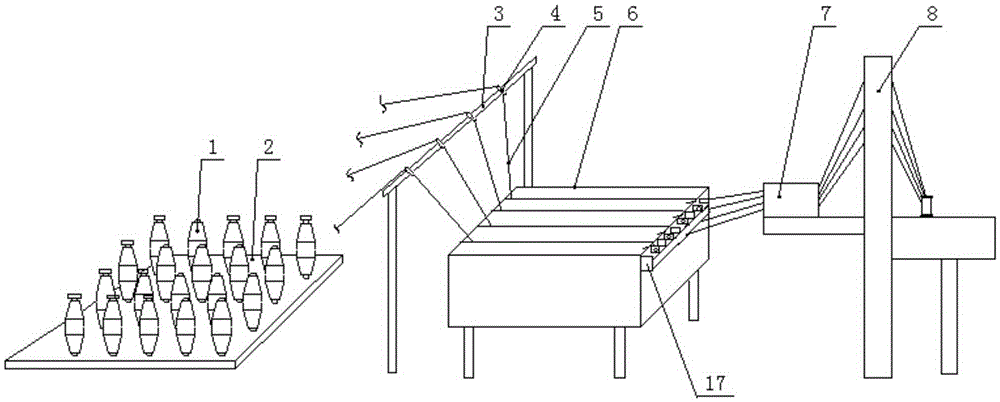

Cleaning method of spooling machine preorder spun polyester threads

ActiveCN105386288ASave operating time and manpower consumptionKeep dryDry-cleaning apparatus for textilesPolyesterYarn

The invention relates to a cleaning method of spooling machine preorder spun polyester threads. The cleaning method comprises the steps of doubling spun polyester threads on a plurality of large spools into silk thread groups through a doubling machine and drawing the doubled silk thread groups to small spools on a spooling machine for spooling, and is characterized by also comprising the following steps: (1) soaking and cleaning the doubled silk thread groups through a water tank of a cleaning mechanism; (2) wiping water on the cleaned silk thread groups through wiping sponge on a wiping mechanism; (3) drying the wiped silk thread groups through a heating mechanism; (4) drawing the dried silk thread groups to the small spools on the spooling machine for spooling. The cleaning method provided by the invention is scientific and reasonable, has the advantages of being convenient to operate, high in cleaning efficiency, labor-saving, and good in quality of processed products, and is a cleaning method of the spooling machine preorder spun polyester threads with relatively high novelty.

Owner:TIANJIN HUAZHIYANG SPECIAL CABLE

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com