Continuous rapid preparing device of semi-solid slurry of automobile aluminum alloy wheels

A technology of semi-solid slurry and preparation device, which is applied in the field of continuous and rapid preparation device for semi-solid slurry of automobile aluminum alloy wheels, can solve the problems of cold scar, loose casting, improper proportion of slurry solid and liquid, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] specific implementation

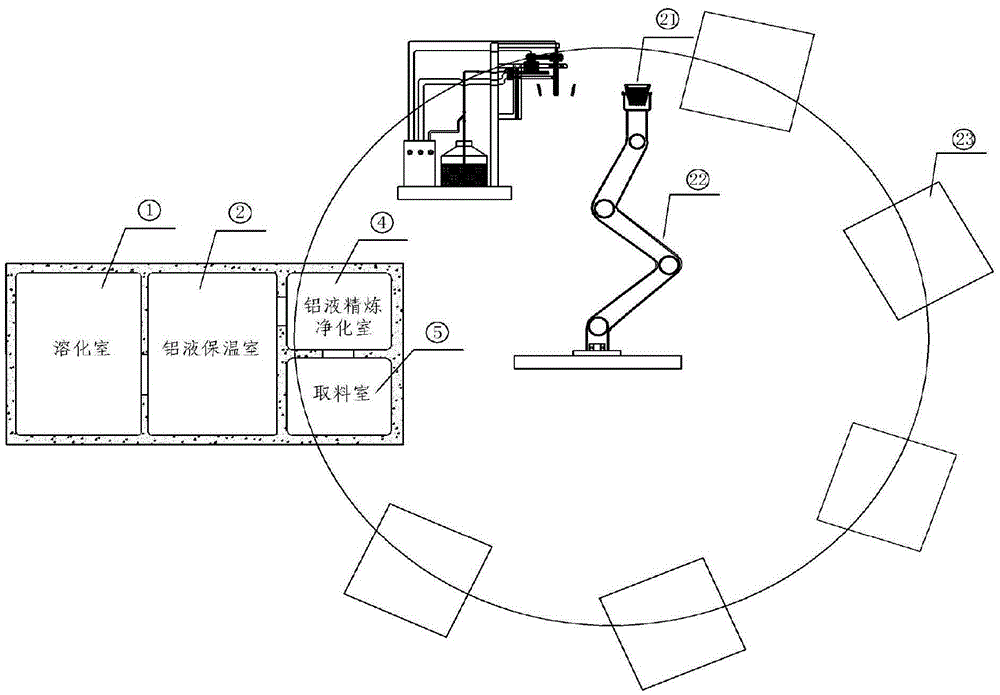

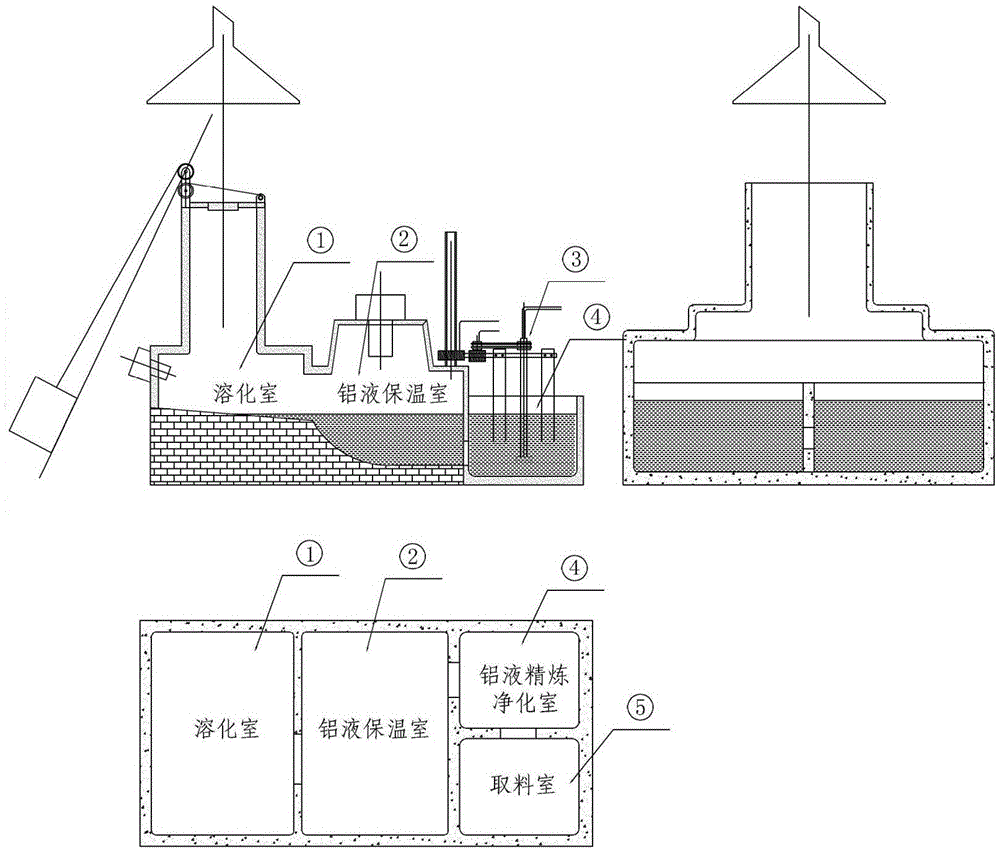

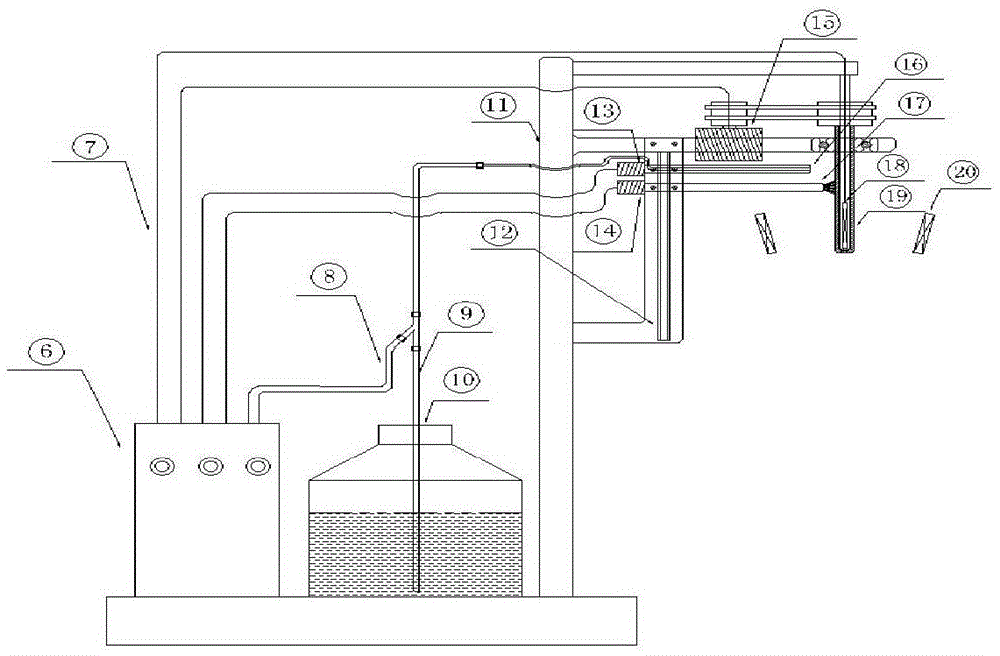

[0010] like figure 1 , figure 2 and image 3 As shown, a continuous and rapid preparation device for semi-solid slurry of aluminum alloy wheels for automobiles, including a material continuous melting refining purification furnace, a rapid slurry stirring device, a slurry transfer crucible, and an intelligent assisting arm. The material continuous melting refining purification furnace is composed of a melting Room 1, heat preservation room 2, refining and purification device 3, refining and purification room 4 and material reclaiming room 5; the slurry rapid mixing equipment consists of control cabinet 6, wire 7, compressed air conduit 8, paint conduit 9, paint storage tank 10, Support frame 11, up and down moving control board 12, drive motor one (13), drive motor two (14), drive motor three (15), paint nozzle 16, scraper plate 17, electromagnetic stirrer one 18, graphite tube (19 ), electromagnetic stirrer two (20); material continuous re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com