Patents

Literature

32results about How to "Fine and evenly distributed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

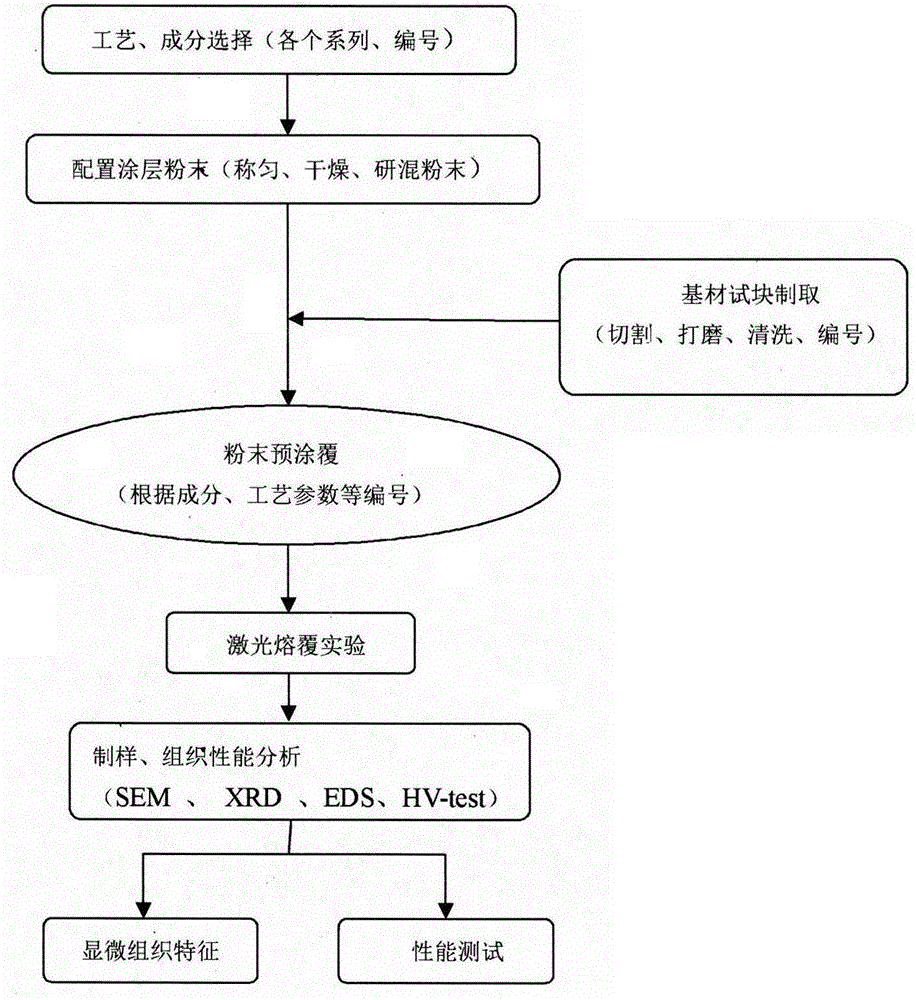

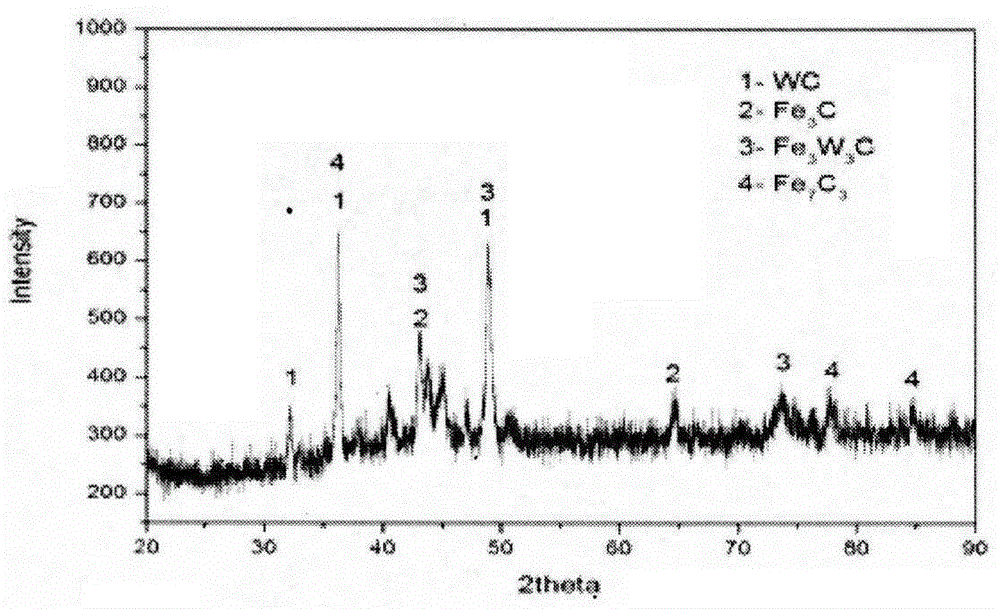

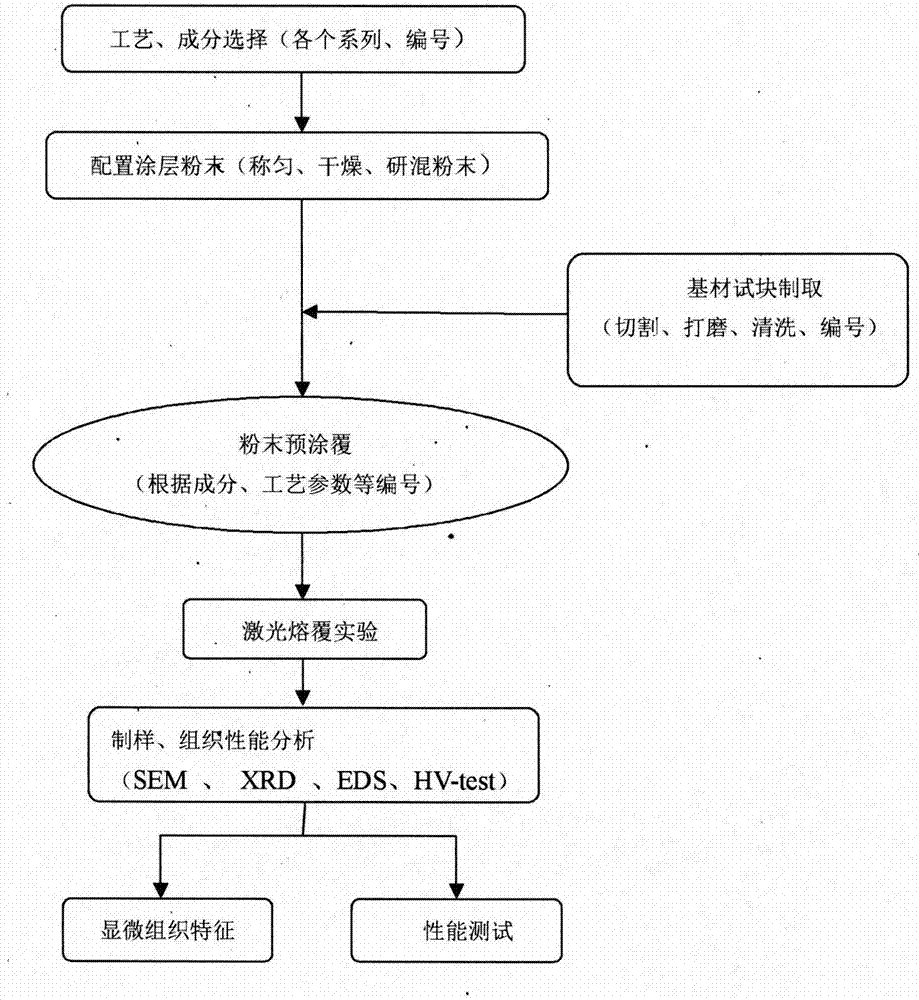

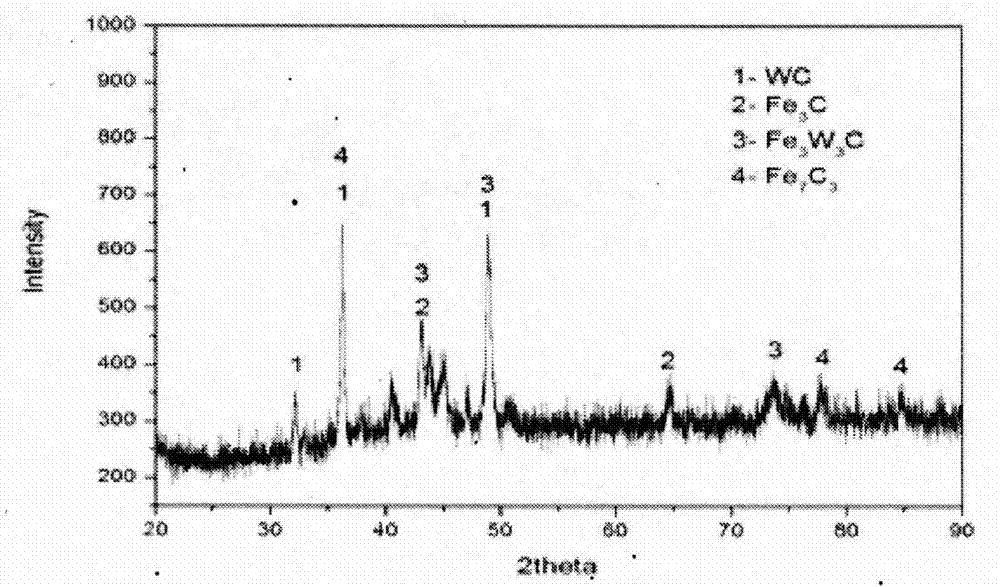

Laser-cladding tungsten carbide ceramic particle reinforced metal-based coating and processing method thereof

ActiveCN105112908AImprove bindingImprove wettabilityMetallic material coating processesAlloyMetallic Nickel

The invention discloses a laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. The coating comprises alloy powder; the alloy powder comprises tungsten powder and graphite with the mole ratio of 2:1 and further comprises reduced iron powder, chromium powder, nickel powder, boron powder, silicon powder and copper powder; further, the alloy powder preferentially comprises the following components in percentage by mass: 55-60% of tungsten powder, 7-9% of graphite, 23-30% of reduced iron powder, 0-3% of chromium powder, 2-6% of nickel powder, 0.3-1% of boron powder and 0.4-1% of silicon powder. The invention further discloses a processing method for the laser-cladding tungsten carbide ceramic particle reinforced metal-based coating. According to the invention, a tungsten carbide particle reinforcing phase for reinforcing the iron-based composite is successfully prepared through a laser cladding in-situ synthesis technology, and a transition layer is arranged between the coating and the matrix, so that atom binding between the coating and the matrix is realized and the bonding strength is relatively high.

Owner:WENZHOU UNIVERSITY

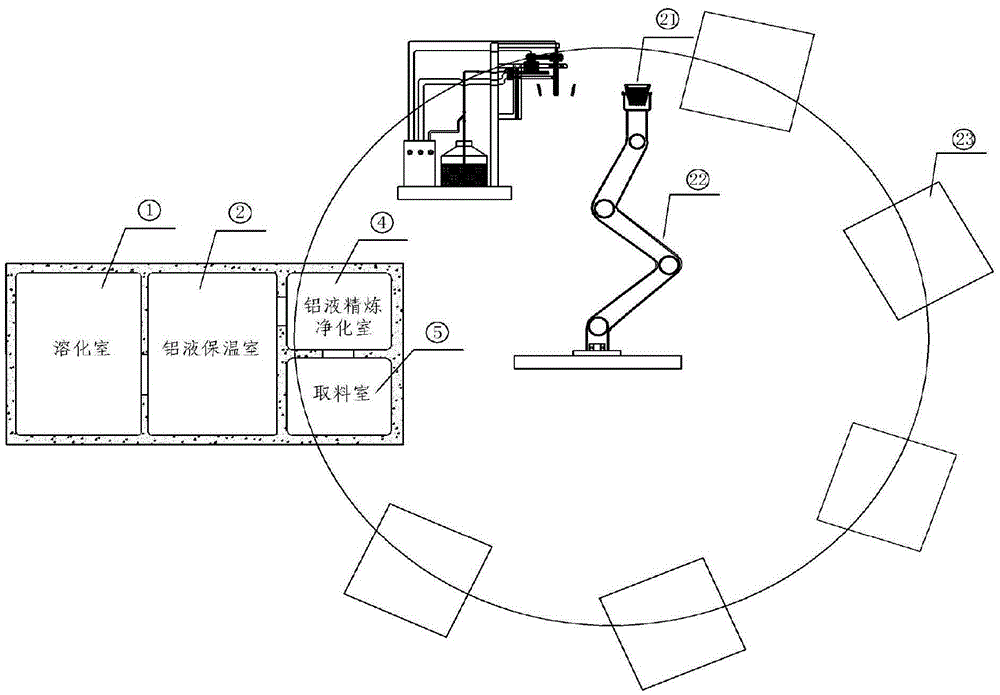

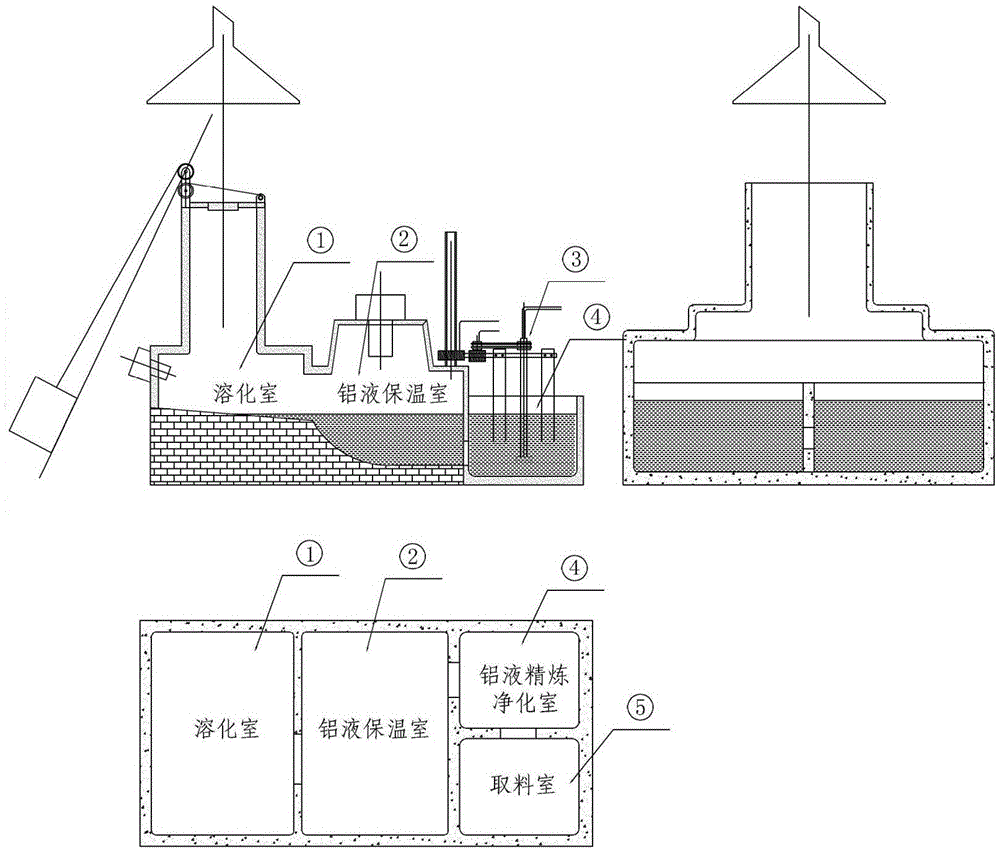

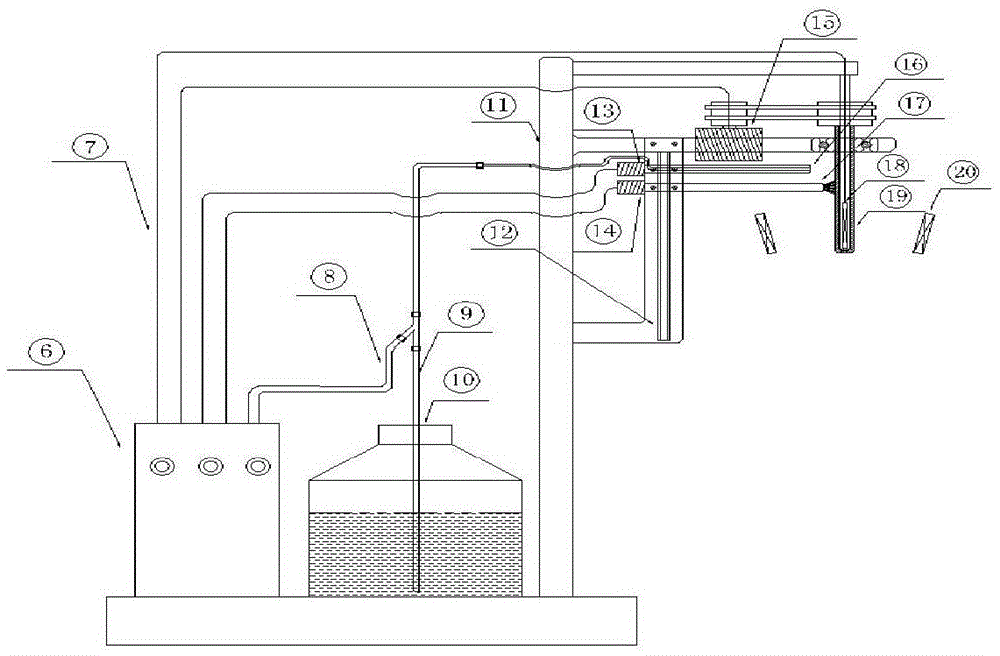

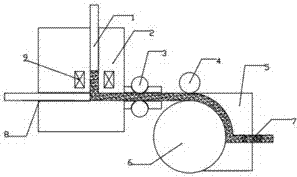

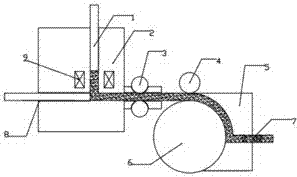

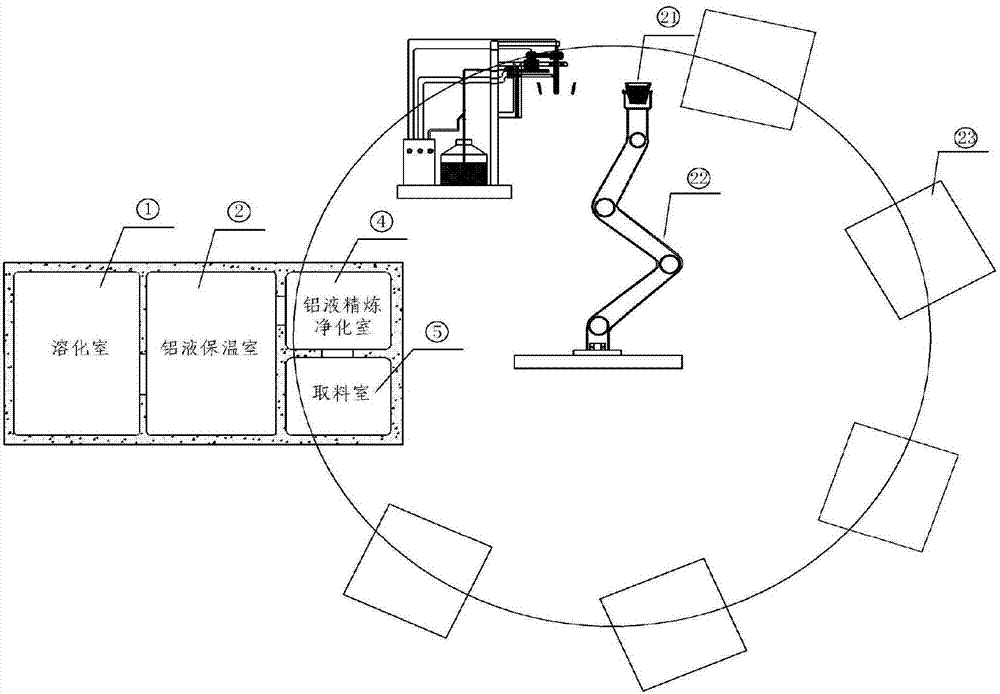

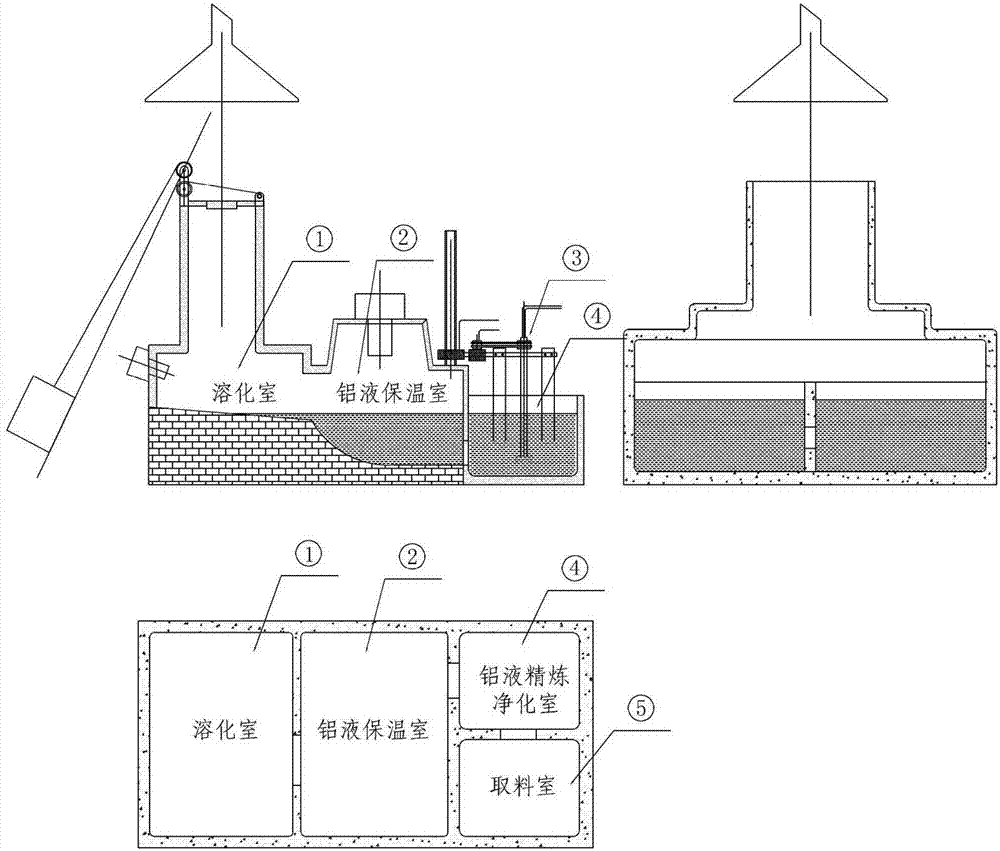

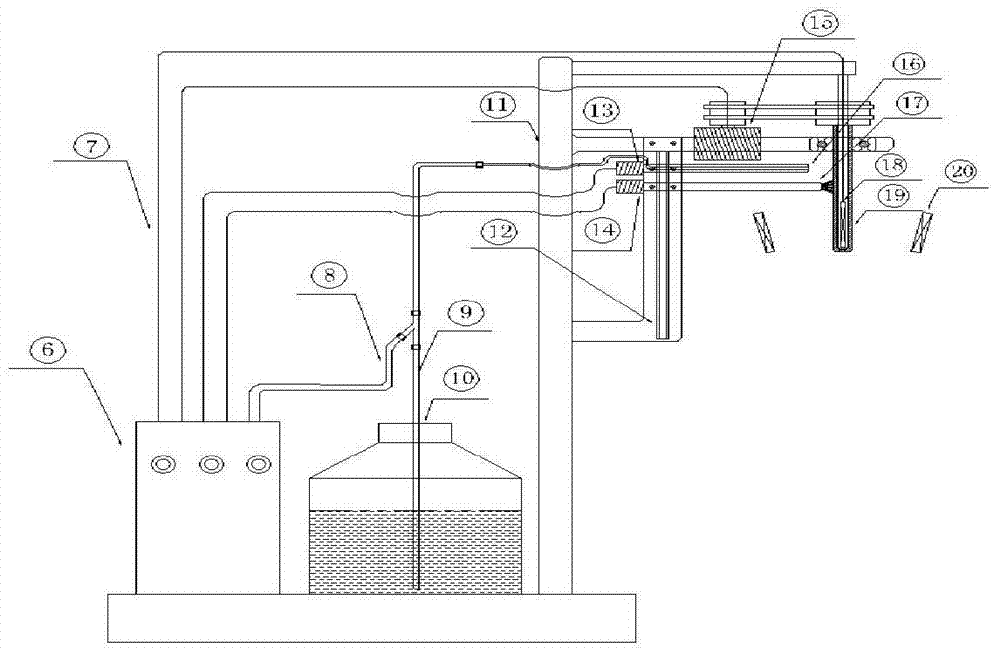

Continuous rapid preparing device of semi-solid slurry of automobile aluminum alloy wheels

The invention discloses a continuous repaid repairing device of semi-solid slurry of automobile aluminum alloy wheels. The device is composed of a continuous melting refining purification furnace, a slurry rapid stirring device, a slurry transfer crucible and an intelligent assistance arm. The material continuous refining purification furnace, the slurry rapid stirring device and die-casting machines (or die forging machines) are distributed on the circumference of the circle with the intelligent assistance arm as the center; the slurry transfer crucible is mounted on the intelligent assistance arm and inputs the motion program of the intelligent assistance arm to a computer; according to the slurry transfer crucible, in a material taking chamber, a liquid face oxide thin film is put aside, a certain amount of molten aluminum is taken, and then is transferred to the position below a graphite pipe of the slurry rapid stirring device, the graphite pipe is inserted into slurry in the center area of the slurry transfer crucible, and an electromagnetic stirrer in the graphite pipe and an electromagnetic stirrer on the periphery of the slurry transfer crucible are started to carry out electromagnetic stirring; the slurry stirred to be qualified is rapidly transferred to the die-casting machines (or die forging machines) for production. According to the technical scheme, semi-solid slurry continuous and rapid preparing and transferring can be achieved, the slurry is stable in quality, and the device is of great significance in semi-solid production of the automobile aluminum alloy wheels.

Owner:JIANGSU KAITE AUTO PARTS

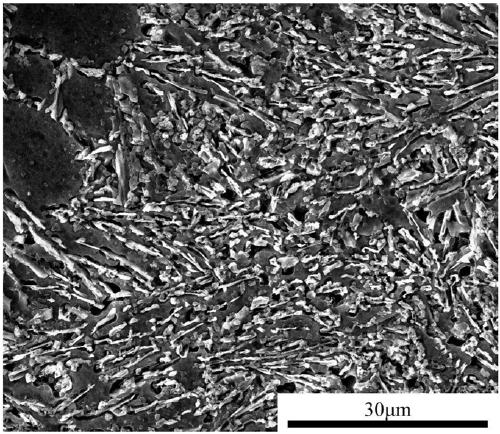

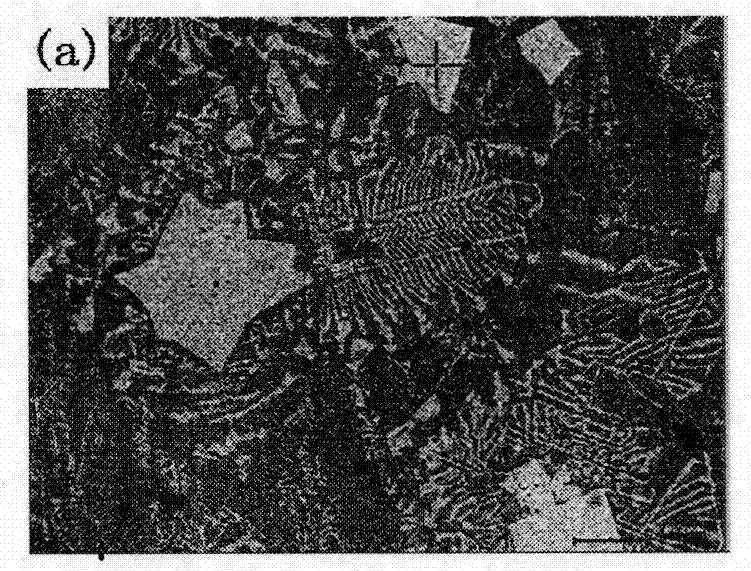

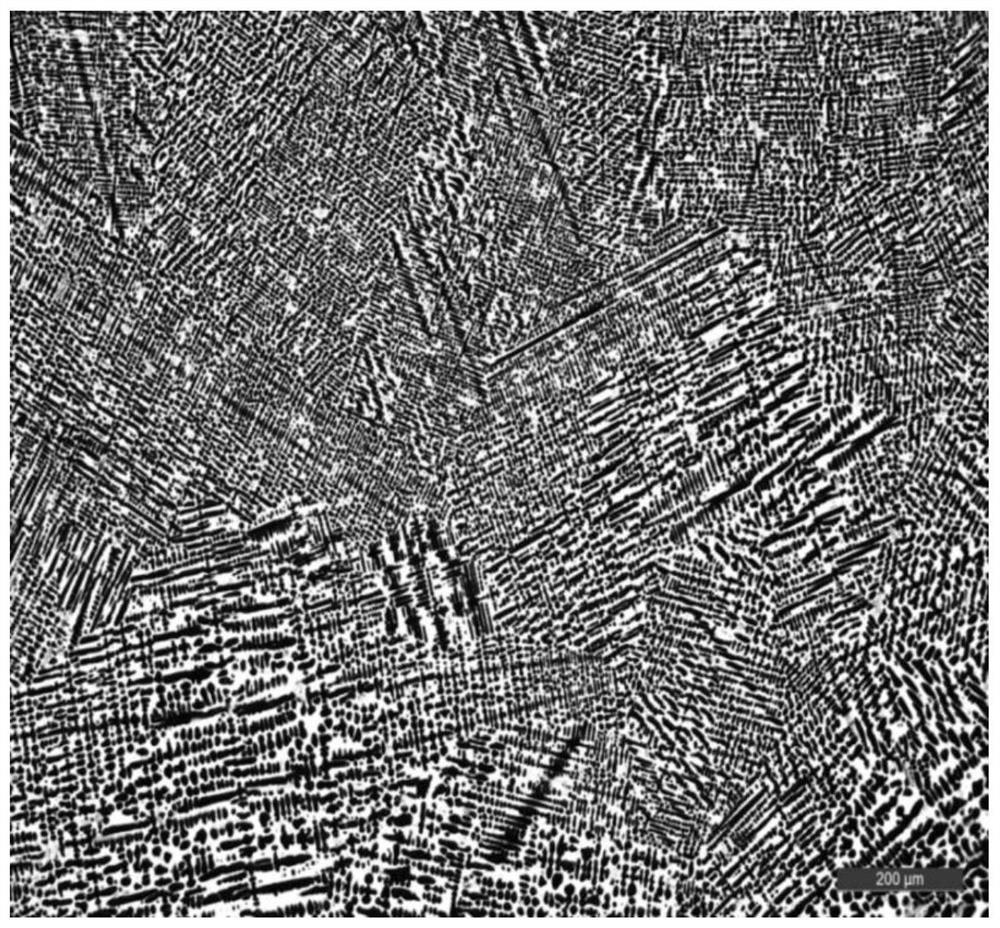

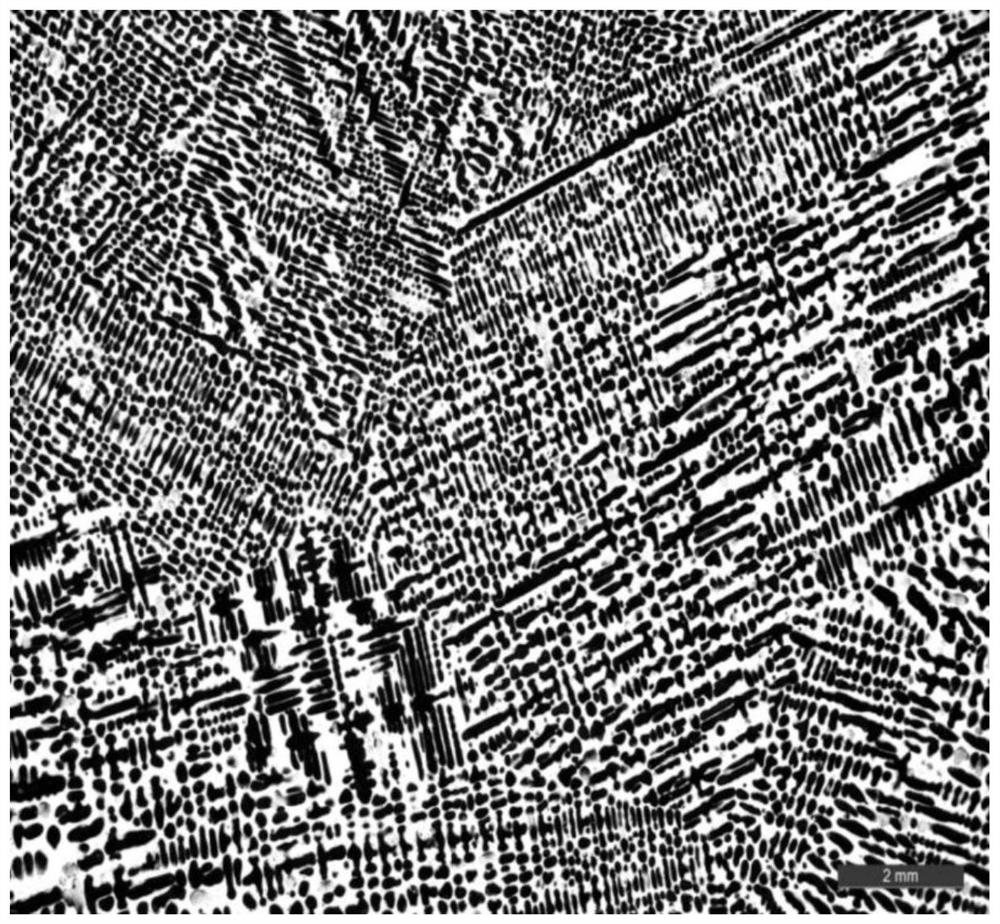

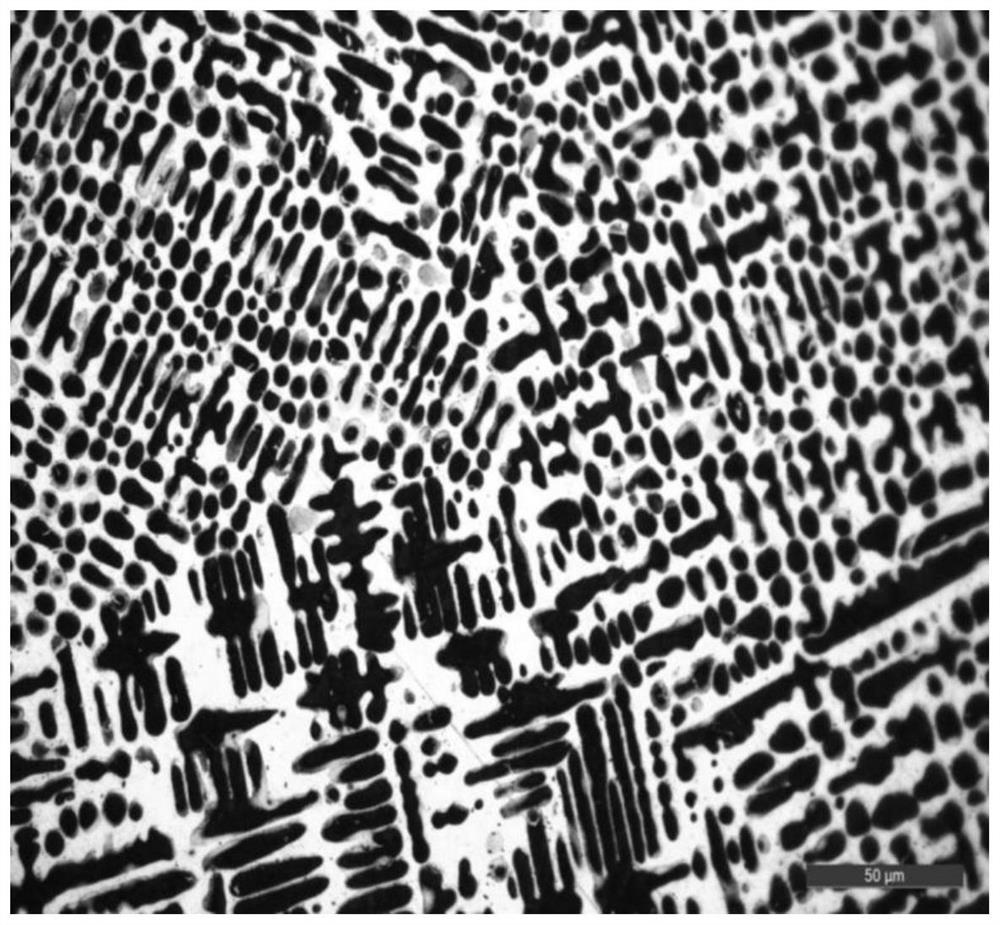

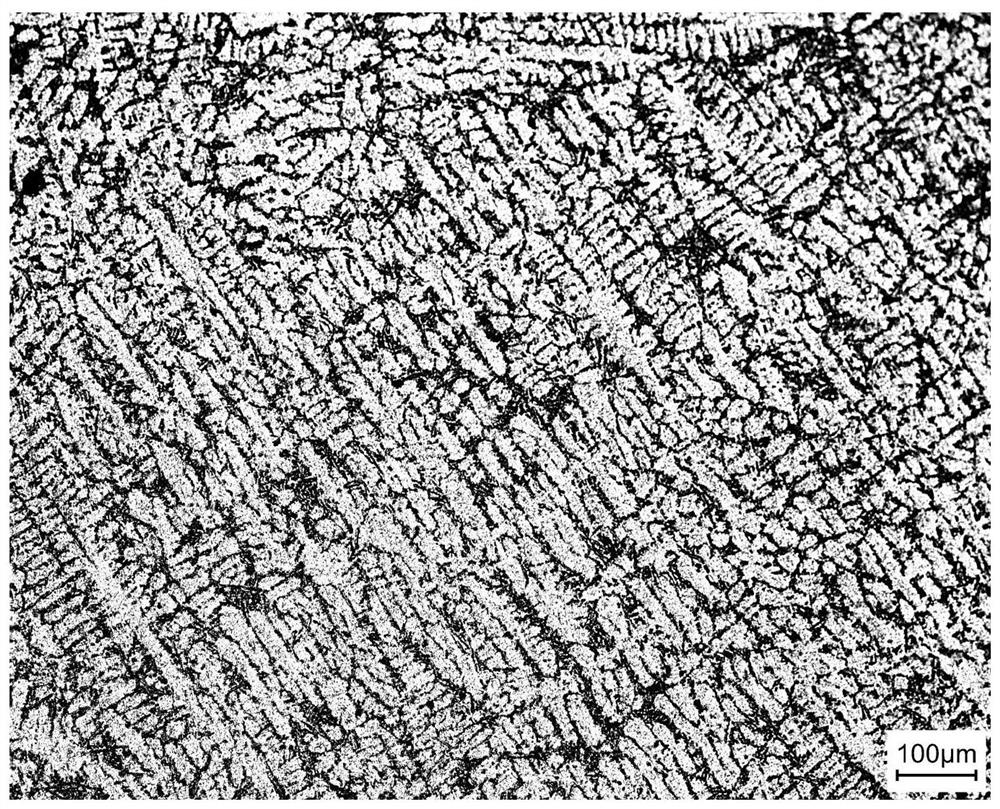

Preparation process of hypoeutectic aluminum-silicon alloy inoculated by high-entropy alloy

ActiveCN109136599AImprove mechanical propertiesFine and evenly distributedSilicon alloyHigh entropy alloys

The invention discloses a preparation process of hypoeutectic aluminum-silicon alloy inoculated by high-entropy alloy. The preparation process comprises the following steps: first, preparing AlCoCrFeNiTix (x=0.5-1.5) high-entropy alloy; mixing pure aluminum and Al-20 Si alloy, melting to obtain an alloy melt and obtaining hypoeutectic Al-(6-9)Si alloy through refined pouring; adding the high-entropy alloy as an inoculant in the hypoeutectic Al-(6-9)Si alloy at different mass fractions for inoculation treatment to obtain a fine and uniform eutectic silicon alpha-Al equiaxed crystal structure. Therefore, the mechanical property of the hypoeutectic aluminum-silicon alloy is improved. The preparation process disclosed by the invention has the benefits that the inoculant can refine alpha-Al crystal grains and obtain the fine and uniformly-distributed eutectic silicon structure, so that the trends of a splitting effect and a stress concentration on a matrix are reduced.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

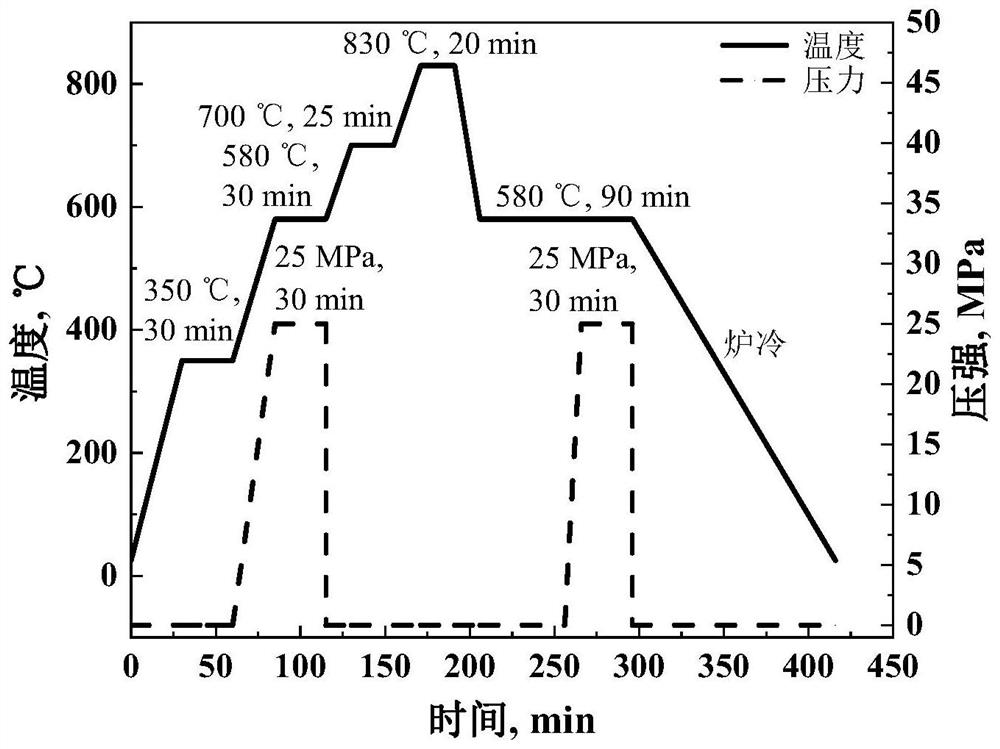

Preparation process and method for controllable medical degradable magnesium alloy

The invention relates to a metal powder forming technology, in particular to preparation of a controllable medical degradable magnesium alloy, and can be applied to the field of biomedical materials.The invention provides a production method of compounding various processes to obtain metal powder solidified materials of different grain sizes to ensure plasticity. Under the circumstance of good processing manufacturability, nanometer intensifying of the material is achieved, and the strength of the material as a medical stent material is guaranteed. Furthermore, according to the actual demandin the period, the degrading period of the material is adjusted by adjusting the grain sizes, so that degradation of the magnesium alloy in body fluids is controlled more reliably and efficiently.

Owner:SHANDONG JIANZHU UNIV

Casting-molded aluminum-silicon lightweight refractory material

The invention belongs to the technical field of refractory materials, and discloses a casting-molded aluminum-silicon lightweight refractory material which comprises raw materials and solvents, wherein the raw materials comprise ceramic powder as base packing; the solvent comprises water, a thickening agent and a dispersing agent; the raw material of the aluminum-silicon lightweight refractory materials further comprise pure calcium aluminate cement and ceramic fiber for improving the strength and the thermal shock resistance of a product; the solvent further comprise silica sol; the pure calcium aluminate cement and the silica sol act together to complete the hardening process of the refractory material; when the refractory material is hardened, the pure calcium aluminate cement is hydrated and hardened in a solvent and acts with the silica sol to form the framework of the lightweight refractory material, and the ceramic powder and water molecules can be adhered to the framework of the lightweight refractory material. The casting-molded aluminum-silicon lightweight refractory material has the characteristics of fine aperture, uniformity in distribution, good thermal insulation property, high strength, good erosion resistance and good washout resistance.

Owner:SINOSTEEL LUOYANG INST OF REFRACTORIES RES

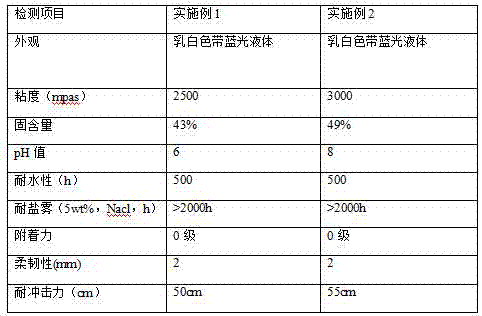

Acrylic emulsion with self-crosslinked core-shell structure, and preparation method of acrylic emulsion

ActiveCN106977654AGood compatibilityImprove stabilityFireproof paintsAnti-corrosive paintsFunctional monomerPolymer science

The invention relates to an acrylic emulsion with a self-crosslinked core-shell structure, and a preparation method of the acrylic emulsion. The preparation method comprises the following steps: compounding acrylic hard monomers and acrylic soft monomers, adding functional monomers such as vinylidene, phosphate monomers and organic fluorine active monomers, adding self-crosslinked monomers to obtain the acrylic emulsion with the self-crosslinked core-shell structure by using an emulsion polymerization method under the special emulsifier combination. Through core-shell interpenetration technology and special raw material matching, the emulsion has good water resistance and corrosion resistance performances, is high in adhesion force, has excellent comprehensive performance, and can be directly coated into maintenance engineering of various steel structure members and mechanical equipment, and the like, thus having wide application prospects.

Owner:HUIZHOU CITY HUIYANG DISTRICT JIATAI PAINT CO LTD

Method for preparing base of vertical annealing furnace

ActiveCN102489669AGood spherical effectReduce white mouth tendencyFoundry mouldsFoundry coresCompressive strengthLost-foam casting

The invention discloses a method for preparing a base of a vertical annealing furnace. The method provided by the invention is characterized in that a lost foam casting technology is adopted; molten iron is injected into a mold from the bottom to form a casting; a pour-over spheroidizing technology is adopted; and a spheroidizing inoculation technology is adopted. The base obtained by the method has advantages of good mechanical properties, good flexibility, high tensile strength, high compression strength, low rejection rate, high heat resistance, high fatigue resistance, and large elongation.

Owner:SICHUAN CHUANJIAN PIPES

Rolling mill guide roller and preparation method thereof

The invention discloses a rolling mill guide roller and a preparation method thereof. The rolling mill guide roller comprises the following components in percentage by mass: 2.5-2.8% of C, 15-17% of Cr and the balance of Fe, wherein the mass percentage ratio of Cr to C is 5-7. The preparation method of the rolling mill guide roller comprises the following steps: preparing and loading the materials, smelting alloy, performing fine casting, annealing, performing rough processing, quenching, tempering, and performing fine processing. The rolling mill guide roller and the preparation method disclosed by the invention have the advantages that the high-temperature wearing resistance, the high-temperature heat resistance, the thermal stability and the like of a guide roller material can be improved.

Owner:HEFEI ORIENT METALLURGICAL EQUIP

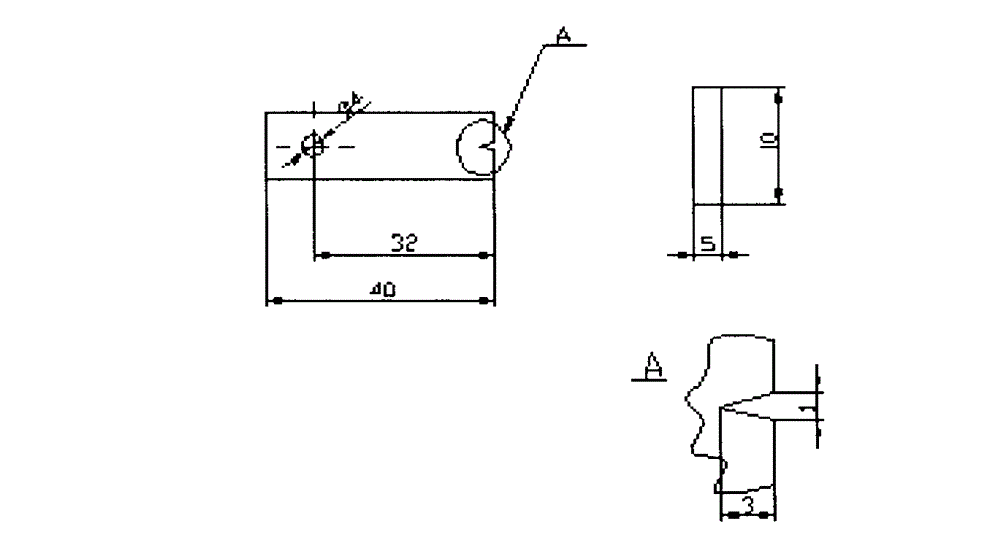

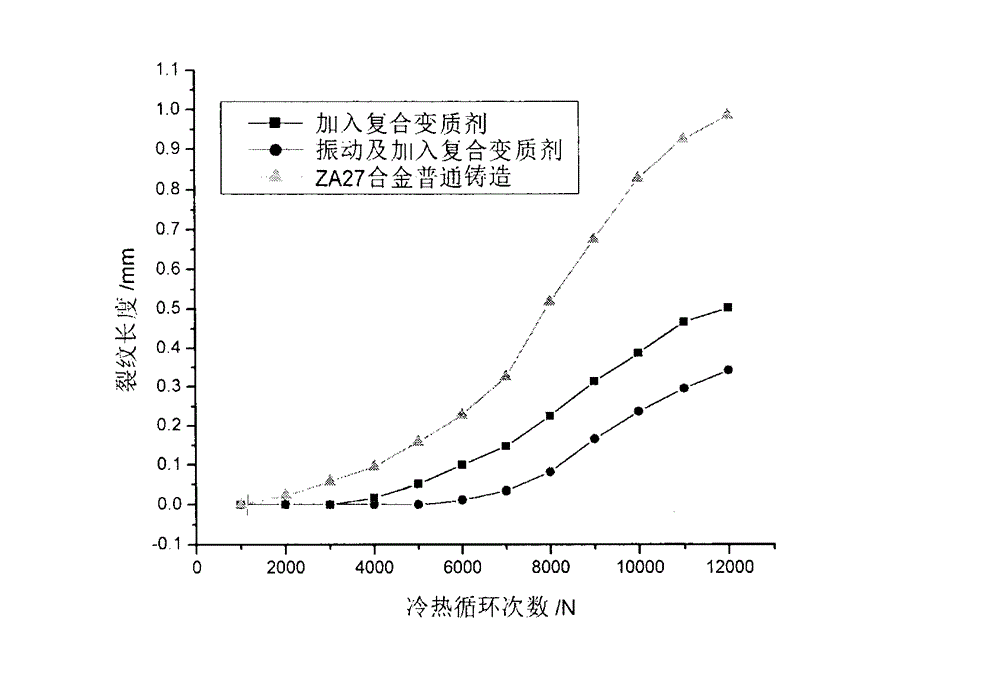

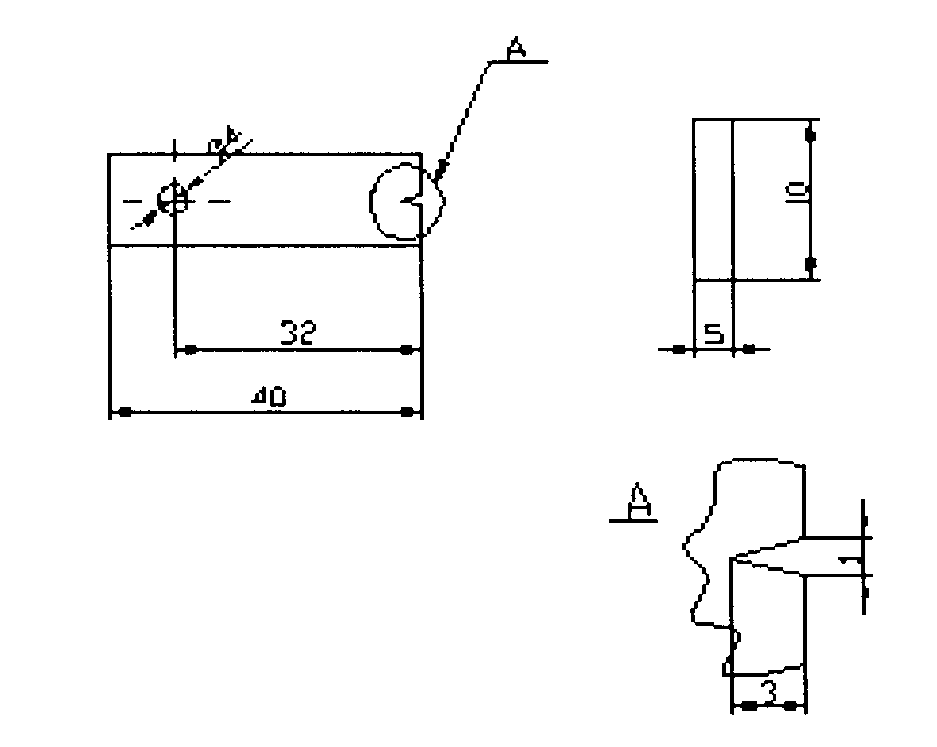

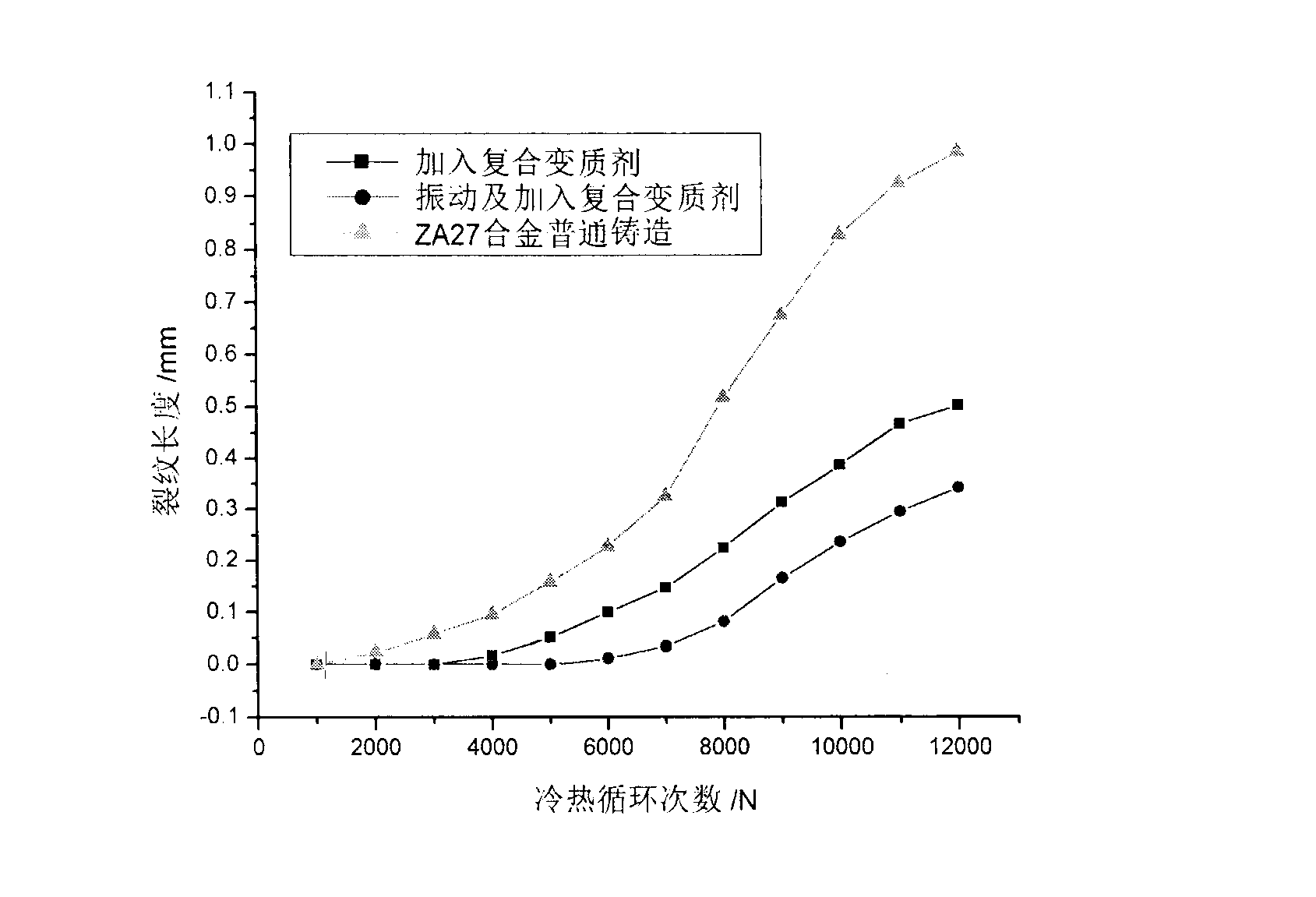

Process method capable of improving thermal fatigue property of polynary zinc-aluminum alloy

The invention discloses a process method capable of improving the thermal fatigue property of a polynary zinc-aluminum alloy and belongs to the technical field of zinc-aluminum alloy preparation. The process method is characterized in that industrial aluminum ingots A00, zinc ingots 0, electrolytic copper, composite modifiers (wherein 20-30% of Ni, 15-25% of Ti, 5-15% of Mn, 5-15% of Cr, 5-10% ofSi, 5-10% of Ce, 5-10% of La, 1-6% of Y, 1-6% of Nb, 1-6% of V and the balance aluminum) and pure magnesium are used as raw materials. The method includes: proportionally weighing, by weight, 27-29% of Al, 2-2.5% of Cu, 0.2-1.2% of the composite modifiers, 0.01-0.02% of Mg and the balance Zn, melting the components in a medium-frequency induction melting furnace, pouring the melted zinc-aluminum alloy on common metal molds and vibratory metal molds, then processing the poured metal molds to test bars meeting national standards and sampling on blanks so that thermal fatigue testing specimens are processed by wire cutting.

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

Laser cladding tungsten carbide ceramic particle reinforced metal-based coating and its processing method

ActiveCN105112908BImprove bindingImprove wettabilityMetallic material coating processesAlloyChromium

The invention discloses a metal-based coating reinforced by laser cladding tungsten carbide ceramic particles, which includes alloy powder, the alloy powder includes tungsten powder and graphite with a molar ratio of 2:1, and the alloy powder also includes reduced iron powder and chromium powder , nickel powder, boron powder, silicon powder and copper powder; the composition and percentage mass ratio of further preferred alloy powder are respectively: tungsten powder 55-60%, graphite 7-9%, reduced iron powder 23-30%, chromium 0-3% nickel powder, 2-6% nickel powder, 0.3-1% boron powder, and 0.4-1% silicon powder; the invention also discloses a processing method for laser cladding tungsten carbide ceramic particle reinforced metal-based coating, the invention The tungsten carbide particle reinforcement phase was successfully prepared by laser cladding in-situ synthesis technology to strengthen the iron-based composite material. There is a transition layer between the coating and the substrate, indicating that they are atomically bonded and have a high bonding strength.

Owner:WENZHOU UNIVERSITY

Pouring molding aluminum-silicon series light refractory material

The invention belongs to the technical field of refractory materials, and provides a pouring molding aluminum-silicon series light refractory material. The aluminum-silicon series light refractory material comprises raw materials and solvents. The raw materials comprise ceramic powder as a basic filler, and the solvents comprise water, a thickener and a dispersant; the raw materials of the aluminum-silicon series light refractory material also comprise pure calcium aluminate cement and ceramic fiber to improve the strength and thermal shock resistance of the product. The solvents also comprise silica sol. The pure calcium aluminate cement is combined with the silica sol to complete the hardening process of the refractory material together. During the hardening process of the refractory material, the pure calcium aluminate cement hydrates and hardens in the solvents and interacts with the silica sol to form a framework of the lightweight refractory material, and thus the ceramic powder and water molecules are adsorbed on the framework of the lightweight refractory material. The pouring molding aluminum-silicon series light refractory material has the characteristics of small pore diameter, good heat insulation property, uniform distribution, high strength, good erosion resistance and good erosion resistance.

Owner:长兴县新宏信耐火材料有限公司

Pickling method of zinc-selenium-rich yellow croaker with spicy zanthoxylum armatum

PendingCN111713655AAdd flavorPromote absorptionFood freezingFood ingredient as taste affecting agentBiotechnologyAnimal science

The invention discloses a pickling method of zinc-selenium-rich yellow croaker with spicy zanthoxylum armatum. The pickling method comprises the following steps: cleaning fresh and alive yellow croaker with water, removing dirt and mucosa on the surface, removing fish scales, gills and fins, removing internal organs, and cleaning blood stains and black membranes; removing fish bone and fishbone; cutting into fish slices; pickling the yellow croaker slices, sterilizing the yellow croaker slices by an ozone machine in a workshop, uniformly stirring, pickling the yellow croaker slices in fish sauce for 3 minutes, bagging and weighing; using a seasoning packet and the preliminarily pickled fish slices according to a weight ratio of (0.2-0.5): 10, wherein the seasoning packet contains 30-60% ofyeast extract; carrying out ultrasonic segmentation treatment; freezing at-50 DEG C for 10 minutes to complete pickling; and packaging in vacuum, and storing at a temperature lower than-15 DEG C. Through pickling and seasoning twice, the flavor is layered, and the yeast extract is arranged in the seasoning bag, so that the flavor of the fish meat is effectively improved; ultrasonic waves have anauxiliary quick-freezing effect, so that the salted yellow croaker quality is improved; and ultrasonic segmentation treatment is adopted, so that the influence of the ultrasonic segmentation treatmenton the yellow croaker fillets can be reduced.

Owner:福建三都澳食品有限公司

Residual-temperature normalizing process

The invention discloses a residual-temperature normalizing process. The residual-temperature normalizing process comprises the steps of forged part micro-heating, heat preservation, forced cooling, dispersion air cooling, stack cooling and the like. According to the residual-temperature normalizing process, forging waste heat is fully utilized, and high efficiency of energy utilization is guaranteed; the heat preservation time is reduced, the time of the process procedure is shortened, and treatment efficiency is improved; and according to a forged part treated through the residual-temperaturenormalizing process, metallographic structures are fine and are evenly distributed, it is guaranteed that the hardness of the forged part ranges from 210 HB to 280 HB, and the depth of a surface layer decarburization layer is smaller than 0.3 mm.

Owner:WANXIANGQIANCHAO CO LTD +1

Ultrahigh-strength aluminum alloy and preparation method thereof

The invention provides an ultrahigh-strength aluminum alloy, which comprises 3.0-10.0wt% of Cu, 2.0-9.7wt% of Mg, 1.7-38wt% of Zn, 0.1-1.3wt% of Nd, 0.05-2wt% of Ni, 0.05-1.77wt% of Mn, 0.01-0.5wt% ofT and the balance of Al. The invention also provides a preparation method of the ultrahigh-strength aluminum alloy. According to the preparation method provided by the invention, an aluminum alloy material is prepared by adopting a specific formula and a spray forming process, the micro-structure of the aluminum alloy material is obviously refined, and the precipitated phase is fine and uniformlydistributed, so that the mechanical property of the aluminum alloy material is hardly anisotropic, and the aluminum alloy material has the advantages of high strength, high toughness, high rigidity and light weight. Experimental results show that after T6 treatment, the tensile strength of the ultrahigh-strength aluminum alloy provided by the invention is higher than or equal to 917MPa, and the yield strength is higher than or equal to 874MPa.

Owner:薛元良

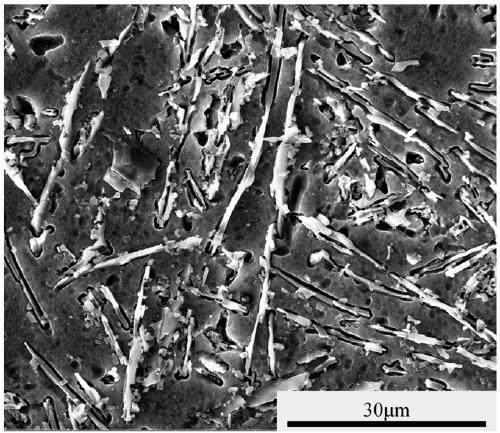

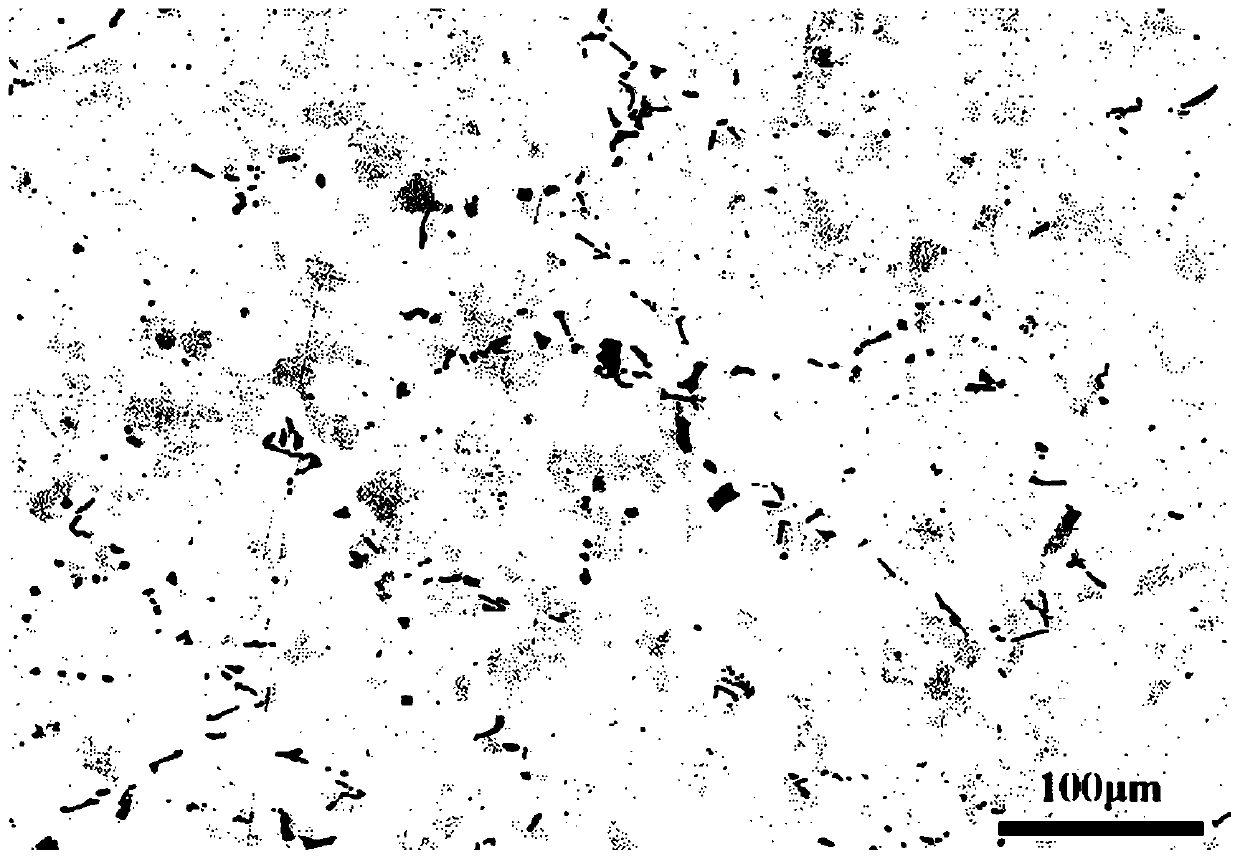

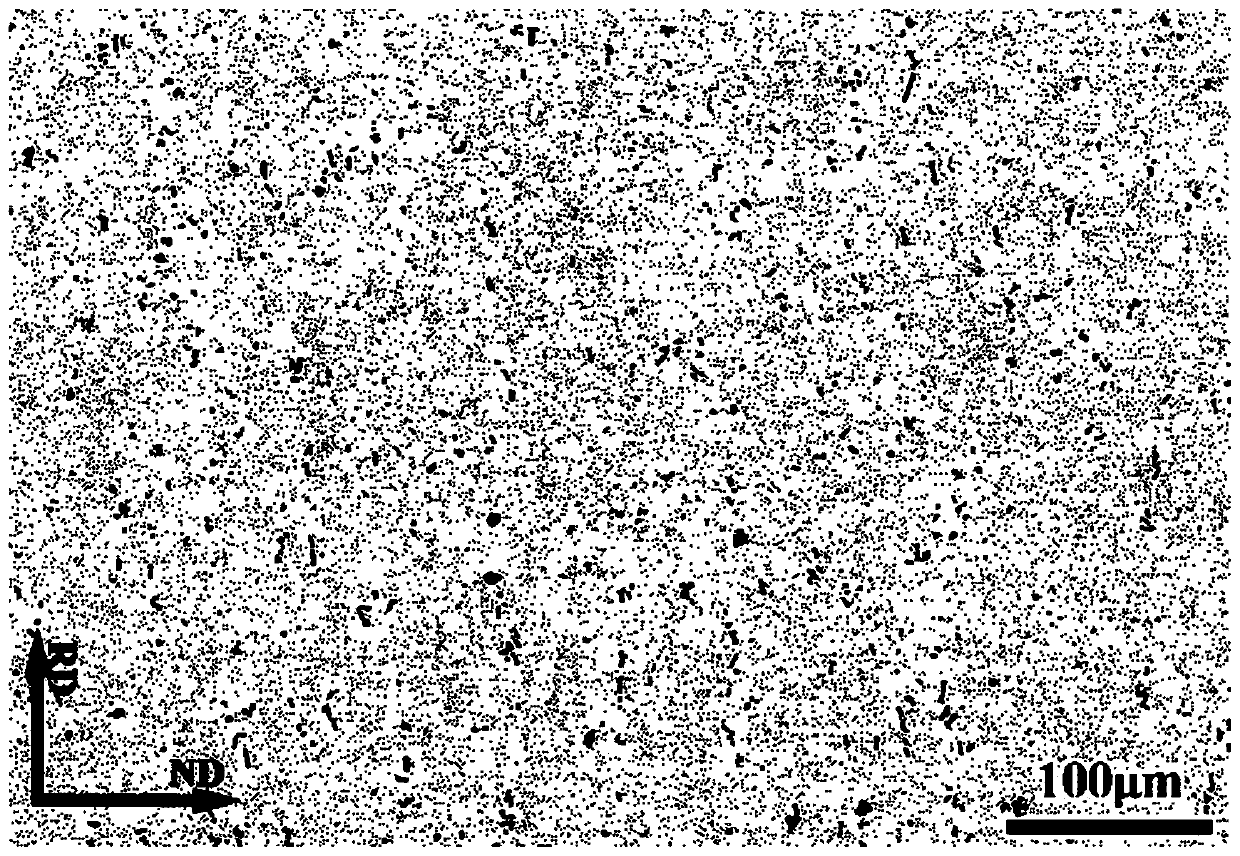

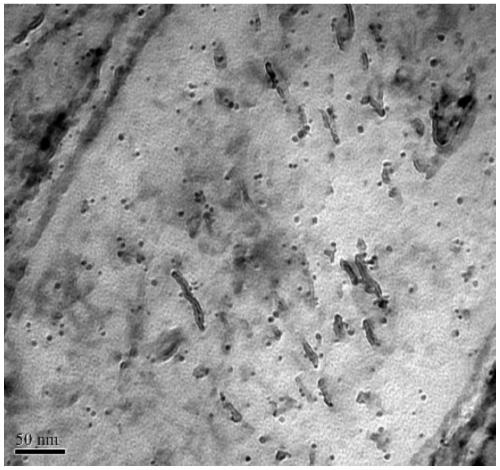

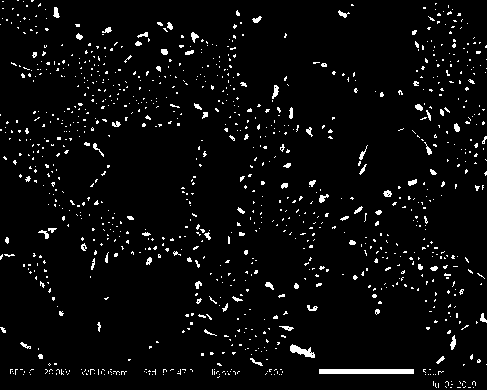

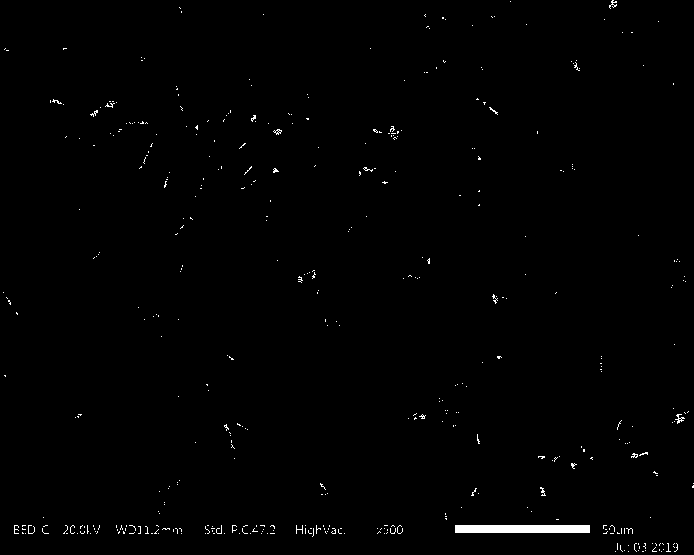

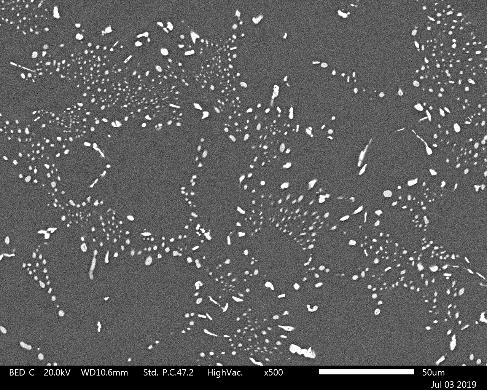

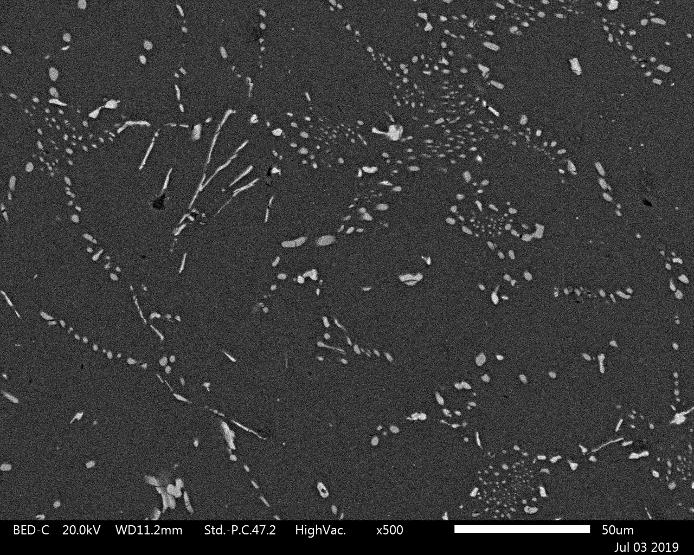

A kind of double-scale tic particle composite strengthening low-alloy super wear-resistant steel and manufacturing method thereof

A dual-scale TiC particle composite reinforced low-alloy super wear-resistant steel. The chemical composition in weight percentage is C: 0.18~0.60%, Si: 0.30~1.20%, Mn: 1.00~3.00%, Cr: 0.20~0.40%, Ti: 0.2~1.00%, Mo: 0.10~0.50%, B: 0.0005~0.003%, S: ≤0.005%, P: ≤0.015, the balance is iron and inevitable impurity elements; among them, the contents of C and Ti Satisfying 0.10%≤C%-Ti% / 4≤0.40%; the low-alloy super wear-resistant steel contains dual-scale TiC particles with uniformly distributed micron-level TiC particles and nano-level TiC particles. The preparation method of super wear-resistant steel includes the steps of smelting, solidification forming, rolling, cooling and heat treatment. During cooling, the rolled steel is ultra-rapidly cooled to 450-750°C, and then heap cooling is performed. The wear-resistant steel of the present invention has a hardness of HB360-550, its wear-resistant performance reaches 1.5 to 3.0 times that of traditional super wear-resistant steel plates with the same hardness, and its performance meets the use requirements of related equipment.

Owner:NORTHEASTERN UNIV LIAONING

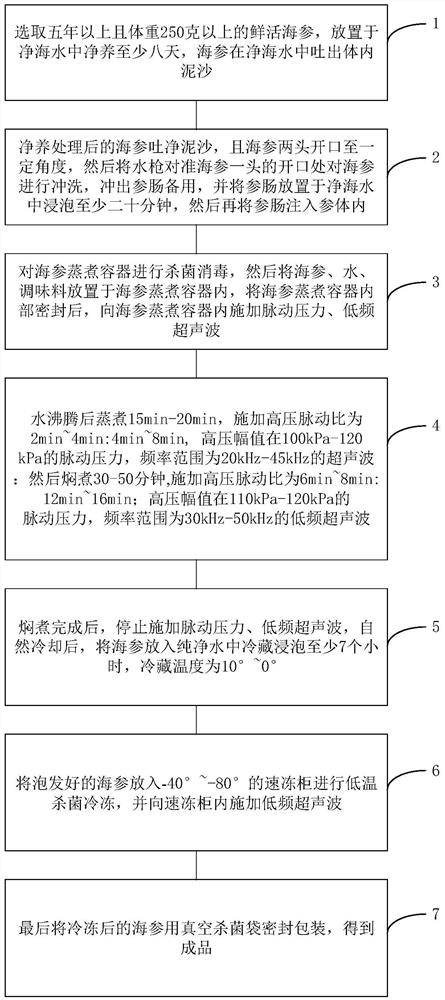

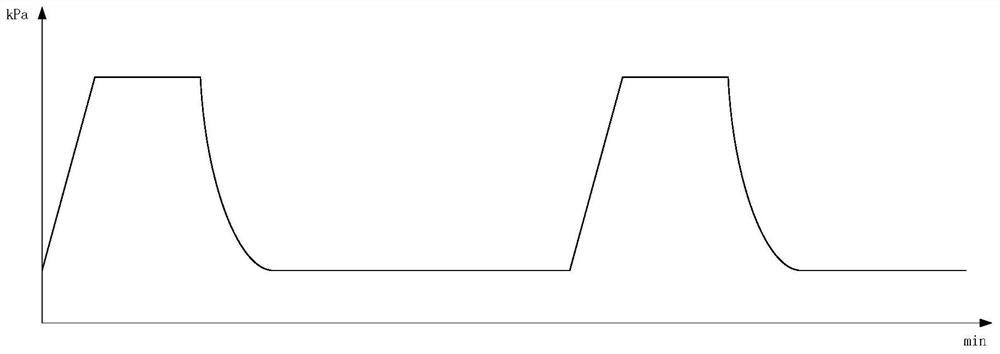

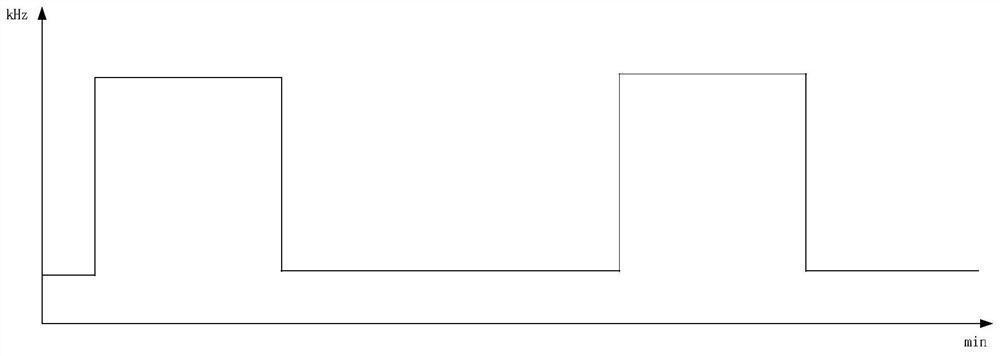

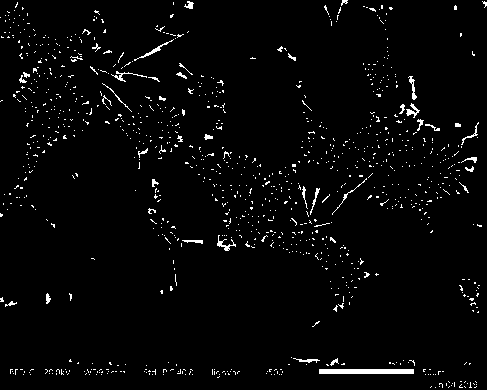

Production method of instant solid sea cucumbers

InactiveCN111838577AReduce processing timeFull of nutritionFood freezingFood ultrasonic treatmentNutritionEnvironmental engineering

The invention provides a production method of instant solid sea cucumbers. The production method comprises the following steps: selecting fresh sea cucumbers which are more than five years old and have the weight of more than 250g, putting the sea cucumbers into clean seawater for clean culture for at least eight days, and spitting silt in bodies of the sea cucumbers in the clean seawater; aligning a water gun with an opening at one end of the sea cucumber to flush the sea cucumber, flushing out sea cucumber intestines for later use, sterilizing and disinfecting, putting the sea cucumber, water and seasonings into a sea cucumber cooking container, sealing the inside of the sea cucumber cooking container, and applying pulsating pressure and low-frequency ultrasonic waves into the sea cucumber cooking container; after natural cooling, putting the sea cucumbers into purified water to be refrigerated and soaked, putting the soaked sea cucumbers into a quick-freezing cabinet to be subjectedto low-temperature sterilization and freezing, applying low-frequency ultrasonic waves into the quick-freezing cabinet, finally sealing and packaging and obtaining finished products. The sea cucumbers are in a pulse high-pressure, sealed and ultrasonic environment in the processing process so that the processing time of the sea cucumbers is shortened, the processing efficiency is improved, and the processed sea cucumbers are rich in nutrition, good in taste and easy to store.

Owner:薛新耀

Method for preparing base of vertical annealing furnace

ActiveCN102489669BGood spherical effectReduce white mouth tendencyFoundry mouldsFoundry coresCompressive strengthLost-foam casting

The invention discloses a method for preparing a base of a vertical annealing furnace. The method provided by the invention is characterized in that a lost foam casting technology is adopted; molten iron is injected into a mold from the bottom to form a casting; a pour-over spheroidizing technology is adopted; and a spheroidizing inoculation technology is adopted. The base obtained by the method has advantages of good mechanical properties, good flexibility, high tensile strength, high compression strength, low rejection rate, high heat resistance, high fatigue resistance, and large elongation.

Owner:SICHUAN CHUANJIAN PIPES

Homogenization and heating combined integrated heat treatment technology and aluminum alloy cast ingot

ActiveCN111020422AImprove pass rateImprove uniformityFurnace typesHeat treatment furnacesIngotFe element

The invention provides a homogenization and heating combined integrated heat treatment technology and an aluminum alloy cast ingot. Aiming at 8000-series aluminum alloy with high Fe element content, the technology comprises a homogenizing heat treatment process and a heating heat treatment process, Fe-containing second phase dispersed distribution in a cast ingot structure can be promoted, rod-shaped intermittent distribution at a grain boundary and spherical dispersion distribution in grains are realized, and the material performance is improved. The aluminum alloy casting part adopting the technology is subsequently processed into a mirror plate, the surface of the mirror plate has no stripe-shaped and pocking mark defects, the glossiness is high, the overall manufacturing cost is reduced, and the technology is suitable for industrial production of high-end 8000-series mirror surface aluminum alloy plate strips.

Owner:中铝河南洛阳铝加工有限公司 +1

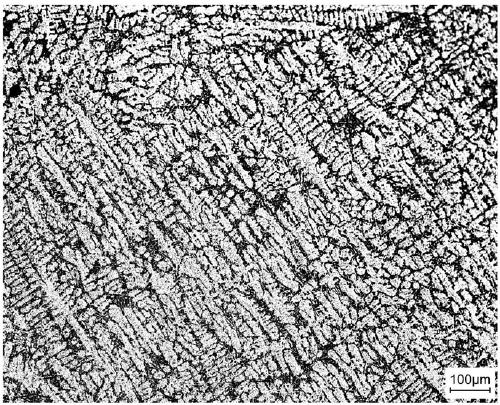

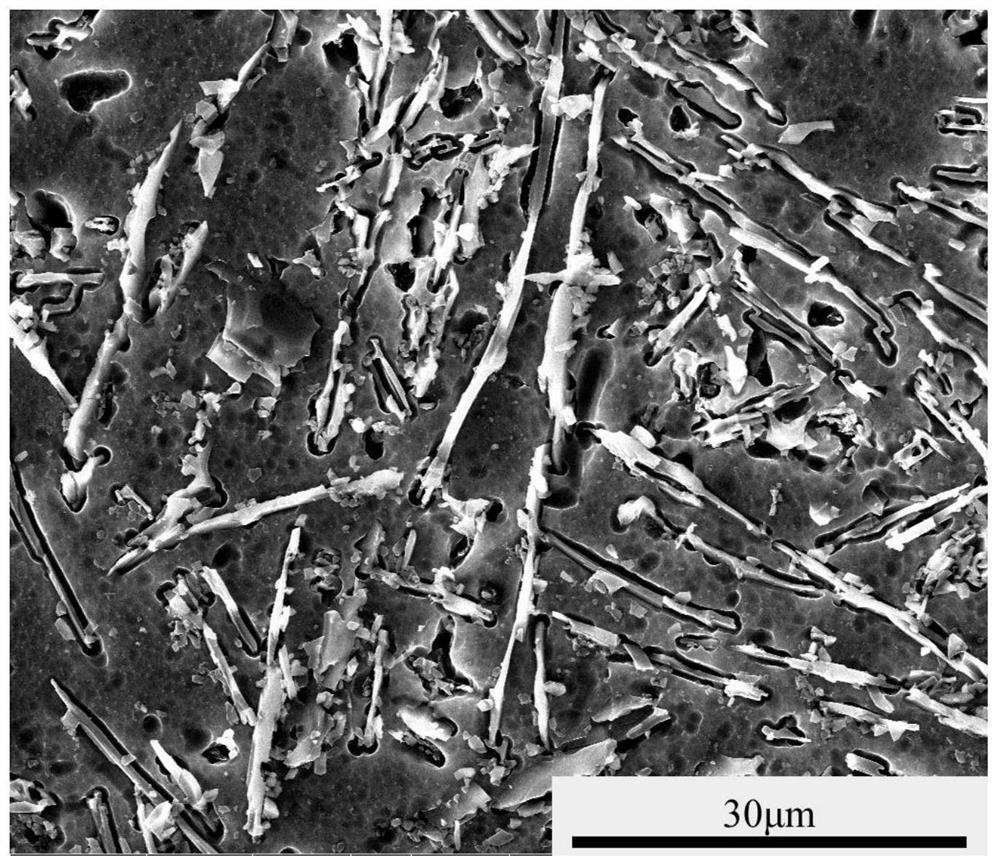

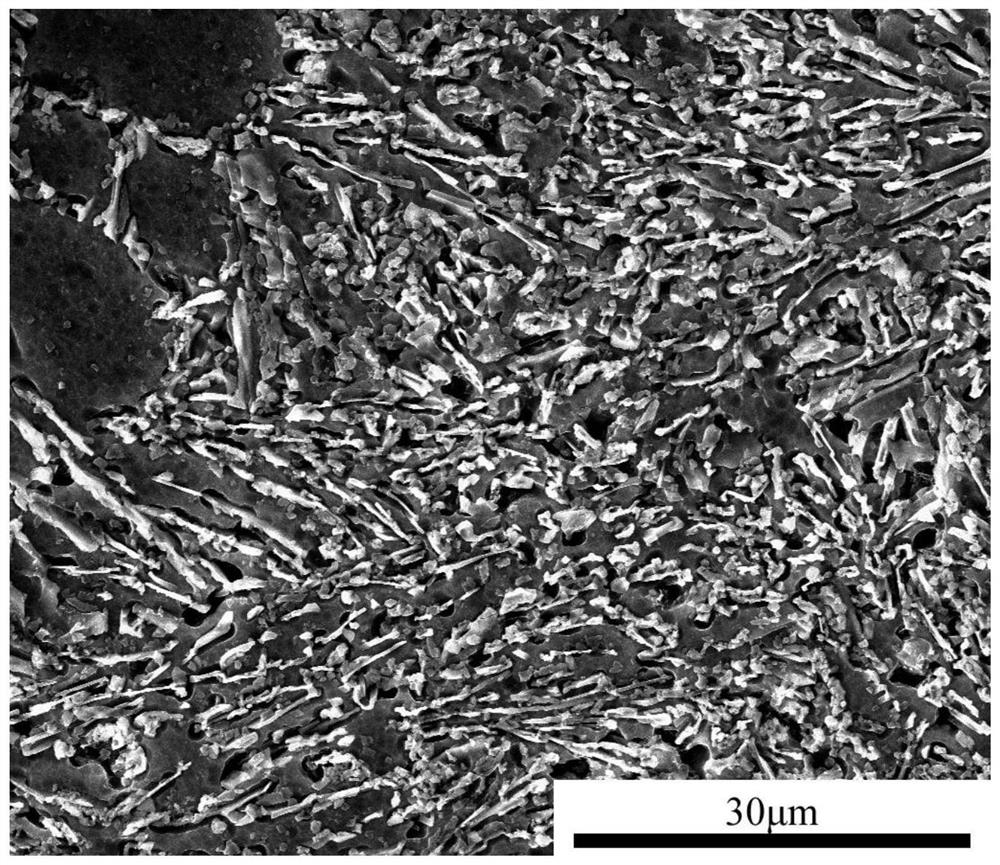

High-temperature wear-resistant alloy material for rolling mill guide and heat treatment method for rolling mill guide

ActiveCN103757545BFine and evenly distributedEffective precipitationGuiding/positioning/aligning arrangementsFurnace typesSolution treatmentWear resistant

The invention discloses a high-temperature wearing-resistance alloy material for a rolling mill guide and guard unit and a rolling mill guide and guard unit thermal treatment method. The high-temperature wearing-resistance alloy material comprises the following components in percentage by mass: 1.45-1.6% of C, 11-12.5% of Cr and the balance of Fe, wherein the mass percent ratio of Cr to C is 7:8. The rolling mill guide and guard unit thermal treatment method comprises the following steps: firstly, performing low-temperature stress relief annealing on the rolling mill guide and guard unit of 200-300 DEG C, subsequently preheating at 500-600 DEG C, performing solution treatment at 960-1,050 DEG C, and finally performing high-temperature tempering at 440-480 DEG C and low-temperature tempering at 270-290 DEG C. The high-temperature wearing-resistance alloy material for the rolling mill guide and guard unit and the rolling mill guide and guard unit thermal treatment method disclosed by the invention have the advantages that high-temperature wearing resistance, high-temperature thermal strength and thermal stability of a guide and guard material are improved, the service life of the rolling mill guide and guard unit is prolonged by 3-4 times, and the like.

Owner:安徽东方新材料有限公司

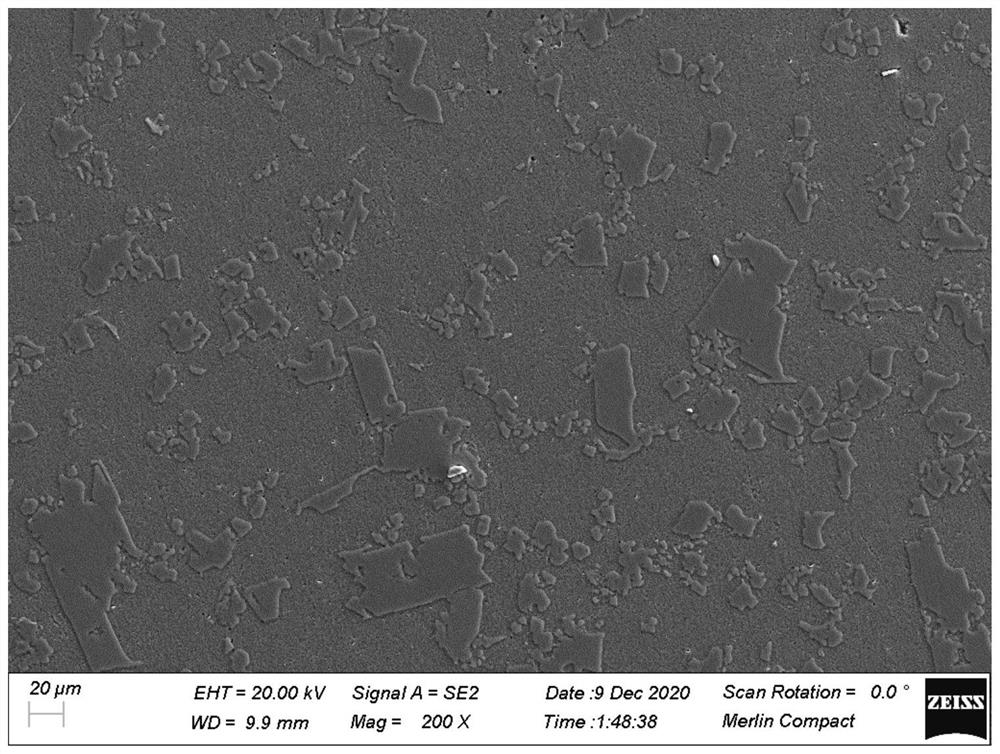

A kind of high-density, controllable composition of high-silicon aluminum alloy material and preparation method

The invention belongs to the technical field of alloy processing and discloses a high-silicon aluminum alloy material with high density and controllable composition and a preparation method. Wherein, the preparation method includes the following steps: 10 AlMgSi was prepared by multi-stage hot pressing sintering after mixing alloy powder and silicon powder X Alloys where X is greater than 10. The high silicon aluminum alloy material of the present invention has higher strength, elastic modulus and density.

Owner:HARBIN INST OF TECH +1

Closed hot extrusion forging processing method for universal joint duplex fork

InactiveCN114147155ASemi-automatic detachmentFast cracking speedRevolution surface grinding machinesFurnace typesSand blastingUniversal joint

The invention discloses a universal joint duplex fork closed hot extrusion forging machining method. Workpiece forging comprises the specific steps that reverse extrusion treatment is conducted on a forged piece coarse material; the forging coarse material is heated through an intermediate frequency furnace, rapid cooling annealing treatment is carried out after heating, and the step is repeated for multiple times, so that the pre-sheared excess material is cracked near the interior of the excess material block, a plurality of holes are formed between the excess material block and the forging coarse material, the connection strength is reduced, and the forging coarse material is annealed firstly and then subjected to upsetting treatment. Performing shot blasting and phosphorus saponification treatment to obtain a pre-forged piece; the pre-forged piece is subjected to precision forging forming, a closed forging technology is adopted for a precision forging die, flash-free forging is conducted, and vent holes are designed in the precision forging die; the surface of the workpiece subjected to normalizing treatment is subjected to sand blasting treatment, and the workpiece subjected to sand blasting treatment is subjected to rust-proof treatment, so that the rejection rate of products is reduced, the qualification rate of the products is improved, and the energy consumption is greatly reduced.

Owner:安徽永益汽车部件有限公司

Forging method of bearing ring

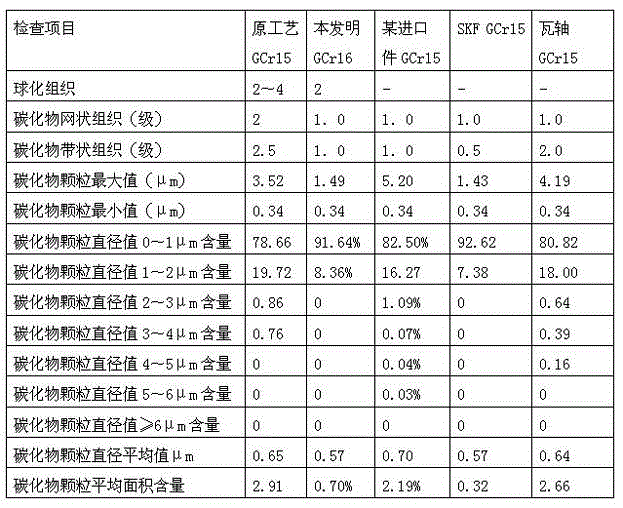

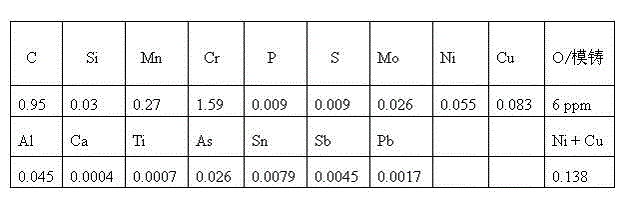

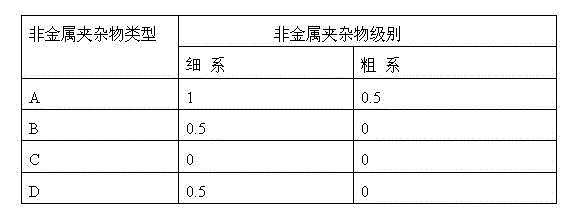

ActiveCN102756070BFine and evenly distributedImprove contact fatigue lifeEngine componentsTO-18Carbide

The invention relates to a forging method of a bearing ring. The forging method is characterized by comprising the following steps of heating, raising the temperature, preserving the temperature, forging, quickly cooling and naturally cooling, wherein in the heating step, a bearing ring blank is heated from common temperature to the temperature of 900 DEG C; in the temperature raising step, the temperature of the bearing ring blank is raised from 900 DEG C to 1150 DEG C; in the temperature preserving step, the temperature of the bearing sleeve blank is preserved for 0.5 to 1 hour at 1150 DEG C; and in forging step, the bearing ring forged is at 930 to 980 DEG C; and in the quickly cooling step, the forged bearing ring is dipped into a cooling medium for being quickly cooled to reach 700 DEG C. According to the forging method, the cooling medium is water; the quick cooling is carried out for 7 to 18 seconds; the heating is carried out for 4 to 7 seconds; and the temperature raising time is 2 to 3 seconds; and the forging is carried out for 4 to 7 seconds. With the adoption of the forging method, spherical, small and uniformly distributed quenching structures of carbide can be obtained, and the dimension of carbide particle is not greater than 5 um to the maximum, thus reaching the value below the critical value of cracking initiated by amorphous impurity; and the contact fatigue life of a bearing is prolonged.

Owner:DEQING TIANMA BEARING CO LTD

A continuous and rapid preparation device for semi-solid slurry of automobile aluminum alloy wheels

A device for continuous and rapid preparation of semi-solid slurry for aluminum alloy wheels of automobiles. Stirring equipment and die-casting machine (or die forging machine) are distributed around the circle centered on the intelligent power-assist arm. In the material chamber, take a certain amount of aluminum liquid by leaving aside the oxide film on the liquid surface, then transfer it to the bottom of the graphite tube of the slurry rapid stirring device, insert the graphite tube into the slurry in the central area of the slurry transfer crucible, and turn on the electromagnetic stirrer in the graphite tube Electromagnetic stirring is performed with the electromagnetic stirrer on the periphery of the slurry transfer crucible, and the stirred slurry is quickly transferred to the die-casting machine (or die forging machine) for production. The technical solution can realize the continuous and rapid preparation and transfer of semi-solid slurry, and the quality of the slurry is stable, which is of great significance for the semi-solid production of automobile aluminum alloy wheels.

Owner:JIANGSU KAITE AUTO PARTS

6 series low alloy composition with high long-term thermal stability and preparation method thereof

Owner:CHINA ZHONGWANG

Process method capable of improving thermal fatigue property of polynary zinc-aluminum alloy

Owner:ZHENJIANG YINUOWEI SHAPE MEMORY ALLOYS

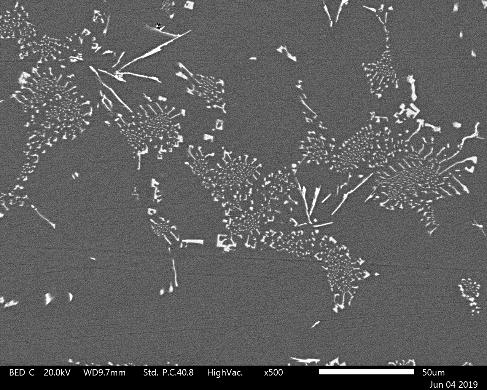

A kind of copper-iron master alloy with uniform composition and preparation method thereof

The invention belongs to the technical field of nonferrous metal smelting, and relates to a copper-iron master alloy with uniform composition and a preparation method thereof. The present invention changes the surface energy between the two phases of copper and iron by adding impurity elements Ti, P, Zr, Mg to offset the excess Gibbs free energy, and then blows oxygen to the melt to make Ti, P, Zr, Mg, etc. Oxidation of elements, and then removal by slagging, not only improves the wettability between the copper and iron phases, but also ensures the purity of the copper-iron master alloy. The copper-iron master alloy of the present invention can be prepared in a non-vacuum environment, the preparation cost is low, and the production efficiency is high. The prepared copper-iron master alloy has no pores, uniform composition, and no separation of copper and iron. At the same time, the iron phase can be fine and uniform. distribution, the average size of the iron-rich phase is ≤30 μm.

Owner:NINGBO XINGYE SHENGTAI GROUP +1

An integrated heat treatment process combining homogenization and heating and aluminum alloy ingot casting

ActiveCN111020422BImprove pass rateImprove uniformityFurnace typesHeat treatment furnacesIngot castingGrain boundary

The invention provides an integrated heat treatment process combining homogenization and heating and aluminum alloy castings. The process is aimed at 8000 series aluminum alloys with high Fe element content, including a homogenization heat treatment process and a heating heat treatment process, which can promote the ingot microstructure The second phase containing Fe is diffusely distributed, discontinuously distributed in a rod shape at the grain boundary, and spherically dispersed in the grain, which improves the material properties. The aluminum alloy castings using this process are subsequently processed into mirror panels without streaks and pitting defects, with high gloss and reduced overall manufacturing costs, which are suitable for industrial production of high-end 8000 series mirror aluminum alloy sheets and strips.

Owner:中铝河南洛阳铝加工有限公司 +1

Ultra-high-strength aluminum alloy and its preparation method

The invention provides an ultrahigh-strength aluminum alloy, which comprises 3.0-10.0wt% of Cu, 2.0-9.7wt% of Mg, 1.7-38wt% of Zn, 0.1-1.3wt% of Nd, 0.05-2wt% of Ni, 0.05-1.77wt% of Mn, 0.01-0.5wt% ofT and the balance of Al. The invention also provides a preparation method of the ultrahigh-strength aluminum alloy. According to the preparation method provided by the invention, an aluminum alloy material is prepared by adopting a specific formula and a spray forming process, the micro-structure of the aluminum alloy material is obviously refined, and the precipitated phase is fine and uniformlydistributed, so that the mechanical property of the aluminum alloy material is hardly anisotropic, and the aluminum alloy material has the advantages of high strength, high toughness, high rigidity and light weight. Experimental results show that after T6 treatment, the tensile strength of the ultrahigh-strength aluminum alloy provided by the invention is higher than or equal to 917MPa, and the yield strength is higher than or equal to 874MPa.

Owner:薛元良

Preparation Technology of Hypoeutectic Al-Si Alloy Inoculated with High Entropy Alloy

ActiveCN109136599BImprove mechanical propertiesFine and evenly distributedSilicon alloyHigh entropy alloys

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

High temperature and abrasive-particle wear resistant build-up welding alloy material

InactiveCN1182269CExtended service lifeReduce distributionArc welding apparatusWelding/cutting media/materialsRare-earth elementWear resistant

The invention refers to a high temperature-resisting abrasion build-up welding alloy material, except Fe, C, it includes Cr, MKo, W, Nb, V high temperature strengthening elements, the alloy also includes boron and rare-earth element, the composition is: C 1-5, Cr 10-30, Mo 2-12, W 1-8, Nb 2-15, V 1-5, B 1-6, rare-earth 0.01-2, the other is Fe.

Owner:威海三盾焊接材料工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com