Patents

Literature

57results about How to "Fast cracking speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

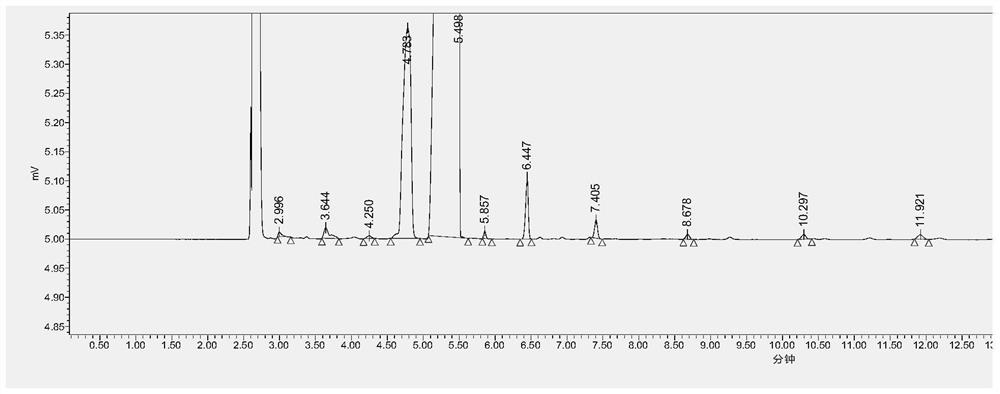

Real-time fluorescence quantification PCR method with magnetic bead nucleic acid extraction and amplification conducted in one tube

ActiveCN105420403ANucleic acid extraction effect optimizationFast cracking speedMicrobiological testing/measurementLAUROYL SARCOSINEPyrolysis

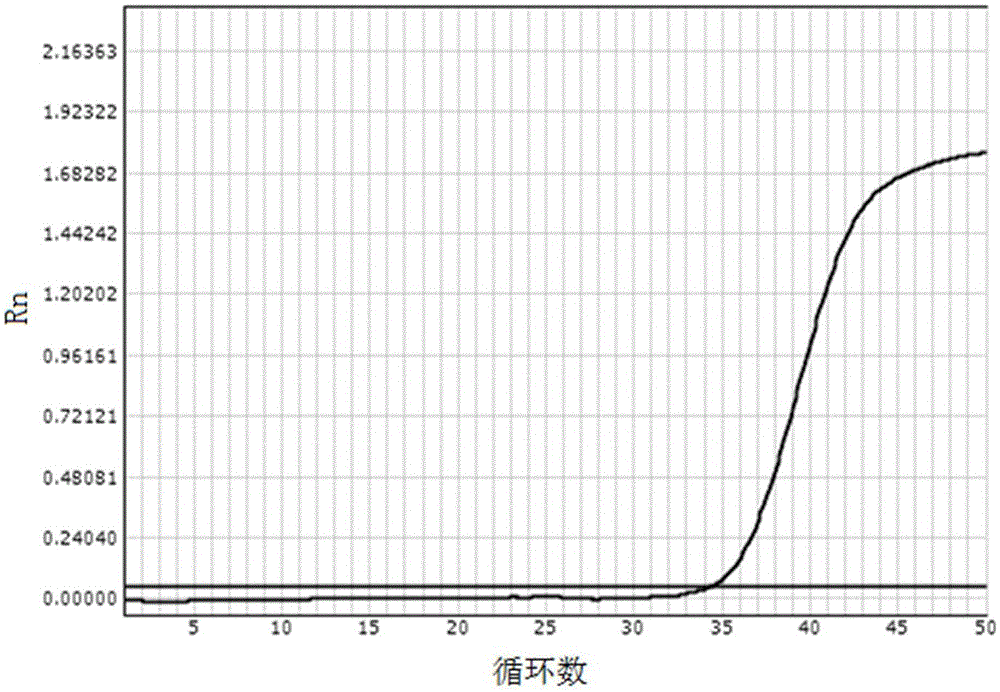

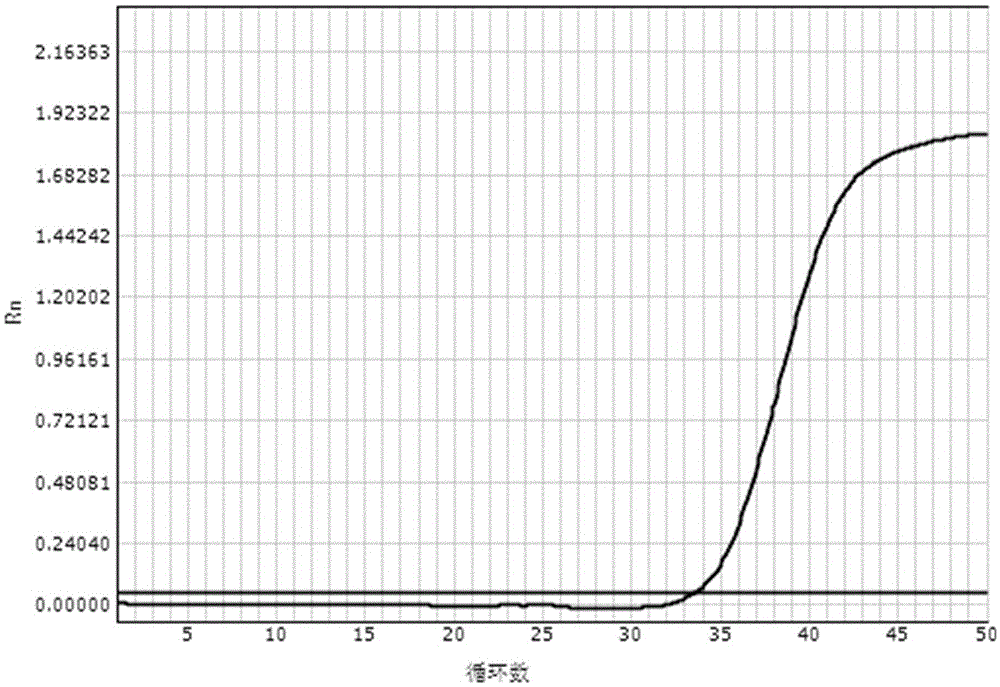

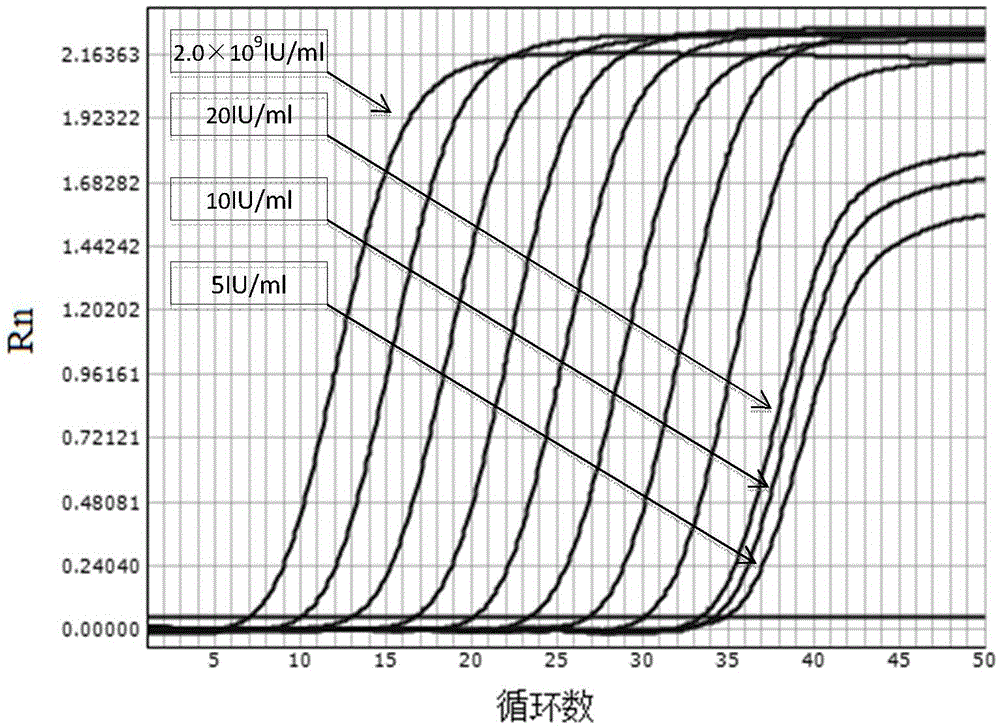

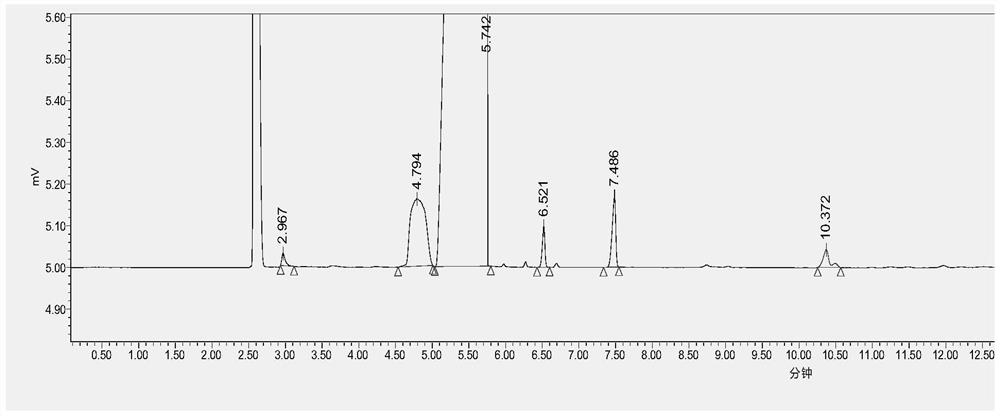

The invention provides a real-time fluorescence quantification PCR method with magnetic bead nucleic acid extraction and amplification conducted in one tube. A lysis solution mixed with magnetic beads and a sample to be detected are added to a PCR amplification tube, even mixing and standing are conducted, mixed liquor is extracted after magnetic extraction, and obtained magnetic beads are washed once; a well prepared PCR liquid is added into the PCR amplification tube for real-time fluorescence quantification PCR of target nucleic acid; the lysis solution is prepared from 0.2-0.4N sodium hydroxide, 0.3-0.6M potassium chloride, 0.01-0.05%N-sodium lauroyl sarcosine, 5mM EDTA, 0.3-0.6M Tris-HCL, and 1-2% Triton X-100. According to the method, heating is not needed, indoor-temperature pyrolysis is conducted for about 5-10 min only, static washing is needed only once, and then laboratory pollution and magnetic bead nucleic acid loss are reduced, pollution possibility brought by step-by-step operation is avoided and detection time is shortened. By taking HBV DNA quantification as an example, sensitivity can be as low as 5 IU / ML, and repeatability is high.

Owner:BEIJING NAGENE DIAGNOSTIC REAGENT CO LTD

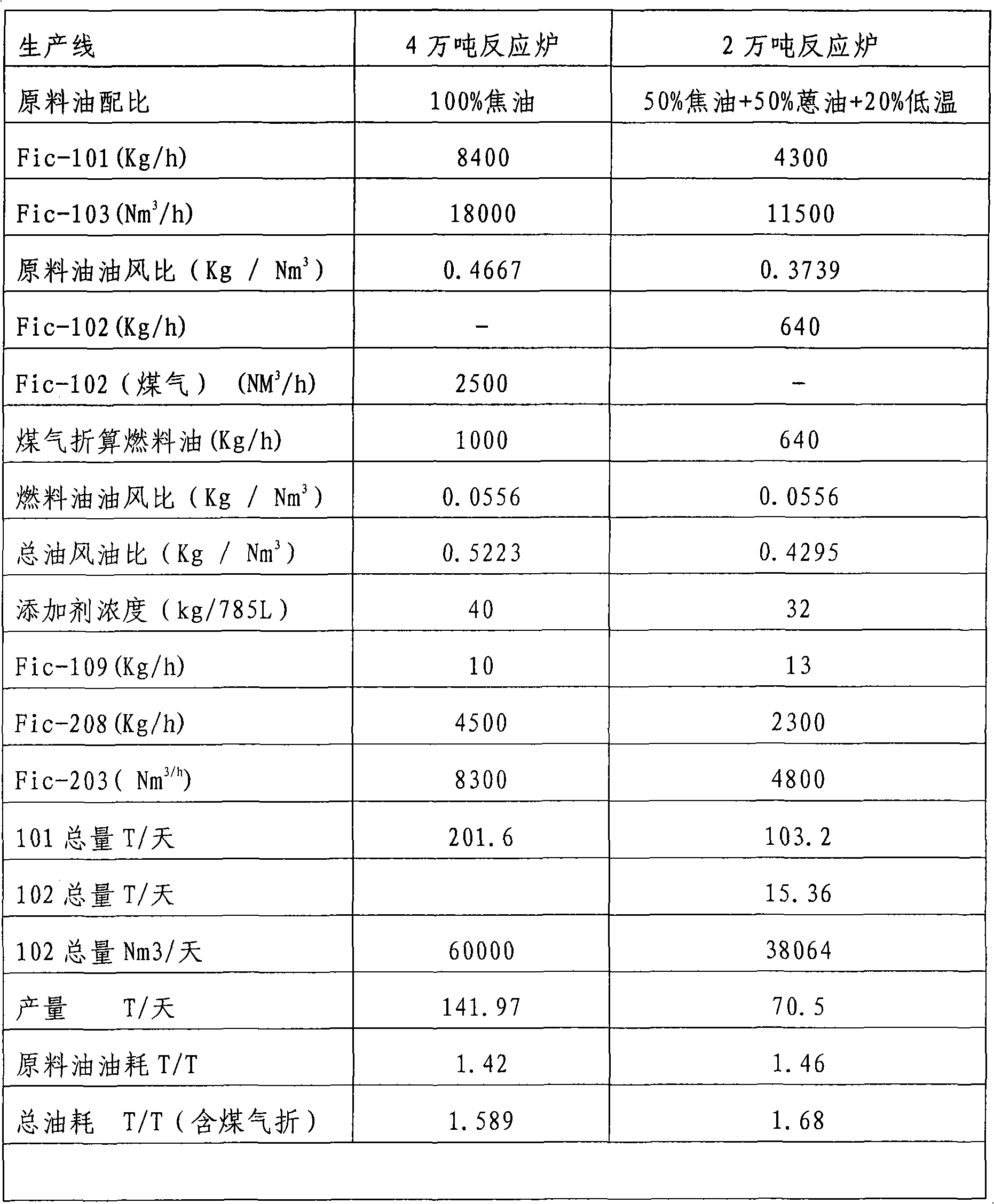

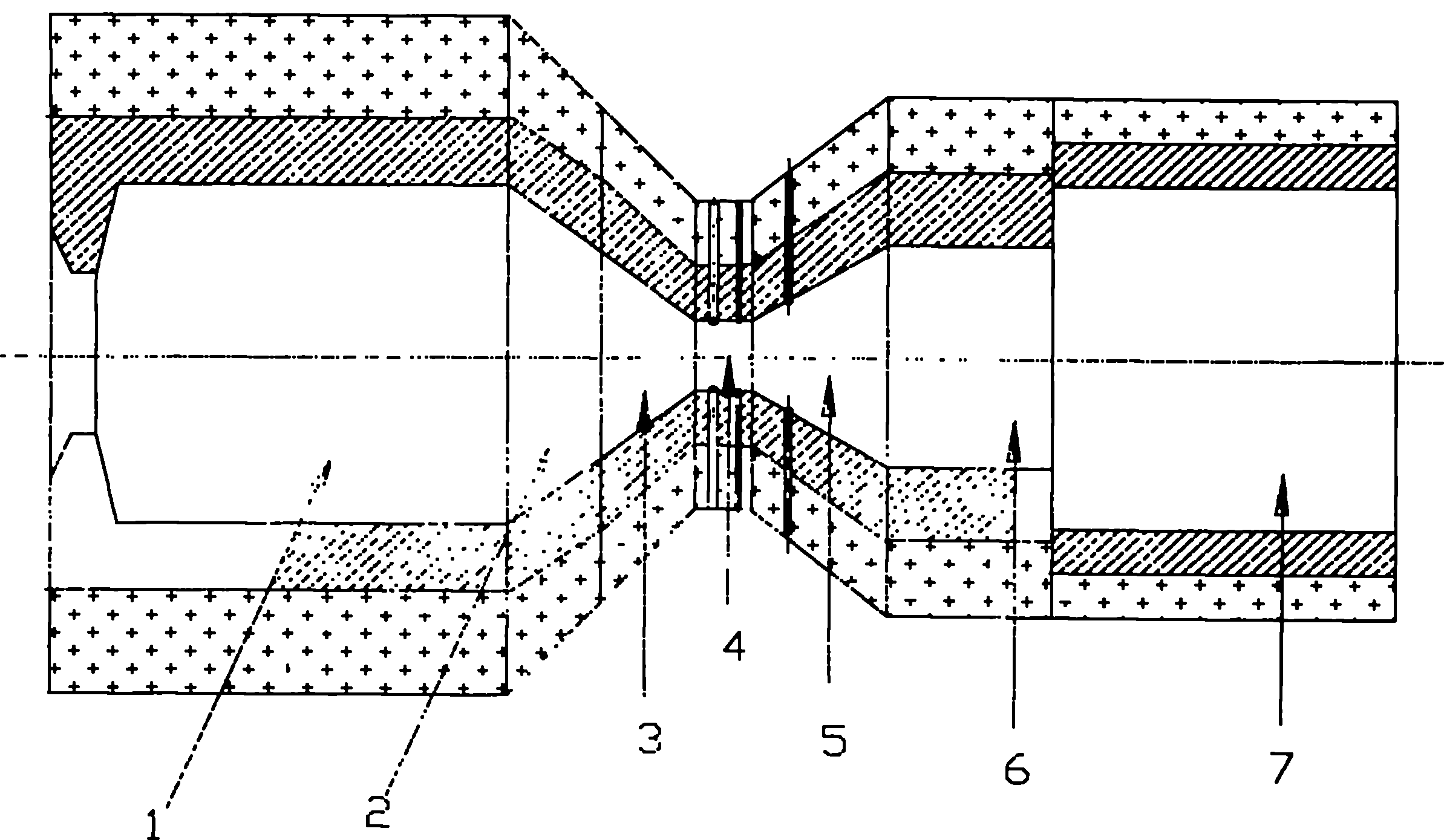

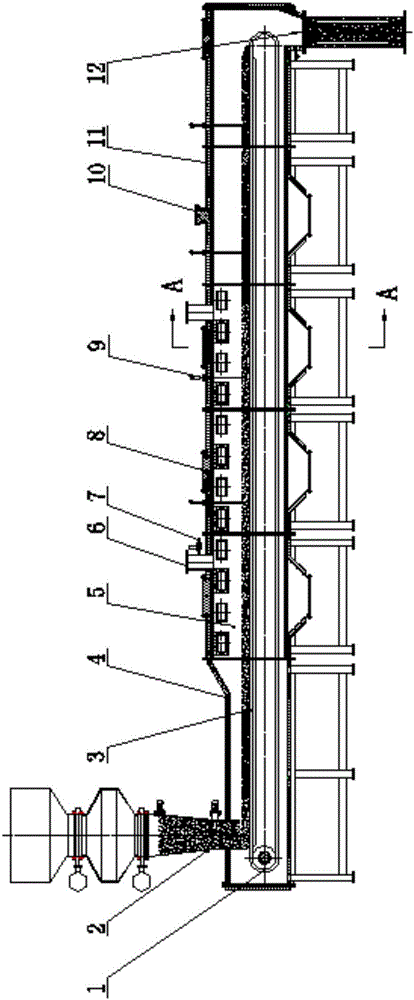

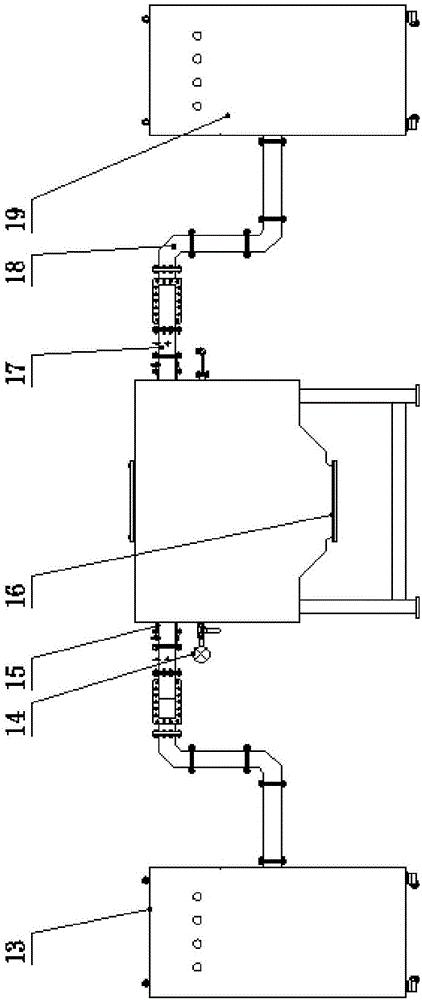

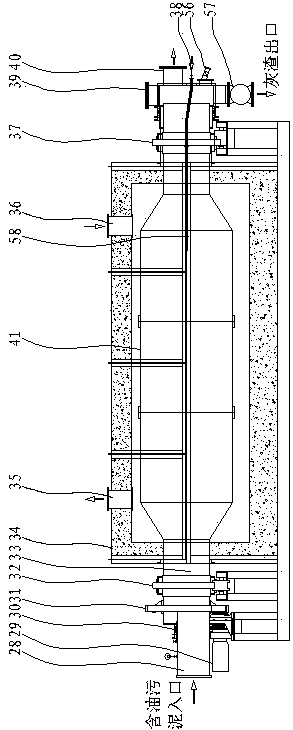

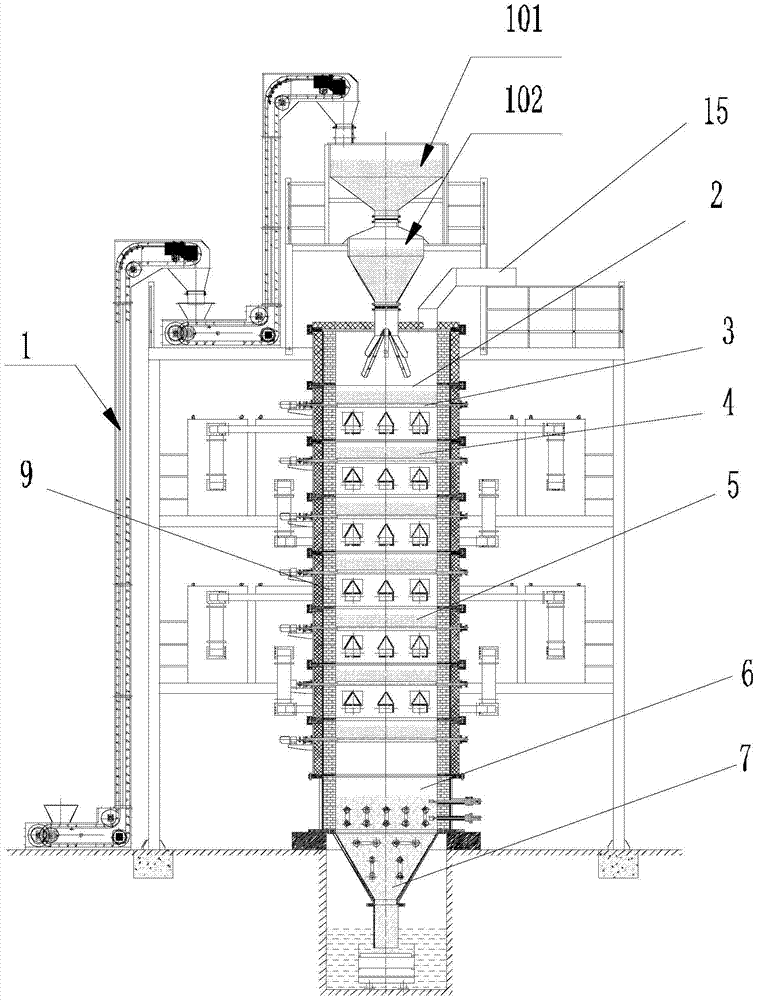

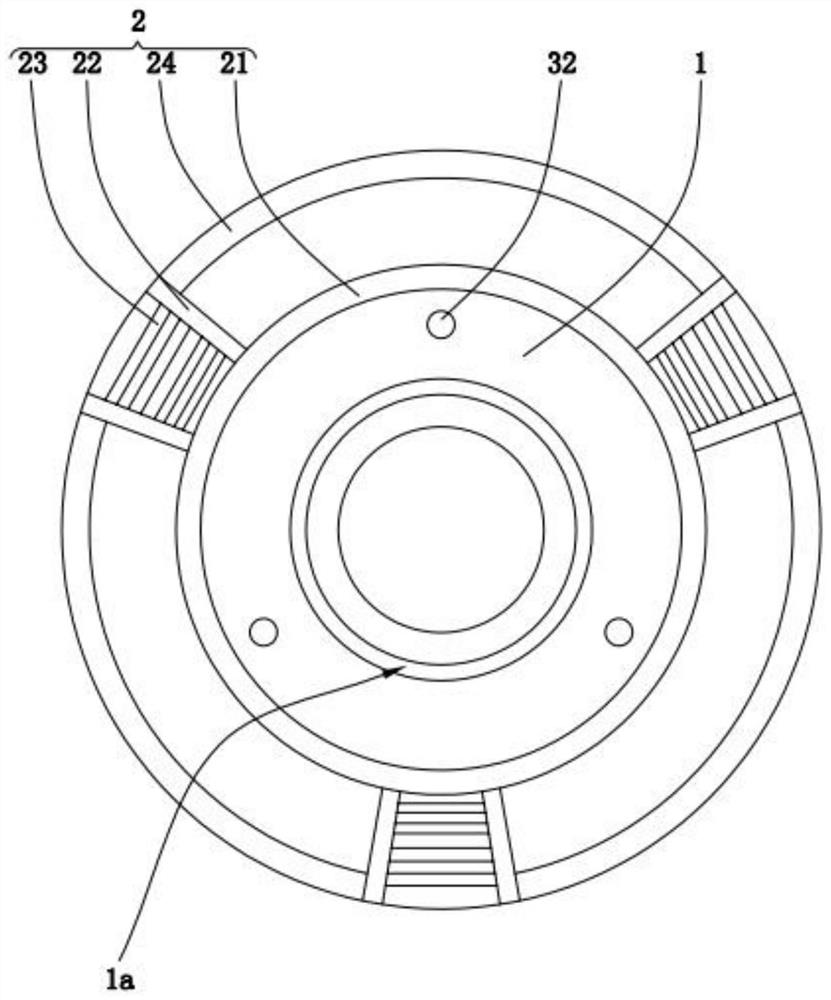

40-thousand-ton hard carbon black reaction furnace and production process of carbon black

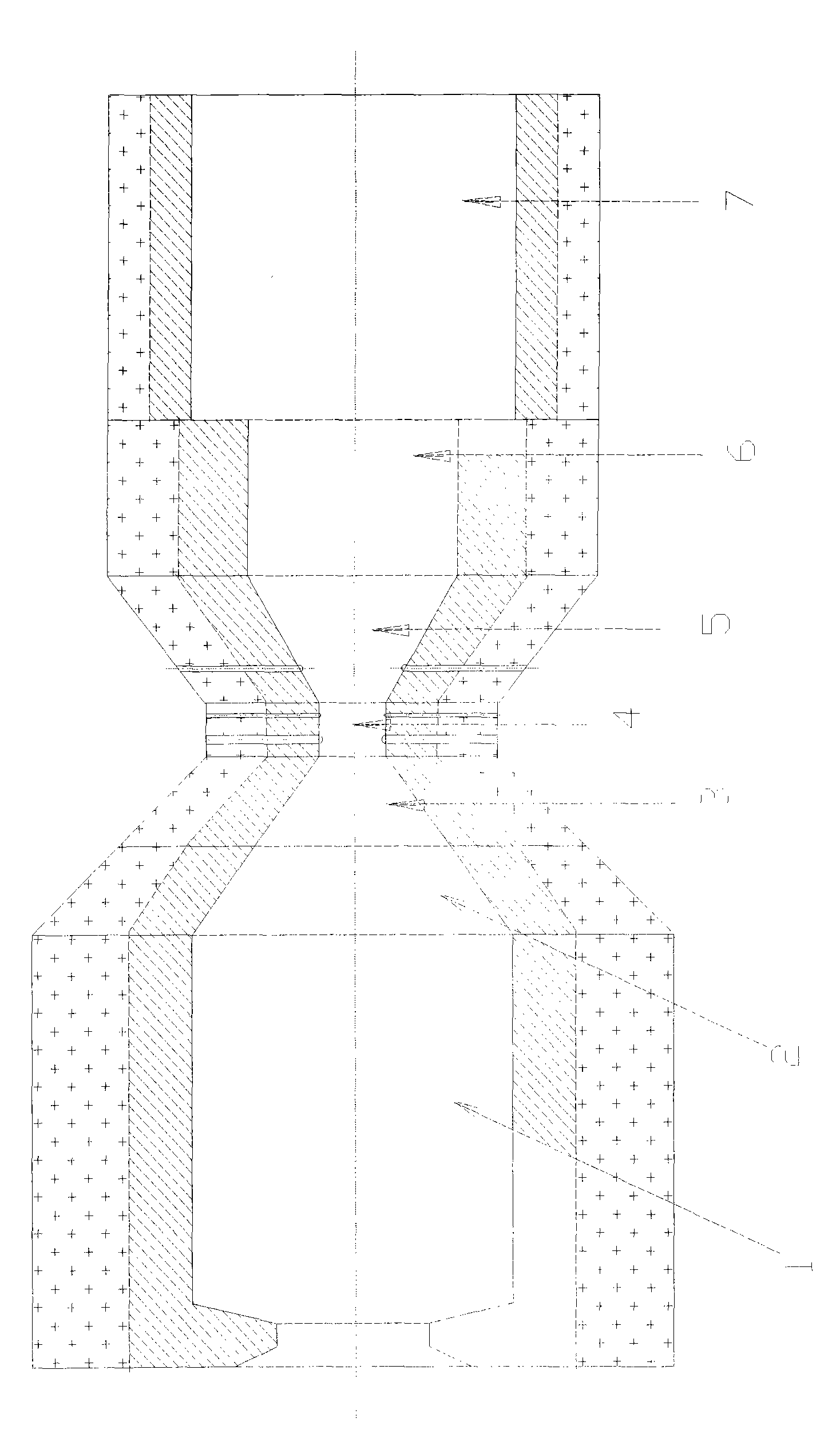

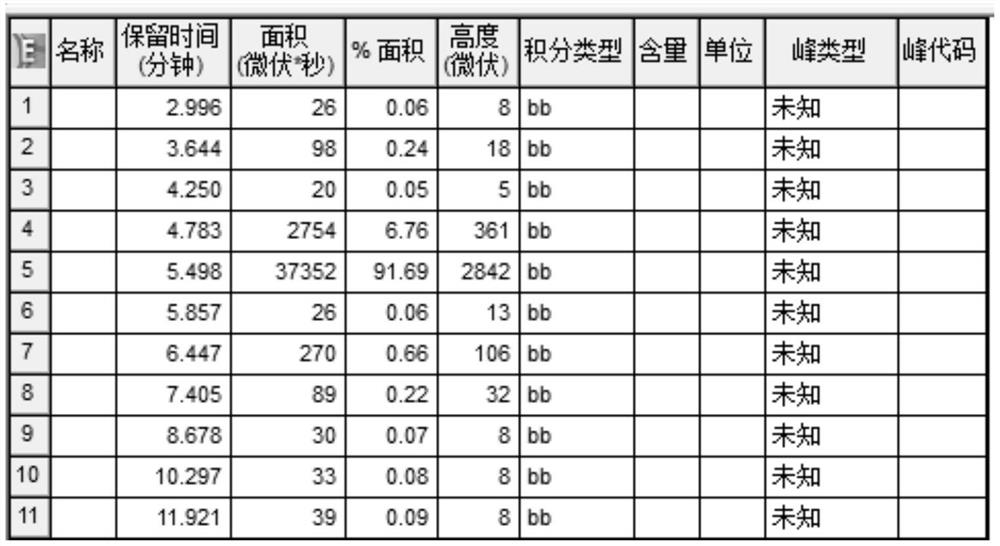

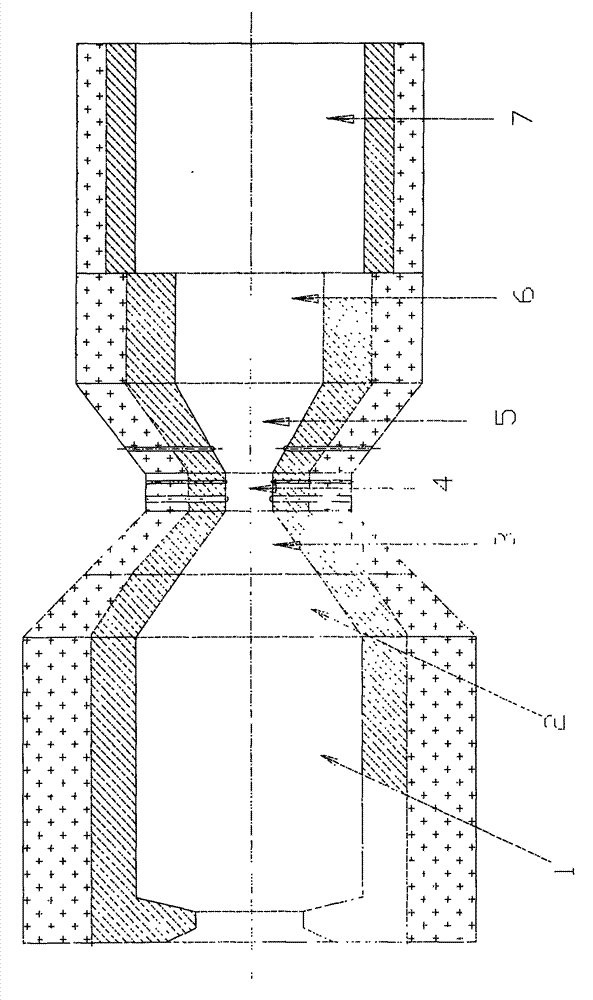

The invention discloses a 40-thousand-ton hard carbon black reaction furnace and a production process of carbon black. The carbon black reaction furnace comprises a combustion chamber, a venturi tube, a reaction chamber, and a quench zone. The uniquely designed combustion chamber of the reaction furnace ensures that the distribution of the temperature field of the carbon black production is more reasonable, the appropriate angle, length and inner diameter of the venturi tube ensure that raw oil is fully vaporized and sheared on the venturi tube part; and the reasonably designed reaction section and the matched quench zone ensure that the carbon black cracking reaction can be performed quickly, and the side reaction can be inhibited. Coal gas or natural gas is used as a fuel, the range of the raw oil is wider, the production capacity of the carbon black is high, unit consumption is low, a small amount of polluted product is discharged and the quality of the carbon black is high.

Owner:WUHAI BLACK CAT CARBON BLACK

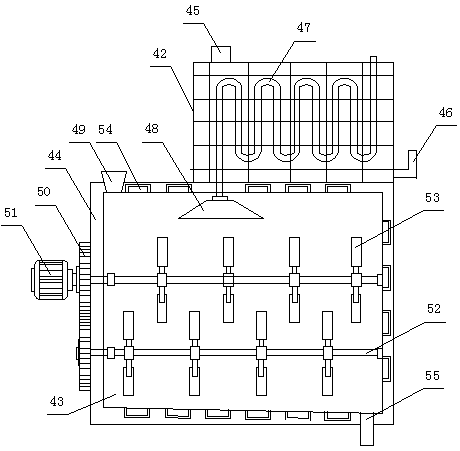

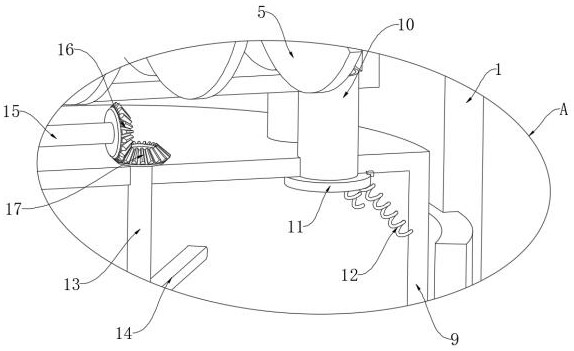

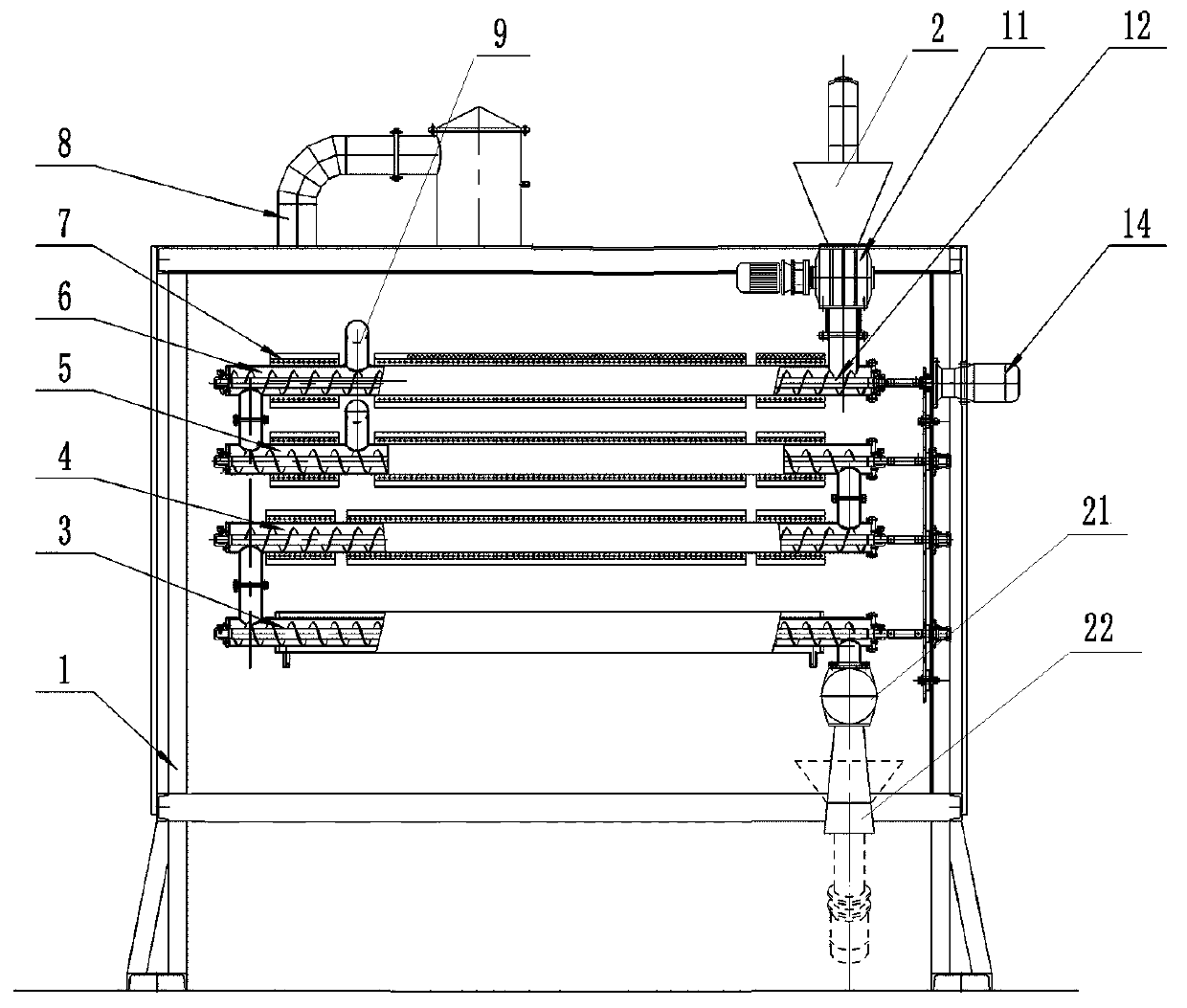

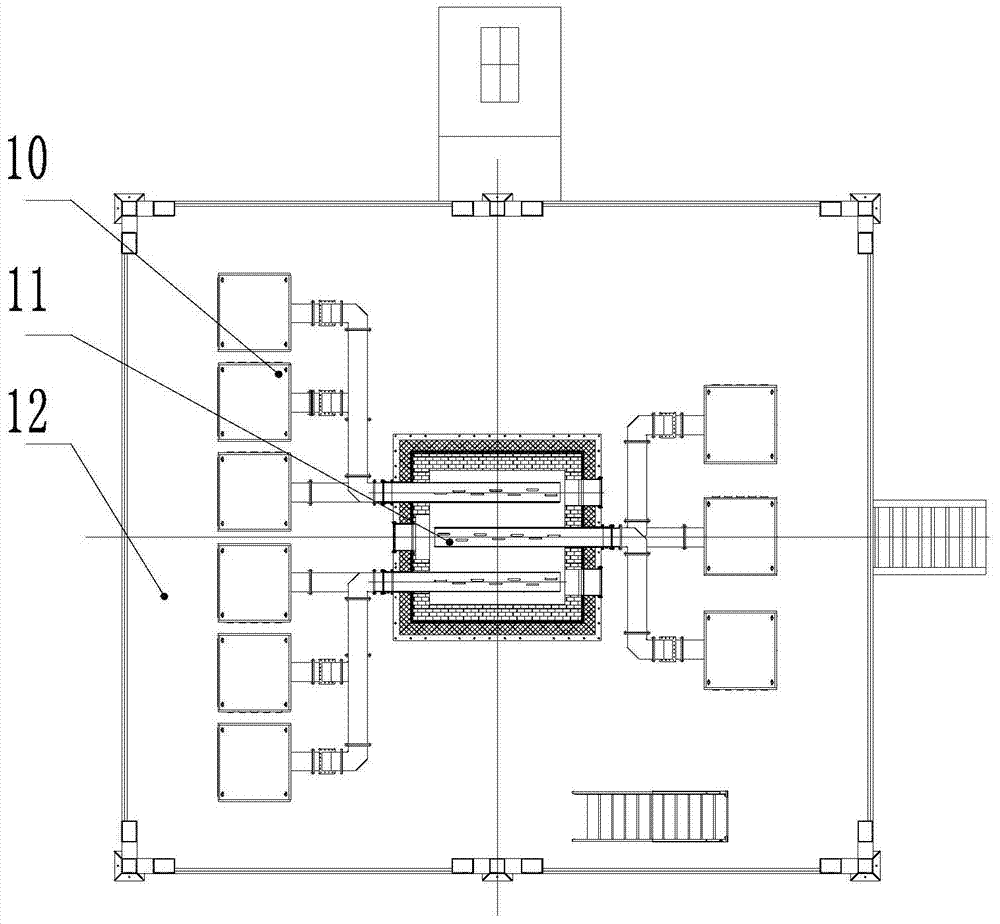

Horizontal microwave cracking furnace for solid organic matter

ActiveCN106147807AEasy to collectImprove qualitySpecial form destructive distillationMicrowave pyrolysisMicrowave oven

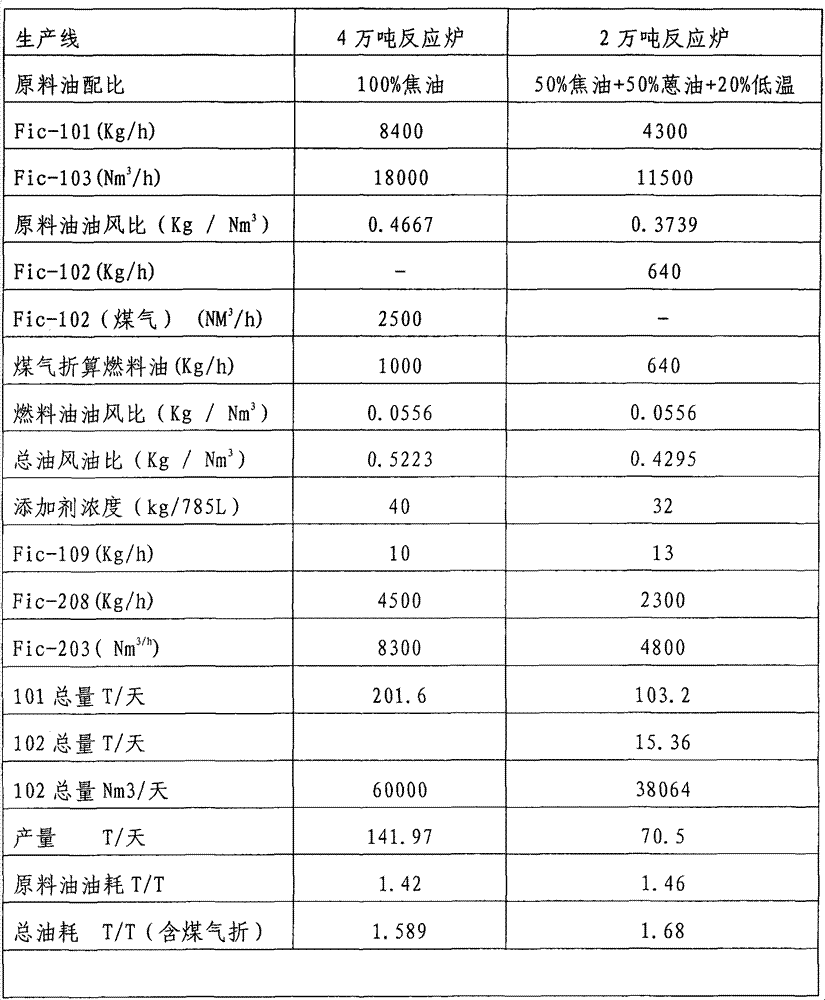

The invention discloses a horizontal microwave cracking furnace for solid organic matter. A furnace chamber formed by sequential butt joint of a feeding device (2), a feeding microwave inhibitor (4), a microwave oven (5), a discharging microwave inhibitor (11) and a discharging device (12) is installed on a machine frame (1), a conveyer (3) is installed in the furnace chamber and passes through the microwave oven (5), one end of the conveyer (3) is in butt joint with the feeding device (2), the other end of the conveyer (3) is in butt joint with the discharging device (12), and the center axis of a whole furnace body is placed horizontally. A microwave pyrolysis technique is adopted, and heating speed is high; due to the fact that microwave heating is integral heating, microwaves can directly act on medium molecules for heat energy conversion, the inside and outside of a material can be heated at the same time, and microwaves can penetrate through the material evenly no matter the shape of the material; meanwhile, based on microwave non-thermal catalytic effect, cracking speed is high, cracking is thorough, the quality of obtained products is high, energy can be saved greatly, and control is easy; besides, microwave energy is transmitted in an airtight chamber made of metal and a waveguide tube, so that leakage and emission of harmful gases are avoided, and safety performance is quite high.

Owner:湖南省中晟热能科技有限公司

Recovery method of silicone rubber

InactiveCN103626796AEvenly heatedIncrease heat transfer rateSilicon organic compoundsRecovery methodCircular economy

The invention relates to a recovery method of silicone rubber by alkali solvent cracking. In a high temperature resistant inert solvent medium, an alkaline compound is employed to carry on cracking on silicone rubber. The cracking products are subjected to separation and purification to obtain organic siloxane ring monomers and silica. The method does not generate new wastes, and is consistent with the requirements of circular economy.

Owner:杨晓林

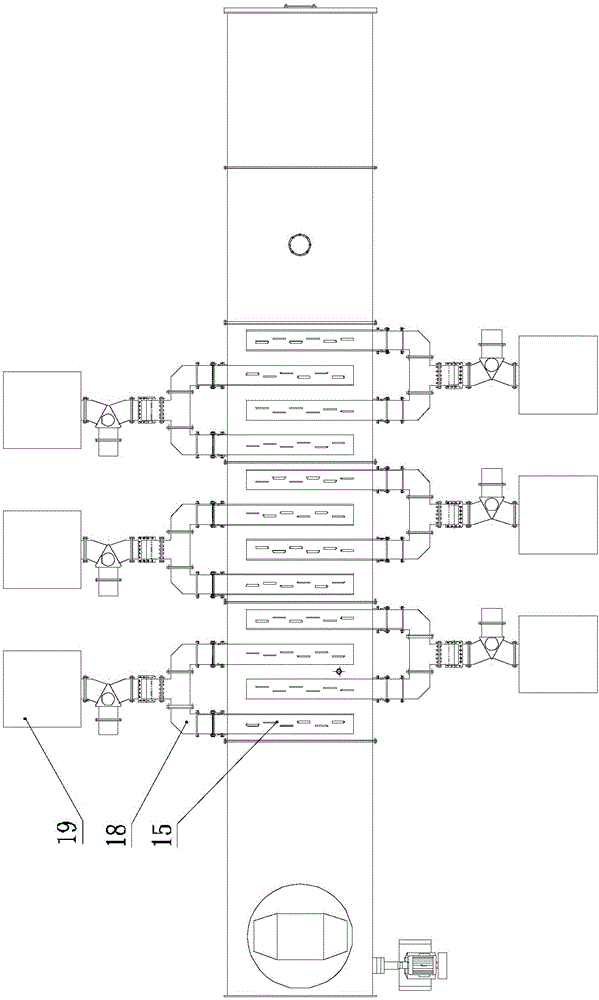

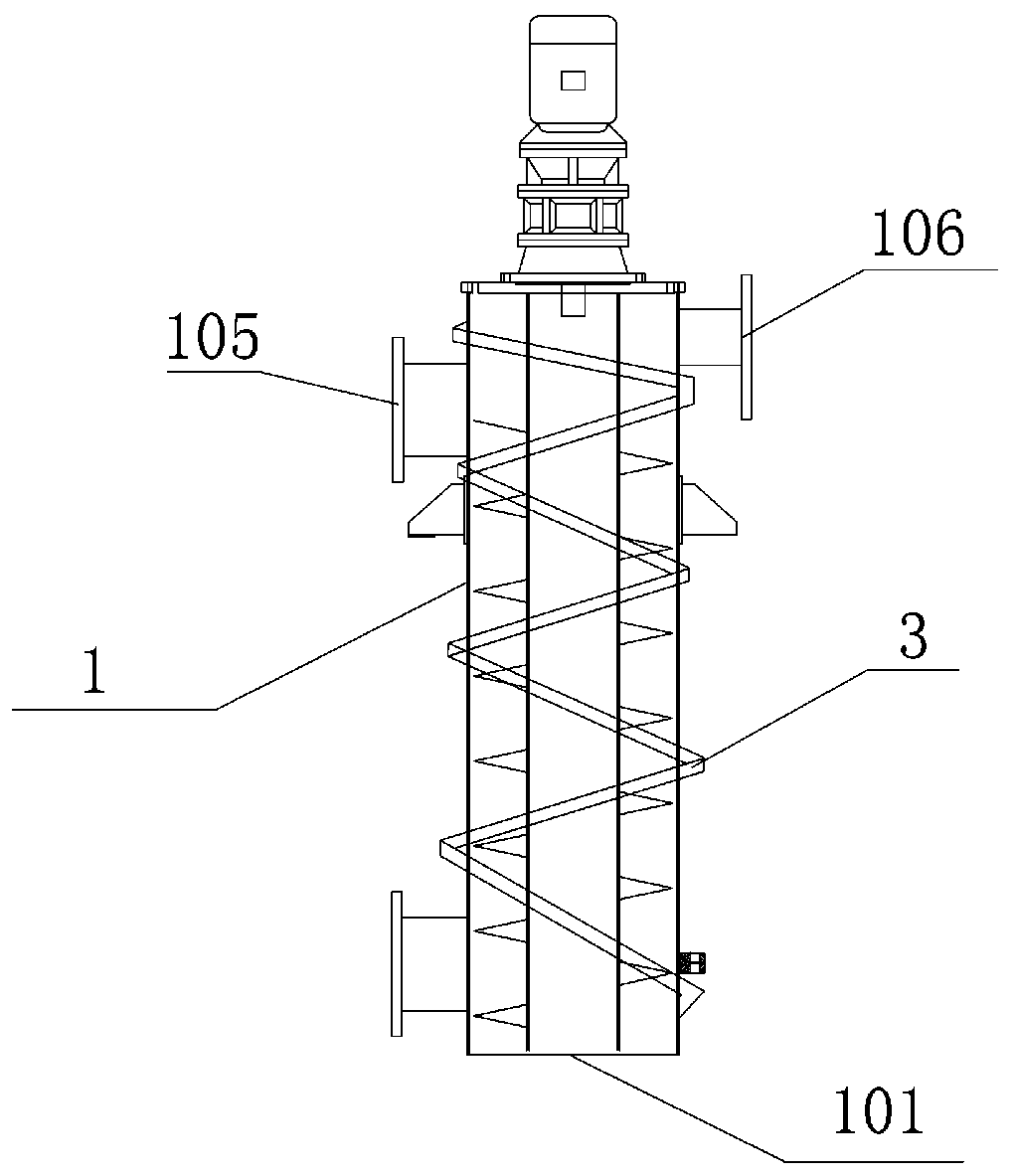

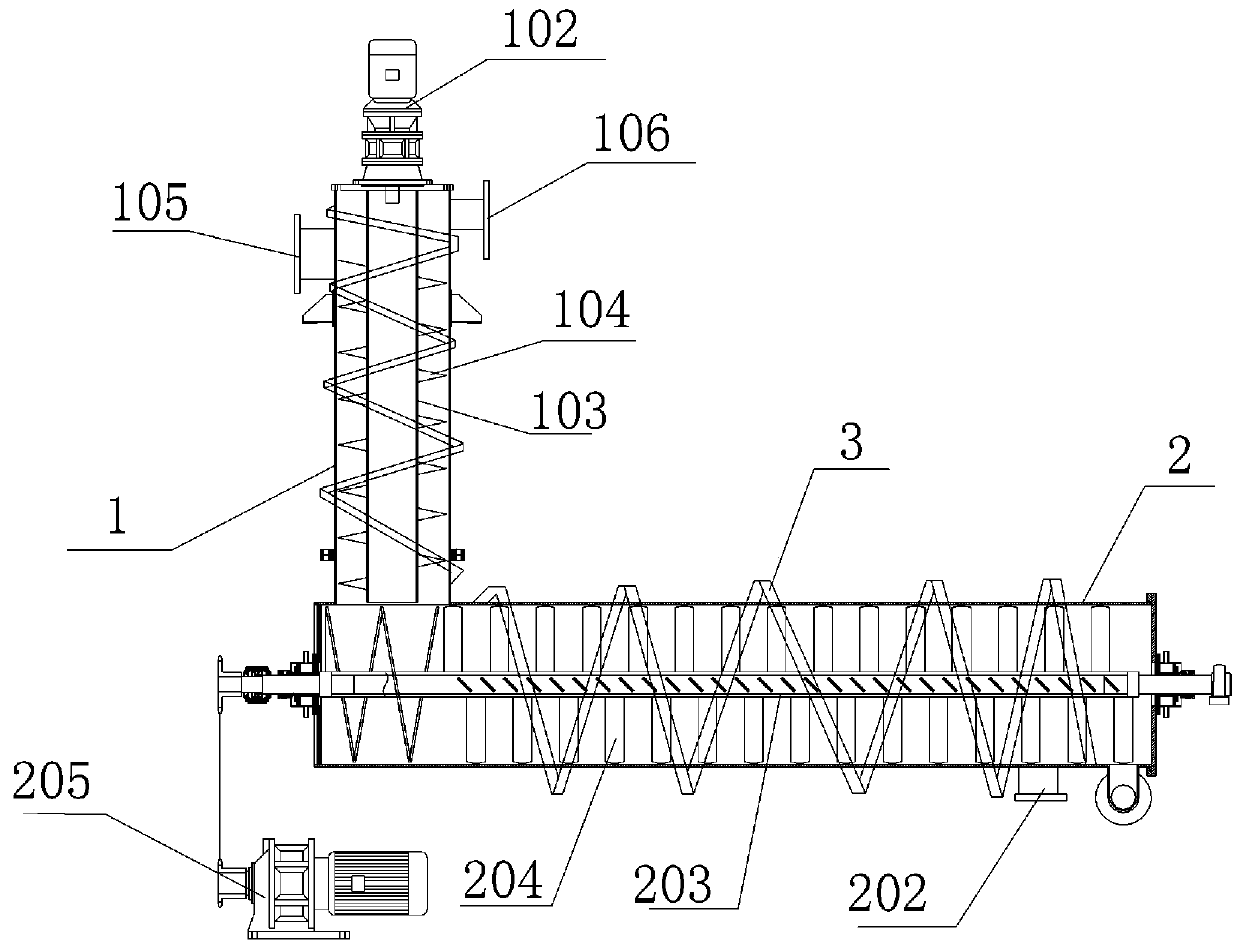

Oil sludge cracking device

ActiveCN108911458AIncrease the heat exchange areaFast cracking speedWater contaminantsSludge treatment by pyrolysisNational standardResidual oil

The invention belongs to the technical field of environmental protection, and particularly relates to an oil sludge cracking device. The oil sludge cracking device comprises an outer cylinder body andan inner cylinder body; a spiral conveyer belt is arranged on the inner wall of the inner cylinder body; and heat conduction pipes are arranged on the spiral conveyer belt. Through the adoption of the device provided by the invention, the heat exchange area in an oil sludge cracking process is enlarged, and the heat exchange efficiency is improved, so that the utilization rate of heat is greatlyimproved. The cracking speed of the oil sludge is increased at a relatively low temperature, oil in the oil sludge is fully recycled, and the amount of residual oil in treated soil reaches the national standard, so that treatment and application of reduction, harmlessness and reclamation of oil sludge are realized, no secondary pollution is generated, and the device is economical, is friendly to the environment and is safe.

Owner:NIUTECH ENVIRONMENT TECHNOLOGY CORPORATION

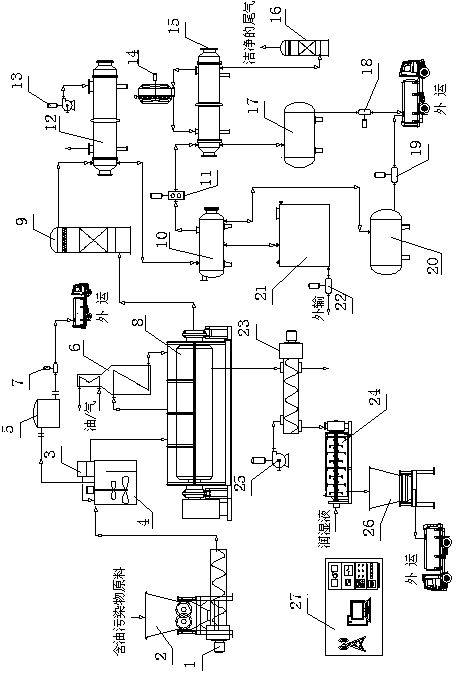

Oil-containing pollutant treatment method performing indirect heating using heat-conducting oil and device thereof

PendingCN108531207AAchieve ultra-clean treatmentAvoid cokingSolid waste disposalTransportation and packagingBrickHeat conducting

The invention provides an oil-containing pollutant treatment method performing indirect heating using heat-conducting oil and a device thereof, and relates to the technical field of oil-containing pollutant treatment technologies. The method comprises five steps of breaking, hot washing, thermal desorption, oil-gas treating and ash treating. Breaking and hot washing are firstly conducted on oil-containing pollutants, then thermal desorption is conducted on solid pollutants on which initial oil removing is conducted, heat exchange is conducted by a thermal desorption device using the heat-conducting oil used for heating a heating furnace as a medium to heat the oil-containing pollutants in the absence of oxygen, the pollutants are volatilized or separated from pollution mediums, and the ultra-clean treatment of the oil-containing pollutants is achieved; wasted oil and residual of the device can be adopted as raw materials of the heating furnace to reduce operation cost; oil and gas treated by the thermal desorption device enter a subsequent gas treating system to further perform condensing, filtering and separating, atomizing condensing crystallizing processing is conducted on treated ashes, the ashes can be adopted as excellent raw material of construction materials such as floor bricks, hollow bricks and the like, and solid particle and dust pollution is avoided.

Owner:大庆百世环保科技开发有限公司

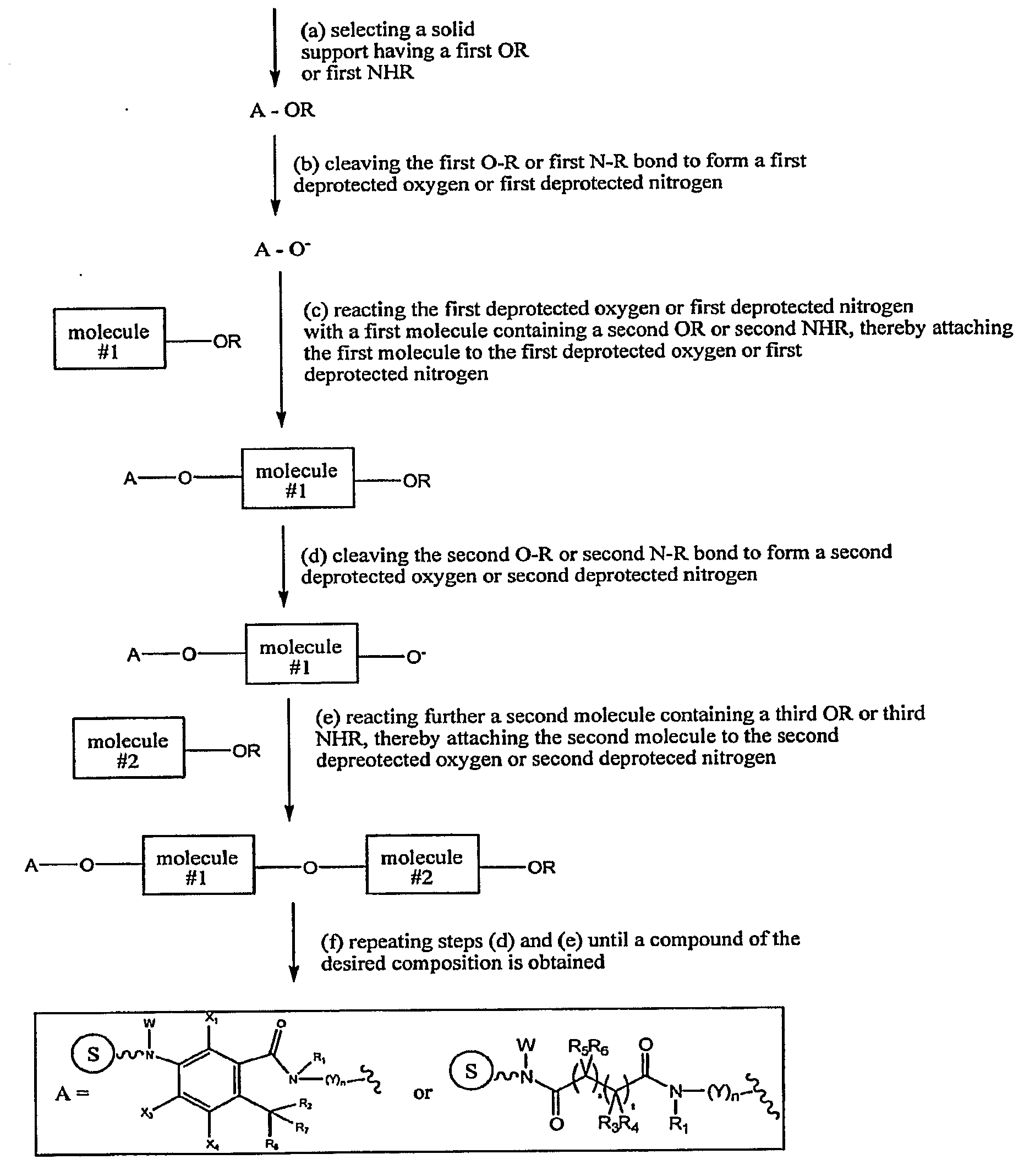

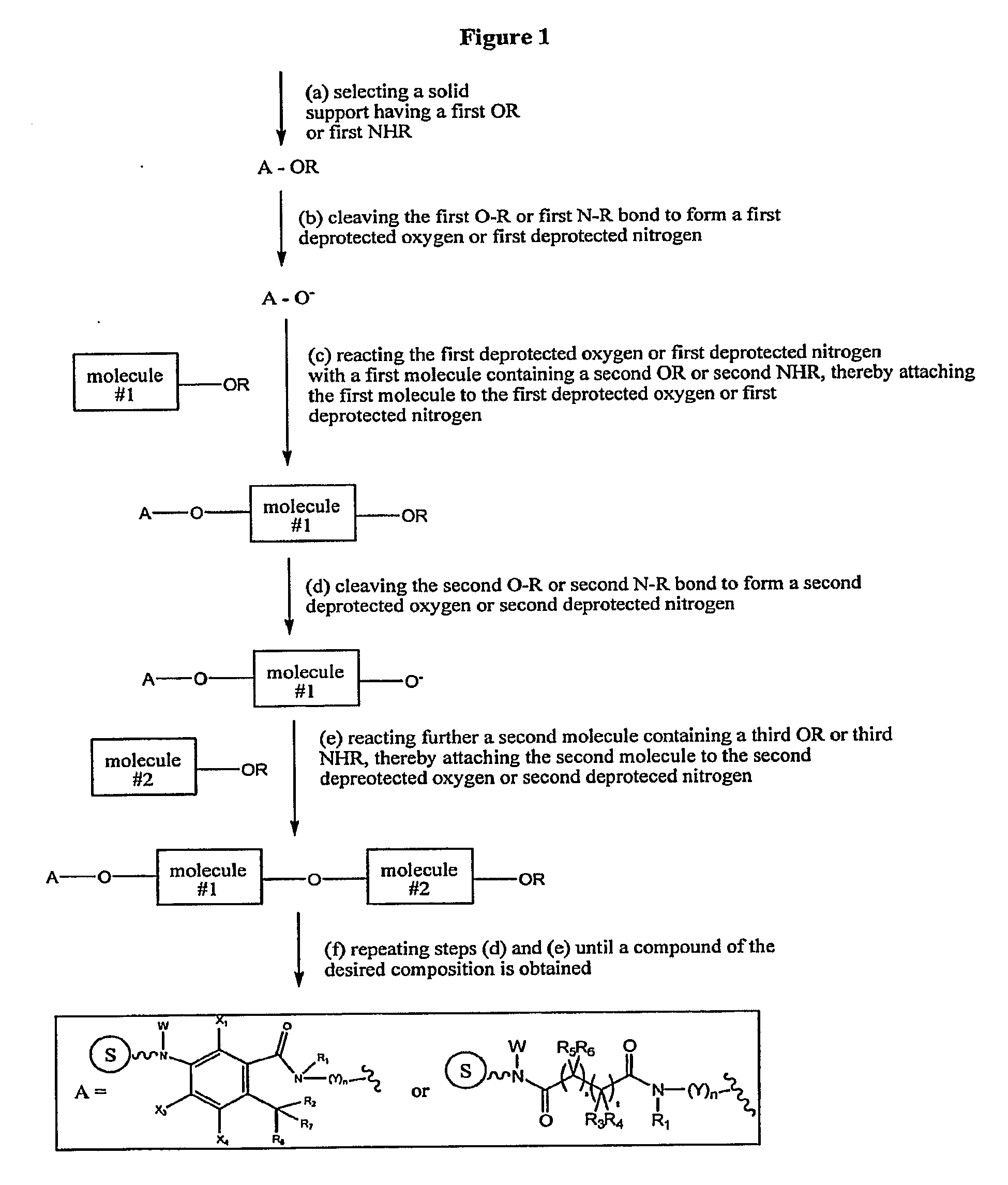

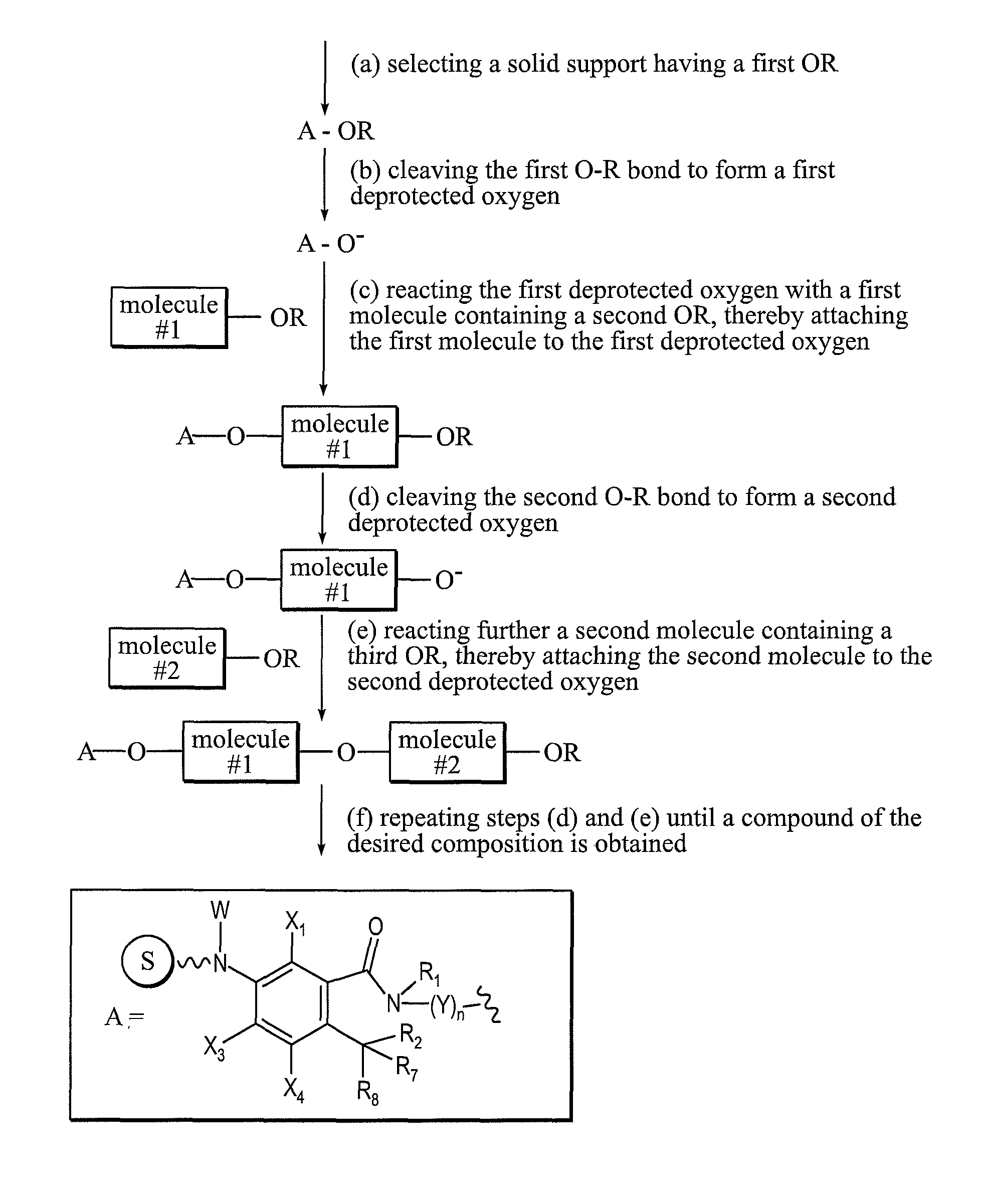

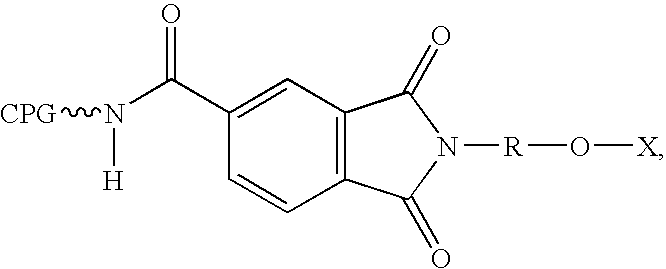

Solid Support Reagents for Synthesis

InactiveUS20100041866A1Adequate compression strengthShort timeSugar derivativesPeptide/protein ingredientsHalogenMedicinal chemistry

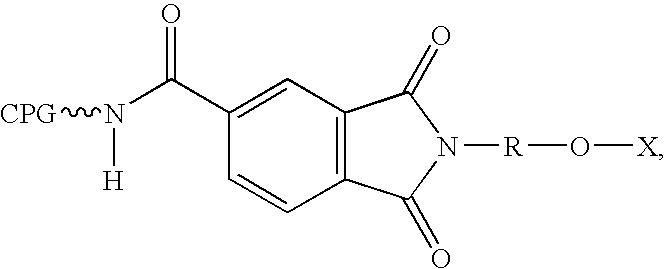

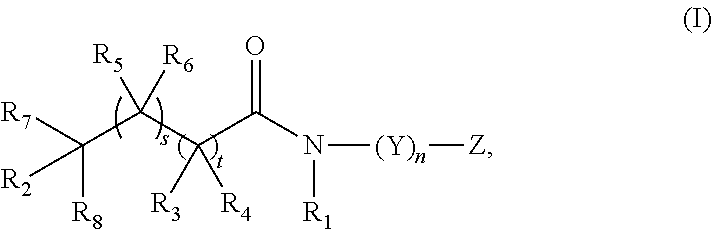

A compound which can be attached to a solid support and used as a reagent for methods of solid phase synthesis has the following structure: (I) where Ri is selected from hydrogen and C1-C6 alkyl; R2 is selected from hydrogen, hydroxy, and C1-C6 alkoxy, or together R1 and R2 form a single bond; R3, R4, R5 and R6 are the same or different from each other and each represents hydrogen, C1-C6 alkyl, and halogen, or together R3 and R4 with R5 and R6 form an aromatic ring, further wherein the aromatic ring is substituted with one or more X; X is selected from halogen, nitro, amino, and aminocarbonyl; s is 0, 1, 2, or 3, t is 0, 1, 2, or 3, wherein s+t≧1; R7 and R8 are the same or different from each other and each represents hydroxy, halogen, hydrogen, C1-C6 alkoxy, oxyacyl, or together R7 and R8 form a carbonyl; Y is selected from a methylene or substituted methylene, nucleoside, nucleotide, protected nucleoside, protected nucleotide, C1-C6 aryl, arylalkyl, heteroalkyl, heterocycle, and heteroaryl; n is 1, 2, 3, 4, 5, 6, 7, 8, 9, or 10; Z is selected from OR and NHR; R is selected from hydrogen, SiRa, RbRc, CRaRb, Rc, heteroalkyl, and C1-C6 alkyl; Ra, Rb, and Rc are the same as or different from each other and each represents methyl, ethyl, i-propyl, t-butyl, phenyl or substituted phenyl.

Owner:ARCHEMIX CORP

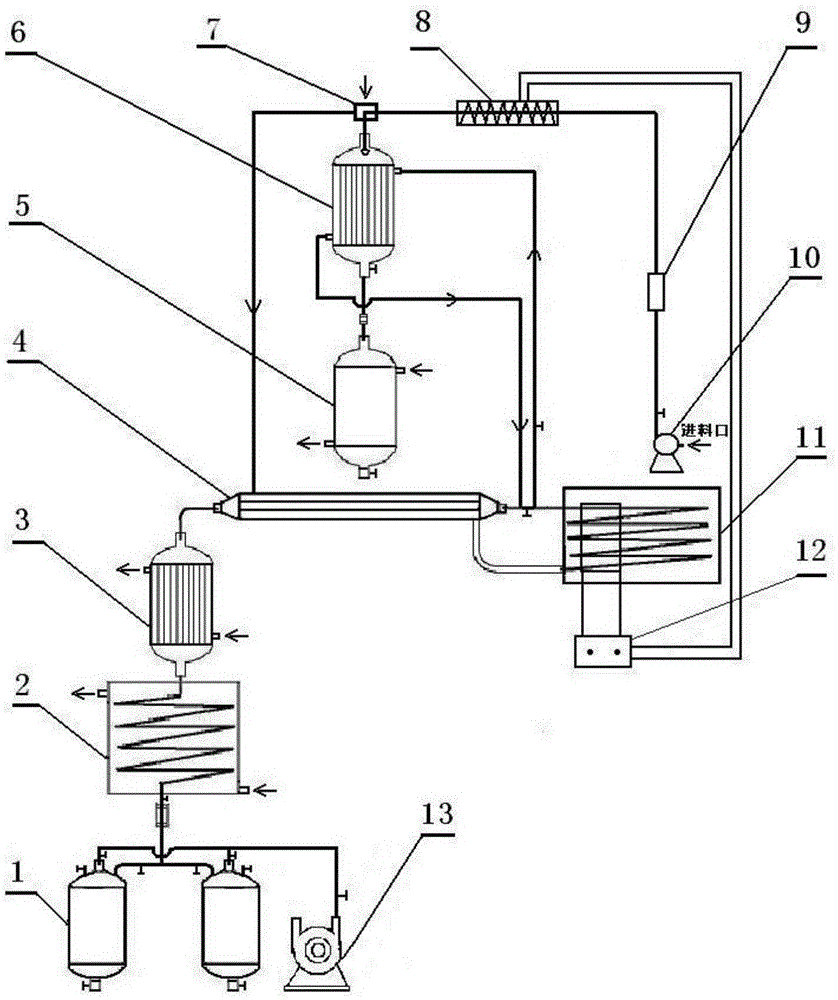

Apparatus for continuously cracking beta-pinene to produce laurene

ActiveCN105481632ASave energyRapid coolingHydrocarbon by isomerisationChemical industryEngineeringGuide tube

The invention discloses an apparatus for continuously cracking beta-pinene to produce laurene. The apparatus comprises a charging pump, a vaporizer, a cracker, a heat exchanger, a cooler and a product collector which are sequentially connected; the charging port of the charging pump is connected with a raw material tank, the discharging port of the charging pump is connected with the upper end of the vaporizer through a guide tube, a nonvolatile matter collector is connected below the vaporizer, a gas mixing chamber is arranged above the vaporizer, the heat conduction material inlet and the heat conduction material outlet of the vaporizer are respectively connected with an eduction tube in front of and behind the eduction tube valve of the cracker, the gas mixing chamber is connected with the heat conduction material inlet of the heat exchanger, the heat conduction material outlet of the heat exchanger is connected with the charging port of the cracker, the charging port of the heat exchanger is connected with the discharging port of the cracker through a valve, and the heat exchanger is connected with the product collector. The apparatus has the advantages of low energy consumption, high reaction efficiency, uniform heating, low cost, high laurene output and realization of continuous cracking production of laurene.

Owner:GUANGXI BEILIU ZHAOZHOU FOREST PROD

Sulfur-fixation, denitration and coke-cleaning additive for coal-fired boiler

InactiveCN107739642AImprove breathabilityAccelerated destructionSolid fuelsEmission standardRare earth

The invention discloses a coal-fired boiler sulfur-fixing, denitrification and coke-clearing additive, which is composed of the following raw materials in parts by weight: 8-20 parts of nano-titanium dioxide; 20-50 parts of natural marble; 1-6 parts of rare earth components; 20-20 parts of nitrate 30 parts; 3-10 parts of plant ash; 5-10 parts of activated carbon; each raw material in said parts by weight is stirred evenly and added to coal powder for further mixing. The invention can effectively reduce coal consumption, reduce sulfur dioxide emission rate and nitrogen oxide emission, and has coke cleaning effect, realize effective sulfur fixation, denitrification and coke cleaning, stable performance, high coal saving rate, high emission reduction rate, simple use and convenient application Advantages, what is more characteristic is that it overcomes the defects of traditional pulverized coal boilers relying on external exhaust pipes to implement flue gas desulfurization and denitrification equipment with large investment and poor results. The invention is combined with the traditional flue gas wet desulfurization and denitrification process, can effectively reduce the desulfurization and denitrification cost of enterprises, and fully complies with the national air pollution emission standards.

Owner:李旺

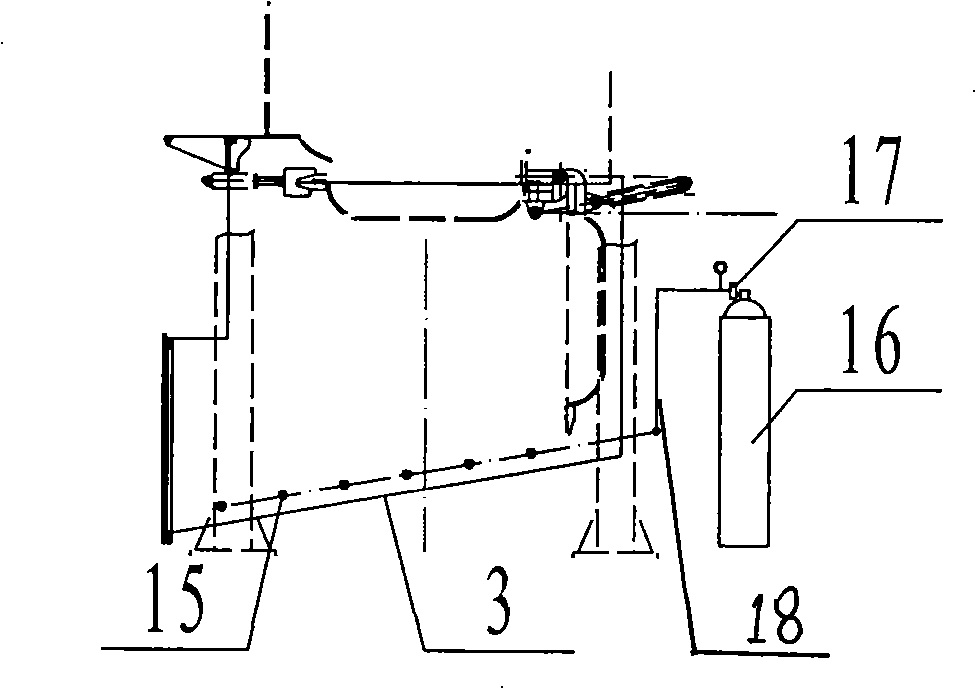

Gas-oil mixed pyrolysis furnace

InactiveCN101328417AEvenly heatedFully lysedPigmenting treatmentGaseous fuelsCombustorCombustion chamber

The invention relates to the scrap rubber cracking field, in particular to a gas-oil mixed cracking furnace for the scrap rubber, solving the problems during cracking in the prior art for the scrap rubber by a thermal cracking technology, such as insufficient and uneven heating, poor cooling effect for a lysate and so on. The gas-oil mixed cracking furnace comprises a cracking bin and a cooling bin, wherein the cracking bin is formed by a material cracking chamber and a combusting and heating chamber; a cracking gas internal circulation outlet pipe is arranged above the material cracking chamber, and is connected with an air inlet of a centrifugal fan; an air outlet of the centrifugal fan is connected with an air return pipe; the lower end of the air return pipe is connected with an air return hole; the bottom of the combusting and heating chamber is provided with a combustion chamber and a combustor; and a dry ice cooling jet orifice is arranged in the cooling bin. The gas-oil mixed cracking furnace for the scrap rubber adopts a cracking gas internal circulation heating system and a heating chamber externally enclosed heating mode to further heat a cracking material sufficiently and evenly without a dead area, so that the scrap rubber can be cracked more sufficiently and more quickly; the dry ice can quickly cool a cracked product with good effect; and the gas-oil mixed cracking furnace has the advantages of integrally sealed equipment, high energy utilization and high performance of the cracked product.

Owner:温小兵

Nano composite type coal-saving desulfurization and denitrification additive

InactiveCN103666634AReduce contentExtended active reaction temperature rangeSolid fuelsFiberWater dispersible

The invention discloses a nano composite type coal-saving desulfurization and denitrification additive and belongs to the environmental-friendly coal-saving field. The coal-saving desulfurization and denitrification additive is water dispersible solution and consists of solute and a solvent, wherein the solute comprises the following components in parts by weight: 15-45 parts of nano titanium dioxide, 2-8 parts of rare earth lanthanum and high-alumina bauxite, 1-3 parts of triethanolamine acetate, 25-35 parts of nitrate and 5-10 parts of active carbon fiber; the solvent is deionized water, and the mass percentage concentration of the coal-saving desulfurization and denitrification additive is 10-35%. The nano composite type coal-saving desulfurization and denitrification additive disclosed by the invention has the beneficial effects that the burning condition of coal can be effectively improved, the coal consumption can be reduced, and the emission of main pollutants such as SO2 and NOx is reduced, and also has the advantages of stable performance, convenience in storage, good coal-saving effect, obvious emission reduction, simple use and fast investment return and the like.

Owner:MAANSHAN CHINASEA NEW MATERIAL

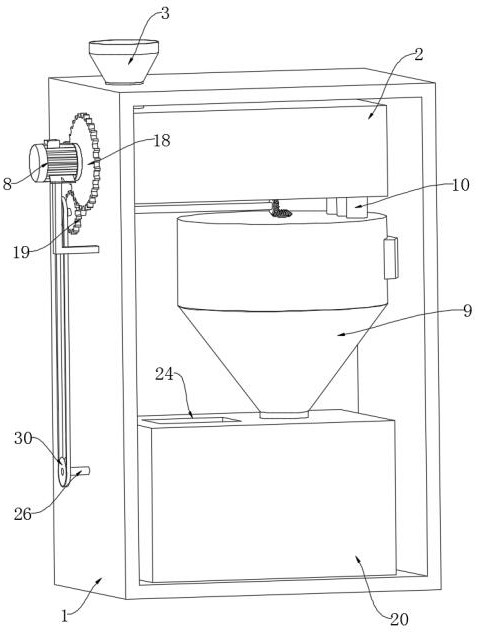

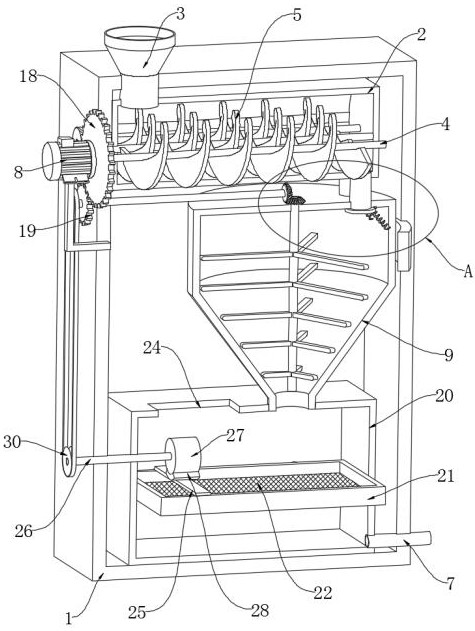

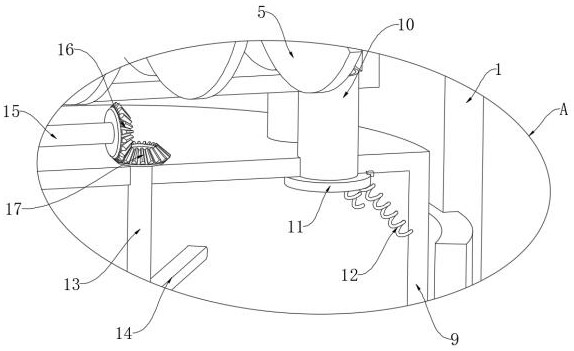

Waste rubber tire cracking and recycling equipment

ActiveCN113635488AFast cracking speedStir quicklyPlastic recyclingMechanical material recoveryWaste rubberElectric machinery

The invention discloses waste rubber tire cracking and recycling equipment. The waste rubber tire cracking and recycling equipment comprises a shell, a grinding mechanism for grinding tires is arranged in the shell and comprises a grinding box fixedly connected to the upper portion of the inner wall of the shell, a feeding pipe is fixedly connected to the top of the grinding box, multiple rotating shafts are rotatably connected to the inner wall of the grinding box, and spiral grinding blades are fixedly connected to the side walls of the multiple rotating shafts, every two adjacent spiral grinding blades are arranged in a staggered mode, one end of each rotating shaft penetrates through the grinding box and the side wall of the shell and the multiple rotating shafts are fixedly connected with multiple synchronous wheels, the multiple synchronous wheels are connected through a synchronous belt, and a motor is fixedly connected to the side wall of the shell through a support. The movable end of the motor is fixedly connected with one end of one rotating shaft. According to the waste rubber tire cracking and recycling equipment, grinding mechanism is arranged, so that multiple spiral grinding blades rotate, tires can be conveyed and crushed, and the tire cracking speed is increased.

Owner:江苏绿源橡胶资源循环利用创新中心有限公司

Solid support reagents for synthesis

InactiveUS8362234B2Short timeFast cracking speedSugar derivativesPeptide/protein ingredientsCombinatorial chemistrySolid-phase synthesis

The present invention relates to a compound according to the formula:wherein R1, R2, R3, R4, R5, R6, R7, R8, Y, Z, n, s, and t are as defined herein. These compounds are useful for methods of solid phase synthesis.

Owner:ARCHEMIX CORP

Preparation method of lactide

PendingCN114315788AIncrease the number ofIncrease the speed of crackingOrganic chemistryPolymer scienceLactide

The invention discloses a lactide preparation method which comprises the following steps: performing dehydration oligomerization on a lactic acid monomer, a polyethylene glycol polymer and polycarboxylic acid under the action of a catalyst to obtain hyperbranched oligomeric lactic acid, and then cracking to generate lactide. According to the process disclosed by the invention, the polyethylene glycol polymer and the polycarboxylic acid are added during lactic acid oligomerization to synthesize hyperbranched oligomeric lactic acid with a random structure, the number of terminal groups is increased, the cracking speed of the oligomeric lactic acid is increased, and meanwhile, due to the addition of the polyethylene glycol polymer, the viscosity of the oligomeric lactic acid can be reduced when the viscosity is relatively high in the later stage of dehydration; and the melting point of the polylactic acid with the random structure is low, so that the cracking temperature of the polylactic acid is reduced, the carbonization rate of the polylactic acid is reduced, the contact area of the polylactic acid can be increased, and the mass transfer and heat transfer efficiency of the polylactic acid is improved.

Owner:普立思生物科技有限公司

40-thousand-ton hard carbon black reaction furnace and production process of carbon black

ActiveCN102181178BHigh tinting strengthHigh strengthPigmenting treatmentCombustion chamberHeating furnace

The invention discloses a 40-thousand-ton hard carbon black reaction furnace and a production process of carbon black. The carbon black reaction furnace comprises a combustion chamber, a venturi tube, a reaction chamber, and a quench zone. The uniquely designed combustion chamber of the reaction furnace ensures that the distribution of the temperature field of the carbon black production is more reasonable, the appropriate angle, length and inner diameter of the venturi tube ensure that raw oil is fully vaporized and sheared on the venturi tube part; and the reasonably designed reaction section and the matched quench zone ensure that the carbon black cracking reaction can be performed quickly, and the side reaction can be inhibited. Coal gas or natural gas is used as a fuel, the range of the raw oil is wider, the production capacity of the carbon black is high, unit consumption is low, a small amount of polluted product is discharged and the quality of the carbon black is high.

Owner:WUHAI BLACK CAT CARBON BLACK

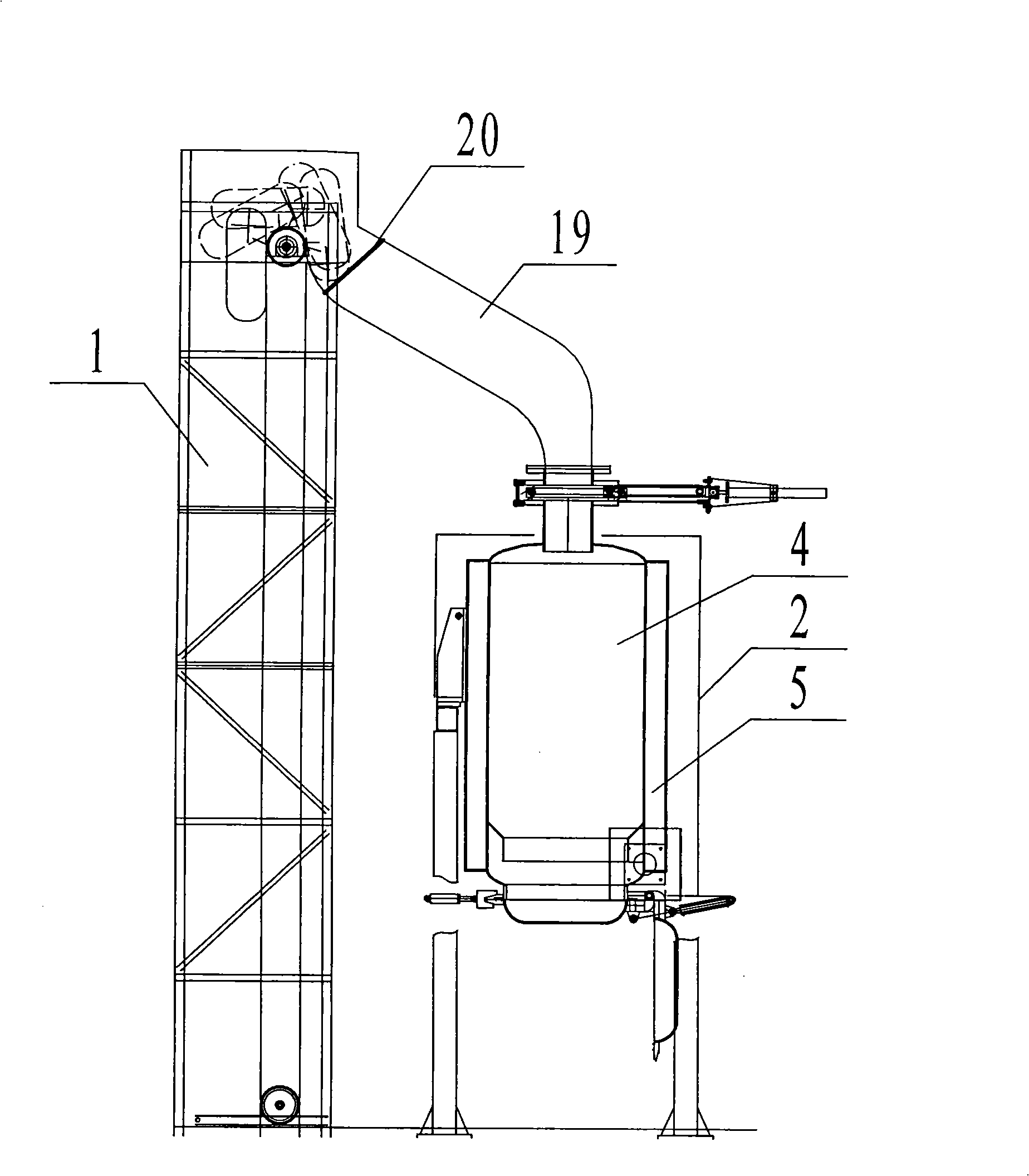

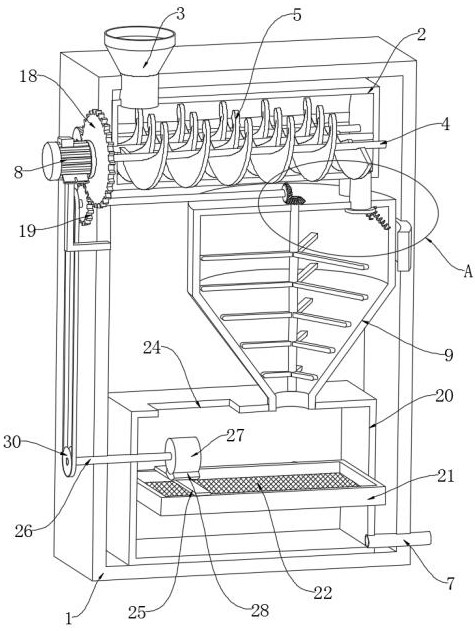

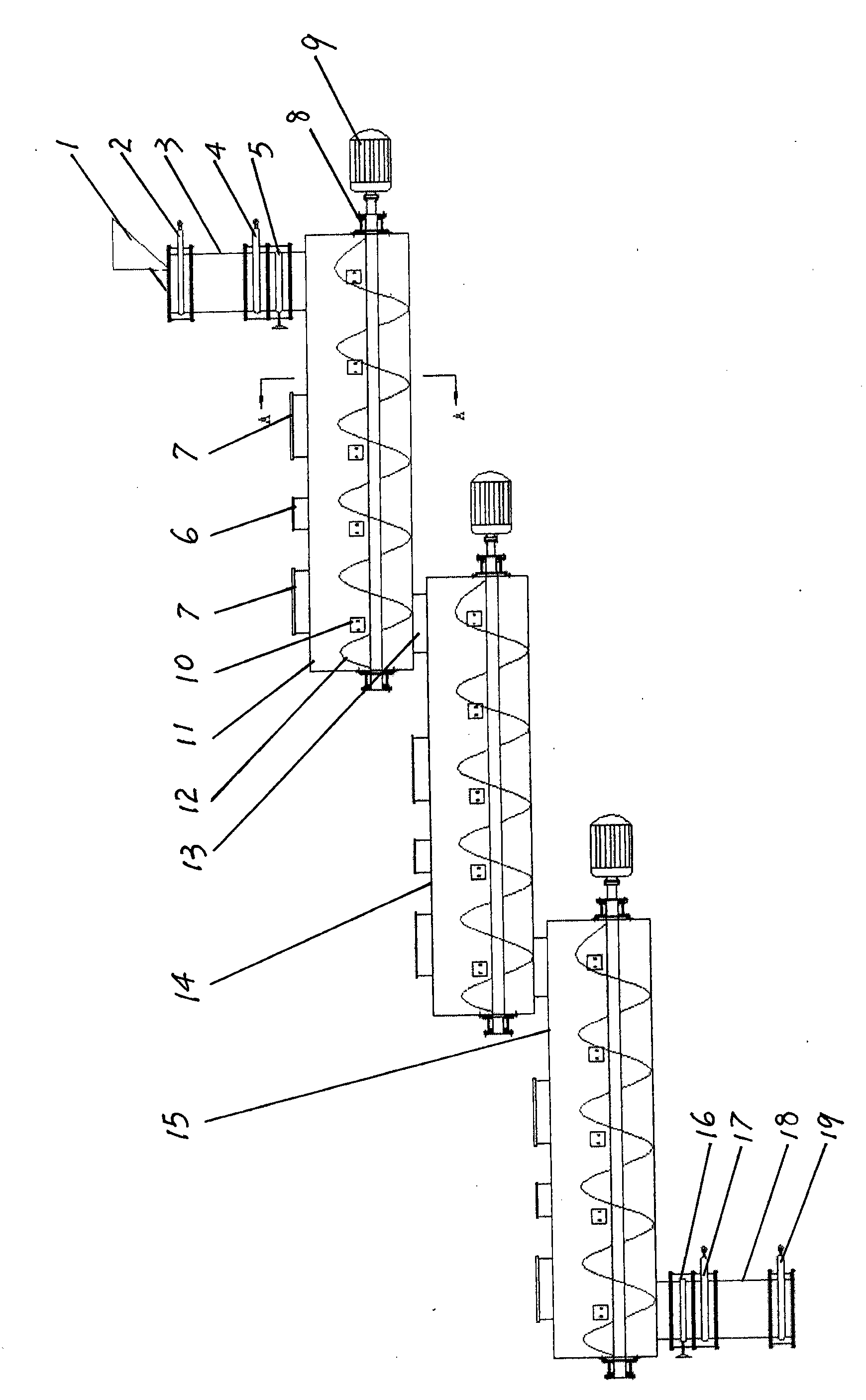

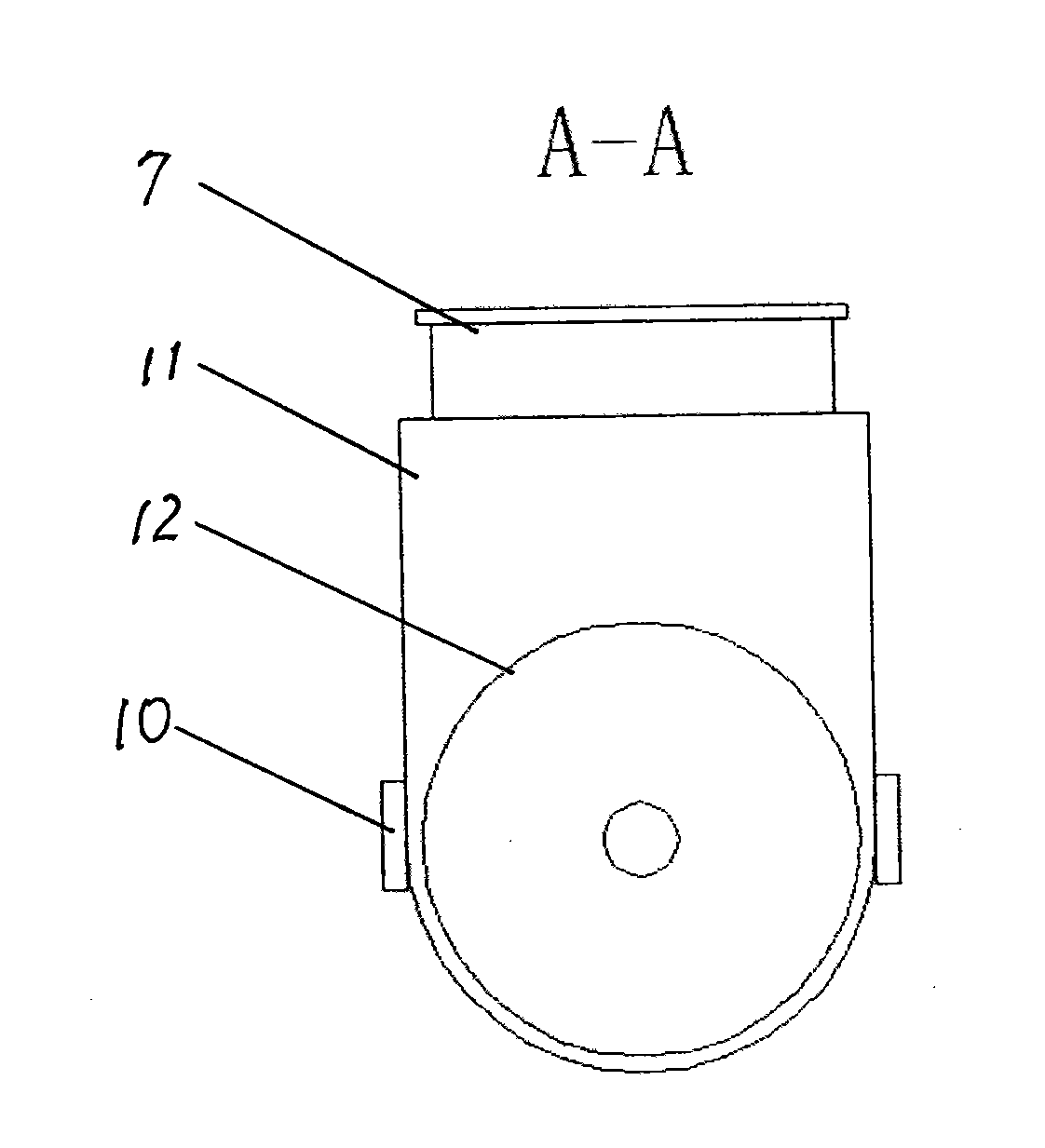

Biomass dry distillation type cracking furnace

PendingCN110527535AImprove qualityAvoid pollutionElectrical coke oven heatingBiofuelsFlue gasPropeller

The invention discloses a biomass dry distillation type cracking furnace. The biomass dry distillation type cracking furnace comprises a feeding unit, a carbonization unit and a separation and recycling unit; the feeding unit comprises a spiral feeder; the carbonization unit comprises a feeding port, a carbonizer, a cooler and a discharging port which sequentially communicate with one another; thecarbonizer and the cooler are tubular, and a raw material conveying propeller is arranged inside each of the carbonizer and the cooler; the separation and recycling unit comprises a fine powder separator which communicates with an exhaust port and a flue gas condenser which communicates with the upper end of the fine powder separator; the lower side of the flue gas condenser communicates with a flue gas filter; and a negative pressure fan is arranged on the lower side of the flue gas filter. The biomass dry distillation type cracking furnace has the advantages that the recycled carbon powderis pure, and the carbon yield is high; the heat value of the recycled gas is high; cyclic production without stopping is realized, and the working efficiency is improved; and zero emission is realizedin the whole cracking process, and environmental pollution is completely eradicated.

Owner:突泉县瑞尔生物质能源开发有限公司

A microwave pulverized coal pyrolysis and carbonization furnace

ActiveCN105062527BEfficient use ofWide adaptabilitySpecial form destructive distillationHeat carrierMicrowave

Owner:中国有色金属工业西安勘察设计研究院有限公司

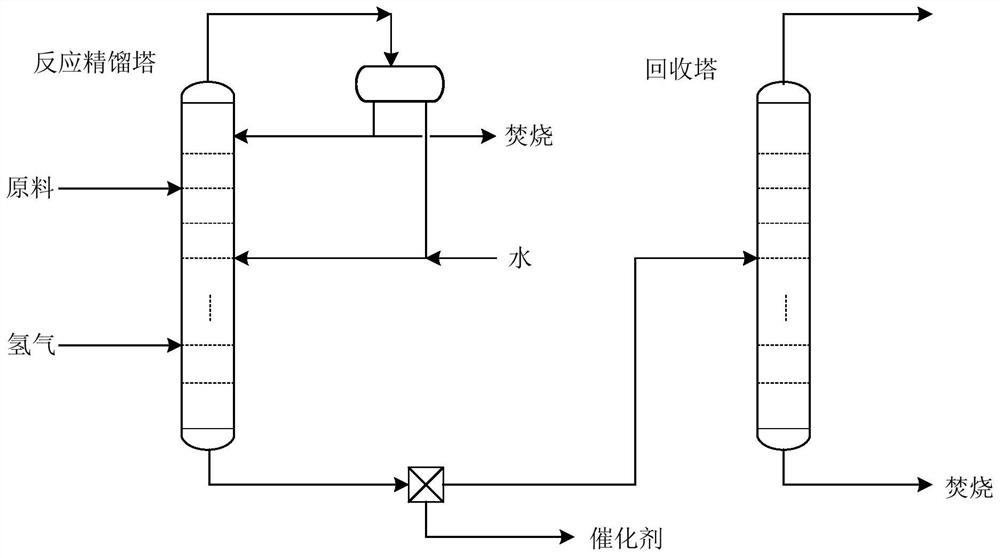

Comprehensive recovery treatment process of aniline tar

ActiveCN113121311AHigh purityFast cracking speedAmino compound purification/separationOrganic compound preparationOrganic acidProcess engineering

The invention belongs to the technical field of comprehensive recovery and utilization of chemical wastes, and particularly relates to a comprehensive recovery treatment process of aniline tar in aniline production. According to the comprehensive recovery treatment process of aniline tar, aniline tar and an organic solvent at least containing organic acid are mixed and then introduced into a rectifying tower for hydrotreating, tar is subjected to cracking reaction to generate corresponding ketoamine and other micromolecular components in the upper section of the rectifying tower under the action of a catalyst and the organic solvent, the lower section of the rectifying tower realizes hydrogenation of tar cracking products, and generated alcohol amine and other components and the catalyst are discharged from the bottom of the rectifying tower together. According to the process disclosed by the invention, the tar is changed into micromolecular components through hydrocracking, so that high-economic-value products such as alkylol amine and the like are obtained, the toxic action of the tar on the activity of the catalyst is solved, the activity of the separated noble metal catalyst can be effectively recovered, and the separated noble metal catalyst can be returned to a device, so that the recycling of the catalyst is realized, and the comprehensive utilization benefit of the device is improved.

Owner:WANHUA CHEM GRP +1

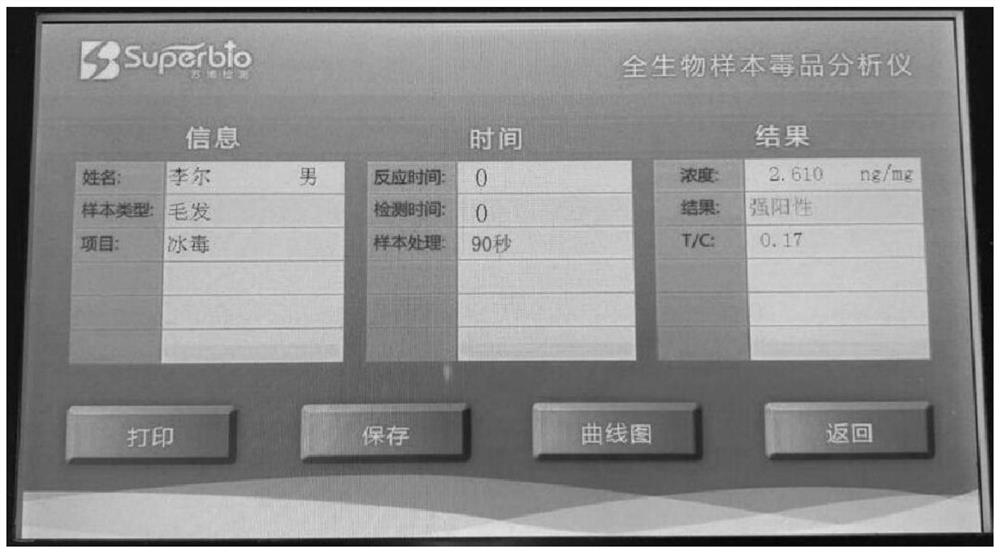

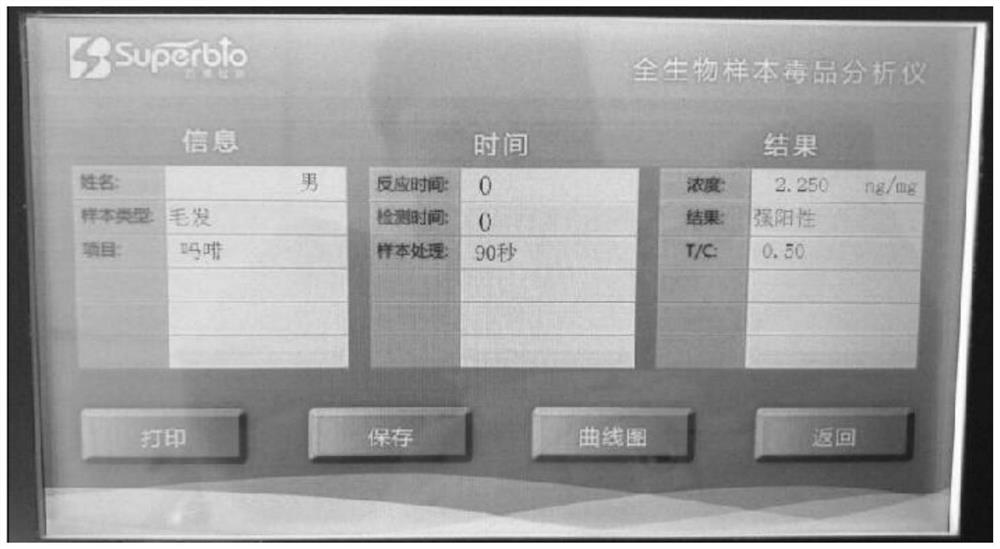

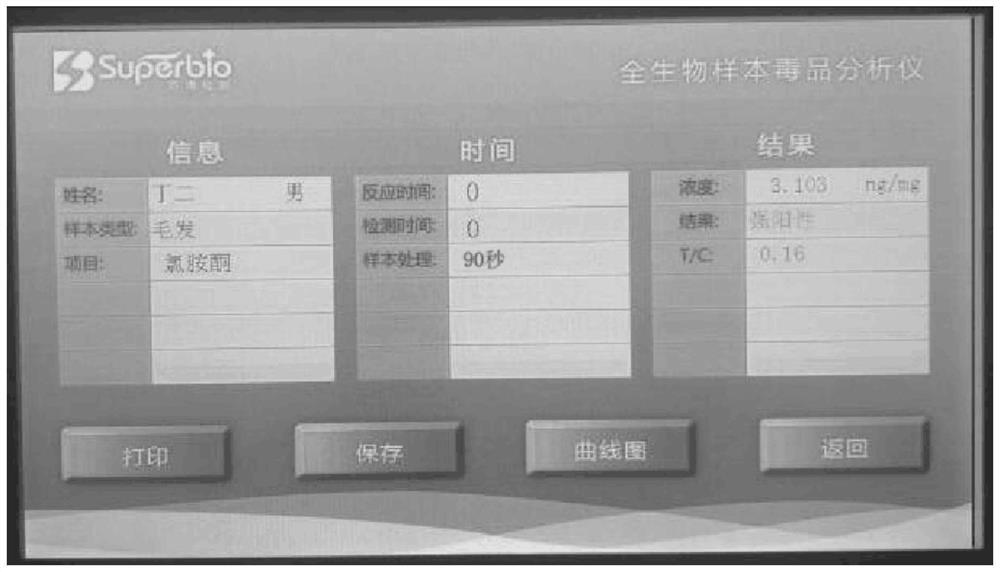

A kind of rapid lysate of human hair for trace drug detection and its application

ActiveCN110208072BIncrease release rateSpeed up the release processPreparing sample for investigationBiological testingDrug release ratePolyethylene glycol

The invention discloses a human hair rapid lysate for trace drug detection and application thereof. The human hair rapid lyse for trace drug detection has a raw material component comprising: 50-100nM alkaline protease AH-101 , 0.5‑2% thioglycolic acid, 25‑75 mM glycine, 30‑60 mM tris hydrochloride buffer, 40‑80 mM sodium chloride‑sodium hydroxide buffer, and 0.5‑1.5% polyethylene glycol octane phenyl phenyl ether (Triton X-100); wherein, nM is nanomoles per liter, mM is millimoles per liter, and % is volume percent. The present invention can quickly extract trace drug small molecules from human hair samples, has high release rate of drugs, little influence of impurities, non-toxic and pollution; Quickly, the whole cracking time only needs 90 seconds, so that the drug molecules are effectively released, compared with the cracking method in the prior art, the operation time is greatly shortened, and the authenticity and reliability of the experimental results are guaranteed.

Owner:江苏苏博生物医学科技南京有限公司 +1

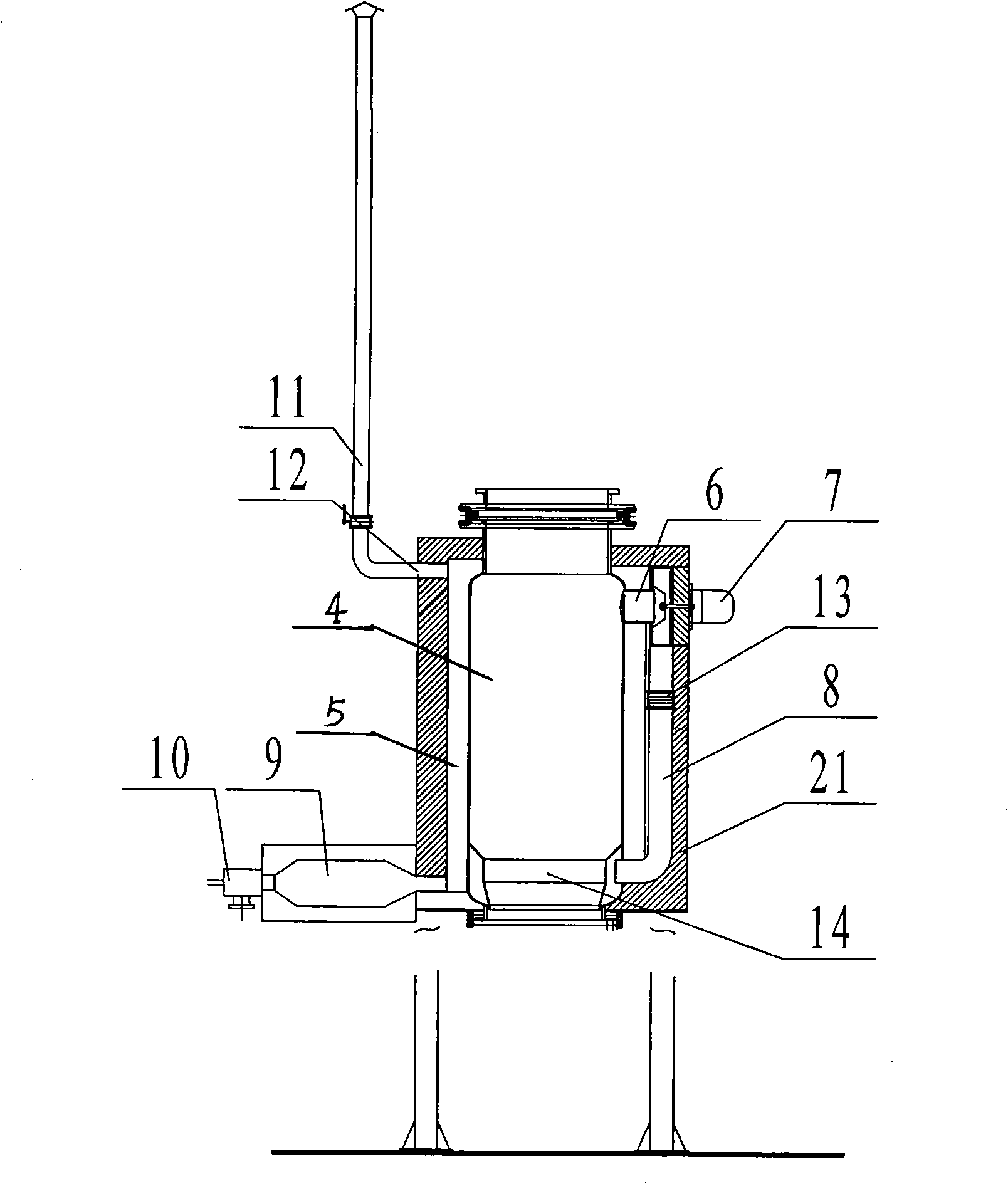

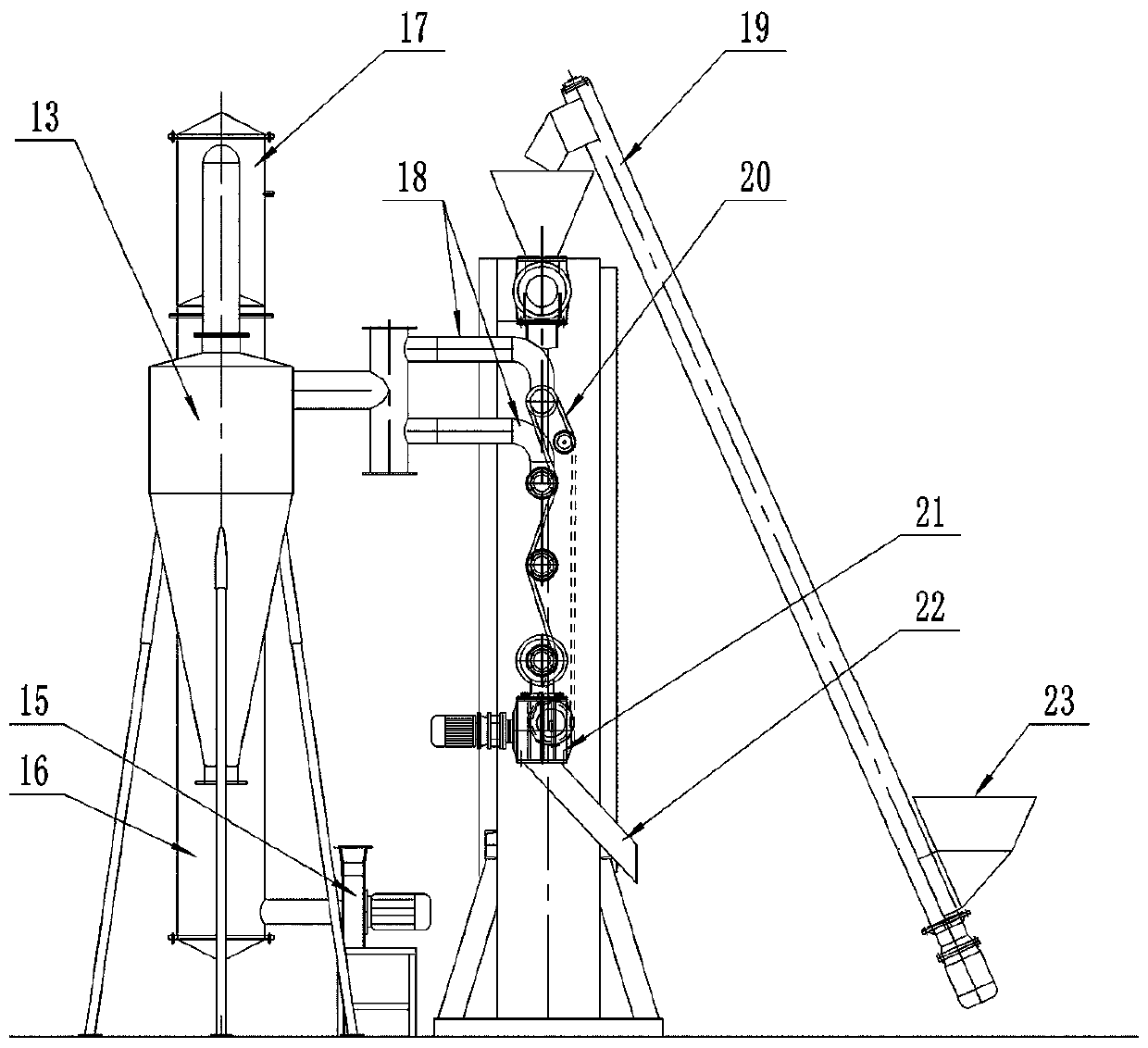

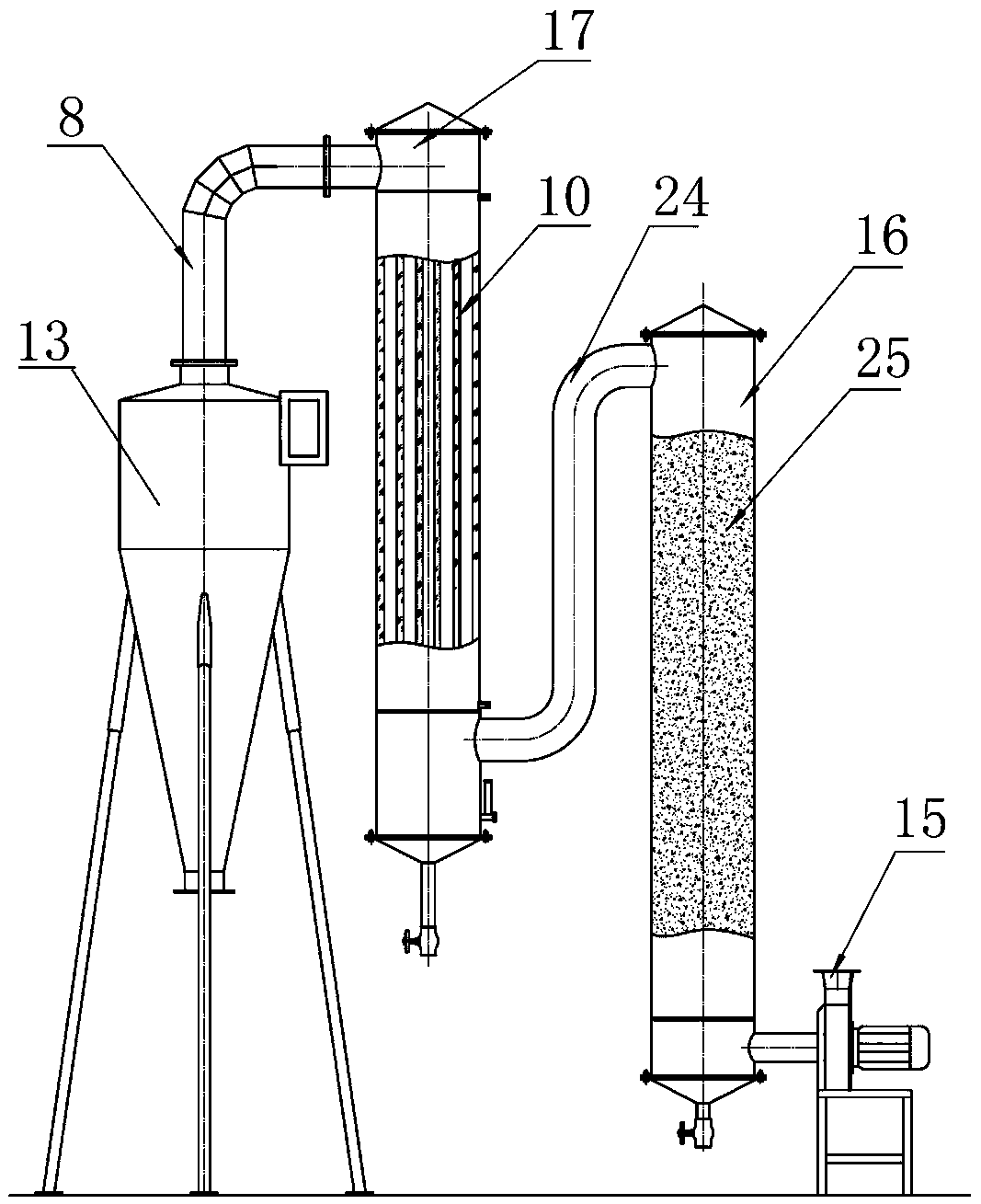

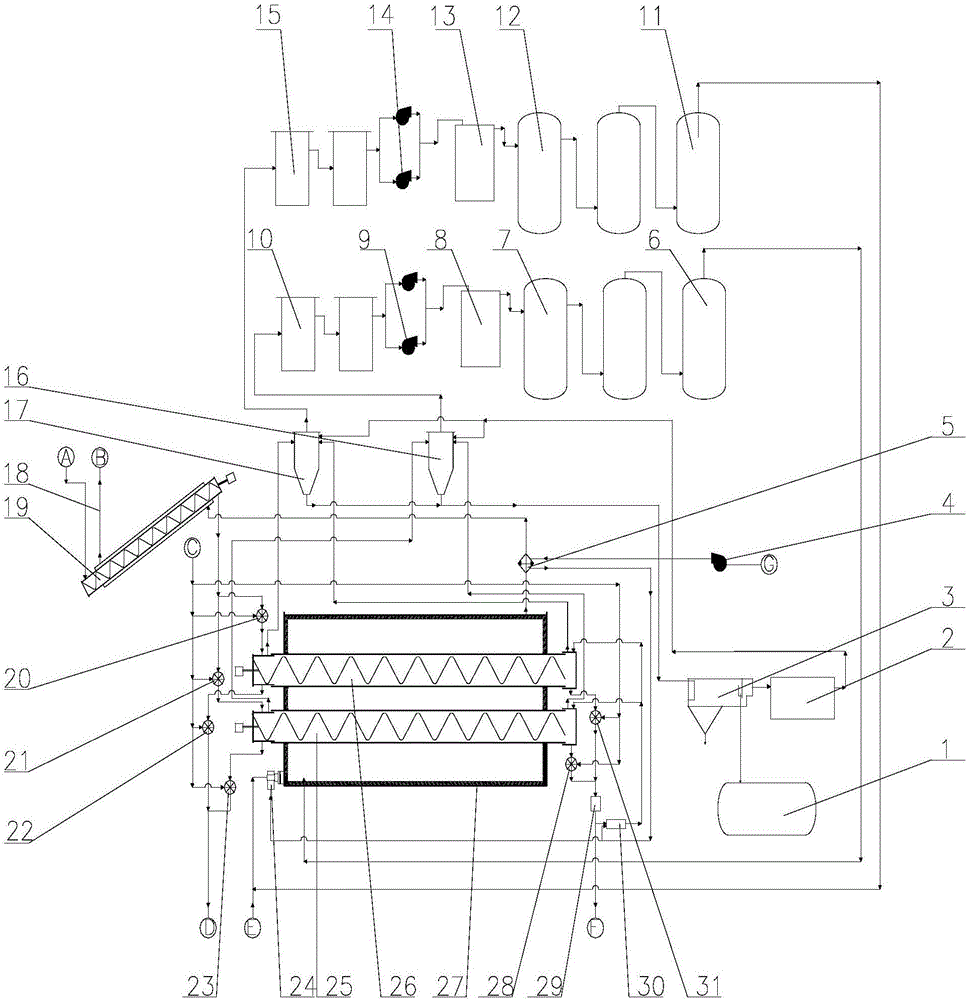

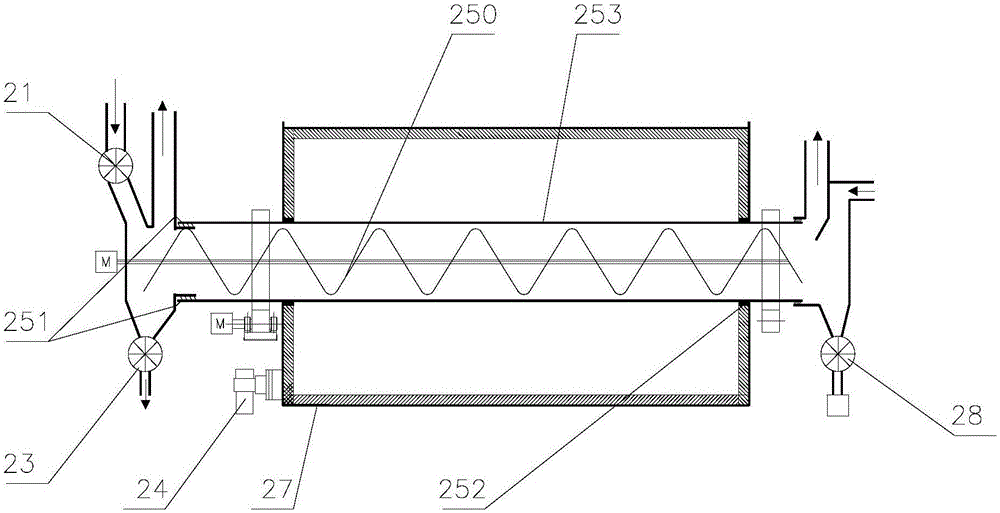

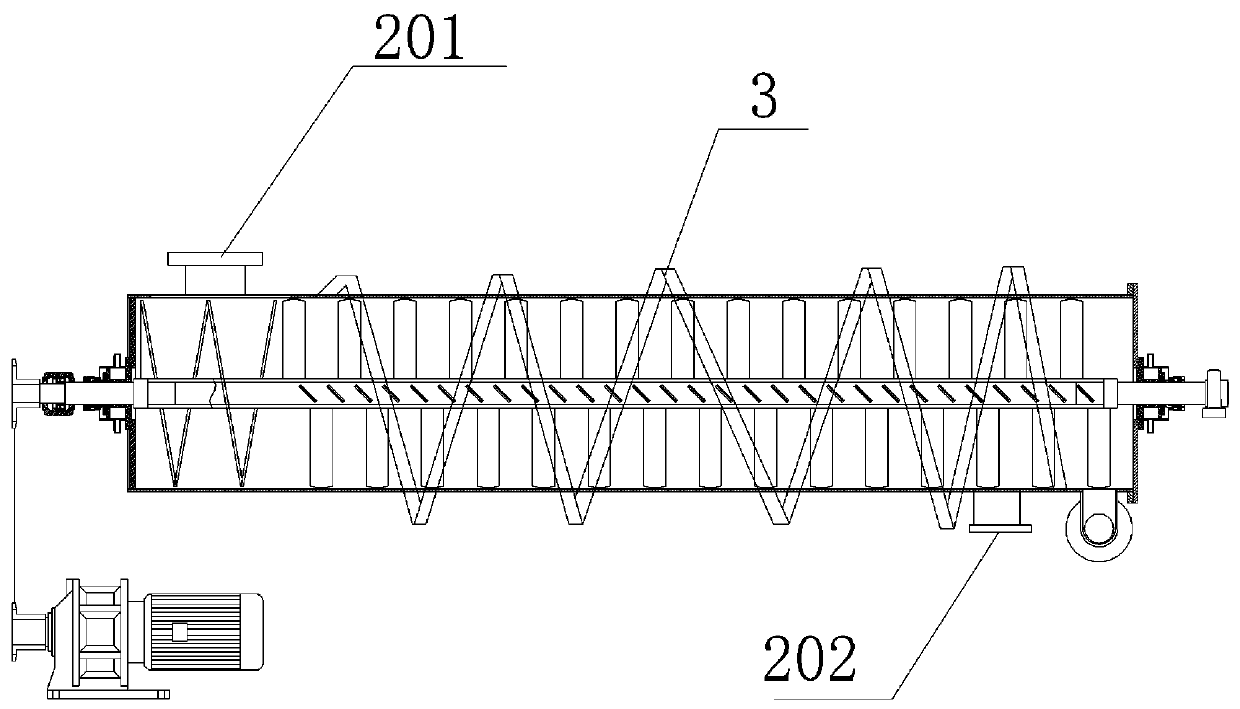

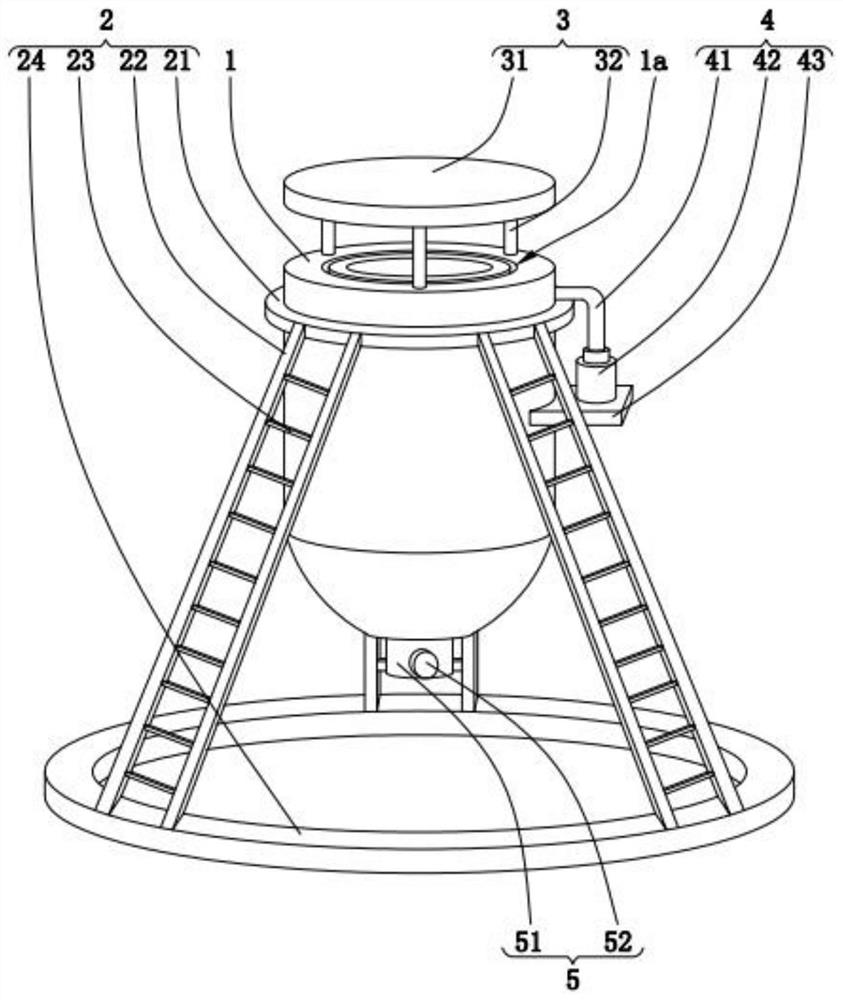

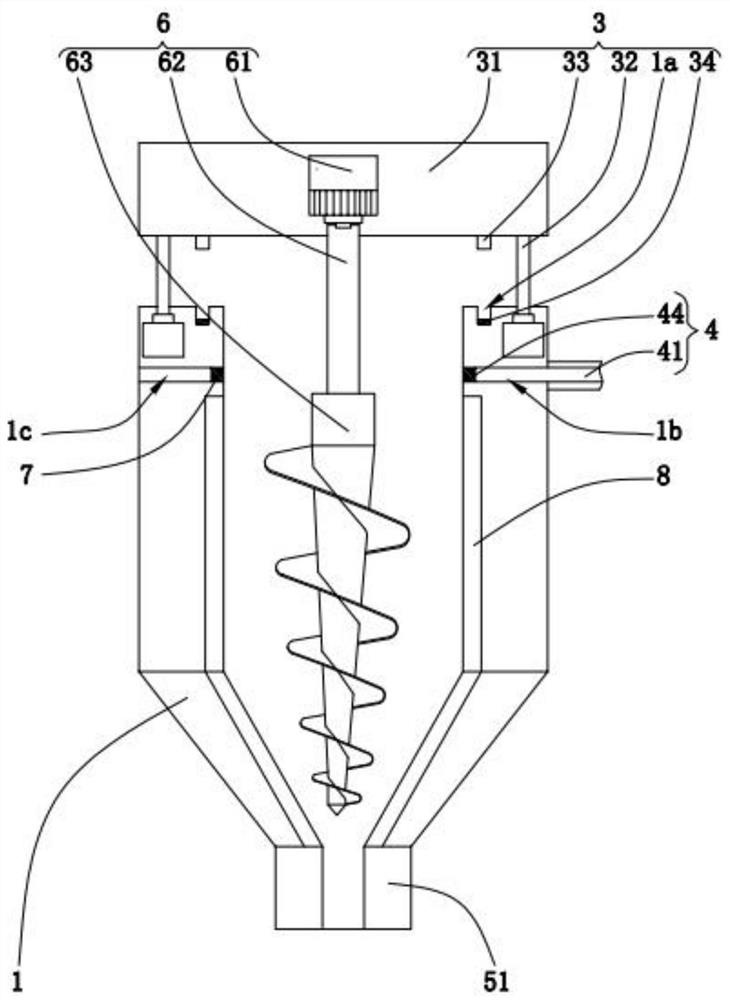

Energy-efficient indirect thermal desorption carbonization device and treatment method thereof

ActiveCN106675592AFast cracking speedIncrease the heat exchange areaCombination devicesUsing liquid separation agentSolid phasesHeating system

The invention belongs to the technical field of organic solid waste treatment, and particularly relates to an energy-efficient indirect thermal desorption carbonization device and a treatment method thereof. The carbonization device comprises a preheating feed system and a material heating system, wherein the preheating feed system comprises a heat-exchange-jacket-bearing spiral feeder and a chimney pipeline; the material heating system comprises a heating furnace, a first resolution chamber and a second resolution chamber; the first resolution chamber and second resolution chamber respectively comprise a feed end aggregate hood, a discharge end aggregate hood and a silicon-carbide-lined refractory steel cylinder; and a first rotatable screw conveyer and a second rotatable screw conveyer are correspondingly arranged inside the refractory steel cylinders of the first resolution chamber and second resolution chamber. The carbonization device can solve the problems of high deformation tendency, high abrasion tendency and low corrosion resistance in the chamber pipe wall and the problem of incomplete combustion of noncondensable gas. The carbonization device can remove inorganic carbon in the overproof solid-phase residues to implement further decrement, lower the heat consumption of indirect thermal desorption equipment and reduce the residue landfill disposition cost.

Owner:无锡爱普特设备科技有限公司

Method for treating garbage, cracking furnace and cracking device thereof

The invention belongs to the technical field of garbage treatment and specifically relates to a method for treating garbage, a cracking furnace and a cracking device thereof. The method for treating garbage comprises the following steps: pretreating garbage and then mixing with calcium carbonate powder; cracking in the cracking furnace, thereby forming biomass charcoal and high-temperature smoke at 200-350 DEG C; discharging the high-temperature smoke and condensing into liquid oil. The method is high in cracking speed, environment-friendly and energy-saving.

Owner:河南银洲新型建材有限公司

Thermal treatment process for connector of 42CrMo texture

InactiveCN109112469AImprove tensile propertiesImprove stress resistanceSolid state diffusion coatingFurnace typesThermal treatmentInternal stress

The invention discloses a thermal treatment process for a connector of 42CrMo texture, relating to the field of thermal treatment process. The process mainly comprises a heating phase, a carburizationphase at 900-920 DEG C, a graded oil cooling phase at 100-120 DEG C and a high-temperature tempering phase at 410-430 DEG C, wherein the carburization phase comprises the phases of strong permeability, diffusion and heat preservation. The thermal treatment process has the following advantages and effects: by arranging a long-time strong permeability phase and a high-temperature diffusion phase, the hardenability of the connector is improved, the tensile resistant and anti-pressure ability thereof are improved, and the effect of long service life is achieved. Meanwhile, graded oil cooling is adopted to reduce internal stress inside the connector, and the connector is prevented from deforming and cracking; by additionally arranging a heat preservation phase after the diffusion phase, the decarbonization phenomeon of the connector is prevented from occurrence. The tempered cable troostite tissue is obtained as well through high-temperature tempering, the comprehensive mechanical propertyof the connector is improved, and the service life of the connector is further improved.

Owner:温岭市大山热处理厂(普通合伙)

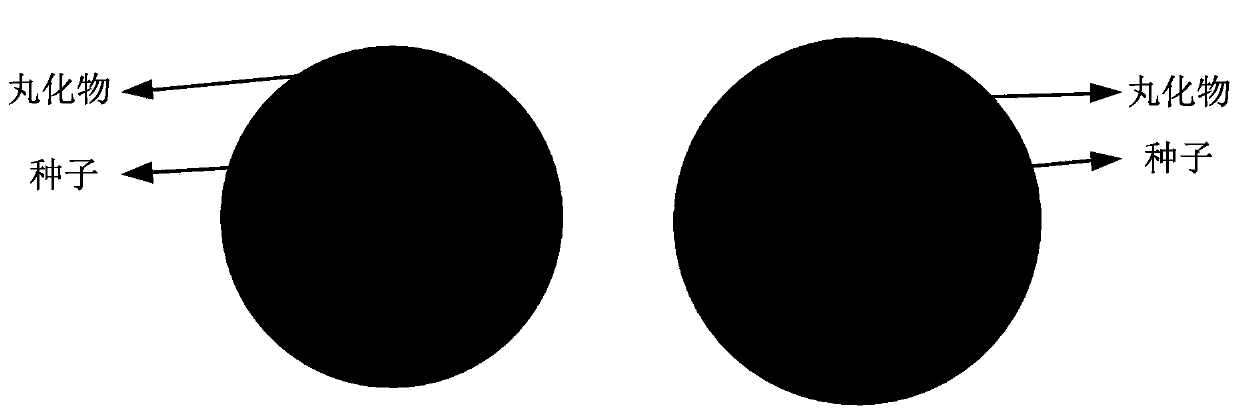

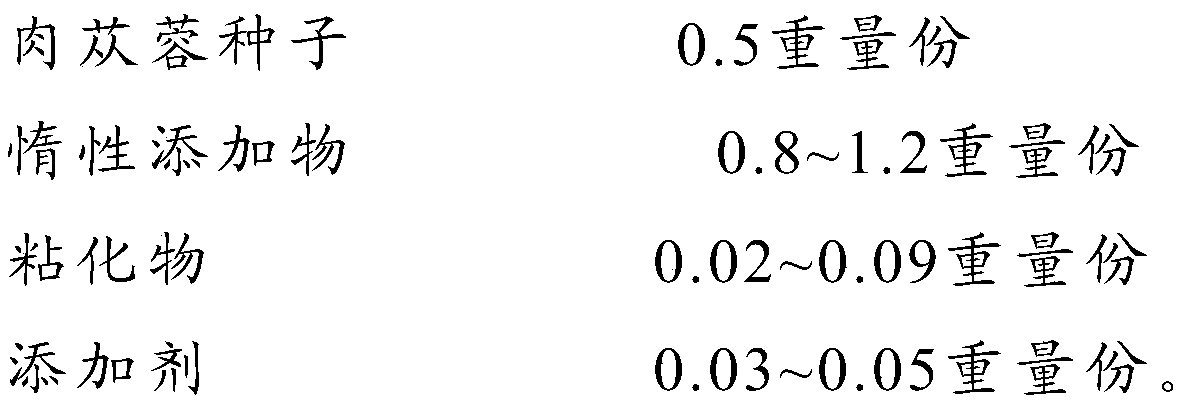

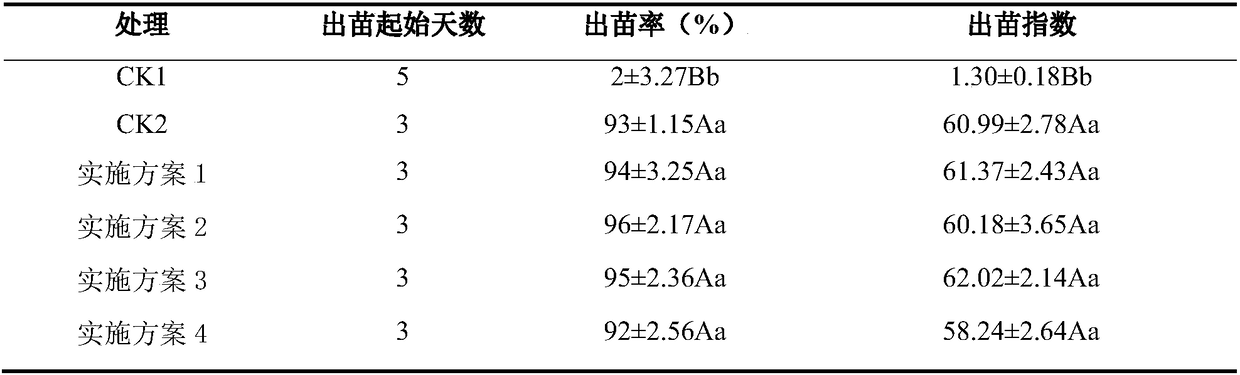

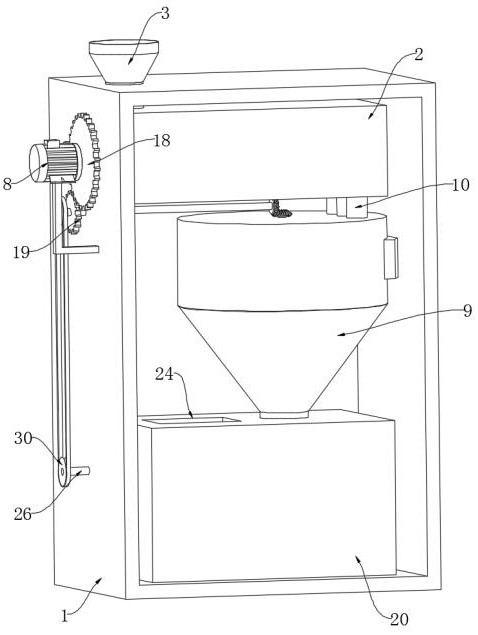

Quick-germinating herba cistanche seed grains and preparation technology thereof

PendingCN110226387AIncrease in sizeReduce seeding rateSeed coating/dressingParasitismParasitic animal

The invention provides quick-germinating herba cistanche seed grains and a preparation technology thereof, and discloses the herba cistanche seed grains, the preparation technology and a herba cistanche planting method. The herba cistanche seed grains are prepared from herba cistanche seeds, inert additives, adhesive matter and an addition agent in a certain weight ratio, the seeding rate can be reduced, and the parasitism rate is increased; according to the preparation technology, the herba cistanche seeds are pretreated, so that the seed neatness and uniformity are improved, then the herba cistanche seeds are mixed with the inert additives, the adhesive matter and the addition agent, the seed grains are prepared, the preparation method is simple, conditions are easy to control, and the cost is low.

Owner:HEXI UNIV +1

Liquorice seed stress-resistant coating nutrition pill and preparation method thereof

InactiveCN109197025AIncrease in sizeEasy sowingBiocidePlant growth regulatorsAdditive ingredientGLYCYRRHIZA EXTRACT

The invention discloses a liquorice seed stress-resistant coating nutrition pill, which is prepared from the following ingredients in parts by mass according to the recipe proportion: 10 parts of liquorice seeds, 30 to 50 parts of inert pill compounds and 1.5 to 2.5 parts of bonding agents. Meanwhile, the invention also discloses a preparation method of the liquorice seed stress-resistant coatingnutrition pill. The liquorice seed stress-resistant coating nutrition pill and the preparation method thereof have the beneficial effects that the liquorice seeds are subjected to stress-resistant coating pelleting so as to increase the liquorice seed volume; the pressure-resistant intensity of the seeds is enhanced; the cracking speed of the seeds in wet soil is accelerated; the stress-resistantcoating pelleting seeds have the functions of water storage, water retention and water supply; the drought resistance capability of the liquorice seed can be improved; water preserving agents in the stress-resistant pelleting liquorice seeds absorb and dilute the salt content solution to reduce the concentration when meeting water; the adverse influence of the soil salt on seed germination can bereduced; the young seedling cold resistance, sand dust resistance and salt and alkali resistant capability can be improved through the stress-resistant coating pelleting liquorice seeds.

Owner:HEXI UNIV

A waste rubber tire pyrolysis recycling equipment

ActiveCN113635488BFast cracking speedStir quicklyPlastic recyclingMechanical material recoveryWaste rubberElectric machinery

The invention discloses a cracking and recycling equipment for waste rubber tires, which comprises a casing, a crushing mechanism for crushing tires is arranged in the casing, and the crushing mechanism includes a crushing box fixedly connected above the inner wall of the casing , the top of the crushing box is fixedly connected with a feeding pipe, the inner wall of the crushing box is rotatably connected with a plurality of rotating shafts, and the side walls of the plurality of rotating shafts are fixedly connected with spiral crushing leaves, and between two adjacent spiral crushing leaves One end of the plurality of rotating shafts runs through the crushing box and the side wall of the housing respectively and is fixedly connected with a plurality of synchronous wheels, which are connected by a synchronous belt, and the side wall of the housing is connected by a bracket A motor is fixedly connected, and the movable end of the motor is fixedly connected with one end of one of the rotating shafts. In the present invention, by setting a crushing mechanism, the rotation of a plurality of spiral crushing leaves can not only transport the tires, but also crush the tires, thereby accelerating the cracking speed of the tires.

Owner:江苏绿源橡胶资源循环利用创新中心有限公司

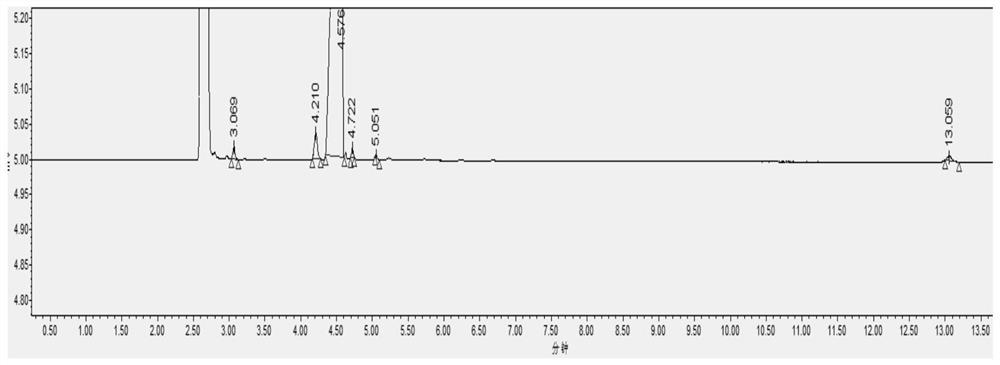

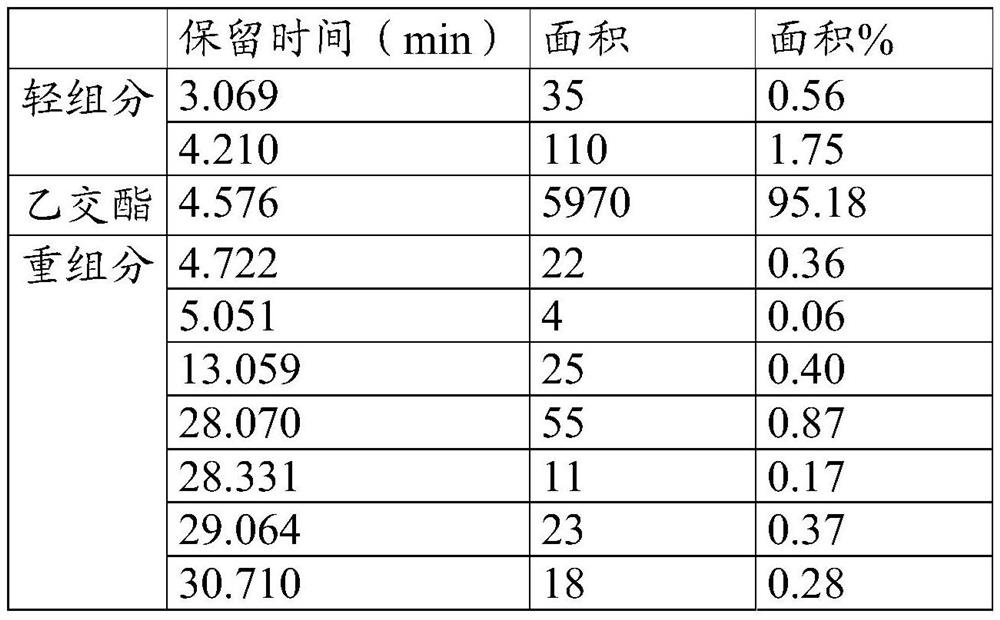

Preparation method of glycolide

ActiveCN114437020AFast cracking speedLow melting pointOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsPolymer sciencePolyolefin

The invention provides a glycolide preparation method, which comprises: carrying out a condensation polymerization reaction on a glycolic acid monomer, a polyolefin polyol and a binary acid monomer under the action of a catalyst to obtain a branched polyolefin-glycolic acid copolymer, or carrying out condensation polymerization on the glycollic acid monomer, the polyolefin polybasic acid and the dihydric alcohol monomer under the action of the catalyst to obtain the branched polyolefin-glycollic acid copolymer, the branched polyolefin-glycollic acid copolymer is subjected to a cracking reaction, and glycolide is obtained. According to the method provided by the invention, the problems of low glycolic acid cracking speed and product pollution caused by introduction of a high-boiling-point solvent in the cracking process are well solved, the product purity is relatively high, the separation process of glycolide and the solvent in the product is avoided, the production efficiency is improved, the production cost is reduced, and the method can be used for industrial production of glycolide.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Automatic microwave cracking reaction device for waste rubber

ActiveCN102140362BRealize automatic controlAchieve regenerationLiquid hydrocarbon mixture productionAutomatic controlSlag

The invention discloses an automatic microwave cracking reaction device for waste rubber. The device consists of an automatic control system, a variable frequency motor, a spiral propelled microwave cracking reaction bin, a pneumatic closed automatic feeding valve assembly and a pneumatic closed slag discharge valve assembly; microwave magnetrons are uniformly arranged on the outer walls of two sides of a spiral propeller in the spiral propelled microwave cracking reaction bin; the pneumatic closed automatic feeding valve assembly is arranged at the feeding end of the spiral propelled microwave cracking reaction bin; the pneumatic closed slag discharge valve assembly is arranged at the discharge end of the spiral propelled microwave cracking reaction bin and a material distributor is arranged at the feeding hole of the pneumatic closed automatic feeding valve assembly. The device has high automation degree, high treatment quantity, low manufacturing cost, full-closed continuous production, safety and environmental friendliness, can be used for extracting combustible gas, gasoline, diesel oil and industrial crude carbon black, is safe in recycle, does not discharge waste slag or harm gases, and does not cause secondary environmental pollution.

Owner:瑞新环境科技民权县有限公司

A method for improving rubber cracking efficiency

ActiveCN109097090BImprove cracking efficiencyLow melting pointLiquid hydrocarbon mixture productionHydrocarbon oils treatmentPtru catalystPhysical chemistry

The invention relates to the field of rubber cracking and recycling, in particular to a method for improving the efficiency of rubber cracking. The method crushes collected rubber products into blocks with a size close to the size of peanuts; Functional sealed tank, add thinner water to dissolve the rubber, and accelerate the rubber dissolution by stirring; connect the sealed tank directly to the rubber cracking device, keep a high degree of sealing, and perform high-temperature cracking and stirring on the dissolved rubber. Due to the high temperature, thinner The volatilization of water is separated from the solution; the volatilized thinner gas is collected and cooled for recycling; the dissolved rubber is more likely to react with the catalyst, and the heating is more uniform, which can effectively improve the cracking efficiency, and thinner is easy to volatilize and can be collected Cool and reuse.

Owner:DOUBLE COIN GRP ANHUI WARRIOR TIRE CO LTD

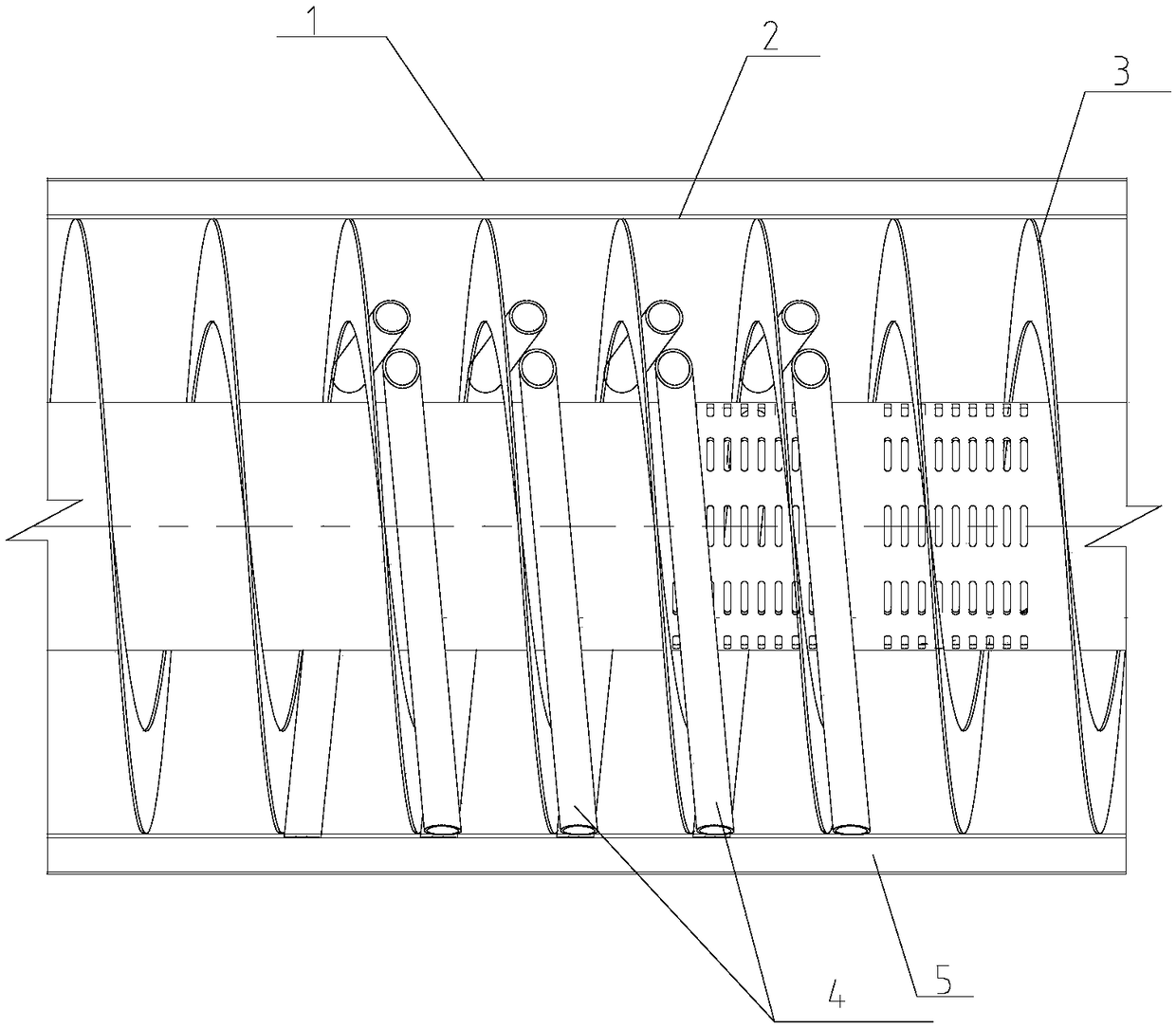

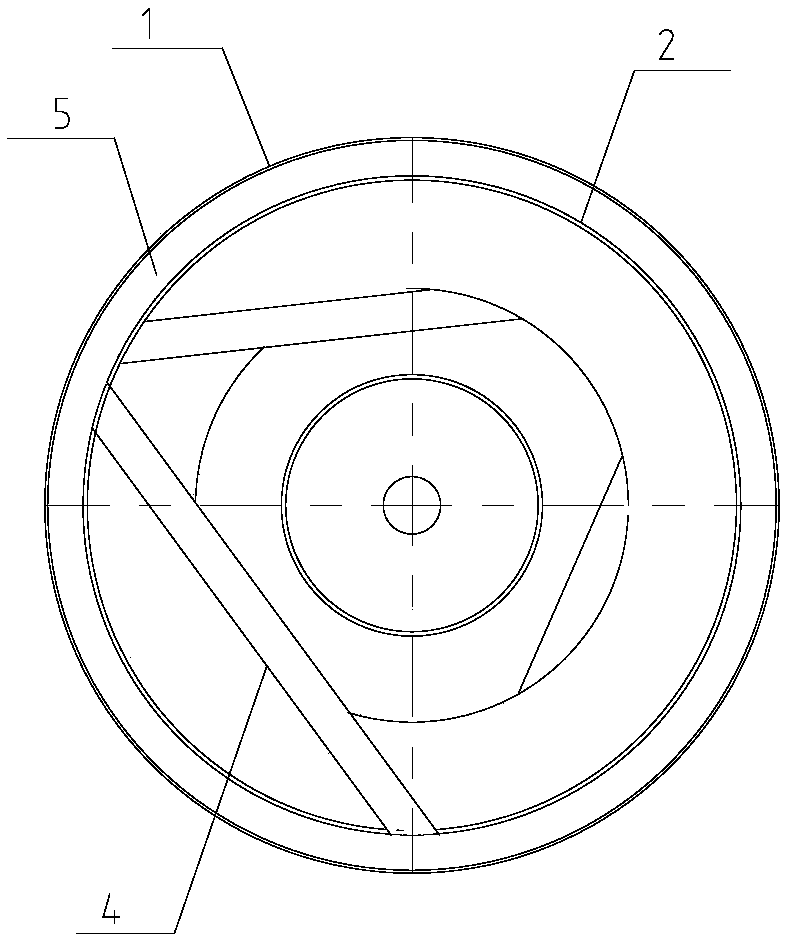

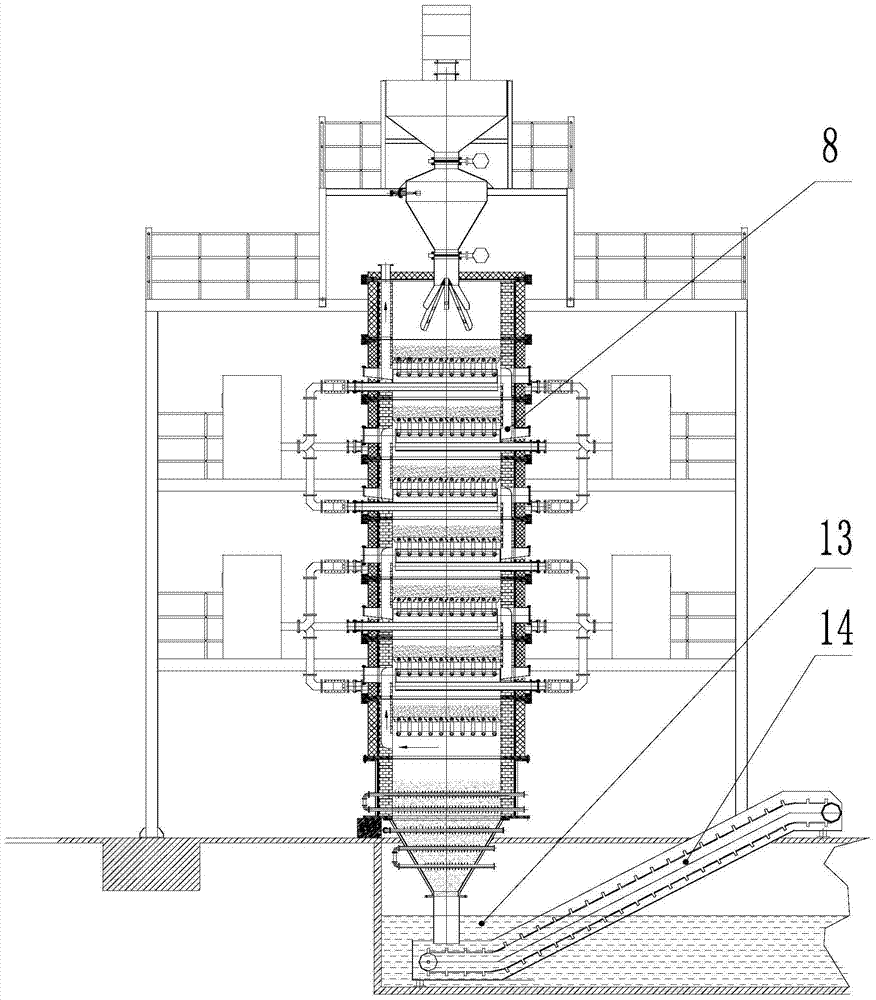

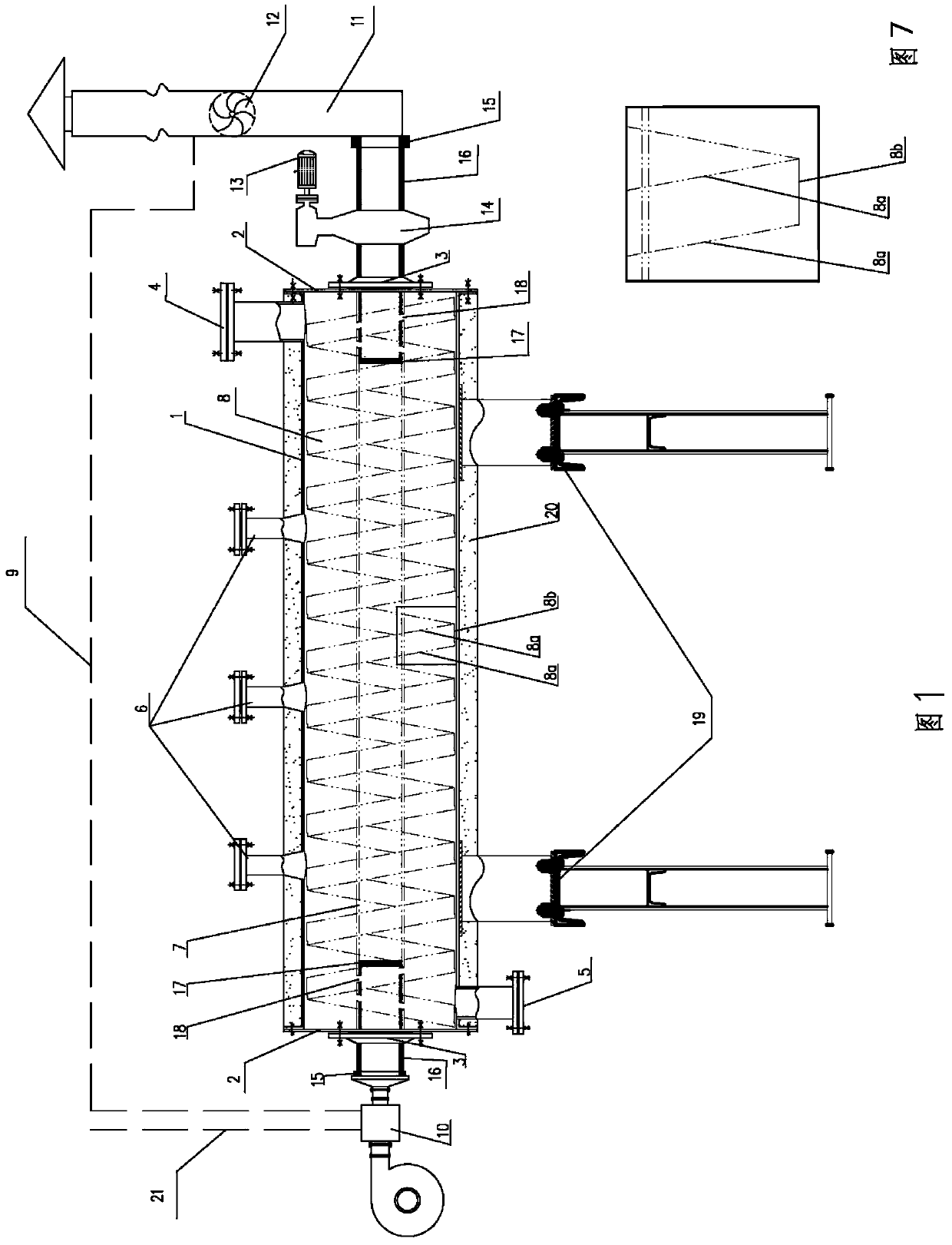

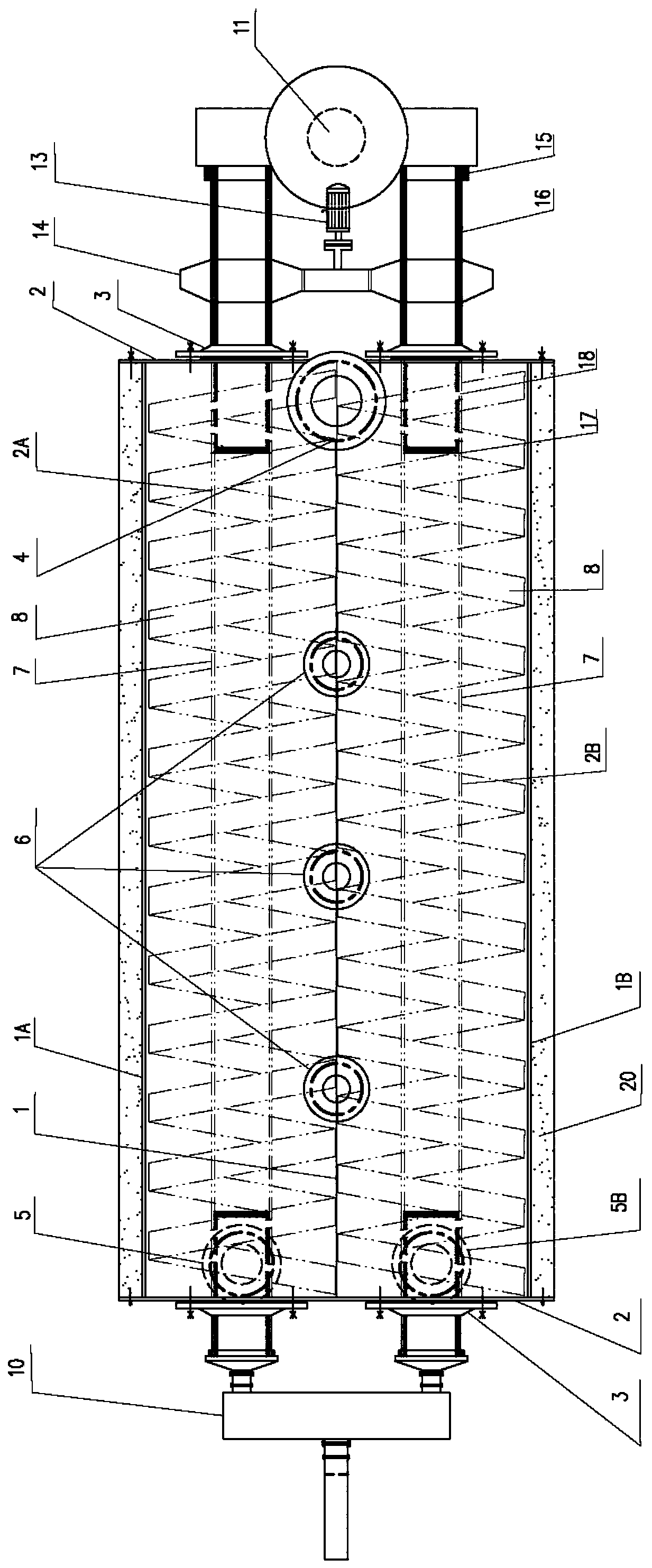

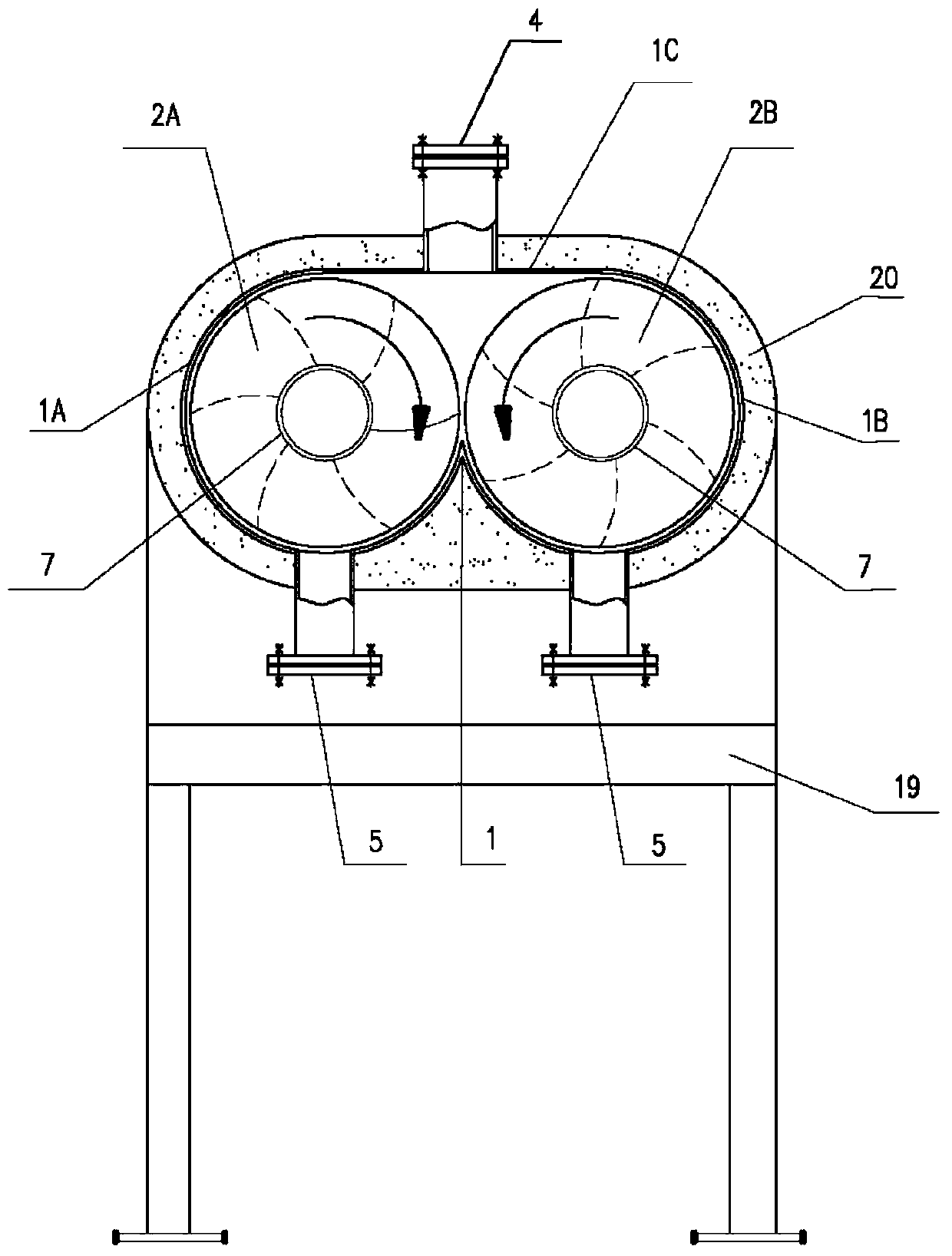

Continuous internal heating double-barrel pyrolysis furnace for solid organic matter

ActiveCN105602584BIncrease production capacityLow costDirect heating destructive distillationLiquid hydrocarbon mixture productionSlagEngineering

A continuous internal heating type double-barrel cracking furnace for solid organic matter is of a fixed horizontal double-barrel-body structure. Continuous feeding is performed on the upper portion of one end of each barrel body. Continuous slag discharging is performed on the lower portion of the other end of each barrel body. The upper portion of each barrel body is provided with a plurality of gas outlets. Two rotors are arranged in the dual barrel bodies side by side. While the rotors are used for heating materials in the barrel bodies in a dividing-wall mode, the materials are propelled and stirred rotationally. Each rotor is composed of a shaft barrel and a screw band, and each screw band is of a hollow structure. High-temperature flue gas firstly enters the shaft barrels and then enters inner cavities of the screw bands through flow guiding holes, the flue gas rotates along with the rotating barrels in the inner cavities of the screw bands and spirally flows along the inner cavities of the screw bands at the same time, heat is fully released, the materials are heated, and then the flue gas enters the shaft barrels to be exhausted. The flue gas and the materials are in countercurrent dividing-wall heat transfer, temperature difference is large, smoke exhaust temperature is low, heating is uniform, cracking gas is exhausted in time, secondary cracking is avoided, and the oil yield is high. The furnace is scientific and reasonable in structure and technology, high in machining capacity, low in cost, capable of achieving energy conservation and environment protection, safe, reliable and low in labor intensity, pollution caused by combustion of dioxin is avoided, resources are reasonably utilized, and market popularization value is great.

Owner:青岛伊诺威能源化工新技术有限公司

Closed hot extrusion forging processing method for universal joint duplex fork

InactiveCN114147155ASemi-automatic detachmentFast cracking speedRevolution surface grinding machinesFurnace typesSand blastingUniversal joint

The invention discloses a universal joint duplex fork closed hot extrusion forging machining method. Workpiece forging comprises the specific steps that reverse extrusion treatment is conducted on a forged piece coarse material; the forging coarse material is heated through an intermediate frequency furnace, rapid cooling annealing treatment is carried out after heating, and the step is repeated for multiple times, so that the pre-sheared excess material is cracked near the interior of the excess material block, a plurality of holes are formed between the excess material block and the forging coarse material, the connection strength is reduced, and the forging coarse material is annealed firstly and then subjected to upsetting treatment. Performing shot blasting and phosphorus saponification treatment to obtain a pre-forged piece; the pre-forged piece is subjected to precision forging forming, a closed forging technology is adopted for a precision forging die, flash-free forging is conducted, and vent holes are designed in the precision forging die; the surface of the workpiece subjected to normalizing treatment is subjected to sand blasting treatment, and the workpiece subjected to sand blasting treatment is subjected to rust-proof treatment, so that the rejection rate of products is reduced, the qualification rate of the products is improved, and the energy consumption is greatly reduced.

Owner:安徽永益汽车部件有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com