Gas-oil mixed pyrolysis furnace

A hybrid, cracking furnace technology, used in the field of waste rubber gas and oil mixed cracking furnace, can solve the problems of uneven cooling effect and insufficient heating of cracked products, and achieve high cost performance, high energy utilization, and low pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

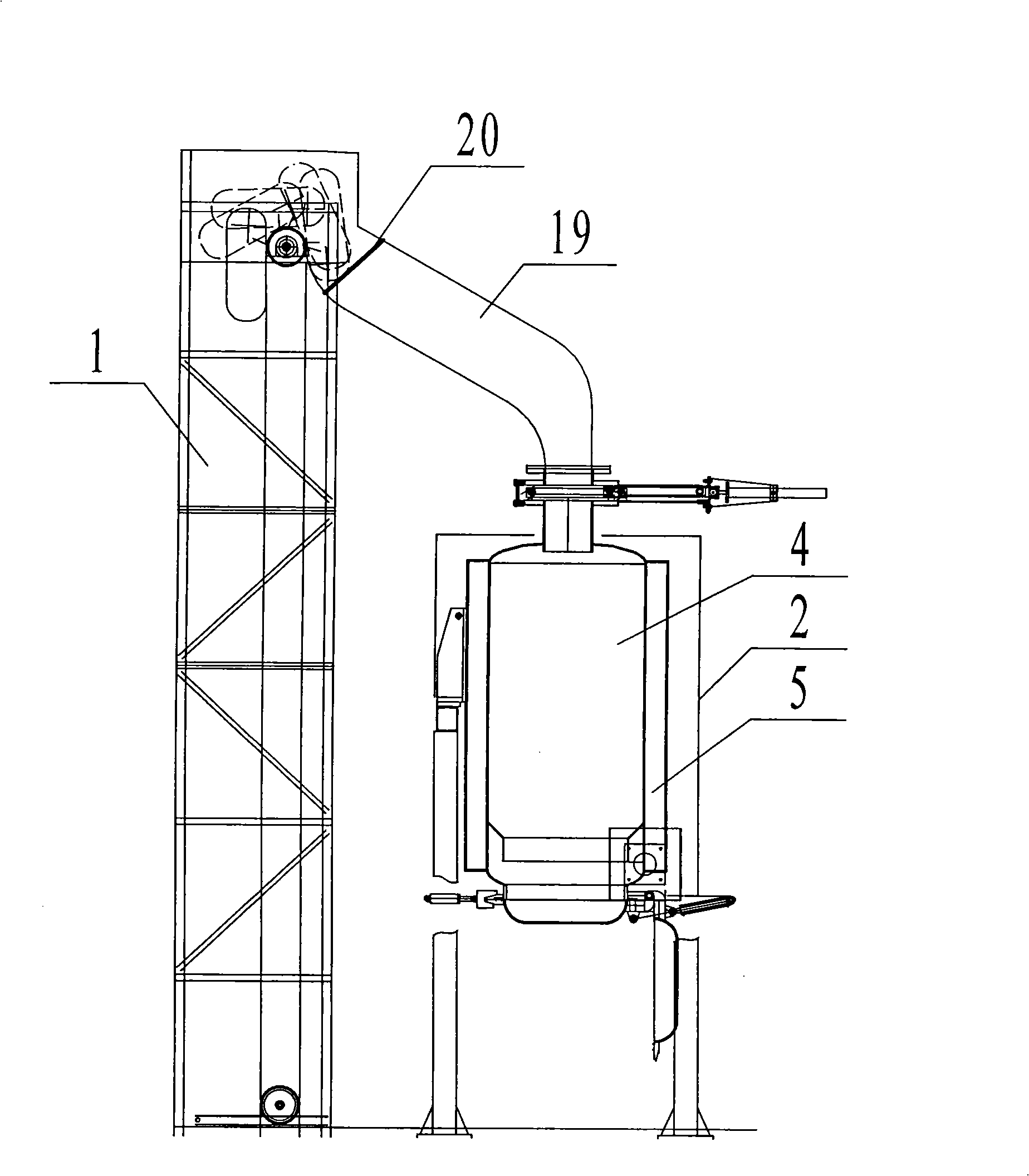

[0018] Gas and oil mixed pyrolysis furnace, including materials. Elevator 1, cracking bin 2, cooling bin 3 and the sorting system below it. The outlet of cracking bin 2 is connected with the inlet of cooling bin 3, such as figure 1 as shown,

[0019] 1) Material hoist 1: adopts a chain-type vertical material hook lifting mechanism, and puts the material into the cracking bin 2 through the opened cracking bin seal door through the material slideway 19;

[0020] 2), material slideway 19: located above the cracking bin 2, the upper part of the material slideway is provided with a guide groove plate 20 connected with the material hoist 1, the lower part of the material slideway 19 has a discharge port, and the discharge port is connected to the cracking bin feed port connection;

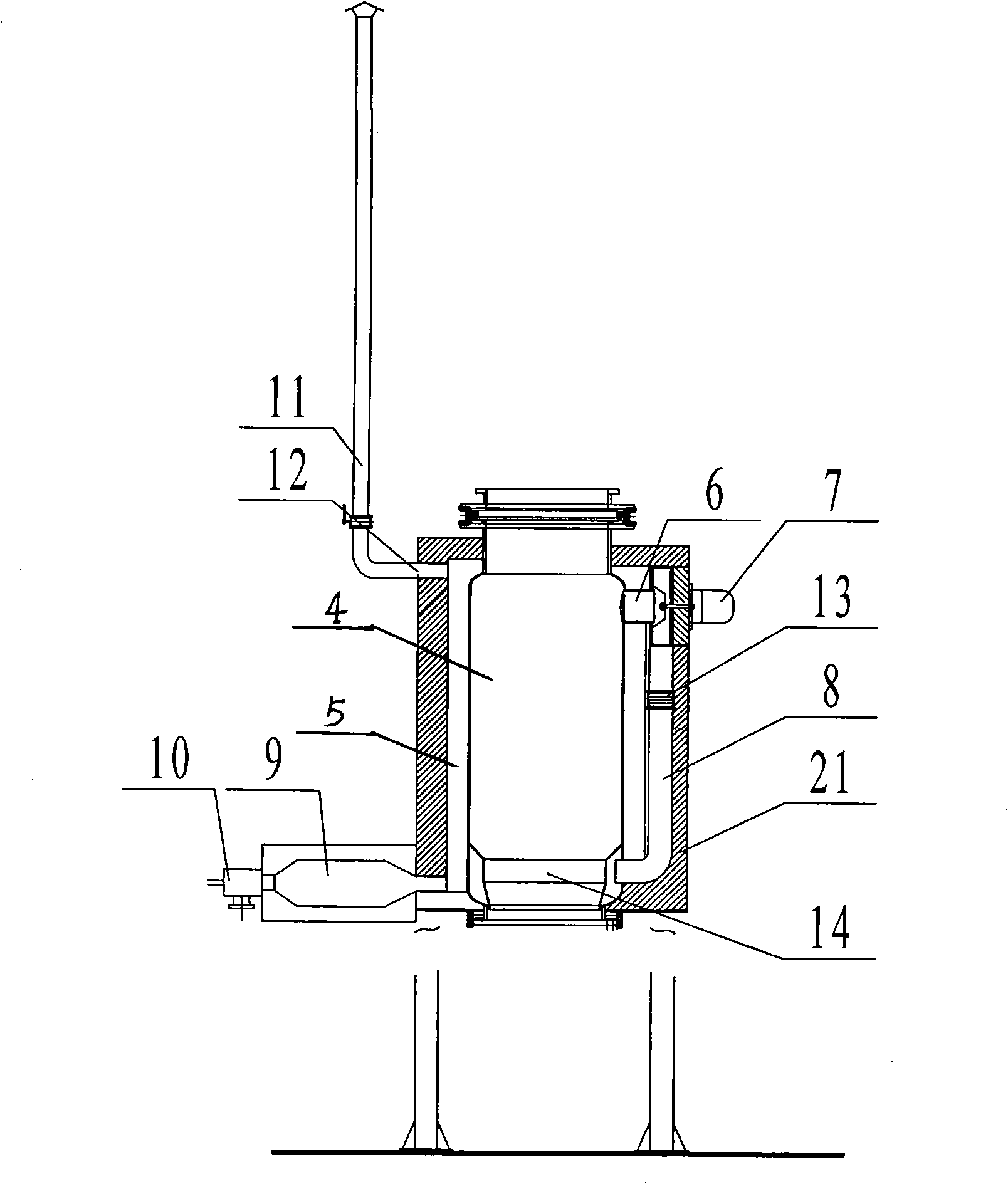

[0021] 3), cracking chamber 2: such as figure 2 As shown, the pyrolysis chamber 2 is formed by two concentric barrels nested together, wherein the inner barrel is used as the material cracking chamber...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com