Method for treating garbage, cracking furnace and cracking device thereof

A technology for waste treatment and cracking device, which is applied in the petroleum industry, preparation of liquid hydrocarbon mixtures, etc., and can solve the problems of long time, large area, soil pollution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

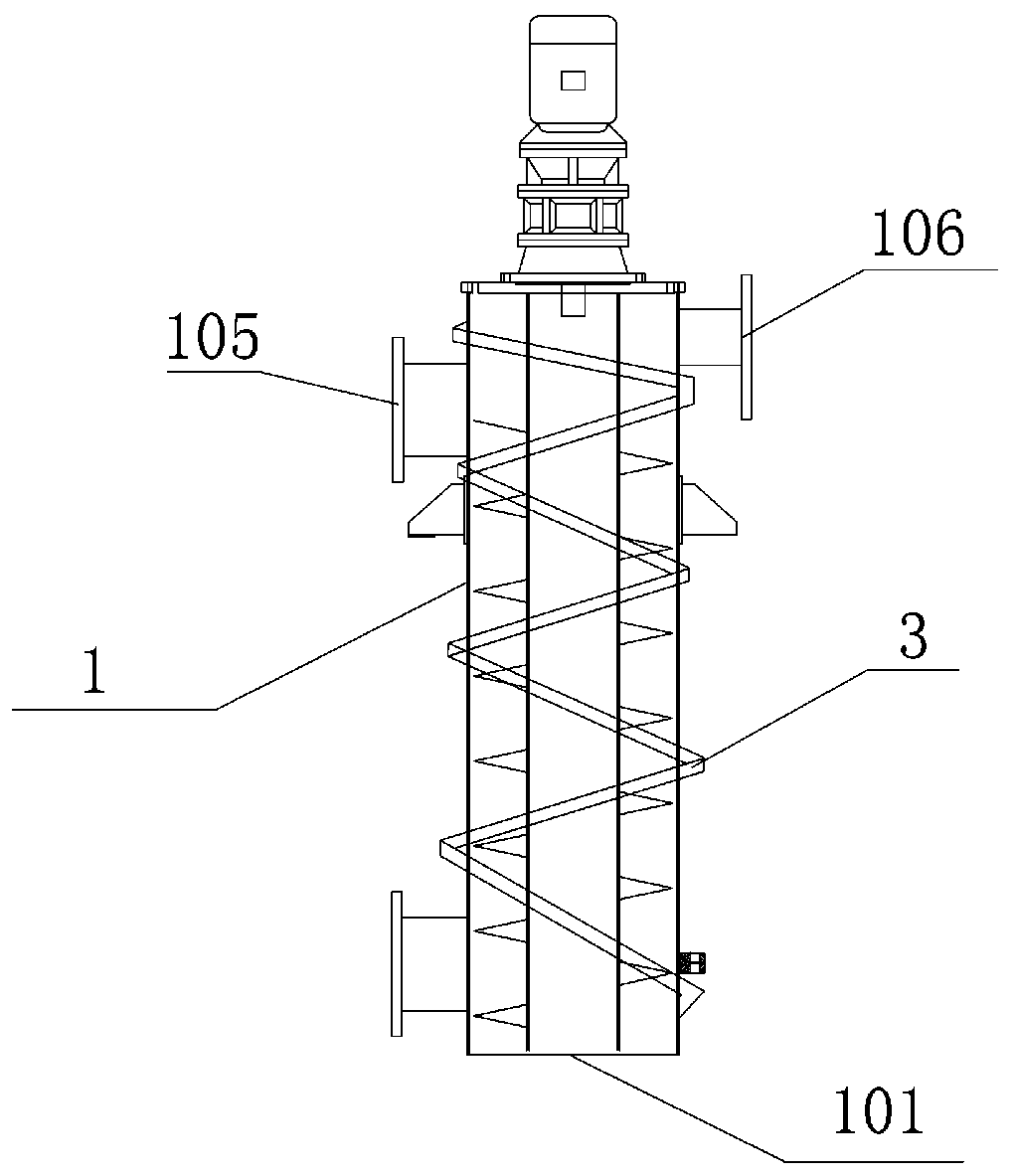

[0032] figure 1 It is a kind of cracking furnace, the inner wall of the cracking furnace is covered with SiC layer, the outer wall of the cracking furnace is wound with electromagnetic wire 3, and the electromagnetic wire 3 is connected to a power supply, and the furnace body is provided with a feed port and a discharge port. The cracking furnace is Vertical cracking furnace 1, the upper side wall of vertical cracking furnace 1 is provided with vertical cracking furnace feed port 105 and vertical cracking furnace flue gas outlet 106, and the lower part of vertical cracking furnace 1 is provided with vertical cracking furnace discharge port 101 .

Embodiment 2

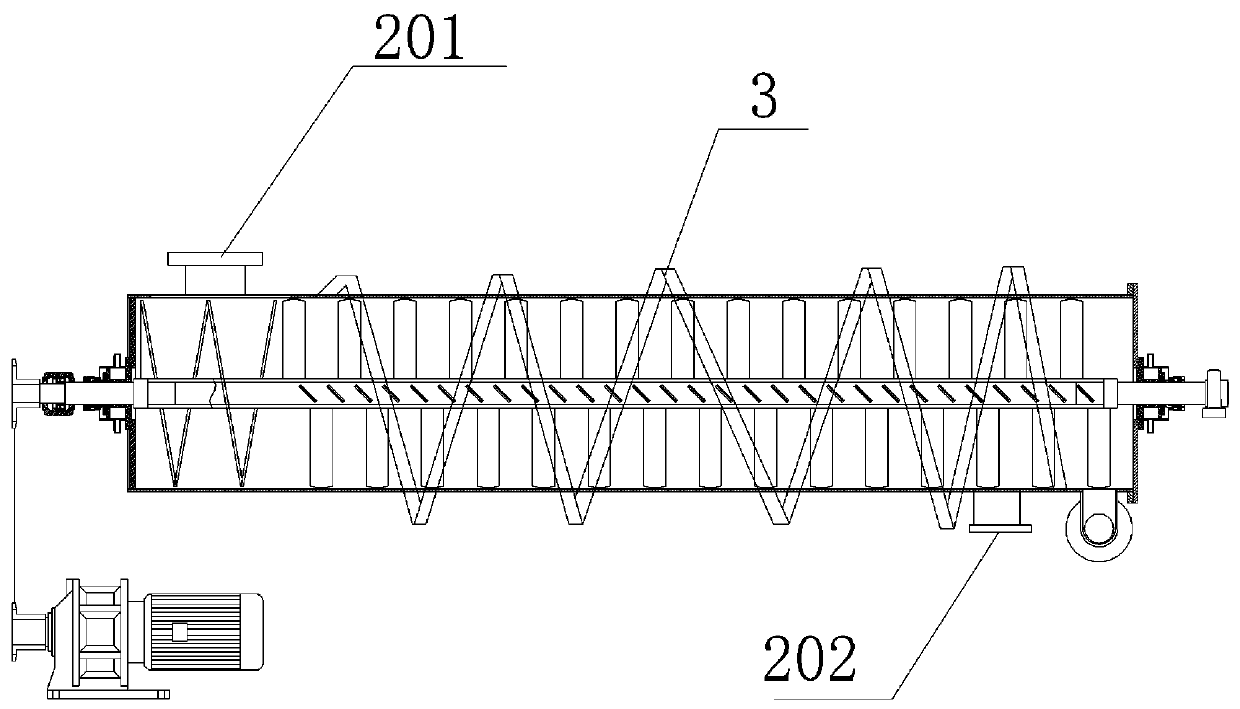

[0034] figure 2 It is a kind of cracking furnace, the inner wall of the cracking furnace is covered with SiC layer, the outer wall of the cracking furnace is wound with electromagnetic wire 3, and the electromagnetic wire 3 is connected to a power supply, and the furnace body is provided with a feed port and a discharge port. The cracking furnace is Horizontal cracking furnace 2 , the horizontal cracking furnace feed port 201 is arranged above the horizontal cracking furnace 2 , and the horizontal cracking furnace discharge port 202 is arranged below the horizontal cracking furnace 2 .

Embodiment 3

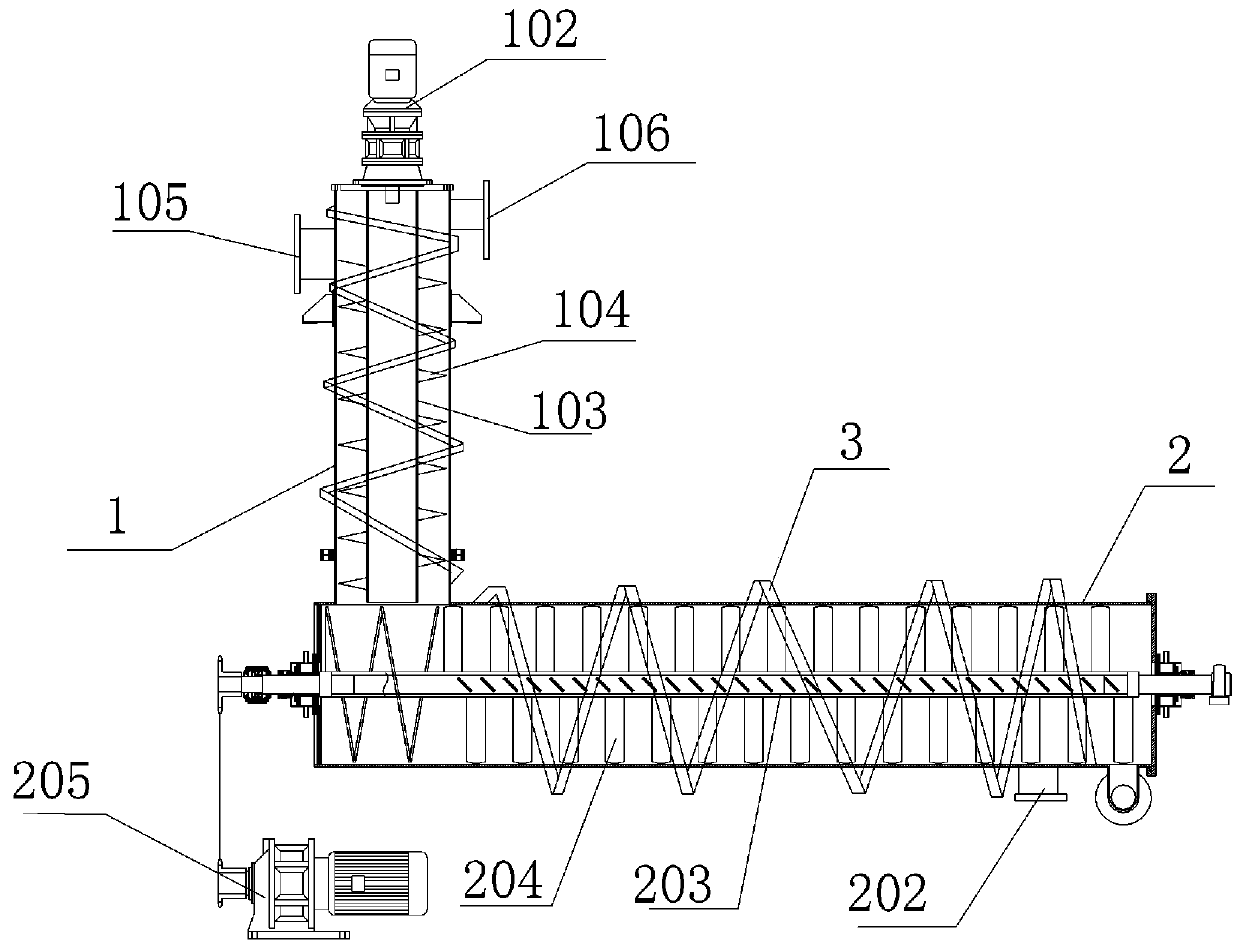

[0036] Such as Figure 3-13 Shown, a kind of cracking device, the inner wall of described cracking furnace covers SiC layer, and this cracking device comprises vertical cracking furnace 1, and the lower end of vertical cracking furnace 1 communicates with horizontal cracking furnace 2, and vertical cracking furnace 1 and The outer wall of the horizontal cracking furnace 2 is wound with a magnet wire 3, and the magnet wire 3 is connected to a power source. The inner wall of the furnace body of the vertical cracking furnace 1 and the horizontal cracking furnace 2 is covered with a SiC layer.

[0037] The upper end face of described vertical cracking furnace 1 is provided with stirring motor 102, and the output shaft of stirring motor 102 runs through vertical cracking furnace 1 and connects stirring feeding shaft 103, and the length direction of stirring feeding shaft 103 is the same as the length of vertical cracking furnace 1. Direction is the same, the outer wall of stirring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com