Preparation method of glycolide

A glycolide and ethanol technology, applied in the field of materials, can solve the problems of increasing the difficulty of product purification, increasing the cost of separation and purification, and increasing the cost of production, so as to reduce production costs, solve product pollution, and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031]1.1 Add 1520g of 100% glycolic acid, 2000g of hydroxyl-terminated polybutadiene (HTPB2500, Zibo Qilong Chemical), 10g of succinic acid and 2g of catalyst stannous octoate into a 5L round-bottomed flask in sequence, and heat up to 130 degrees for stirring , react at normal pressure for 3 hours, then raise the temperature to 160 degrees, vacuumize the polycondensation reaction, P=3000Pa, after 5 hours, increase the vacuum degree to P=600Pa, continue the polycondensation reaction for 10 hours, and obtain hyperbranched polybutadiene-oligomeric Glycolic acid copolymer 3100g.

[0032] The hyperbranched polybutadiene-oligoglycolic acid copolymer obtained in the present invention is analyzed by gel permeation chromatography, and the number average molecular weight of the polymer is measured to be 5100 g / mol.

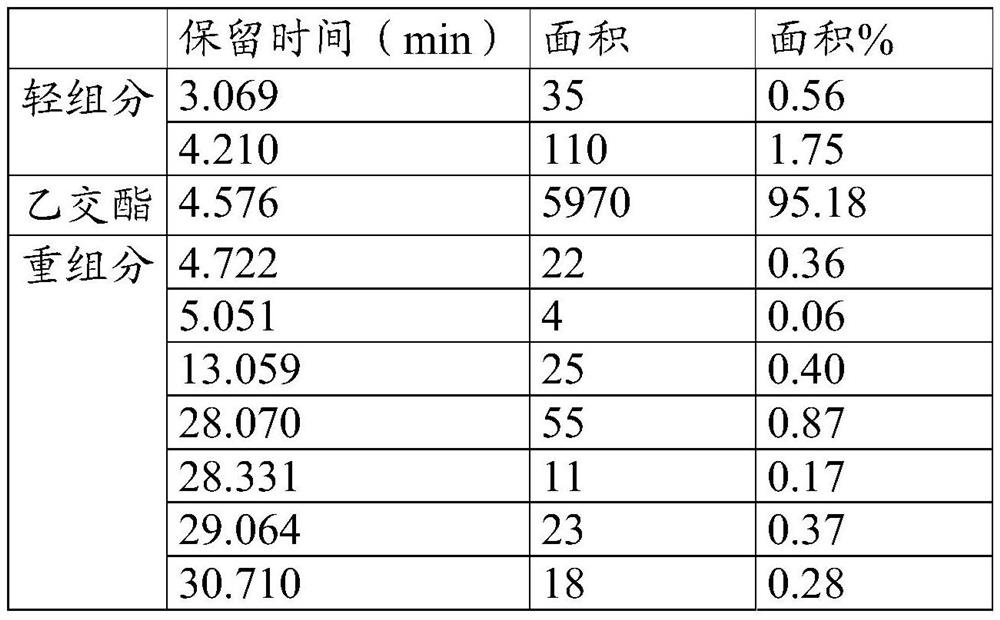

[0033] 1.2 The hyperbranched polybutadiene-oligoglycolic acid copolymer among the embodiment 1.1 and 5g cracking catalyst antimony trioxide are warmed up to 220 degree, af...

Embodiment 2

[0039] 2.1 Add 1520g of 100% glycolic acid, 3000g of hydroxyl-terminated polybutadiene (HTPB2500, Zibo Qilong Chemical), 20g of succinic acid and 3g of catalyst stannous chloride into a 5L round-bottomed flask in turn, and heat up to 140 degrees to carry out Stir, react at normal pressure for 3 hours, then heat up to 170 degrees, vacuumize for polycondensation reaction, P=3000Pa, after 4 hours, increase the vacuum degree to P=700Pa, continue polycondensation reaction for 10 hours, and obtain hyperbranched polybutadiene-low Polyglycolic acid copolymer 4095g.

[0040] The hyperbranched polybutadiene-oligoglycolic acid copolymer obtained in the present invention is analyzed by gel permeation chromatography, and the number average molecular weight of the polymer is measured to be 5500 g / mol.

[0041] 2.2 The hyperbranched polybutadiene-oligoglycolic acid copolymer in embodiment 2.1 and 7g cracking catalyst zinc oxide are warmed up to 230 degrees, after the copolymer melts complete...

Embodiment 3

[0045] 3.1 Add 1520g of 100% glycolic acid, 2000g of hydroxyl-terminated polybutadiene (HTPB4500, Zibo Qilong Chemical), 20g of adipic acid and 4g of catalyst stannous benzoate into a 5L round-bottomed flask in turn, and heat up to 150 degrees for Stir, react at normal pressure for 3 hours, then heat up to 170 degrees, vacuumize for polycondensation reaction, P=3000Pa, after 2 hours, increase the vacuum degree to P=700Pa, continue polycondensation reaction for 10 hours, and obtain hyperbranched polybutadiene-low Polyglycolic acid copolymer 3098g.

[0046] The hyperbranched polybutadiene-oligoglycolic acid copolymer obtained in the present invention is analyzed by gel permeation chromatography, and the number average molecular weight of the polymer is 7500 g / mol.

[0047] 3.2 The hyperbranched polybutadiene-oligoglycolic acid copolymer in embodiment 3.1 and 5g cracking catalyst antimony acetate are warmed up to 240 degrees, after the copolymer melts completely, depolymerize by ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com