Automatic microwave cracking reaction device for waste rubber

A technology of cracking reaction and waste rubber, which is applied in the petroleum industry and the preparation of liquid hydrocarbon mixtures, etc., can solve the problems of affecting workers' health, leakage of carbon residue and dust, secondary pollution of the environment, etc., and achieves light weight, regeneration, and automation. high degree of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

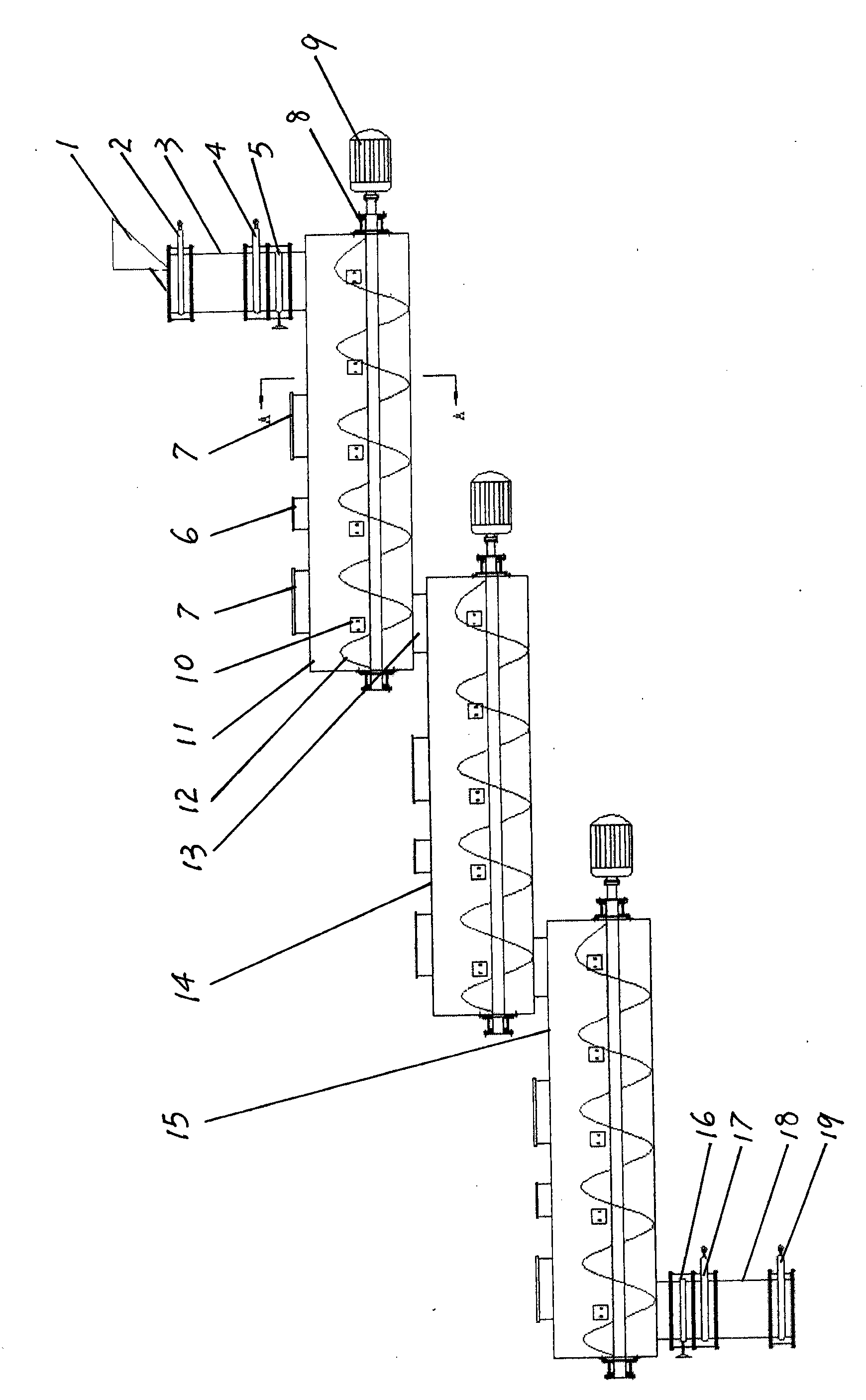

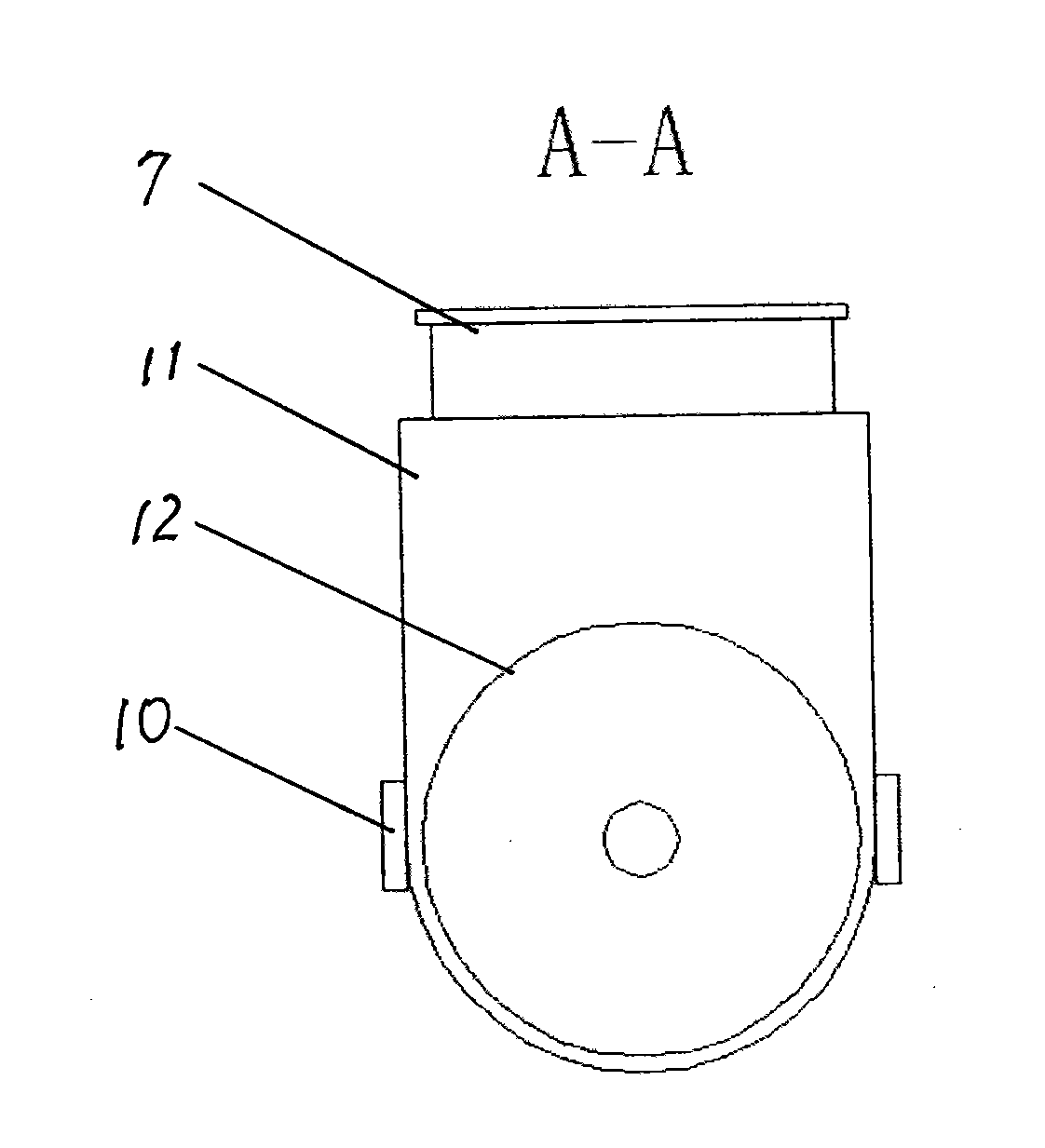

[0012] The invention is attached figure 1 , 2 As shown, it is mainly composed of frequency conversion motor 9, screw propulsion microwave cracking reaction chamber, pneumatic airtight automatic feeding valve combination and pneumatic airtight slag discharge valve combination. The feed end of the microwave cracking reaction chamber 14 is connected to the discharge end of the first screw propulsion microwave cracking reaction chamber 11 through the connecting pipe 13, and the feed end of the third spiral propulsion type microwave cracking reaction chamber 15 is connected to The pipe is connected to the discharge end of the second screw propulsion type microwave cracking reaction chamber 14; the combination of the material distributor 1 and the pneumatic airtight feed valve is connected to the feed end of the first screw propulsion type microwave cracking reaction chamber 11, and the pneumatic The airtight slag discharge valve assembly is connected to the discharge end of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com