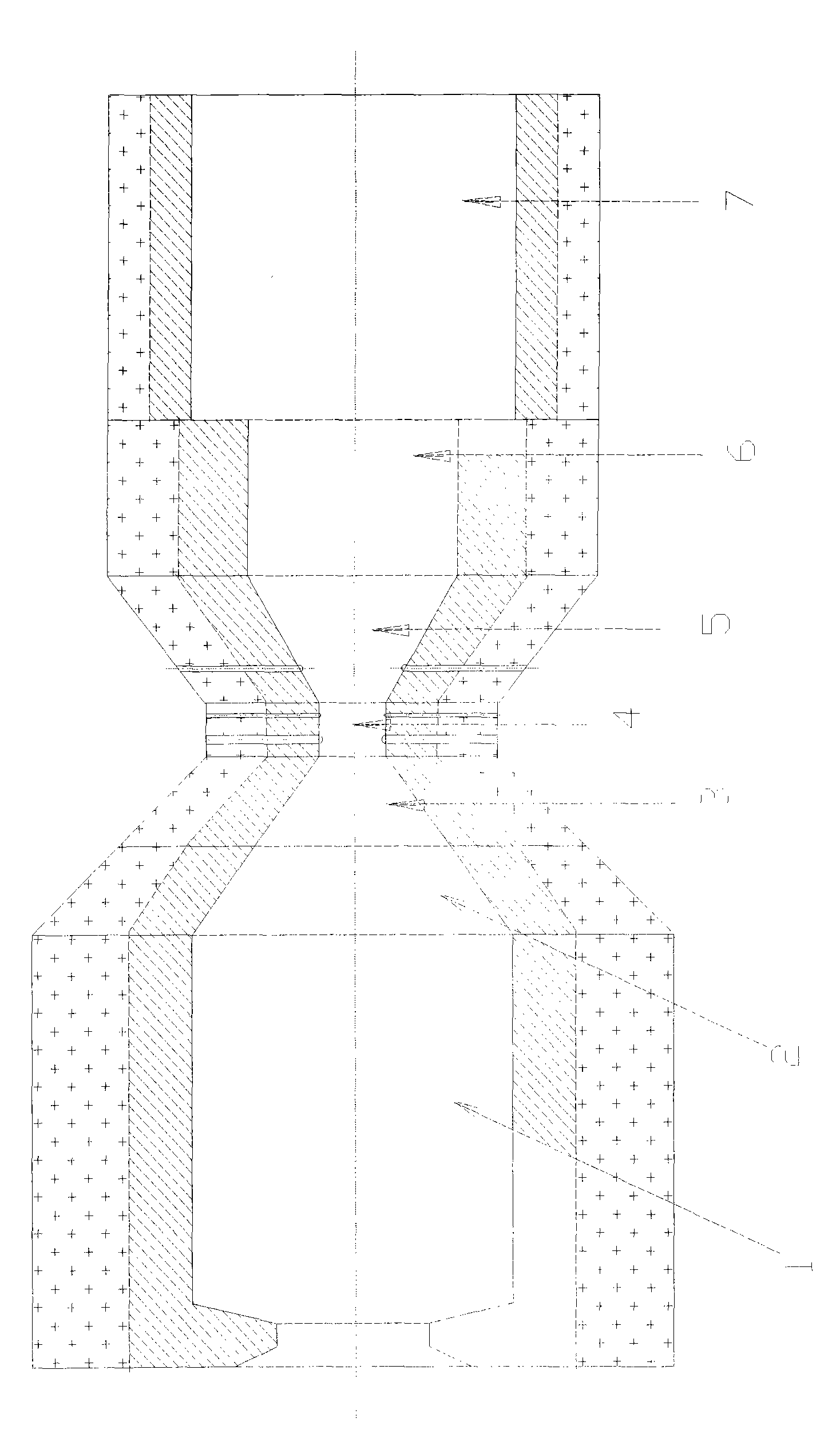

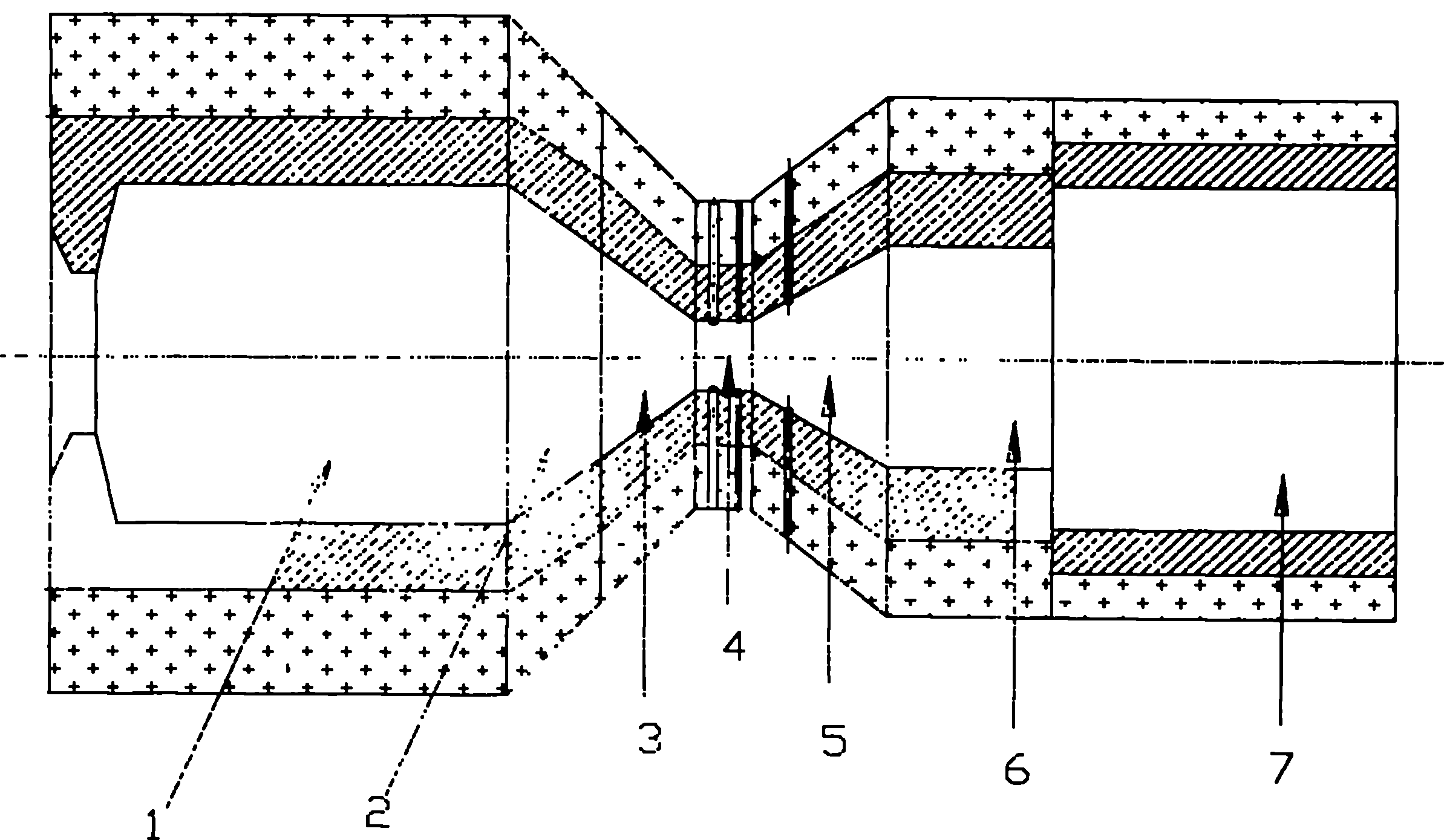

40-thousand-ton hard carbon black reaction furnace and production process of carbon black

A technology of hard carbon black and reaction furnace, applied in fibrous fillers and other directions, can solve the problems that the quality cannot meet the quality requirements of all-steel radial tires, the high quality of raw material oil, and the high consumption of carbon black per ton, and achieve low cost, The effect of improving quality and expanding production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

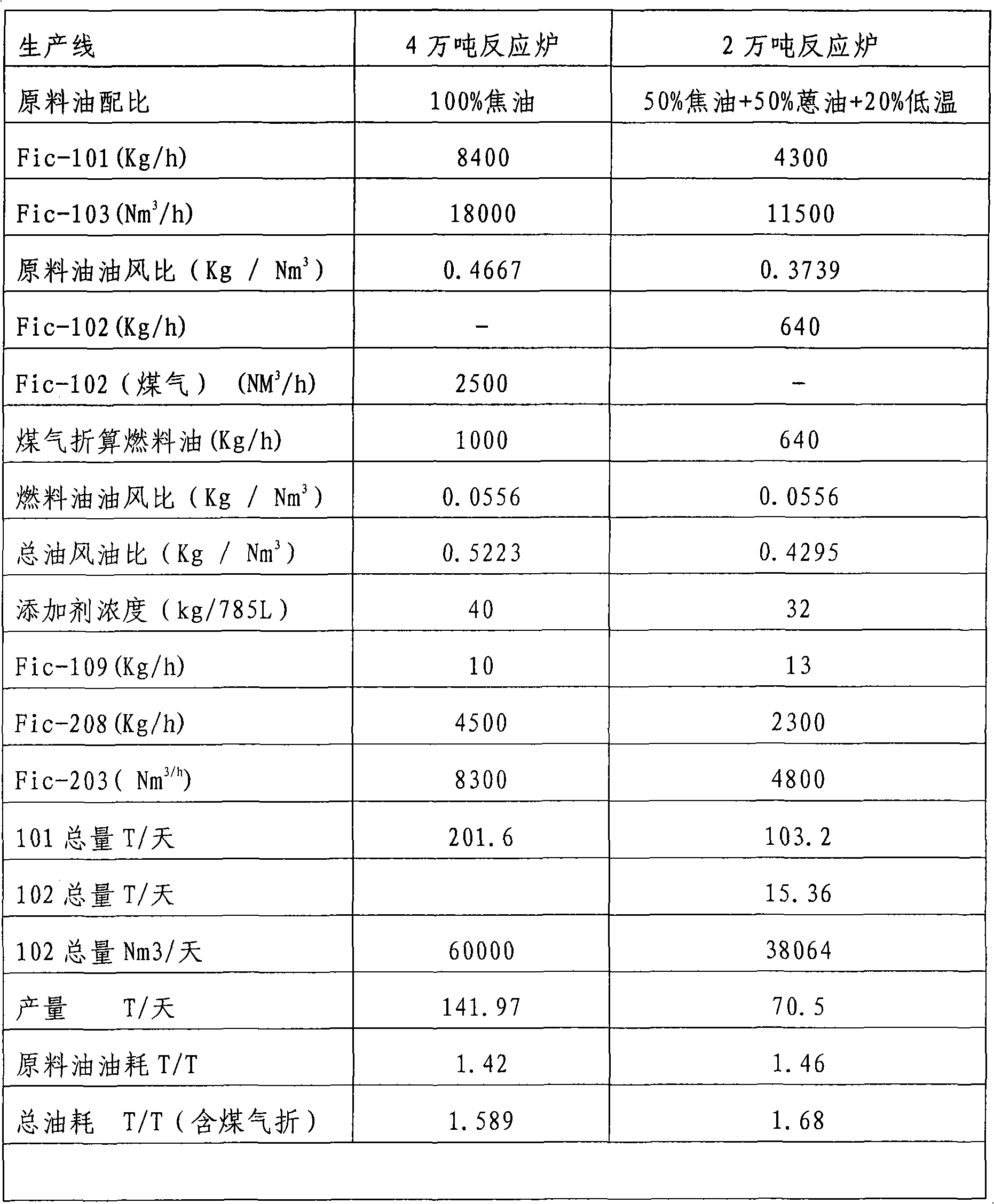

[0028] The reaction furnace of the present invention is used to produce carbon black variety N326, and coke oven gas is used as fuel, and the raw material oil composed of 30% anthracene oil+50% tar+20% low-temperature tar is sprayed into the throat section in an atomized state and produced by pyrolysis Carbon black, and at the same time supplement coke oven gas 200Nm at the front of the throat 3 / hr, the carbon black flue gas is collected after quenching into carbon black. It can be seen from the table below that when using a 40,000-ton reaction furnace to produce N326 carbon black, the quality of the produced carbon black is obviously better than that produced by a 20,000-ton carbon black reaction furnace. This is concentrated in the coloring strength of the product (Tint) and compression oil absorption value, the Tint value of the product produced by the 40,000-ton reactor is about 3% higher than that of the product produced by the 20,000-ton reactor, and the compression oil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com