Oil sludge cracking device

A cracking device and oil sludge technology, which is applied in the petroleum industry, hydrocarbon oil treatment, sludge treatment by pyrolysis, etc., can solve the problems of difficult dehydration, high cost of treatment process, secondary pollution, etc., so as to improve the utilization rate of heat and reduce The effect of producing secondary pollution and increasing the cracking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

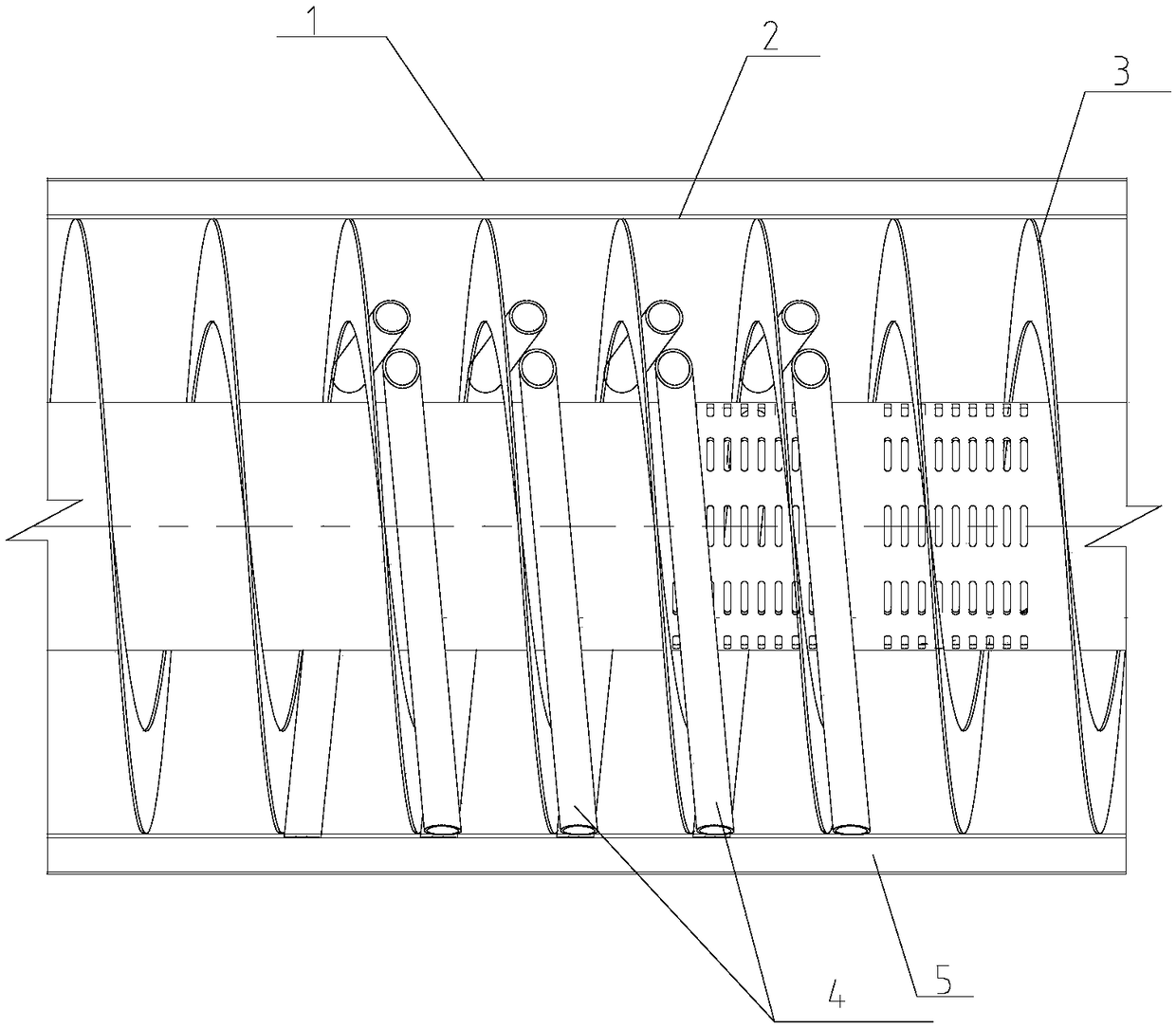

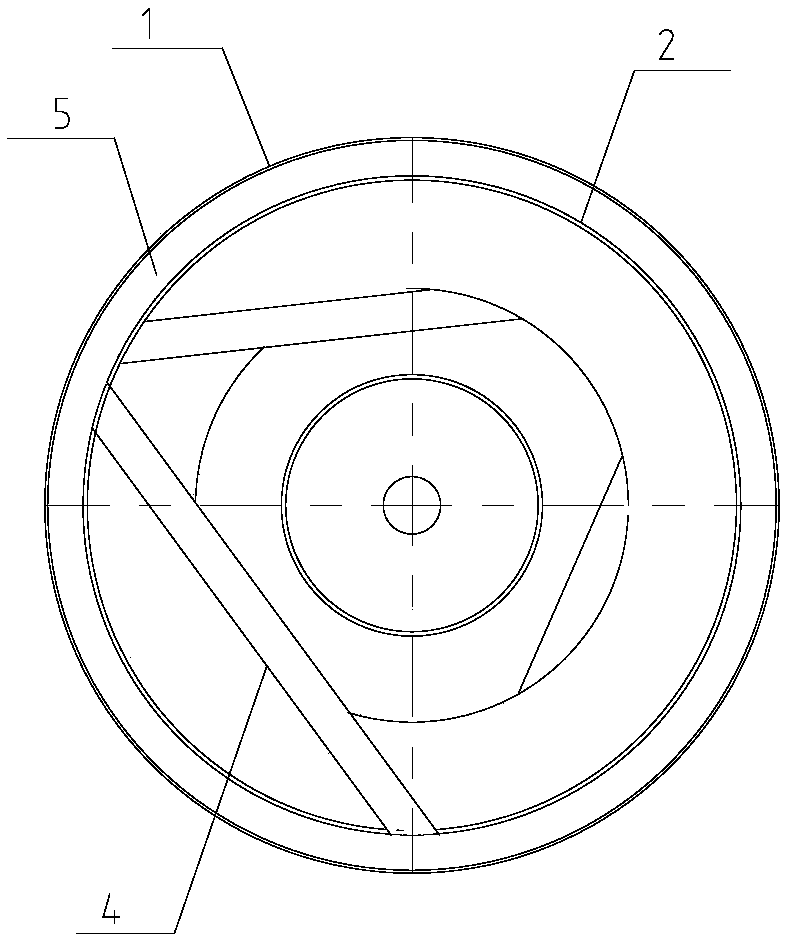

[0015] An oil sludge cracking device comprises an outer cylinder body and an inner cylinder body, the inner wall of the inner cylinder is provided with a spiral conveyor belt, and a heat conduction pipe is arranged on the spiral conveyor belt.

[0016] The heat pipe is a hollow pipe.

[0017] A solid heat carrier is dispersed in the inner cylinder.

Embodiment 2

[0019] An oil sludge cracking device comprises an outer cylinder body and an inner cylinder body, the inner wall of the inner cylinder is provided with a spiral conveyor belt, and a heat conduction pipe is arranged on the spiral conveyor belt.

[0020] Heat conduction pipes are uniformly arranged on each pitch of the spiral conveyor belt. Each pitch is provided with a heat pipe.

[0021] The heat pipe is a hollow pipe.

[0022] A solid heat carrier is dispersed in the inner cylinder.

[0023] The solid heat carrier is a non-metallic sphere.

[0024] The diameter of the non-metallic sphere is 5-25mm.

Embodiment 3

[0026] An oil sludge cracking device comprises an outer cylinder body and an inner cylinder body, the inner wall of the inner cylinder is provided with a spiral conveyor belt, and a heat conduction pipe is arranged on the spiral conveyor belt.

[0027] Heat conduction pipes are uniformly arranged on each pitch of the spiral conveyor belt. Two heat pipes are arranged on each pitch.

[0028] The heat pipe is a hollow pipe.

[0029] A solid heat carrier is dispersed in the inner cylinder.

[0030] The solid heat carrier is a metal sphere.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com