Apparatus for continuously cracking beta-pinene to produce laurene

A technology of myrcene and pinene, applied in the field of continuous cracking of β-pinene to produce myrcene, can solve the problems of less research on production equipment, high production cost, uneven heating, etc., and achieve rapid cooling and effective recovery of heat energy , low cost, and the effect of accelerating the cracking speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

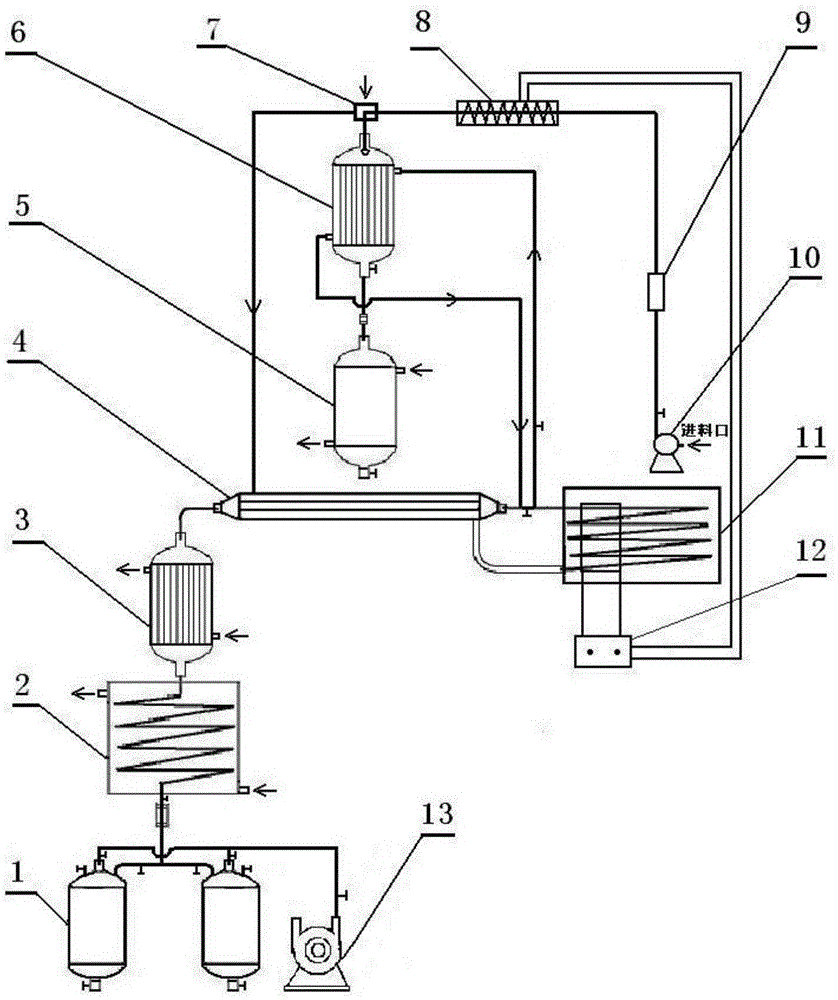

[0026] As shown in accompanying drawing 1, the device of β-pinene continuous cracking production myrcene comprises feed pump 10, vaporizer 6, cracker 11, heat exchanger 4, cooling unit and product collector 1, and they are connected successively; The feed port of the feed pump 10 is connected to the raw material tank, the discharge port of the feed pump 10 is connected to the upper end of the vaporizer 6 through a conduit, an electric heater 8 is provided on the conduit, and a flow meter 9 is also provided above the feed pump 10; The bottom of the vaporizer 6 is connected to the non-volatile matter collector 5, and the top of the vaporizer 6 is also provided with a gas mixing chamber 7. The heat-conducting material inlet and the heat-conducting material outlet of the vaporizer 6 are respectively connected with the lead-out pipes before and after the lead-out pipe valve of the cracker 11, and the vaporizer The feed pump 10 feed outlet of the upper end of 6 is provided with the s...

Embodiment 2

[0030]As shown in accompanying drawing 1, the device of β-pinene continuous cracking production myrcene comprises feed pump 10, vaporizer 6, cracker 11, heat exchanger 4, cooling unit and product collector 1, and they are connected successively; The feed port of the feed pump 10 is connected to the raw material tank, the discharge port of the feed pump 10 is connected to the upper end of the vaporizer 6 through a conduit, an electric heater 8 is provided on the conduit, and a flow meter 9 is also provided above the feed pump 10; The bottom of the vaporizer 6 is connected to the non-volatile matter collector 5, and the top of the vaporizer 6 is also provided with a gas mixing chamber 7. The heat-conducting material inlet and the heat-conducting material outlet of the vaporizer 6 are respectively connected with the lead-out pipes before and after the lead-out pipe valve of the cracker 11, and the vaporizer The feed pump 10 feed outlet of the upper end of 6 is provided with the sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com