Production method of instant solid sea cucumbers

A production method and sea cucumber technology, applied in the field of ready-to-eat solid sea cucumber production, can solve the problems of nutrient loss, sea cucumber taste, poor quality, poor processing quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

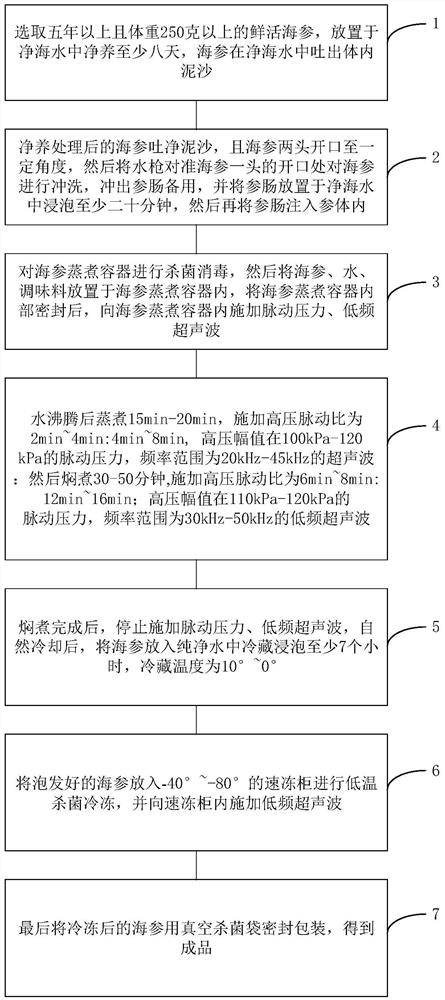

[0042] The invention provides a kind of instant solid sea cucumber production method, such as Figure 1-3 shown, including the following steps:

[0043] Step 1. Select fresh sea cucumbers that are more than five years old and weigh more than 250 grams, and place them in clean sea water for at least eight days. The sea cucumbers spit out the sediment in the clean sea water;

[0044] Step 2: After cleaning the sea cucumbers, spit out the silt, and open the two ends of the sea cucumbers to a certain angle, then point the water gun at the opening of one end of the sea cucumbers to rinse the sea cucumbers, flush out the intestines for later use, and place the intestines in the net Soak in seawater for at least 20 minutes, and then inject the ginseng into the body; the pressure of the water gun is 0.5MPa-1.1MPa, and the pressure of the water gun is preferably 0.5MPa, 0.6MPa, 0.8MPa, 0.9MPa, 1MPa, 1.1MPa. Through experimental comparison, it can be seen that when the pressure of the wa...

Embodiment 2

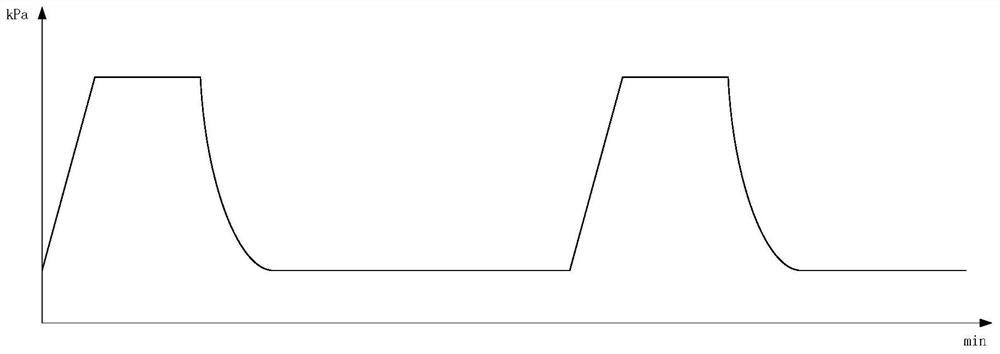

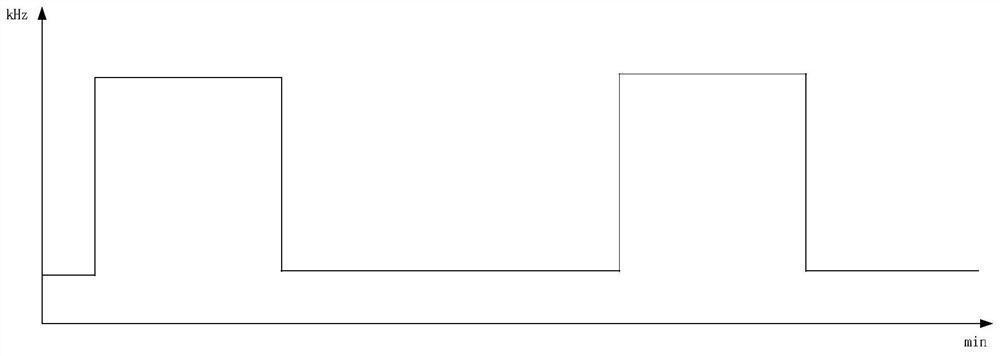

[0060] Embodiment 2 The difference between this embodiment and Embodiment 1 is that in step 4, after boiling the water, cook for 20 minutes, apply a high-pressure pulsation ratio of 4min:8min, a pulsating pressure with a high-pressure amplitude of 100kPa, and a low-frequency ultrasonic wave with a frequency range of 20kHz: Then simmer for 50 minutes, apply high pressure pulsation ratio of 8min:16min; pulsation pressure with high amplitude at 110kPa, and ultrasonic waves with a frequency range of 50kHz.

Embodiment 3

[0061] Embodiment 3 The difference between this embodiment and Embodiment 2 is that in step 4, after boiling the water, cook for 15 minutes, apply a high-pressure pulsation ratio of 3min:6min, a pulsating pressure with a high-pressure amplitude of 120kPa, and a low-frequency ultrasonic wave with a frequency range of 40kHz: Then simmer for 45 minutes, apply high-pressure pulsation ratio of 8min:16min; pulsation pressure with high-pressure amplitude at 120kPa, and low-frequency ultrasonic waves with a frequency range of 35kHz.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com