Patents

Literature

98 results about "Pressure amplitude" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Definition: The amplitude is the maximum displacement from equilibrium. For a longitudinal wave which is a pressure wave this would be the maximum increase (or decrease) in pressure from the equilibrium pressure that is cause when a compression (or rarefaction) passes a point.

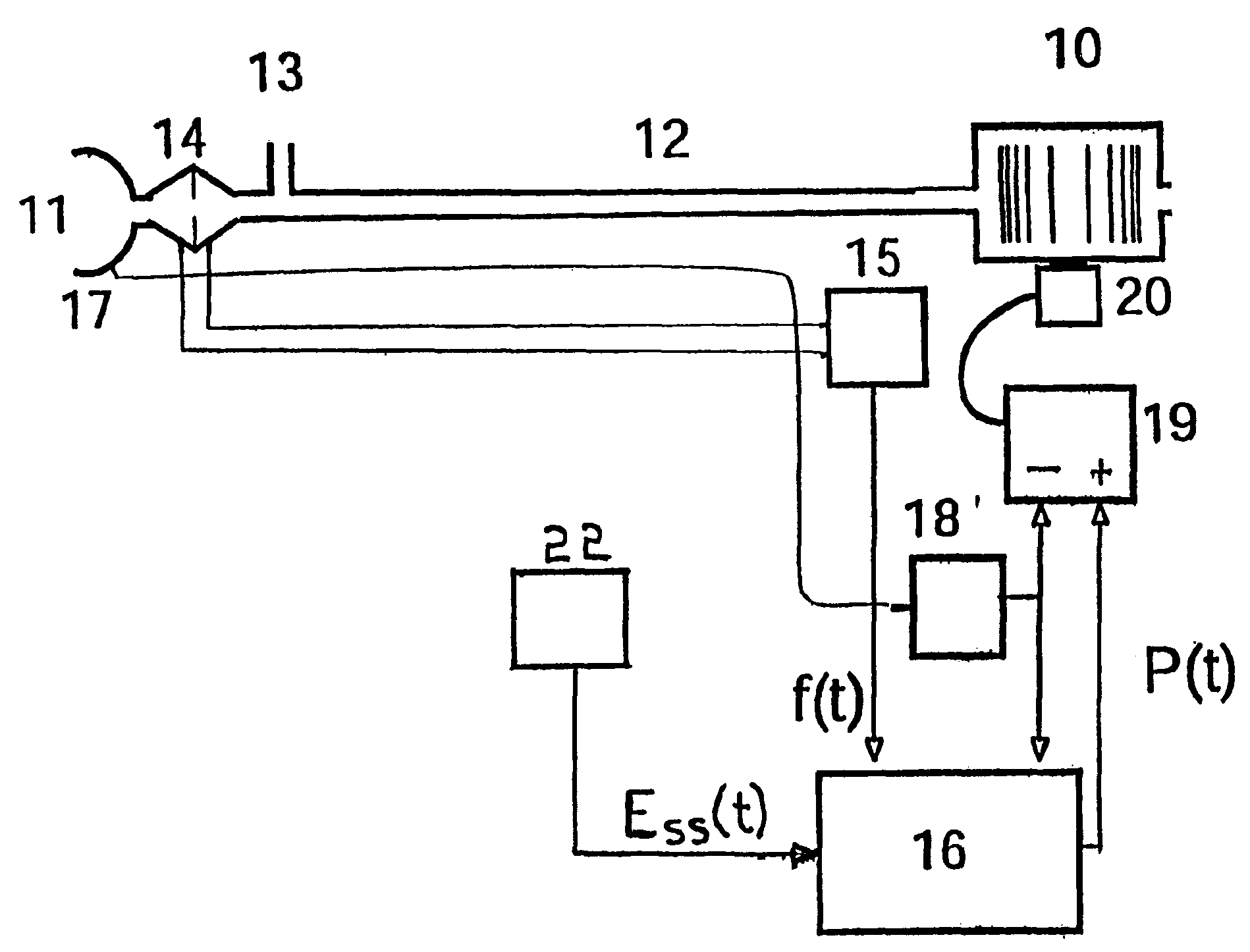

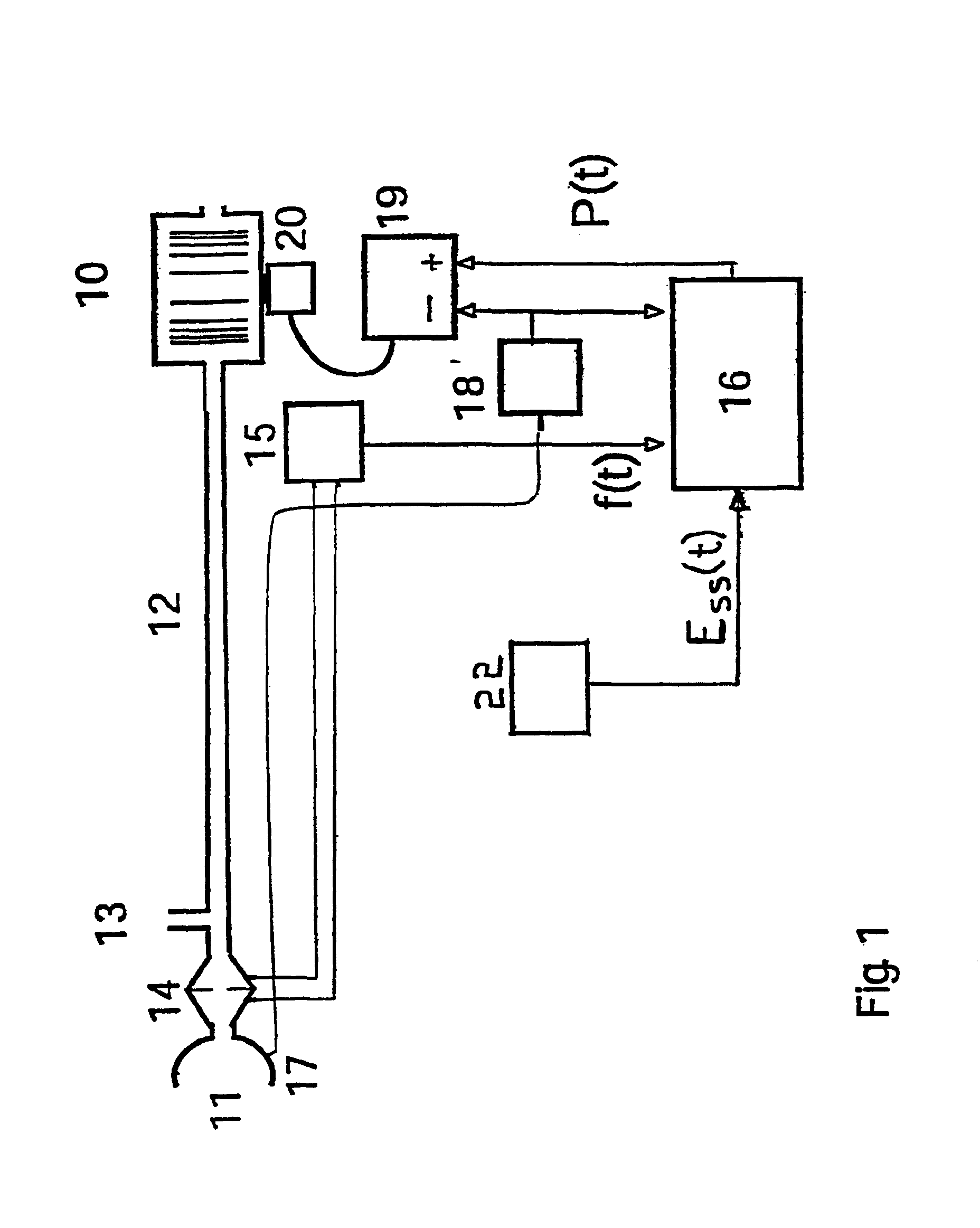

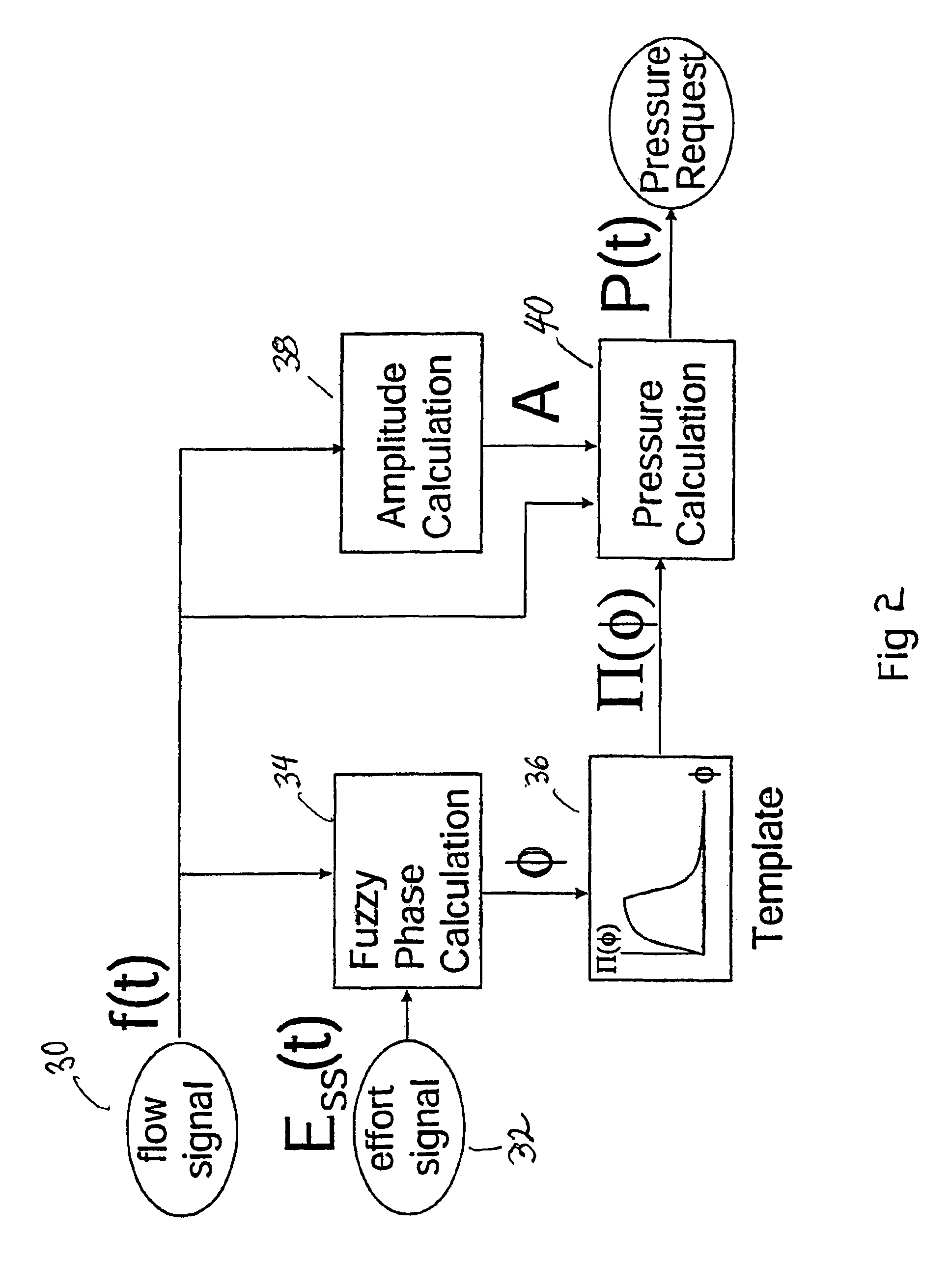

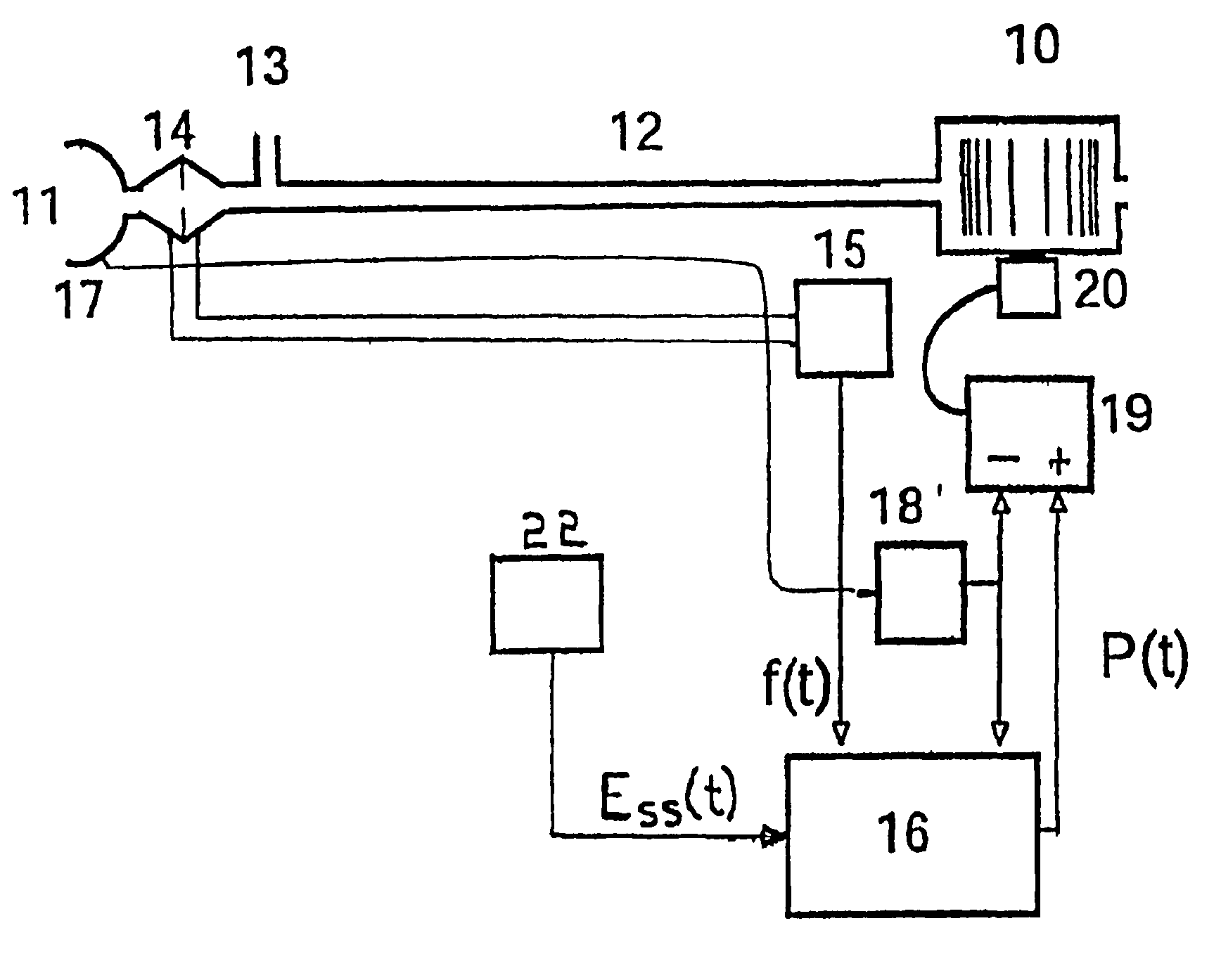

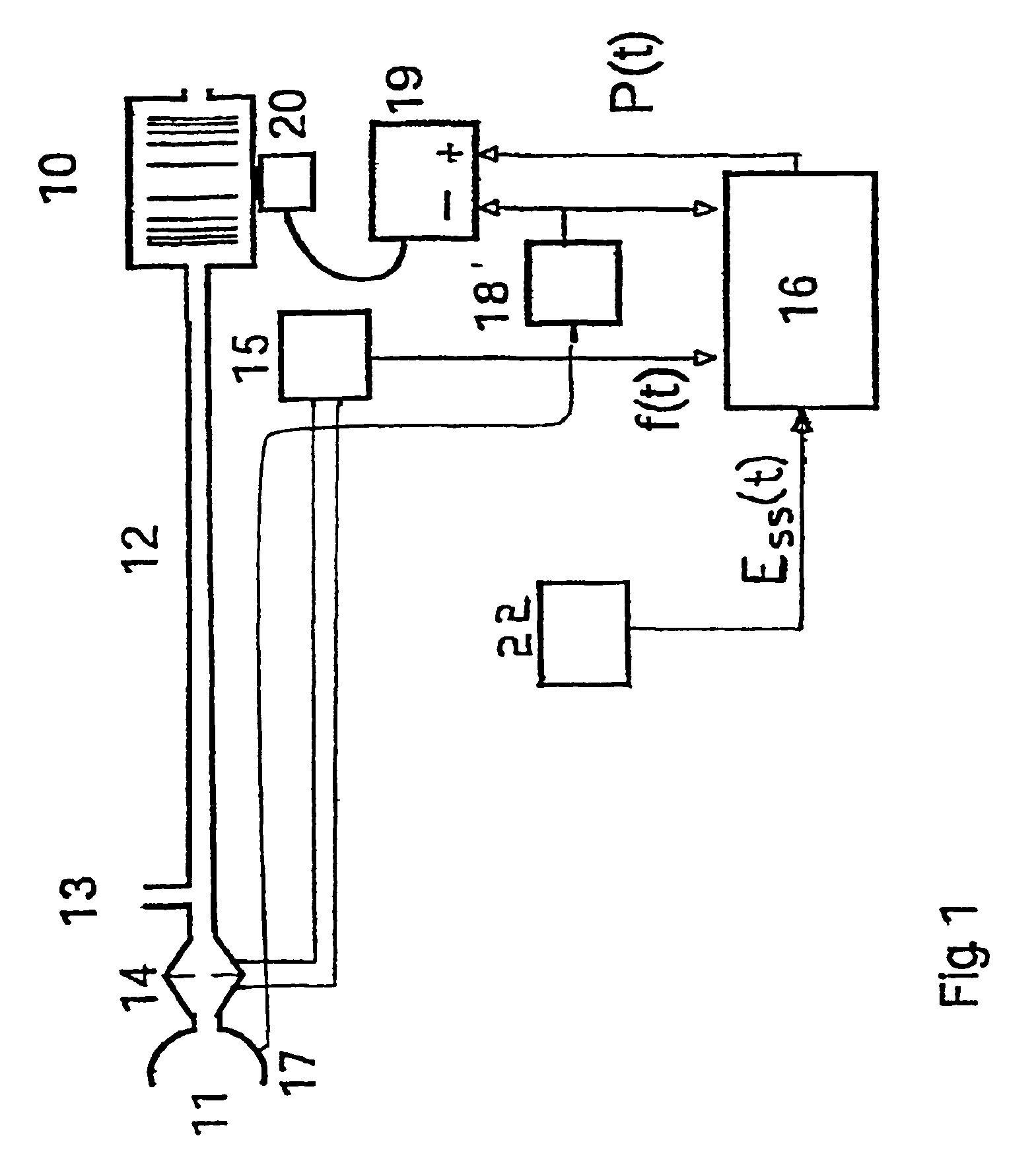

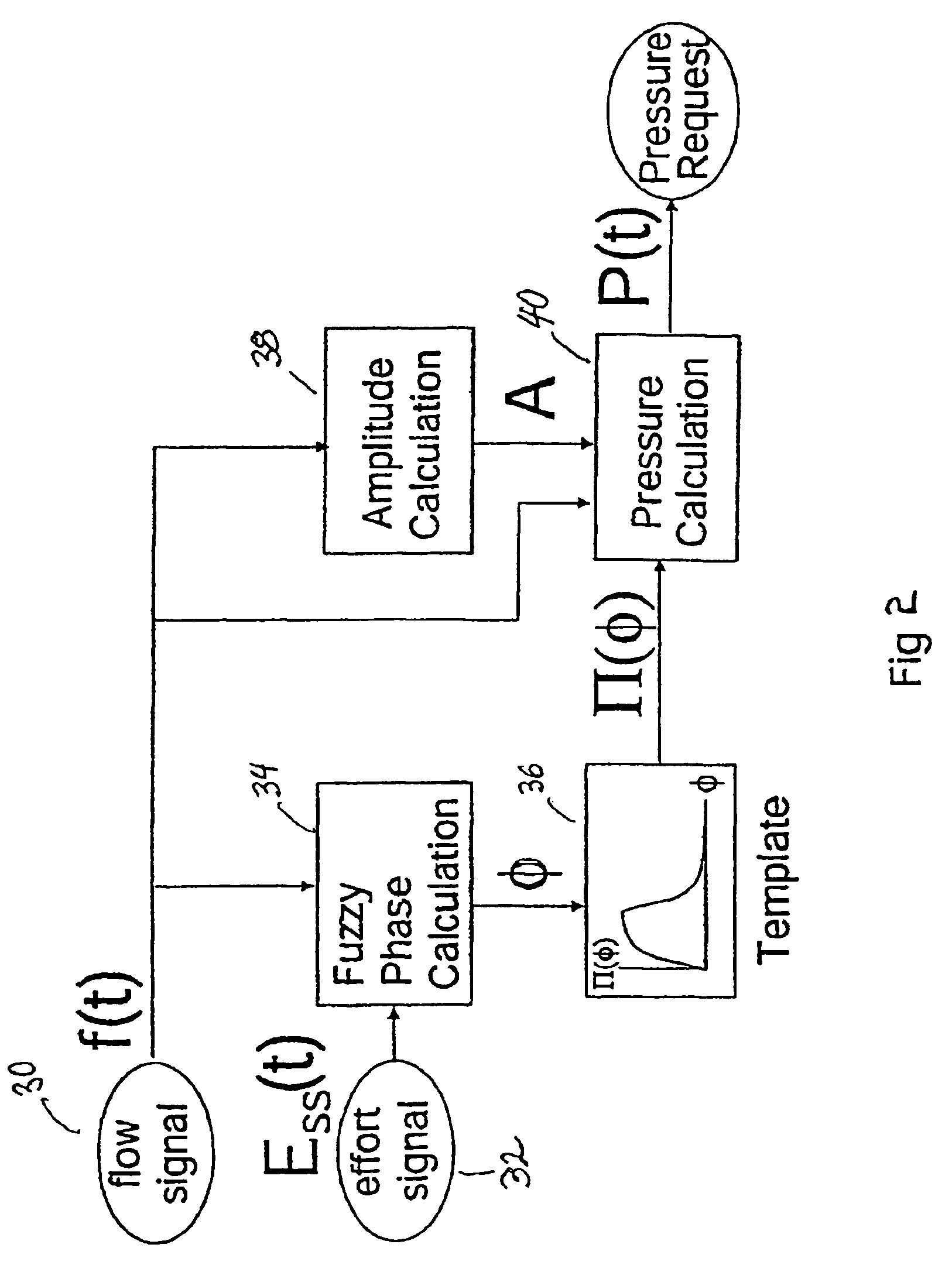

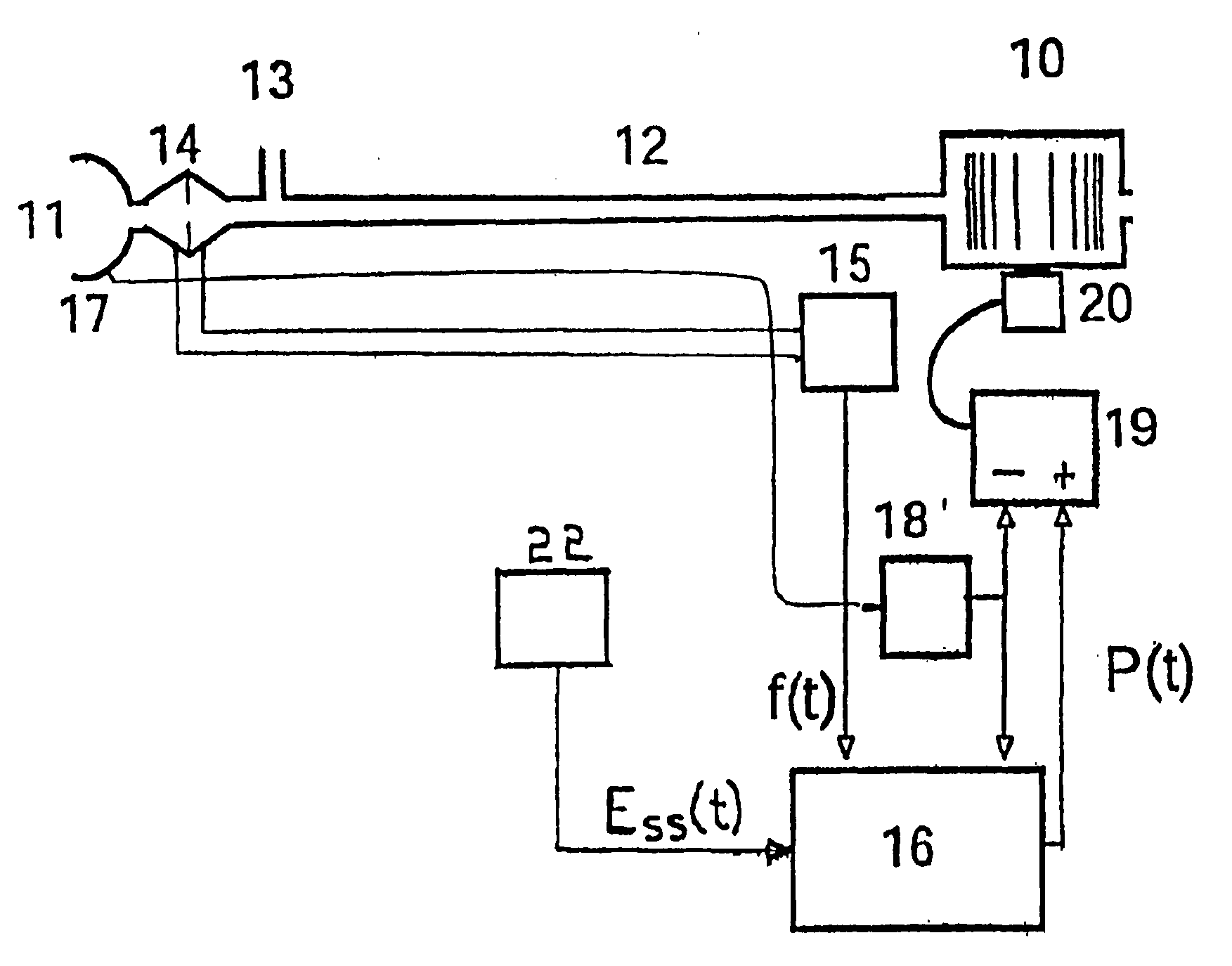

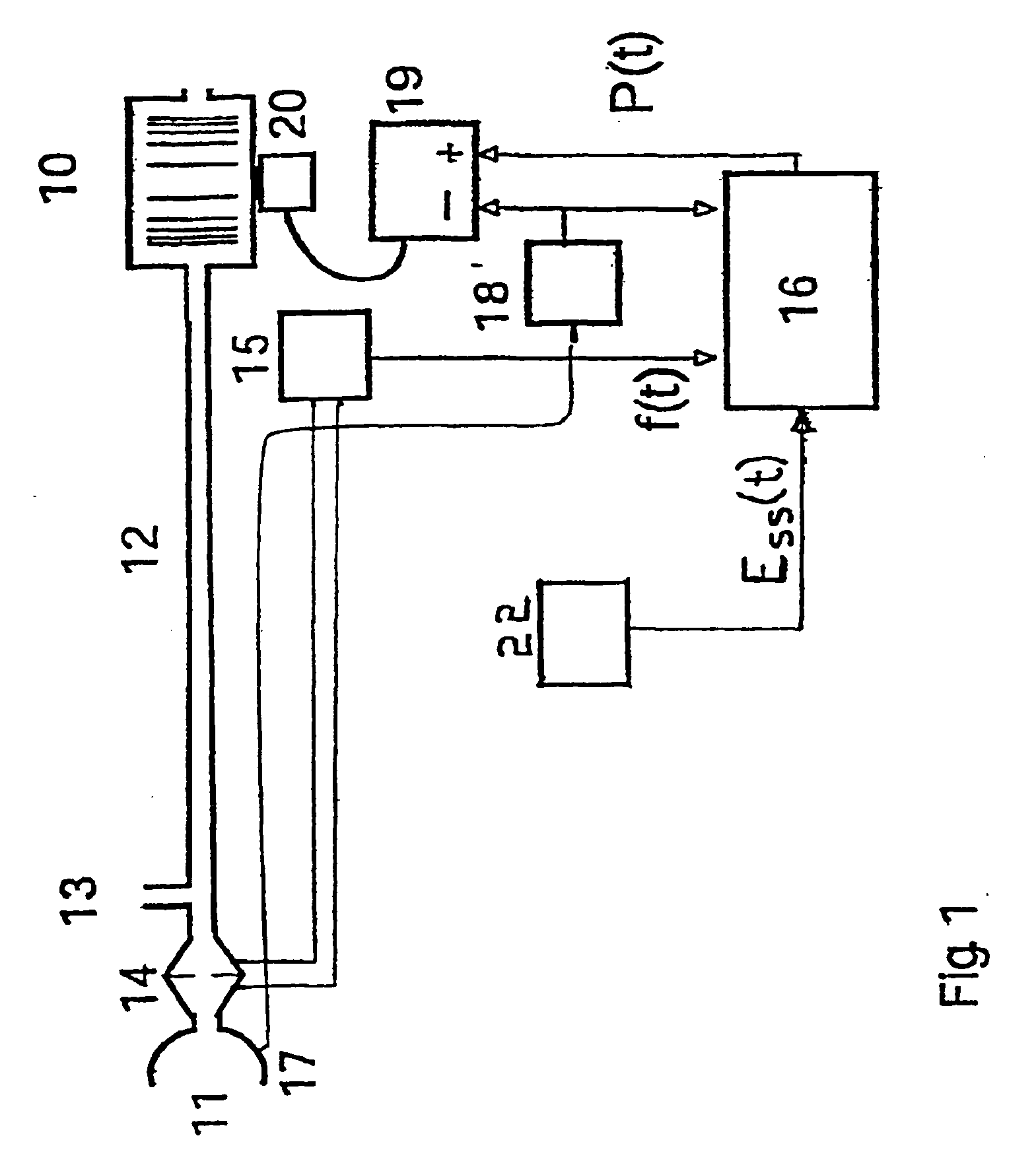

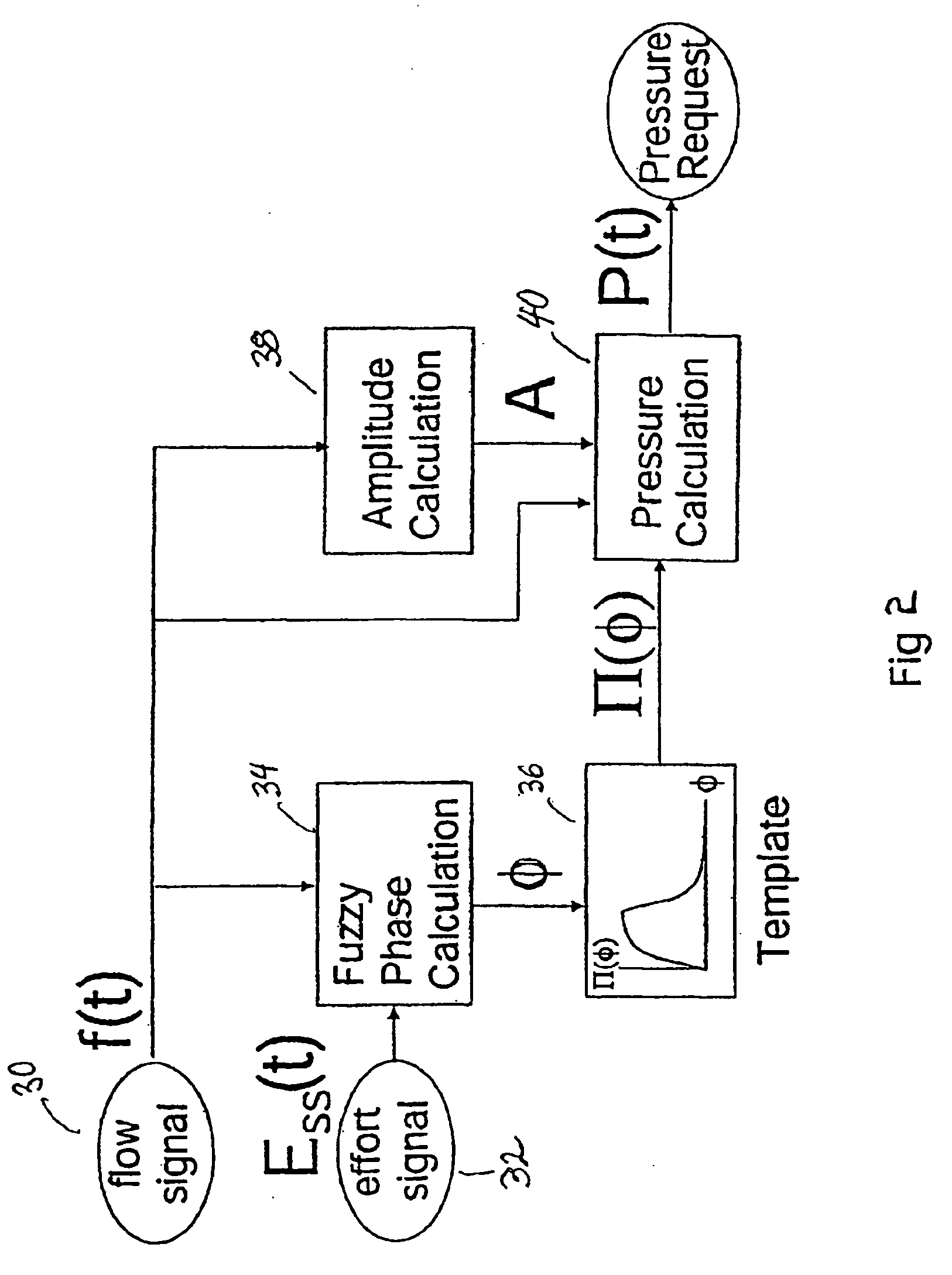

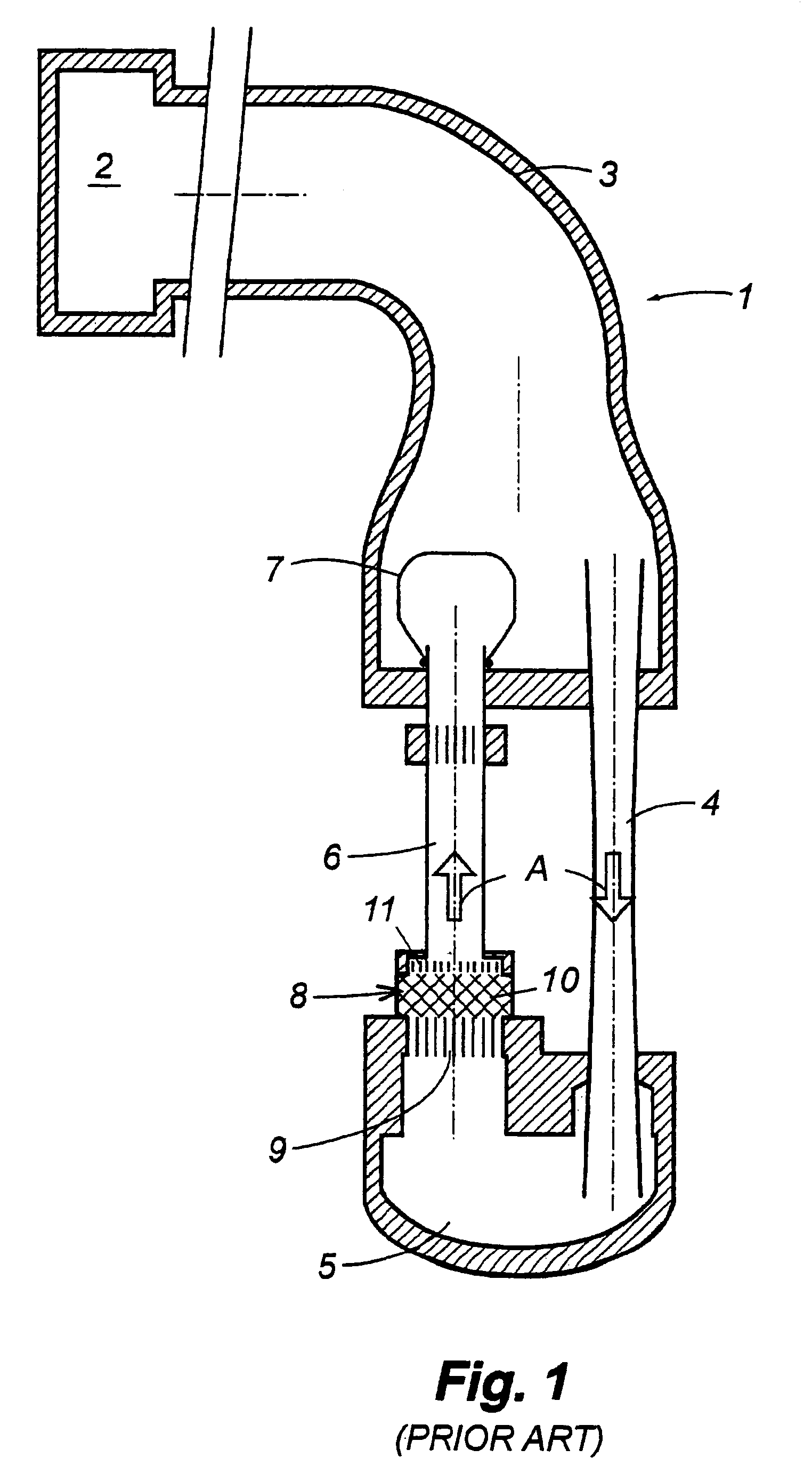

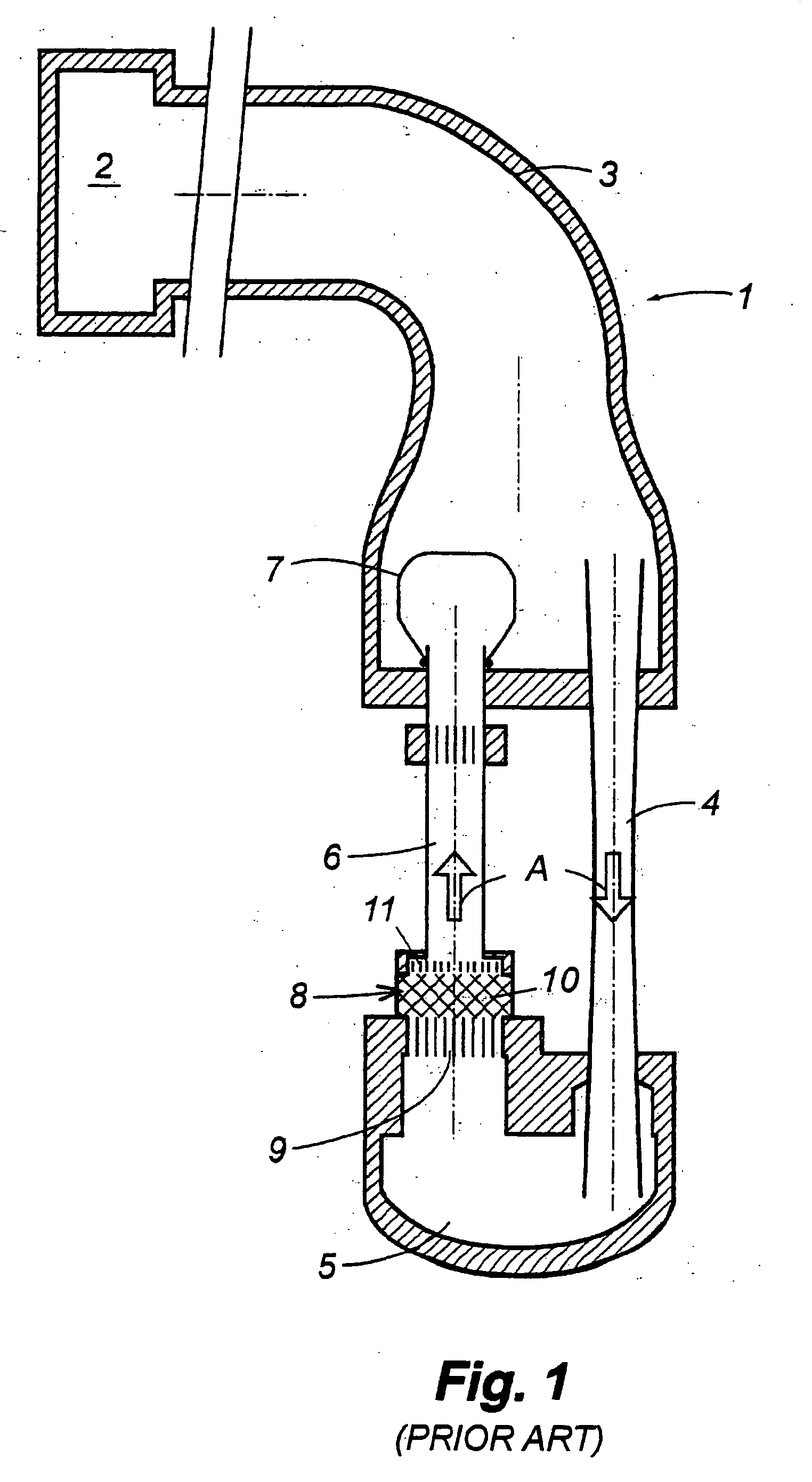

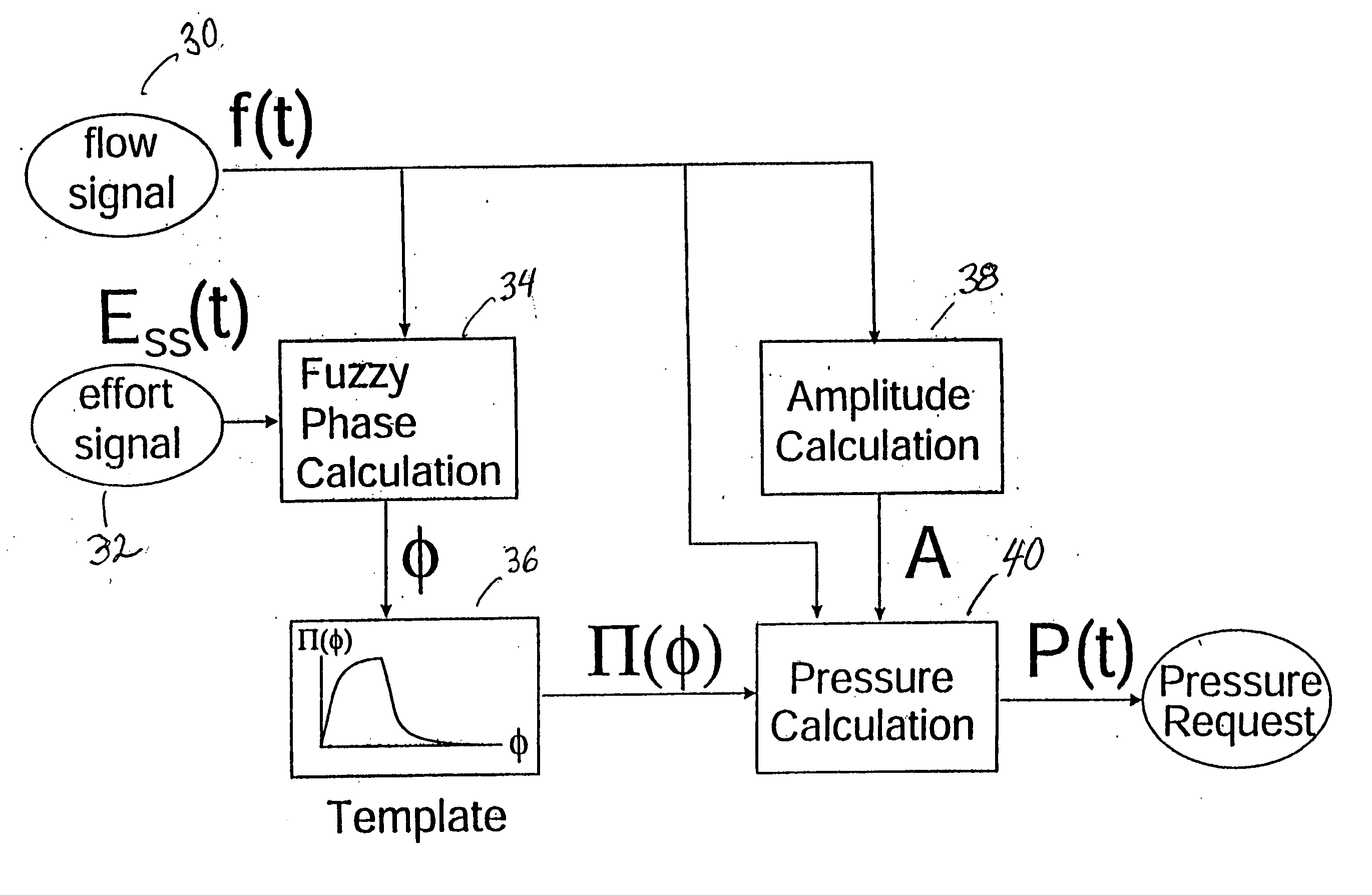

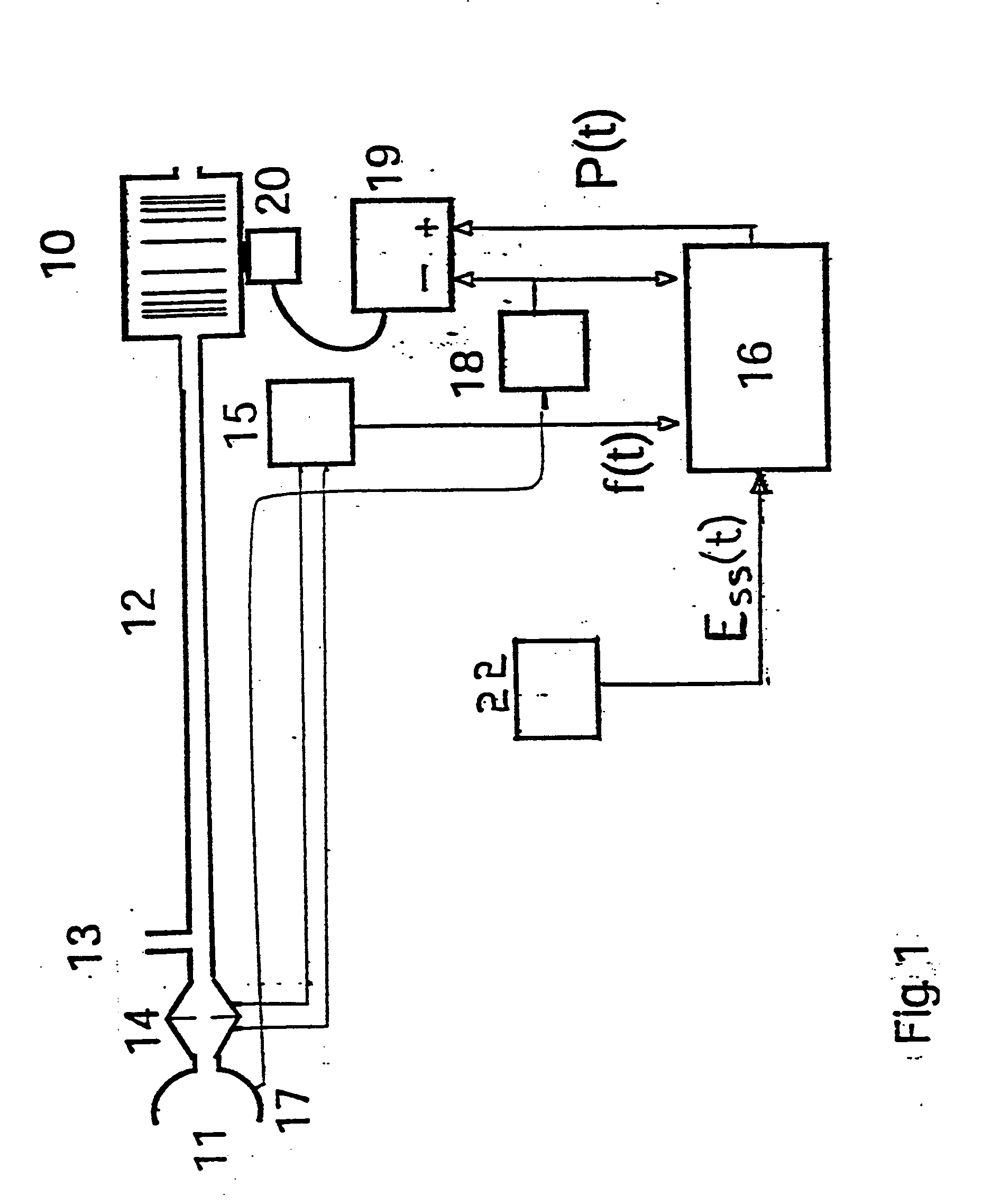

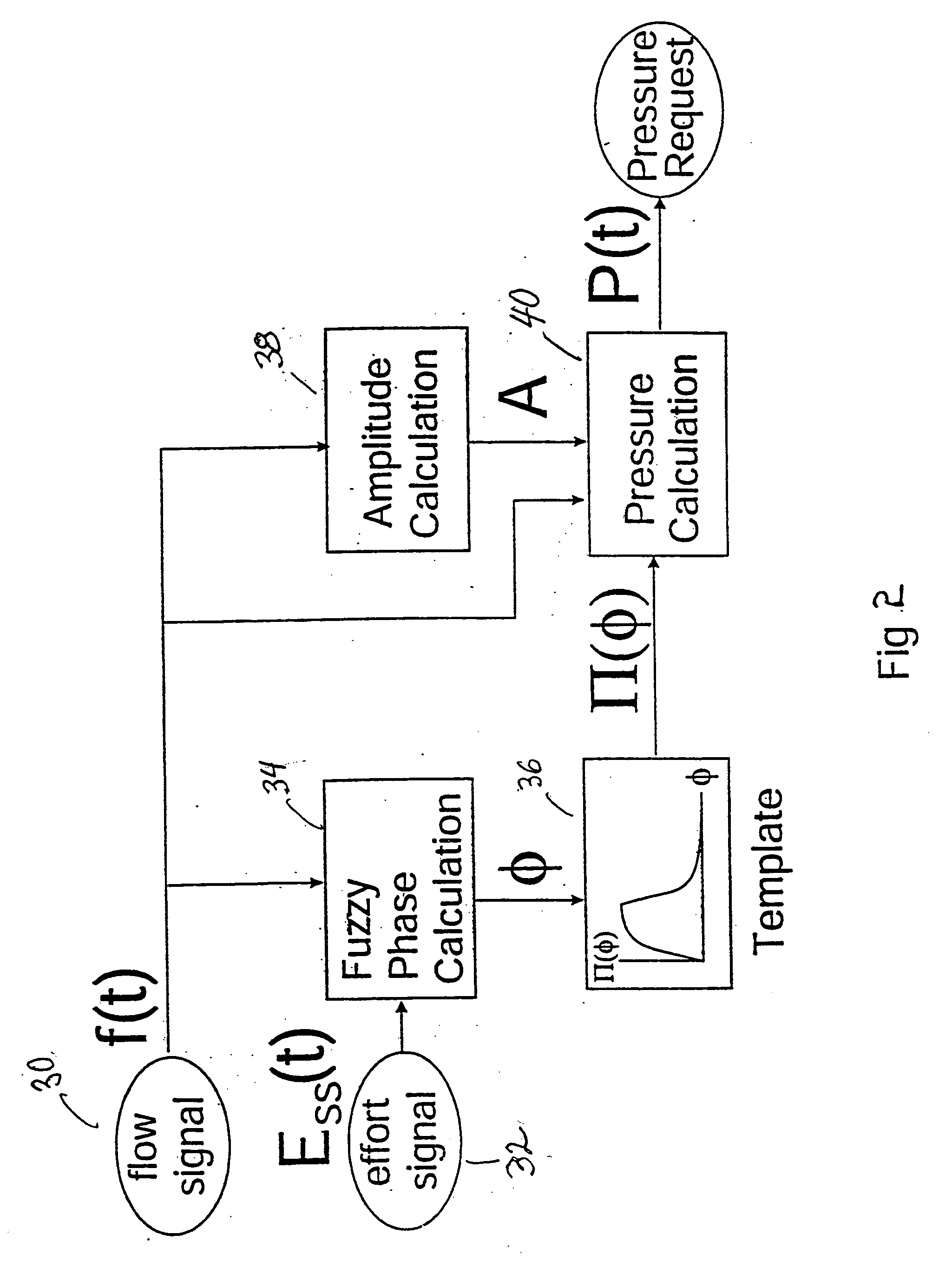

Patient-ventilator synchronization using dual phase sensors

InactiveUS6910480B1Minimum ventilationImprove determinationRespiratorsOperating means/releasing devices for valvesRespiratory phasePressure amplitude

An improved ventilator which delivers ventilatory support that is synchronized with the phase of the patient's respiratory efforts and guarantees a targeted minimum ventilation. Improved synchronization is achieved through an instantaneous respiratory phase determination process based upon measured respiratory airflow as well as measured respiratory effort using an effort sensor accessory, preferably a suprasternal notch sensor. The ventilator processes a respiratory airflow signal, a respiratory effort signal and their respective rates of change to determine a phase using standard fuzzy logic methods. A calculated pressure amplitude is adjusted based upon the calculated phase and a smooth pressure waveform template to deliver synchronized ventilation.

Owner:RESMED LTD

Patient-ventilator synchronization using dual phase sensors

InactiveUS7934499B2Minimum ventilationImprove determinationRespiratorsRespiratory device testingRespiratory phasePressure amplitude

An improved ventilator which delivers ventilatory support that is synchronized with the phase of the patients respiratory efforts and guarantees a targeted minimum ventilation. Improved synchronization is achieved through an instantaneous respiratory phase determination process based upon measured respiratory airflow as well as measured respiratory effort using an effort sensor accessory, preferably a suprasternal notch sensor. The ventilator processes a respiratory airflow signal, a respiratory effort signal and their respective rates of change to determine a phase using standard fuzzy logic methods. A calculated pressure amplitude is adjusted based upon the calculated phase and a smooth pressure waveform template to deliver synchronized ventilation.

Owner:RESMED LTD

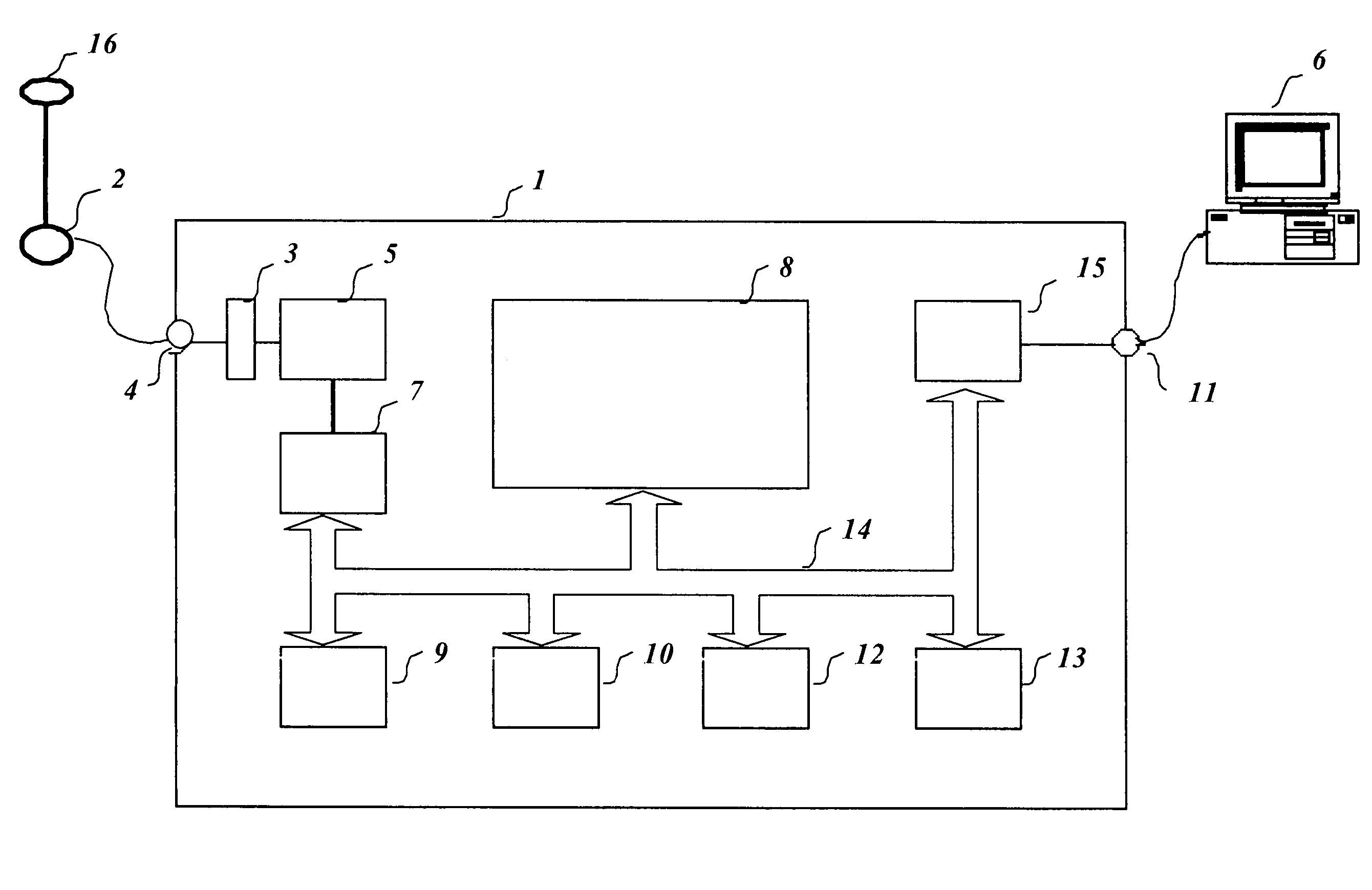

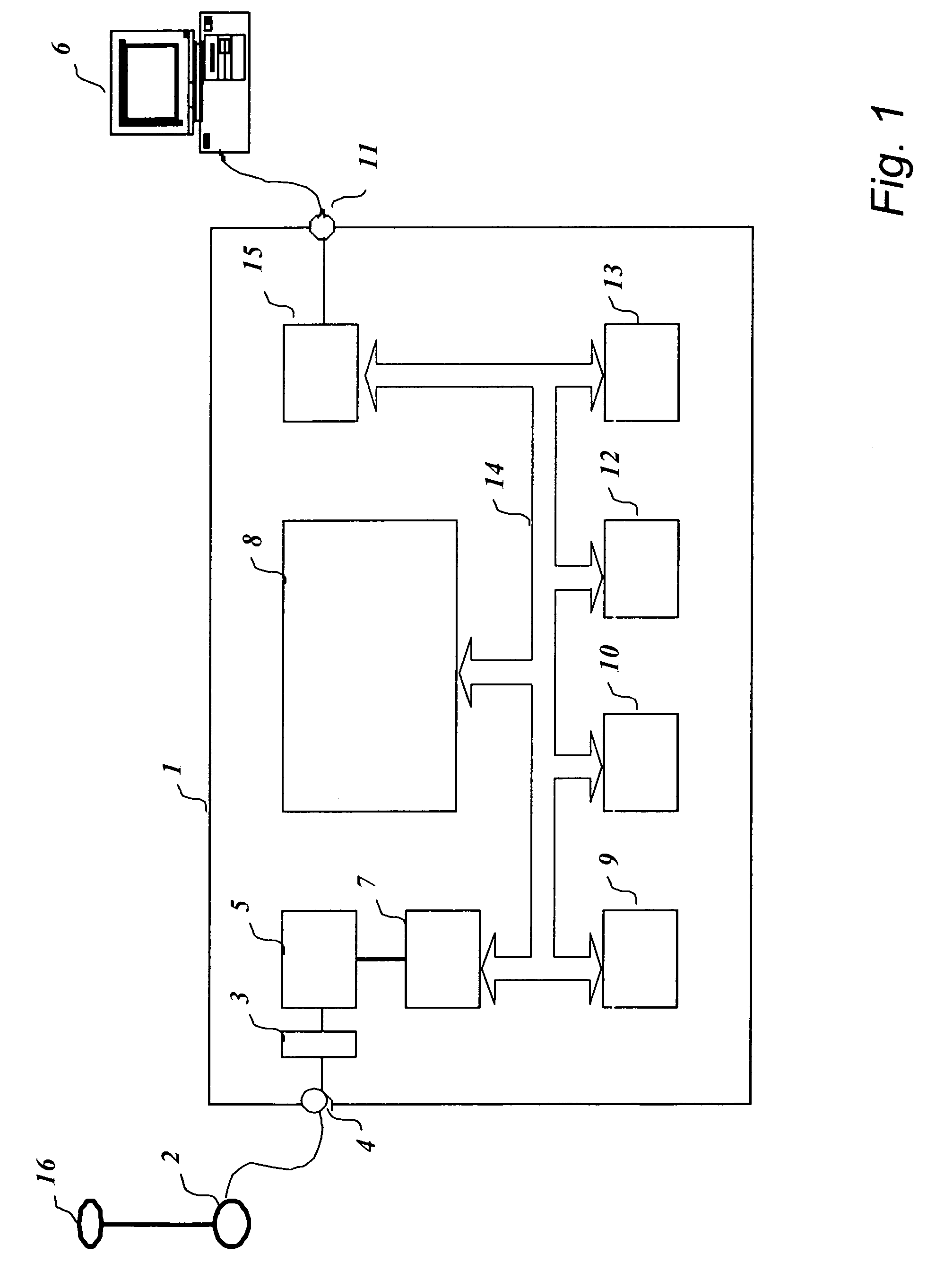

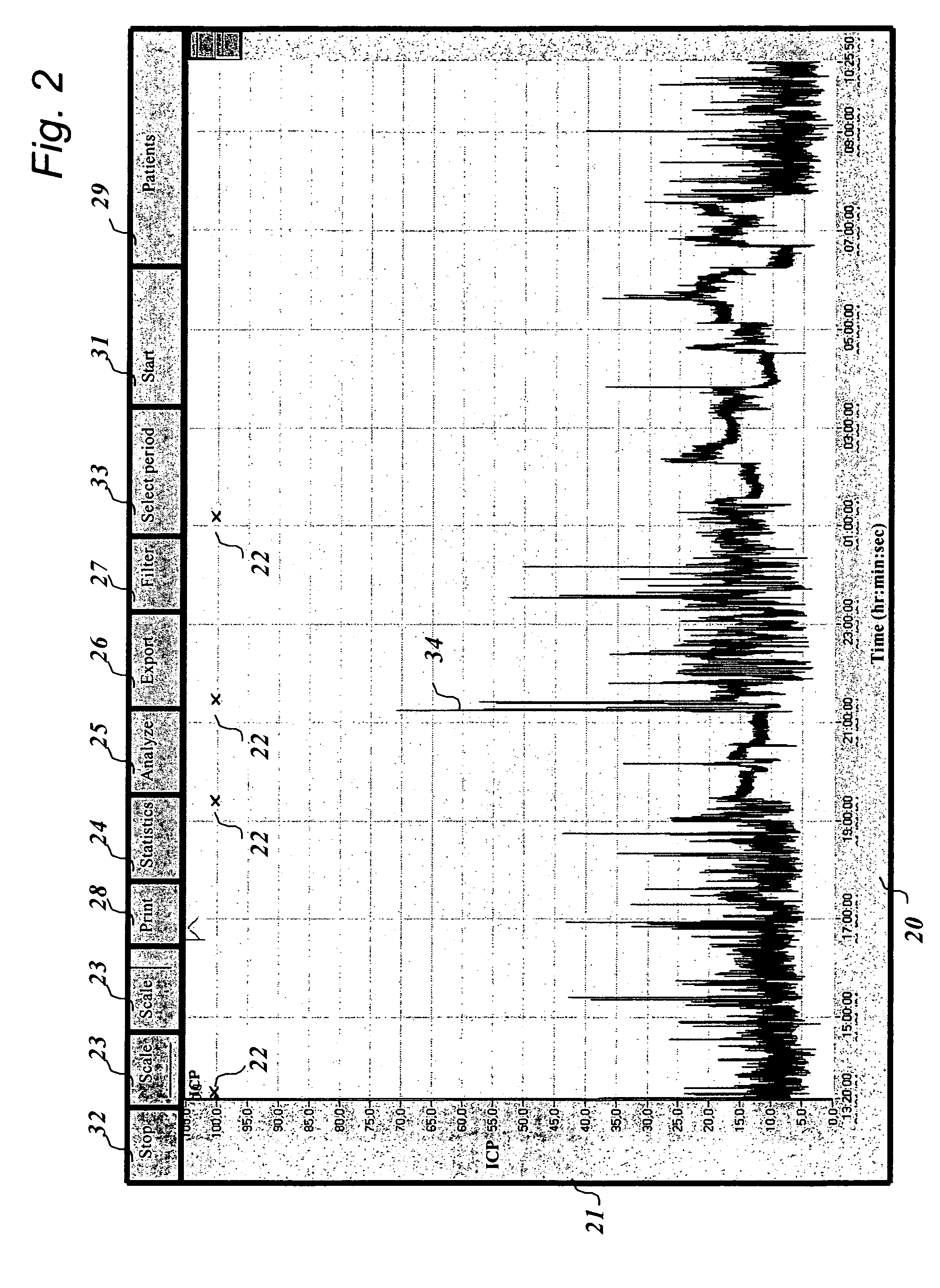

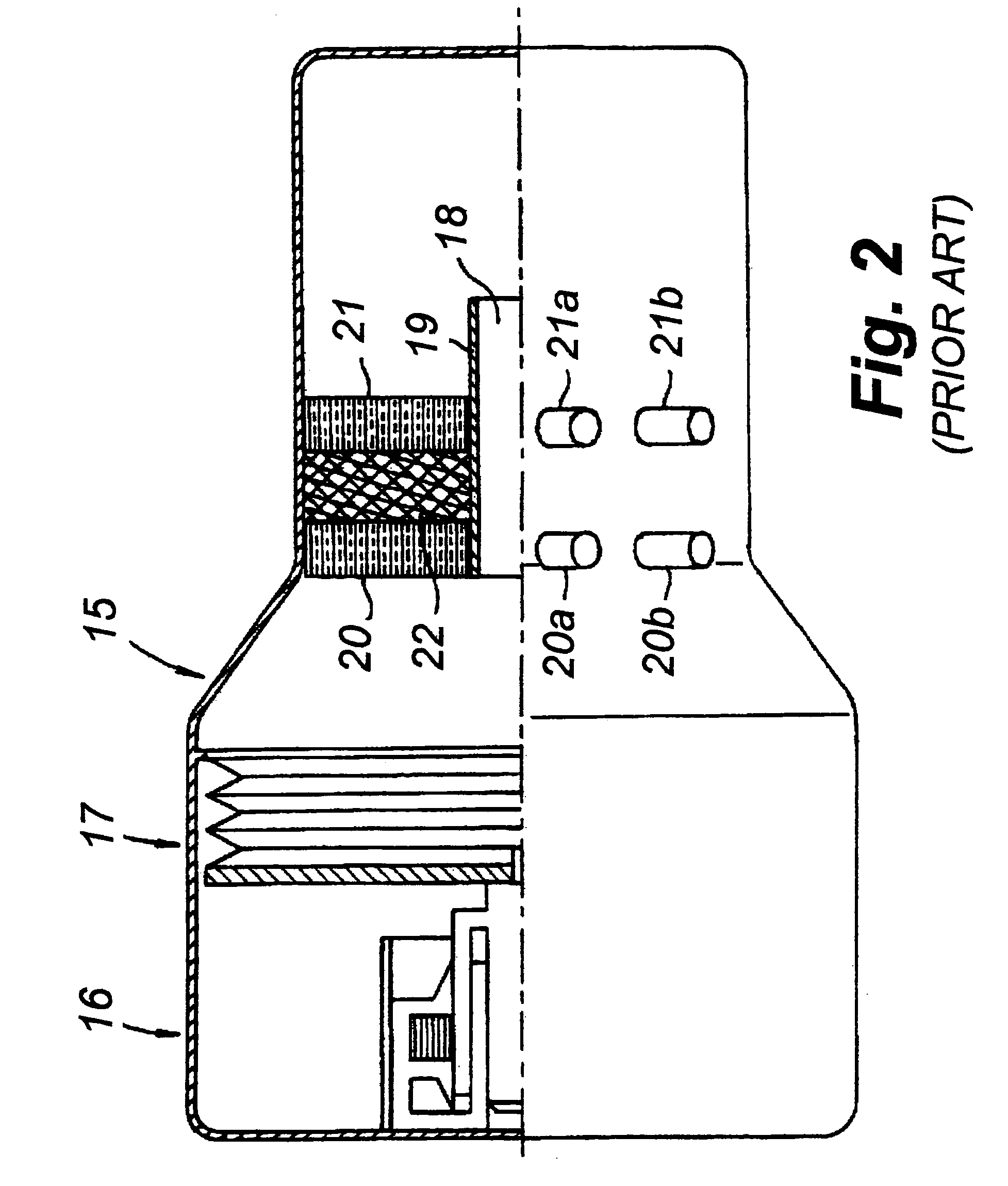

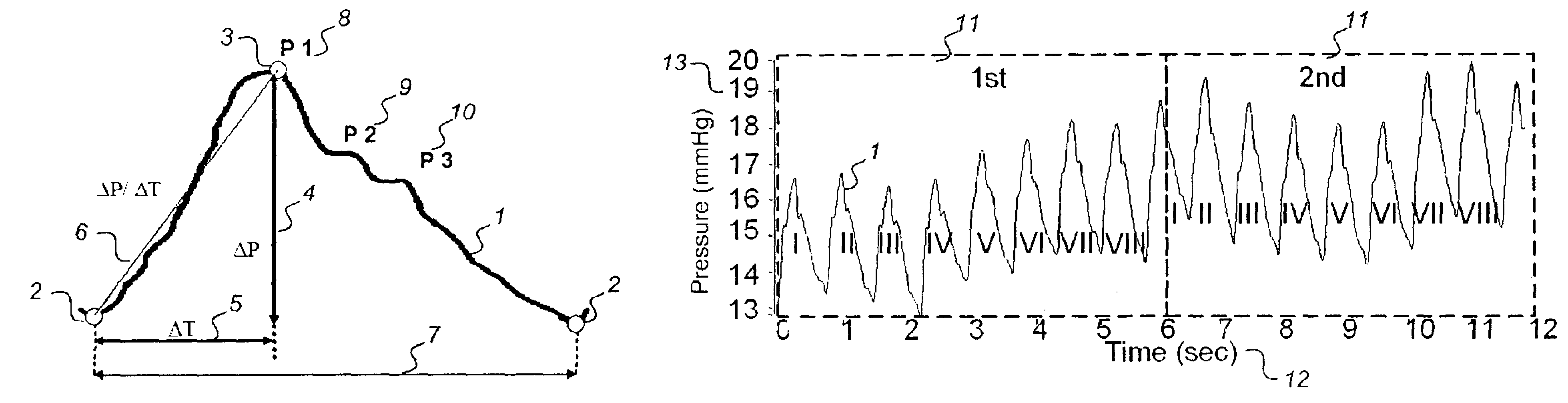

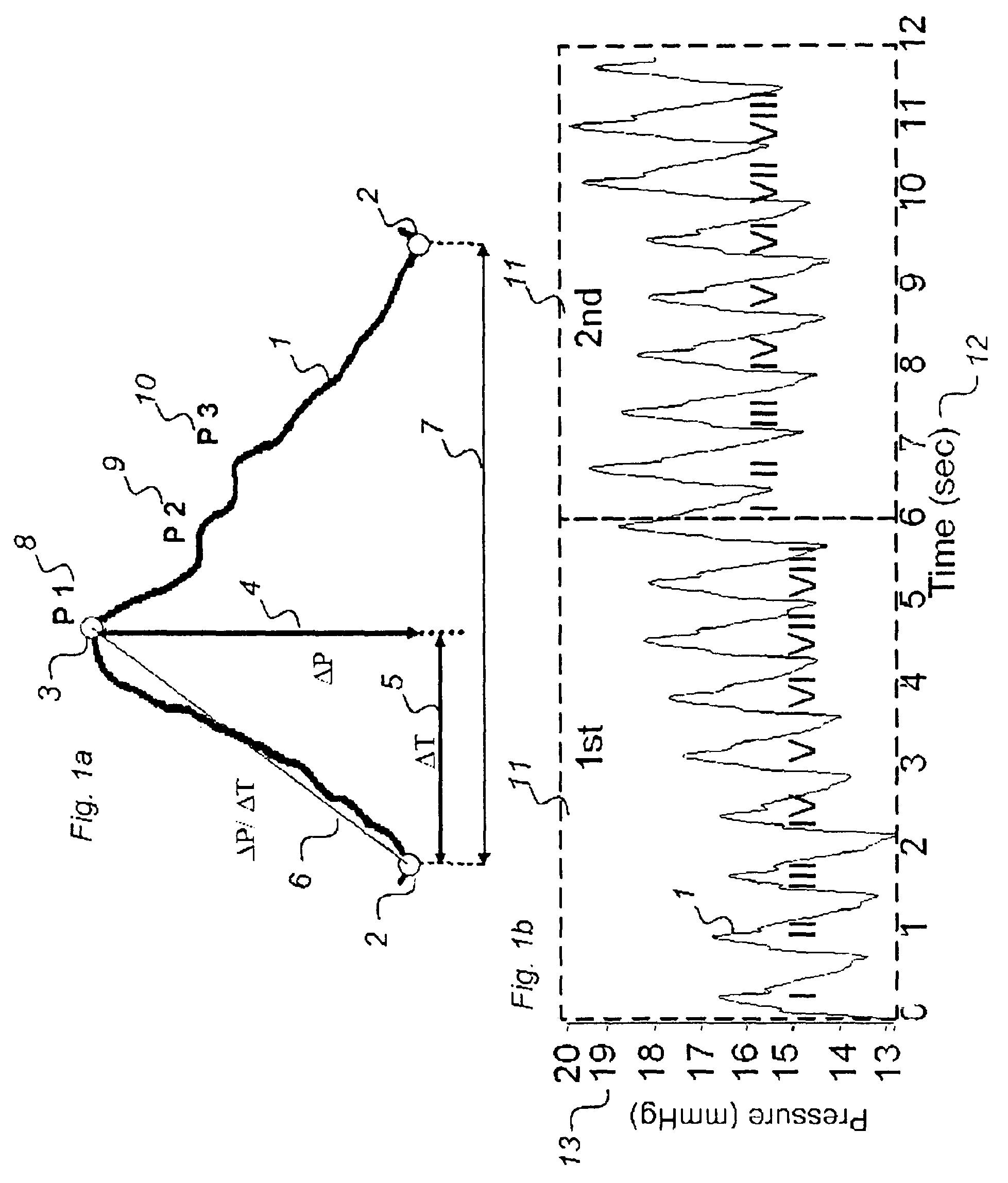

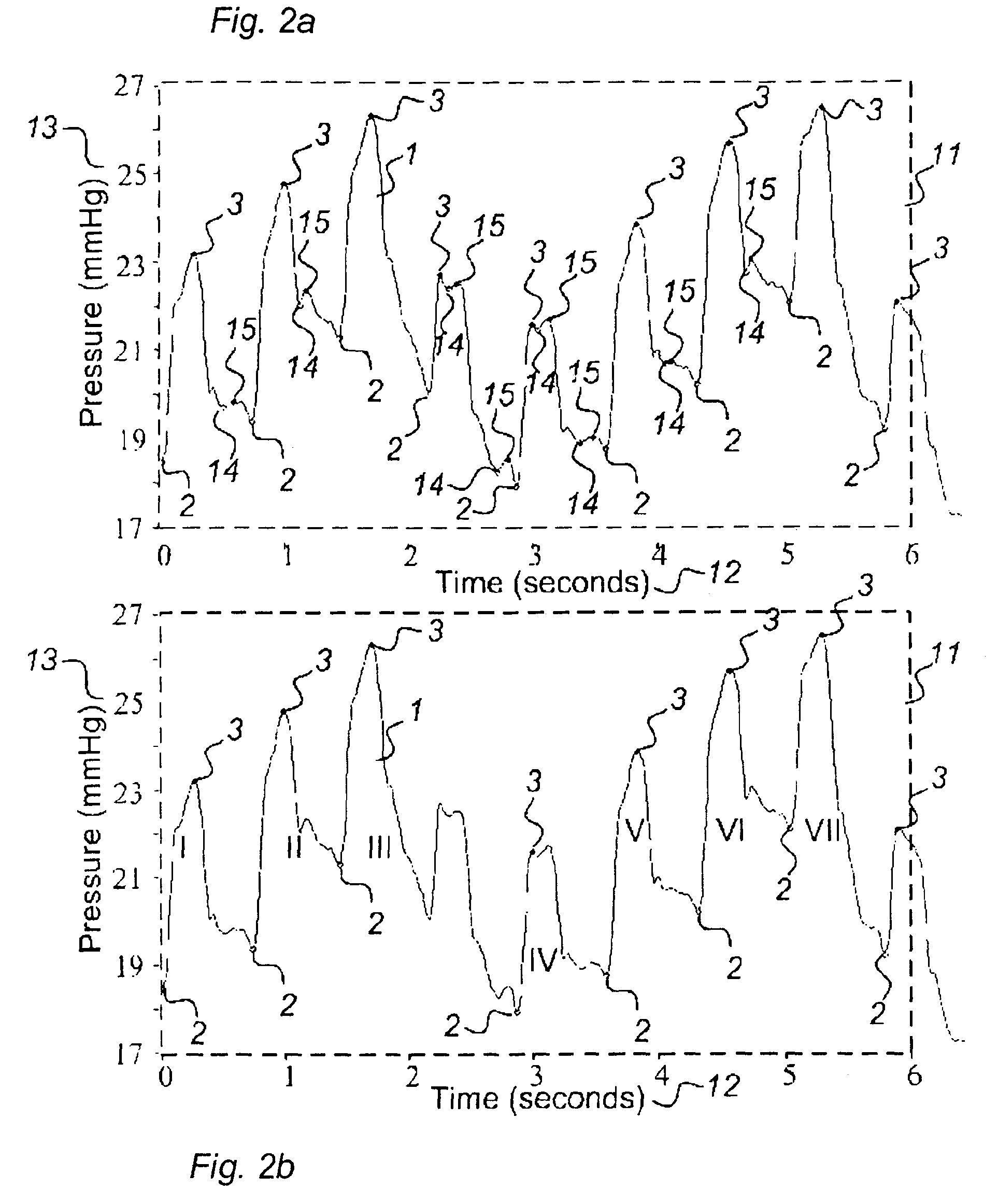

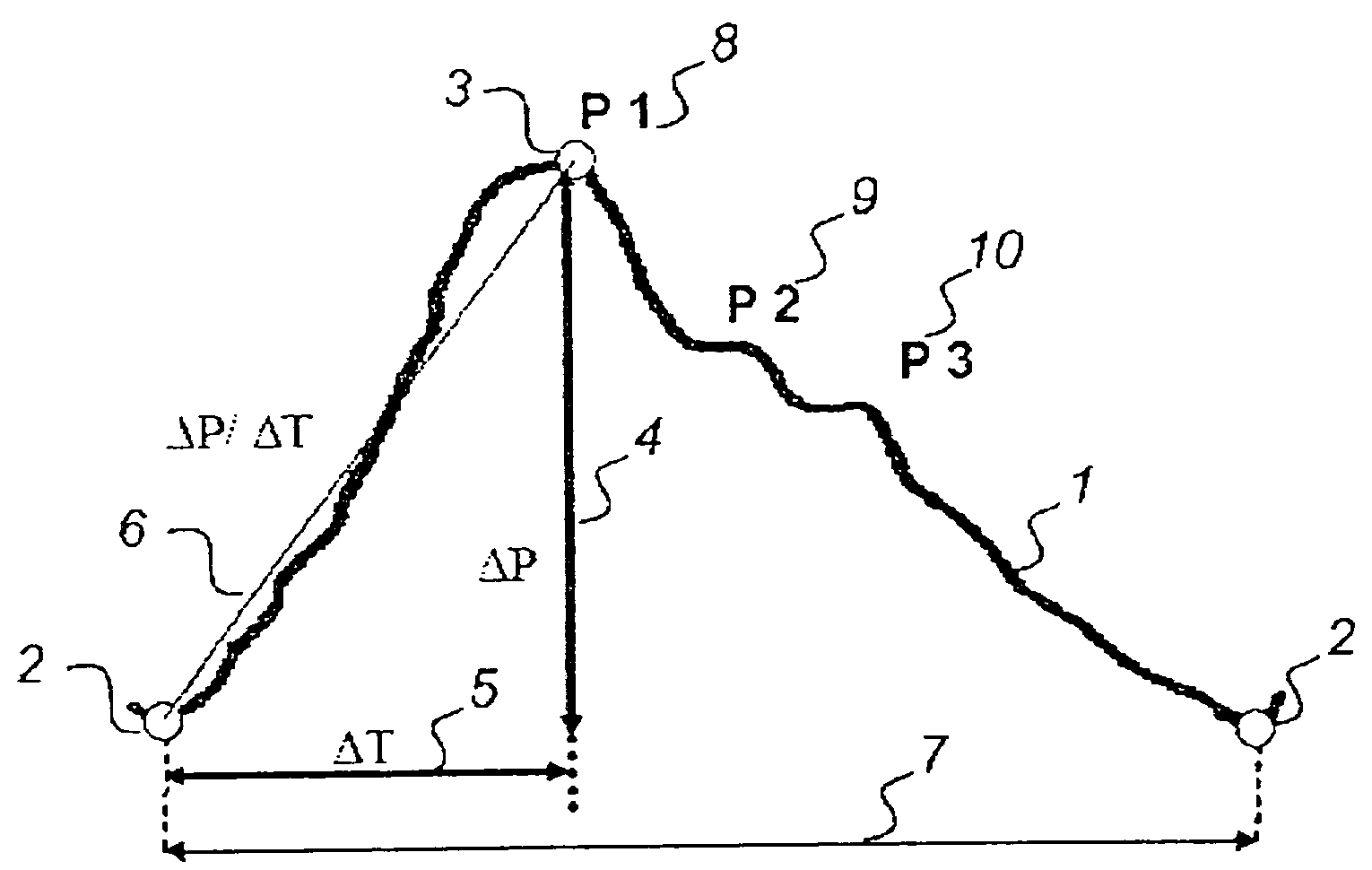

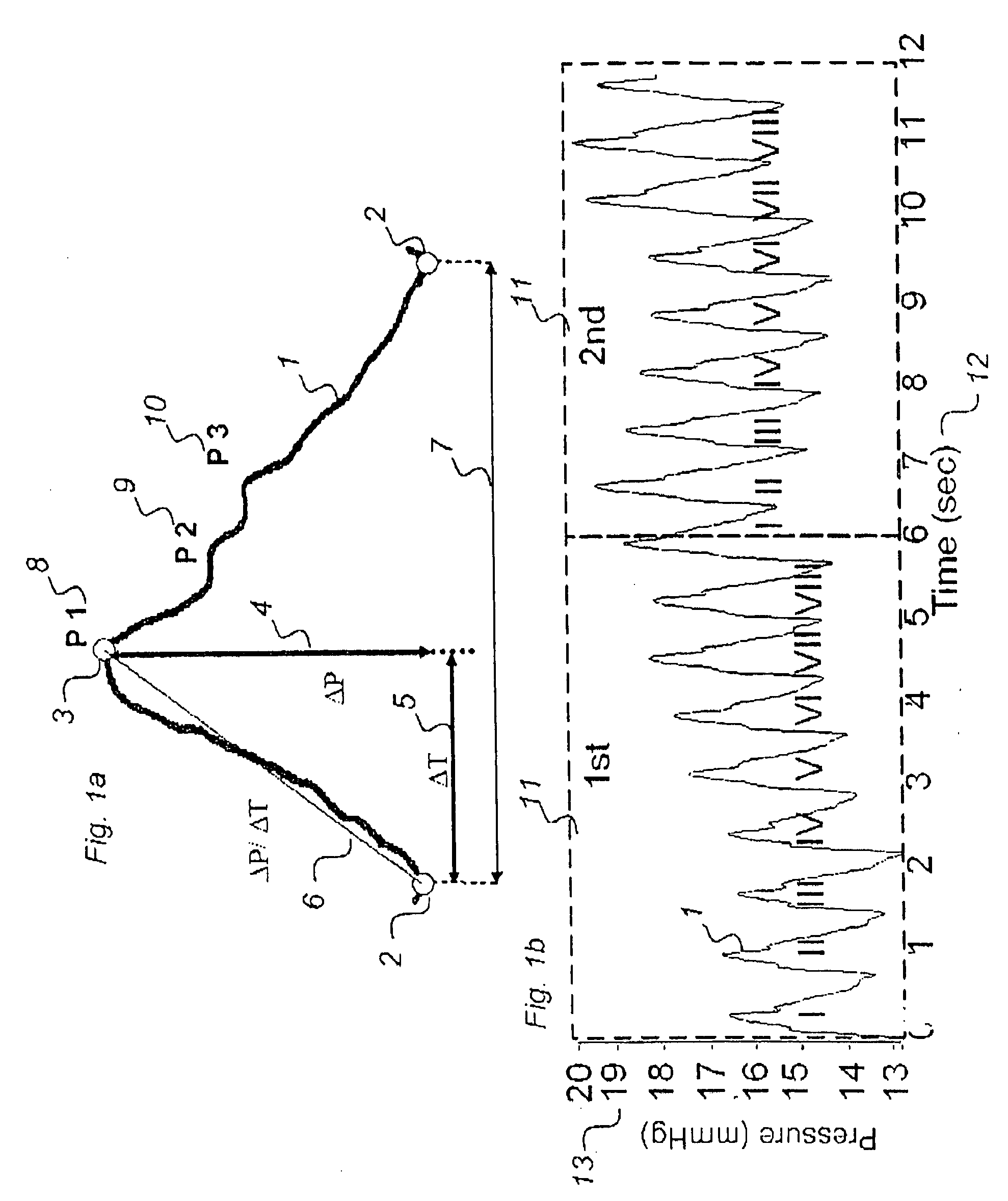

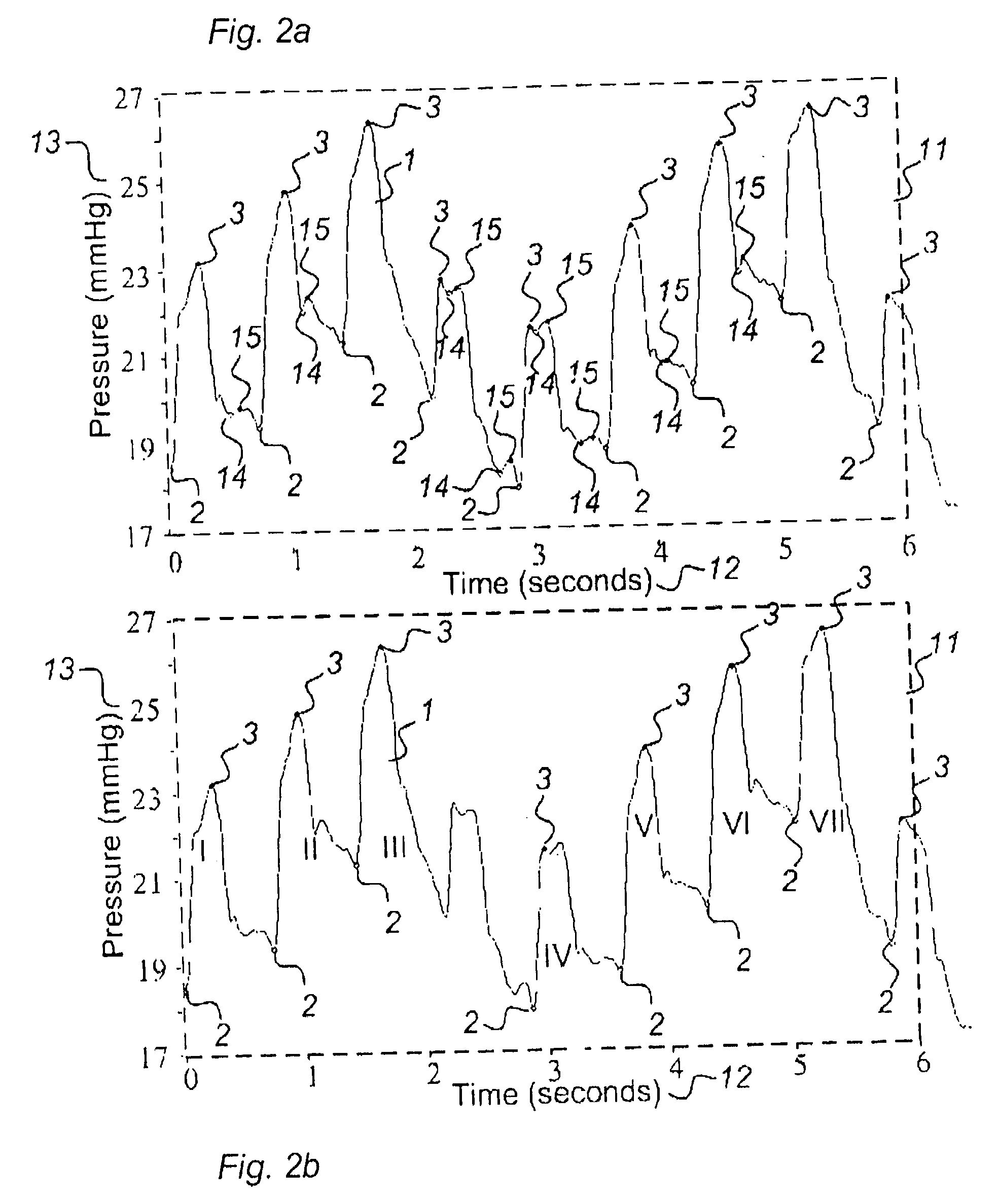

System for performing an analysis of pressure-signals derivable from pressure measurements on or in a body

InactiveUS7335162B2Reduce pressureEvaluation of blood vesselsCatheterDigital dataVisual presentation

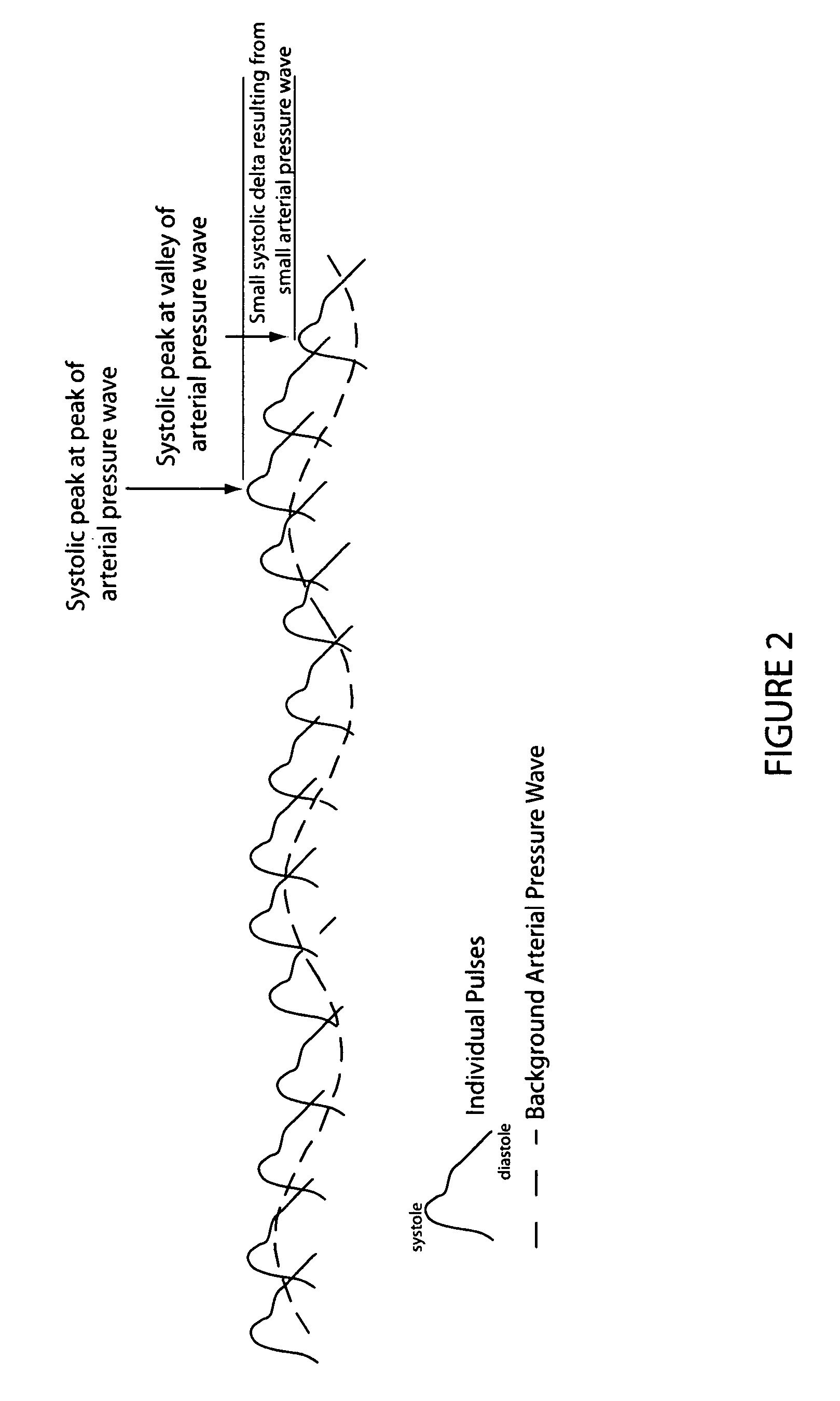

A system for performing an analysis of pressure-signals derivable from pressure measurements on or in a body of a human being or animal, includes a communication interface for receiving a set of digital pressure sample values, a memory for storing these values, and a processor capable of performing the analysis, the processor having means to identify features related to single pressure waves in the pressure signals based on input of the digital data into the processor, and the processor further having determination means which based on the features is configured to a) determine a minimum pressure value related to diastolic minimum value and a maximum pressure value related to systolic maximum value, b) determine at least one parameter of the single wave parameters elected from the group of: pressure amplitude=ΔP=[(maximum pressure value)−(minimum pressure value)], latency (ΔT), rise time or rise time coefficient=ΔP / ΔT, and wavelength of the single wave, c) determine number of the single pressure waves occurring during a given time sequence, including determination of the number of single pressure waves with pre-selected values of one or more of the single pressure wave parameters during the given time sequence, and d) determine number of single pressure waves with pre-selected combinations of two or more of the single pressure wave parameters during the given time sequence. Further, the system has a display for visual presentation of the result of analysis performed by the processor.

Owner:SENSOMETRICS AS (NO)

Patient-ventilator synchronization using dual phase sensors

InactiveUS20060102180A1Improve determinationMinimum ventilationRespiratorsOperating means/releasing devices for valvesRespiratory phasePressure amplitude

An improved ventilator which delivers ventilatory support that is synchronized with the phase of the patients respiratory efforts and guarantees a targeted minimum ventilation. Improved synchronization is achieved through an instantaneous respiratory phase determination process based upon measured respiratory airflow as well as measured respiratory effort using an effort sensor accessory, preferably a suprasternal notch sensor. The ventilator processes a respiratory airflow signal, a respiratory effort signal and their respective rates of change to determine a phase using standard fuzzy logic methods. A calculated pressure amplitude is adjusted based upon the calculated phase and a smooth pressure waveform template to deliver synchronized ventilation.

Owner:RESMED LTD

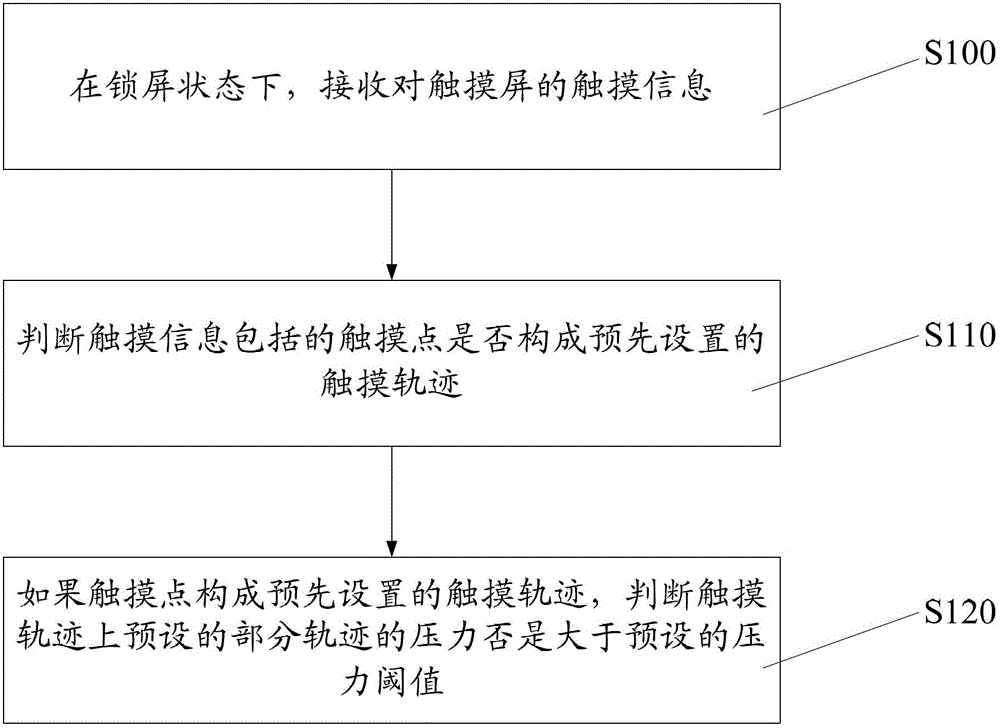

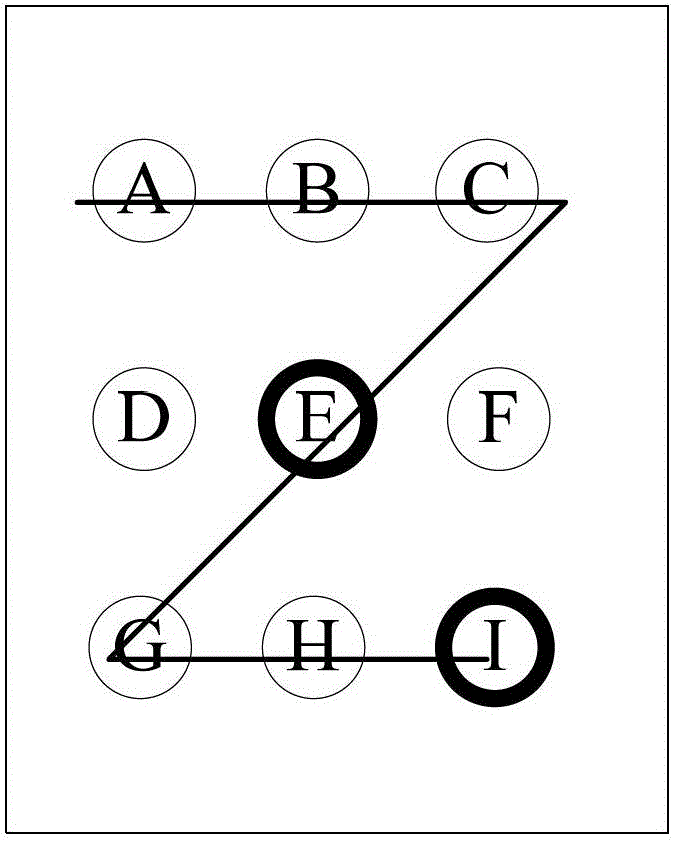

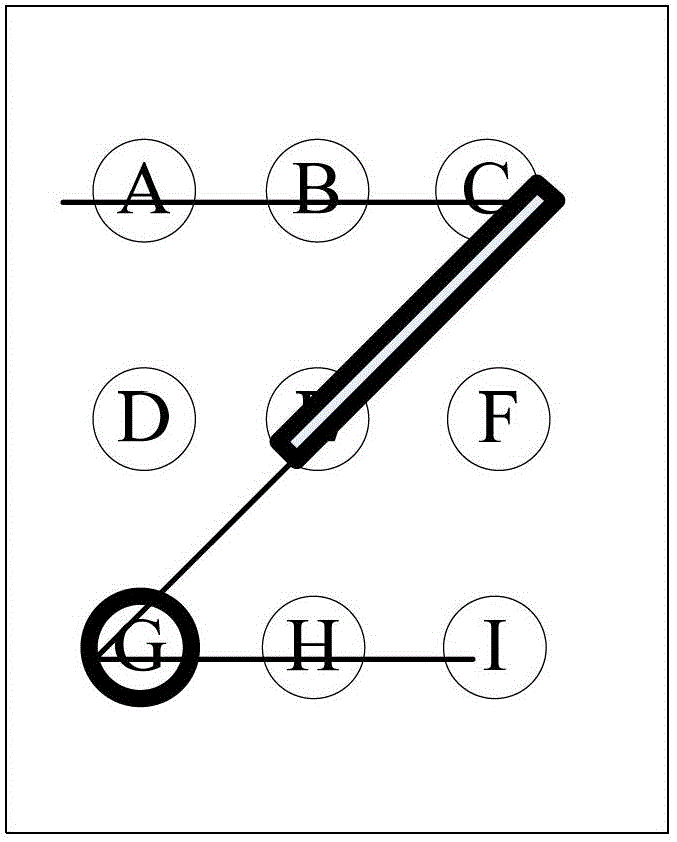

Unlocking method and device of touch screen

InactiveCN102722283AUnlocking Information ConfidentialityEasy to useInput/output processes for data processingPressure amplitudeTouchscreen

The embodiment of the invention provides an unlocking method of a touch screen. The unlocking method comprises the following steps of: A, receiving touch information on the touch screen in a screen lock state; and B, when judging that a preset touch track is constructed by touch points included in the touch information and when judging that the pressure amplitude of a part of track preset on the touch track is matched with the preset pressure amplitude, unlocking the touch screen. The embodiment of the invention also provides an unlocking device of the touch screen. By arranging the unlocking information as the touch track and applying pressure value information to the touch track, the unlocking information of the touch screen has higher security, and the system is safer in use.

Owner:北京中自投资管理有限公司

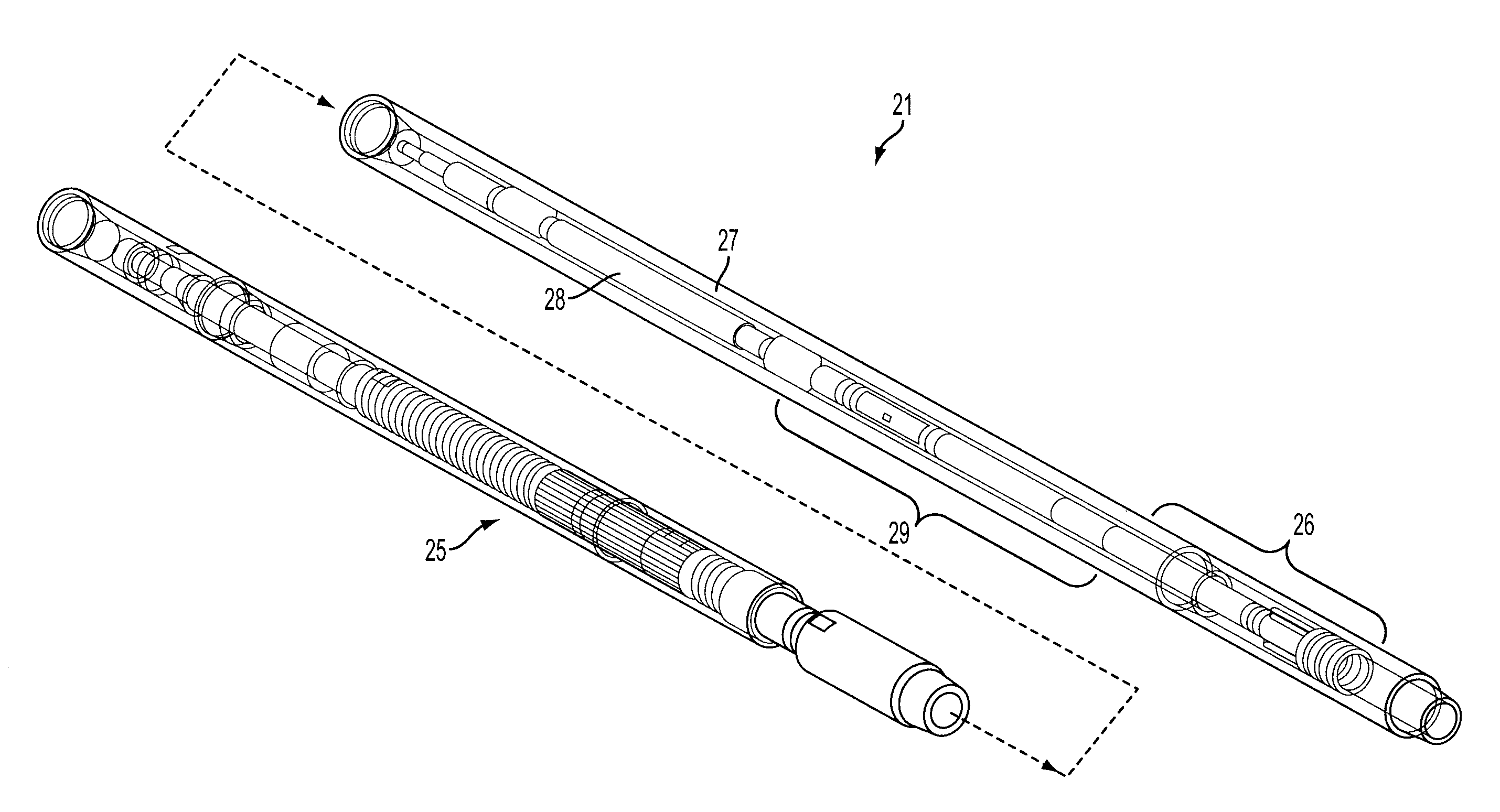

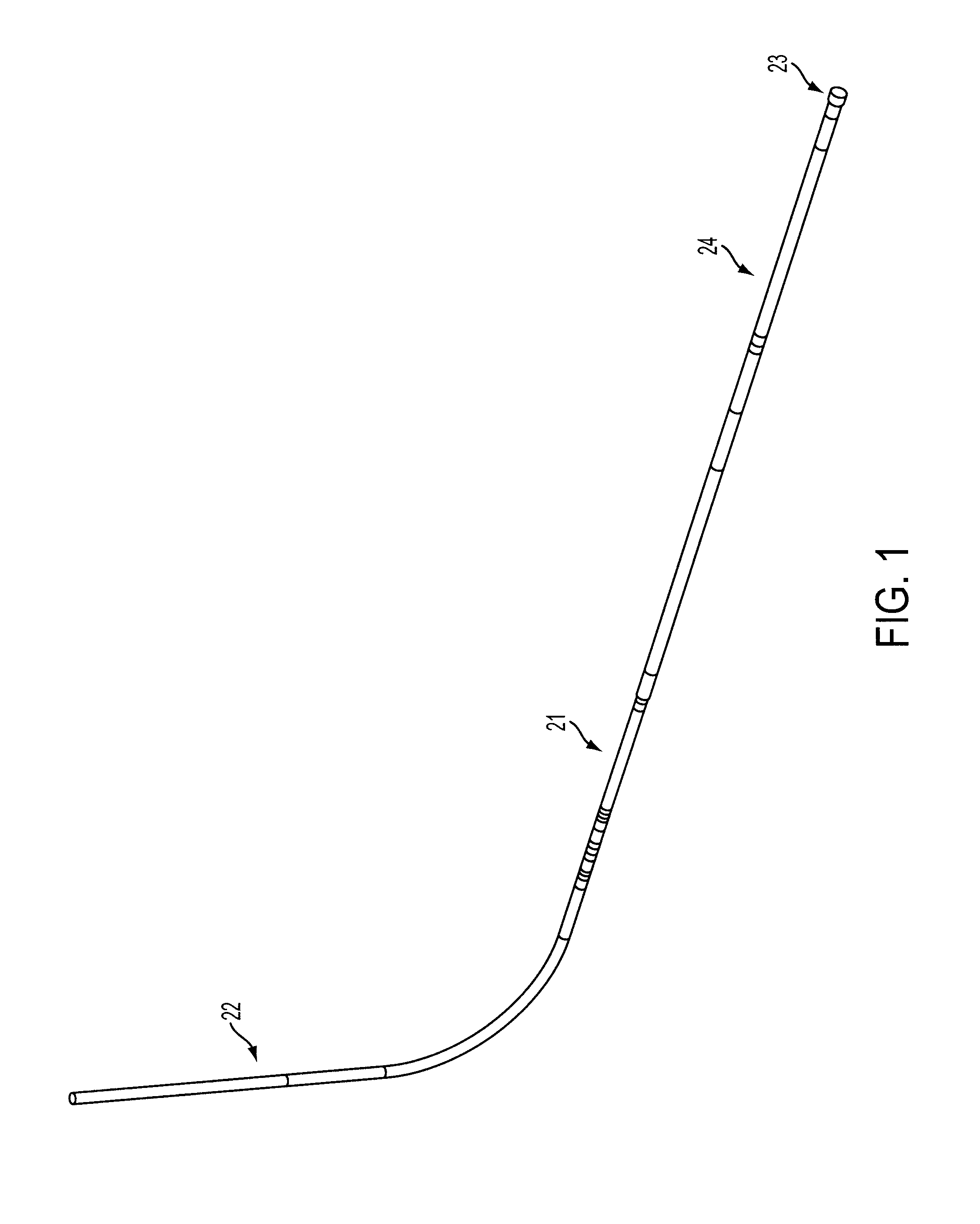

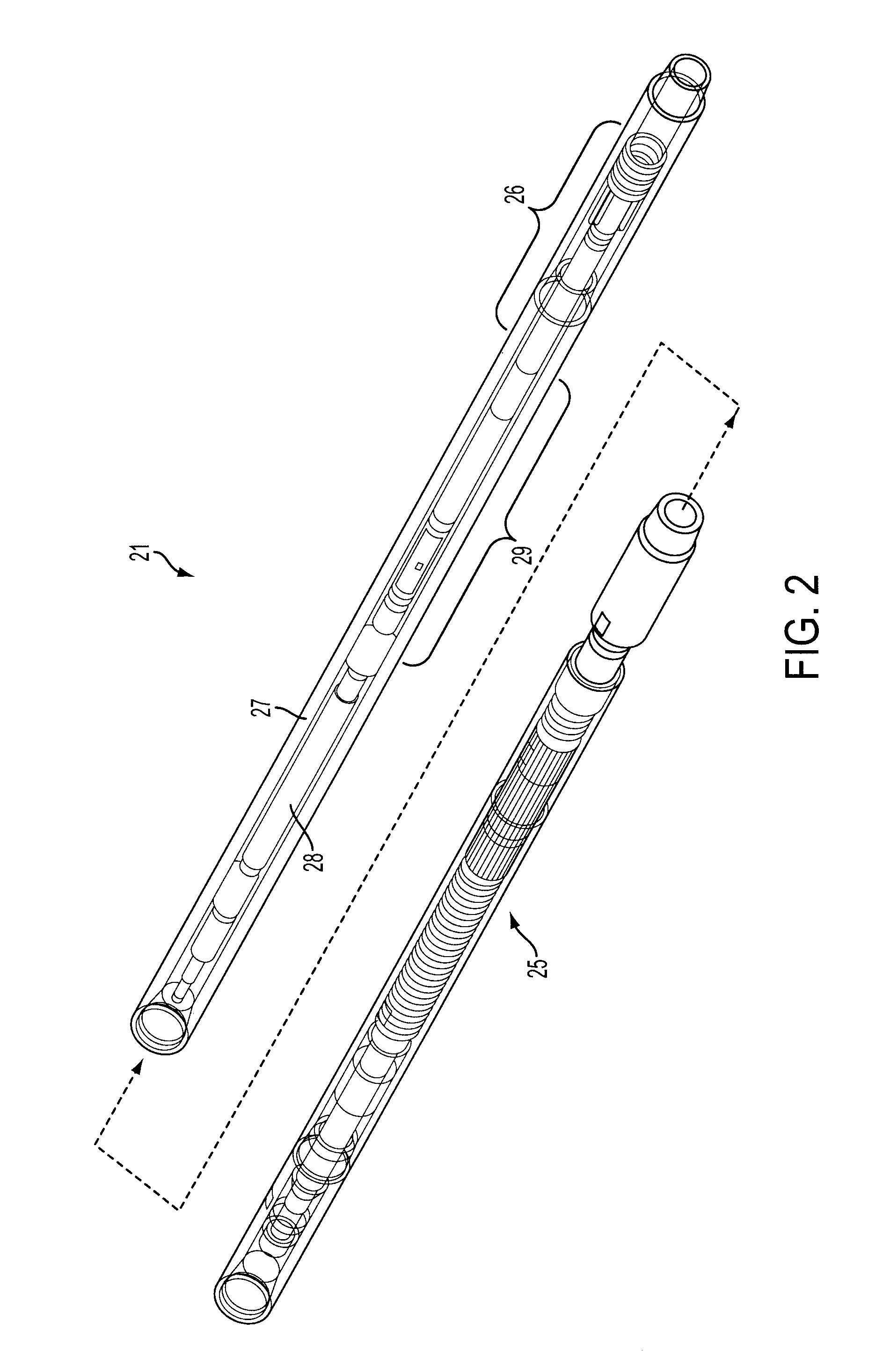

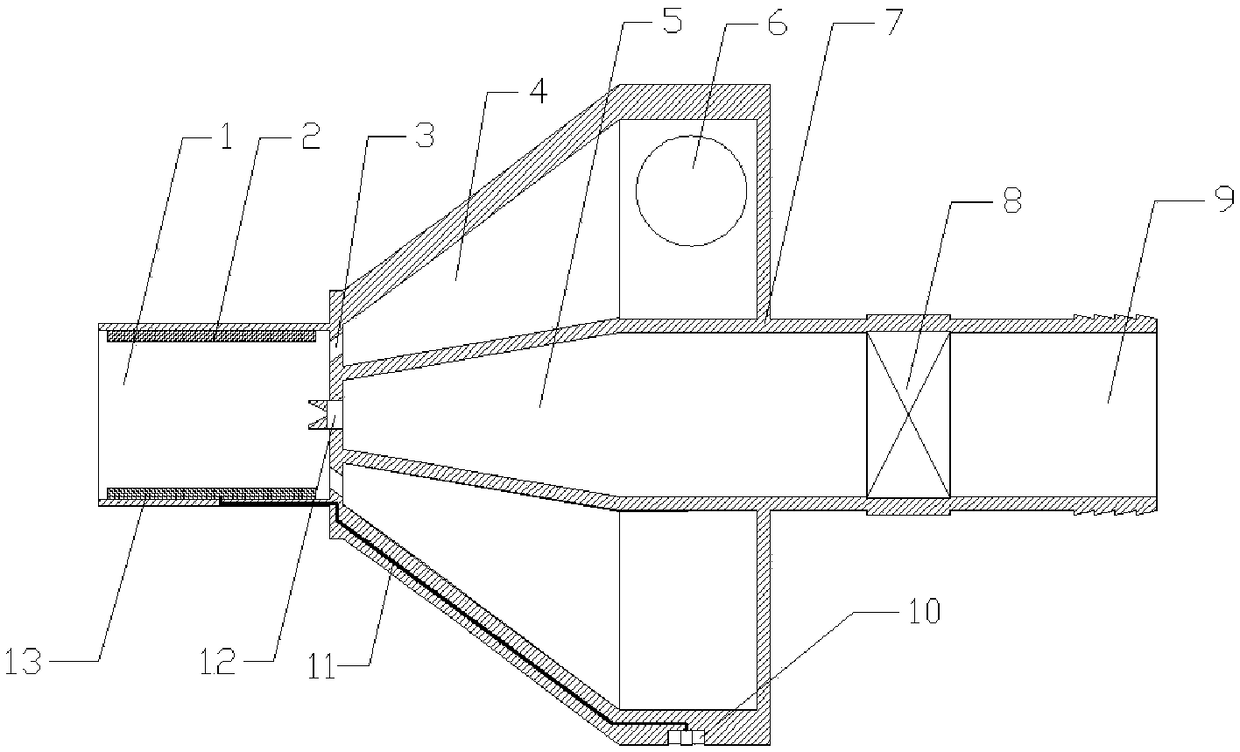

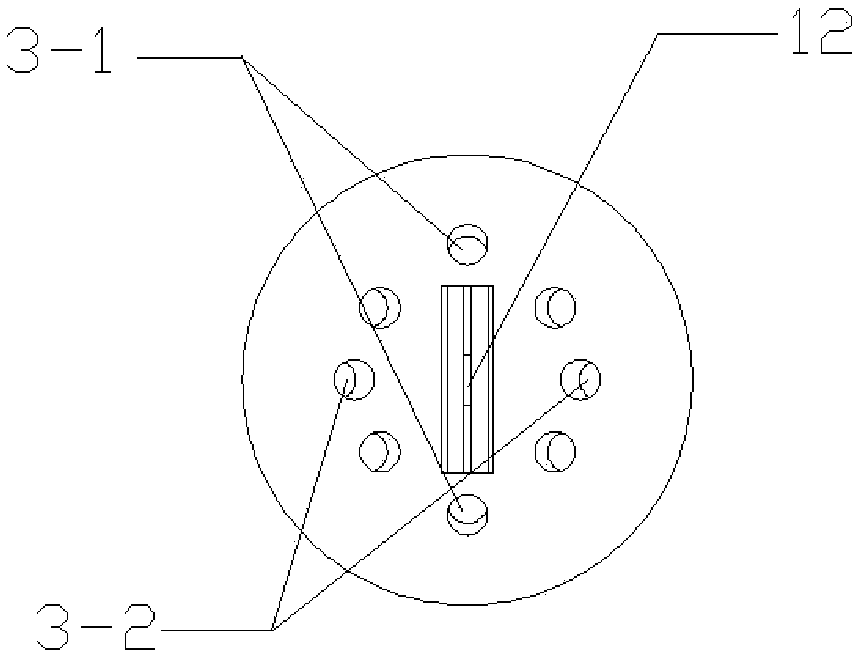

System, method and apparatus for drilling agitator

InactiveUS20120048619A1Promote sportsDrilling rodsReciprocating drilling machinesPressure amplitudeReciprocating motion

A drilling agitator tool, system and method facilitates axial movement of a drill string in a well. The tool has a valve assembly that provides pulses of fluid pressure in the drill string. A valve control assembly controls a frequency and pressure amplitude of the pulses induced by the valve assembly. The valve control assembly monitors real-time pressure and vibration levels of the drill string. An agitator assembly reciprocates in response to the pulses of fluid pressure to provide axial movement of the drill string in the well.

Owner:1473706 ALBERTA

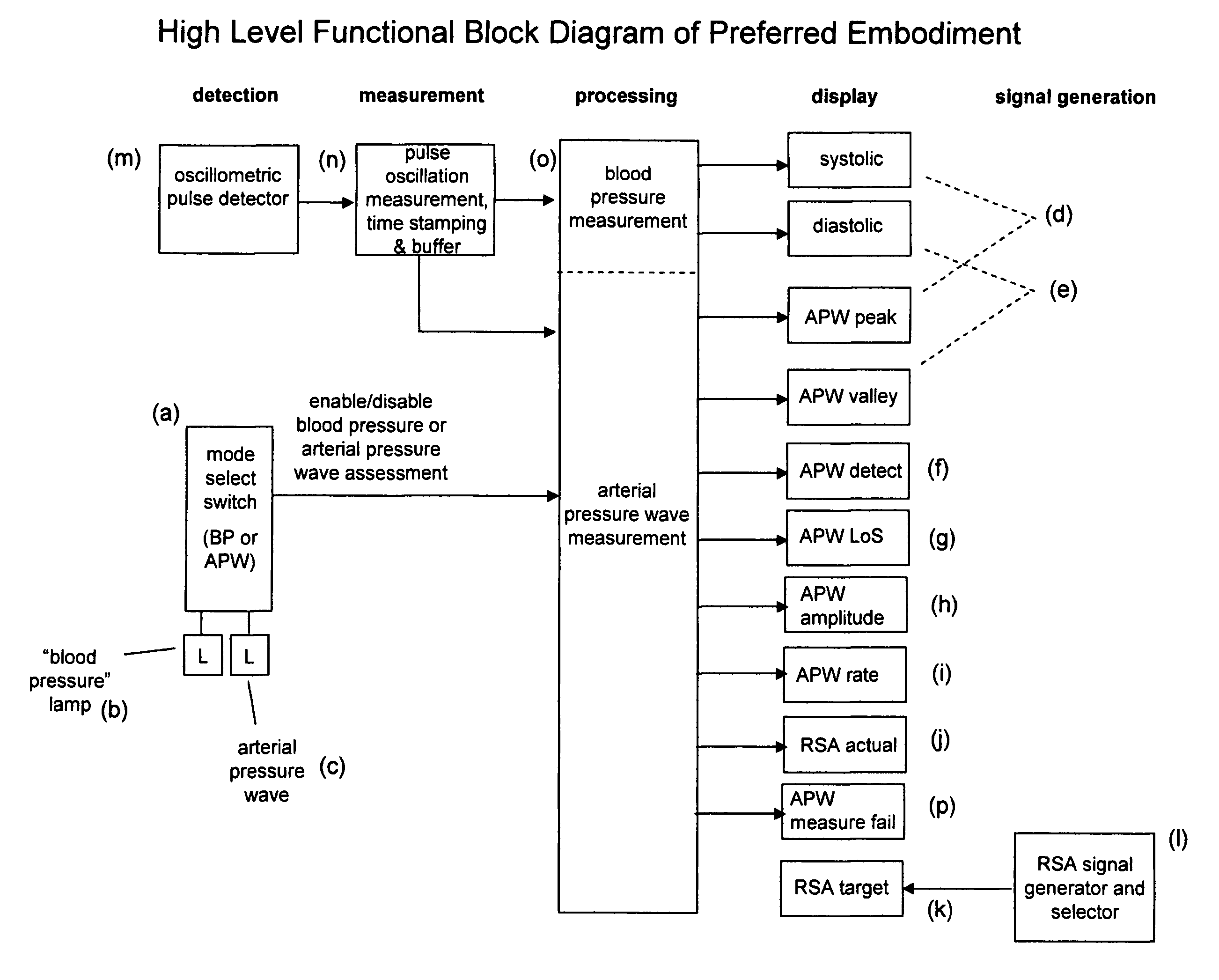

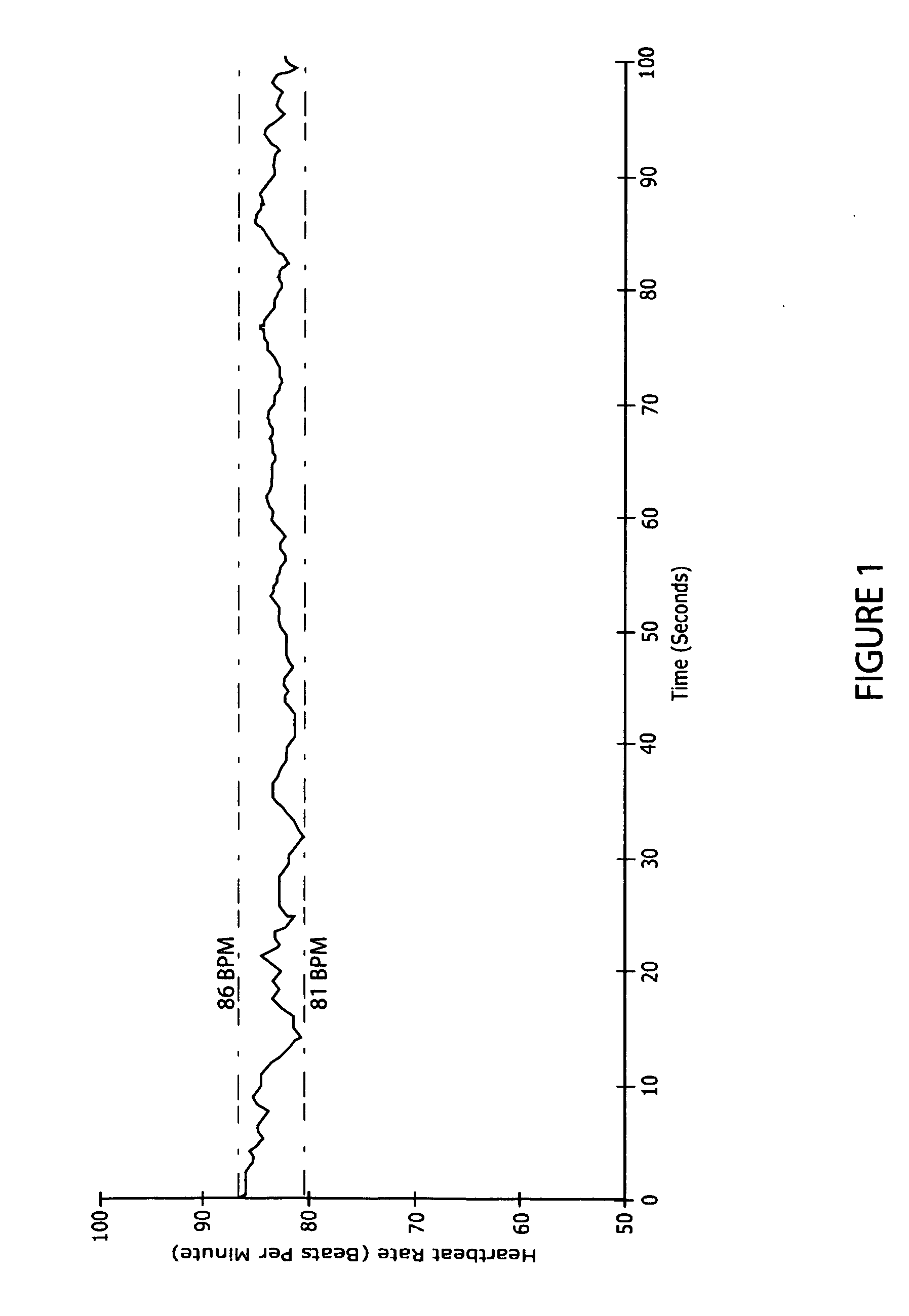

Method and system for assessing breathing effectiveness via assessment of the dynamic arterial pressure wave using the oscillometric measurement technique

The present invention specifies a method and system for assessing breathing effectiveness via dynamic assessment of respiratory sinus arrhythmia and the consequent arterial pressure wave using the oscillometric measurement technique. Arterial pressure wave peak pressure, valley pressure, amplitude, and rate are characterized and displayed for diagnostic and remedial purposes. The dynamic change in respiratory sinus arrhythmia and resultant arterial pressure wave is visually presented in real time as user biofeedback. A respiratory sinus arrhythmia generator generates varying frequencies to which the user synchronizes their breathing cycle for purposes of increasing arterial pressure wave amplitude with a consequent increase in breathing depth and decrease in breathing frequency. An instructive method in the application of the present invention is also specified.

Owner:COHERENCE

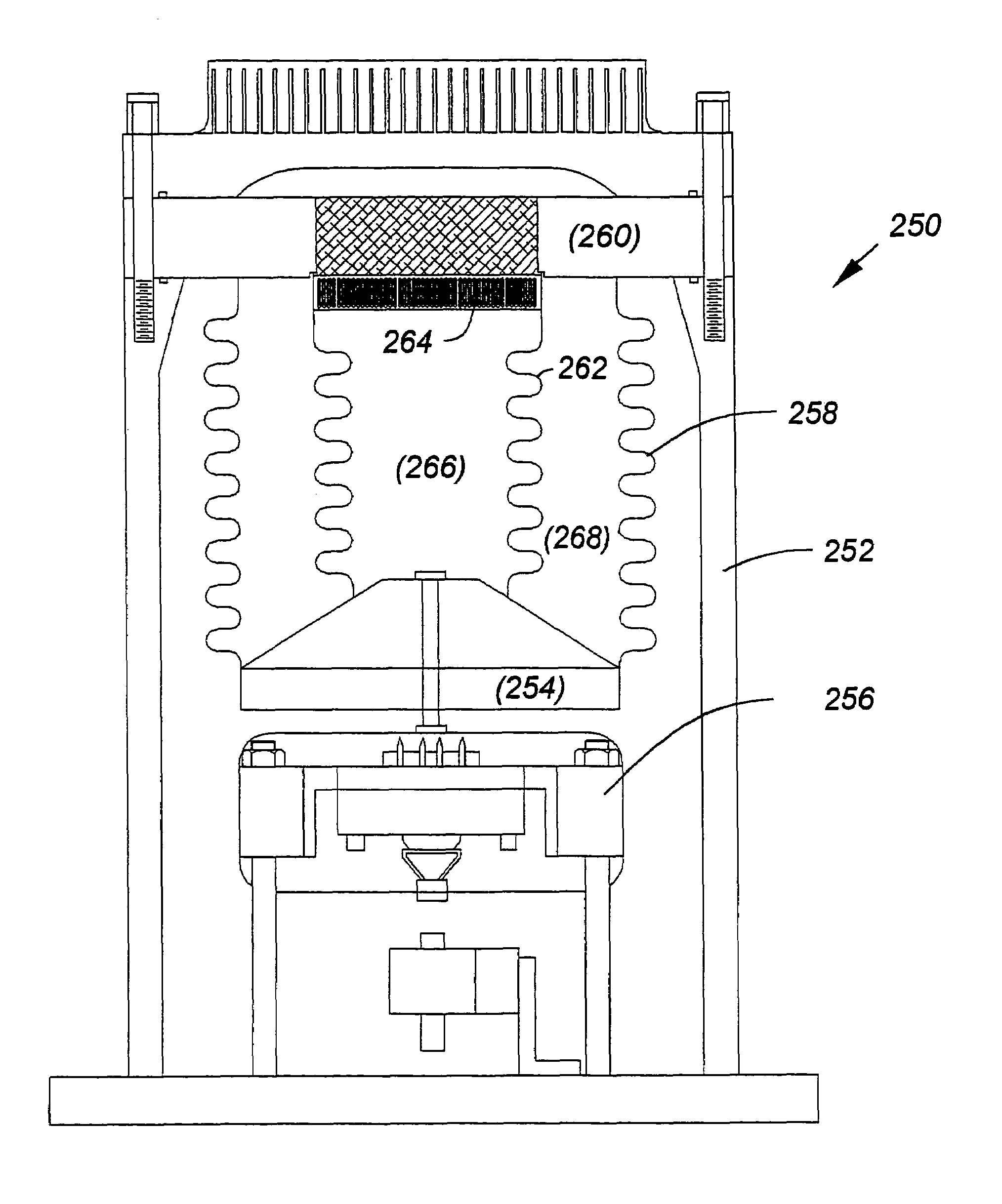

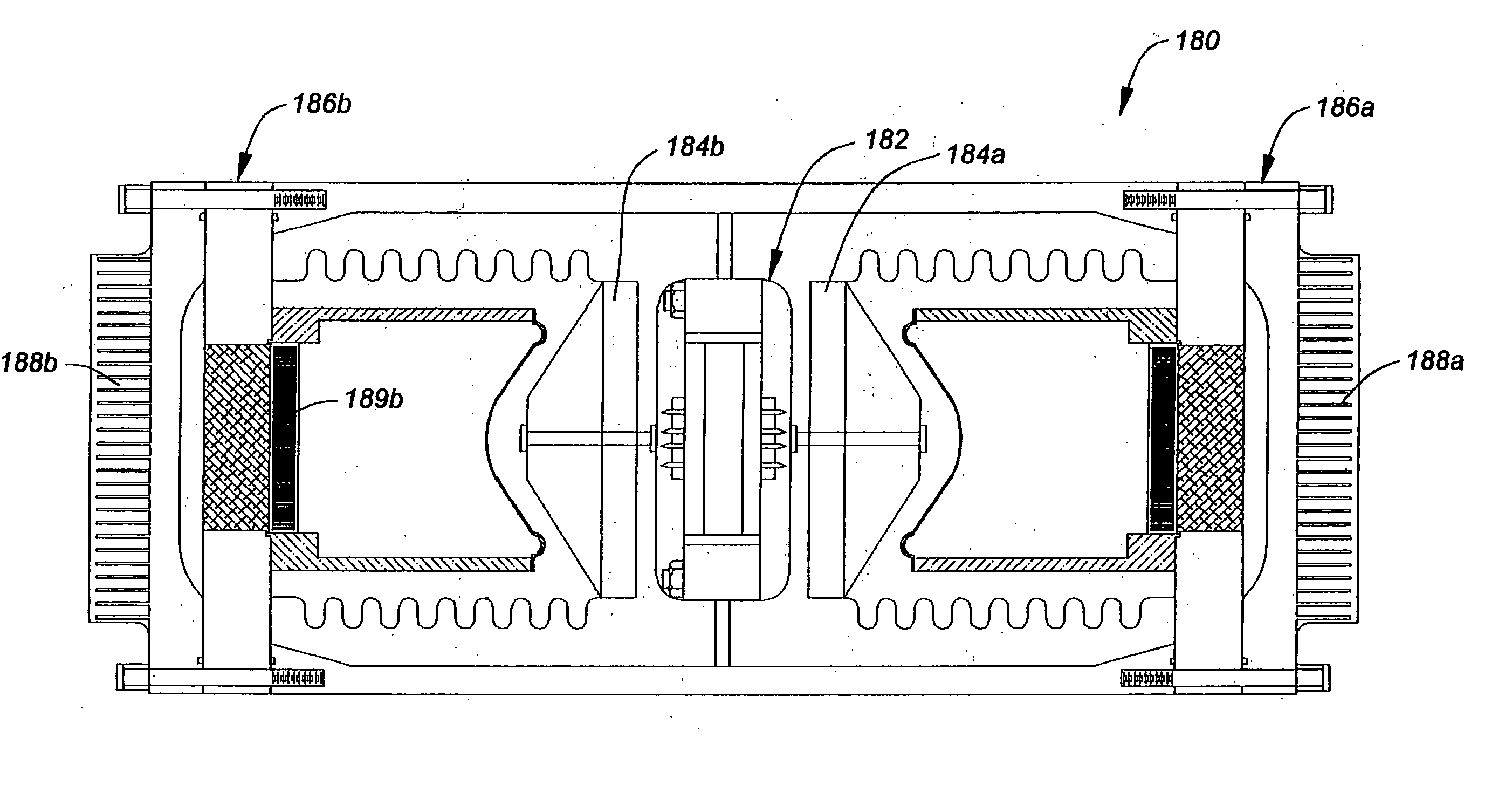

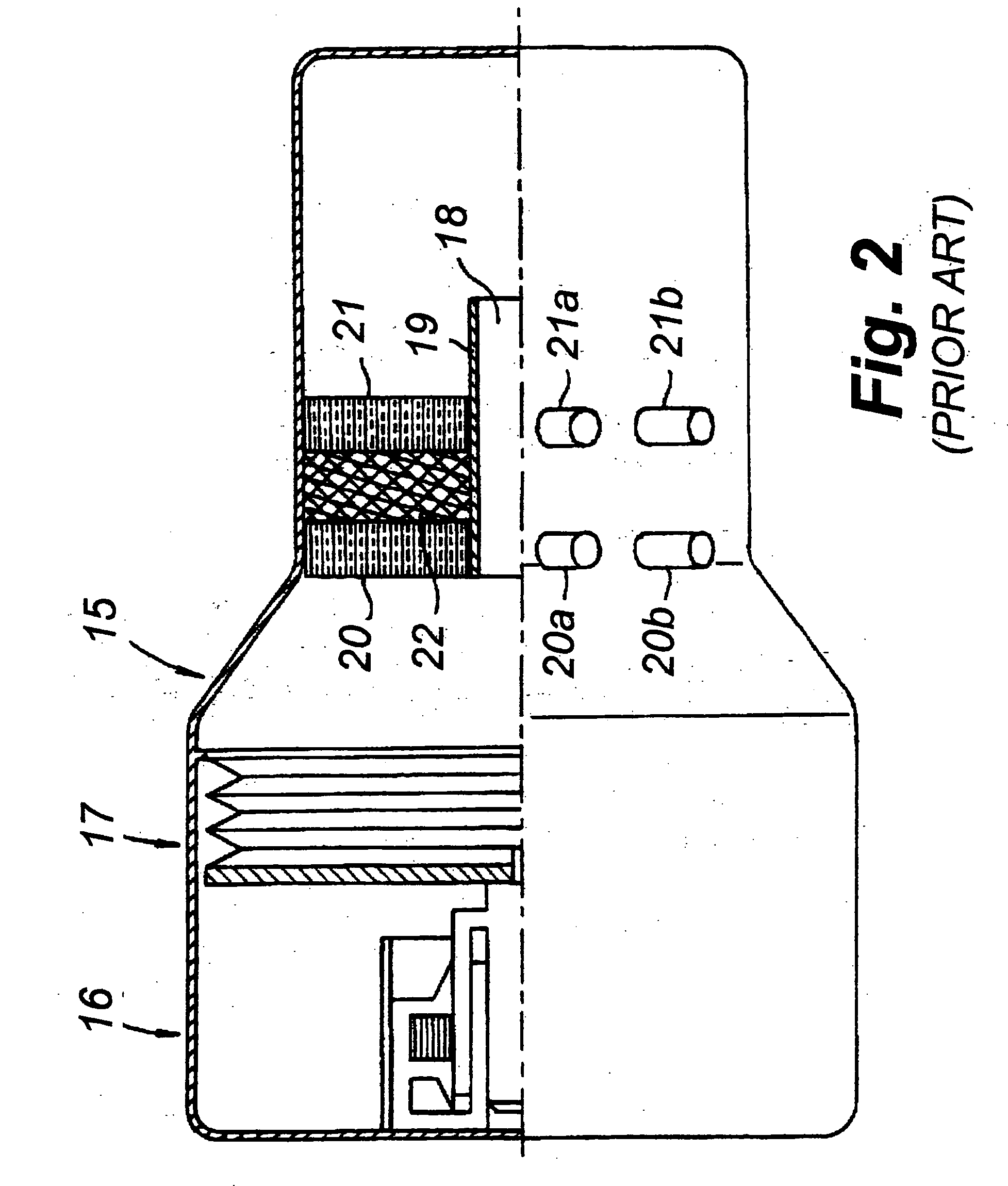

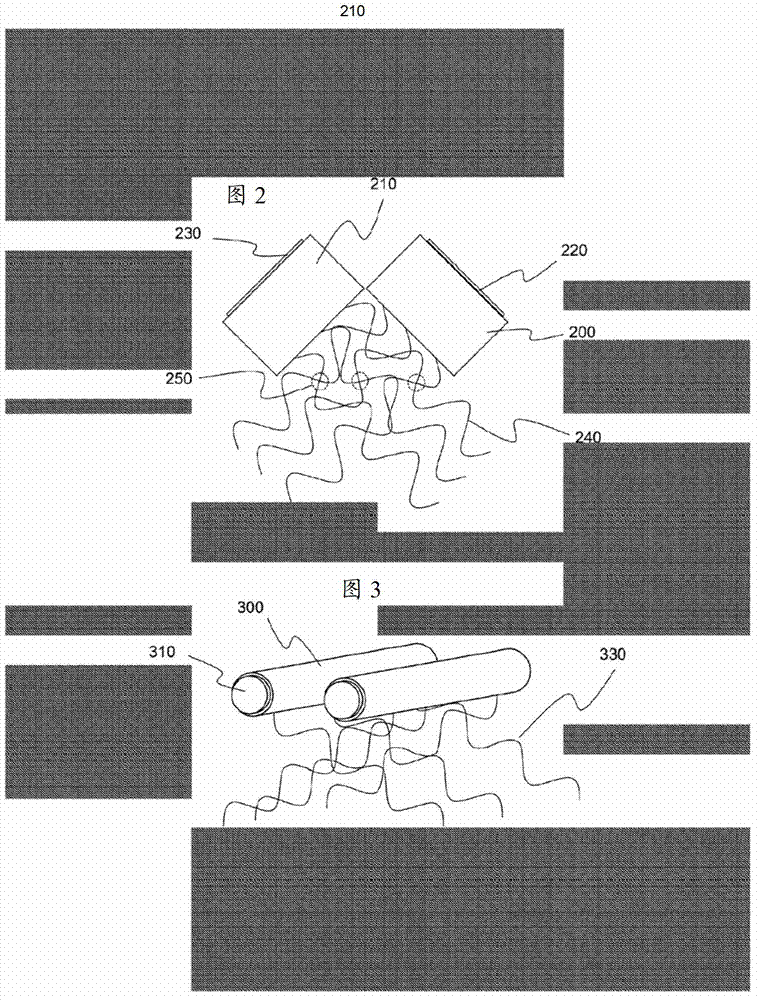

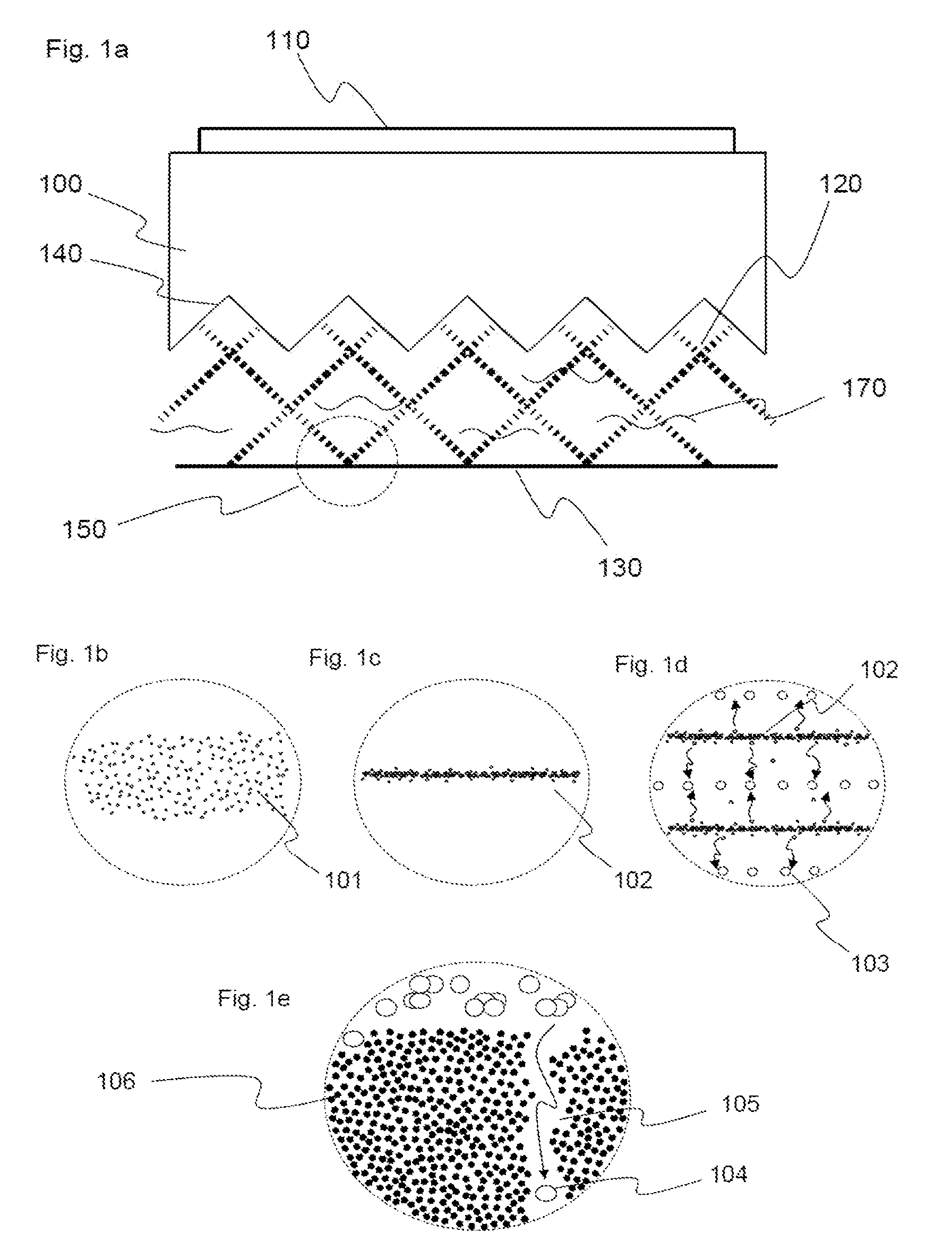

Thermoacoustic device

A thermocoustic device includes a housing with a thermal core supported in the housing and having a first and a second surface. The thermal core includes a first heat exchanger defining the first surface of the thermal core and a second heat exchanger defining the second surface of the thermal core. A main chamber is in fluid communication with the first surface of the thermal core and a secondary multiplier chamber is in fluid communication with the second surface of the thermal core. A working volume of a gaseous working fluid fills the main chamber, the multiplier chamber, and the thermal core at a pressure. An equilibrium pressure is defined as the pressure of the working volume of gaseous working fluids with the thermoacoustic device is in a non-operating mode. The main chamber includes a first oscillating member that is operable when the thermoacoustic device is in an operating mode to oscillate such that the pressure in both the main chamber and in the multiplier chamber is oscillated between a peak pressure greater than the equilibrium pressure and a minimum pressure less than the equilibrium pressure. A main pressure amplitude is defined as one-half of the difference between the peak pressure and the minimum pressure in the main chamber. The secondary multiplier chamber includes a second oscillating member that is operable when the thermoacoustic device is in the operating mode to oscillate such that the pressure in the multiplier chamber is oscillated between a peak pressure greater than the equilibrium pressure and a minimum pressure less than the equilibrium pressure. A multiplier pressure amplitude is defined as one-half of the difference between the peak pressure and the minimum pressure in the multiplier chamber. The first and second oscillating members oscillate at substantially the same frequency and such that the pressure oscillations in the main chamber and the multiplier chamber are substantially in phase with each other. The multiplier pressure amplitude is greater than the main pressure amplitude.

Owner:PENN STATE RES FOUND

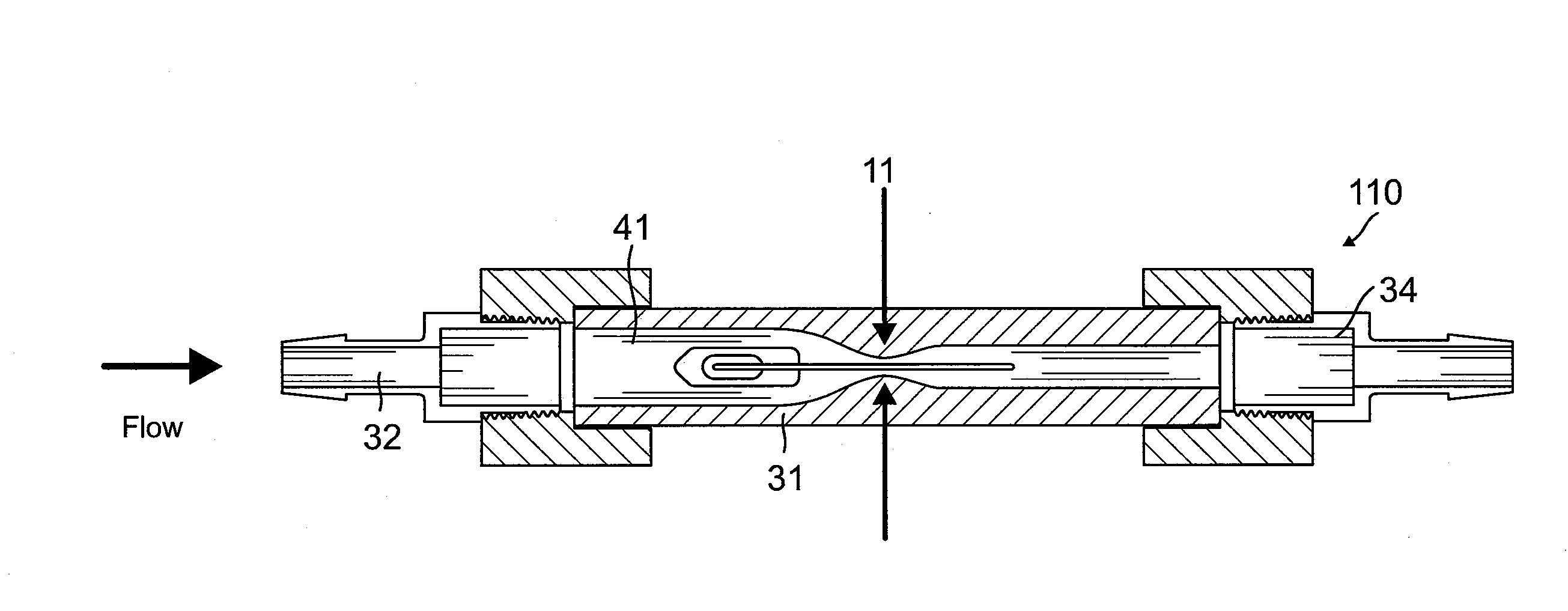

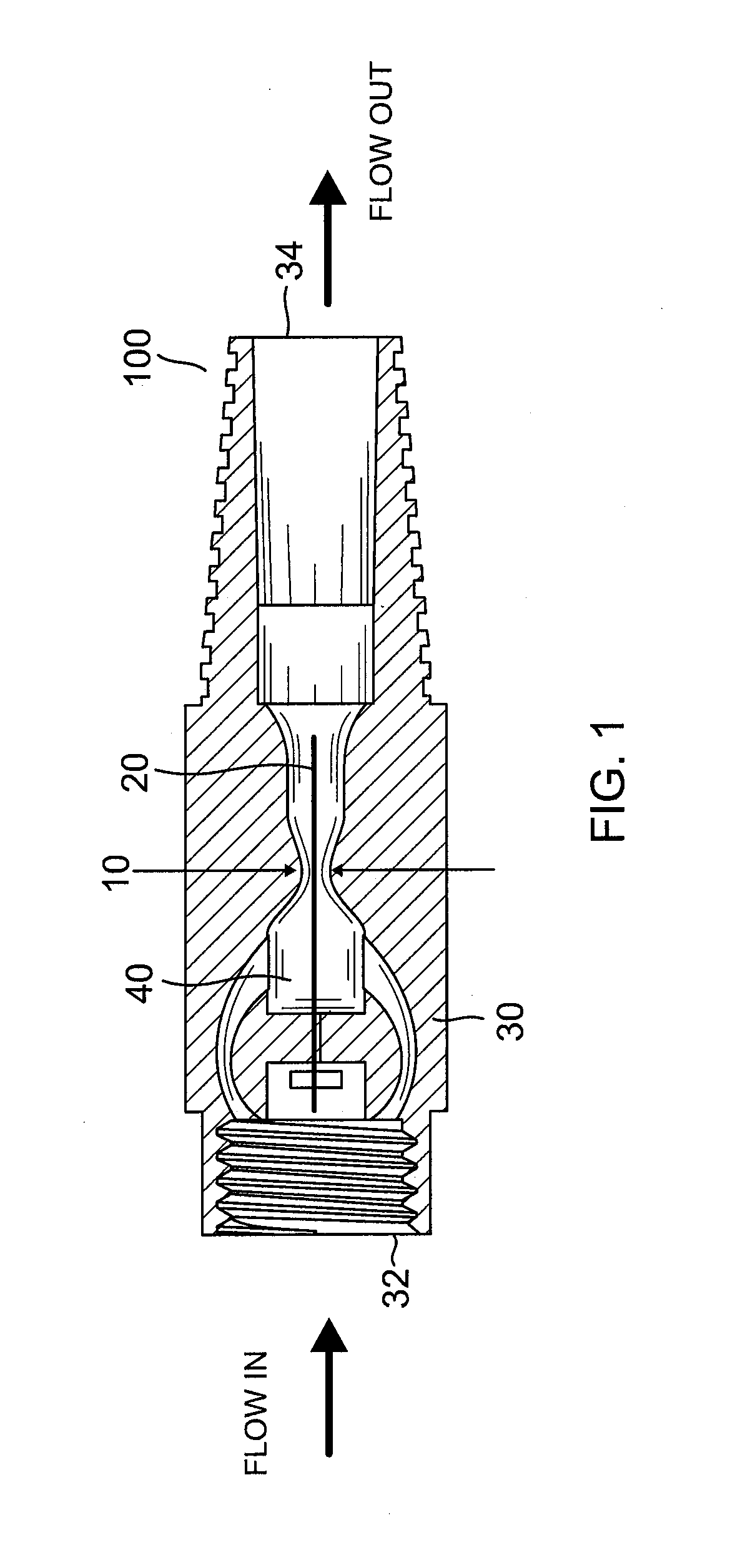

Flow energy piezoelectric bimorph nozzle harvester

ActiveUS20140319970A1Reduce complexityReduce difficultyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric/electrostrictive/magnetostrictive devicesElectricityPressure amplitude

A flow energy harvesting device having a harvester pipe includes a flow inlet that receives flow from a primary pipe, a flow outlet that returns the flow into the primary pipe, and a flow diverter within the harvester pipe having an inlet section coupled to the flow inlet, a flow constriction section coupled to the inlet section and positioned at a midpoint of the harvester pipe and having a spline shape with a substantially reduced flow opening size at a constriction point along the spline shape, and an outlet section coupled to the constriction section. The harvester pipe may further include a piezoelectric structure extending from the inlet section through the constriction section and point such that the fluid flow past the constriction point results in oscillatory pressure amplitude inducing vibrations in the piezoelectric structure sufficient to cause a direct piezoelectric effect and to generate electrical power for harvesting.

Owner:CALIFORNIA INST OF TECH +1

Thermoacoustic device

InactiveUS20050274123A1Suppress Gedeon streamingIncrease or decrease volumeElectrical transducersStirling type enginesPressure amplitudeWorking fluid

A thermocoustic device includes a housing with a thermal core supported in the housing and having a first and a second surface. The thermal core includes a first heat exchanger defining the first surface of the thermal core and a second heat exchanger defining the second surface of the thermal core. A main chamber is in fluid communication with the first surface of the thermal core and a secondary multiplier chamber is in fluid communication with the second surface of the thermal core. A working volume of a gaseous working fluid fills the main chamber, the multiplier chamber, and the thermal core at a pressure. An equilibrium pressure is defined as the pressure of the working volume of gaseous working fluids with the thermoacoustic device is in a non-operating mode. The main chamber includes a first oscillating member that is operable when the thermoacoustic device is in an operating mode to oscillate such that the pressure in both the main chamber and in the multiplier chamber is oscillated between a peak pressure greater than the equilibrium pressure and a minimum pressure less than the equilibrium pressure. A main pressure amplitude is defined as one-half of the difference between the peak pressure and the minimum pressure in the main chamber. The secondary multiplier chamber includes a second oscillating member that is operable when the thermoacoustic device is in the operating mode to oscillate such that the pressure in the multiplier chamber is oscillated between a peak pressure greater than the equilibrium pressure and a minimum pressure less than the equilibrium pressure. A multiplier pressure amplitude is defined as one-half of the difference between the peak pressure and the minimum pressure in the multiplier chamber. The first and second oscillating members oscillate at substantially the same frequency and such that the pressure oscillations in the main chamber and the multiplier chamber are substantially in phase with each other. The multiplier pressure amplitude is greater than the main pressure amplitude.

Owner:PENN STATE RES FOUND

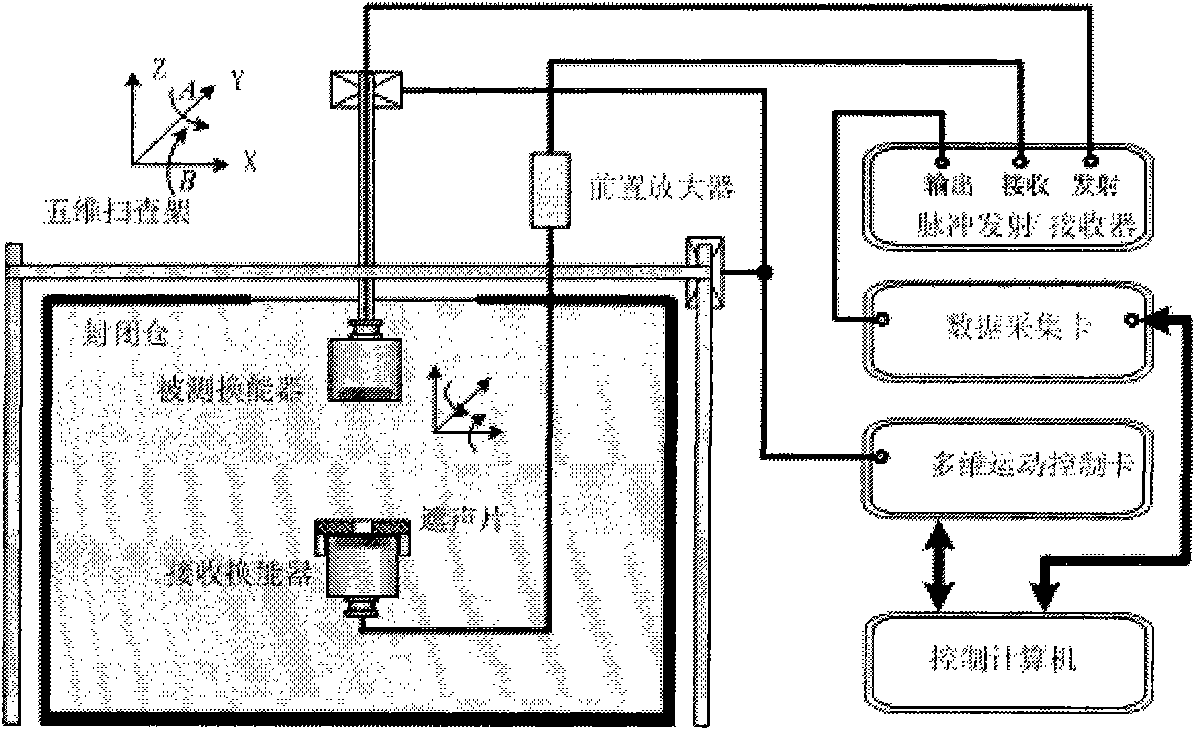

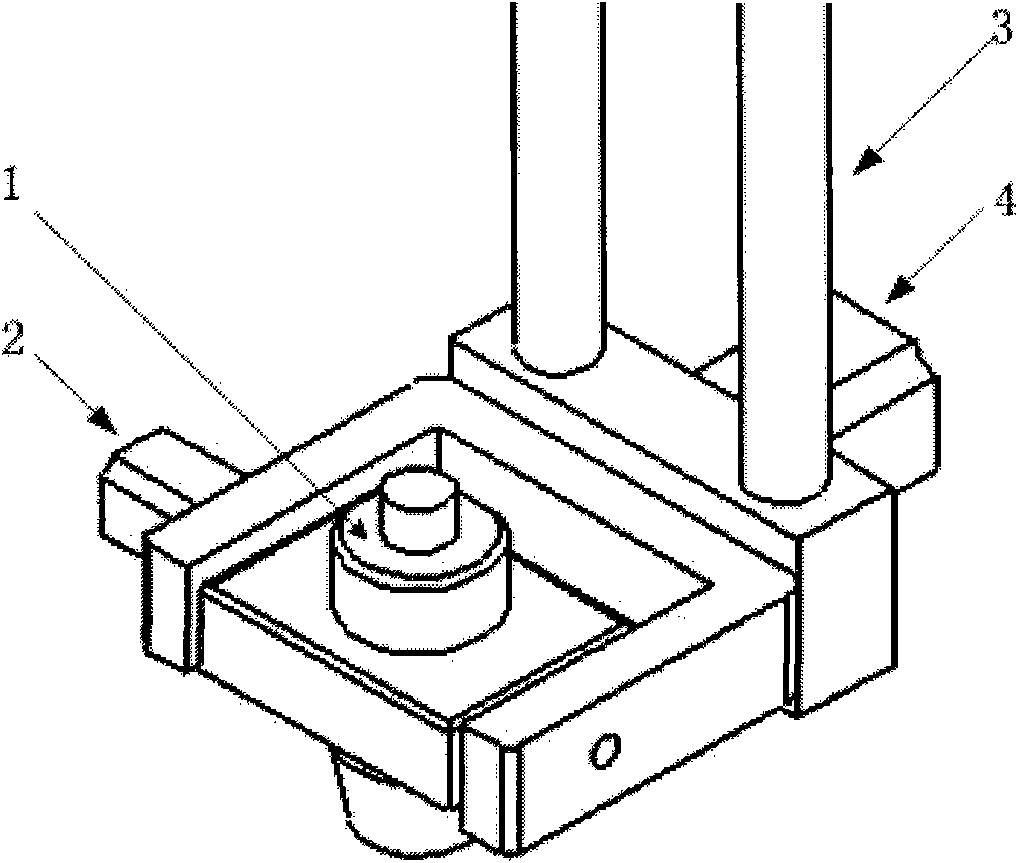

Air-coupled ultrasonic testing transducer sound field characteristic measuring device

InactiveCN102279045ATroubleshooting Sound Field Characteristic Calibration IssuesAchieve focal lengthSubsonic/sonic/ultrasonic wave measurementMeasurement devicePressure amplitude

The invention relates to a device suitable for measuring the sound field characteristics of an air-coupled ultrasonic detection transducer, which solves the problem of calibration of the sound field characteristics of the air-coupled ultrasonic transducer and realizes automatic measurement of the focal length, focal area length and focal area width of the transducer's sound field. and sound beam spread angle characteristics. The sound field measurement device of the present invention includes: a scanning mechanism, an ultrasonic transceiver and signal acquisition system, a motion control system, a sound axis alignment mechanism, and a micro-hole silencer. The ultrasonic transceiver mode of the measurement system is a transmit-receive mode, and is carried out in a closed transparent chamber. During measurement, the receiving transducer is installed on a fixed bracket, and the measured air-coupled transducer is installed through the acoustic axis alignment mechanism. The sound beam axis is adjusted to coincide with the Z-axis. The pulse sound field emitted by the air-coupled ultrasonic transducer is received by the receiving transducer with a micro-hole silencer attached. The peak value of the pulse echo signal is calculated by the computer through the data acquisition card, and this voltage peak is used as the sound pressure of the acoustic signal. amplitude. The computer drives the ultrasonic transducer to perform spatial scanning motion relative to the receiving aperture through the motion control system, and the spatial sound field sound pressure distribution of the air-coupled ultrasonic transducer can be measured.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

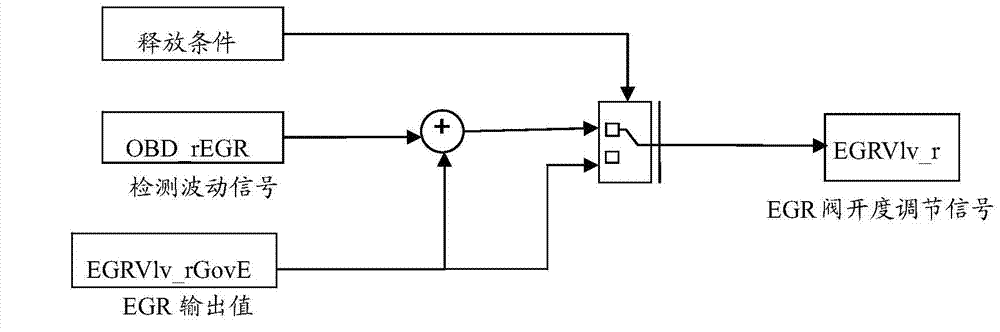

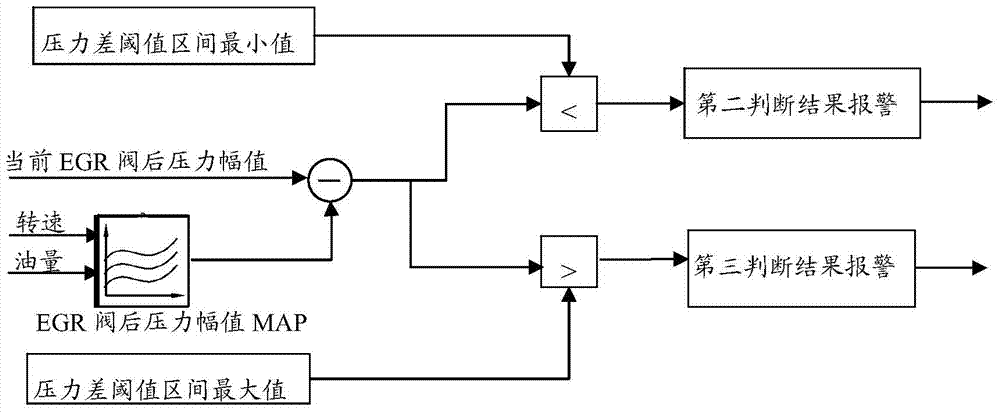

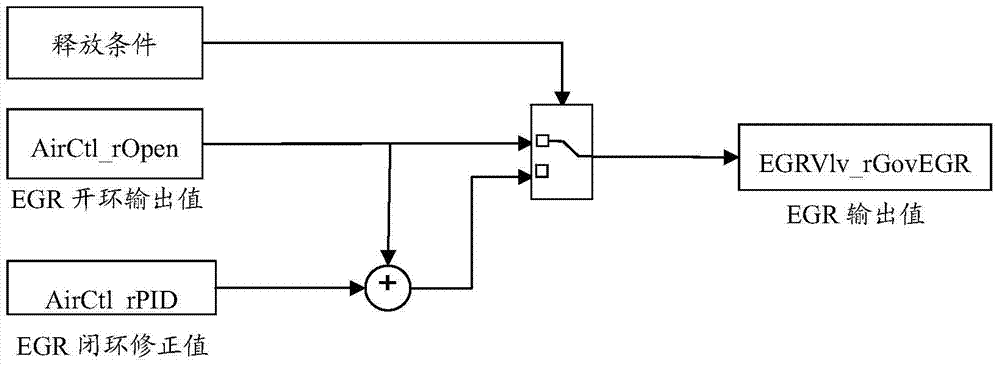

EGR (exhaust gas recirculation) system pipeline state detection method, device and vehicle with device

ActiveCN103758649AGuaranteed detection accuracyAvoid influenceElectrical controlNon-fuel substance addition to fuelPressure amplitudeWater vapor

The invention discloses an EGR (exhaust gas recirculation) system pipeline state detection method which includes the steps: pre-calibrating an EGR downstream pressure amplitude MAP based on engine speed and fuel injection quantity; superposing a fluctuation detection signal to an EGR valve output signal to adjust the opening of an EGR valve; searching the EGR downstream pressure amplitude MAP according to the current engine speed and the fuel injection quantity to obtain an EGR downstream pressure amplitude threshold value based on the fluctuation detection signal; acquiring the current EGR downstream pressure amplitude and comparing the current EGR downstream pressure amplitude with the EGR downstream pressure amplitude threshold value to determine the pipeline state of a system. The EGR system pipeline state detection method can effectively reduce the influence of dust and water vapor on detection precision, and is reliably applicable to different models. On the basis, the invention further provides an EGR system pipeline state detection device and a vehicle with the same.

Owner:WEICHAI POWER CO LTD

Method for analysis of single pulse pressure waves

InactiveUS7559898B2Easy to analyzeEasy to detectEvaluation of blood vesselsCatheterPressure amplitudeWave parameter

Owner:DPCOM AS

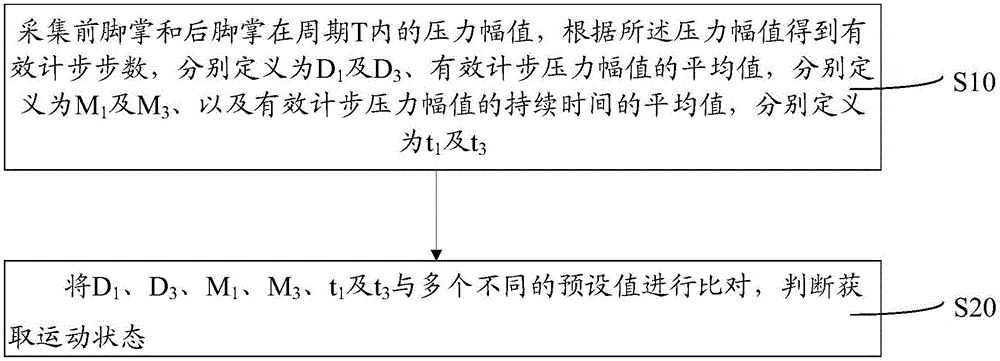

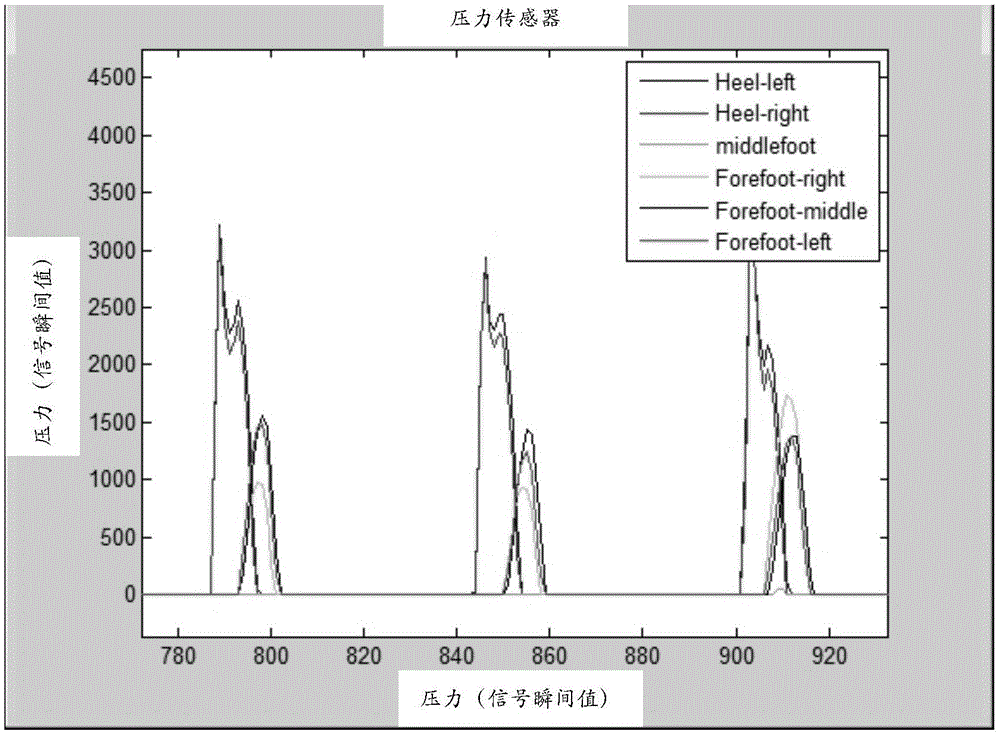

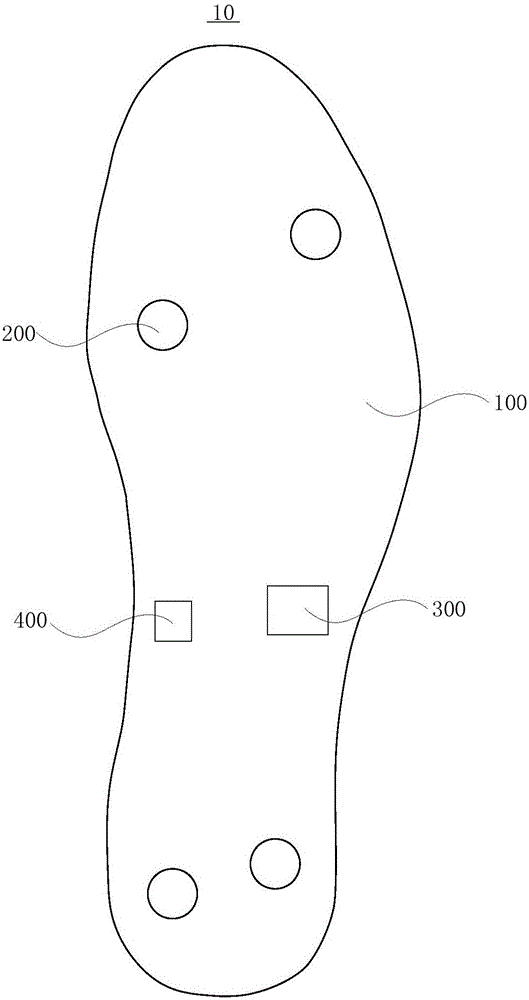

Judgment method for motion state and footwear

ActiveCN105030260AReduce complexityReduce power consumptionDiagnostic recording/measuringSensorsPressure amplitudeAcceleration amplitude

Provided is a judgment method for motion state and footwear. The judgment method comprises following steps of: step S10: acquiring pressure amplitude of forefeet and rear feet within the period T, obtaining effective step numbers by calculating steps based on pressure amplitude, respectively defining the numbers as D1 and D3, effectively calculating average value of pressure amplitude and respectively defining the value as M1 and M3, and effectively calculating average value of time of duration for pressure amplitude and respectively defining the value as t1 and t3; step 20: making comparisons among D1, D3, M1, M3, t1, t3 and multiple different preset value in order to determine and acquire motion state. The above judgment method for motion state is less susceptible to interference of other unrelated motion so that high judgment accuracy is obtained. Low algorithm complexity is adopted by the above judgment method for motion state.Moreover, motion state is judged to be more accurate by introducing acceleration amplitude, absolute value of angle amplitude and the feature of maximum value for absolute value of angle amplitude.

Owner:SHENZHEN HORN AUDIO

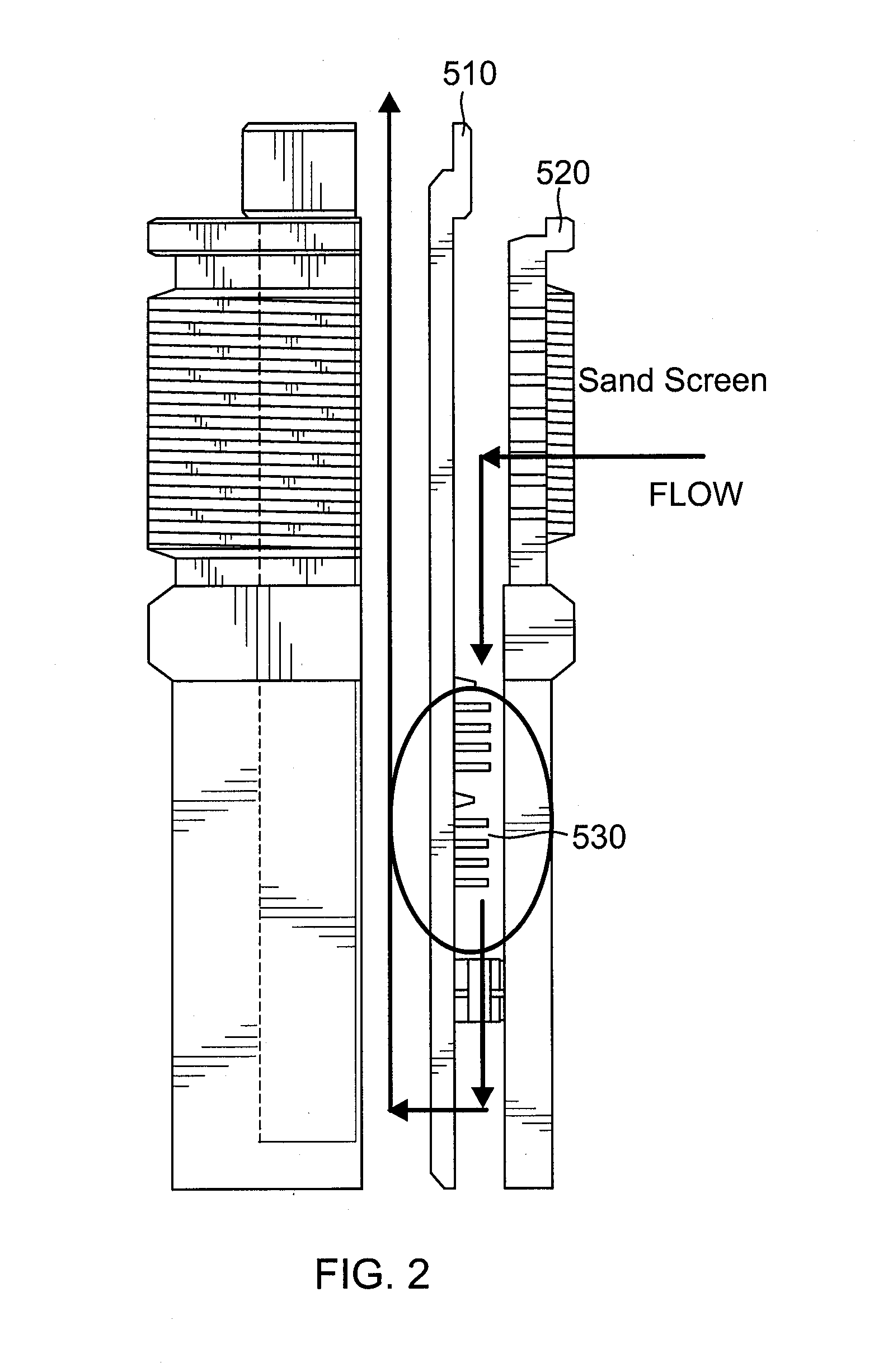

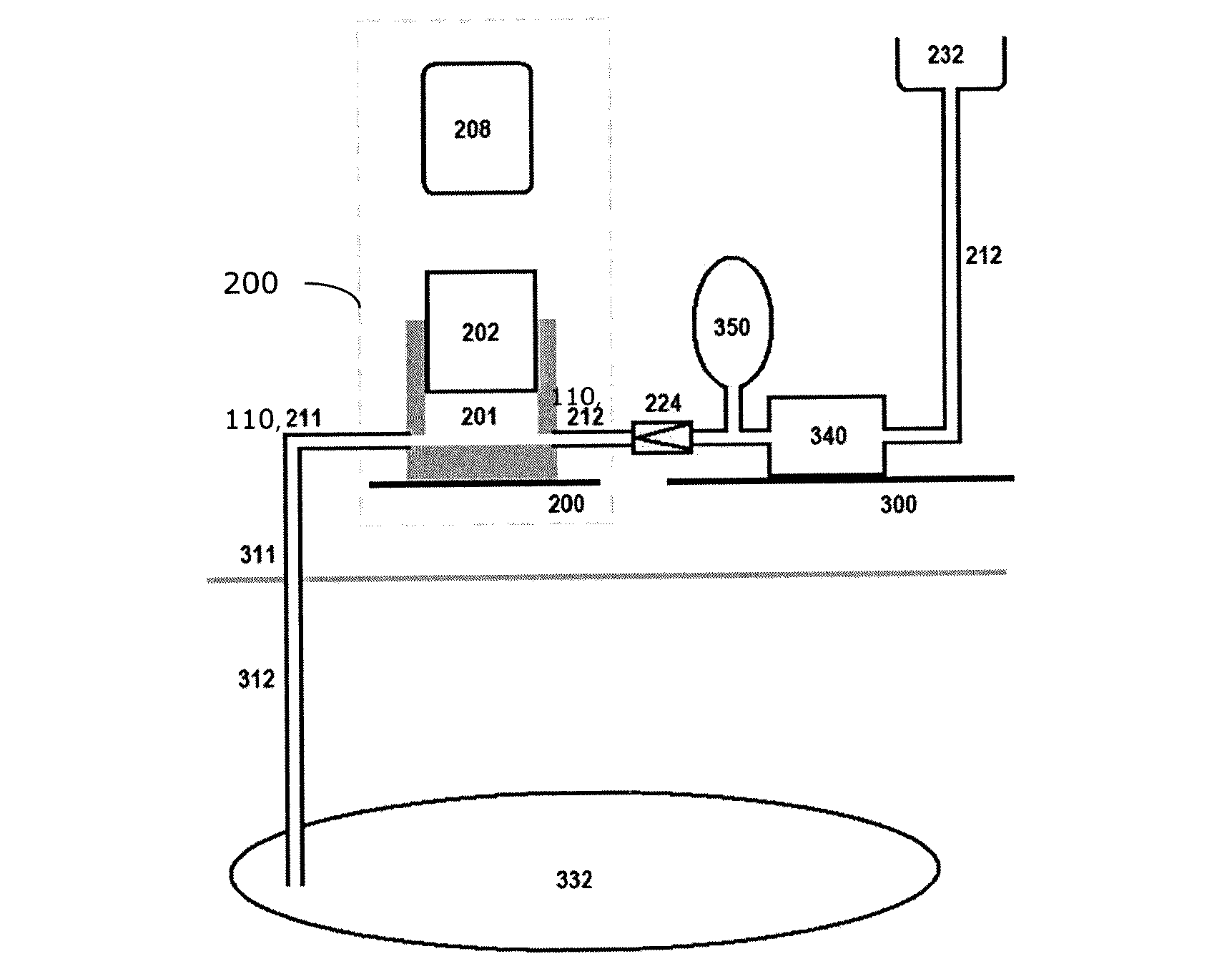

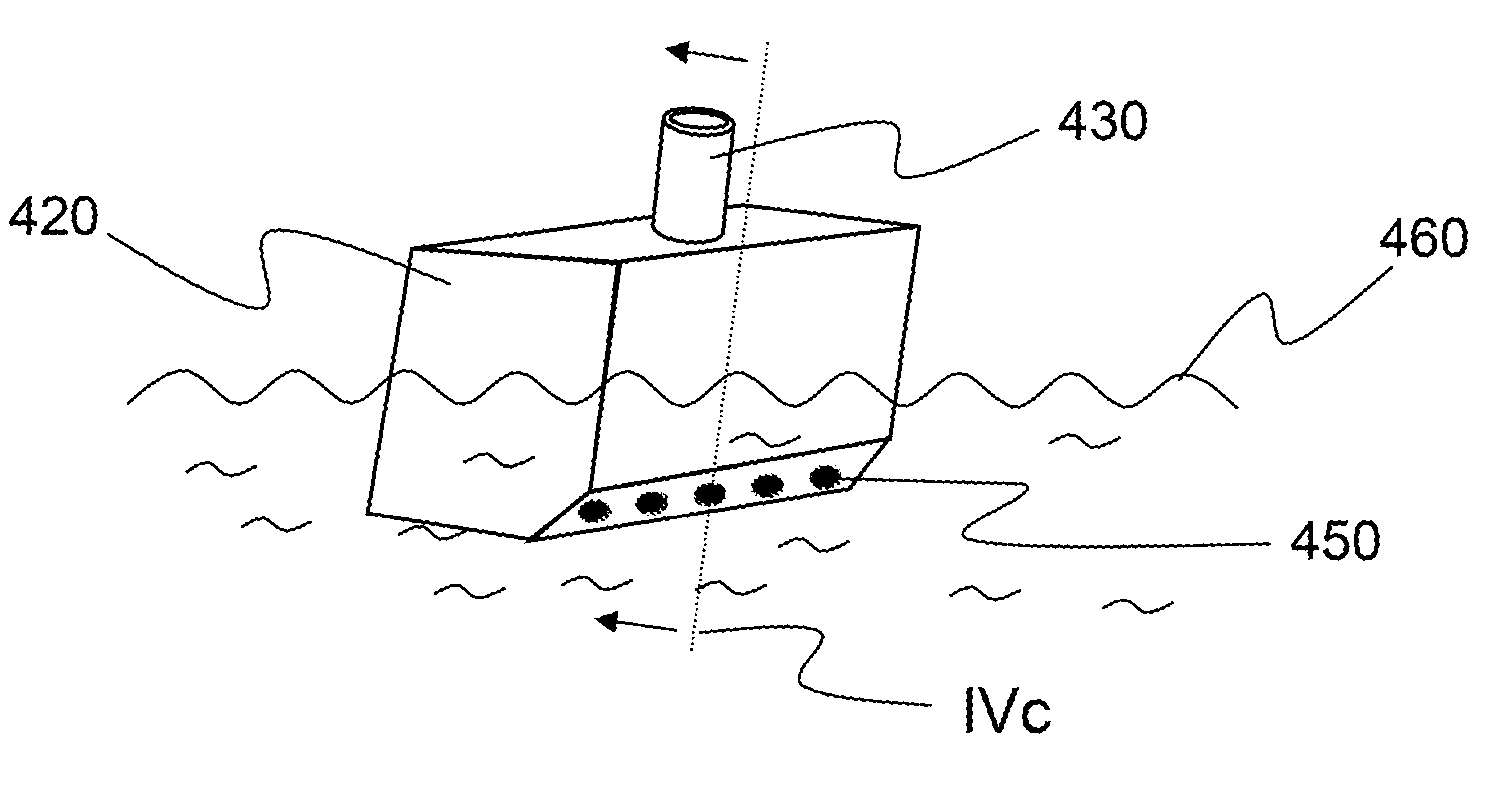

Method for recovery of hydrocarbon fluid

InactiveUS20140338895A1Increase hydrocarbon recovery factorPromote recoverySurveyFluid removalPressure risePressure amplitude

A method is described for recovery of a hydrocarbon fluid from a porous medium by injection of a fluid into the porous medium. The method includes determining a Rayleigh time on the basis of the density of the fluid and the hydrocarbon fluid, the median pore diameter of the porous medium, and surface tension between the fluid and the hydrocarbon fluid. Further, pressure stimulation is provided in the fluid and generated by a collision process with a collision contact rise time which is of the range of 1-100 times the Rayleigh time. Alternatively or additionally, the providing a pressure stimulation in the fluid include generating an impact pressure with a pressure amplitude I and a pressure rise time Δt, where the pressure amplitude is larger than the relation γcΔt / a2, where γ is the surface tension between the fluid and the hydrocarbon fluid, and c is the speed of sound in the porous media. In aspects of the invention, the method includes arranging a chamber in fluid communication with the porous medium via at least one conduit, and having the chamber comprising first and second wall parts movable relative to each other. The pressure stimulation includes providing an impact pressure in the fluid to propagate to the porous medium via the conduit, and where the impact pressure is generated by the collision process between an object arranged outside of the fluid and the first wall parts for the first wall part to impact on the fluid in the chamber.

Owner:IMPACT TECH SYST

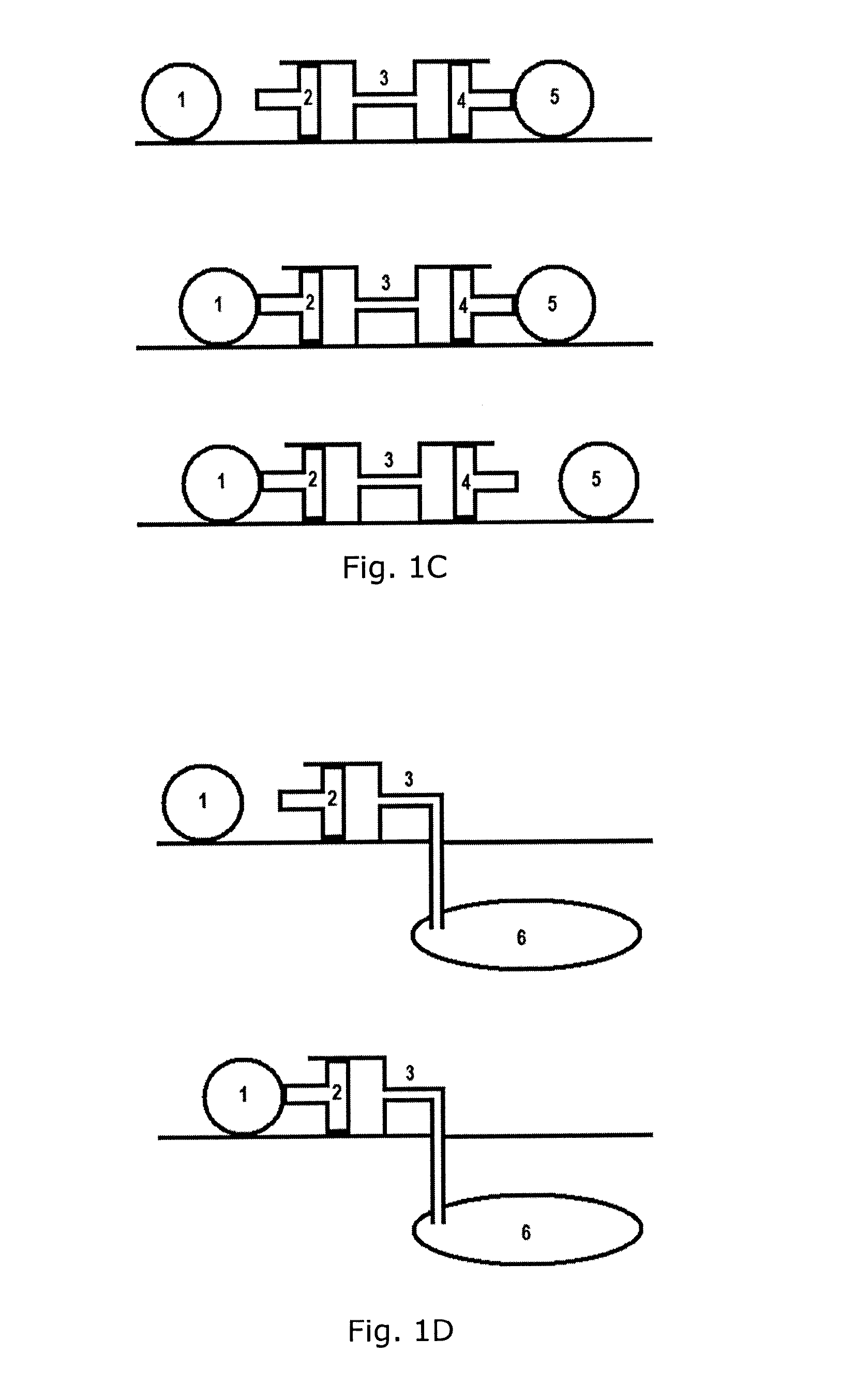

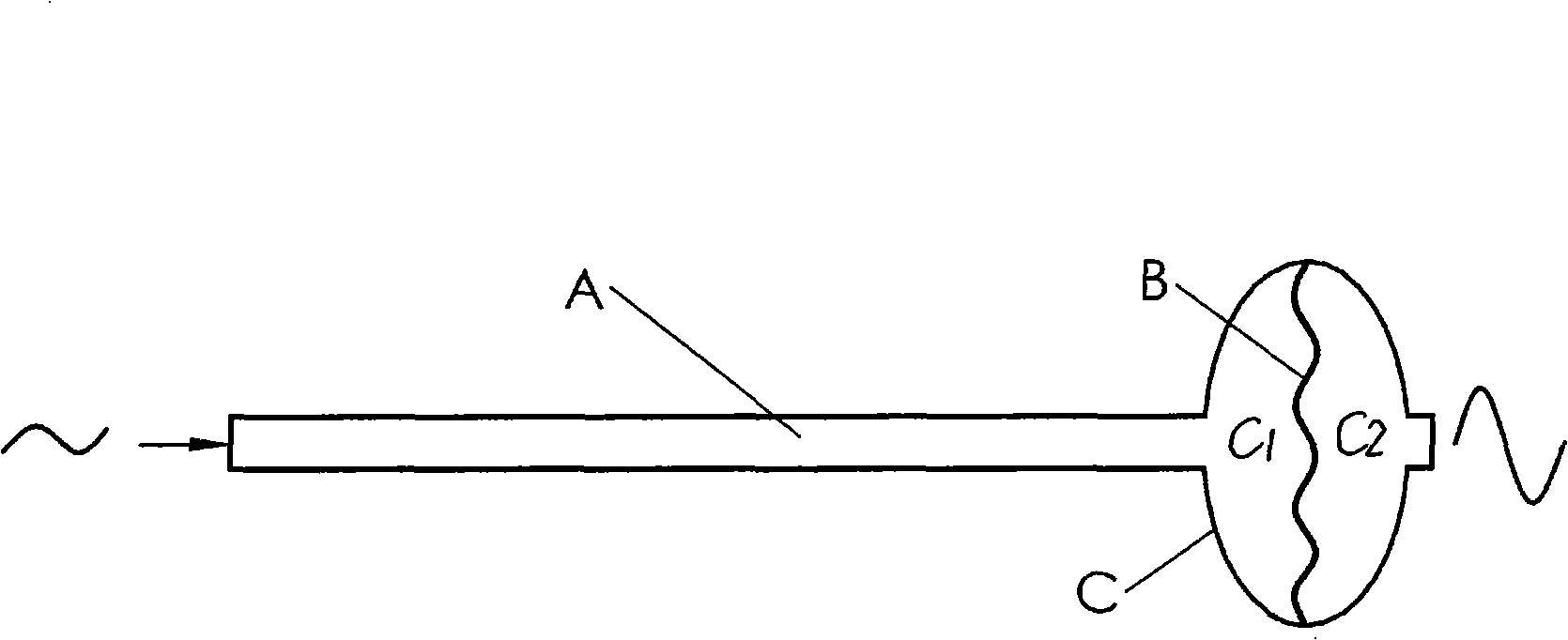

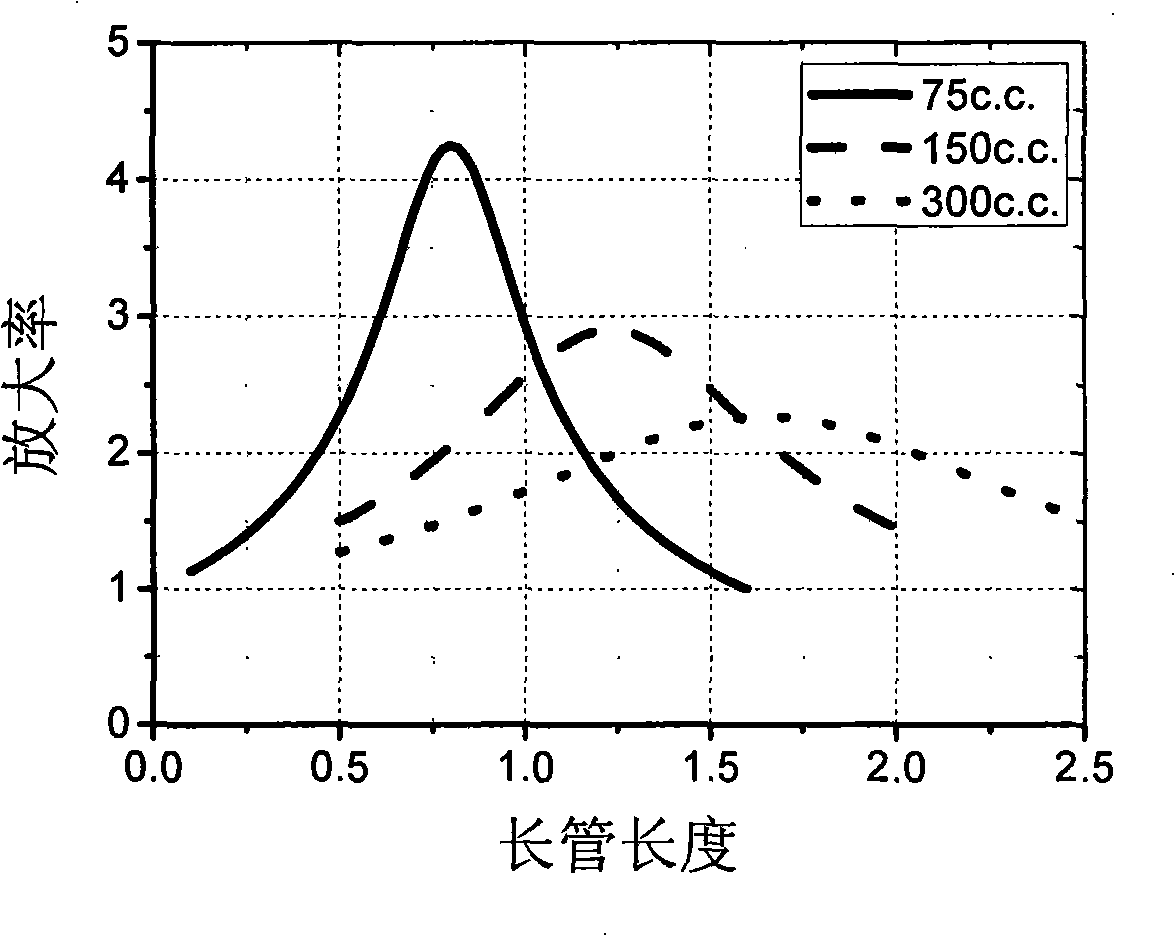

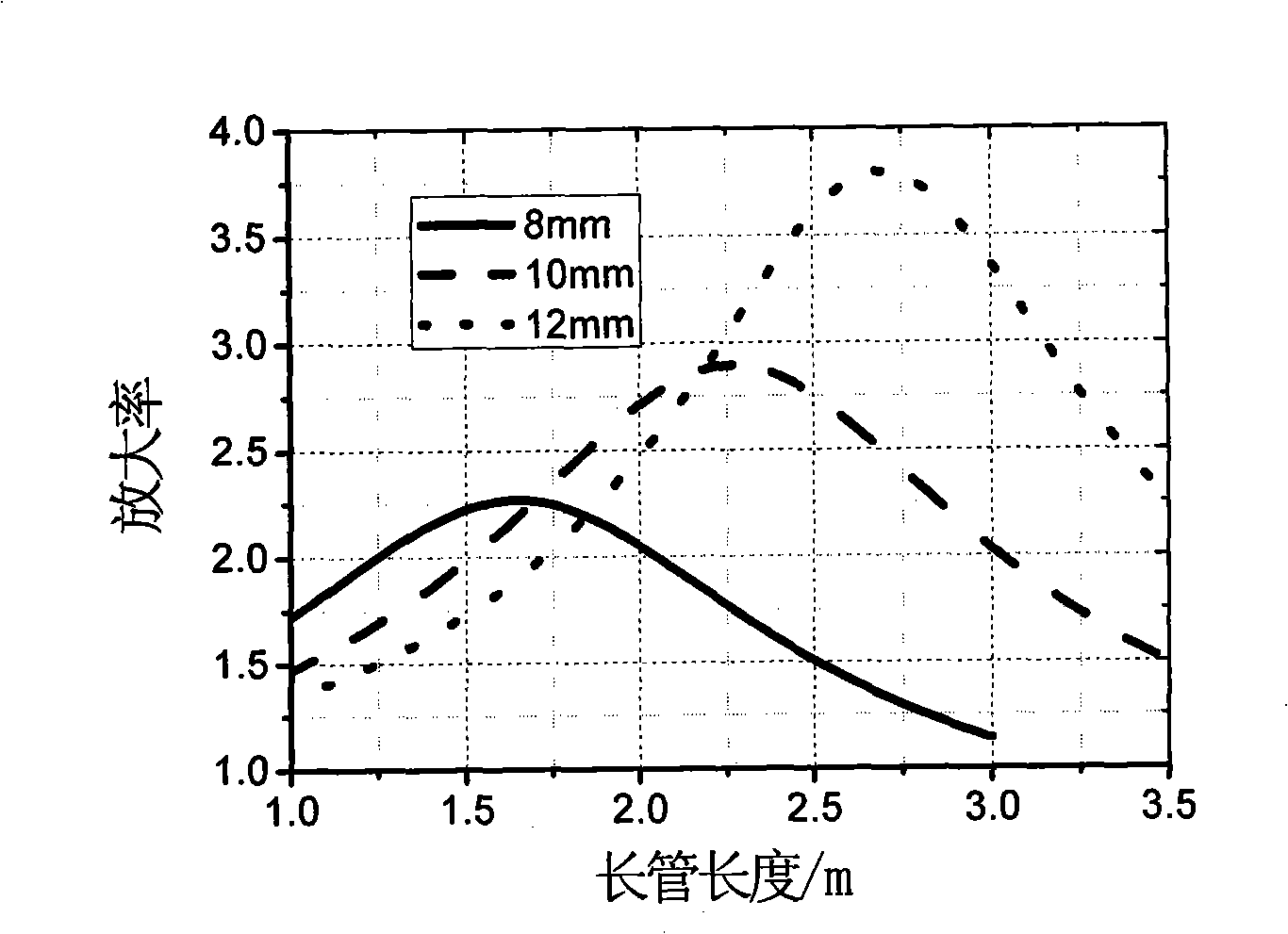

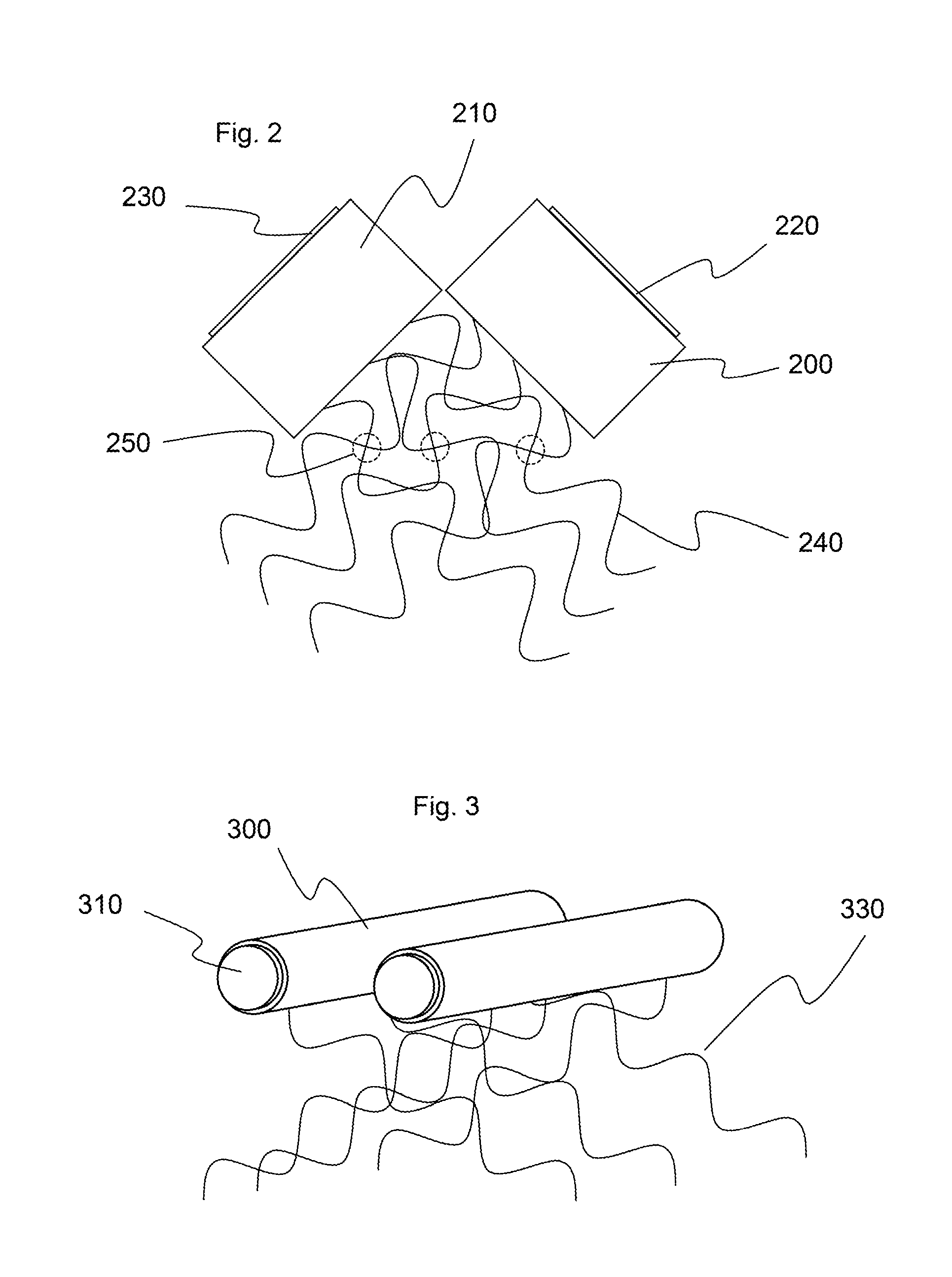

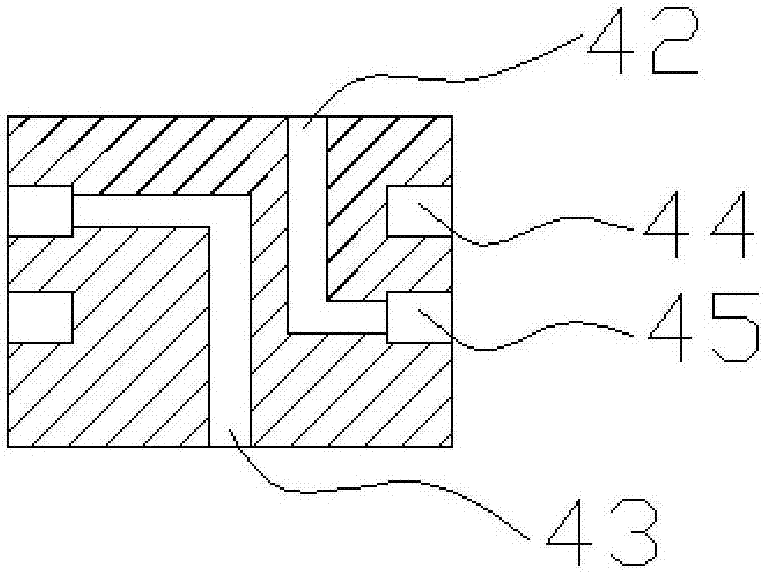

Coupled apparatus used between heat phonomotor and refrigerating device driven by the same

InactiveCN101280977AReduce penetrationAvoid mixingCompression machinesGas cycle refrigeration machinesPressure amplitudeProduct gas

The invention relates to a coupling device for thermo-acoustic engine and cooler driven by the thermo-acoustic engine, comprising: a hollow cavity; an elastic film installed within the hollow cavity, the elastic film divides the hollow cavity into a first chamber and a second chamber; a long pipe communicated with one sidewall of the hollow cavity and with the first chamber; a short pipe communicated with another sidewall of the hollow cavity and with the second chamber; another end of the long pipe is communicated with a feedback pipe of the thermo-acoustic engine; another end of the short pipe is communicated with a water cooler of the cooler; the cooling device can enable pressure wave generated by the thermo-acoustic engine to amplify pressure amplitude when passing through the long pipe and the hollow cavity, thus improving utilization rate of system acoustic power by the cooler; the elastic film installed within the hollow cavity separates working gas in the cooler from the engine so that the engine can use the gases, such as nitrogen, to reduce system frequency for working substance, meanwhile, the cooler can use the gases, such as helium gas, to maintain good cooling performance for the working substance.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

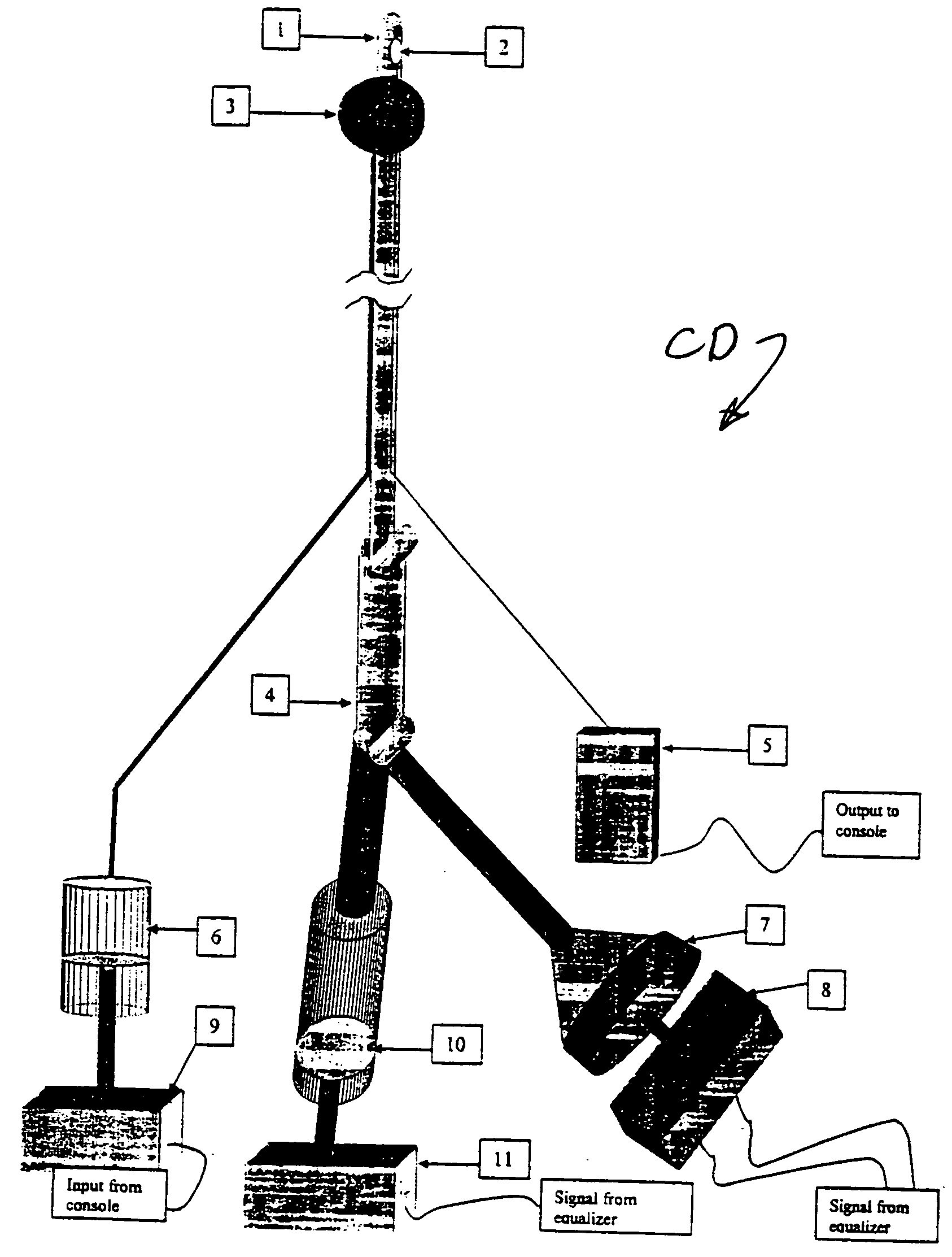

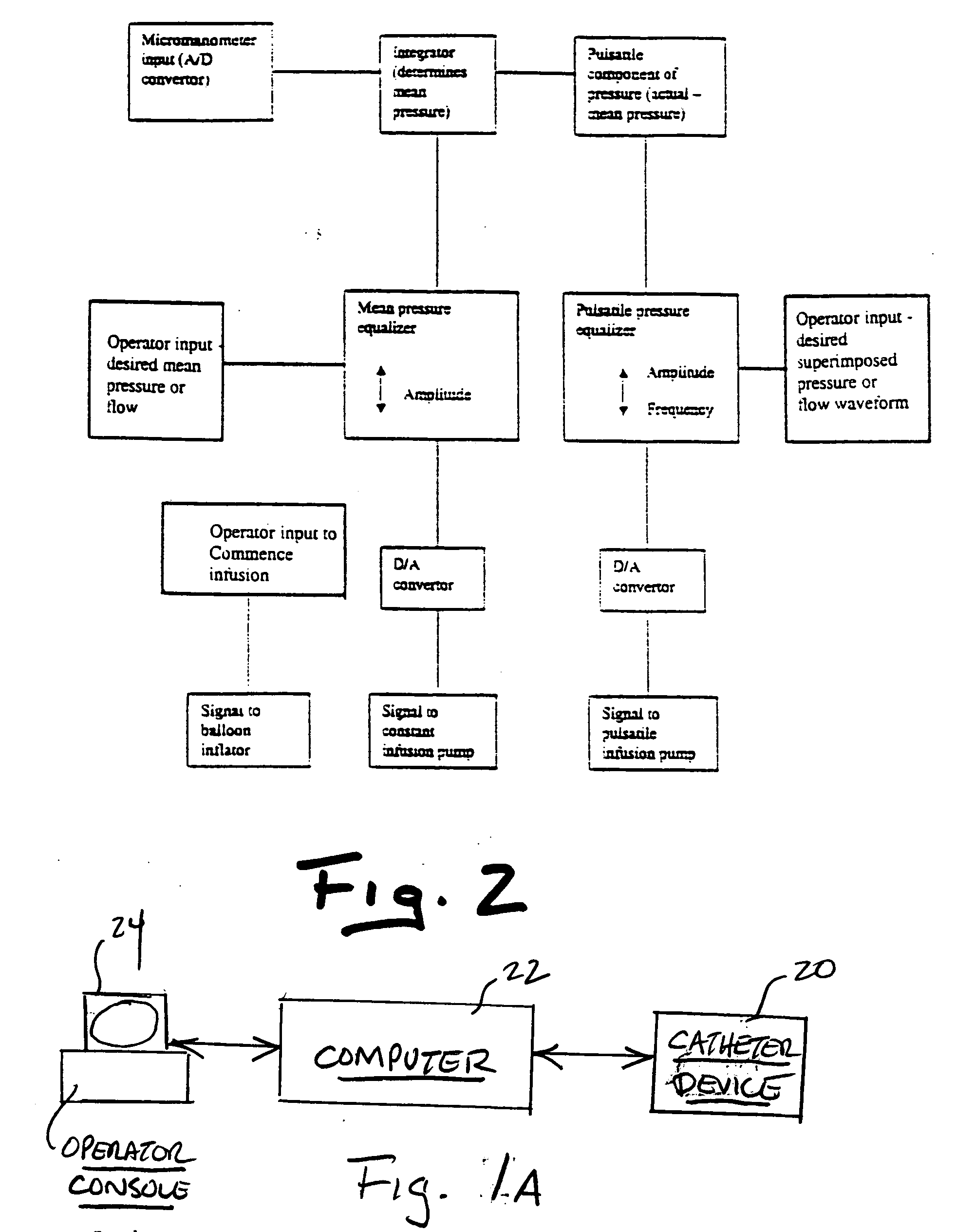

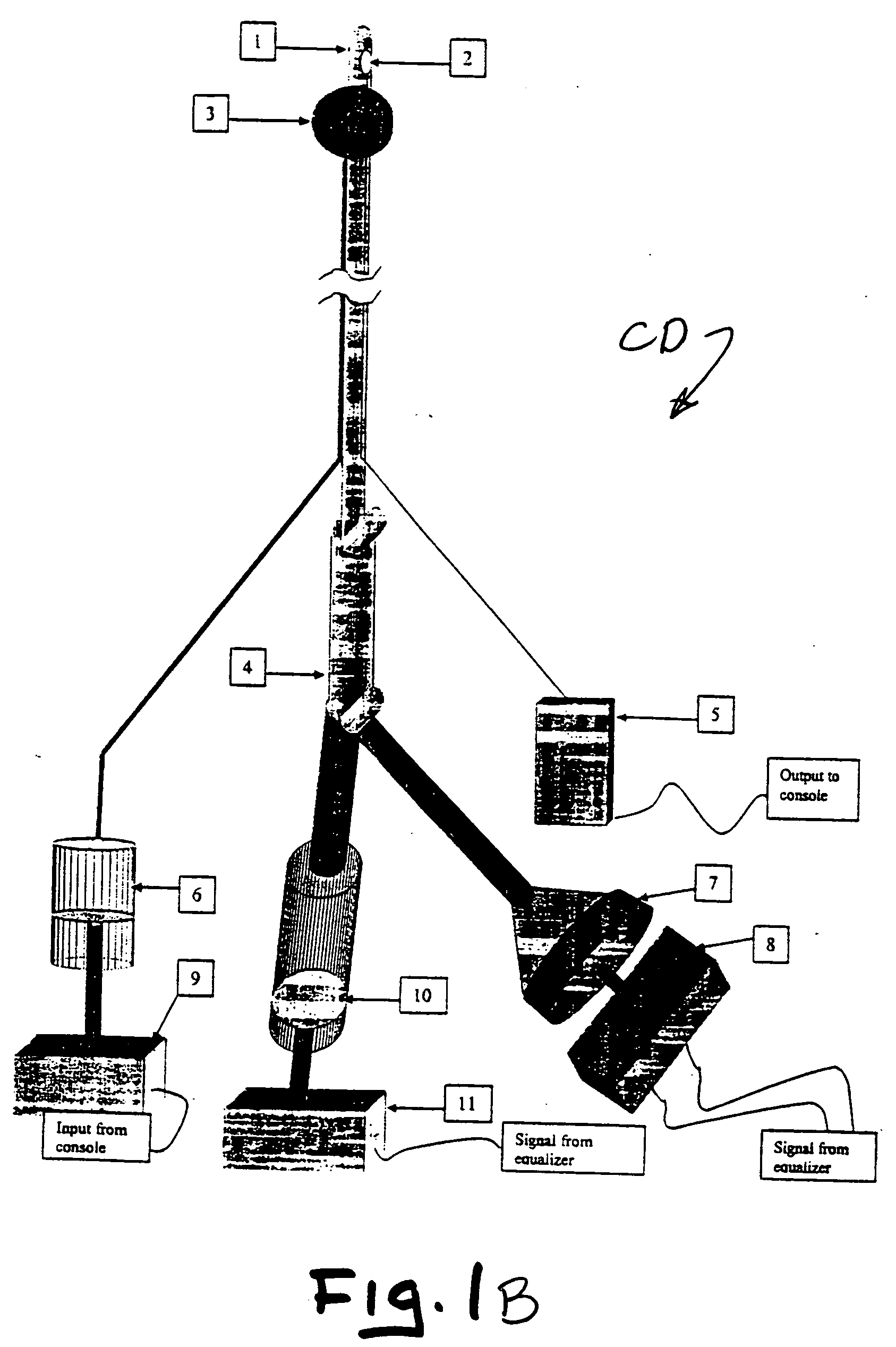

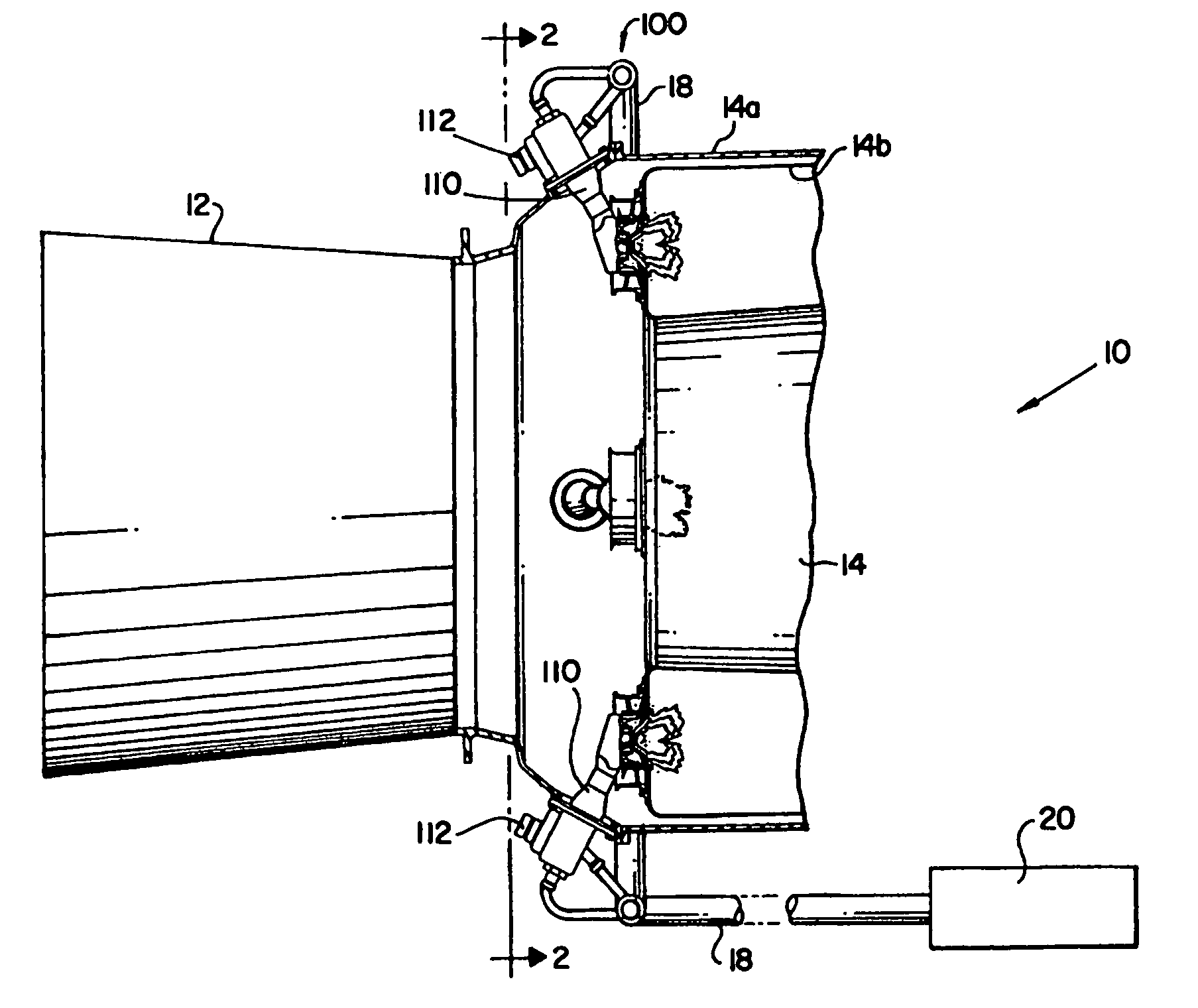

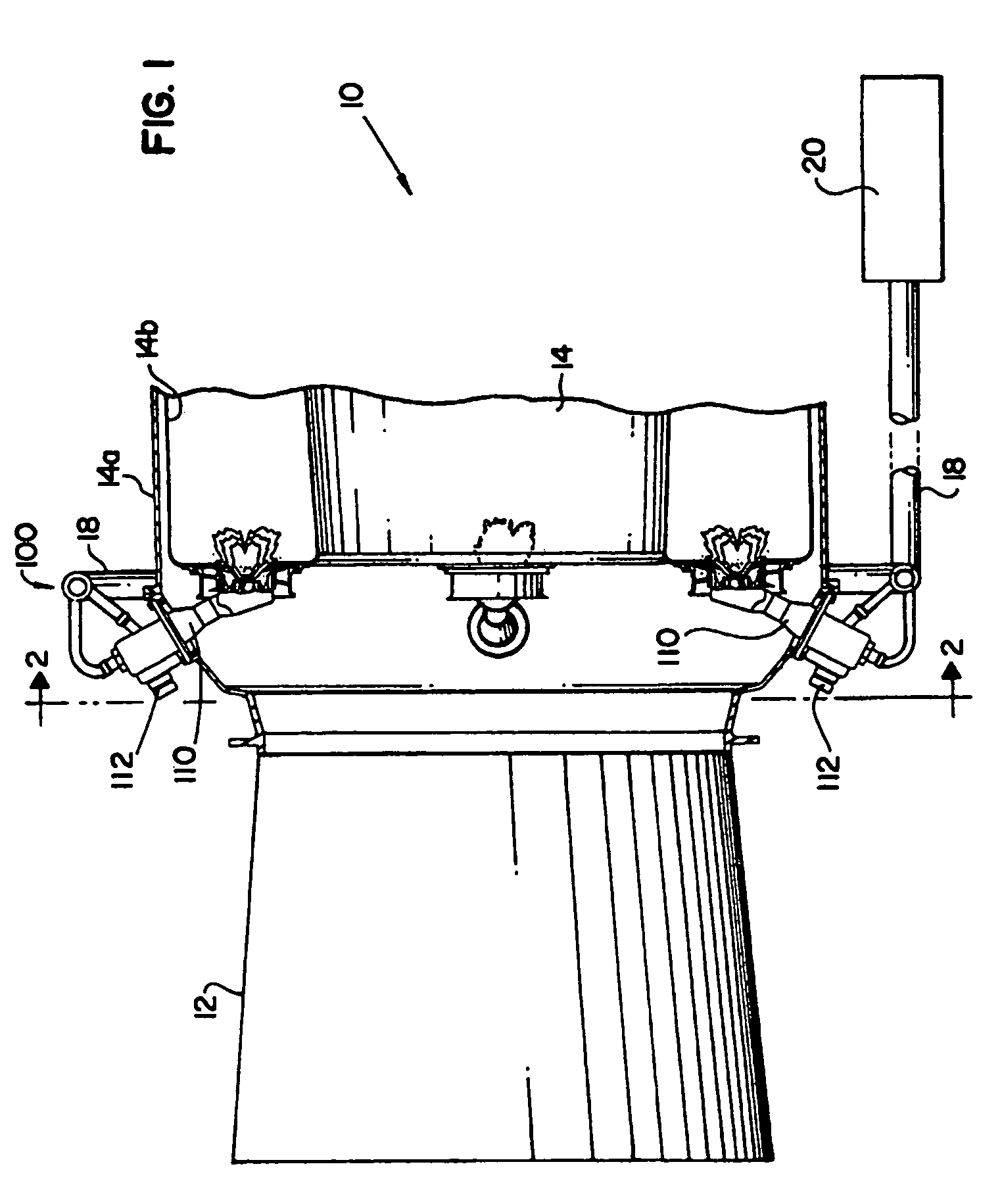

Methods and devices for catheter-based intracoronary myocardial delivery of cellular, genetic or biological materials

Methods and systems infuse therapeutic materials into a vascular vessel by means of a catheter based infusion system. In especially preferred forms, the infusate (which comprises a therapeutic material) is infused through a distal end of the catheter and into the vascular vessel by delivering the infusate to the catheter at a substantially constant flow rate while simultaneously imparting a pressure amplitude and frequency to the infusate in dependence upon a sensed pressure condition within the vessel. Preferably, and the pressure amplitude imparted to the constant flow rate of infusate is about twice the vessel systolic pressure. The present invention is therefore especially well suited for the catheter-based infusion of relatively large particles, such as cellular, genetic, viral, polymeric or proteinaceous materials, intravascularly in dependence upon the pressure and flow characteristics of the infusate.

Owner:DUKE UNIV

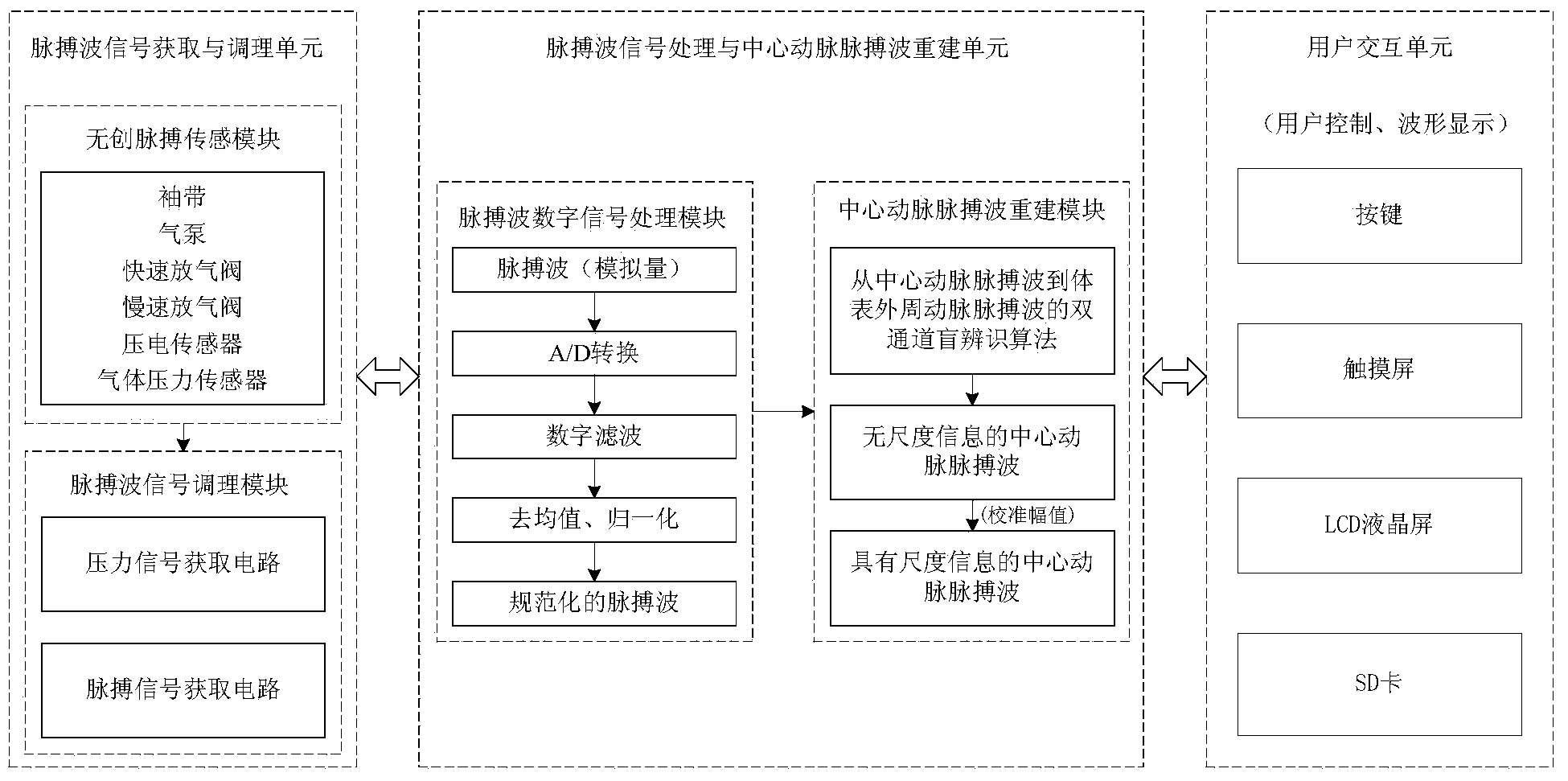

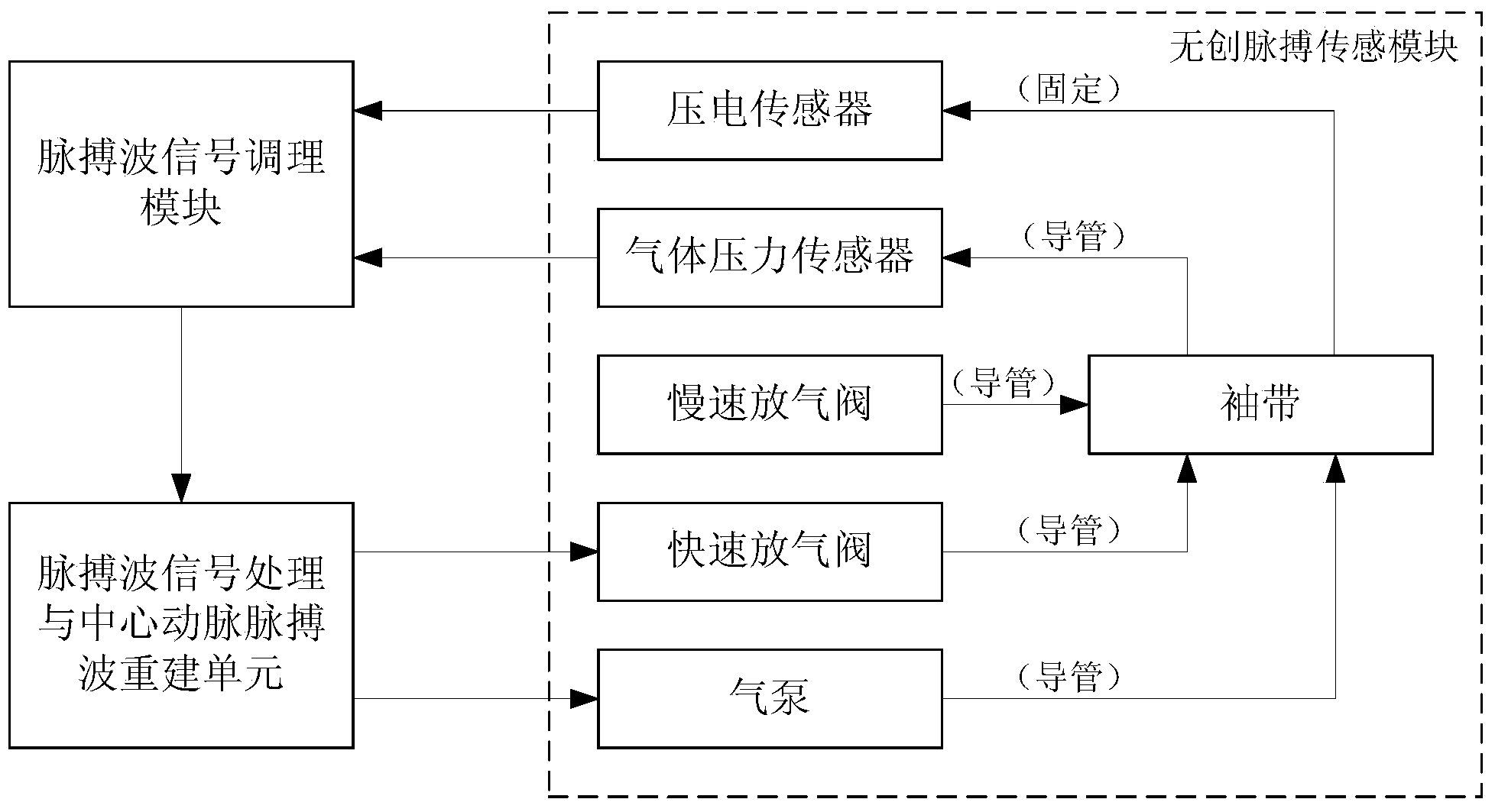

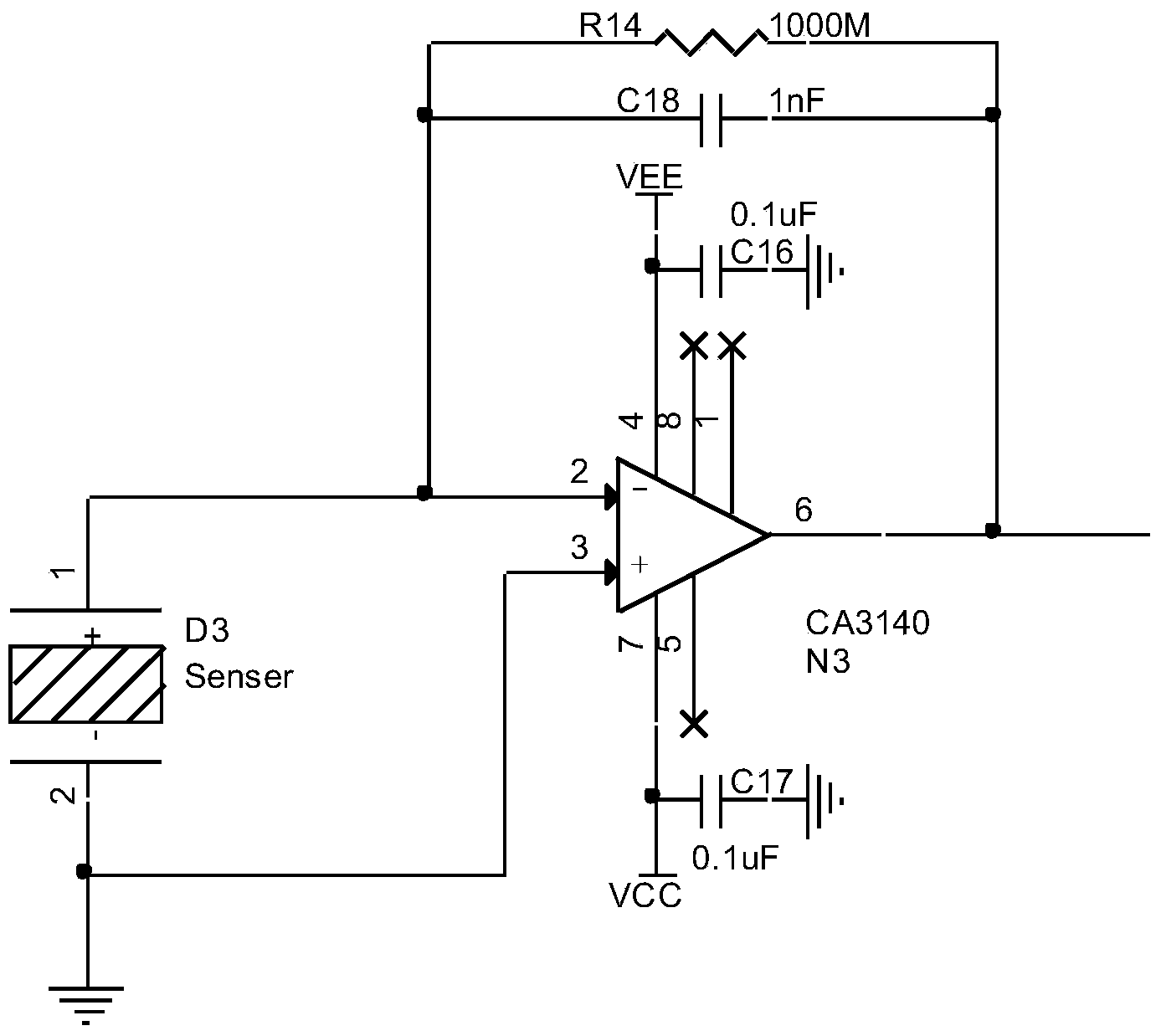

Body surface two point pulse wave based central arterial pulse monitoring system and method

ActiveCN104000573ARealize personalized non-invasive real-time monitoringAngiographyPressure amplitudeContact pressure

The invention provides a body surface two point pulse wave based central arterial pulse monitoring system and method. The body surface two point pulse wave based central arterial pulse monitoring system comprises a pulse wave signal obtaining and conditioning unit, a pulse wave signal processing and central arterial pulse wave reconstruction unit and a user interaction unit, wherein the user interaction unit comprises an LCD (Liquid Crystal Display), a touch screen and an SD (Security Digital) card. The body surface two point pulse wave based central arterial pulse monitoring method comprising placing a piezoelectric sensor at any two points of the body surface artery, binding a cuff, confirming the corresponding contact pressure when the pulse wave is at a largest amplitude and detecting pulse wave signals when air pressure inside the cuff achieves the contact pressure; intercepting pulse wave signals and performing standardized processing; calculating an FIR model of a branch vessel channel; reconstructing central arterial pulse waves and calibrating the central arterial pulse waves to have a real pressure amplitude. According to the body surface two point pulse wave based central arterial pulse monitoring system and method, reconstruction of the central arterial pulse waves not depends on a cardiovascular system transcendental function or model and individualized noninvasive real-time monitoring of the central arterial pulse waves is achieved due to the double-channel blind identification technology from the central arterial pulse waves to the body surface peripheral arterial pulse waves.

Owner:NORTHEASTERN UNIV

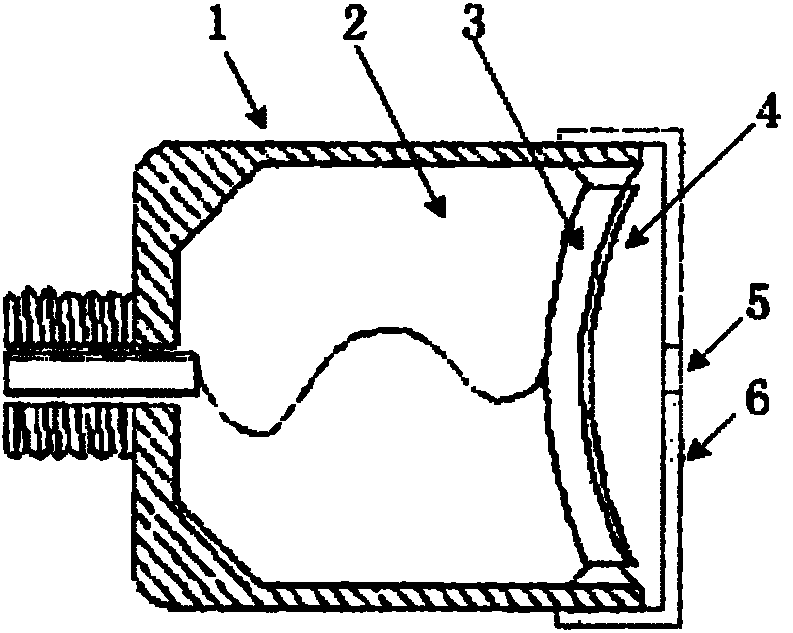

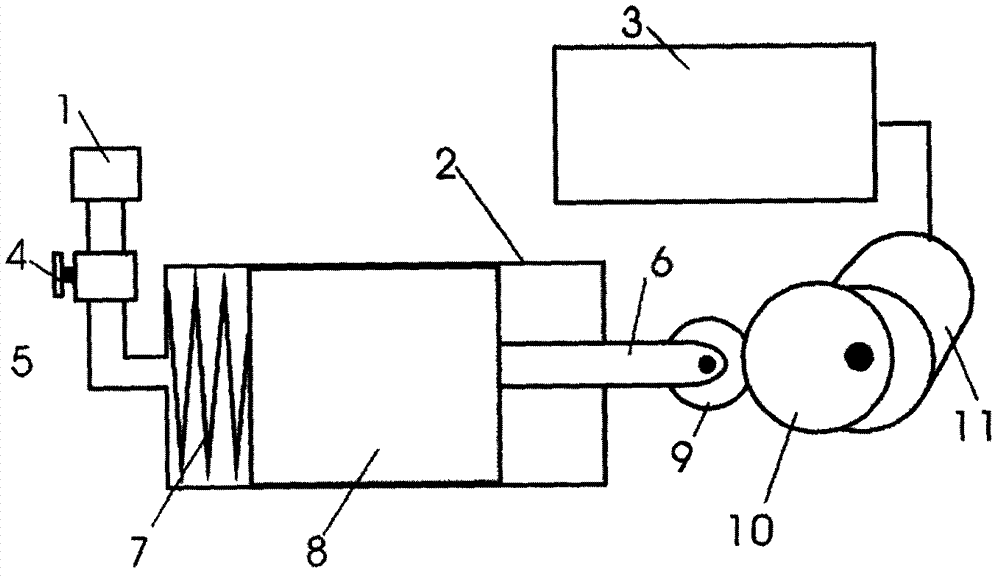

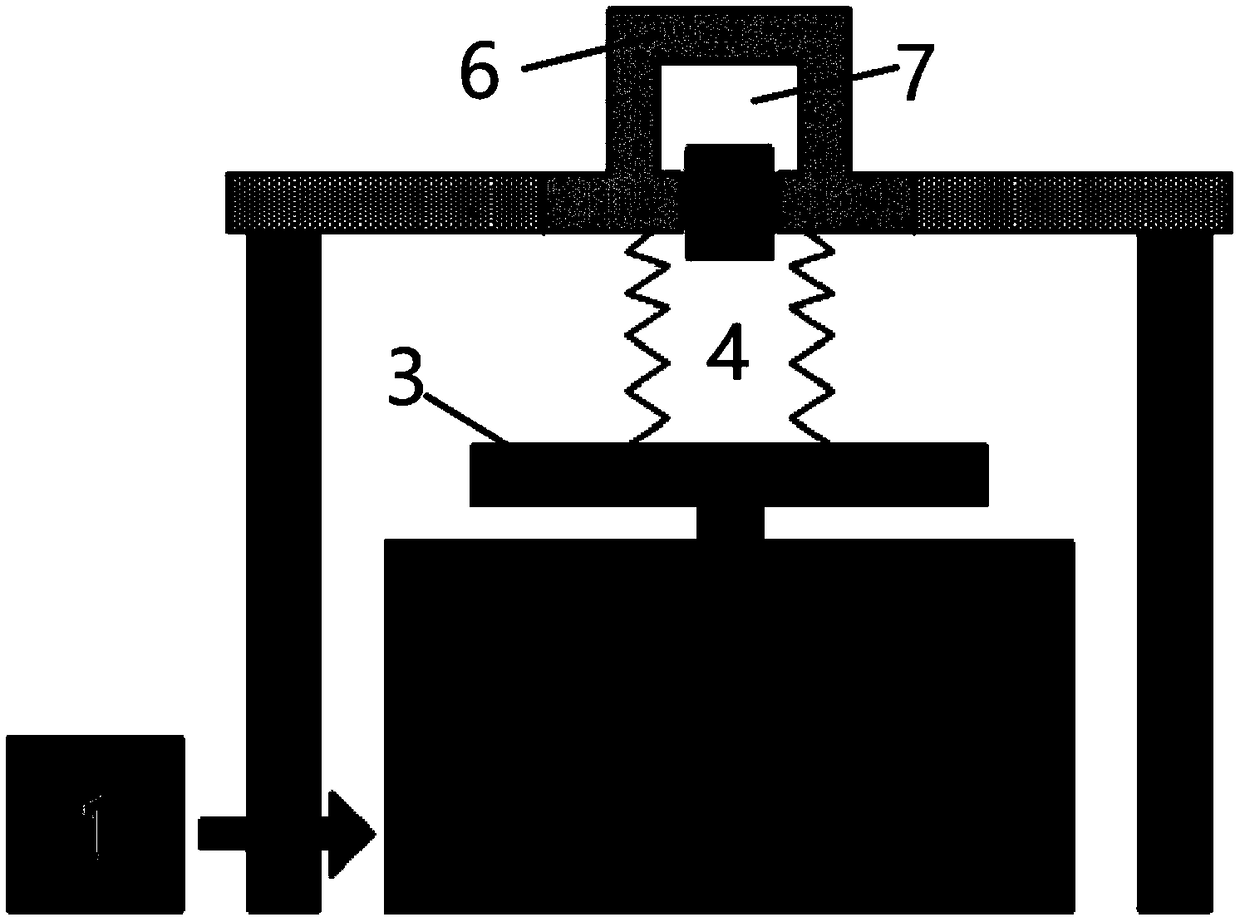

Low-frequency micro pulsating pressure generator

The invention discloses a low-frequency micro pulsating pressure generator which comprises an air cylinder body, a piston arranged in the air cylinder body, a spring connected with the bottom of the piston, and a piston rod connected with the top of the piston, wherein the piston rod penetrates through the air cylinder body and extends to the outside of the air cylinder body; a micro pulley is arranged at the end part of the piston rod outside the air cylinder body, and connected with an eccentric wheel; the eccentric wheel is connected with a rotating shaft of a stepping motor; and the stepping motor is connected with a stepping motor controller by a line. A groove is formed in the surface of the eccentric wheel, and the micro pulley is embedded into the groove to exert a directional effect on the piston. A pressure amplitude regulating valve is arranged on an output connection pipe below a pressure output interface. The generator overcomes the defect that the former pulsating pressure generator cannot generate lower-frequency trace pressure signals. The generator can provide low-frequency trace pressure signals below 5Hz for producing dynamic pressure instruments and equipment.

Owner:上海示才生物科技有限公司

Patient-ventilator synchronization using dual phase sensors

InactiveUS20050081855A1Minimum ventilationImprove determinationRespiratorsOperating means/releasing devices for valvesPressure amplitudeRespiratory phase

An improved ventilator which delivers ventilatory support that is synchronized with the phase of the patent's respiratory efforts and guarantees a targeted minimum ventilation. Improved synchronization is achieved through an instantaneous respiratory phase determination process based upon measured respiratory airflow as well as measured respiratory effort using an effort sensor accessory, preferably a suprastemal notch sensor. The ventilator processes a respiratory airflow signal, a respiratory effort signal and their respective rates. of change to determine a phase using standard fuzzy logic methods. A calculated pressure amplitude is adjusted based upon the calculated phase and a smooth pressure waveform template to deliver synchronized ventilation.

Owner:RESMED LTD

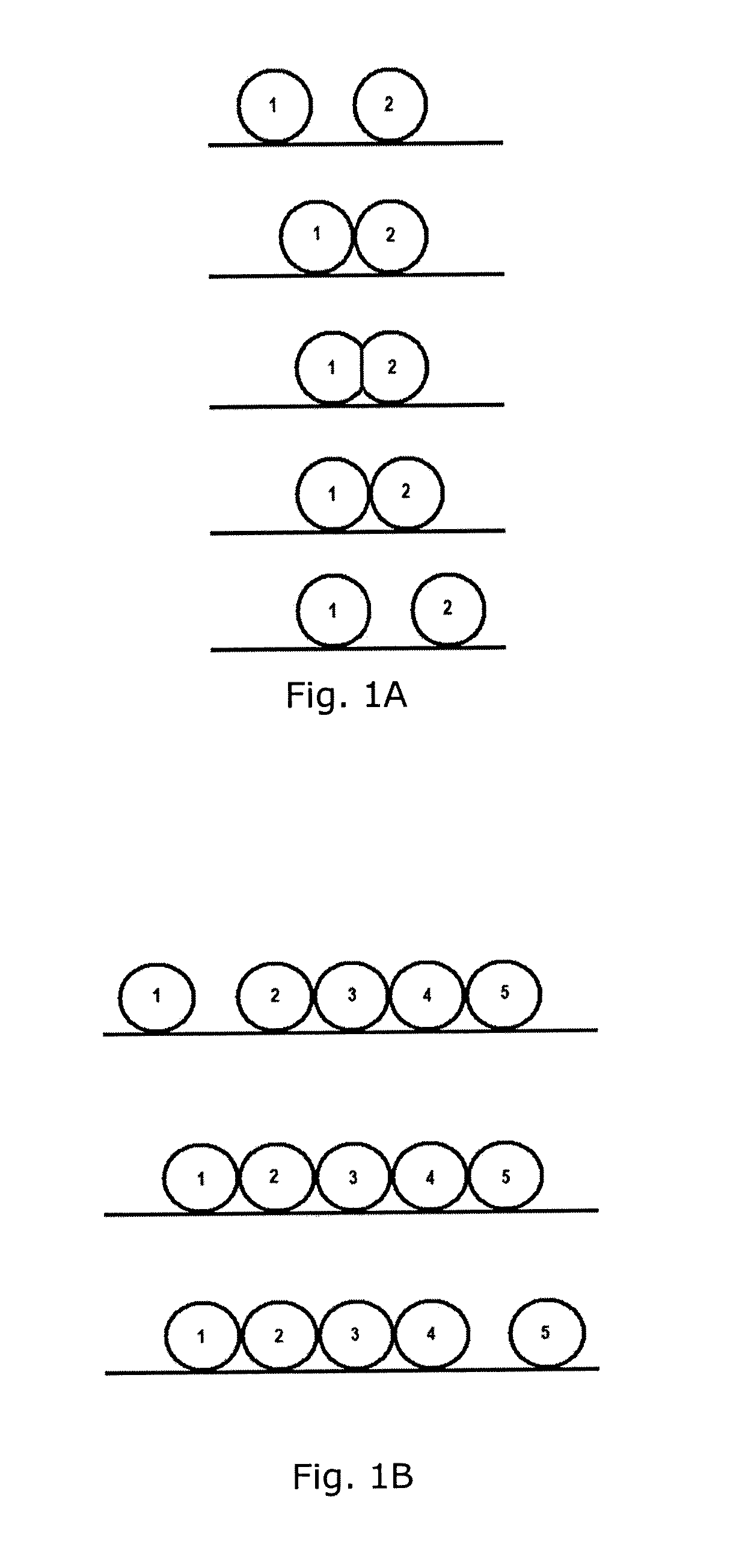

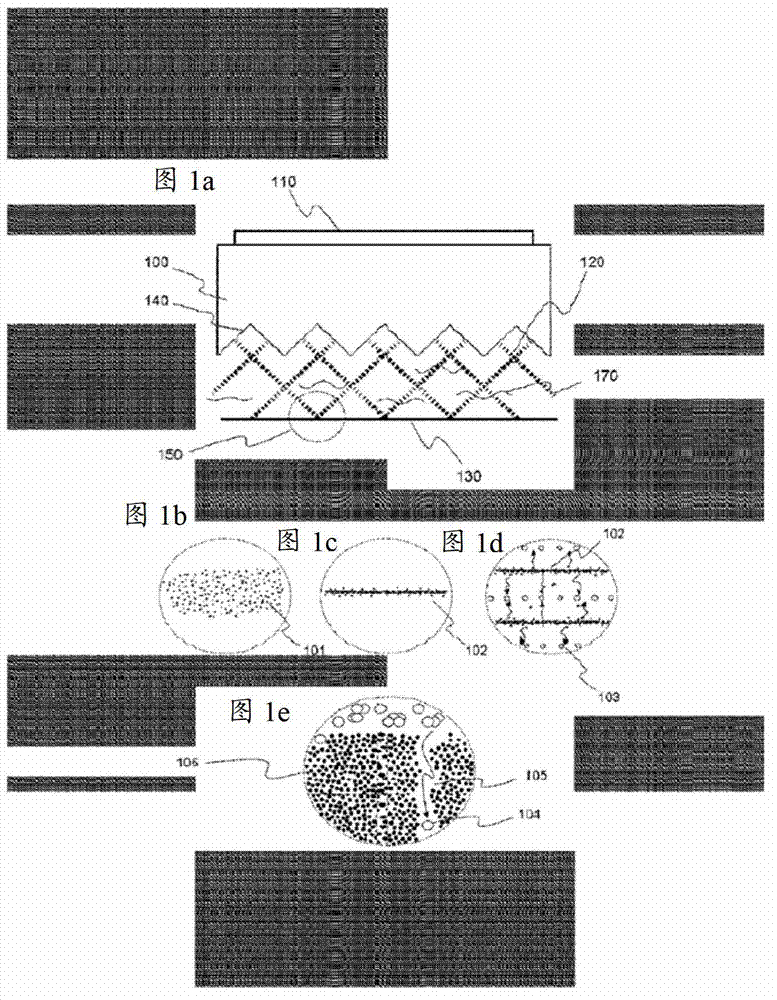

Improved ultrasonic cleaning method and apparatus

ActiveCN103118810ANot intended to limit the scope of protectionSemiconductor/solid-state device manufacturingCleaning using liquidsCavitationPressure amplitude

A device and method for treating the surface of a semiconductor wafer provides a treatment fluid in the form of a dispersion of gas bubbles in a treatment liquid generated at acoustic pressures less than those required to induce cavitation in the treatment liquid. A resonator supplies ultrasonic or megasonic energy to the treatment fluid and is configured to create an interference pattern in the treatment fluid comprising regions of pressure amplitude minima and maxima at an interface of the treatment fluid and the semiconductor wafer.

Owner:LAM RES CORP

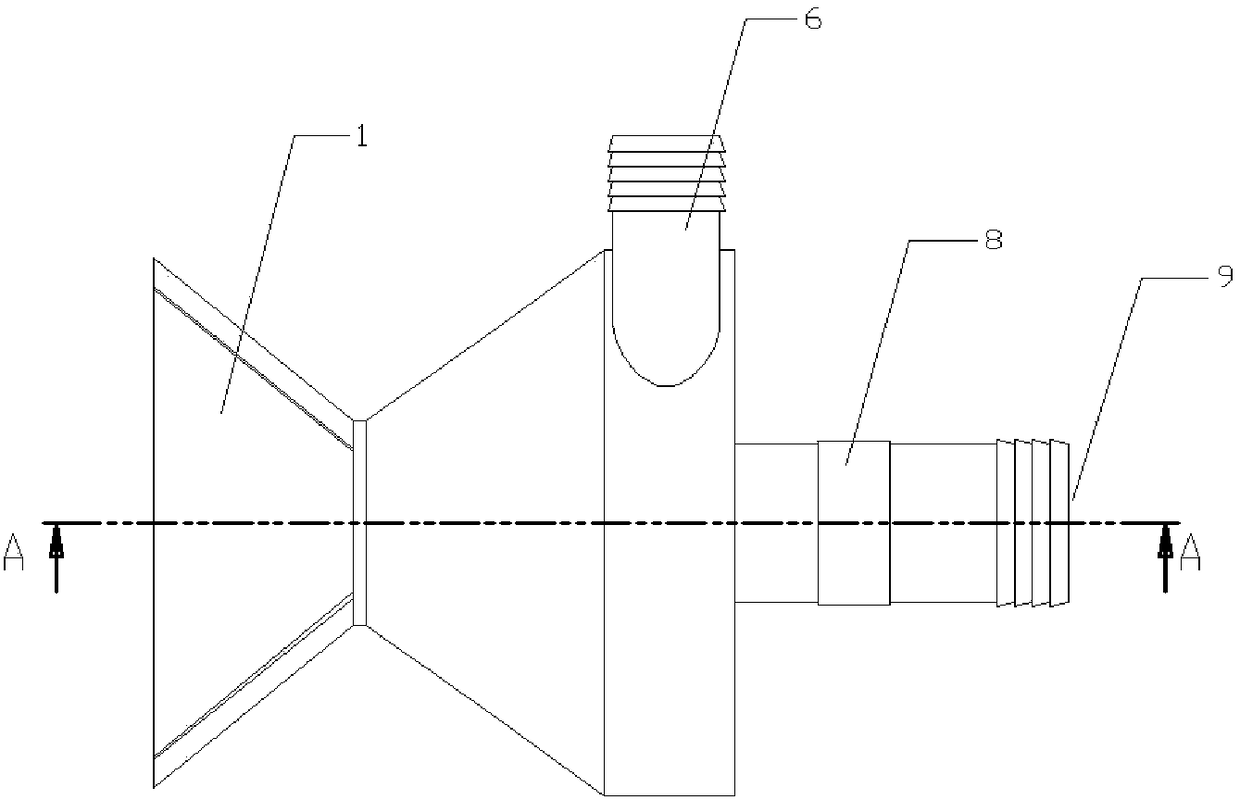

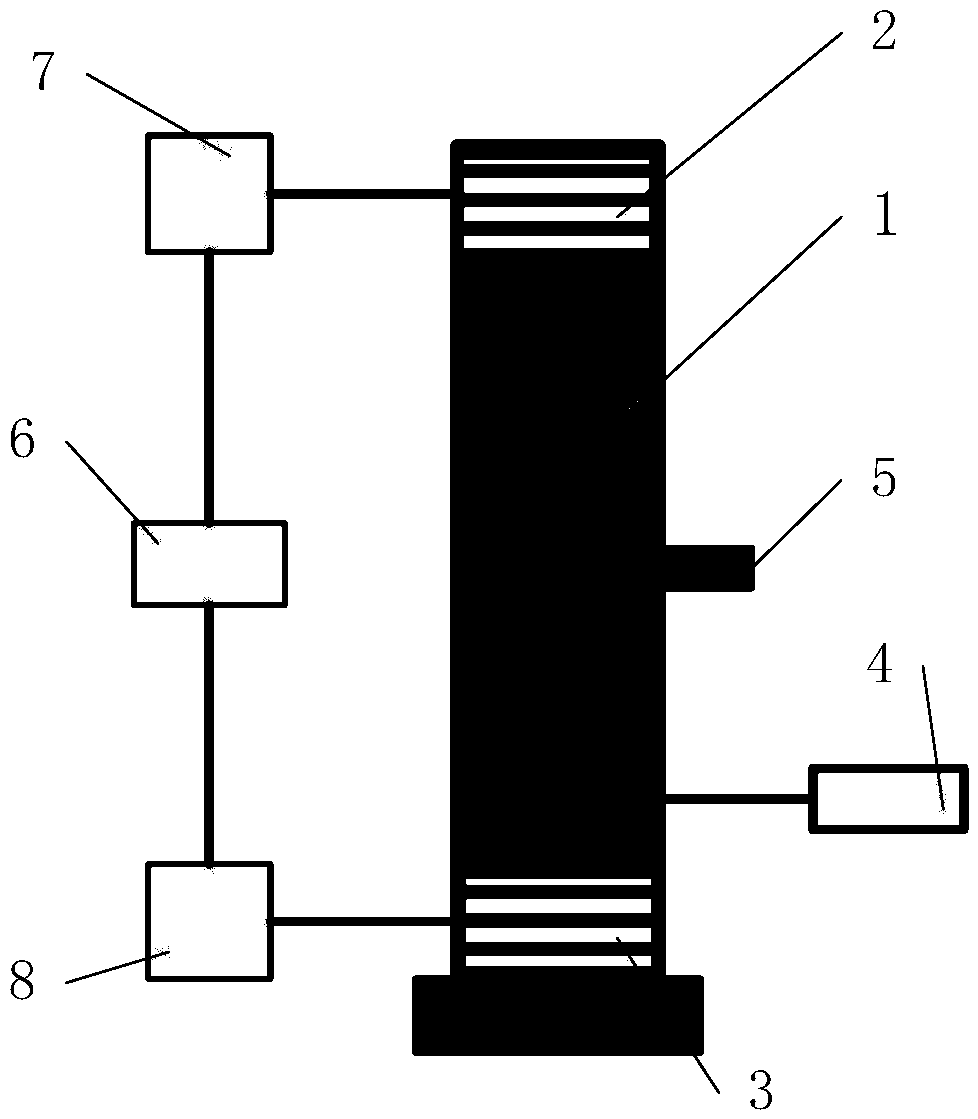

Micro dynamic pressure generator based on liquid-gas pressure conversion and working method

ActiveCN109236807AReduce or eliminate longevity effectsIncrease the pressure amplitudeFluid pressure measurementForce/torque/work measurement apparatus calibration/testingPressure amplitudeEngineering

The invention discloses a micro dynamic pressure generator based on liquid-gas pressure conversion and a working method of the micro dynamic pressure generator, belonging to the technical field of metering and testing. The micro dynamic pressure generator based on the liquid-gas pressure conversion is mainly composed of a vibration table controller, a vibration table body, a vibration table surface, a variable volume hydraulic cavity, a piston, a piston sleeve and a gas pressure chamber; the vibration table controller is connected with the vibration table body; the vibration table body is fixed on the vibration isolation foundation and is vertically fixedly connected with the vibrating table surface, and the vibrating table body pushes the vibrating table surface to move up and down; the variable volume hydraulic cavity is fixedly arranged on the vibration table surface. The invention also discloses a working method of the micro dynamic pressure generator based on liquid-gas pressure conversion. According to the micro dynamic pressure generator, the pressure amplitude generated by the micro dynamic pressure generator in medium and high frequency can be improved, and the influence of lateral displacement and vibration of the vibration table surface on the life of the piston can be reduced or eliminated. The micro dynamic pressure range means that the pulsating pressure of 0.1kPato 10kPa can be generated in an environment of absolute pressure of 20kPa to 300kPa.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Method for analysis of single pulse pressure waves

InactiveUS20070276264A1Optimal single pressure wave detectionHigh pressureEvaluation of blood vesselsCatheterPressure amplitudeWave parameter

This invention relates to a method for analysing pressure-signals derivable from pressure measurements on or in a body of a human being or animal, comprising the steps of identifying during given time sequences in a series of time sequences the single pressure waves, including related parameters [pressure amplitude ΔP, latency (ΔT), rise time coefficient (ΔP / ΔT)], determining numbers of single pressure waves with pre-selected combinations of two or more of said single pressure wave parameters during said time sequence. For the time sequences is further determined the balanced positions of single wave parameters. Two-dimensional values of balanced position may be presented as a one dimensional value after weighting of the matrix cells. The signal processing method may be used for more optimal detection of single pressure waves by means of non-invasive sensor devices.

Owner:EIDE PER KRISTIAN

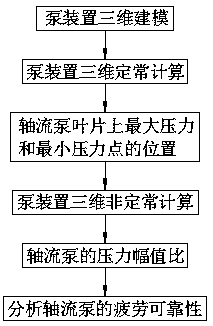

Method of analyzing fatigue reliability of axial pump based on pump device

ActiveCN107844668ASimple methodEasy to operateGeometric CADDesign optimisation/simulationAxial-flow pumpTime domain

The invention relates to a method of analyzing fatigue reliability of an axial pump based on a pump device; the method comprises the steps of 1), constructing a three-dimensional mathematical model for the axial pump device, and solving by calculating three-dimensional constant values according to flow conditions of the axial pump device; 2), determining positions of maximum and minium pressures on axial pump blades, and setting the positions as monitoring points; 3), calculating an average pressure of the monitoring points, and averaging pressure values in pressure time-domain graphs of the monitoring points, and calculating to obtain main frequency pressure amplitudes of the monitoring points so as to obtain pressure-amplitude ratio of the axial pump; 4), analyzing axial flow pump fatigue reliability for the axial pump device operating under multiple flow conditions. By using the method herein, analysis on the fatigue reliability of the axial pump with the axial pump device operatingunder multiple flow conditions is facilitated.

Owner:SHANGHAI LIANCHENG(GRP) CO LTD +6

Anti-drifting pneumatic atomizer capable of regulating and controlling particle size of fog drops on line and control method

PendingCN108114822AReduce loadReduce power consumptionSpray nozzlesLiquid spraying apparatusPressure amplitudeWave field

The invention relates to an anti-drifting pneumatic atomizer capable of regulating and controlling the particle size of fog drops on line and a control method thereof. The atomizer comprises an atomizer body and a fan-shaped atomizing cavity; the atomizer body is composed of a chemical liquid flow guide cavity, a gas flow guide cavity and an electromagnetic flow valve; the rear part of the chemical liquid flow guide cavity is connected to the electromagnetic flow valve; the front part of the chemical liquid flow guide cavity is provided with a fan-shaped nozzle; the gas flow guide cavity is ahollow cone and wraps the outer side of the chemical liquid flow guide cavity; a plurality of circular gas outlets with different gas outlet angles are formed in the front part of the gas flow guide cavity and are distributed around the fan-shaped nozzle. According to the atomizer, a pneumatic atomizing mode is adopted to carry out primary atomizing on chemical liquid by means of crossed gas flow,in addition, the gas flow and the chemical liquid flow are adjusted independently, and therefore different gas-liquid mixing ratios are dynamically achieved, and the requirements for the anti-drifting capability and the penetrating capability of the fog drops are met; and meanwhile, the pressure amplitude of an ultrasonic stationary field in the fan-shaped atomizing cavity is adjusted on line, ultrasonic secondary atomizing is carried out on the fog drops, and therefore on-line dynamic regulation and control over the particle size of the fog drops are realized, and the atomizing uniformity isimproved.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Proportional fuel pressure amplitude control in gas turbine engines

InactiveUS20090277185A1Increase pressure dropReduce trafficTurbine/propulsion engine ignitionTurbine/propulsion engine startersPressure amplitudeEngineering

Valve systems for controlling a flow of fuel in a gas turbine engine and related methods are provided. In one embodiment, the valve system includes a supply conduit, a proportional valve portion, and a pulsating valve portion. The supply conduit is adapted and configured for receiving and carrying a flow of fuel. The proportional valve portion is in fluid connection with the supply conduit adapted and configured to gradually adjust a pressure drop thereacross and thus a flow rate of fuel flowing therethrough. The pulsating valve portion is in fluid connection with the supply conduit, in parallel with the proportional valve portion, and is adapted and configured to rapidly adjust a pressure drop thereacross and thus a flow rate of fuel flowing therethrough.

Owner:DELAVAN

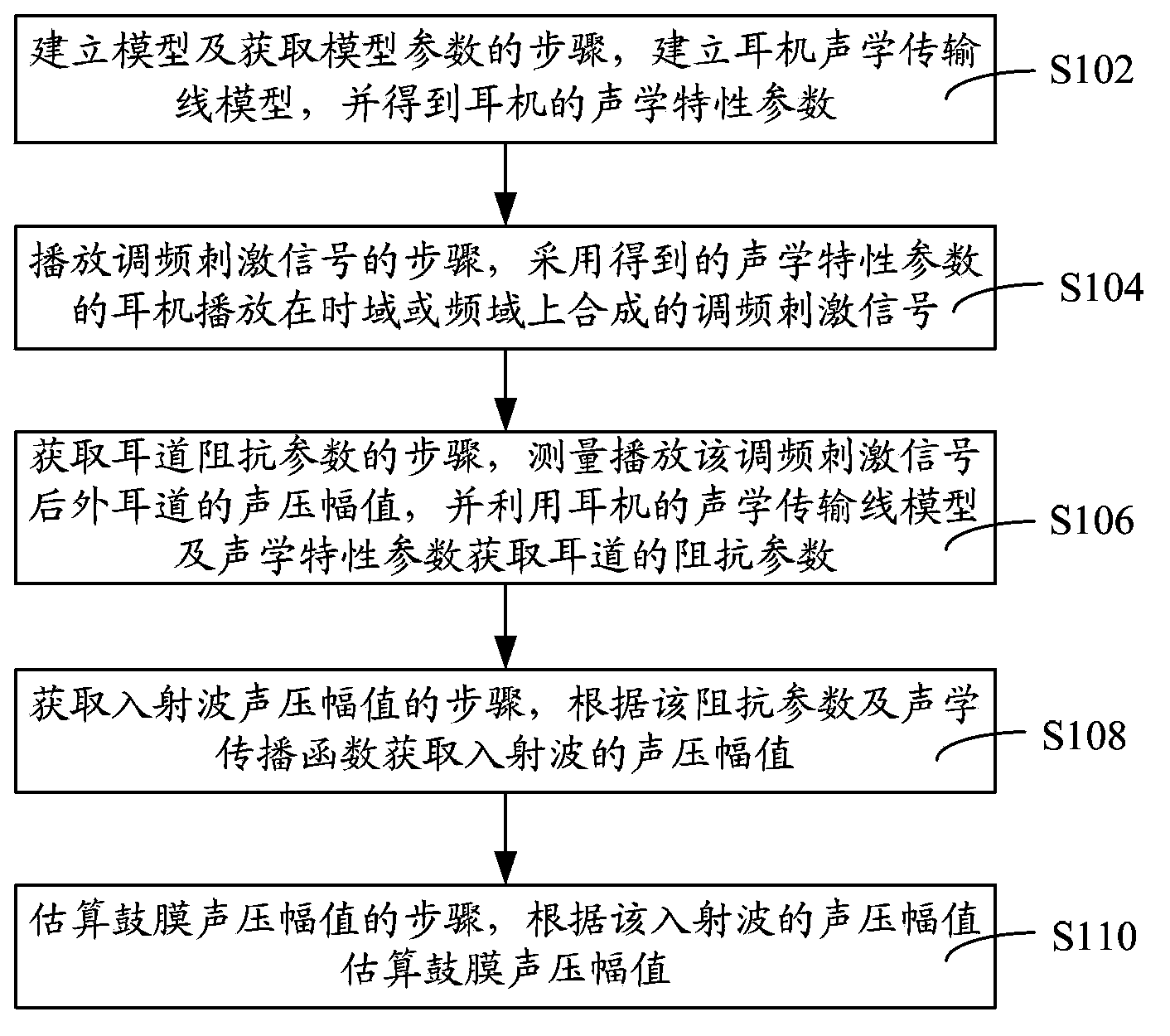

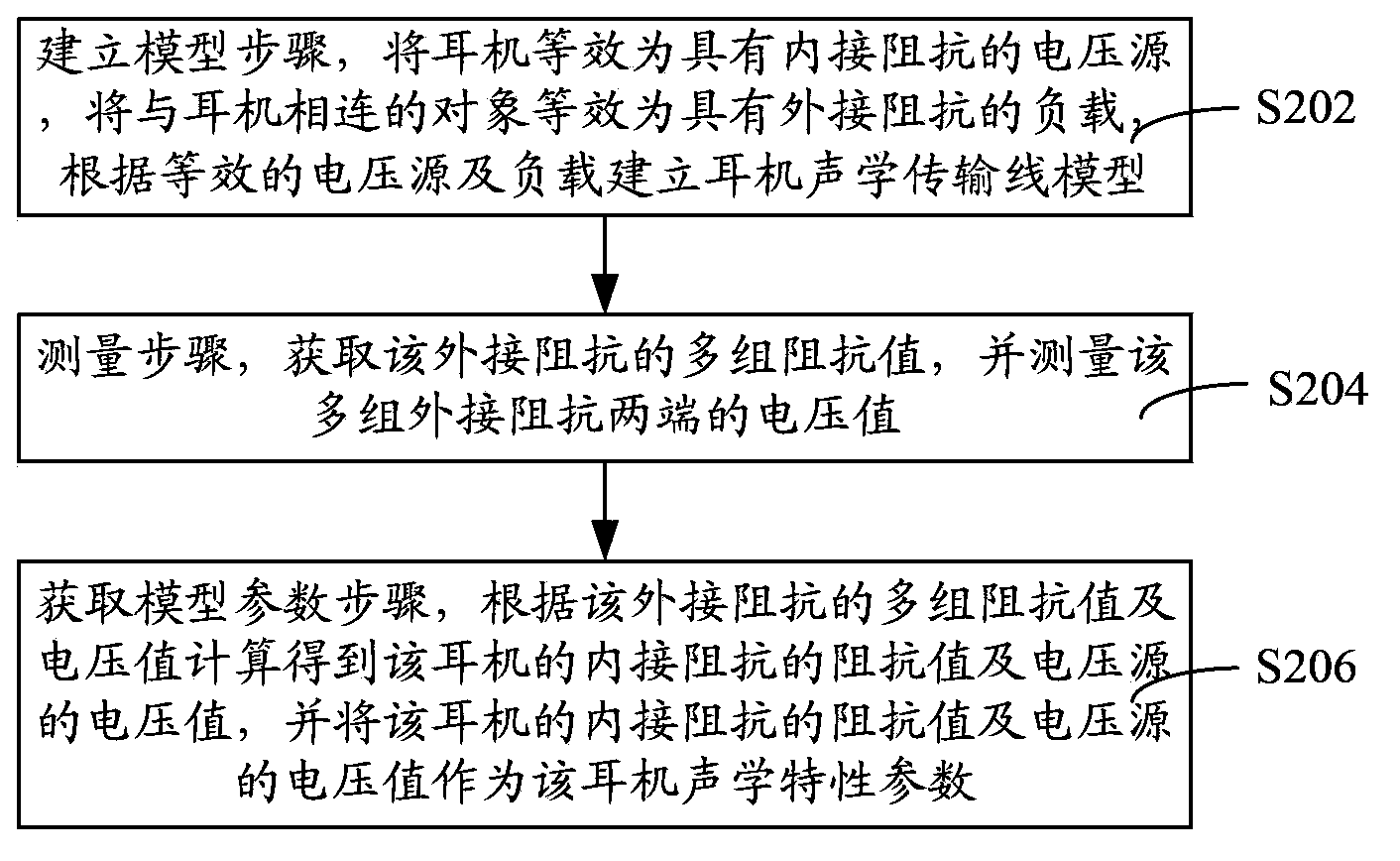

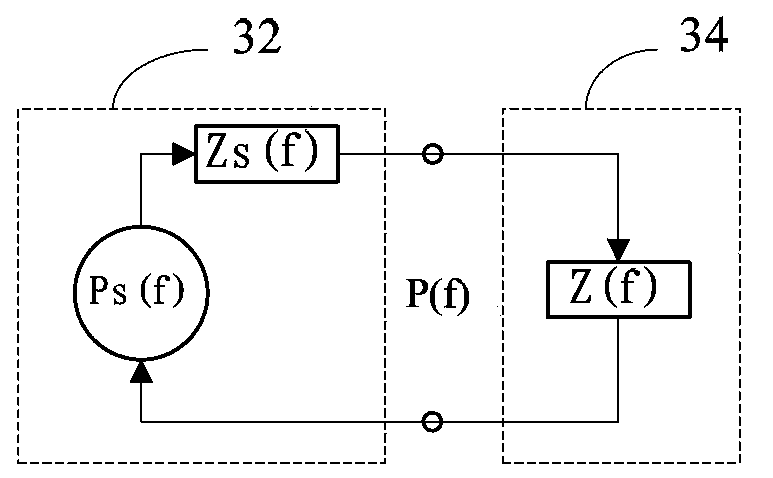

Eardrum acoustic pressure detection method and eardrum acoustic pressure detection system

ActiveCN104248439AImprove accuracyReduce fatigueAudiometeringExternal Auditory CanalsPressure amplitude

The invention relates to an eardrum acoustic pressure detection method and an eardrum acoustic pressure detection system. The method comprises the following steps: establishing an earphone acoustic transmission line model and acquiring acoustic characteristic parameters of an earphone; playing a frequency-modulated stimulation signal synthesized in a time domain or a frequency domain by use of the obtained earphone with the acoustic characteristic parameters; measuring an acoustic pressure amplitude value of an external auditory canal after the frequency-modulated signal is played, and acquiring impedance parameters of the auditory canal by use of the acoustic transmission line model and acoustic characteristic parameters of the earphone; acquiring the acoustic pressure amplitude value of incident waves according to the impedance parameters and an acoustic propagation function; estimating an eardrum acoustic pressure amplitude value according to the acoustic pressure amplitude value of the incident waves. According to the eardrum acoustic pressure detection method and the eardrum acoustic pressure detection system, the frequency-modulated stimulation signal in the time domain or frequency domain is utilized for measurement, so that acoustic pressures within a wide frequency range can be detected in one step, the detection efficiency is improved, influence of individual difference is avoided, the detection method and the detection system are wide in application range, the detection result accuracy is high, and the frequency resolution and the detection security are improved.

Owner:SHENZHEN INST OF ADVANCED TECH

Ultrasonic cleaning method and apparatus

ActiveUS20120073596A1Extended processing timeOptimization of cleaning uniformitySemiconductor/solid-state device manufacturingElectrostatic cleaningPressure amplitudeCavitation

A device and method for treating the surface of a semiconductor wafer provides a treatment fluid in the form of a dispersion of gas bubbles in a treatment liquid generated at acoustic pressures less than those required to induce cavitation in the treatment liquid. A resonator supplies ultrasonic or megasonic energy to the treatment fluid and is configured to create an interference pattern in the treatment fluid comprising regions of pressure amplitude minima and maxima at an interface of the treatment fluid and the semiconductor wafer.

Owner:LAM RES AG

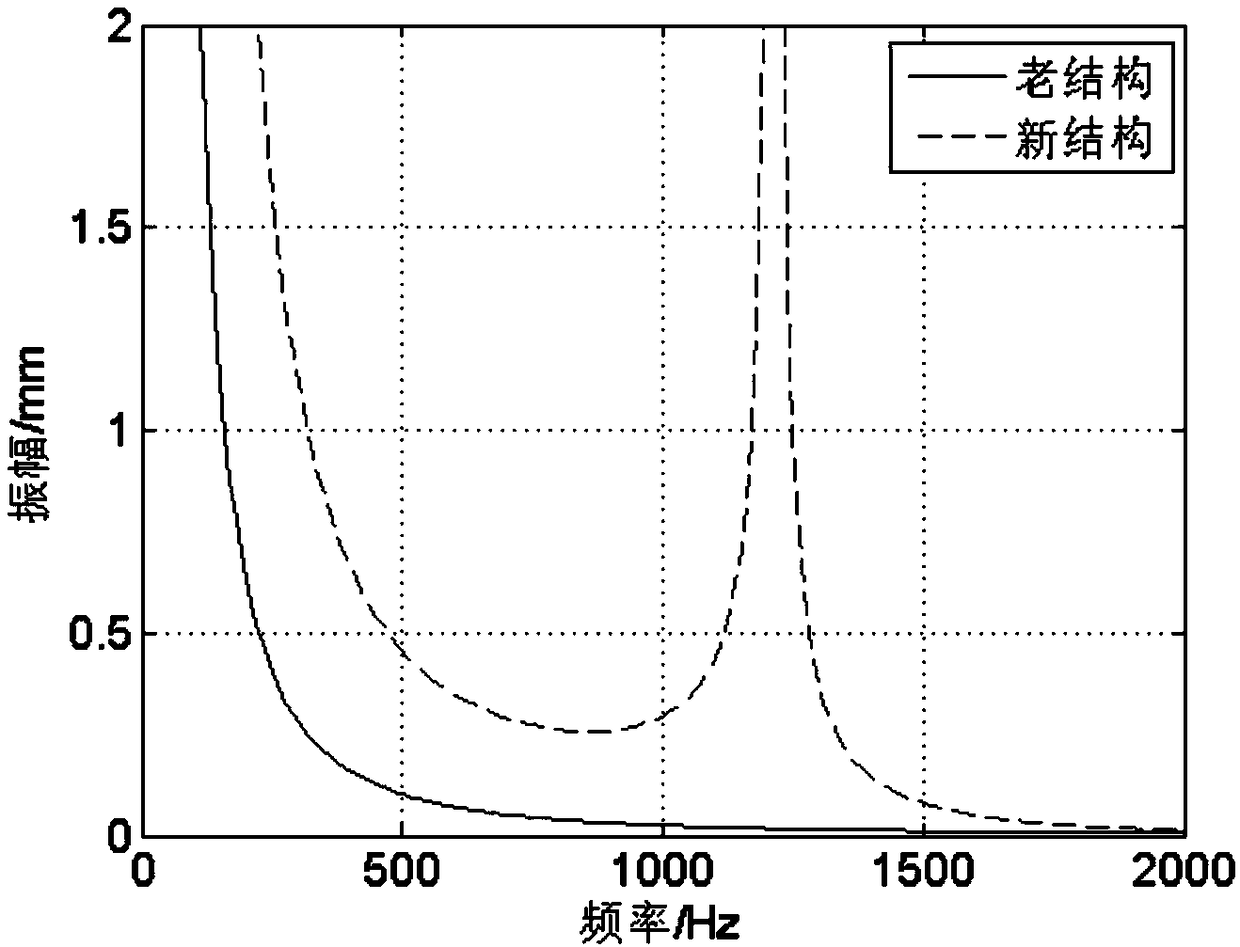

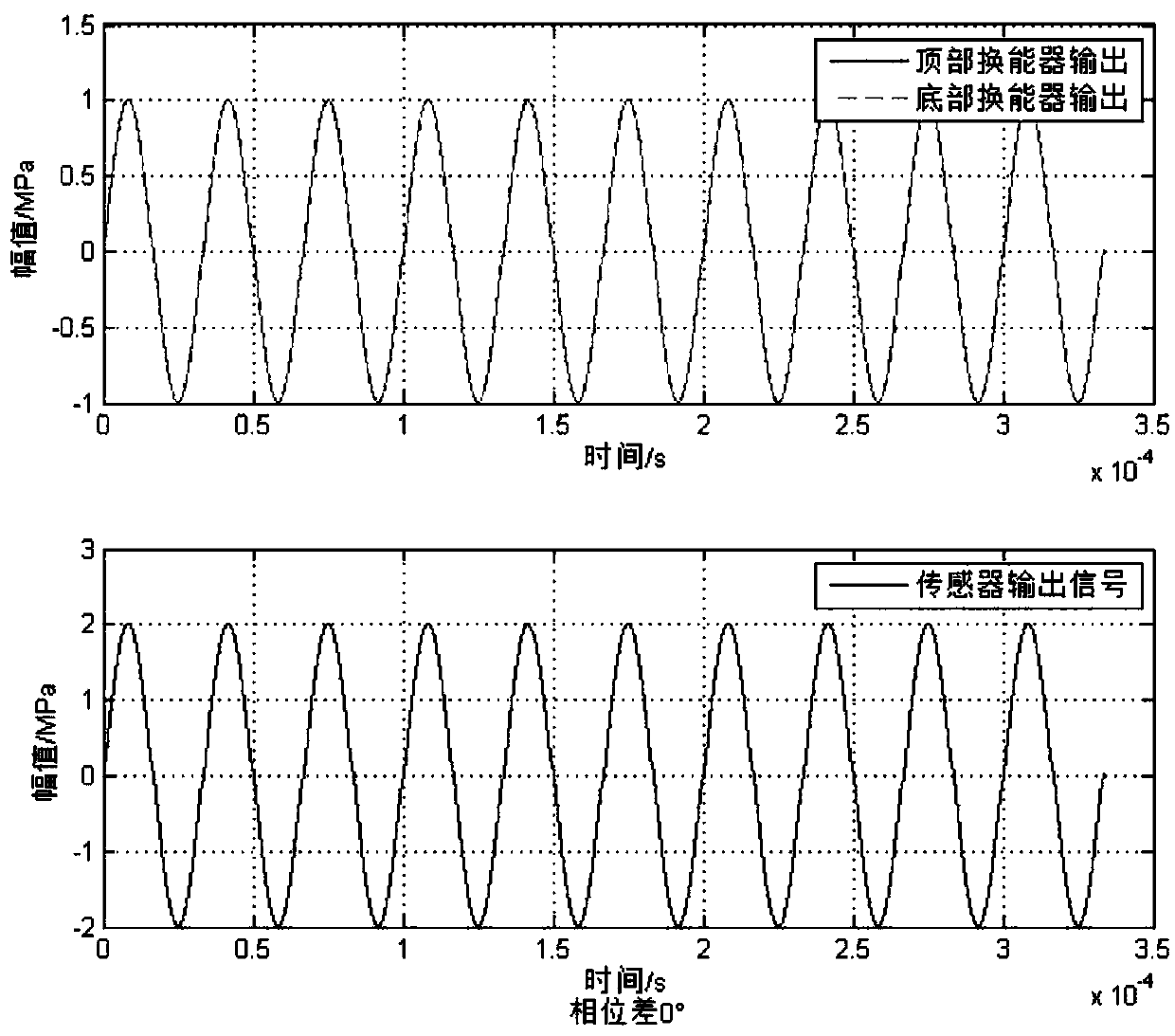

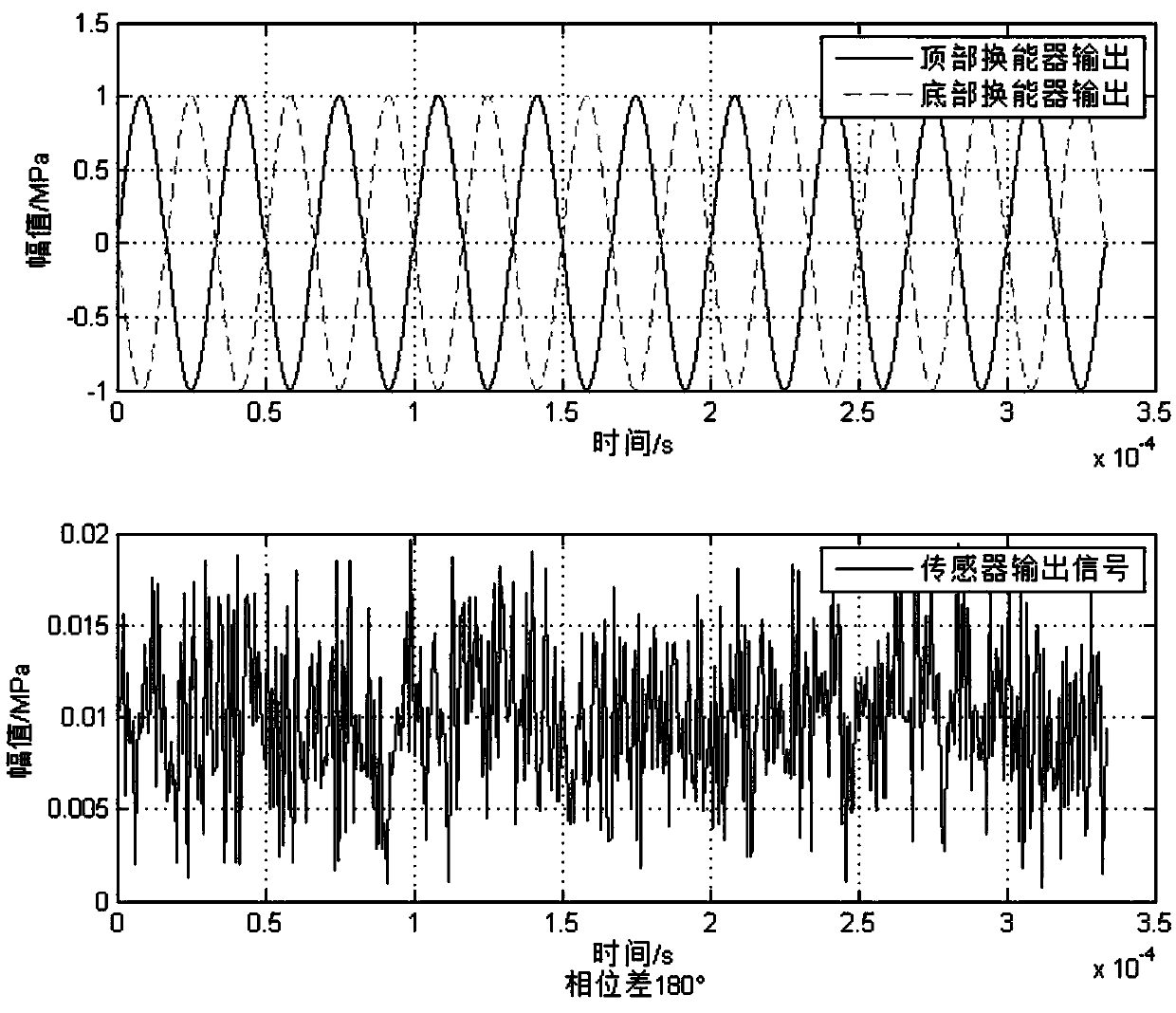

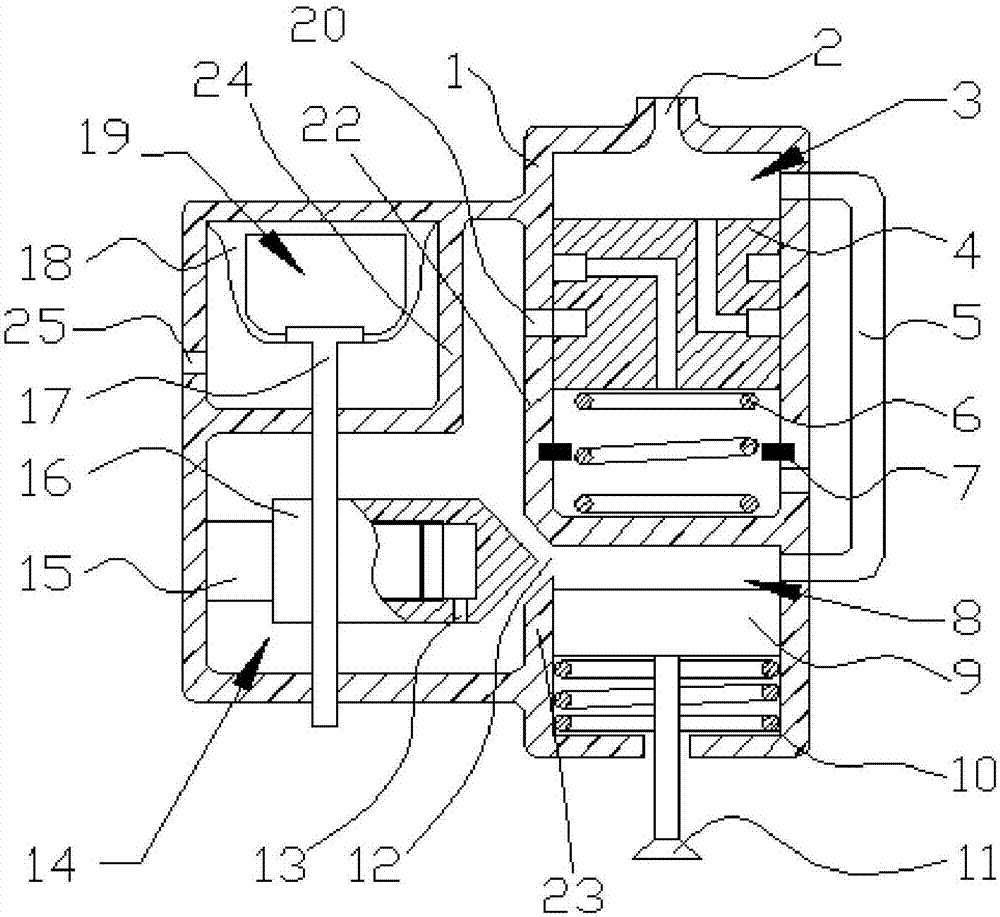

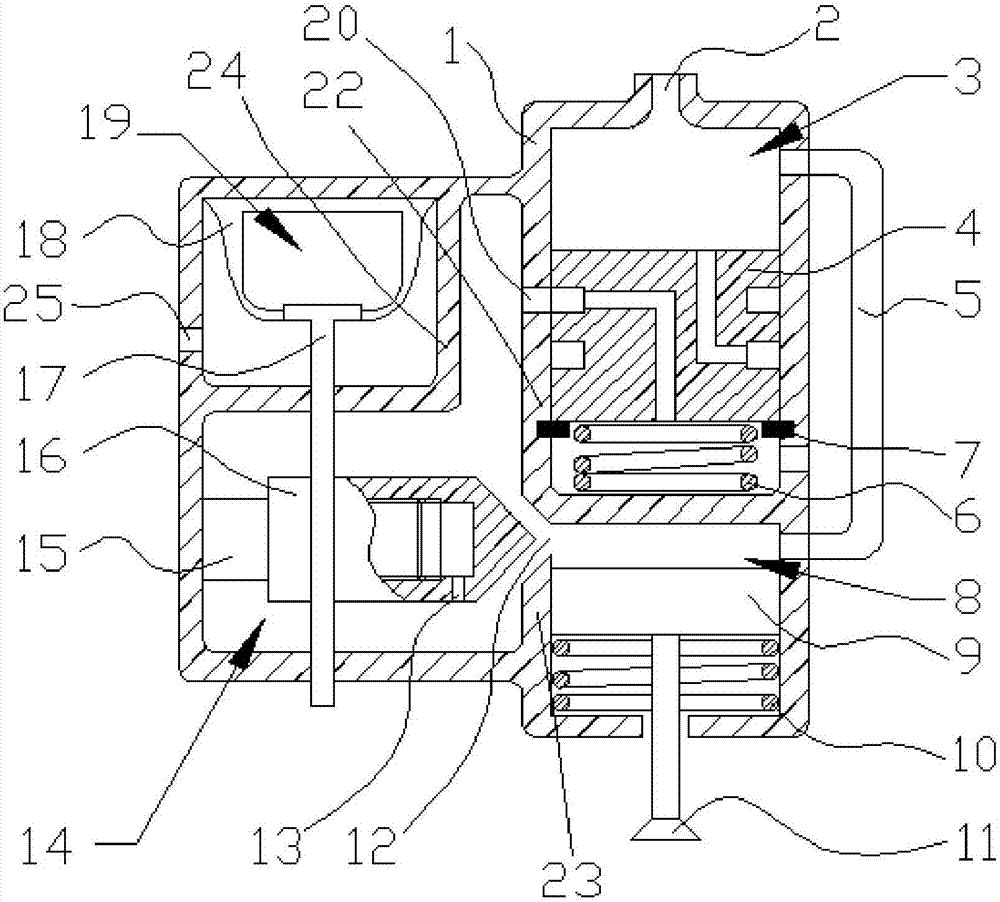

High-frequency sinusoidal pressure generator of double-element combination type, and pressure generation method

ActiveCN108982008AHigh sinusoidal pressure amplitudeHigh frequencyFluid pressure measurementPressure amplitudeEngineering

The invention discloses a high-frequency sinusoidal pressure generator of a double-element combination type, and a pressure generation method, and belongs to the technical field of metering and testing. The high-frequency sinusoidal pressure generator comprises a hydraulic pipe, a top piezoelectric transducer, a bottom piezoelectric transducer, a pressure controller, a pressure measurement chamber, a signal generator, a top power amplifier, and a bottom power amplifier. The invention also discloses a high-frequency sinusoidal pressure generation method implemented based on the high-frequency sinusoidal pressure generator. The high-frequency sinusoidal pressure generator can generate a higher pressure amplitude value in the frequency range of 1-30kHz, so as to meet the demands of the calibration of an increasing number of dynamic pressure sensors. The demands of the calibration of the dynamic pressure sensors comprise the calibration demands of the dynamic pressure sensors in a development process of an engine, bullets and high-speed trains in the range of 1-30kHz. The high-frequency sinusoidal pressure generator has the following advantages that the calibration range is large; theamplitude is higher, and the frequency is higher; the signal is stable; and the later maintenance and replacement are facilitated.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Turbocharger deflation valve capable of being self-adapted to height above sea level

ActiveCN107060993ASimple structurePrecise control with little impactInternal combustion piston enginesInterior spacePressure amplitude

The invention provides a turbocharger deflation valve capable of being self-adapted to a height above the sea level. The turbocharger deflation valve is matched with gas pressure of a gas intake boosting channel to adjust exhaust airflow flowing towards a turbocharger and comprises a shell. A plurality of splitter plates are arranged inside the shell. The inner space of the shell is divided into four sub parts of a two-position three-way pneumatic valve, an actuator, an adjustable throttling device and a gas-bag-type pressure compensation device. The two-position three-way pneumatic valve and the actuator both communicate with the gas intake boosting channel. The two-position three-way pneumatic valve controls the moving direction of the airflow flowing through the actuator. The adjustable throttling device changes the pressure amplitude of gas flowing past the actuator. The gas-bag-type pressure compensation device controls the opening degree of the adjustable throttling device. The turbocharger deflation valve capable of being self-adapted to the height above the sea level is simple in structure, no external energy is required, and the accurate control influence on the opening pressure of the turbocharger deflation valve by real-time change of the gas intake pressure is small.

Owner:CHINA NORTH ENGINE INST TIANJIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com