Anti-drifting pneumatic atomizer capable of regulating and controlling particle size of fog drops on line and control method

A technology of droplet size and atomization nozzle, applied in the direction of spray device, spray device, liquid spray device, etc., can solve the problems of lack, uneven particle size distribution, poor atomization effect, etc., to reduce the load and Power consumption, reduction of droplet size spectrum, enhancement of atomization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing, the patent of the present invention is further described.

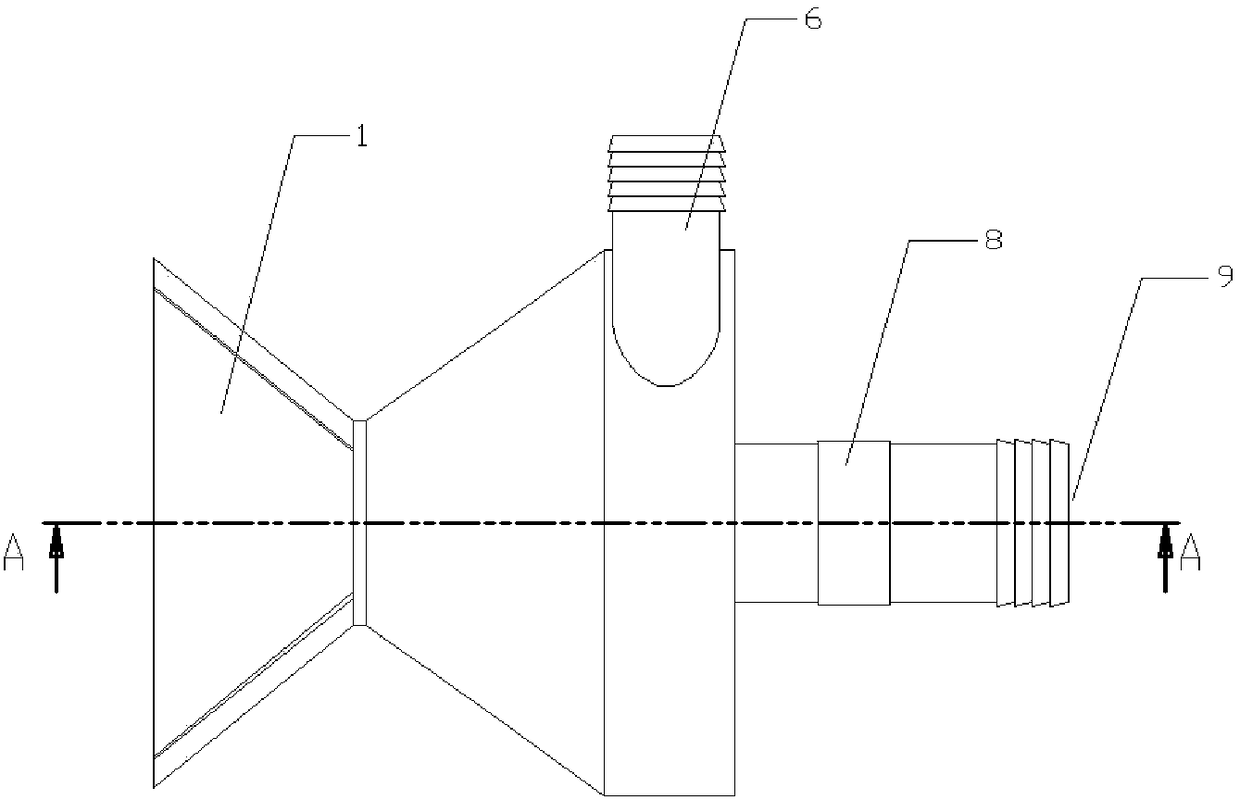

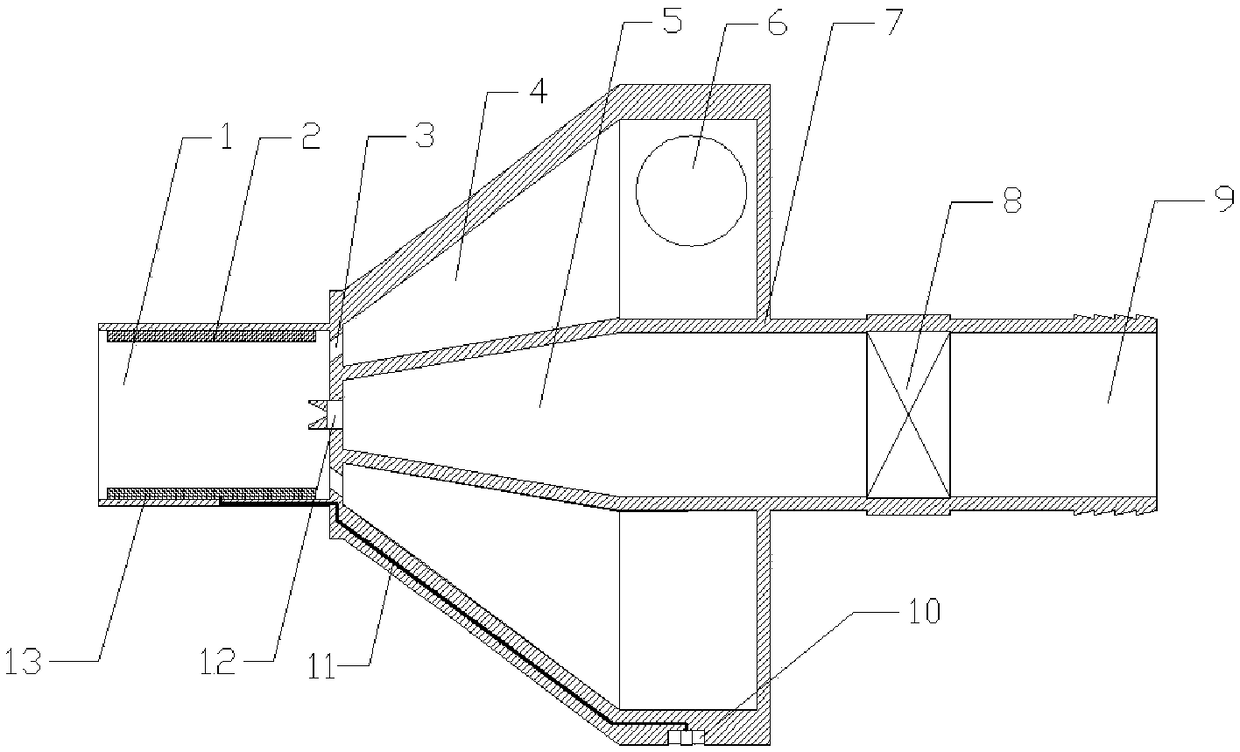

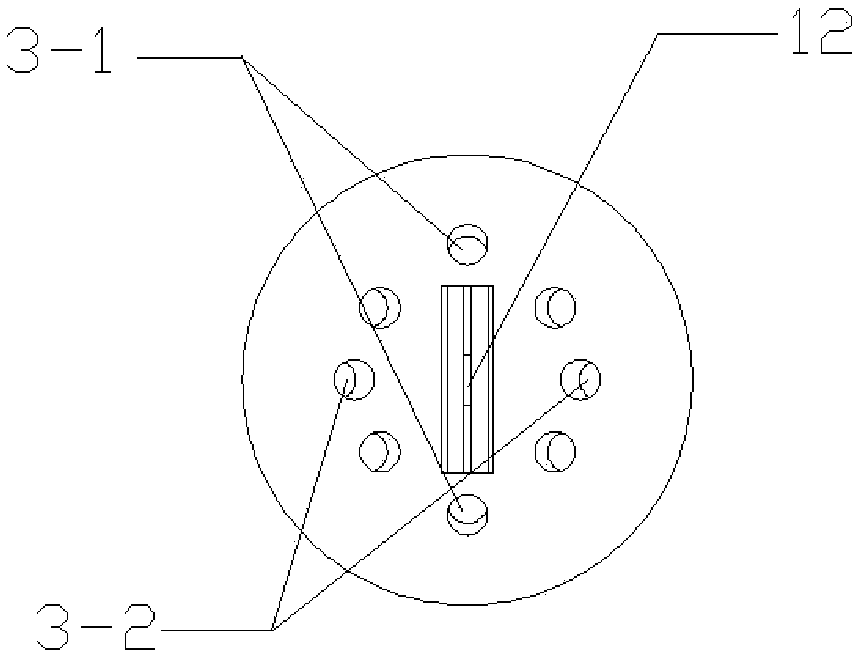

[0028] The anti-drift pneumatic atomization nozzle for online regulation and control of the droplet size of the present invention has the following structure: Figure 1~4 As shown, the spray head includes a spray body 7 and a fan-shaped atomization chamber 1 . The spray body 7 is composed of a gas diversion chamber 4, a medicinal liquid diversion chamber 5, and an electromagnetic flow valve 8; The front part of the chamber is a fan-shaped nozzle 12; the gas diversion chamber 4 is a hollow cone, wrapped on the outside of the liquid medicine diversion chamber 5, and there is an airflow inlet 6 at the rear, and the front part of the chamber has different gas outlet angles. Two sets of circular air outlets 3-1, 3-2; the wall of the gas diversion chamber 4 is built with a signal line 11 and a quick-connect plug 10, which can transmit external voltage excitation signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com