Method of analyzing fatigue reliability of axial pump based on pump device

An analysis method and technology of axial flow pumps, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as time-consuming, cumbersome calculation process, and difficult to master

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

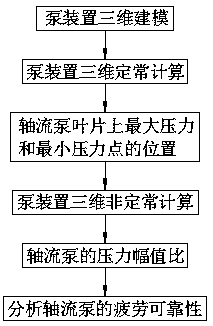

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. A flow chart of fatigue reliability analysis of an axial flow pump based on a pump device is as follows: figure 1 shown.

[0023] Taking the axial flow pump device using the ZM3.0 hydraulic model as an example, the three-dimensional mathematical model of the axial flow pump device was constructed using three-dimensional modeling software, and then the three flow rates of the vertical axial flow pump device were simulated using numerical simulation technology. Working conditions (small flow conditions Q =240 L / s, the optimal working condition is 320 L / s and the large flow working condition is 400 L / s), the three-dimensional constant value calculations, the three flow working conditions are all satisfied that the residual convergence accuracy of each physical quantity is lower than 1.0× 10 -5 requirements, and the head change tends to be stable....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com