Micro dynamic pressure generator based on liquid-gas pressure conversion and working method

A dynamic pressure and generator technology, which is applied in fluid pressure actuation devices, fluid pressure actuation system components, fluid pressure measurement, etc., can solve problems affecting service life, small pressure amplitude, piston bending, etc., to improve output Amplitude, increase the pressure amplitude, reduce the effect of lateral displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

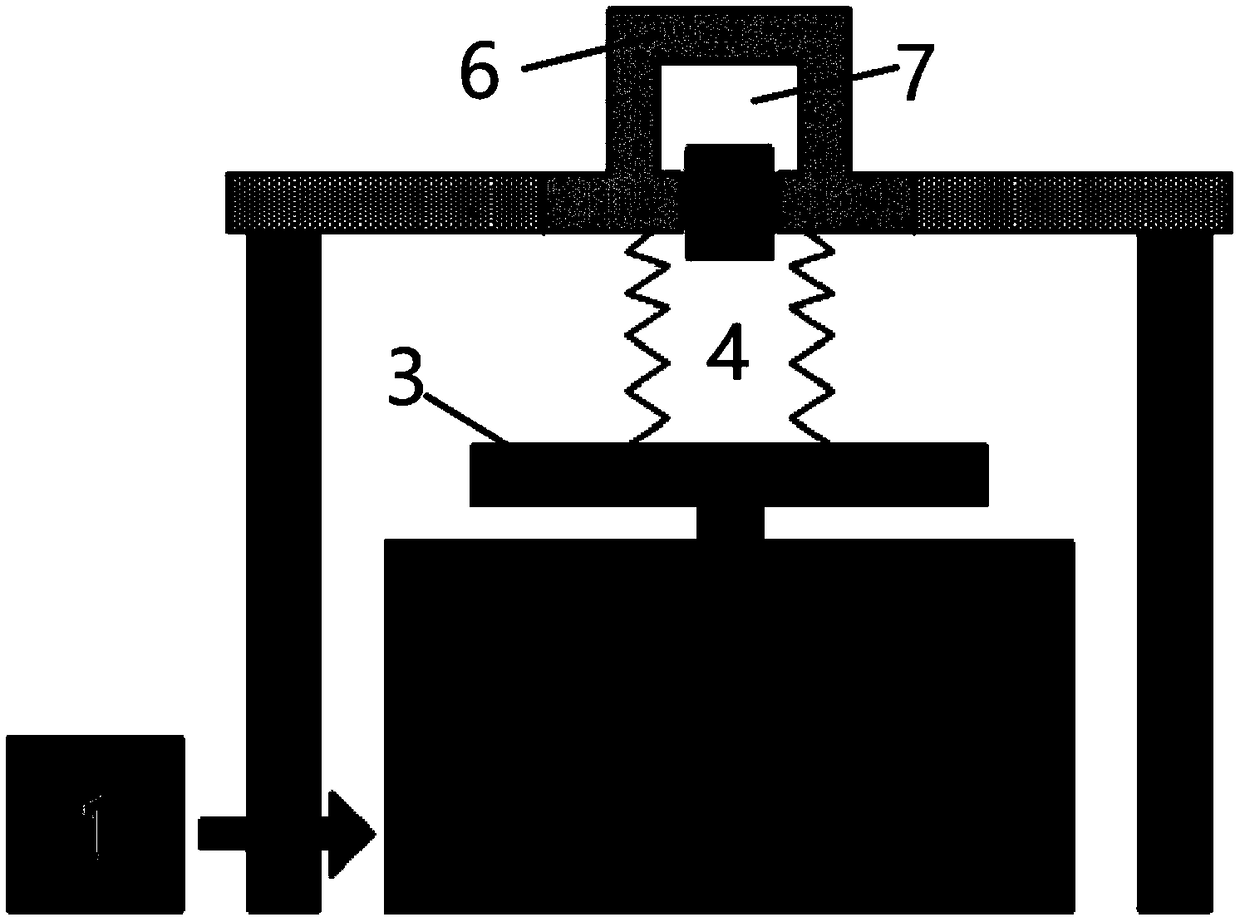

[0029] Such as figure 1 As shown, the tiny dynamic pressure generator based on liquid-pneumatic pressure conversion disclosed in this embodiment consists of a vibrating table controller 1, a vibrating table body 2, a vibrating table surface 3, a variable volume hydraulic cavity 4, a piston 5, a piston cylinder 6, The gas pressure chamber 7 is composed.

[0030] The vibrating table controller 1 is connected to the vibrating table body 2 to control the movement of the vibrating table body 2 .

[0031] The vibrating table body 2 is fixed on the vibration-isolation foundation and vertically fixedly connected with the vibrating table top 3, and the vibrating table body 2 pushes the vibrating table top 3 to move up and down.

[0032] A variable volume hydraulic cavity 4 is fixedly installed on the vibration table 3 .

[0033] In order to change the internal volume of the variable-volume hydraulic cavity 4 under the premise of ensuring the quality of the liquid medium remains uncha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com