System, method and apparatus for drilling agitator

a technology of agitator and agitation tool, which is applied in the direction of drilling machine and method, earth drilling and mining, construction, etc., can solve the problems of agitation tool inability to compensate, further amplification of friction problem, and costly premature failure of other down hole equipment, so as to facilitate the axial movement of the drill string

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

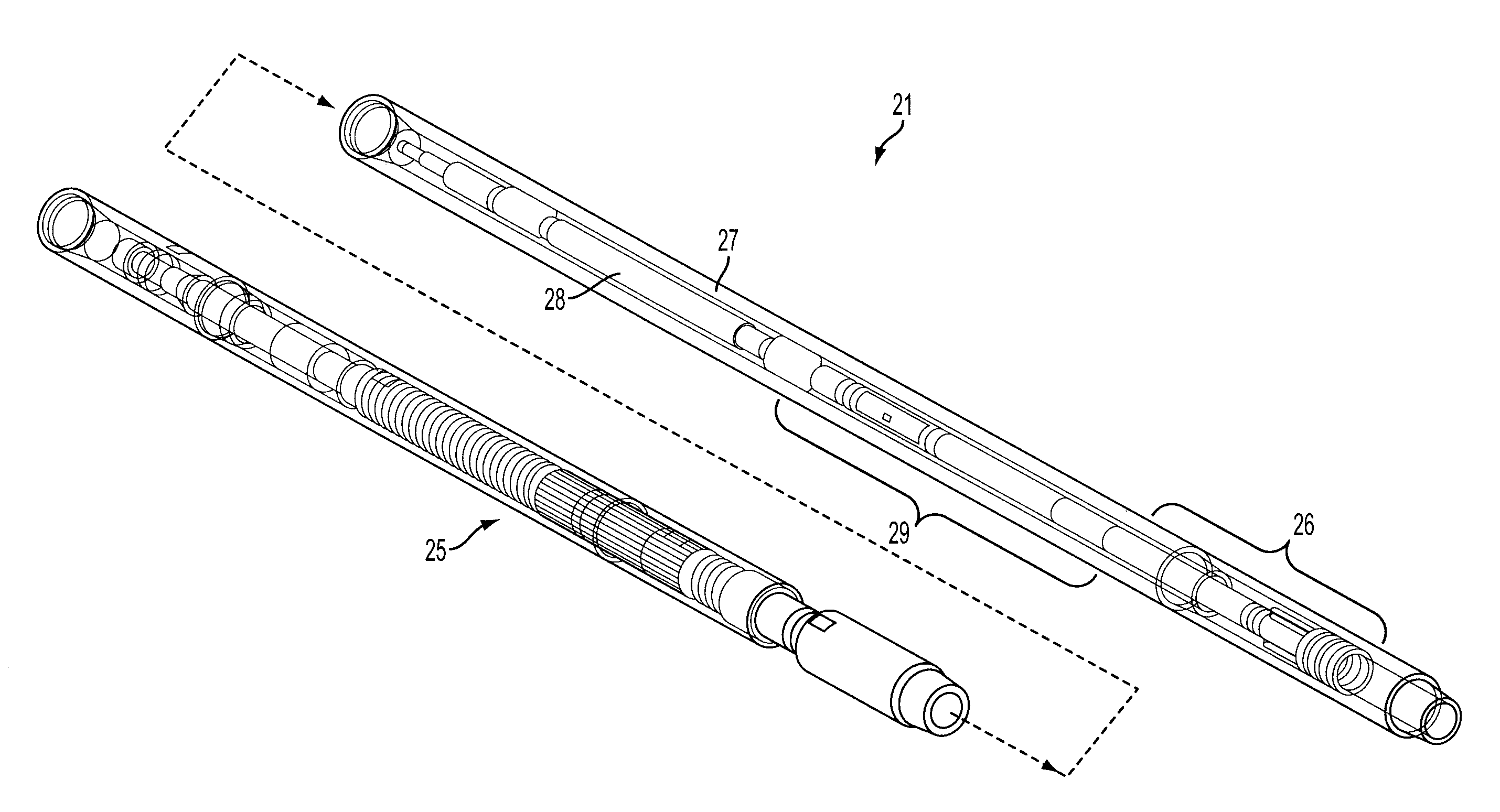

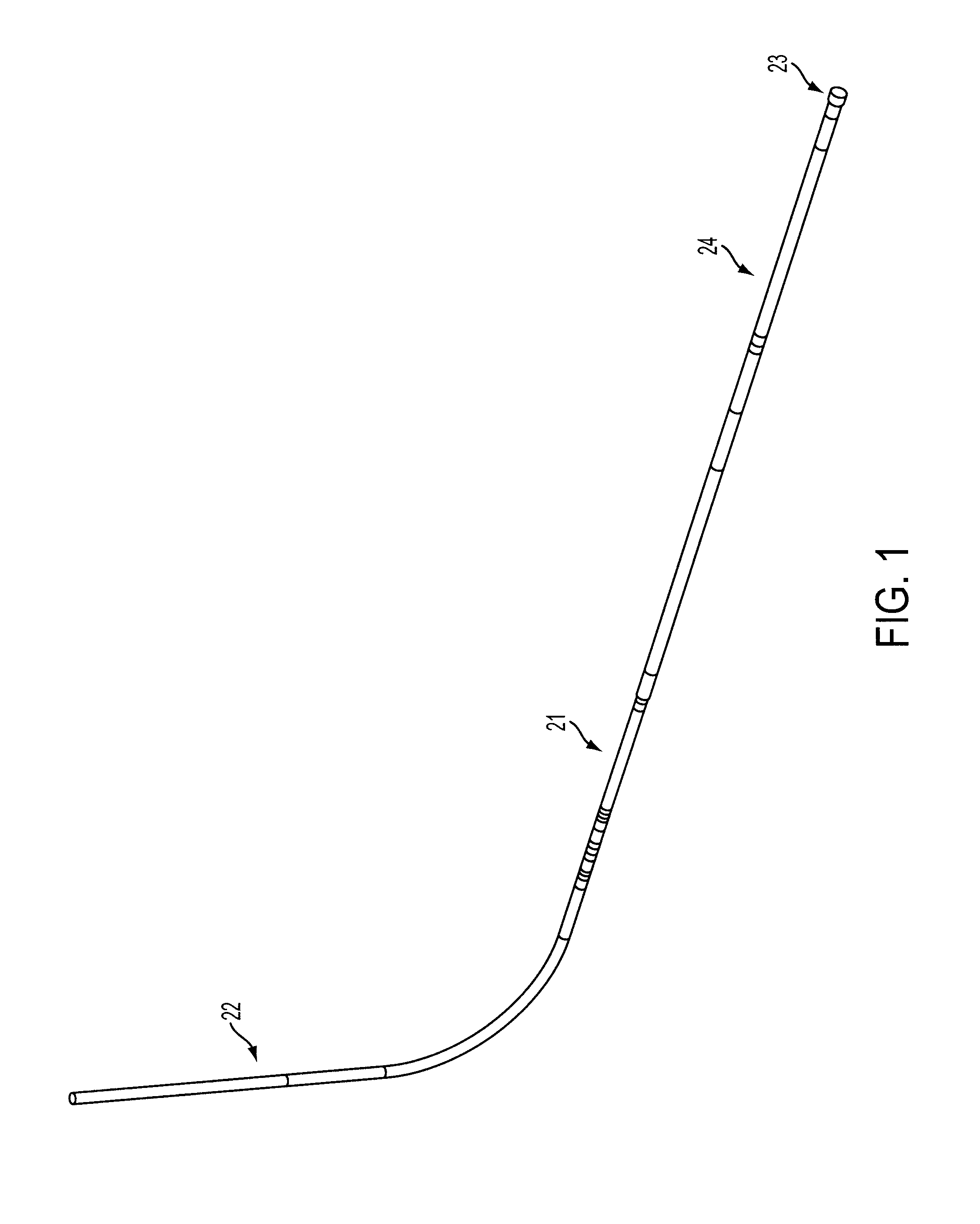

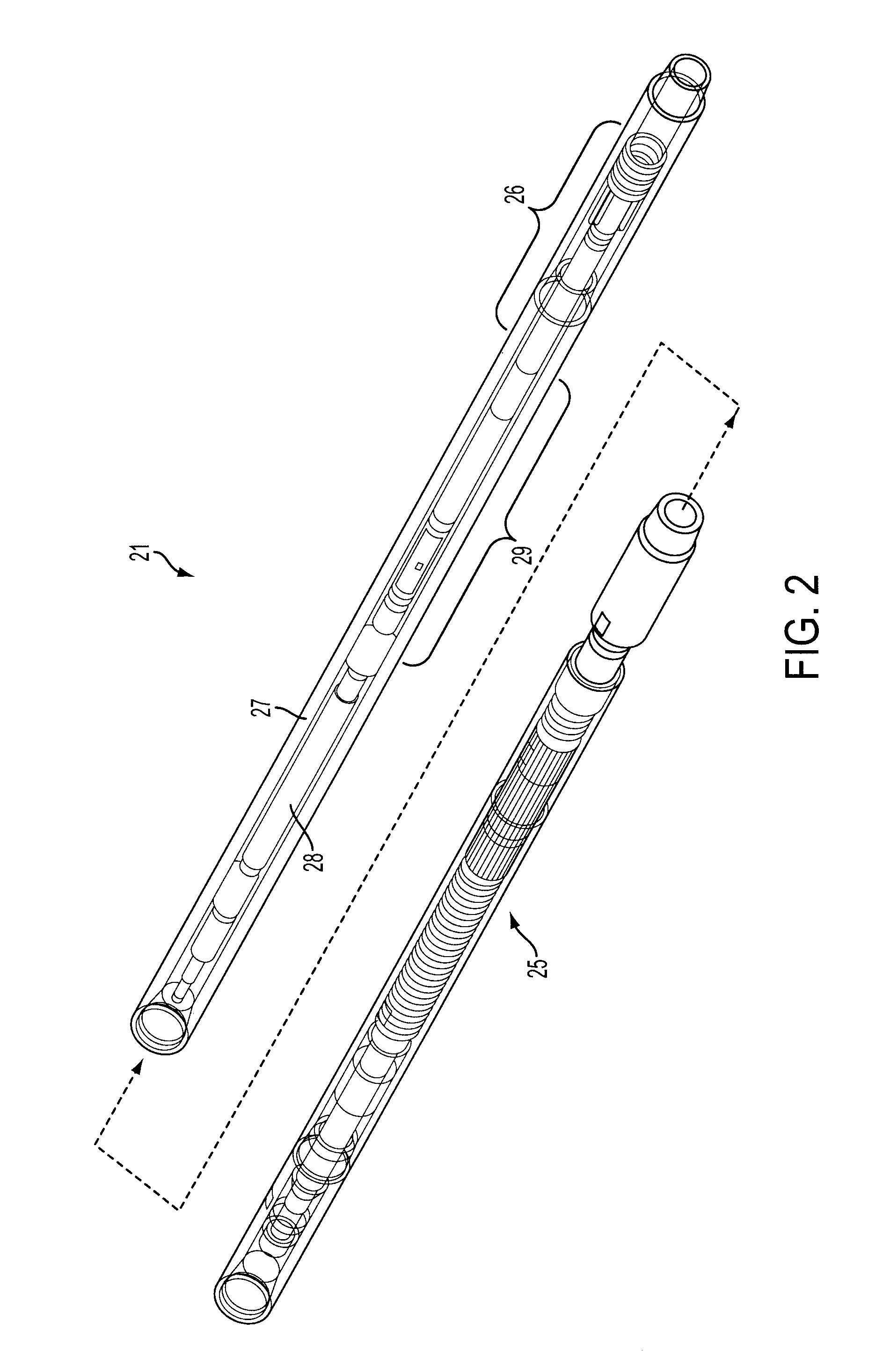

[0022]Embodiments of a system, method and apparatus for facilitating axial movement of a drill string while it is drilling a well are disclosed. It is desirable to maintain movement in a drill string during its operation since the dynamic friction force is substantially less than the static friction force. As horizontal sections of current oil and gas wells increase, the incurred friction forces hamper and affect efficient drilling operations. One method for maintaining continuous movement of the drill string is to utilize a shock tool as an agitating device that is driven by a cyclic pressure wave. The shock tool has an incorporated seal surface that can be extended as pressure increases. The shock tool or agitator contracts when the pressure level decreases.

[0023]The frequency and duration of these pressure fluctuations determines the displacement and acceleration of the shock tool. It is desirable that the movements of the shock tool are controlled to prevent damage to the drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com