Low-frequency micro pulsating pressure generator

A pressure generator and tiny technology, applied in fluid pressure actuation devices, fluid pressure actuation system components, mechanical equipment, etc., can solve problems such as difficulty in generating low-frequency trace pressure signals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

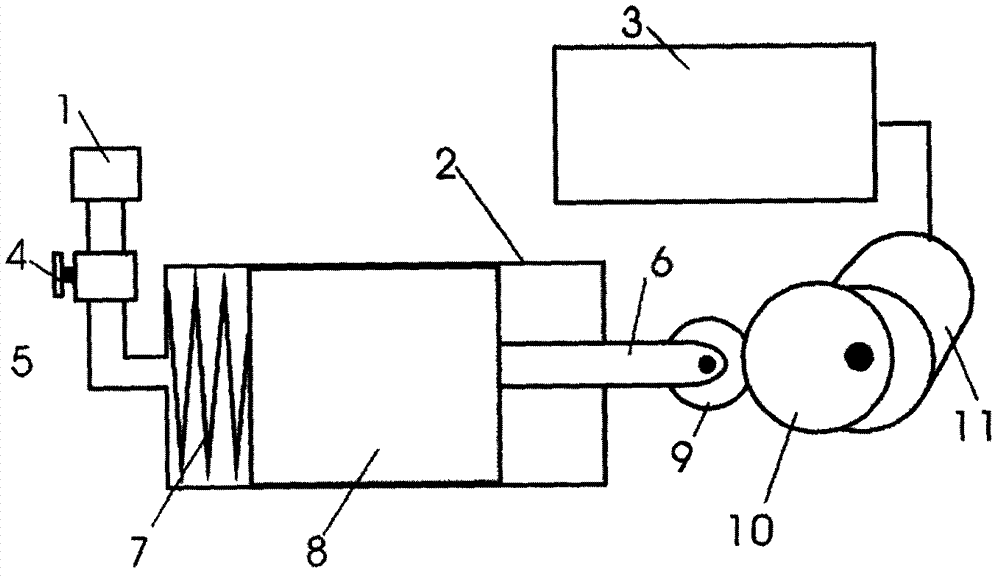

[0016] see figure 1 , a low-frequency micro-pulsation pressure generator, including a cylinder block 2, a piston 8 arranged in the cylinder block 2, a spring 7 connected between the inner wall of the cylinder block 2 and the bottom of the piston 8, and a piston connecting rod connected to the top of the piston 8 6. The piston connecting rod 6 passes through the cylinder block 2 and extends to the outside of the cylinder block 2. At the end of the piston connecting rod 6 outside the cylinder block 2, a miniature pulley 9 is arranged. The miniature pulley 9 connects with the eccentric wheel 10, and the eccentric wheel 10 is connected to the The rotating shafts of the stepping motor 11 are connected, and the stepping motor 11 is connected with the stepping motor controller 3 through a line.

[0017] The bottom of the above-mentioned cylinder block 2 provided with a spring 7 is connected with an output connecting pipe 5, the end of the output connecting pipe 5 is provided with a p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com