Preparation process and method for controllable medical degradable magnesium alloy

A preparation process, magnesium alloy technology, applied in medical science, prosthesis, etc., can solve the problems of inability to maintain mechanical integrity, fast degradation of magnesium alloy, implant failure, etc., to achieve small size, high tissue stability, tissue good stability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] specific implementation plan

[0024] First select raw materials: select commercial pure magnesium powder with a particle size of 200 mesh. Titanium metal powder, particle size is 300 mesh. Calcium granules with a particle size of 40 mesh, metal zinc powder with a particle size of 200 mesh, and 500 milliliters of high-purity isopropanol.

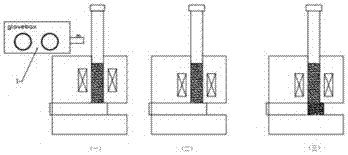

[0025] The selected raw materials were placed in an argon-filled glove box (attached figure 2 Marked in 1) and weighed to prevent oxidation of the material. The ratio is: metal magnesium powder 50%, metal zinc powder 15%, metal calcium powder 15%, metal titanium powder 20%.

[0026] After the metal powders were mixed, they were mixed with 1% by weight isopropanol and stirred for 3 minutes under the protection of argon.

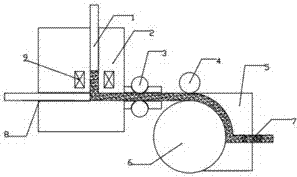

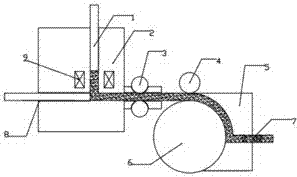

[0027] Subsequently, the element mixture slurry was taken out from the glove box in the sealed container and introduced into the inlet channel in the ECAP mold 2 while the outlet channel was blocked by the baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com