Patents

Literature

49results about How to "Improve contact fatigue life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

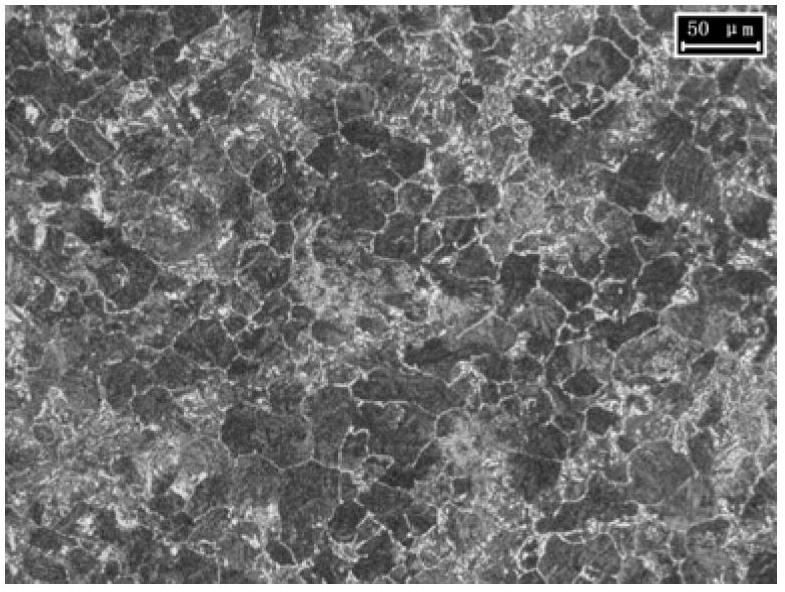

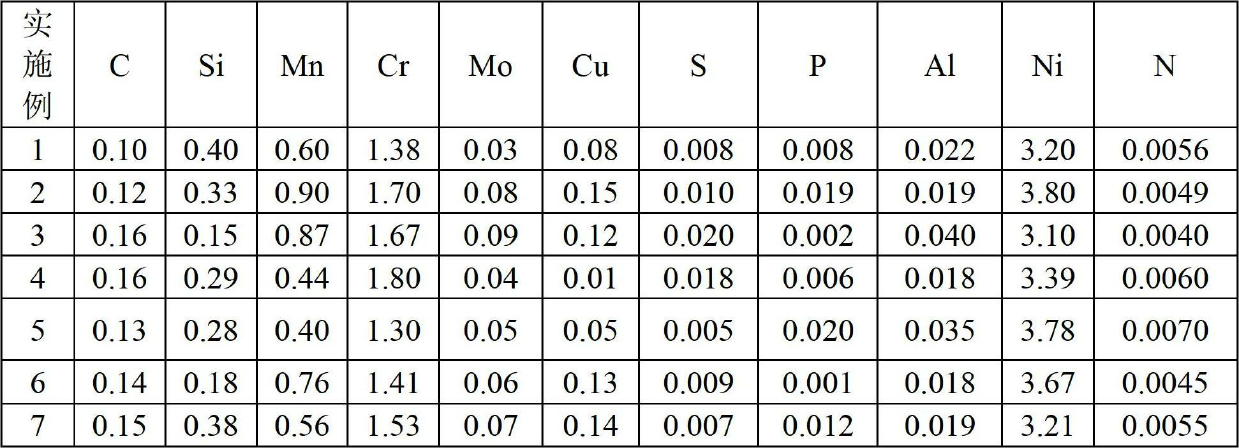

Carburizing bearing steel

The invention discloses a carburizing bearing steel, which comprises the following chemical elements in percentage by mass: 0.10-0.16% of carbon, 0.40-0.90% of manganese, 0.15-0.40% of silicon, 1.30-1.80% of chromium, 3.10-3.80% of nickel, 0.02-0.09% of molybdenum, 0.015-0.040% of aluminum and 0.0040-0.0070% of nitrogen, less than or equal to 0.0010% of oxygen, less than or equal to 0.020% of phosphorus, 0.005-0.020% of sulfur, less than or equal to 0.0020% of titanium, less than or equal to 0.15% of copper, less than or equal to 0.025% of tin, less than or equal to 0.015% of antimony, less than or equal to 0.030% of arsenic, and the balance of Fe and inevitable impurities, wherein the ratio of aluminum / nitrogen is more than or equal to 3. The carburizing bearing steel disclosed by the invention is easy for carburizing surface treatment, and has excellent strength and toughness.

Owner:宝钢特钢有限公司

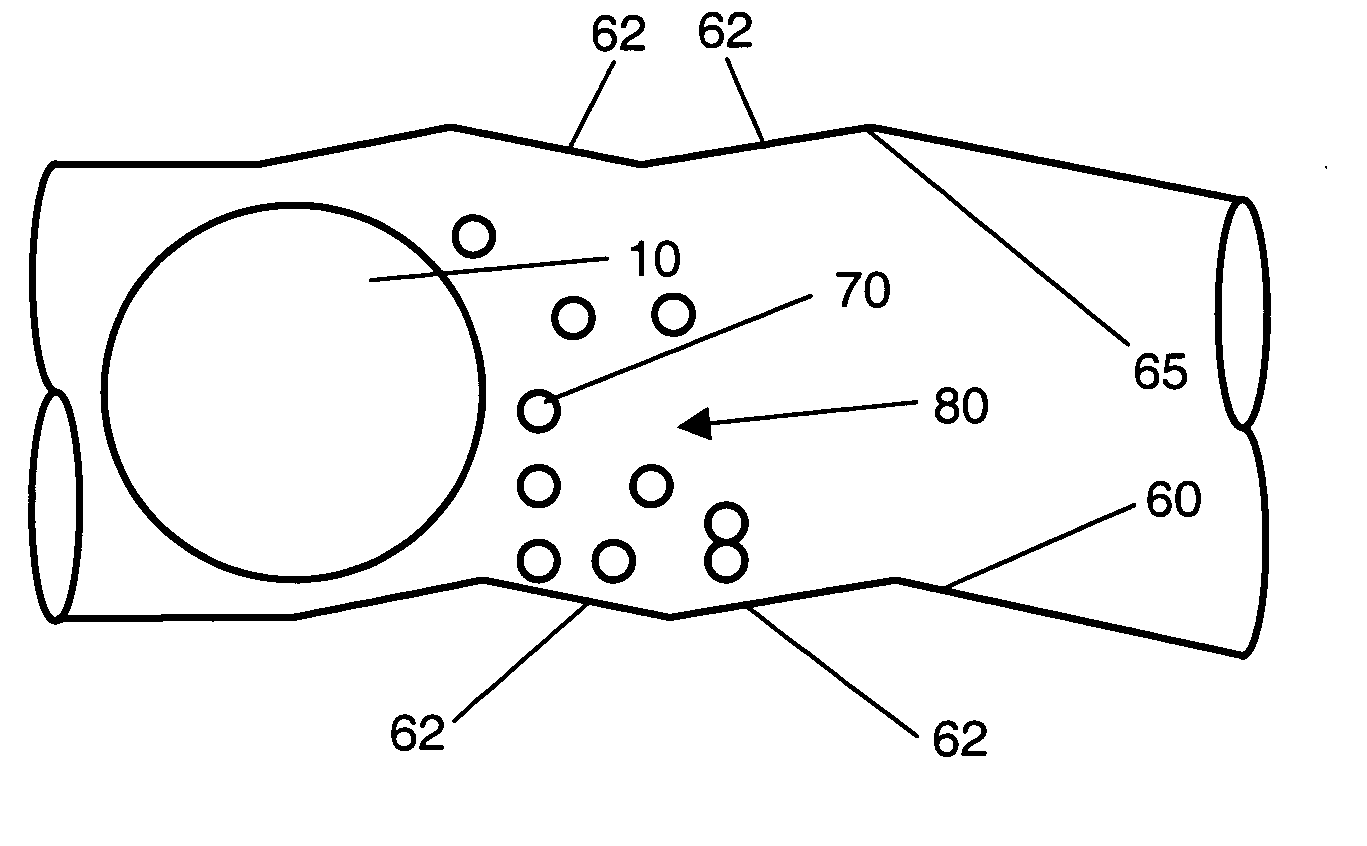

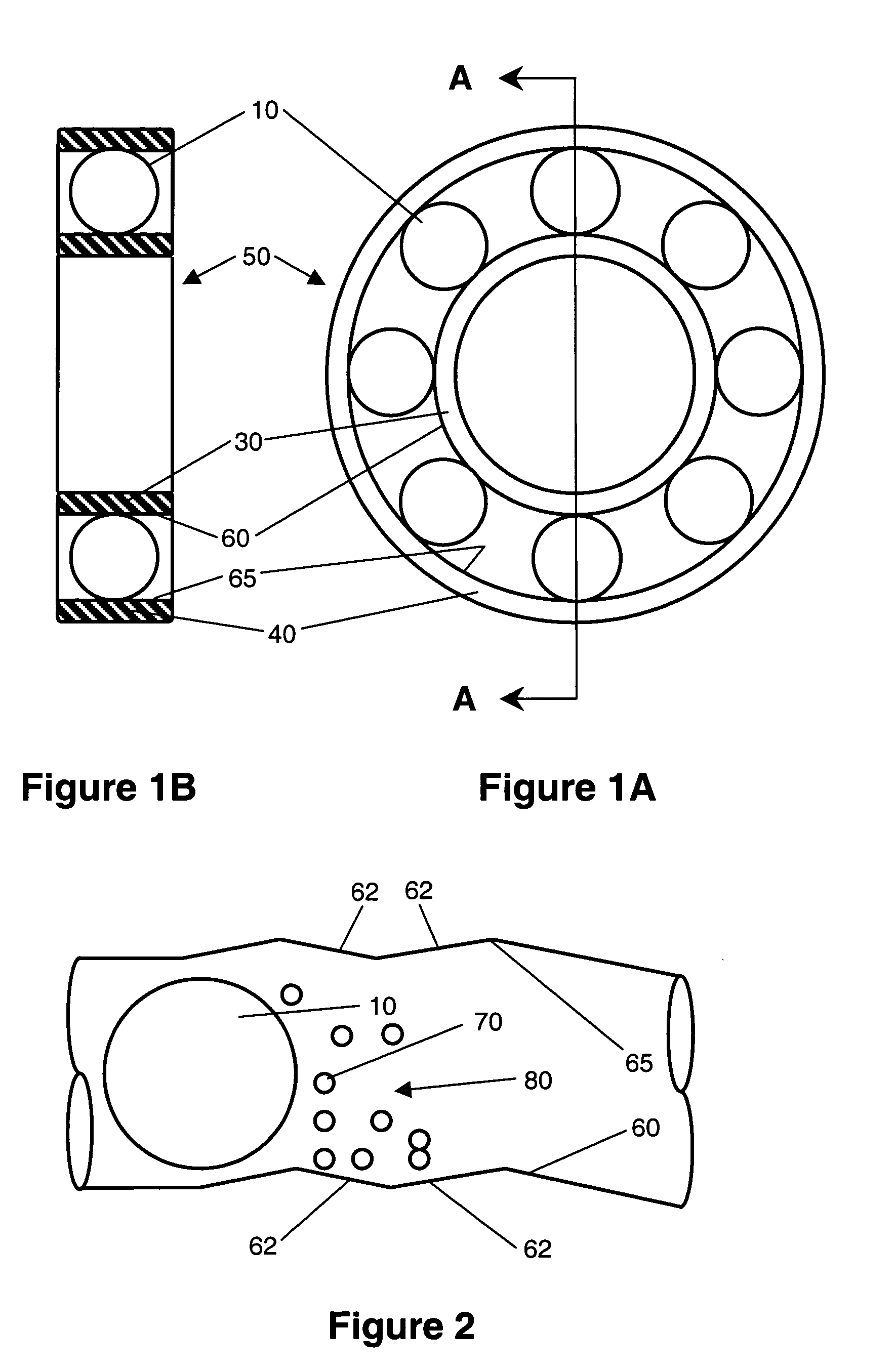

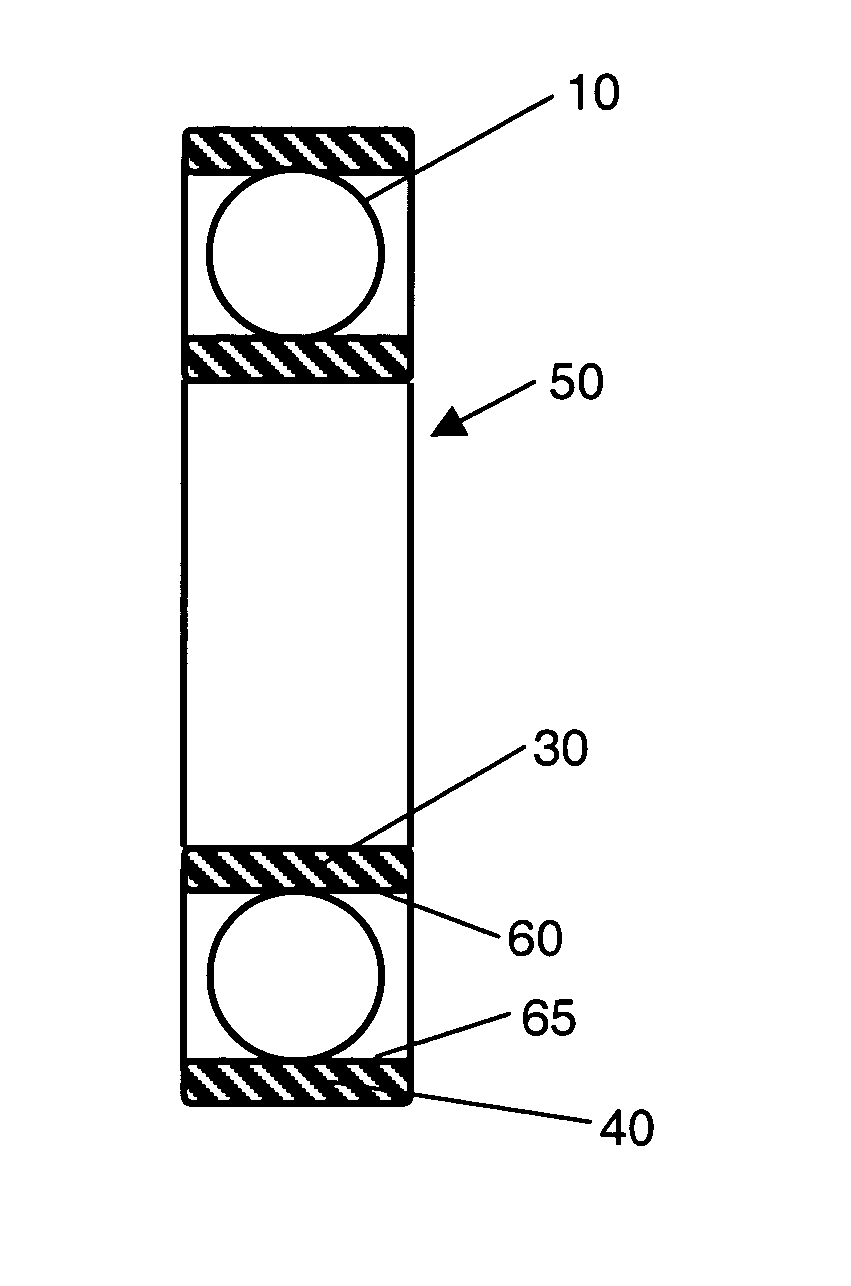

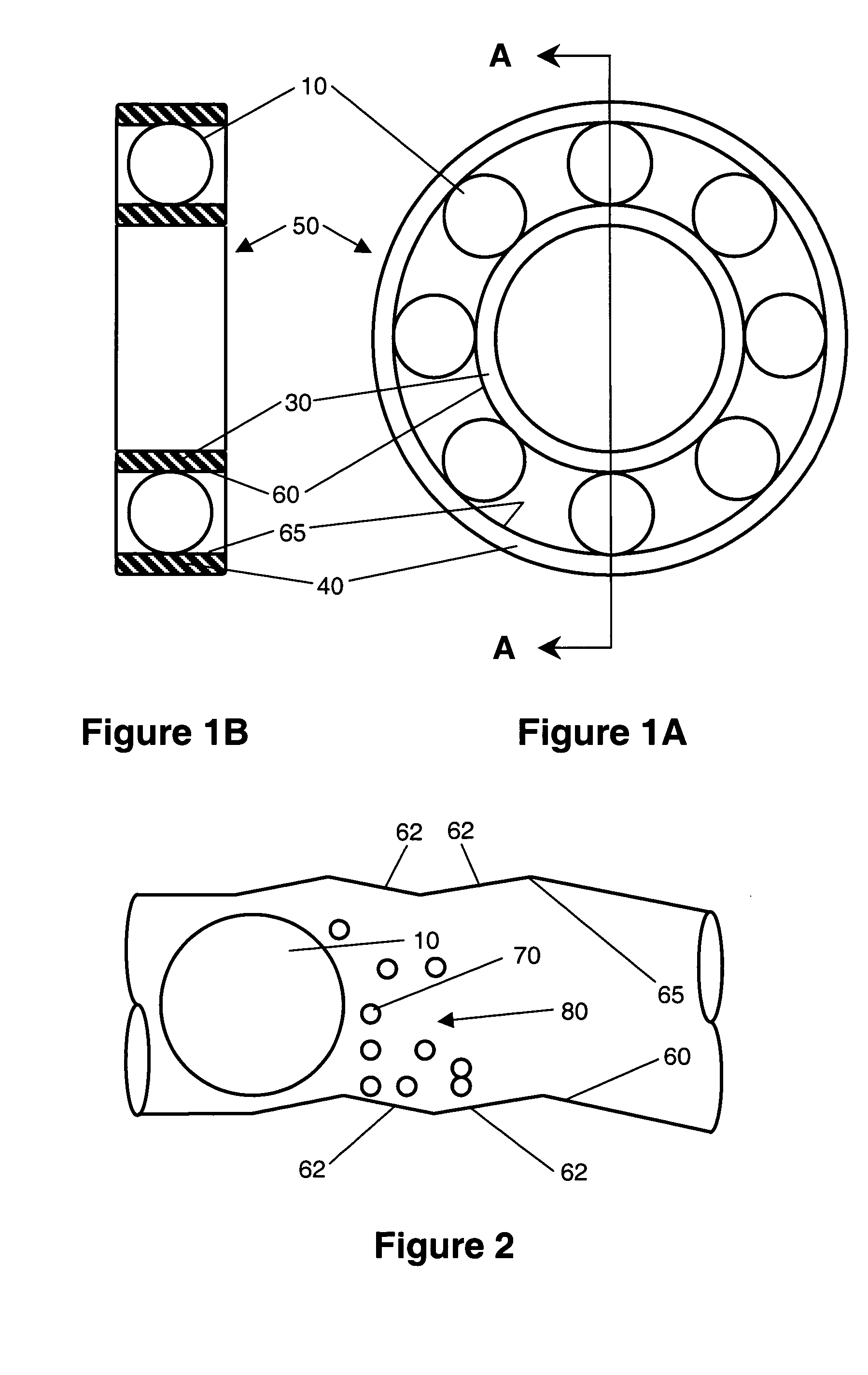

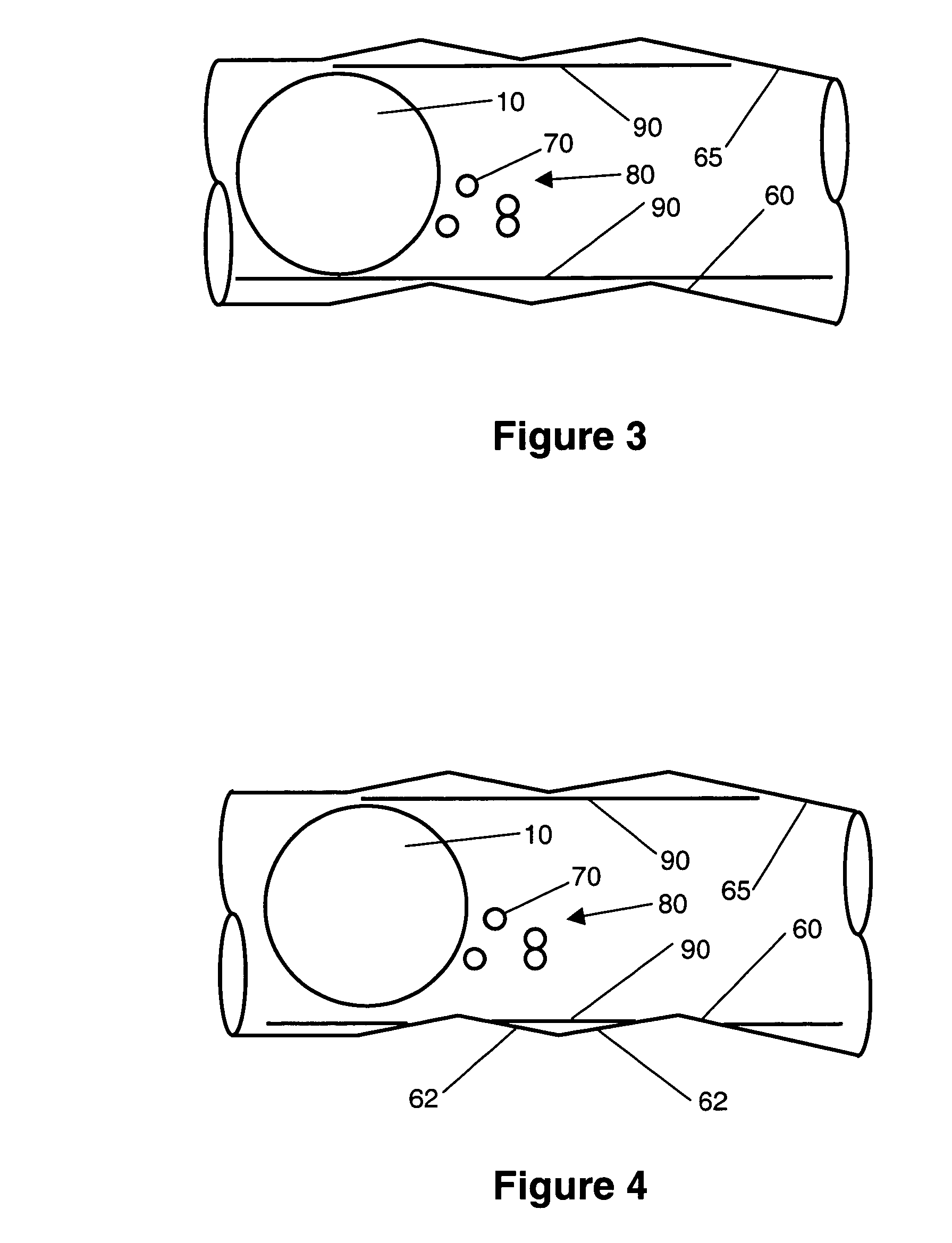

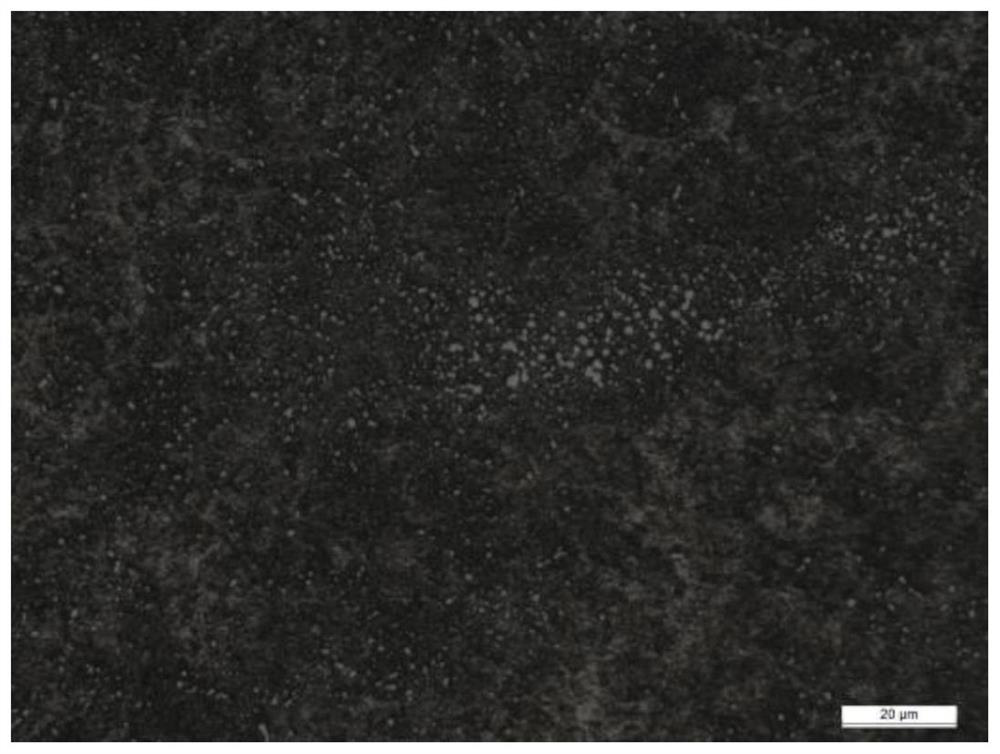

Bearing having anodic nanoparticle lubricant

InactiveUS6945699B2Efficient use ofImprove contact fatigue lifeShaftsBall bearingsNanoparticleLubricant

Owner:REGAL BELOIT AMERICA

Rolling piston and manufacturing method thereof for rotary type cold compressor

ActiveCN101158356ASufficient supplyFair priceRotary/oscillating piston pump componentsLiquid fuel engine componentsRefrigeration compressorHigh energy

The invention provides a rolling piston used for a rotary refrigeration compressor and the manufacture method thereof. The material of the rolling piston is a precise steel pipe made of GCr15 bearing steal cold rolled; the manufacture method of the invention is that (1) the GCr15 bearing steal is selected to be cold rolled to the steel pipe meeting required internal diameter, external diameter and thickness of the rolling piston; (2) the steel pipe is cut according to the length of the rolling piston material; (3) the cut steel pipe is disposed by hot controllable gas; (4) all surfaces of the steel pipe are kibbled; (5) the steel pipe is disposed by heat stabilization; (6) all surfaces of the steel pipe are finely grinded. The invention has the advantages that the made rolling piston has obvious predominance on the anti-wear performance and high contact fatigue life. The work load of the cutting process can be reduced by 50%, and the utilization ratio of the steel material can reach more than 90%, thus reducing the manufacture cost. The invention saves the casting method, avoids the environmental pollution and high energy consumption, and is a good energy-saving method with environmental protection.

Owner:NINGBO YONGWEI GROUP

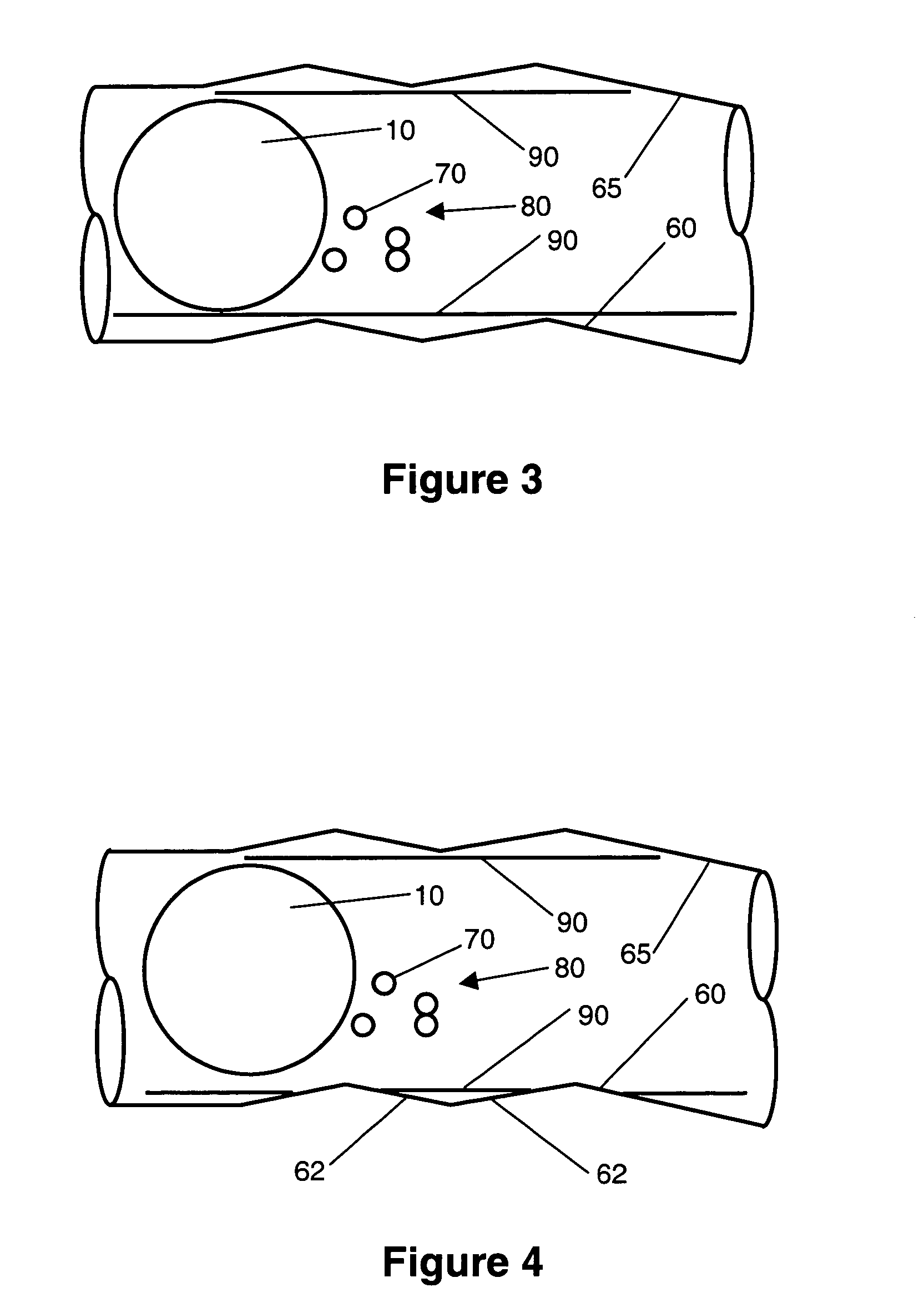

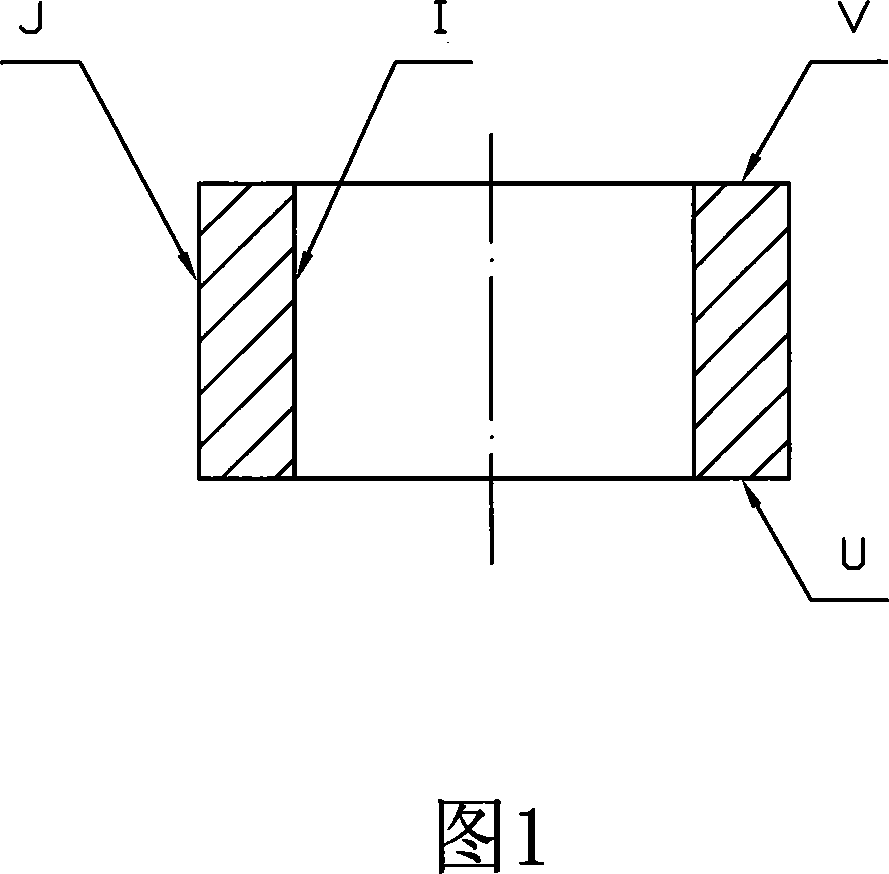

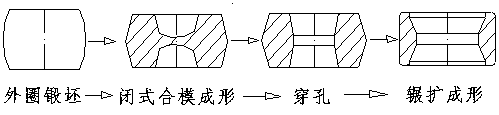

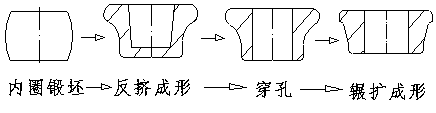

Forging forming method for inner ring and outer ring of motor train unit bearing with reasonable streamline distribution

ActiveCN108465770AImprove mechanical propertiesReasonable structure sizeFurnace typesEngine componentsContact fatigueSoftware

The invention relates to a forging forming method for an inner ring and an outer ring of a motor train unit bearing with reasonable streamline distribution. According to the forging forming method, the structure size of a die used in a forging forming process is optimized and designed by using deform software, the metal streamline distribution is simulated, and the more reasonable die structure size and matching clearance are obtained; carburized steel with low purity is subjected to streamline distribution simulation manufacturing instead of novel carburized steel which has high purity and streamline distribution difficult to observe, the reasonably distributed metal streamline is obtained, the mechanical property of a product is improved, and the contact fatigue life of the product is prolonged. By the adoption of the method for the development, the quality of an actual product formed by forging and forming during mass production of the inner ring and the outer ring of the motor train unit bearing is ensured, and mass production of ferrule forgings for motor train unit bearings is realized.

Owner:LUOYANG LYC BEARING

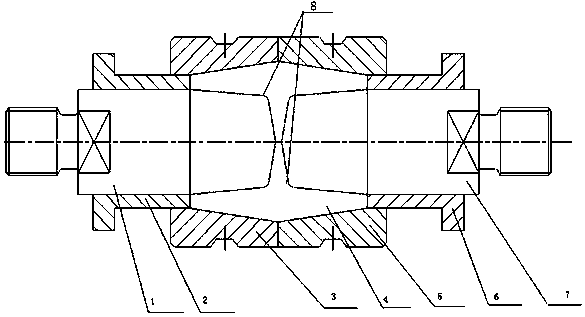

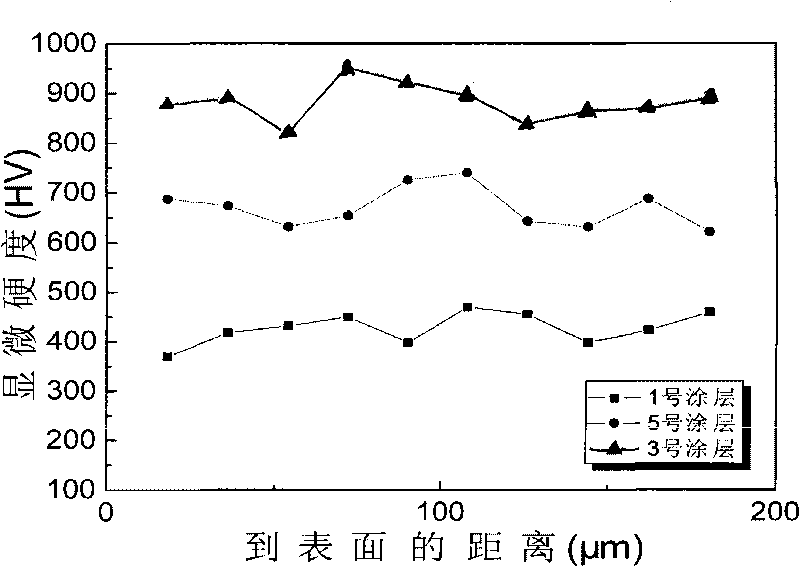

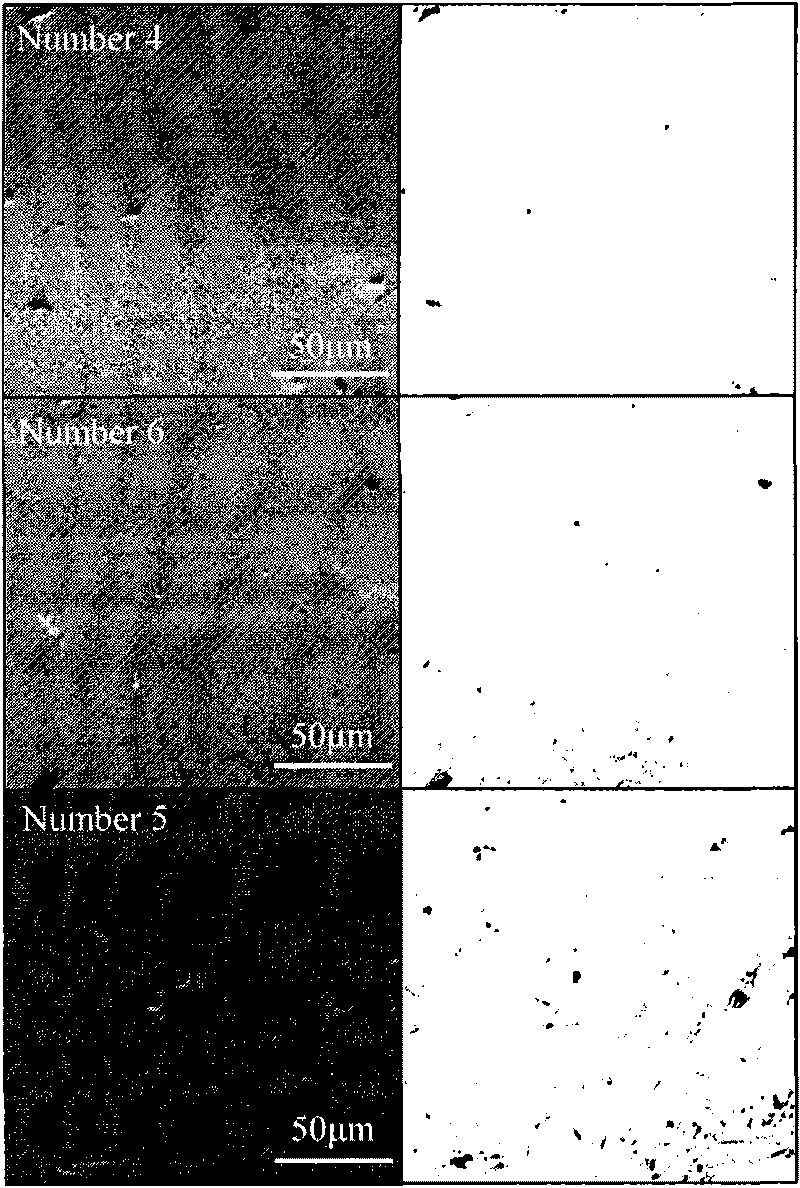

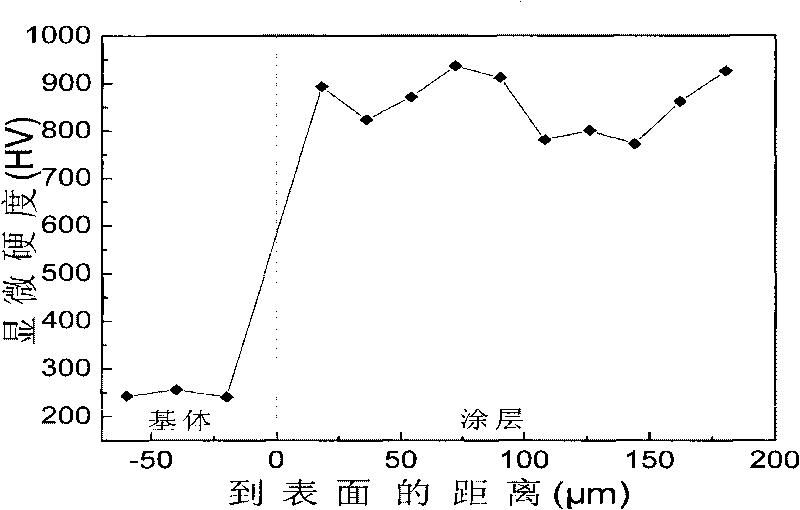

Method for improving contact fatigue life of spray coating layer

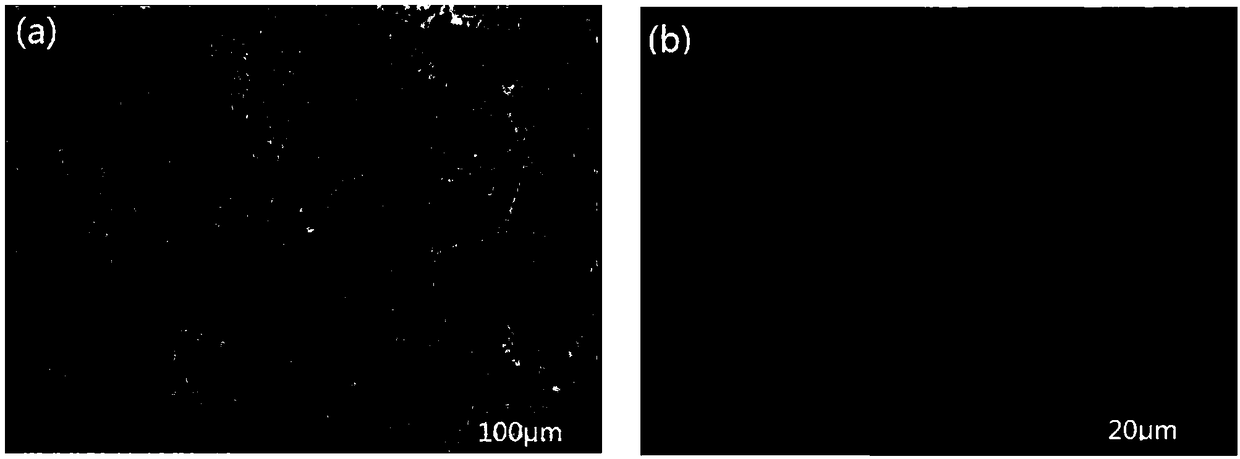

ActiveCN101713059AImprove contact fatigue lifeHigh bonding strengthMolten spray coatingSpecial data processing applicationsPorosityThermal spraying

The invention discloses a method for improving the contact fatigue life of a spraying coating layer, which is characterized by comprising the following steps of: (1) optimizing spraying parameters of a work coating layer, namely calculating the spraying parameters of the work coating layer by using an orthogonal experiment; (2) preparing a Ni / Al bonding bottom layer; and (3) spraying the work coating layer by using a plasma spraying technique. The method adopts an orthogonal design namely a modern applied mathematics method to optimize the spraying parameters, and obtains an optimal parameter combination according to different properties of coating materials. The method is applied to the optimization of thermal spraying parameters of various coating layer materials. The invention provides a new process method through which a coating layer with high hardness, low porosity, good comprehensive performance and high bonding strength is obtained by optimizing a working layer and preparing an undercoat. Through experimental comparison, the new process method can significantly improve the contact fatigue life of the coating layer.

Owner:ACADEMY OF ARMORED FORCES ENG PLA

Method for heat treatment of ultrahigh-carbon bearing steel

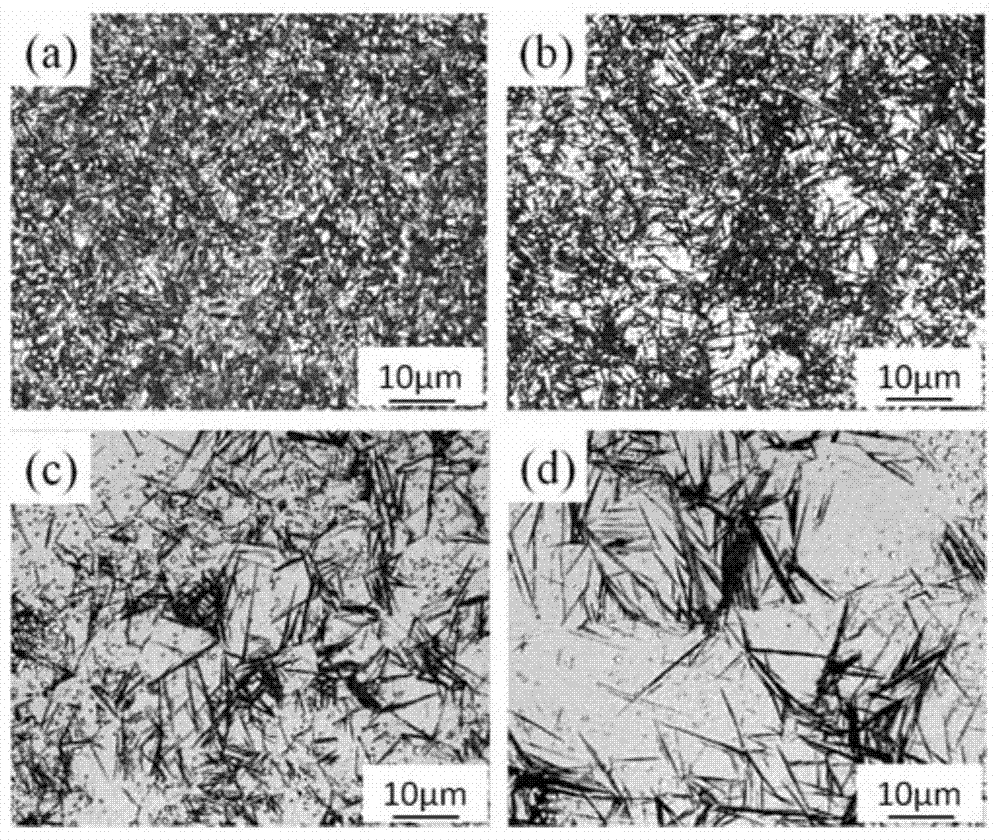

The invention provides a method for heat treatment of ultrahigh-carbon bearing steel. The method comprises the following steps of austenitizing a bearing steel part, keeping a certain amount of residual carbides, performing constant temperature treatment in a lower bainite area to form a certain amount of super bainites, and performing oil quenching or water cooling to obtain part of martensite. The structure of the ultrahigh-carbon bearing steel after the heat treatment comprises super bainites, martensite, the remaining carbides and the residual austenites, and the method ensures that the ultrahigh carbon bearing steel has a longer contact fatigue life and higher impact toughness.

Owner:XI AN JIAOTONG UNIV

Manufacturing method of high wearproof gear steel

ActiveCN111394639AIncrease contentImprove toughnessFurnace typesHeat treatment furnacesTemperingGear wheel

The invention relates to a manufacturing method of high wearproof gear steel. The manufacturing method comprises the following steps: 1, smelting, wherein molten steel comprises the following components: 0.15-0.60% of C, 0.50-1.3% of Si, 0.50-1.2% of Mn, 0.60-1.5% of Cr, equal to or less than 0.030% of P, equal to or less than 0.035% of S, 0.010-0.050% of Al, 0.008-0.025% of N and the balance of Fe; 2, pouring: pouring molten steel into steel billets; 3, rolling: after heating the steel billets, rolling the steel billets in a single-phase region at the initial rolling temperature of 980-1100 DEG C, sequentially carrying out intermediate rolling, pre finish rolling and finish rolling, during the rolling process, controlling cooling, after intermediate rolling, carrying out spraying coolingon the steel billets, after pre finish rolling, carrying out spraying cooling on the steel billets once more, then, carrying out KOCKS finish rolling, and controlling the finishing temperature to be 780-900 DEG C to obtain an unstable austenite; and 4, cooling: carrying out blast cooling the steel billets on a cooling bed, controlling the average cooling rate to be 40-80 DEG C / min and the final cooling temperature to be 300-480 DEG C, after final cooling, carrying out air cooling on the material to the room temperature, and in the cooling process, converting the austenite into ferrite and pearlite. After carburizing, quenching and tempering, the rolled steel has excellent wear resistance.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

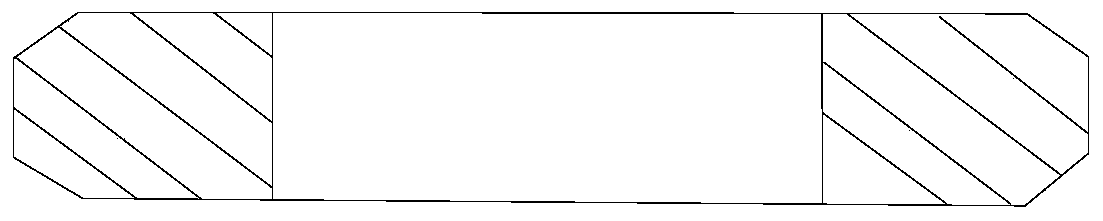

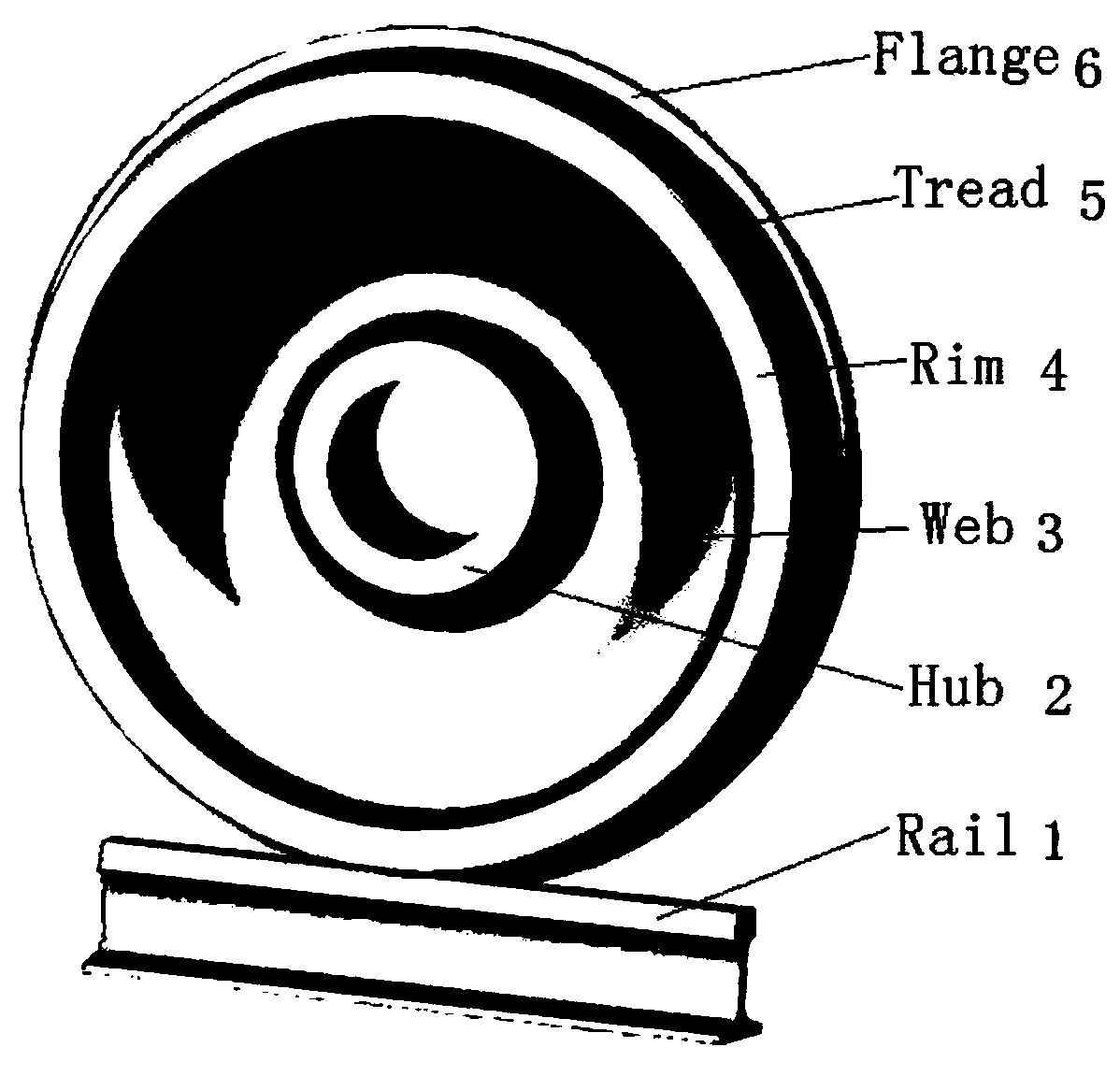

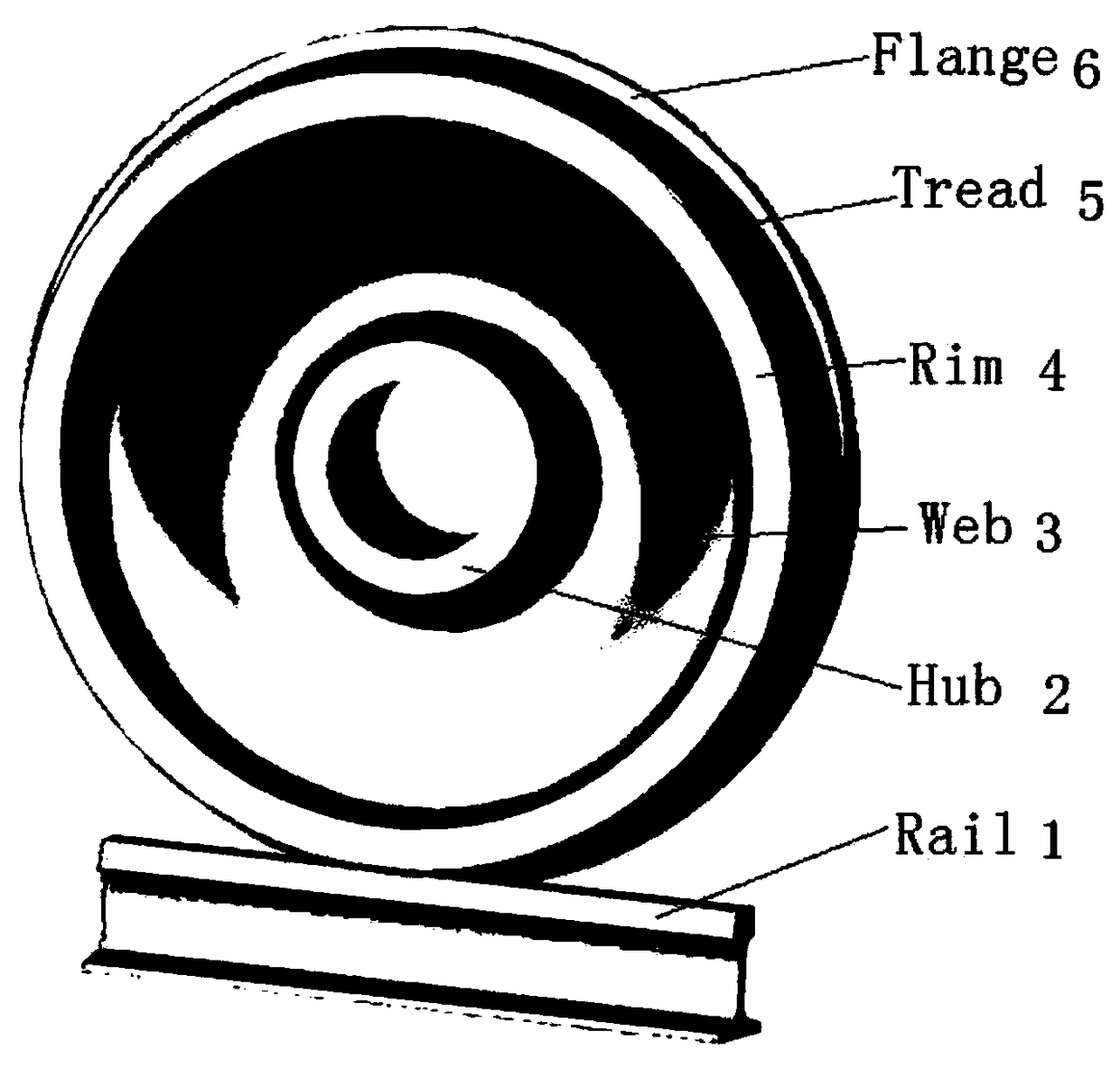

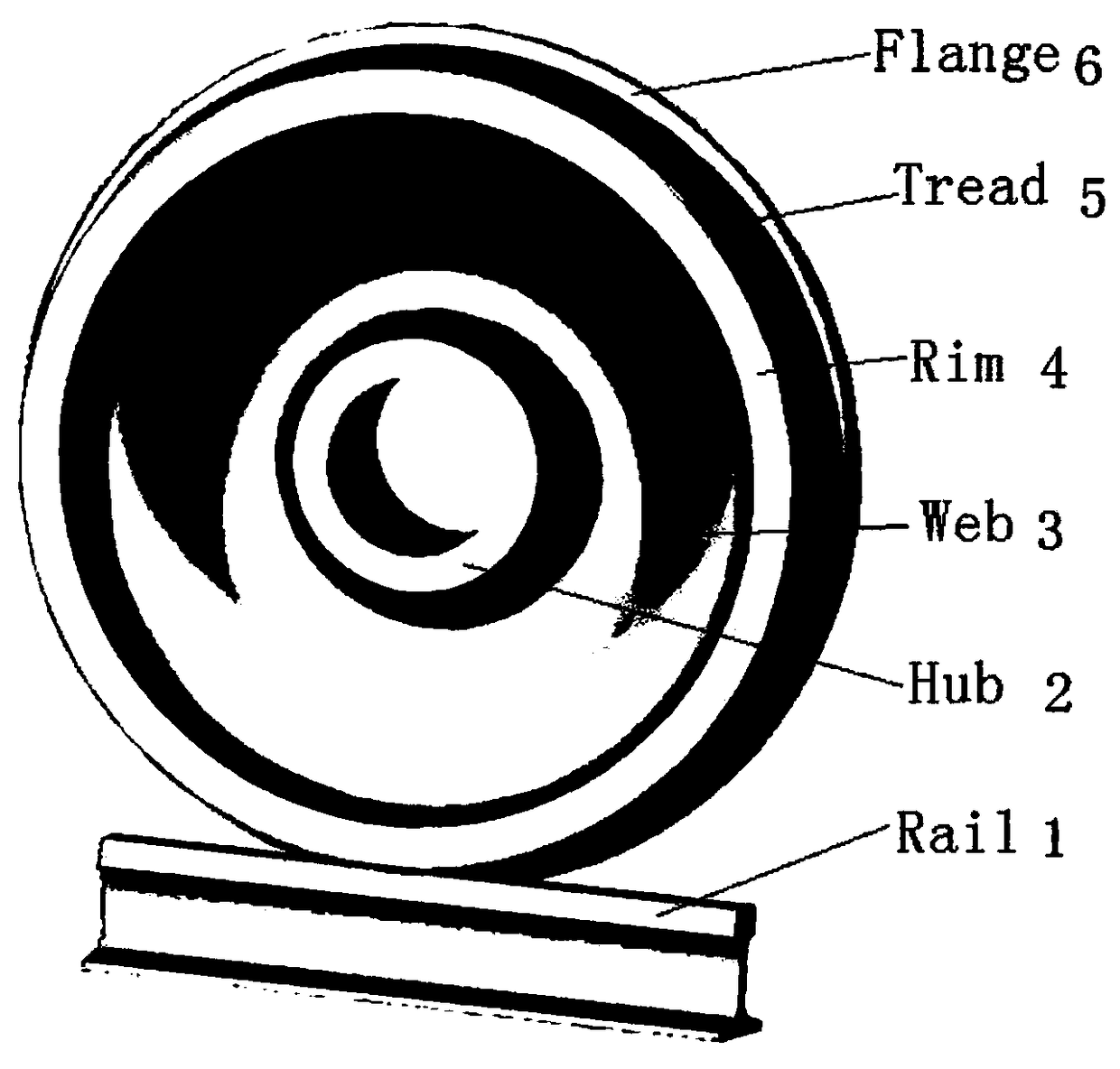

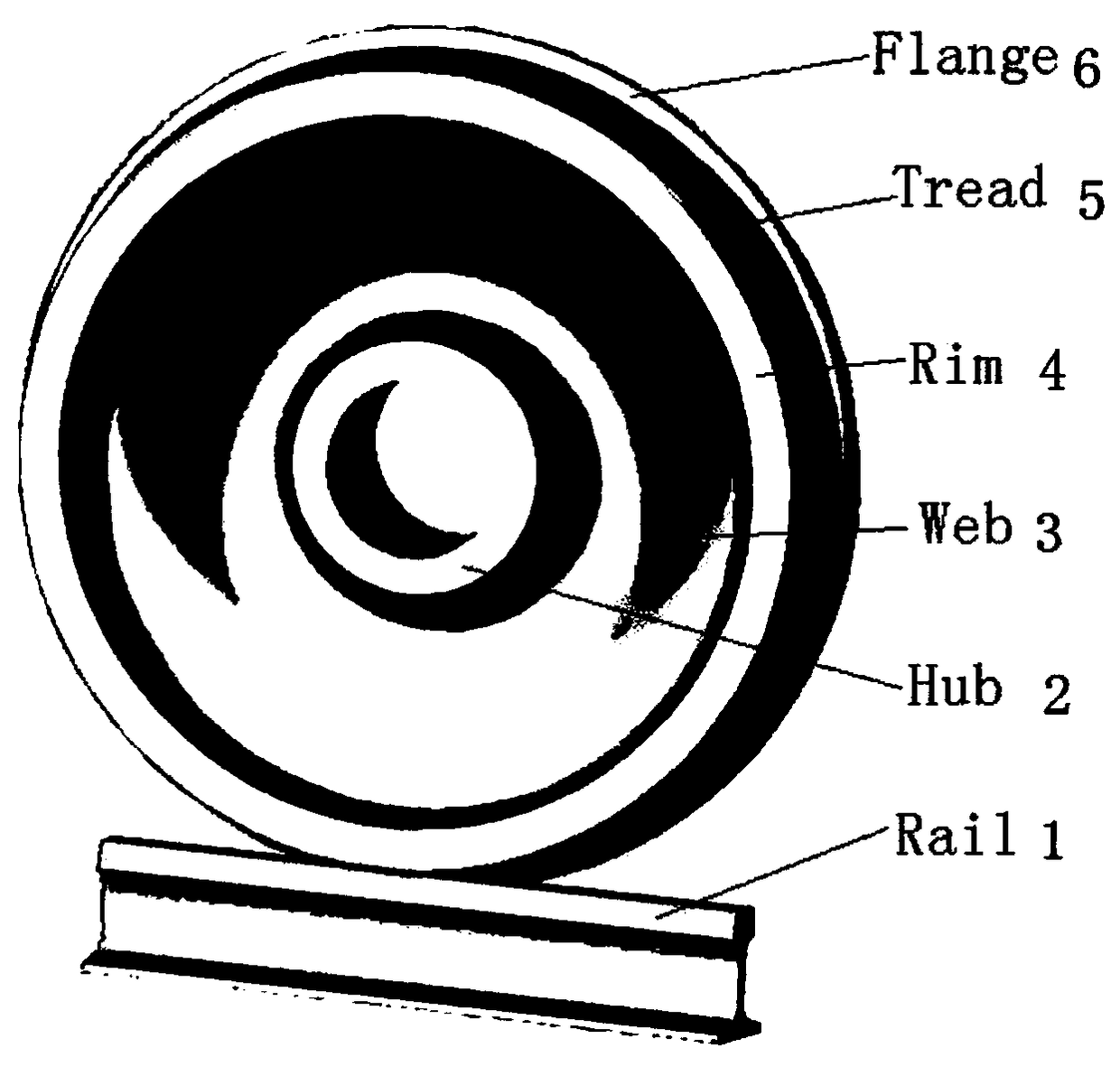

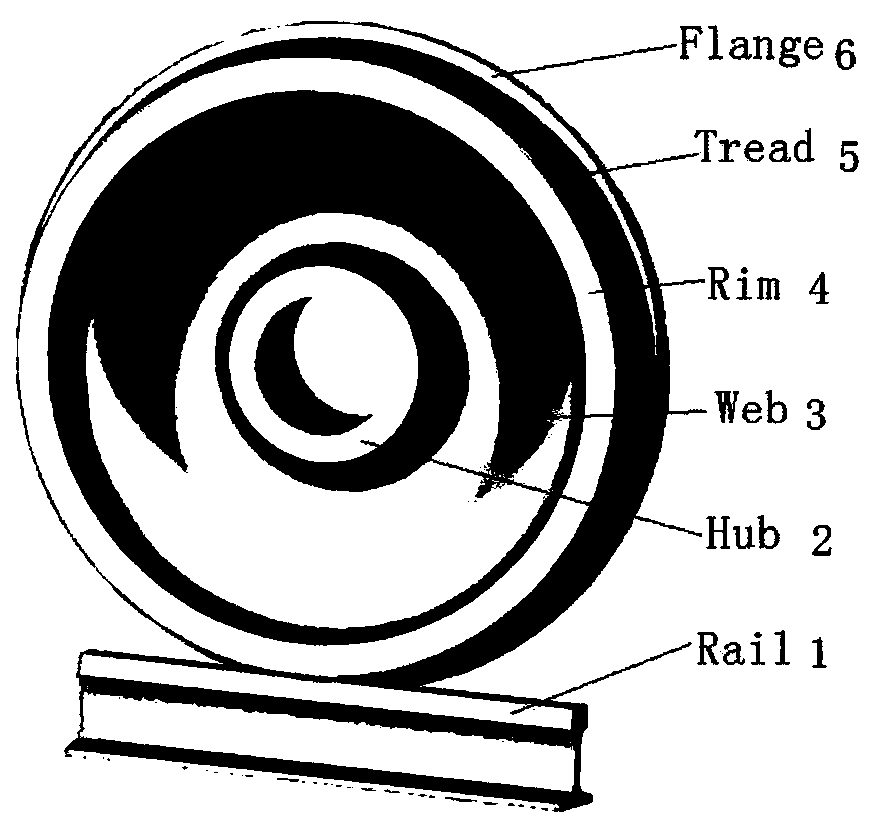

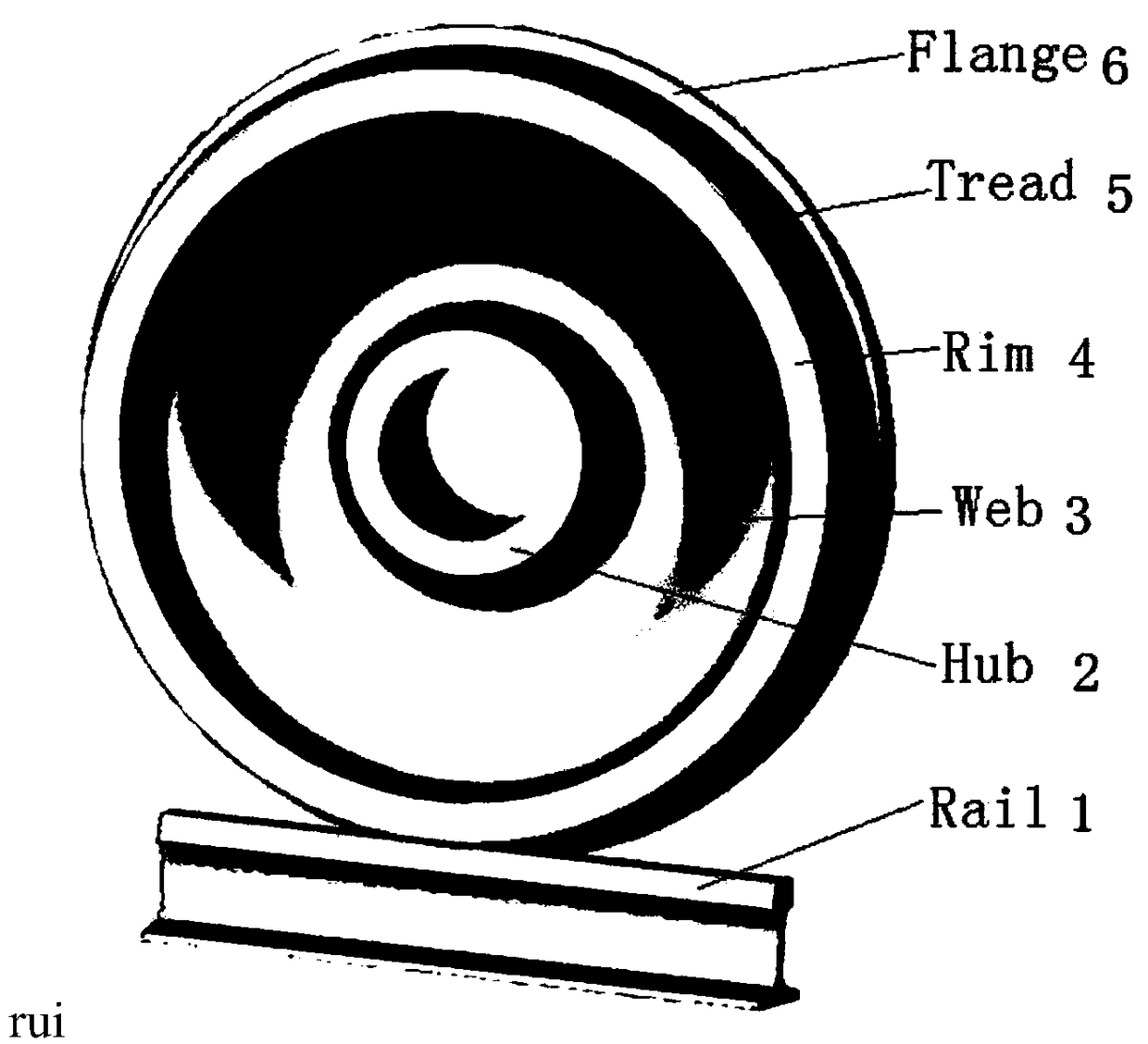

Common rail traffic bainite steel wheel used under cold and rigor service environment and manufacturing method of common rail traffic bainite steel wheel

InactiveCN108707831AHigh yield strengthHigh tensile strengthRail-engaging wheelsFurnace typesChemical compositionCommon rail

The invention discloses a common rail traffic bainite steel wheel used under the cold and rigor service environment and a manufacturing method of the common rail traffic bainite steel wheel. The common rail traffic bainite steel wheel comprises chemical components including 0.05%-0.30% of C, 0.50%-1.50% of Ni, 0.01%-1.20% of Cr, 0.70%-2.10% of Mn, 0.20%-1.00% of Si, 0.01%-1.00% of W, 0.05%-0.60% of Mo, 0.01%-0.80% of Cu, 0.01%-0.20% of V, 0.001%-0.20% of Nb, 0.0001%-0.0350% of B, 0.001%-0.040% of RE, not larger than 0.020% of P, not larger than 0.020% of S and the balance Fe and inevitable residual elements, wherein the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. By adopting a new alloy design system and alloying principle of C-Ni-Mn-Cr-Mo, after thewheel is molded, a rim obtained after advanced heat treatment obtains a carbide-free bainite organization structure, and the wheel has the excellent comprehensive mechanical property, decay resistance and service performance, in particular has the high low-temperature toughness and low-temperature breaking toughness, meets performance and service safety requirement under the low-temperature environment and is suitable for the cold zone under rigor conditions.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Controlled cooling process and water cooler for high carbon and chromium bearing steel pipe blank after hot rolling

InactiveCN101020951AShorten spheroidizing annealing timeImprove contact fatigue lifeFurnace typesHeat treatment process controlSteel tubeChromium

The present invention belongs to the field of alloy steel and its making process, and is especially controlled cooling process and water cooler for high carbon and chromium bearing steel pipe blank after hot rolling. The cooling process includes the following steps: installing 4 water coolers in some interval on the cooling line and water cooling and air cooling the hot rolled pipe alternately in the V-shaped roll way; controlling the finishing temperature of rolled pipe blank to obtain single austenite structure before entering to the water coolers; ensuring the temperature of the hot rolled pipe blank before the first water cooler in 850-910 deg.c and the temperature leaving the fourth water cooler in 560+ / -20 deg.c; air cooling the pipe blank with surface temperature recovered to 650+ / -30 deg.c in the cooling bed; and fast spheroidizing annealing of the pipe blank. The present invention is superior to available technology.

Owner:CENT IRON & STEEL RES INST

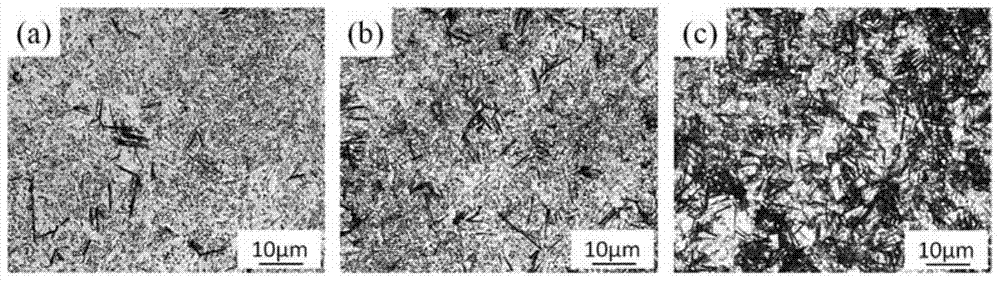

Intrinsic non-net secondary cementite steel and application method thereof

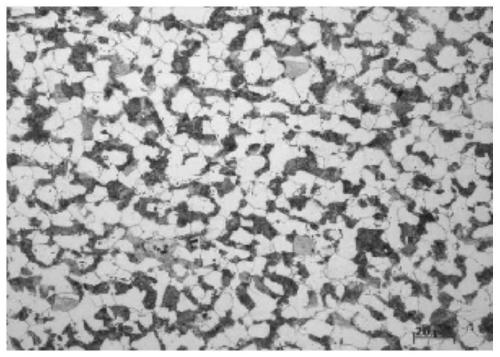

The invention discloses an intrinsic non-net secondary cementite steel and an application method thereof; the steel comprises the following components by weight percent: 0.8-1.8% of C, 0-3.0% of Al, 0-2.5% of Cr, 0.2-0.8% of Mn, 0-2.0% of Si, 0-0.8% of Mo, 0-0.1% of Nb, 0-0.1% of V, 0-0.1% of Ti, 0-0.05% of Re and the balance Fe. The steel does not have net-shaped secondary cementite in common casting state, annealed state and normalized state, secondary cementite is precipitated in pearlite in a dispersive form and the form of organization is pearlite and dispersive spinodal decomposition organization. The organization is easy for nodulizing which can be realized by heating the organization at 800 DEG C for 1-2h after the routine forging technology. The steel can be widely applied in the fields such as tools, abrasive tools, bearings, rail steels and the like and the steel can improve the carbon content, hardness and wear resistance and service life of traditional materials.

Owner:XI AN JIAOTONG UNIV

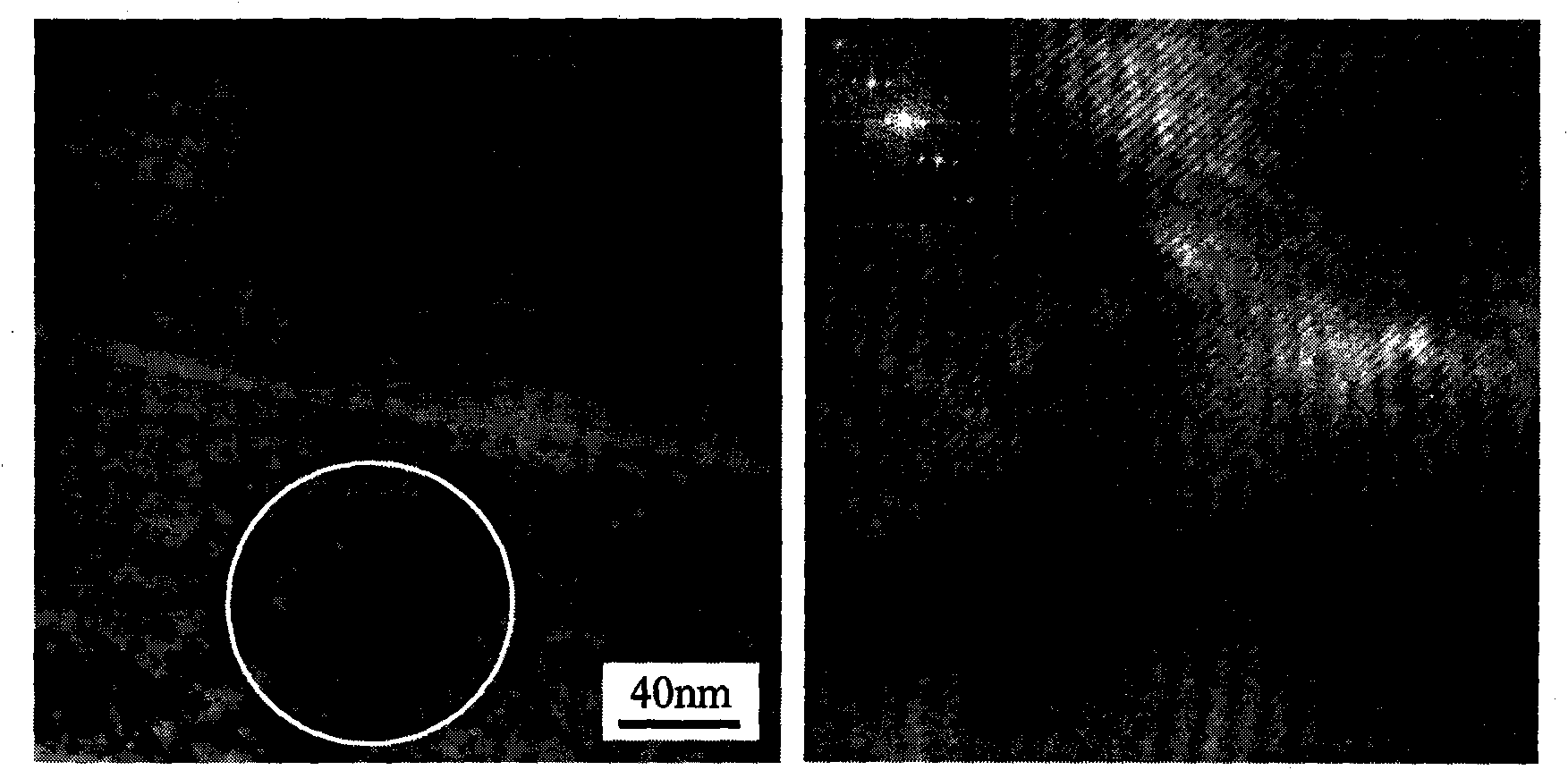

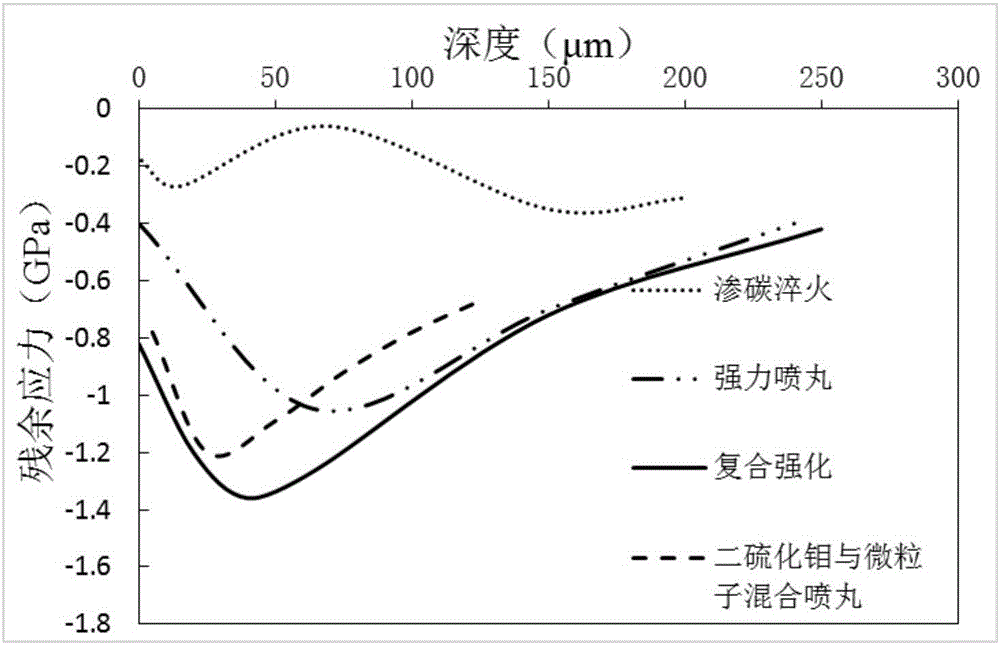

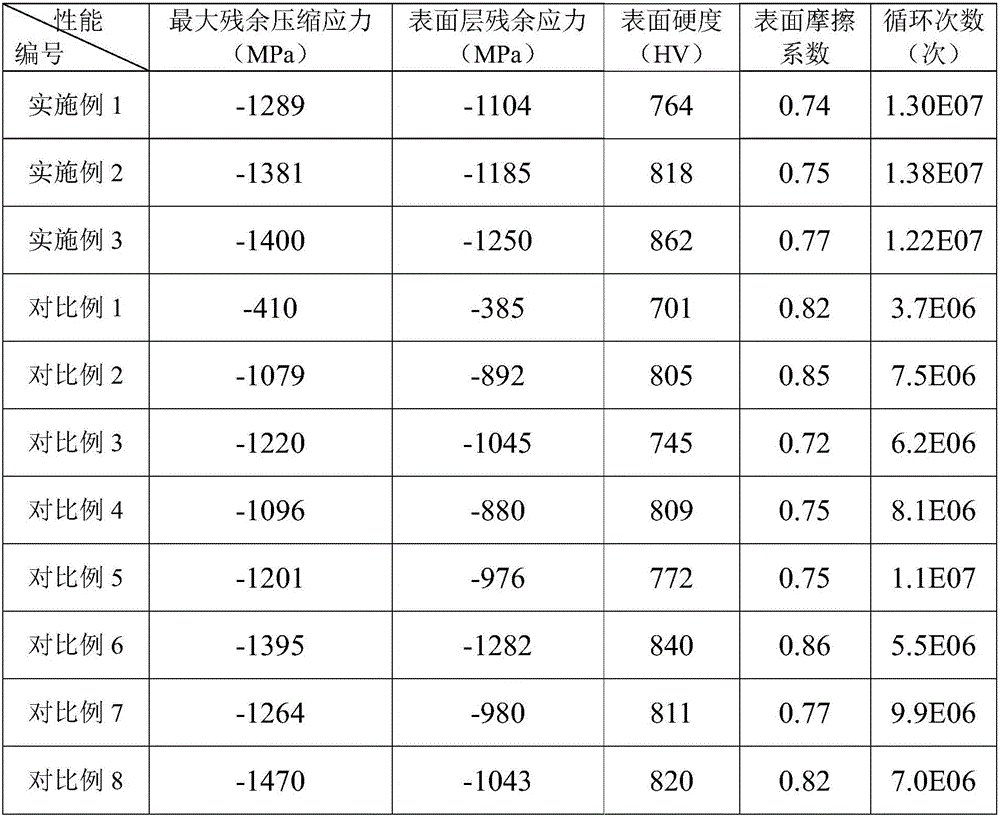

Compound reinforcement method for gear surface

InactiveCN106826571AHigh hardnessReduce vibration and noiseAbrasive blasting machinesSurface finishHardness

The invention relates to a compound reinforcement method for a gear surface. The compound reinforcement method comprises the following steps: firstly, the gear surface is subjected to shot blasting with steel shots with particle size being 0.6-1 mm; then molybdenum disulfide is mixed with particles with particle size being 0.05-0.1 mm, the mixture is used for performing shot blasting continuously on a gear, and the gear with compound reinforced surface is obtained. By means of the coupled effect of two processes including powerful shot blasting and molybdenum disulfide and particle mixed shot blasting, amplitude of tooth surface compressive stress deeper than the stress in single surface treatment process is obtained, and tooth surface hardness is improved substantially. Meanwhile, the lubricity of the gear surface is improved, the friction coefficient of the tooth surface is reduced, the lubricating capacity and the surface smoothness are improved, and gear meshing vibration noise is reduced. The effect of prolonging both the flexible life and contact fatigue life of the gear simultaneously is realized. The method adopts simple process and flexible conditions, can realize batch production and has good application prospect.

Owner:HEBEI UNIV OF TECH

Bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and manufacturing method thereof

InactiveCN109182920AHigh yield strengthHigh tensile strengthRail-engaging wheelsFurnace typesCarbideAlloy

The invention discloses a bainitic steel wheel for rail traffic with capability of resisting against damp, hot and corrosive environments and a manufacturing method thereof. The bainitic steel wheel comprises the following chemical components: 0.05-0.40% of C, 0.40-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% ofV, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, less than or equal to 0.020% of P, less than or equal to 0.020% of S and the balance of Fe and inevitable residual elements, wherein Mn+Cr is more than or equal to 2.0% but less than or equal to 3.0%. The new alloy design system of C-Ni-Mn-Cr-Mo-Cu and alloying principle are adopted by the invention; after a wheel is formed, a rim after advanced thermal treatment is endowed with a carbide-free bainite structure; the wheel has excellent comprehensive mechanical property and service performance, especially, atmospheric corrosion resistance; the wheel is capable of resisting against damp, hot and corrosive environments and reducing the harmful influences of stress corrosion and medium corrosion; the service life and running safetyof the wheel can be further promoted.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Bainite steel wheel for rail traffic D-series high-speed train and manufacturing method thereof

PendingCN108796372AHigh yield strengthHigh tensile strengthFoundry mouldsFurnace typesDesign systemsChemical composition

The invention discloses a bainite steel wheel for a rail traffic D-series high-speed train and a manufacturing method thereof. Chemical components of the bainite steel wheel comprise 0.05-0.30% of C,0.10-1.50% of Ni, 0.01-1.20% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, smaller than or equal to 0.020% of P, smaller than or equal to 0.020% of S and the balance Fe and inevitable residual elements, and the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. According to the bainite steel wheel, the novel C-Ni-Mn-Cr-Mo alloy design system and the alloying principle are adopted, after the wheel is formed and subjected to advanced heattreatment, a rim obtains a no-carbide bainite structure, and the wheel has excellent comprehensive mechanical performance, anticorrosion performance and service performance, and especially has the beneficial effects of being high in strength, high in hardness, high in toughness, high in low-temperature toughness, high in wheeltrack rolling contact fatigue resisting performance (RCF), high in heatcrack resisting performance and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

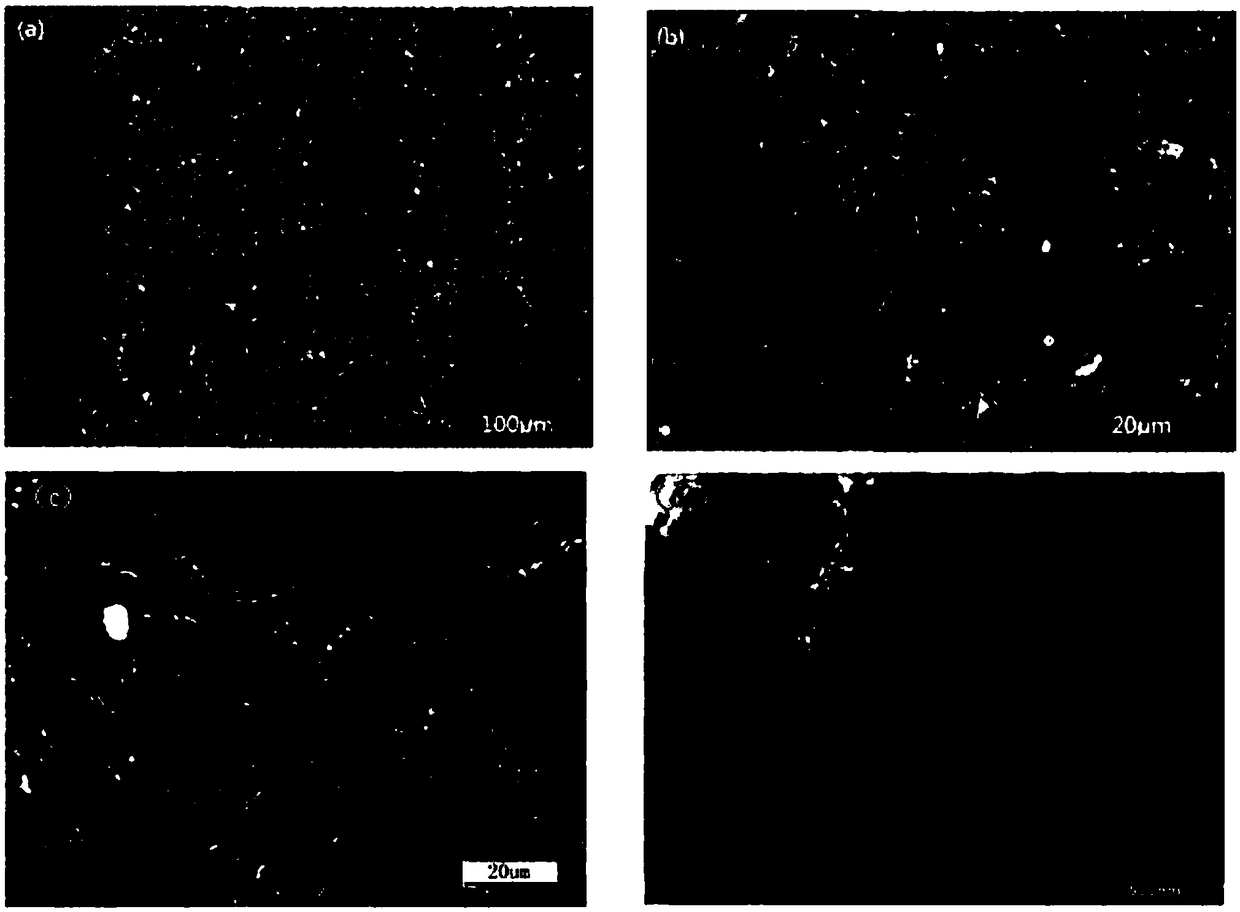

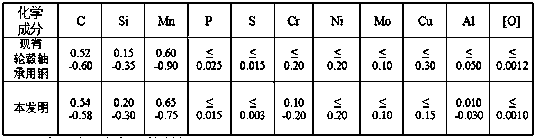

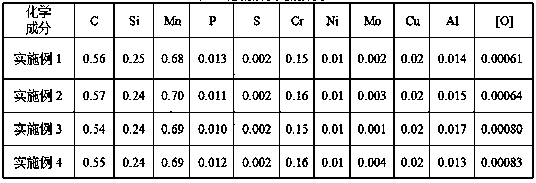

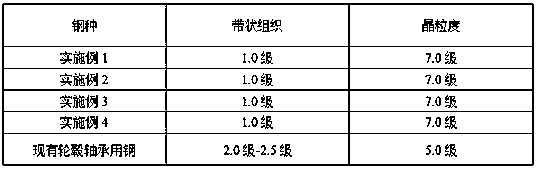

Steel for hub bearing and manufacturing method of steel

ActiveCN109680122AImprove contact fatigue lifeImprove cleanlinessMetal rolling arrangementsContact fatigueMaterials science

The invention discloses steel for a hub bearing. The steel for the hub bearing comprises chemical components, by mass percent, including 0.54%-0.58% of C, 0.20%-0.30% of Si, 0.65%-0.75% of Mn, 0.10%-0.20% of Cr, 0.010%-0.030% of Al, 0.015% or less of P, 0.003% or less of S, 0.0025% or less of Ti, 0.20% or less of Ni, 0.15% or less of Cu, 0.10% or less of Mo, 0.0010% or less of [O] and the balanceFe. From the components of the steel for the hub bearing, alloying is carried out through conventional alloy elements such as the C, the Mn and the Cr, the contact fatigue life of the steel for the hub bearing is longer in performance than G55 in national (Carbon Bearing Steel) (GB / T28417-2012) standard.

Owner:JIANGSU LIHUAI IRON AND STEEL CO LTD +1

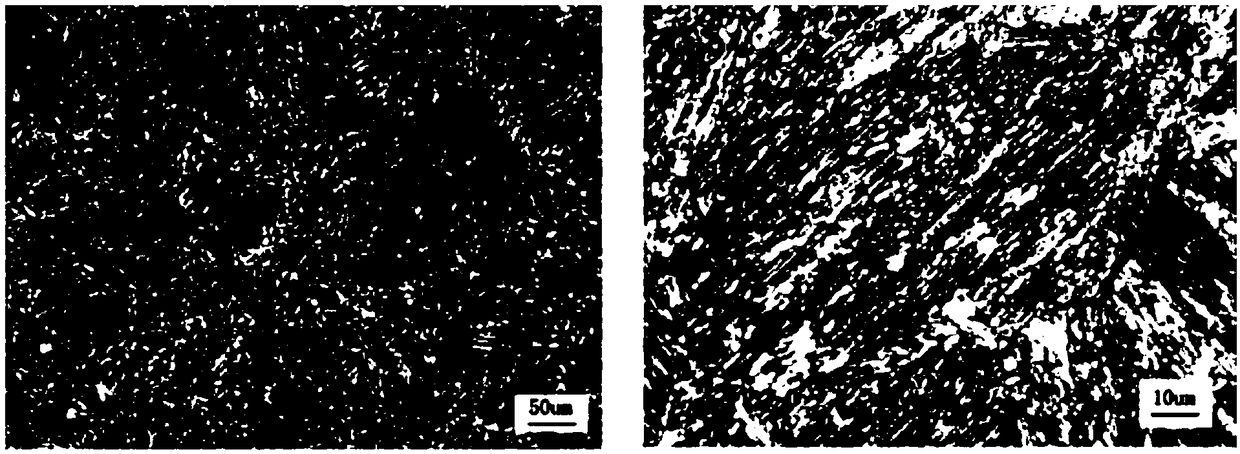

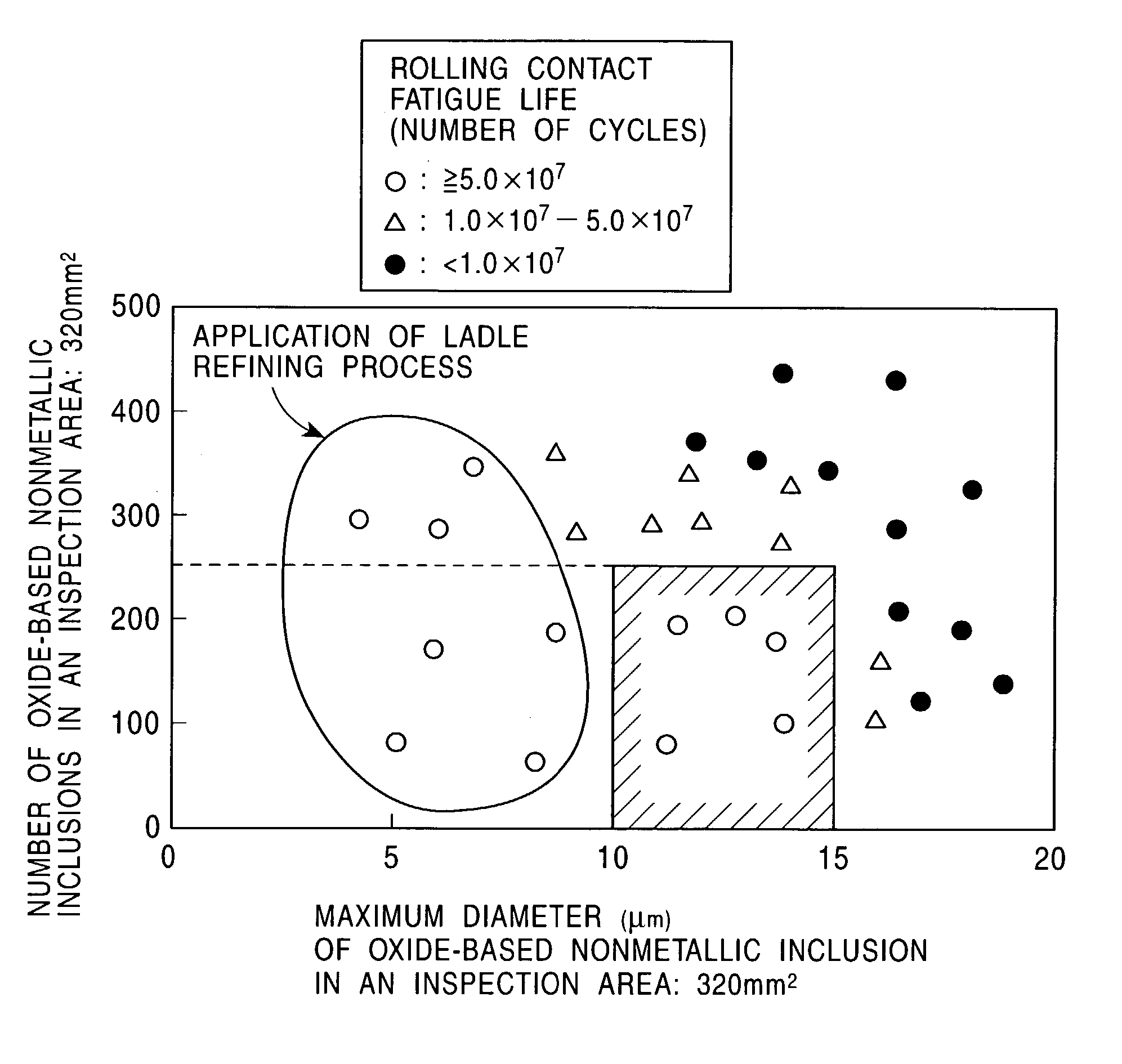

Steel for case hardening bearing excellent in toughness and rolling fatigue life in quasi-high temperature region

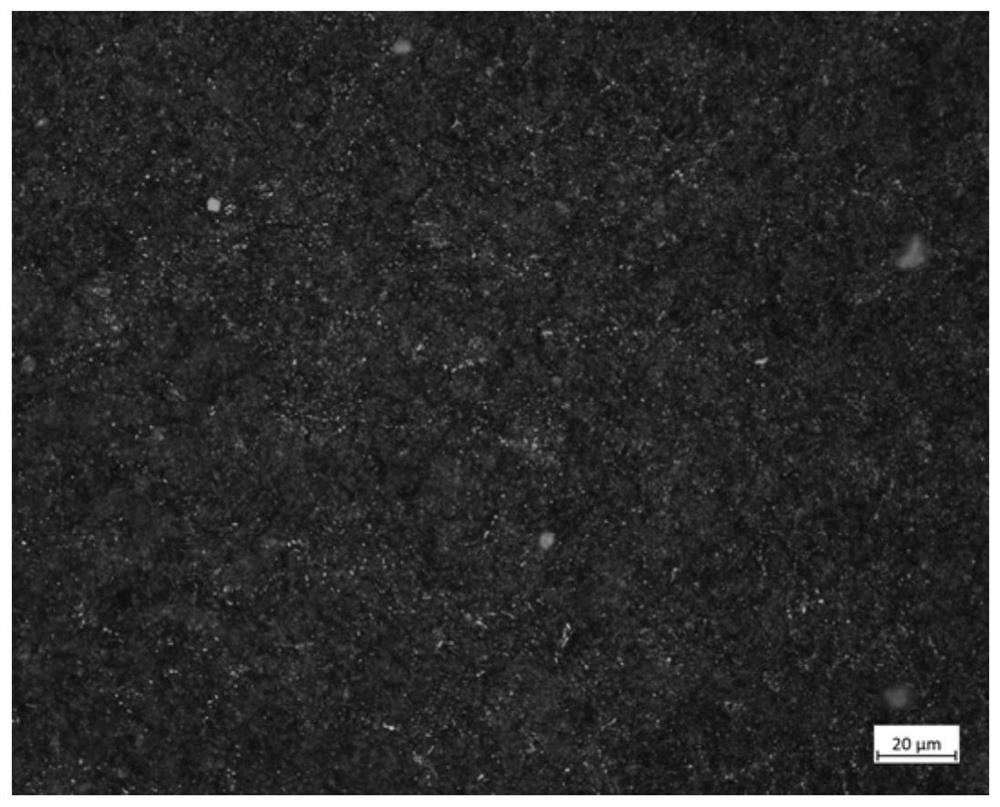

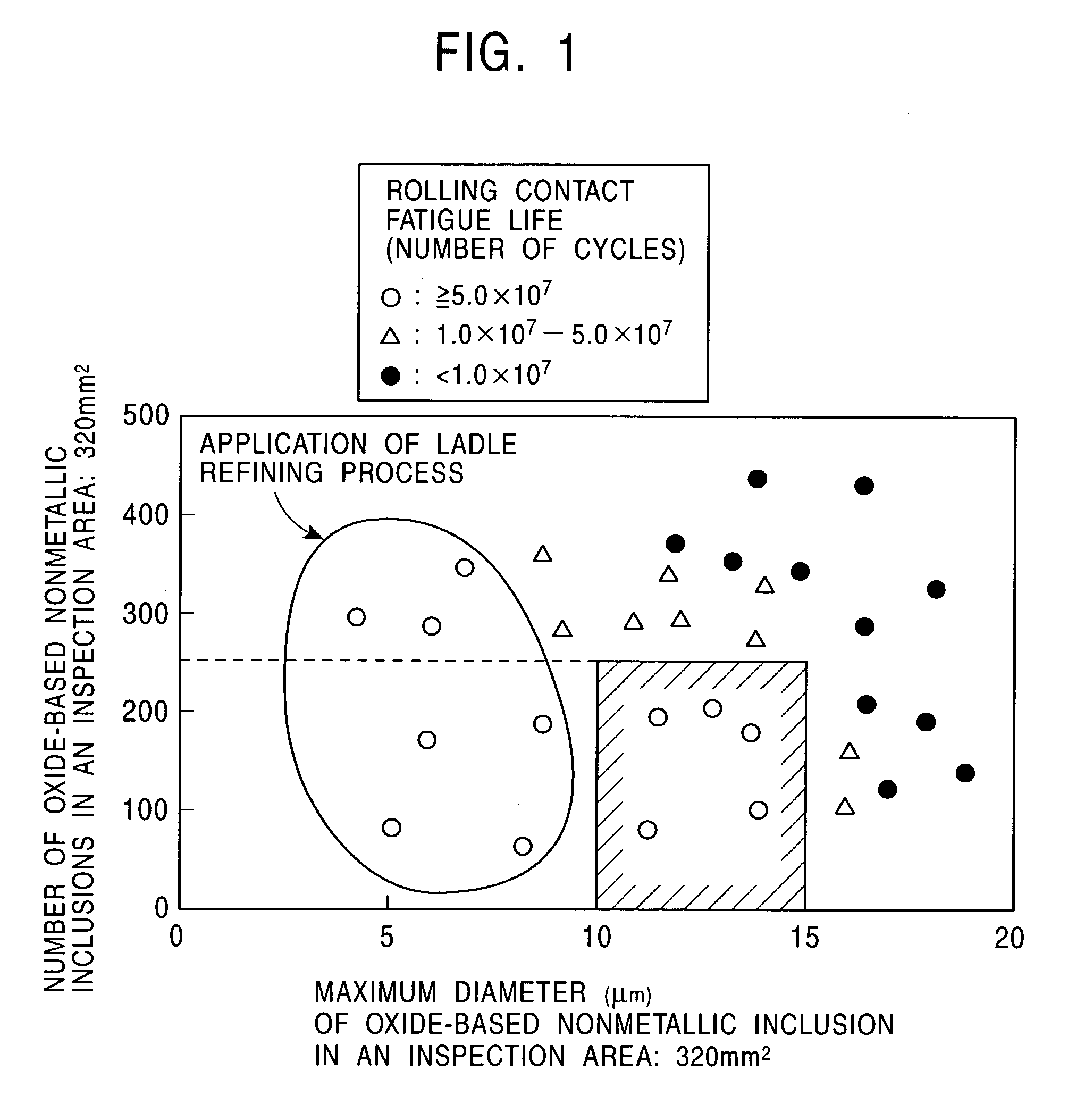

InactiveUS20050081962A1Improve contact fatigue lifeImprove toughnessSolid state diffusion coatingFurnace typesRolling contact fatigueNon-metallic inclusions

A case hardening bearing steel having an excellent rolling contact fatigue life in intermediate temperature, in addition, excellent toughness at room temperature is provided. Specific means for solving the problems are as follows. The composition contains, by mass percent, C of 0.15 to 0.30 mass percent, Si of 0.5 to 2.0 mass percent, Mn of 0.3 to 2.0 mass percent, Cr of 1.3 to 2.5 mass percent, Mo of 0.3 to 1.0 mass percent, and O of not more than 0.0012 mass percent in a range where (Si+Mo)≧1.0 mass percent is satisfied, and contains iron and inevitable impurities as remnant; the maximum size of oxide nonmetallic inclusion is not more than 12.5 μm when examined area is 320 mm2; number of the oxide nonmetallic inclusion having a diameter of equivalent circle of 3 μm or more is not more than 250 when the examined area is 320 mm2; in addition, C density of an outer layer is adjusted to be in a range from 0.7 to 1.2 mass percent by carburization.

Owner:JFE STEEL CORP +1

Carburized bearing steel

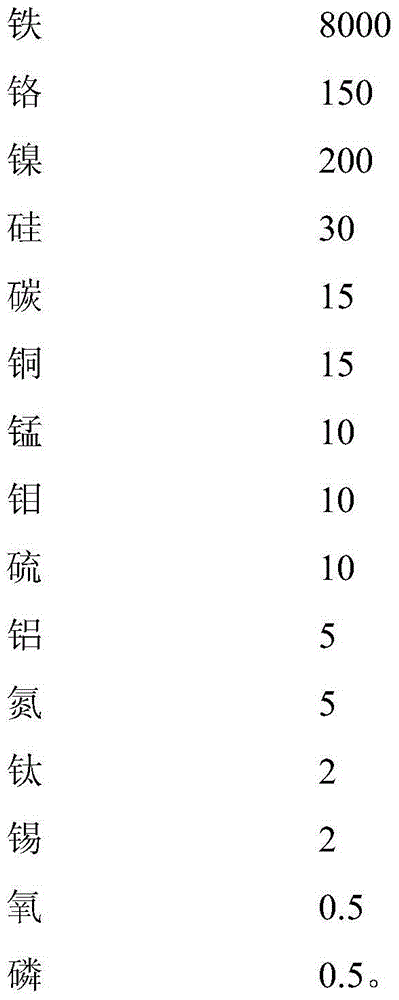

The invention relates to a carburized bearing steel, which consists of the following components by weight: iron, silicon, chromium, nickel, carbon, copper, manganese, molybdenum, sulfur, aluminum, nitrogen, titanium, tin, oxygen and phosphorus. The carburized bearing steel has high relative purity and long contact fatigue life, and the content of trace elements has no influence to purity while optimizing the comprehensive performance of carburized bearing steel. The carburized bearing steel has good comprehensive mechanical properties, and has hardness, strength, elongation and shrinkage degree superior to ordinary bearing steel, thus being suitable for extensive application.

Owner:DALIAN FEIMA OFFICE FURNITURE

Bainite steel wheel for rail traffic truck and manufacturing method of bainite steel wheel

InactiveCN108754329AReduce coefficient of frictionReduce wearFurnace typesProcess efficiency improvementCrack resistanceAlloy

The invention discloses a bainite steel wheel for a rail traffic truck and a manufacturing method of the bainite steel wheel. The bainite steel wheel for the rail traffic truck comprises the followingchemical components: 0.10-0.40% of C, 0.10-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb,0.0001-0.0350% of B, 0.001-0.040% of RE, less than or equal to 0.020% of P, less than or equal to 0.020% of S and the balance of Fe and inevitable residual elements; and moreover, 2.0%< / = Mn+ Cr< / = 3.0%. A novel alloy design system of C-Ni-Mn-Cr-Mo and an alloying principle are adopted, after wheels are formed and subjected to advanced heat treatment, a carbide-free bainite organization structureis obtained, and the wheels have excellent integrated mechanical property, corrosion resistance and service performance, and particularly have the characteristics of high strength, hardness and toughness, high wheel track rolling contact fatigue (RCF) resistance, hot crack resistance and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Heat treatment method of ultrahigh-carbon bearing steel

The invention discloses a heat treatment method of ultrahigh-carbon bearing steel. The ultrahigh-carbon bearing steel comprises the following components in percentage by weight: 1.5%-2.5% of C, 0.6%-1.2% of Mn, 0.01%-0.1% of V, 0.1%-1.0% of B, 0.1%-0.24% of Be, 0.2%-1.8% of Ni, 1.2%-1.8% of Si, 0.4%-0.8% of Ti, 0.05%-0.08% of W, 2.5%-4.5% of Cr, 0.12%-0.16% of Al, 0.05%-0.16% of Re and the balance Fe. The heat treatment method comprises the following steps: (S1) annealing, wherein the steel is insulated by 3-7 h at 780-820 DEG C, is cooled to 700-760 DEG C at a speed of 20-40 DEG C / h for insulation by 1-2 h, is cooled to 550-650 DEG C at a speed of 10-30 DEG C / h for insulation by 1-2 h, and is discharged from a furnace for air cooling; and (S2) normalizing, wherein the temperature in the furnace is increased to 900-980 DEG C; and the steel is put in the furnace for insulation by 2-3 h, and is cooled in air through dispersion. The heat treatment method can guarantee the improvement of the toughness of the bearing steel under the condition of not reducing the hardness, and prominently prolongs the contact fatigue life.

Owner:QINGDAO BRANCH CO., LTD. OF MECHANICAL SCIENCE RESEARCH INSTITUTE

Bearing having anodic nanoparticle lubricant

InactiveUS20050180671A1Efficient use ofImprove contact fatigue lifeShaftsBall bearingsNanoparticleLubricant

Owner:REGAL BELOIT AMERICA

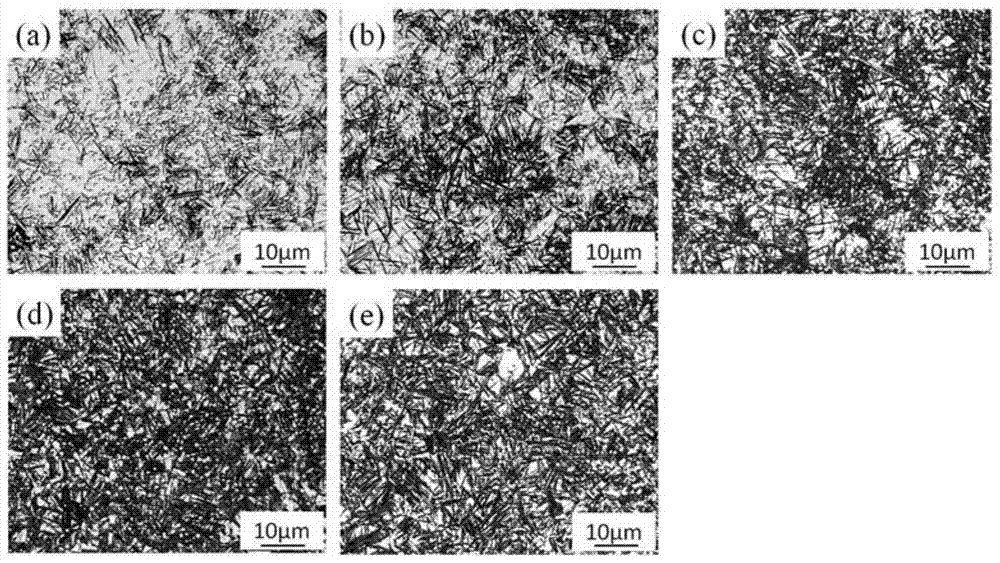

Production process method for reducing carbide mesh grade of GCr15 bearing steel bar

The invention discloses a production process method for reducing the carbide mesh grade of a GCr15 bearing steel bar, and relates to the field of metallurgical special steel production and manufacturing. According to the production process method for reducing the carbide mesh grade of the GCr15 bearing steel bar, in the produced bearing steel bar, the content range of C, Cr, Nb and Re meets the following formula: 1.7 < = 7.88 (% C) + 0.75 (% Nb) + 1.48 (% Re)-4.25 (% C) (% Cr) < = 1.8, and secondary cementite is promoted to be separated out to be finer, more dispersed and more uniform through the compounding and coordinating effect of all the elements; through component design, low-temperature rolling and rapid cooling after rolling, precipitation and aggregation growth of secondary carbides on a grain boundary are inhibited, so that the carbide mesh grade of the GCr15 bearing steel bar is controlled to be smaller than or equal to 1.0 grade, and the method is suitable for producing the bearing steel bar with the specification of phi 16-40 mm.

Owner:MAANSHAN IRON & STEEL CO LTD

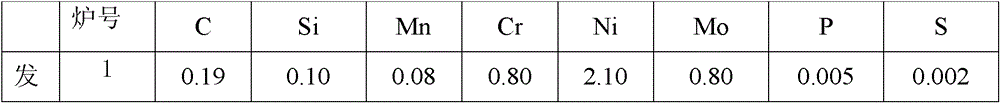

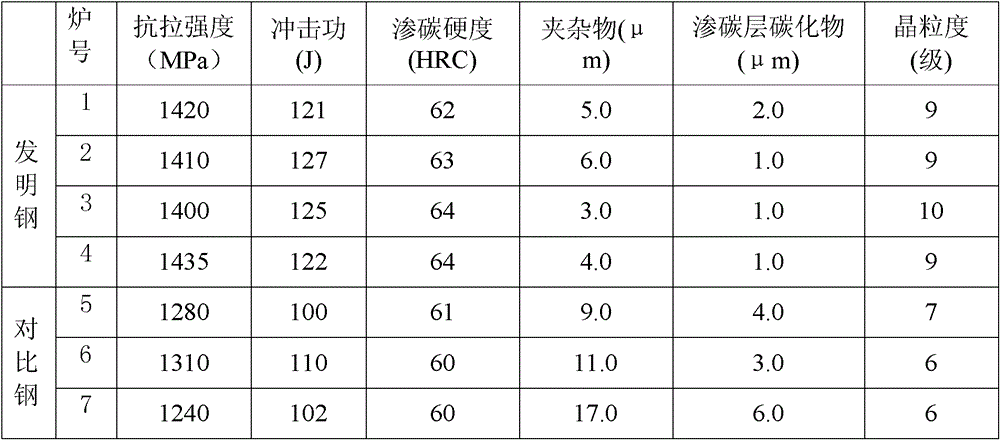

Carburizing bearing steel and preparation method thereof

ActiveCN112030065AImprove contact fatigue lifeImprove tissue uniformityShaftsBearing componentsCarbideCarburizing

Owner:CENT IRON & STEEL RES INST

Bainite steel wheel for rail traffic passenger car and manufacturing method thereof

PendingCN108728750AReduce coefficient of frictionImprove operational efficiencyRail-engaging wheelsFurnace typesDesign systemsCorrosion

The invention discloses a bainite steel wheel for a rail traffic passenger car and a manufacturing method thereof. The bainite steel wheel comprises the chemical components of 0.08-0.35% of C, 0.10-1.50% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, 0-0.020% of P, 0-0.020% of S, and the balance Fe and inevitable residual elements, and in addition, the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. According to thebainite steel wheel for the rail traffic passenger car and the manufacturing method thereof, the novel C-Ni-Mn-Cr-Mo alloy design system and the alloying principle are adopted, after the wheel is formed, advanced heat treatment is conducted, then, the carbide-free bainite structure of a rim is obtained, and the wheel has the characteristics of being excellent in comprehensive mechanical property,corrosion resistance and service performance, high in strength, hardness, toughness, wheel rail rolling contact fatigue (RCF) resistance and hot crack resistance, and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

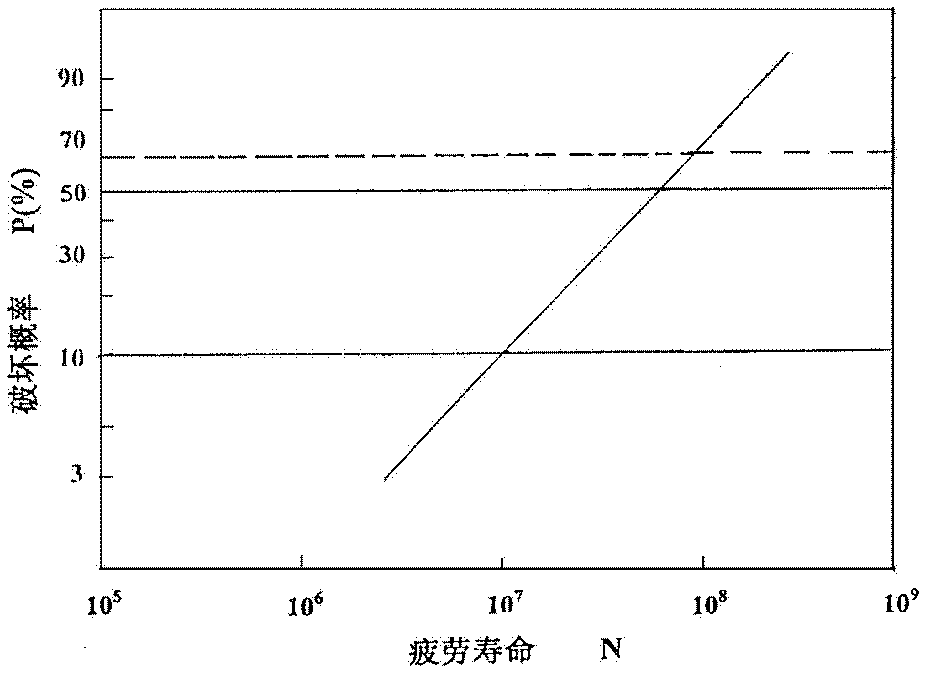

Rare earth-containing high-carbon chromium bearing steel and preparation method thereof

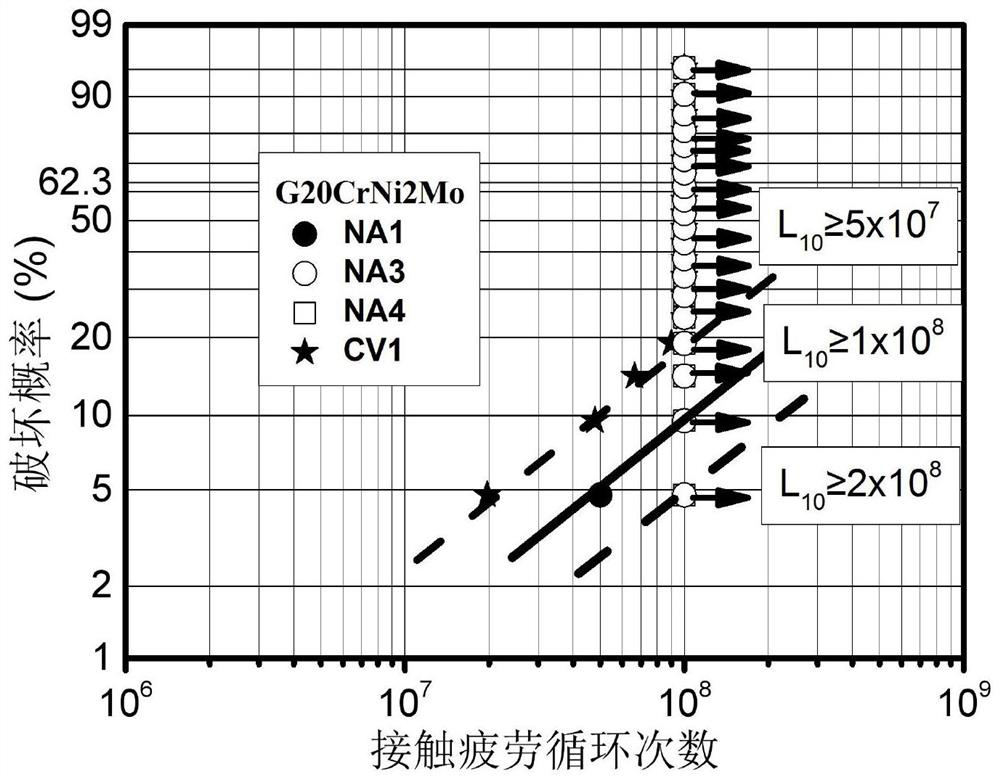

The invention provides rare earth-containing high-carbon chromium bearing steel and a preparation method thereof. The rare earth-containing high-carbon chromium bearing steel is prepared from, by weight, 0.95-1.05% of C, 0.15-0.30% of Si, 0.25-0.40% of Mn, 0.010% or less of P, 0.010% or less of S, 1.50-1.75% of Cr, 0.015-0.035% of RE, 3-5 ppm of O, and the balance of iron and inevitable impurities through blast furnace ironmaking, molten iron pretreatment, converter steelmaking, LF refining, RH refining and continuous casting. The rare earth alloy is divided into two parts, and the two parts are added in two stages after converter tapping and RH vacuum breaking, a better effect can be achieved after the rare earth alloy is matched with an electroslag remelting process, and the contact fatigue life L10 is larger than or equal to 6.1 * 10<7> times.

Owner:UNIV OF SCI & TECH BEIJING

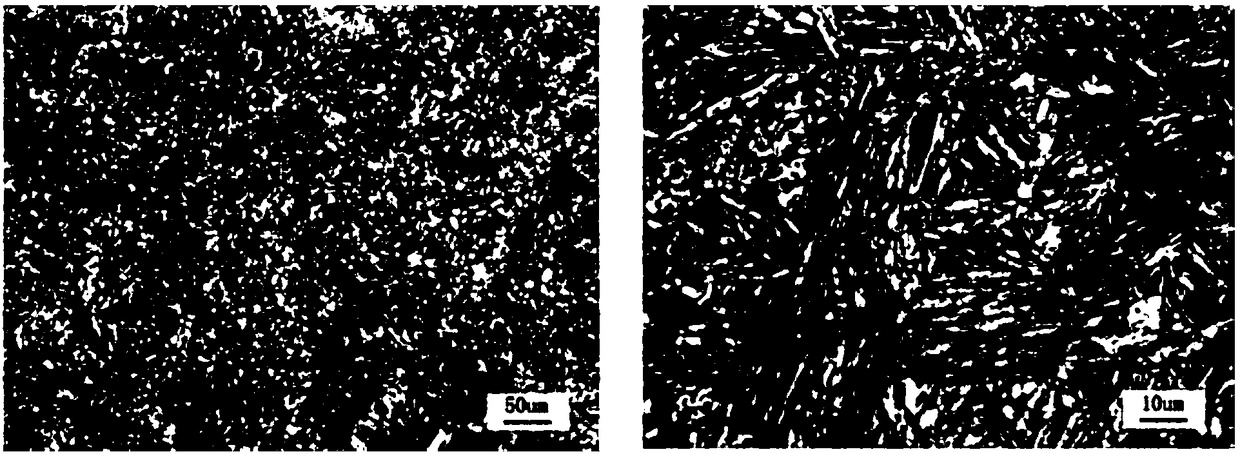

Bearing material

InactiveUS20030136474A1Excellent rolling contact fatigue lifeProcess controlBearing componentsFurnace typesGeneral purposeNon-metallic inclusions

A long-life bearing steel for general purpose use is provided at low cost with no use of specific secondary refining process. Specifically, a bearing material having a component composition in which C: 0.95 to 1.10 mass %, Si: 0.15 to 0.70 mass %, Mn: 1.15 mass % or less, Cr: 0.90 to 1.60 mass %, and P: 0.025 mass % or less are contained, S and O, that are elements forming nonmetallic inclusions, are contained at S: 0.025 mass % or less and O: 0.0012 mass % or less, and the rest is composed of Fe and incidental impurities, wherein the maximum diameter of the oxide-based nonmetallic inclusion is more than 10 mum, but 15 mum or less in an inspection area: 320 mm2, the number of oxide-based nonmetallic inclusions having an equivalent circle diameter of 3 mum or more is 250 or less in the inspection area: 320 mm2, while in the material, AlN is contained at 0.020 mass % or less, and or the number of sulfide-based nonmetallic inclusions having a thickness of 1 mum or more is 1,200 or less in the inspection area: 320 mm2.

Owner:JFE STEEL CORP +1

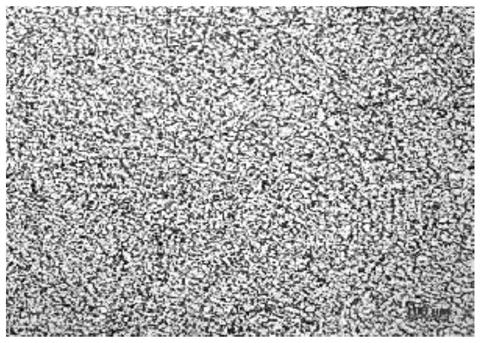

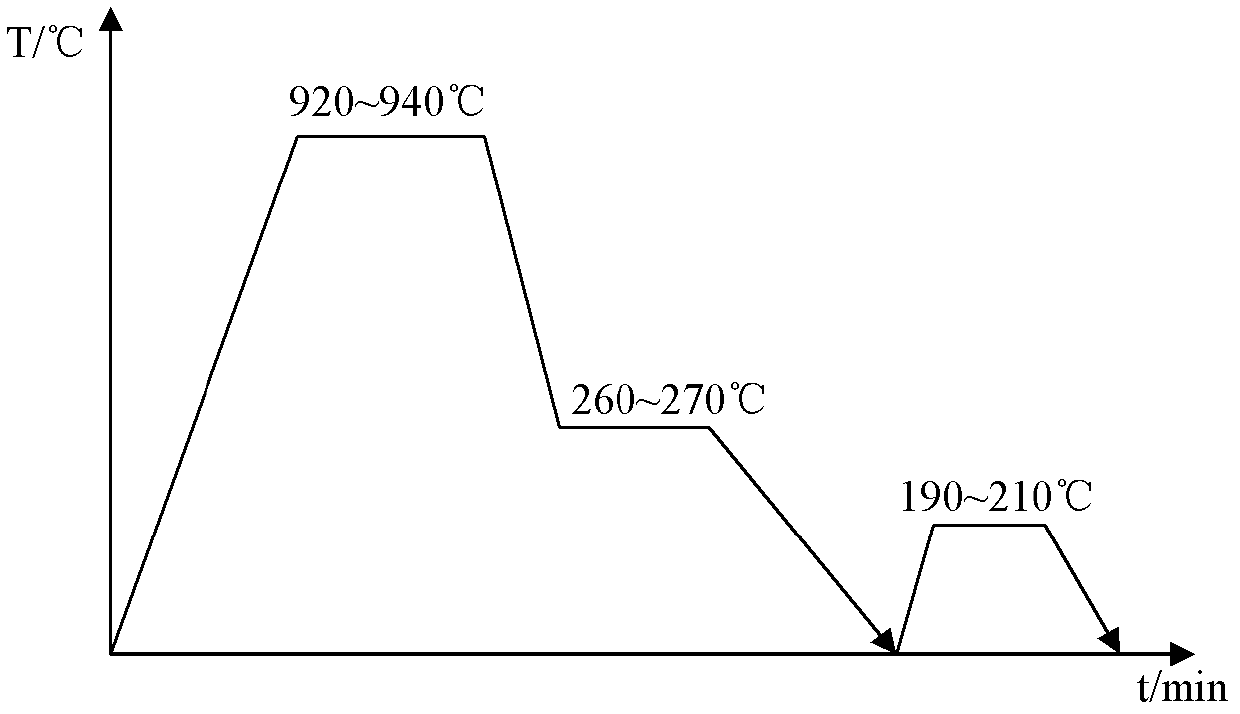

Bainite isothermal quenching thermal treatment process method for medium-carbon bearing steel

ActiveCN102534134BImprove performanceImprove wear resistanceQuenching agentsEconomic benefitsHardness

The invention relates to a bainite isothermal quenching thermal treatment process for medium-carbon bearing steel. The process comprises the following steps of: performing normalizing treatment to obtain a flaky pearlite structure; then performing spheroidizing annealing treatment to obtain a fine and uniform spheroidized structure; and performing bainite isothermal quenching and low-temperature tempering treatment on a spheroidized steel member. The bearing treated by the process method has high hardness, high impact toughness, high wear resistance and long fatigue life, meets the requirements of bearing performance of impact-resistant and heavy-load metallurgical mines, petroleum and the like well, and has better economic benefit.

Owner:LAIWU IRON & STEEL GRP

High-toughness carburized bearing steel with ultra-long contact fatigue life and preparation method thereof

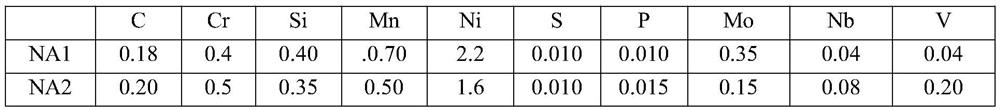

The invention relates to a high-toughness carburized bearing steel with ultra-long contact fatigue life and a preparation method thereof, belonging to the technical field of alloy steel. The steel comprises the following chemical components in percentage by weight: 0.16-0.24% of C, at most 0.10% of Si, at most 0.10% of Mn, 0.30-1.50% of Cr, 1.5-4.5% of Ni, 0.30-1.50% of Mo, 0.02-0.10% of Nb, 0.3-0.9% of V, and the balance of Fe and inevitable impurities, wherein [N]+[O]+[H]+P+S<=0.0080%, and Ti<=0.0030%. The invention particularly relates to a high-toughness carburized bearing steel which has the advantages of high shock resistance load, stable dimension and ultra-long contact fatigue life in the serve process. Compared with the prior art, the invention has the advantages of high surface hardness, high core toughness, high dimensional stability, high bending fatigue strength limit and ultra-long contact fatigue life.

Owner:CENT IRON & STEEL RES INST

Case hardening bearing steel having excellent toughness and rolling contact fatigue life in intermediate temperature

InactiveUS7413704B2Prolong lifeImprove toughnessSolid state diffusion coatingFurnace typesRolling contact fatigueNon-metallic inclusions

A case hardening bearing steel having an excellent rolling contact fatigue life in intermediate temperature, in addition, excellent toughness at room temperature is provided. Specific means for solving the problems are as follows. The composition contains, by mass percent, C of 0.15 to 0.30 mass percent, Si of 0.5 to 2.0 mass percent, Mn of 0.3 to 2.0 mass percent, Cr of 1.3 to 2.5 mass percent, Mo of 0.3 to 1.0 mass percent, and O of not more than 0.0012 mass percent in a range where (Si+Mo)≧1.0 mass percent is satisfied, and contains iron and inevitable impurities as remnant; the maximum size of oxide nonmetallic inclusion is not more than 12.5 μm when examined area is 320 mm2; number of the oxide nonmetallic inclusion having a diameter of equivalent circle of 3 μm or more is not more than 250 when the examined area is 320 mm2; in addition, C density of an outer layer is adjusted to be in a range from 0.7 to 1.2 mass percent by carburization.

Owner:JFE STEEL CORP +1

Bainite steel wheel for rail traffic heavy-duty freight car and manufacturing method thereof

InactiveCN108796371AHigh yield strengthHigh tensile strengthFoundry mouldsFurnace typesCrack resistanceAlloy

The invention discloses a Bainite steel wheel for rail traffic heavy-duty freight car and a manufacturing method thereof. The Bainite steel wheel comprises the chemical components of 0.10-0.40% of C,0.40-2.10% of Ni, 0.25-1.50% of Cr, 0.70-2.10% of Mn, 0.20-1.00% of Si, 0.01-1.00% of W, 0.05-0.60% of Mo, 0.01-0.80% of Cu, 0.01-0.20% of V, 0.001-0.20% of Nb, 0.0001-0.0350% of B, 0.001-0.040% of RE, less than or equal to 0.020% of P, less than or equal to 0.020% of S, and the balance Fe and inevitable residual elements, specifically, the sum of Mn and Cr is larger than or equal to 2.0% and smaller than or equal to 3.0%. By adoption of a novel alloy design system and alloying principle of C-Ni-Mn-Cr-Mo, after the wheel is formed, a rim is of a carbide-free Bainite tissue structure after advanced thermal treatment, and the wheel has excellent comprehensive mechanical properties, corrosion resistance and service performance, and particularly has the characteristics of high strength, hardness and toughness, high wheel track rolling contact fatigue (RCF) performance and hot crack resistance, and the like.

Owner:MAGANG (GROUP) HOLDING CO LTD +1

Carburized bearing roller processing technology

InactiveCN106435397AHigh purityPurity does not affectSolid state diffusion coatingFurnace typesExtensibilityChemical composition

The invention discloses a carburized bearing roller processing technology. The technology comprises the steps that forging is carried out, chemical components in a forged blank comprise, by weight percentage, 0.95-1.05% of C, 0.5-1.2% of N, 0.3% of Mn, 0.2-0.3% of Ni, 0.15-0.35% of Si, 0.020% of S:B, 0.027% of P:B and 1.30-1.65% of Cr, the forged blank is heated to 600 DEG C-700 DEG C, forging is carried out, then heating is carried out to 600 DEG C-800 DEG C, heat is preserved for 5-7 hours, cooling is carried out at the speed of 22 DEG C per hour to 300 DEG C, and then cooling is carried out to normal temperature at the speed of 20 DEG C per hour. According to the technology, the relative purity of carburized bearing roller steel is high, the contact fatigue life is long, and while the content of microelements has the function of optimizing comprehensive performance of the carburized bearing roller steel, the influence on the purity of the carburized bearing roller steel is avoided; and the obtained carburized bearing roller steel has good comprehensive mechanical performance, hardness, strength, extensibility, the shrinkage degree and the like of the carburized bearing roller steel are better than those of common bearing steel, and the carburized bearing roller steel is suitable for being widely applied to poor working conditions such as heavy loads, impact resistance and high pressure and important parts.

Owner:安徽千禧精密轴承制造有限公司

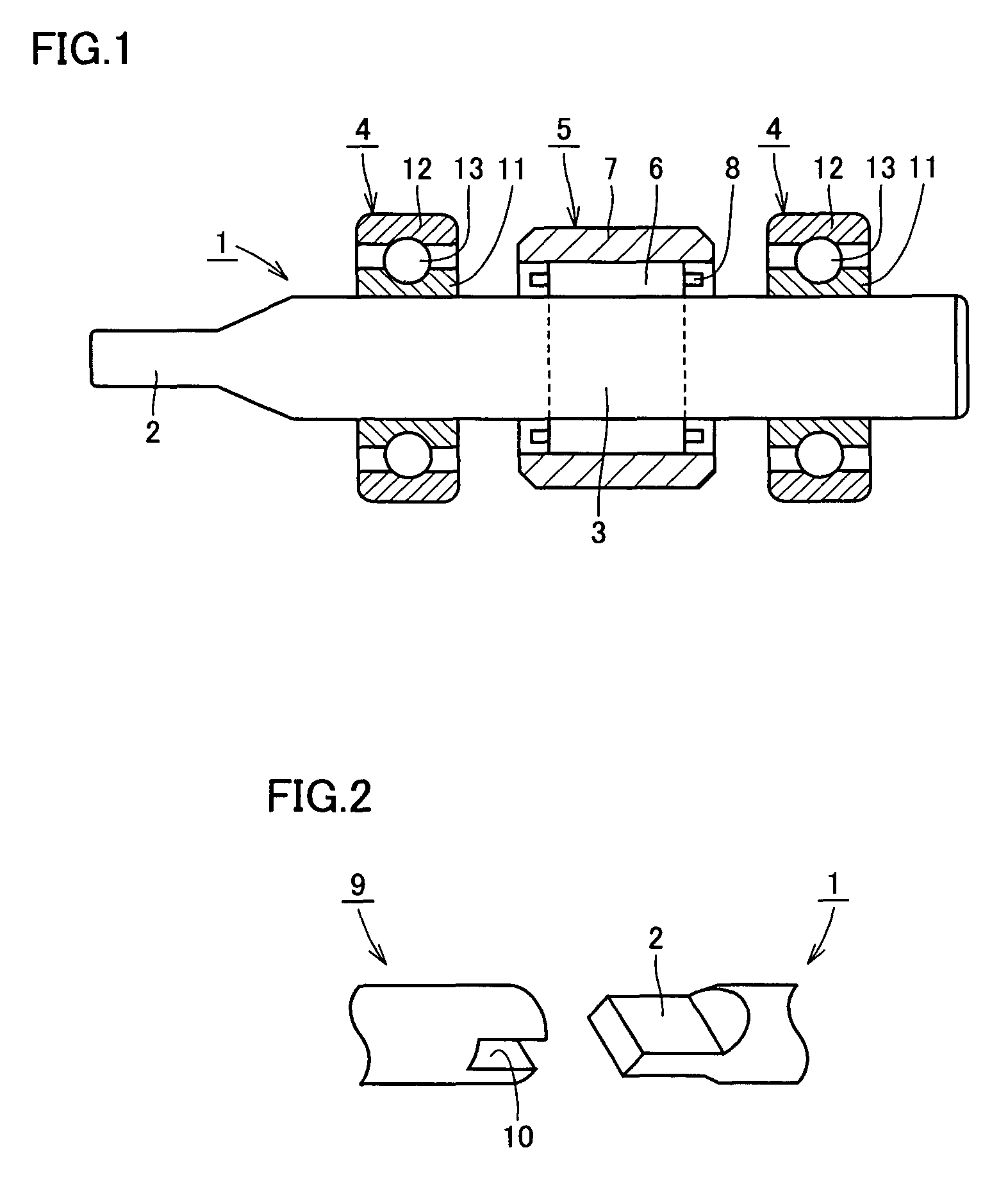

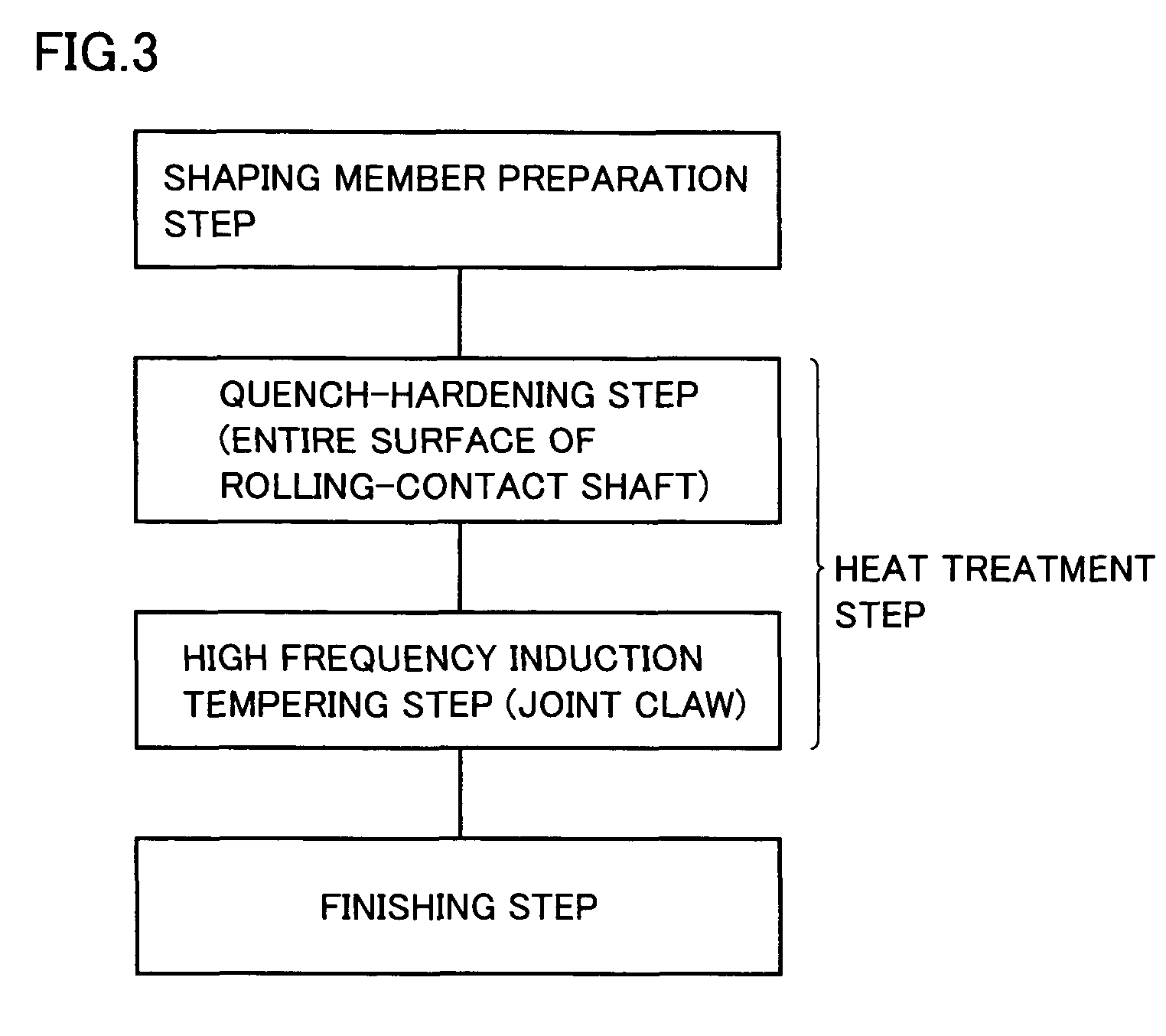

Rolling-contact shaft with joint claw

ActiveUS8066826B2Improve contact fatigue lifeShaftsBearing componentsNeedle roller bearingSurface layer

A steel-made rolling-contact shaft with a joint claw improved in both the rolling contact fatigue life at the raceway and the static fracture strength (torsional strength) at the claw includes a joint claw at one end, and has a portion of the outer cylindrical surface functioning as a raceway of a needle roller qualified as a rolling element of a needle bearing. The joint claw is subjected to tempering by induction heating. A nitrogen-enriched layer is formed at the surface layer of the rolling-contact shaft with a joint claw. The grain size number of austenite grains in the nitrogen-enriched layer exceeds number 10. The hydrogen content of the rolling-contact shaft with a joint claw is not more than 0.5 ppm.

Owner:NTN CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com