Controlled cooling process and water cooler for high carbon and chromium bearing steel pipe blank after hot rolling

A high-carbon chromium bearing and controlled cooling technology, used in heat treatment process control, manufacturing tools, heat treatment furnaces, etc., can solve the problems of reducing rolling mill output, long spheroidizing annealing time, and deteriorating production environment, and achieve high contact fatigue life, The effect of shortening spheroidizing annealing time and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

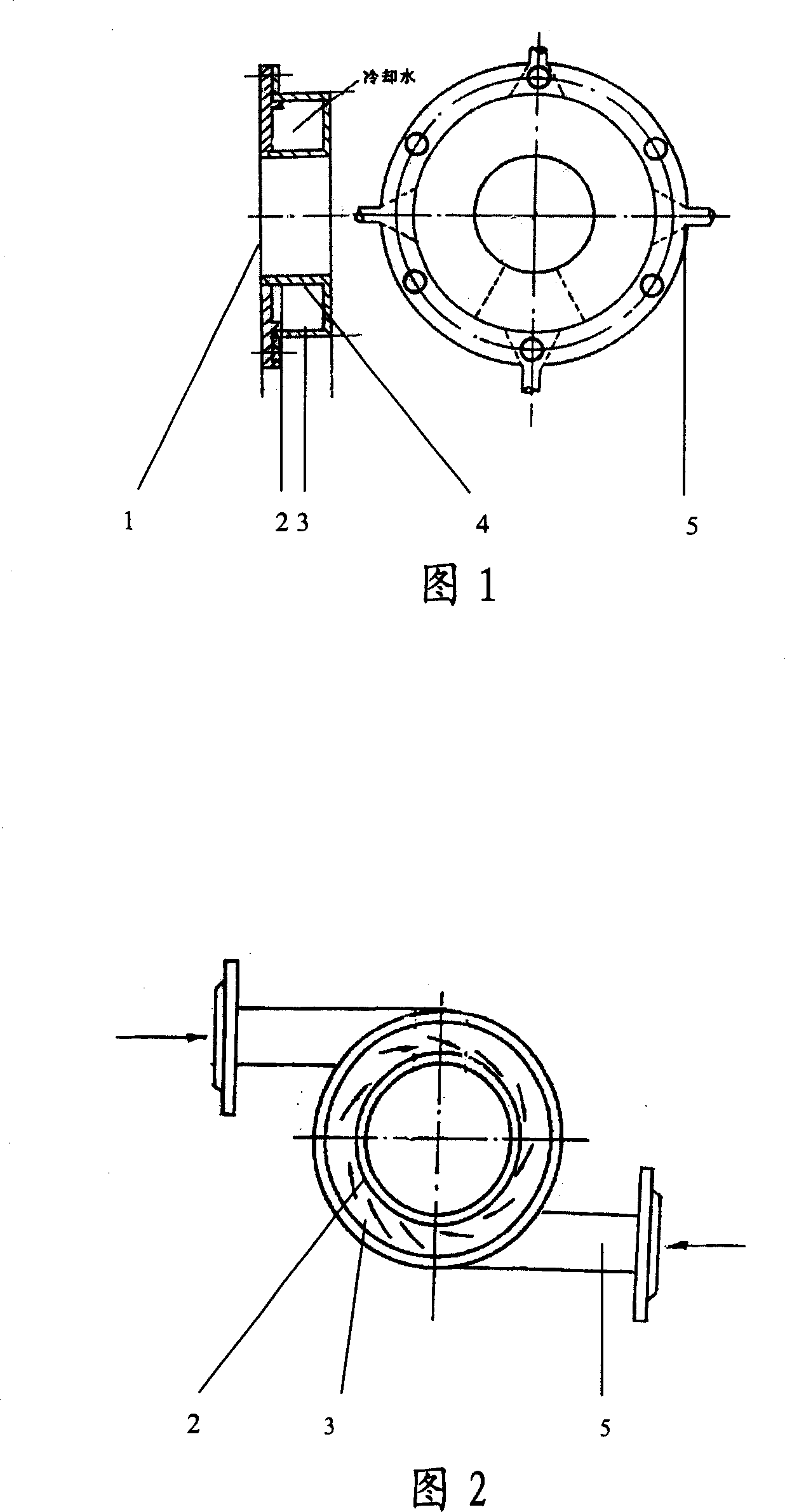

Image

Examples

Embodiment 1

[0031] On-site production of φ95mm×8mm tube blanks in a steel factory

[0032] Brand: high carbon chromium bearing steel GCr15.

[0033] Heat number: 550 / 1692.

[0034] Heating temperature, piercing and final rolling temperature: Heating temperature: 1130-1150°C, the heated tube billet is sent to the φ76 piercing unit for primary piercing and secondary piercing, and the final rolling temperature after primary piercing is 1140-1160°C and secondary piercing The final final rolling temperature is 950-1030°C, and the temperature after the steel pipe hammer is 880-920°C, and then sent to the water cooler by the V-shaped conveying roller for the controlled cooling process.

[0035] Controlled cooling process: Four sets of water coolers are installed at certain intervals on the cooling line, the linear speed of the raceway is 0.7 m / s, water cooling and air cooling are carried out alternately, water cooling time: air cooling time = 1:4. The surface temperature of the steel pipe bill...

Embodiment 2

[0050] On-site production of φ86mm×6mm tube blanks in a steel factory

[0051] Brand: high carbon chromium bearing steel GCr15.

[0052] Furnace number: 550 / 1721.

[0053] Heating temperature, piercing finish rolling temperature: Heating temperature: 1120~1140℃, the heated tube billet is sent to φ76 piercing unit for primary piercing and secondary piercing, the final rolling temperature after primary piercing is 1120~1150℃ and secondary piercing The final final rolling temperature is 920-1010°C, and the temperature after the steel pipe hammer is 870-910°C, and then sent to the water cooler by the V-shaped conveying roller for controlled cooling process.

[0054] Control cooling process: install four sets of water coolers at certain intervals on the cooling line, the linear speed of the raceway is 0.85 m / s, water cooling and air cooling are performed alternately, water cooling time: air cooling time = 1:4. . The surface temperature of the steel pipe billet before entering th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com