Steel for cold working machine structures, and method for producing same

A technology of mechanical structure and manufacturing method, which is applied in the field of steel for cold working mechanical structure and its manufacturing, and can solve the problems of softness that has not been disclosed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

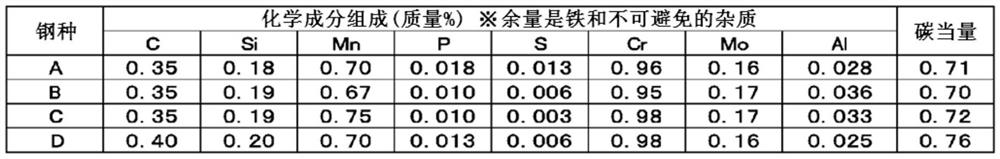

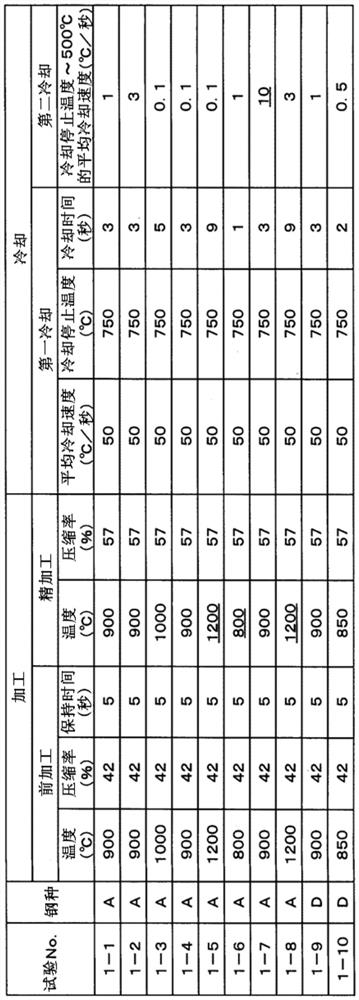

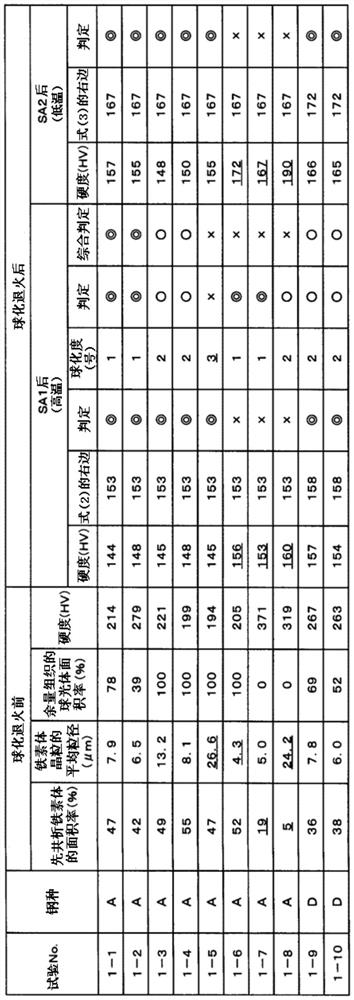

[0128] Using steels with the chemical compositions shown in steel types A and D in Table 1, make A test piece for processing Formaster. Pressing and cooling were carried out with the Formaster test machine under the conditions described in Table 2 using the produced test piece for Formaster processing. Although not described in Table 2, in the cooling in the temperature range of 500° C. or lower, when the average cooling rate during the second cooling is 1° C. / second or more, the average cooling rate during the second cooling is cooled to around room temperature ( 25°C to 40°C), when the average cooling rate during the second cooling is lower than 1°C / s, gas quenching is adopted.

[0129] In Table 1 and Table 2, and Tables 3 to 5 described later, the underlined numerical values indicate a range that deviates from the embodiment of the present invention. In addition, in the column of carbon equivalent of Table 1, the value calculated by following formula (1) is described. ...

Embodiment 2

[0179] Using steels having the chemical composition shown in steel types B and C in Table 1, rolling and cooling were carried out under the conditions in Table 4 on an actual rolling line. In addition, in the rolling line of the real machine, the heating furnace, roughing mill, intermediate rolling mill, intermediate water-cooled belt, wheel rolling mill, sizing rolling mill, product water-cooled belt, cooling conveyor and three-dimensional warehouse are connected in sequence. The processing is carried out with a rolling mill, the finishing is carried out with a sizing mill, and the first cooling and the second cooling are carried out by a cooling conveyor. Although not described in Table 4, the cooling in the temperature range of 500° C. or less was performed by cooling to about 400° C. at the average cooling rate during the second cooling, and then allowing to cool. Samples were taken from the obtained rolled material, and one of them was used as a sample without spheroidizi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com