Metallic member being subjected to rust-preventive treatment and coating composition for the same

A metal parts, anti-rust treatment technology, applied in the direction of anti-corrosion coatings, metal layered products, epoxy resin coatings, etc., can solve the problem of difficult to peel off the coating, hard to soften the coating, and difficult to maintain long-term antirust of the composite zinc film role and other issues, to achieve the effect of inhibiting peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

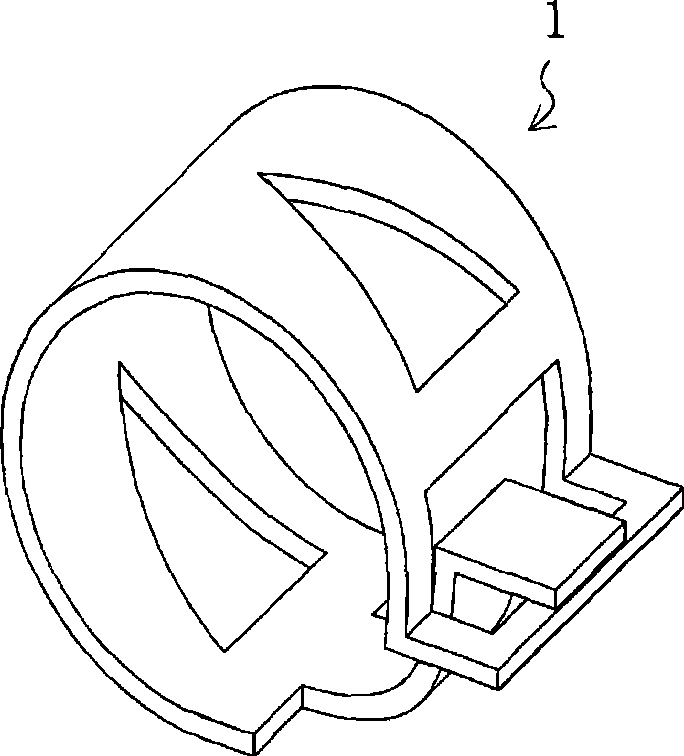

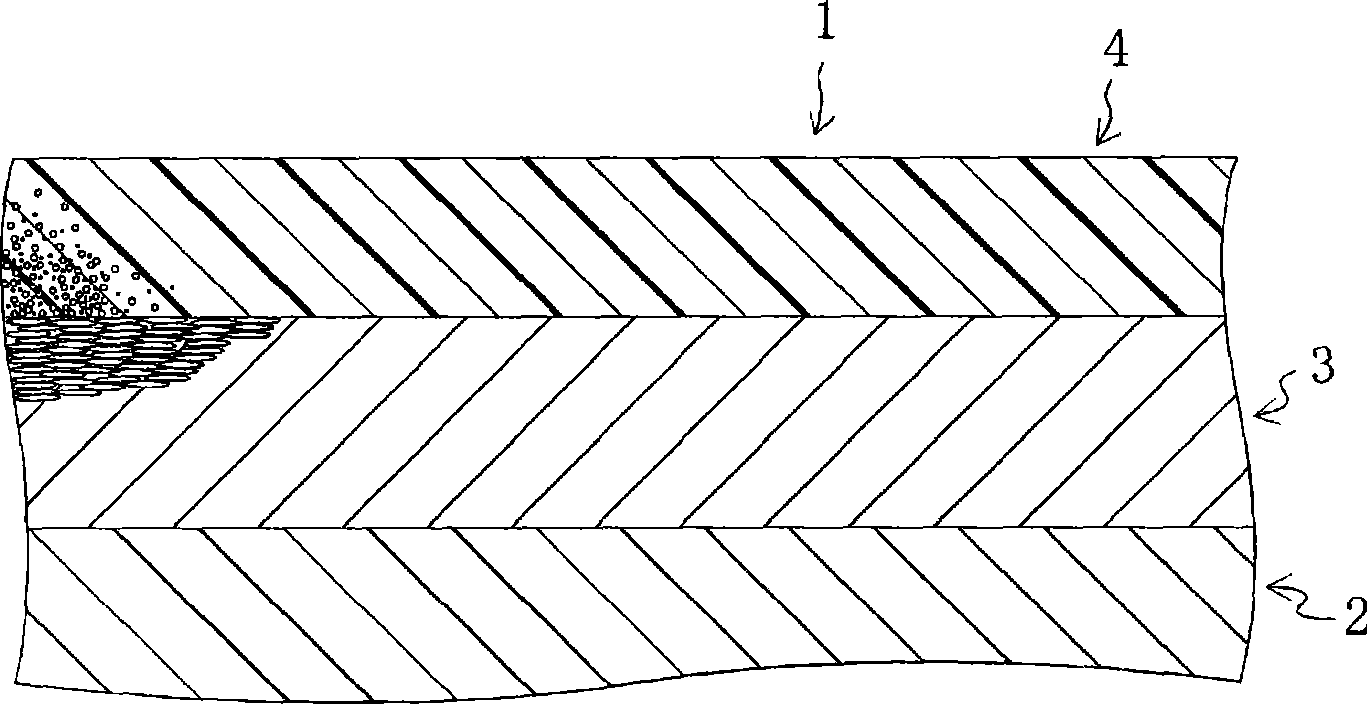

[0058] exist figure 1 A perspective view schematically showing the antirust metal part of Example 1 is shown in . exist figure 2 A cross-sectional view schematically showing the rust-proof metal part of Example 1 is shown in .

[0059] Such as figure 1 As shown in , the antirust metal part 1 of Example 1 is a hose clamp. Such as figure 2 As shown in , the antirust metal part 1 of Example 1 has a metal part 2 , a zinc composite protective film 3 formed on the upper layer of the metal part 2 , and a coating 4 formed on the upper layer of the zinc composite protective film 3 .

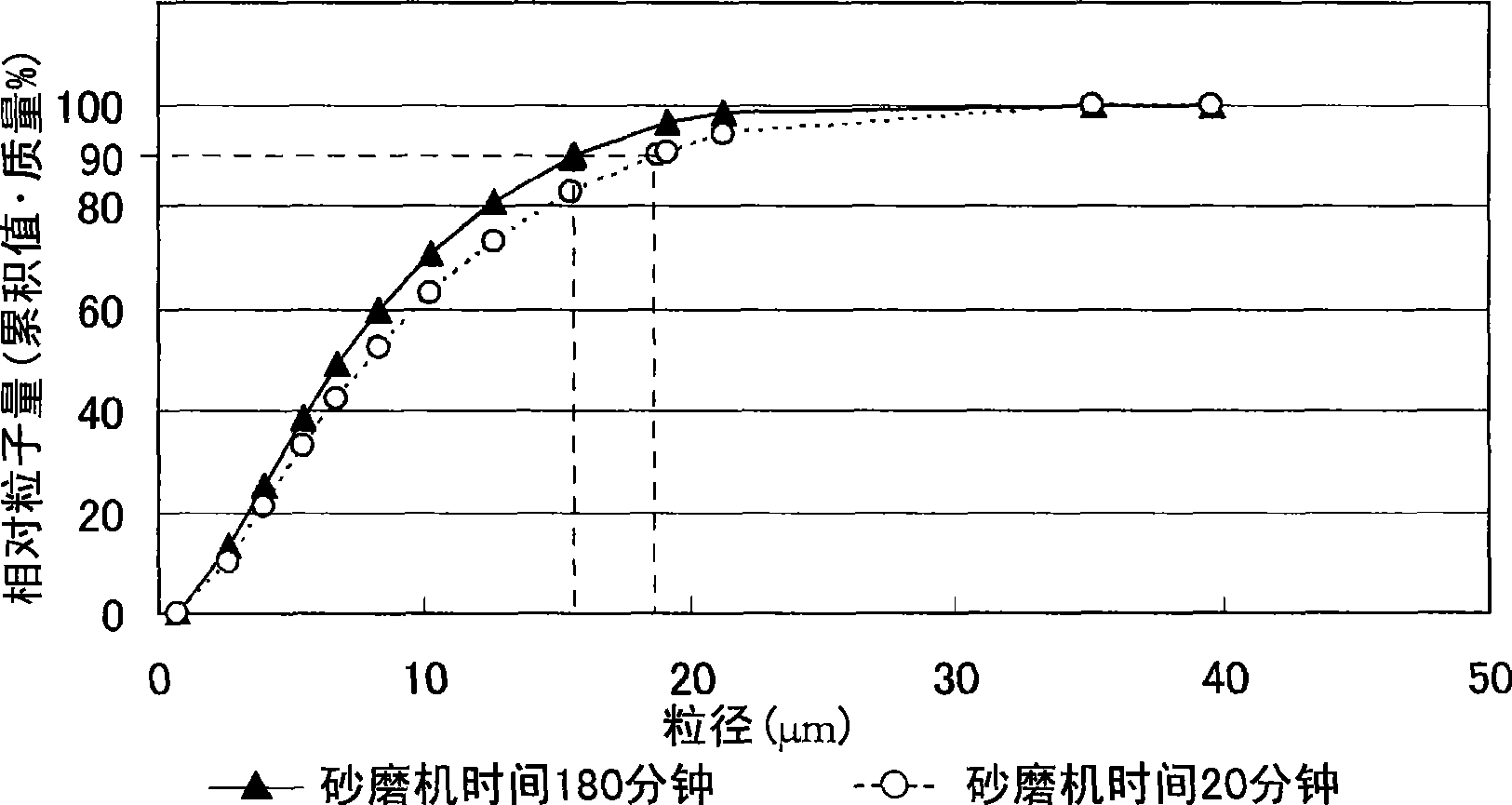

[0060] Metal part 2 is made of steel. and figure 1 The hose clamps shown in are essentially the same shape. As a material of the zinc composite protective film (hereinafter referred to as film material), Geomet 720 (manufactured by Nippon Dakoshi Yamarock) was used. As a coating material (coating paint), 14 parts by mass of epoxy resin (resin material), 21 parts by mass of magnesium silicate (fi...

Embodiment 2

[0065] The antirust metal part of Example 2 is the same as the antirust metal part of Example 1 except for the composition of the coating material. In the antirust metal part of Example 2, as the coating material, 14 parts by mass of phenolic resin (resin material), 21 parts by mass of magnesium silicate, 5 parts by mass of zinc phosphate, 5 parts by mass of titanium oxide, and 55 parts by mass of methyl ethyl ketone were used mixture. With respect to 100% by mass of the coating, the coating in the antirust metal part of Example 2 contains about 31% by mass of resin material, about 47% by mass of filler pigment, about 11% by mass of antirust pigment and about 11% by mass of Coloring pigments. In addition, the stirring time for coating the powder material in Example 2 was 180 minutes.

Embodiment 3

[0067] The antirust metal part of Example 3 is the same as the antirust metal part of Example 1 except for the composition of the coating material. In the antirust metal parts of Example 3, as the coating material, 7 parts by mass of epoxy resin, 7 parts by mass of phenolic resin, 21 parts by mass of magnesium silicate, 5 parts by mass of zinc phosphate, 5 parts by mass of titanium oxide and 55 parts by mass of A mixture of parts by mass of methyl ethyl ketone. With respect to 100% by mass of the coating, the coating in the antirust metal part of Example 3 contains about 31% by mass of resin material, about 47% by mass of filler pigment, about 11% by mass of antirust pigment and about 11% by mass of Coloring pigments. In addition, the stirring time for coating the powder material in Example 3 was 180 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com