Washing preshrinking setting machine

A setting machine and water washing technology, which is applied to dry cleaning fiber products, textile processing machine accessories, vibration treatment, etc., can solve the problems of increased labor intensity and technical requirements, complicated procedures, serious wastewater discharge, etc., and improve the effect of preshrinking , Reduce time cost and labor cost, use flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments. It should be pointed out that the scope of protection of the present invention is not limited to the following embodiments. Retouching should be regarded as the scope of protection of the present invention.

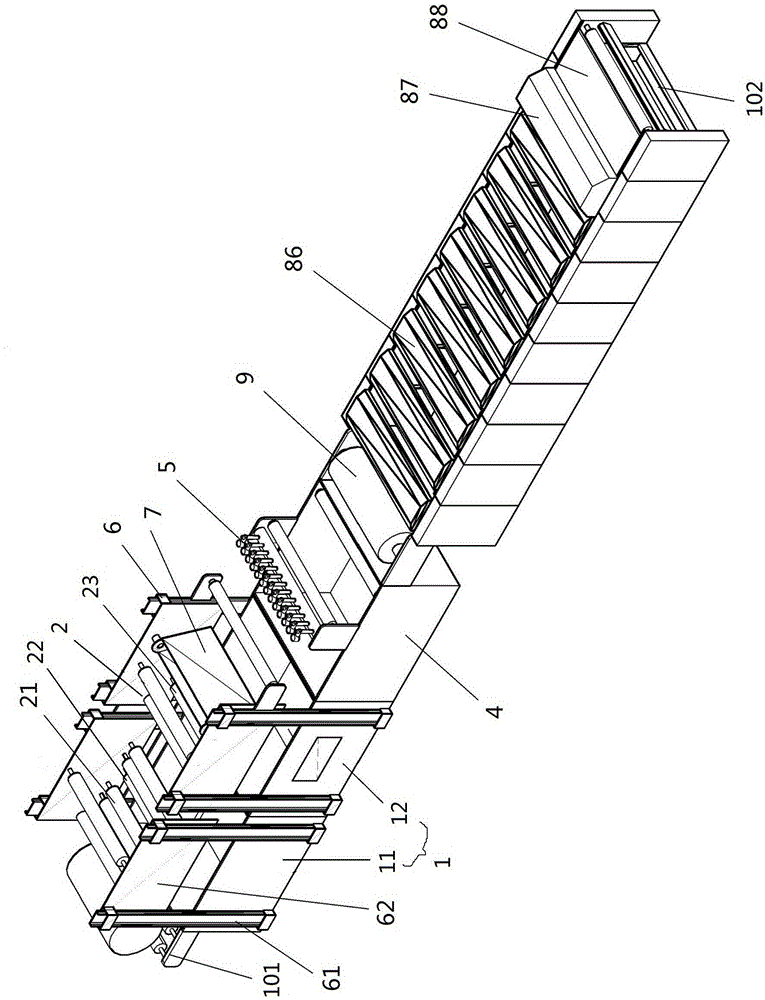

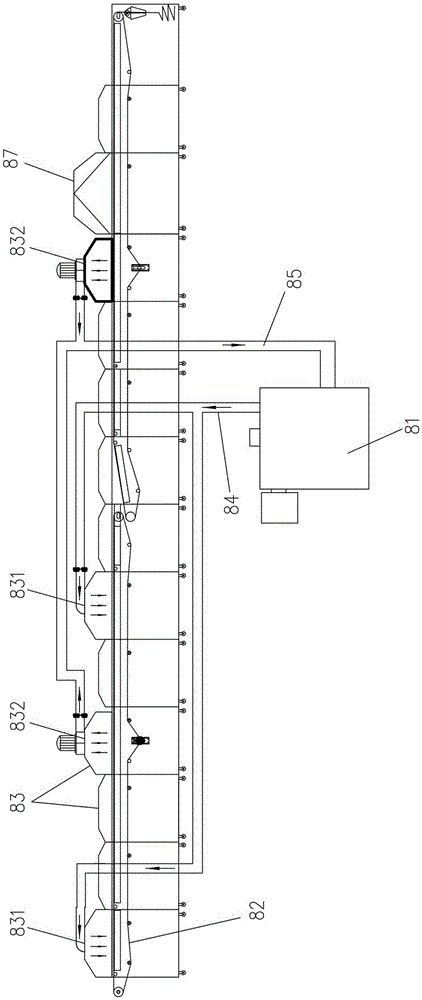

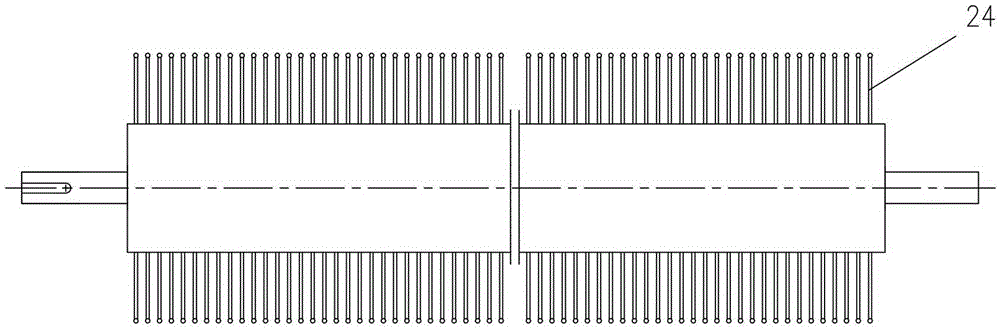

[0027] like figure 1 As shown, the washing water pre-shrinking and setting machine of the present invention includes a washing water assembly and a drying assembly. A cloth folding device 102 for collecting cloth is provided. The washing water assembly includes a scrubbing section and a clear water spray section arranged in sequence according to the procedure, and the scrubbing section is provided with a scrubbing water tank 1 and a cloth guide roller group 2 . The cloth guide roller group 2 is composed of a plurality of cloth guide rollers, and at least has a desizing guide roller 21 , a squeezing cloth guide roller 22 and a fla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com