Shrinkage treatment machine

A processing machine and support seat technology, applied in the direction of adding compressed water, spraying/jetting textile material processing, textile and papermaking, etc., can solve the problems of affecting the production quality of fabrics, insufficient high-temperature steam injection of fabrics, uneven running speed of fabrics, etc. , to achieve the effect of improving the effect of pre-shrinking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

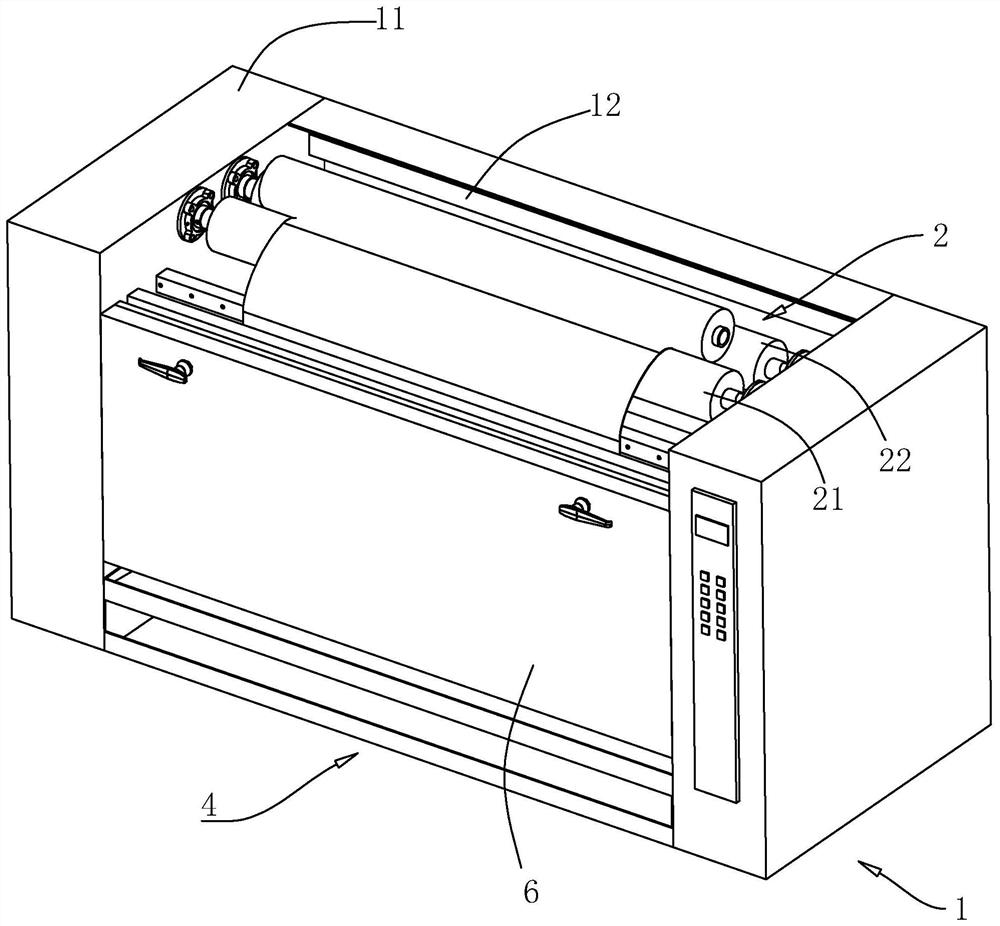

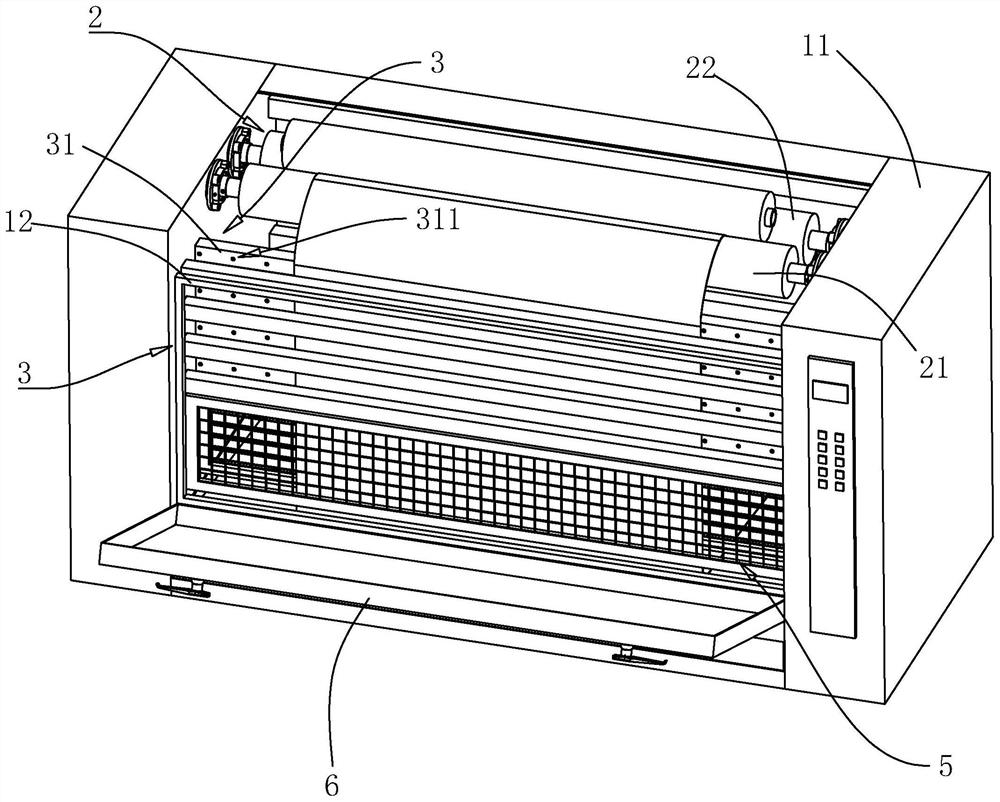

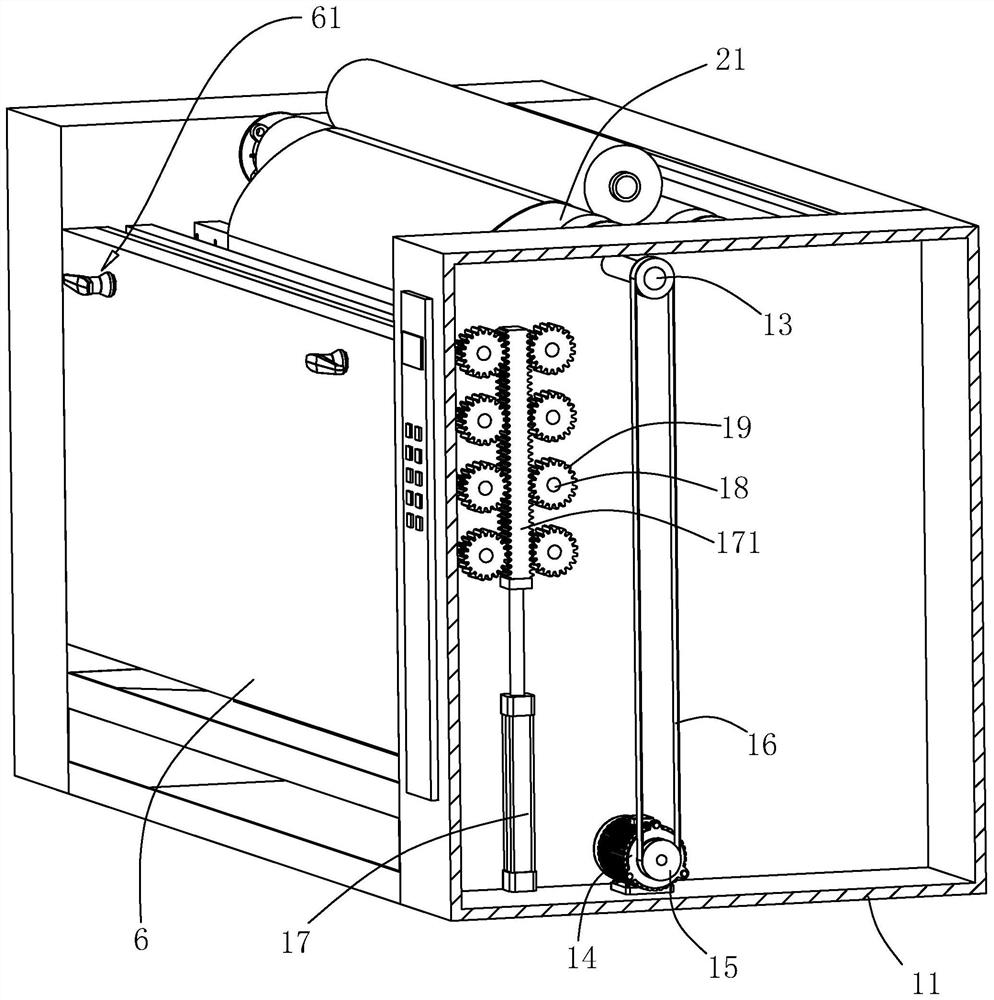

[0037] The embodiment of the present application discloses a shrinkage treatment machine. refer to figure 1 , the shrinking treatment machine includes a support assembly 1, a drive assembly 2 located on the support assembly 1, an air jet assembly 3 and a material receiving assembly 4; 3 is used to spray high-temperature steam on the fabric to realize the pre-shrinking treatment of the fabric, and the material receiving component 4 is used to receive and temporarily store the processed fabric.

[0038] refer to figure 1 and figure 2 The support assembly 1 includes two symmetrically arranged support bases 11 and a plurality of reinforcing rods 12 arranged between the two support bases 11. The plurality of reinforcing rods 12 are divided into two groups and arranged near the two sides of the support base 11. The reinforcing rods 12 The two ends of the two support bases 11 are respectively fixedly connected, so that the two support bases 11 are connected together to facilitate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com