Patents

Literature

154results about How to "Reduce tension fluctuations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

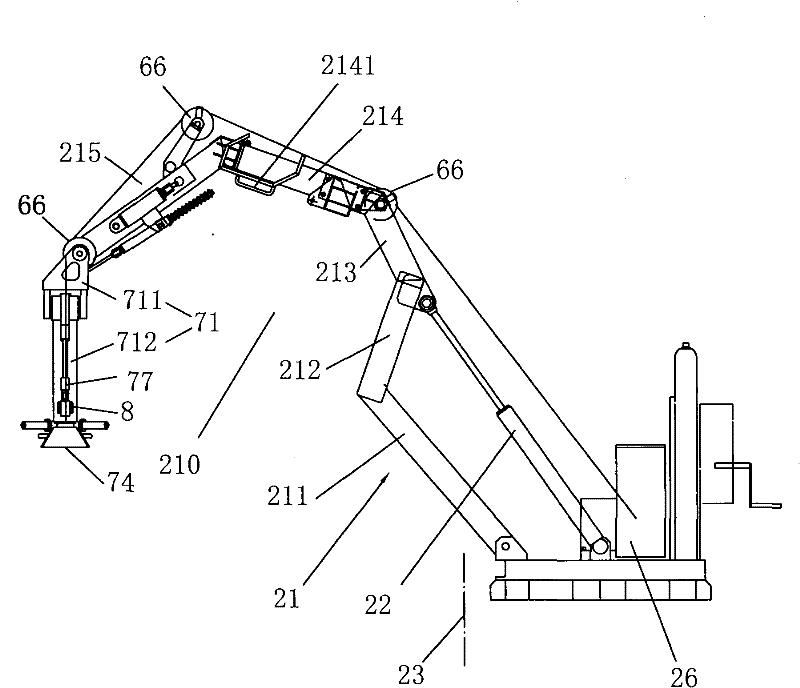

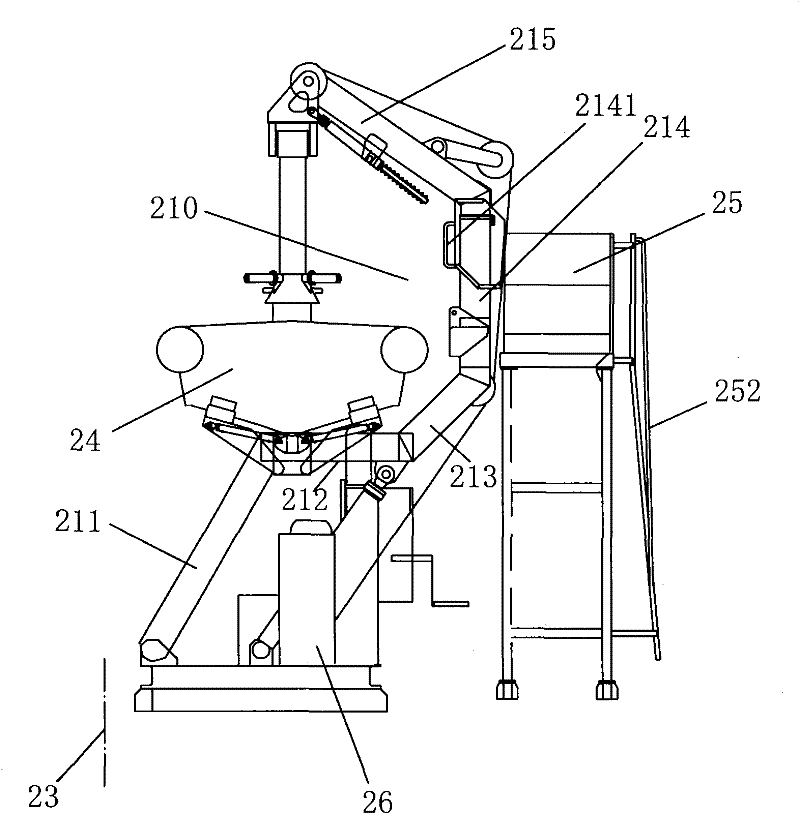

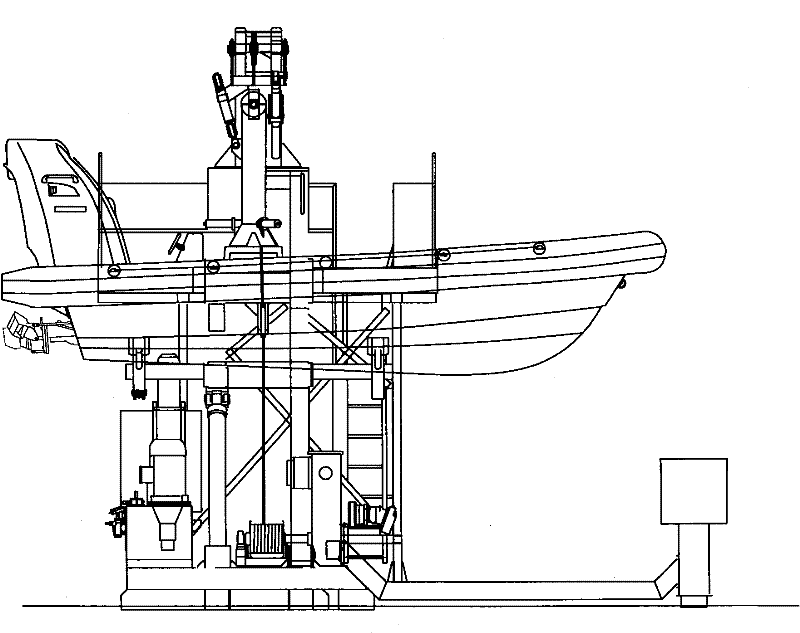

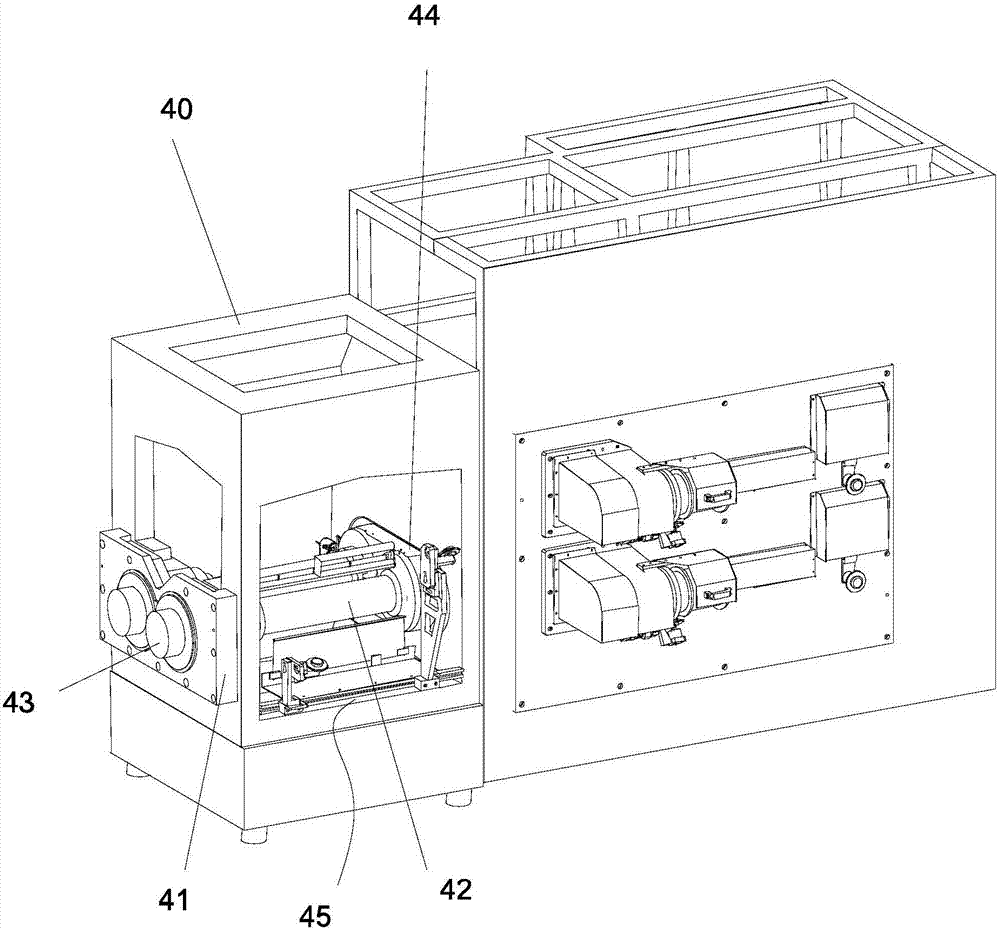

Device for rapidly collecting and releasing boats

ActiveCN101746680ASave spaceAvoid shakingWinding mechanismsLoad-engaging elementsPull forceConductor Coil

The invention relates to a device for rapidly collecting and releasing boats, which comprises a collecting and releasing arm structure, an aligning device, a decoupler, a sling and a winch, wherein one end of the collecting and releasing arm structure is connected with a mother ship and the other end of the collecting and releasing arm structure can be extended or retracted in a suspending way to provide a force applying fulcrum for collecting and releasing the boats; the aligning device is connected at the other end of the collecting and releasing arm structure and is used to align with the lifting and the lowering positions of the boats on sea surface; the decoupler is limited on the aligning device and is used to be connected with the boats; one end of the sling penetrates through a pulley fixed on the collecting and releasing arm structure in a winding way, is connected with the decoupler and is used to transmit pulling force to the decoupler; and the winch is connected with the other end of the sling to provide pulling force for collecting and releasing the boats. The device is a collecting and releasing device with complete functions and can be used to stably and rapidly lower down the boats to sea surface from the mother ship under force-seven wind sea conditions or to collect the boats back to the mother ship from sea surface.

Owner:射阳远洋船舶辅机有限公司

Tension roll control device for plate and strip processing line and tension control method

The invention discloses a tension roll control device for a plate and strip processing line and a tension control method, belonging to the field of tension control of tension rolls on the plate and strip processing line in the metallurgical industry. The tension roll control device comprises a tension roll group, an auxiliary roll frequency converter and a main roll frequency converter, and further comprises an auxiliary roll speed encoder, a main roll speed encoder, a load distributor, a tension regulator, a feedforward compensation unit and a tensiometer, wherein two ends of the load distributor are respectively connected with the auxiliary roll frequency converter and the main roll frequency converter; the auxiliary roll frequency converter comprises an auxiliary roll rotation speed control unit and an auxiliary roll torque control unit; and the main roll frequency converter comprises a main roll rotation speed control unit and a main roll torque control unit. The tension roll control device has the advantages of high control response speed and high control precision. A control method of the tension roll control device comprises the steps of: (1) main / slave load distribution for the tension rolls; (2) complex tension control of the tension rolls; and (C) dynamic compensation. The method has the advantages of small steady state error of a torque loop, short anti-disturbance recover time, constant rotation speed and good anti-disturbance performance.

Owner:安徽马钢输送设备制造有限公司

Rod-like article forming apparatus

InactiveUS20050051181A1Reduce frictional resistanceReduce running resistanceCigar manufactureCigarette manufactureEngineeringContact force

Owner:JAPAN TOBACCO INC

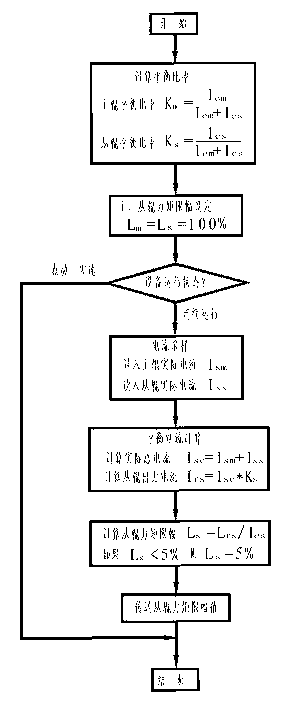

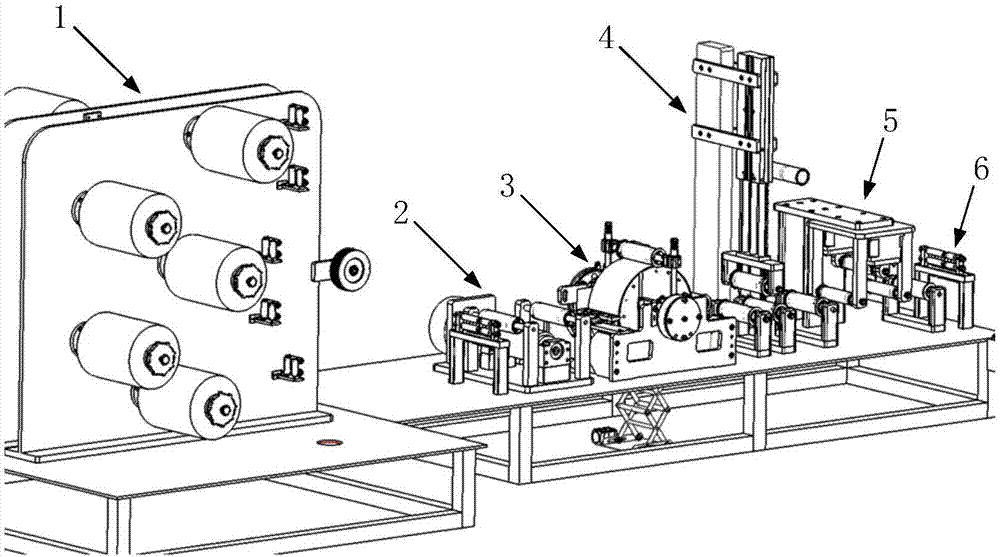

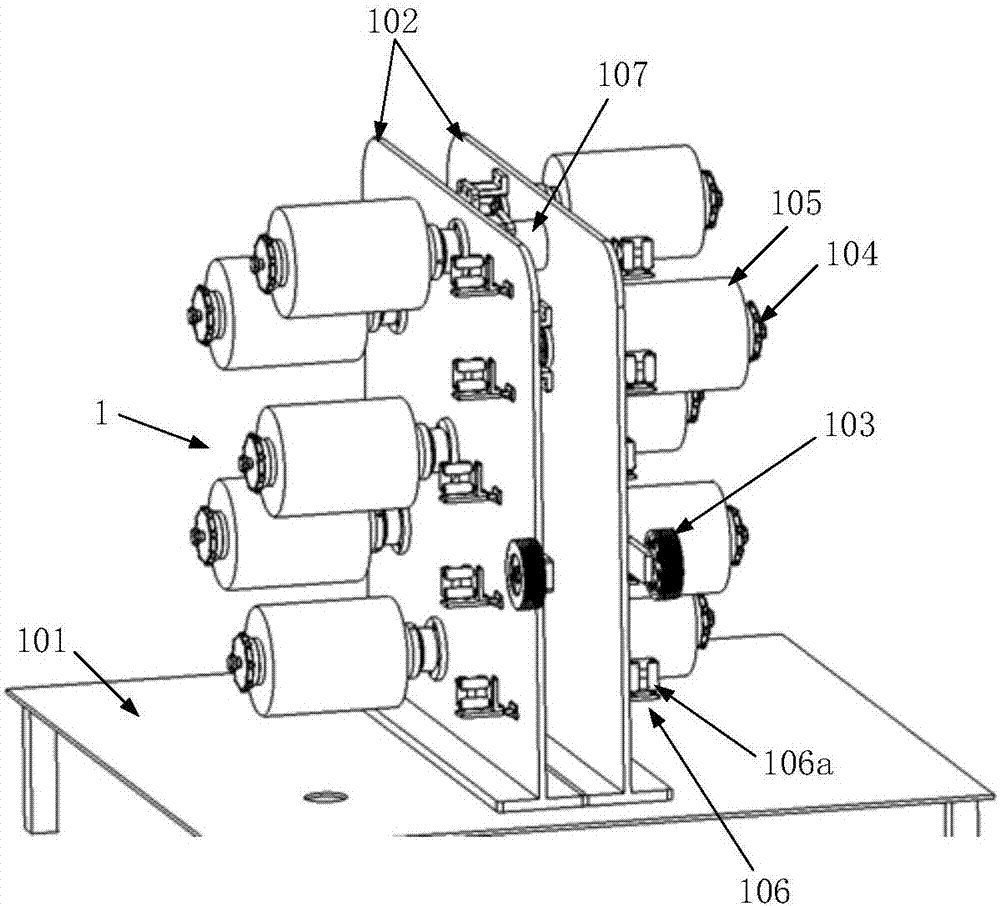

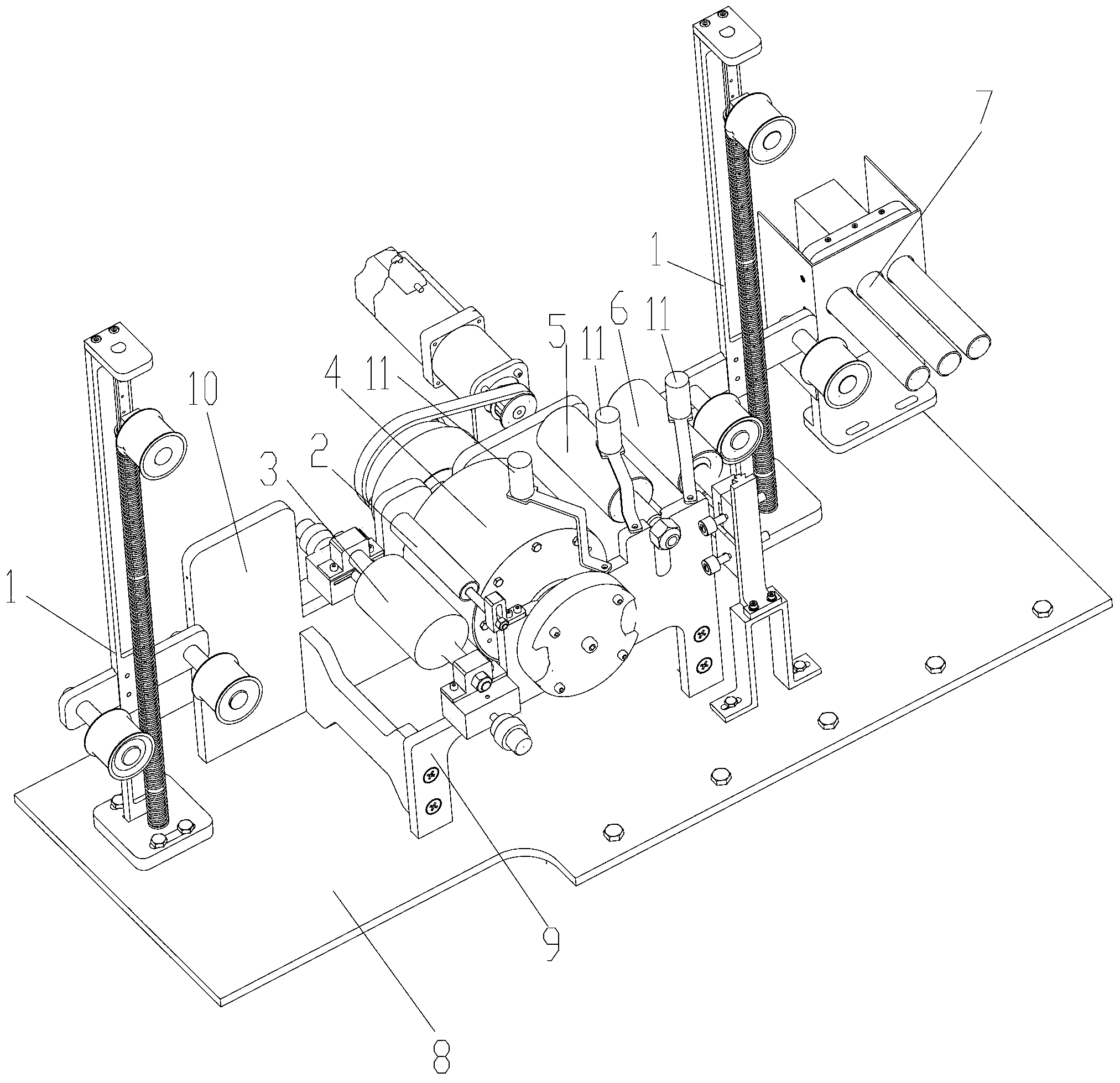

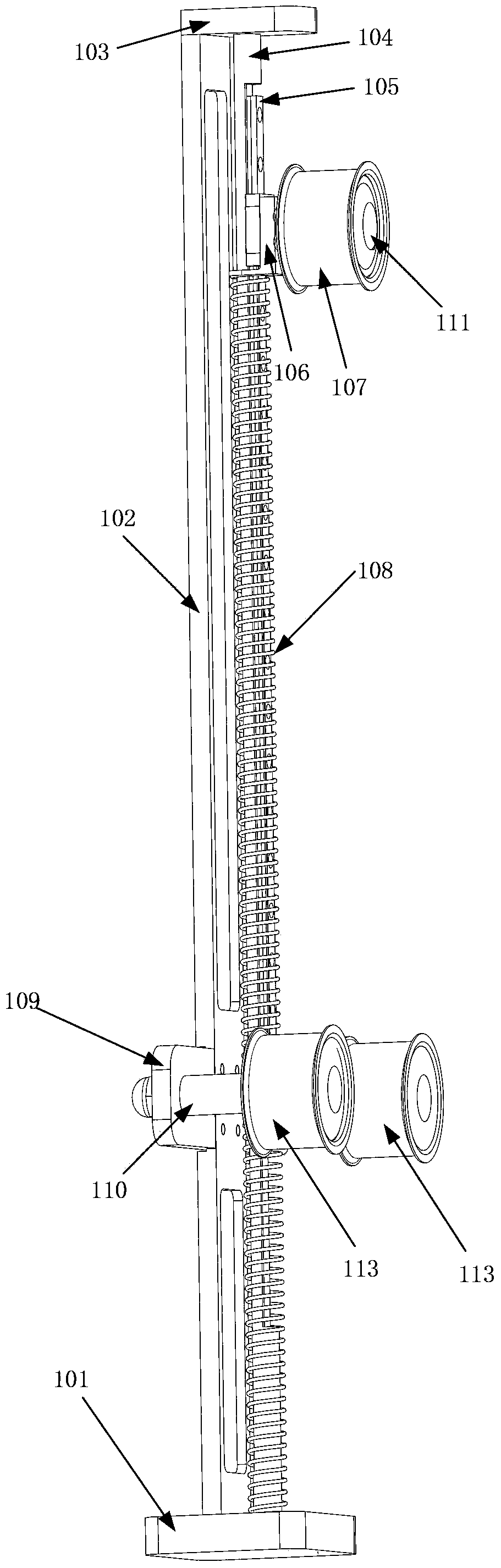

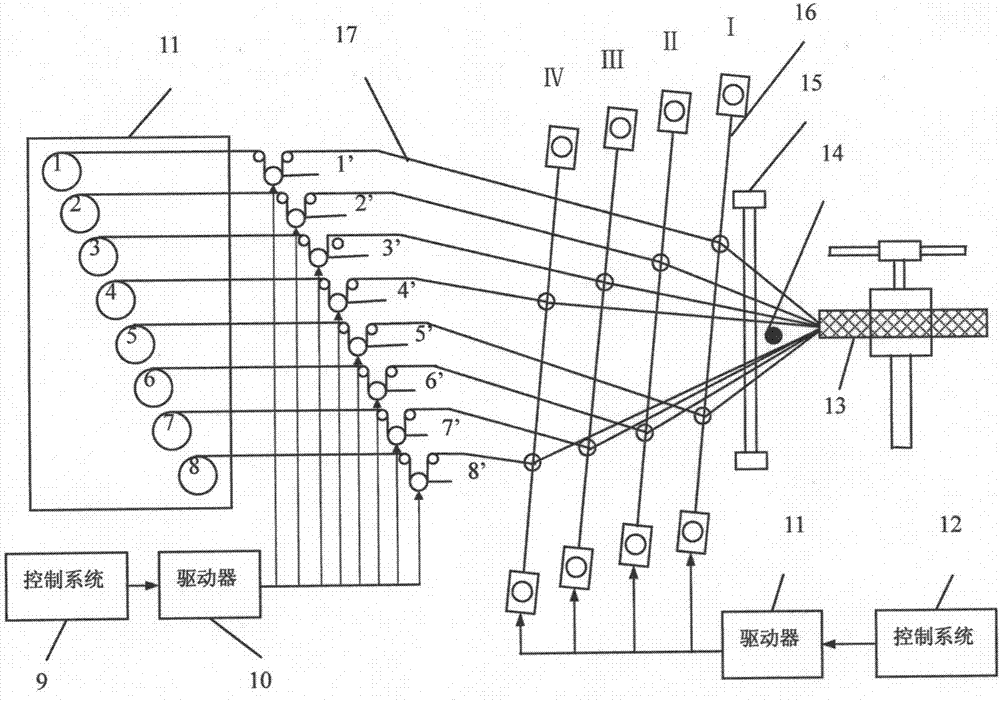

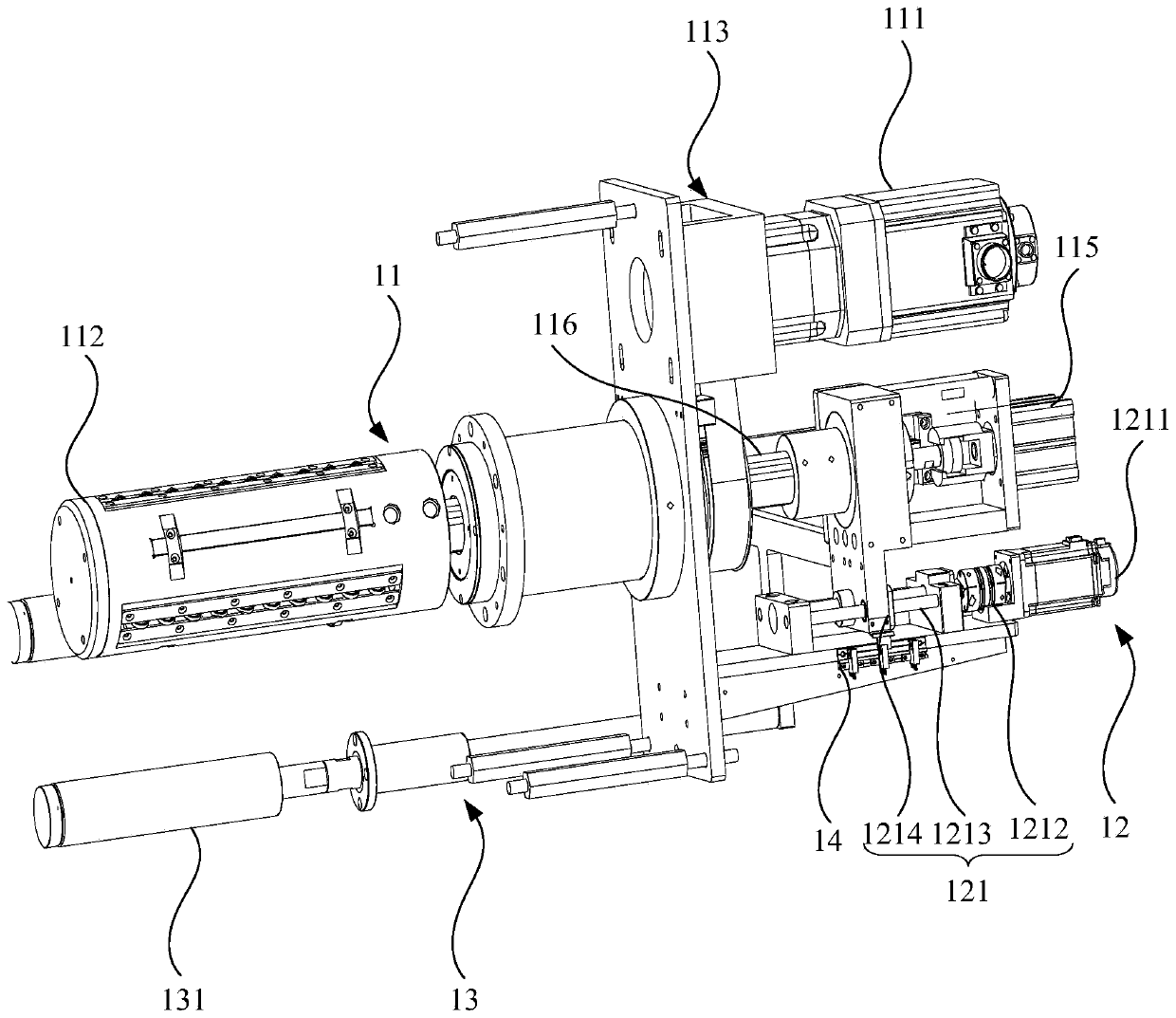

Carbon fiber winding machine process parameter adjusting system and tension adjusting method

The invention relates to a carbon fiber winding machine process parameter adjusting system modular structure and a tension control method. A winding machine process parameter adjusting system comprises an unwinding module used for releasing fibers, a tension generation module generating enough tension when the tension of the fibers is requested to be high, an adhesive impregnation amount adjustingmodule for precisely controlling the fiber adhesive impregnation amount, a temperature adjusting module for controlling the adhesive temperature and the temperature of the adhesive impregnation fiber, a tension stabilizing module for controlling tension and reducing tension fluctuation in the fiber conduction process and a tension measuring module used for measuring the fiber in real time. Through a modular design method, the function requirement of the system can be finally achieved, the stage-by-stage control strategy is adopted in the tension control method, and through the parameter self-adjusting fuzzy PID algorithm, precise control over the tension is achieved.

Owner:BEIHANG UNIV

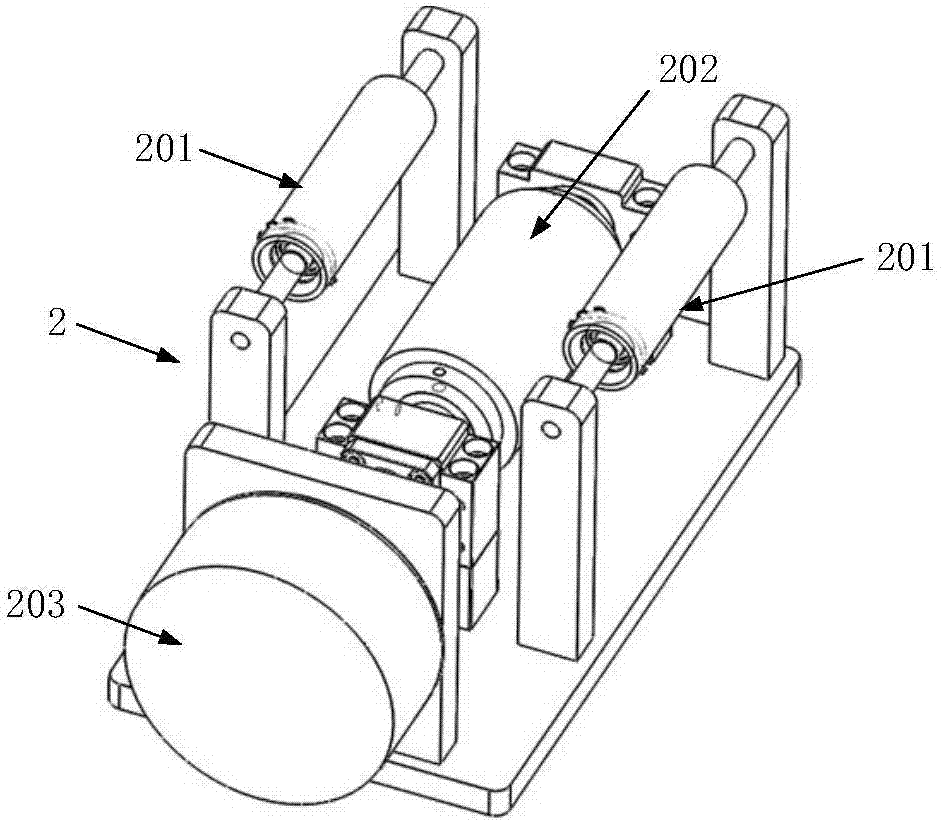

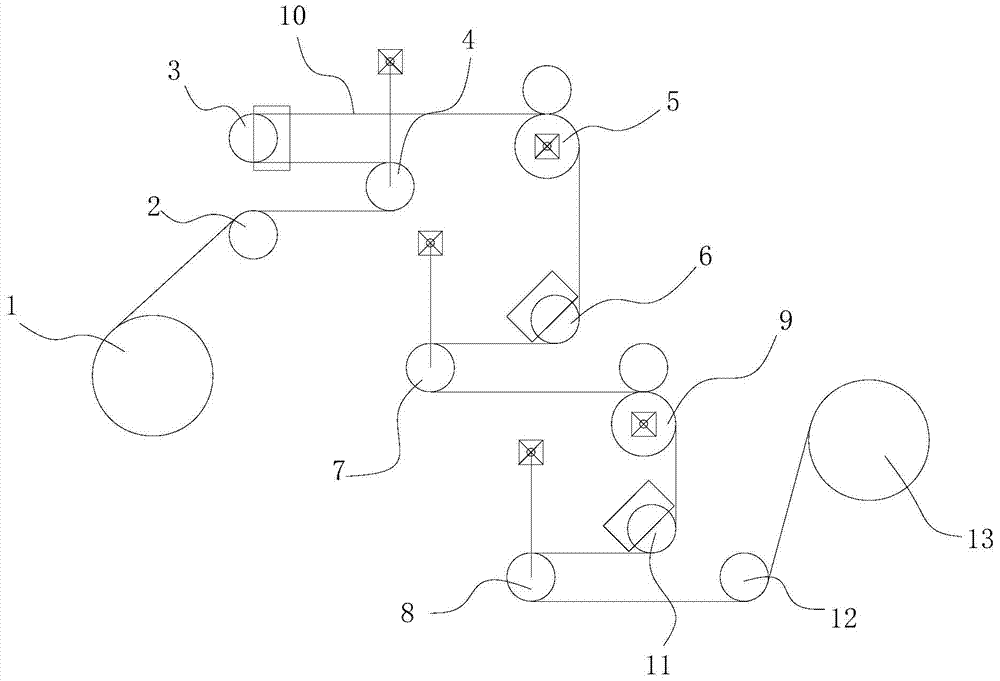

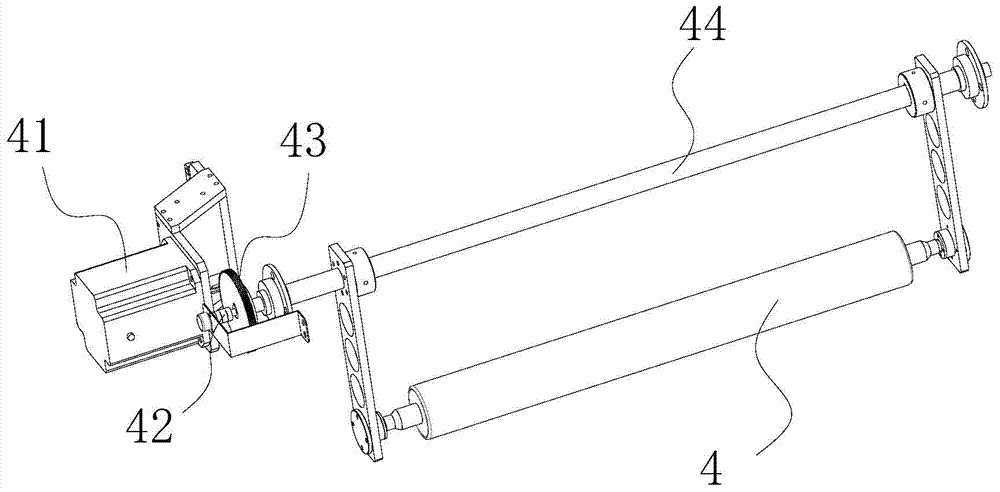

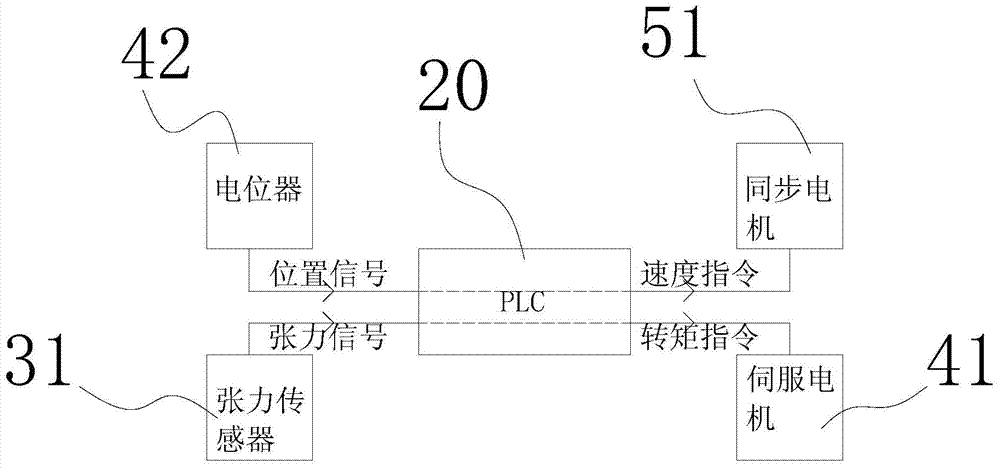

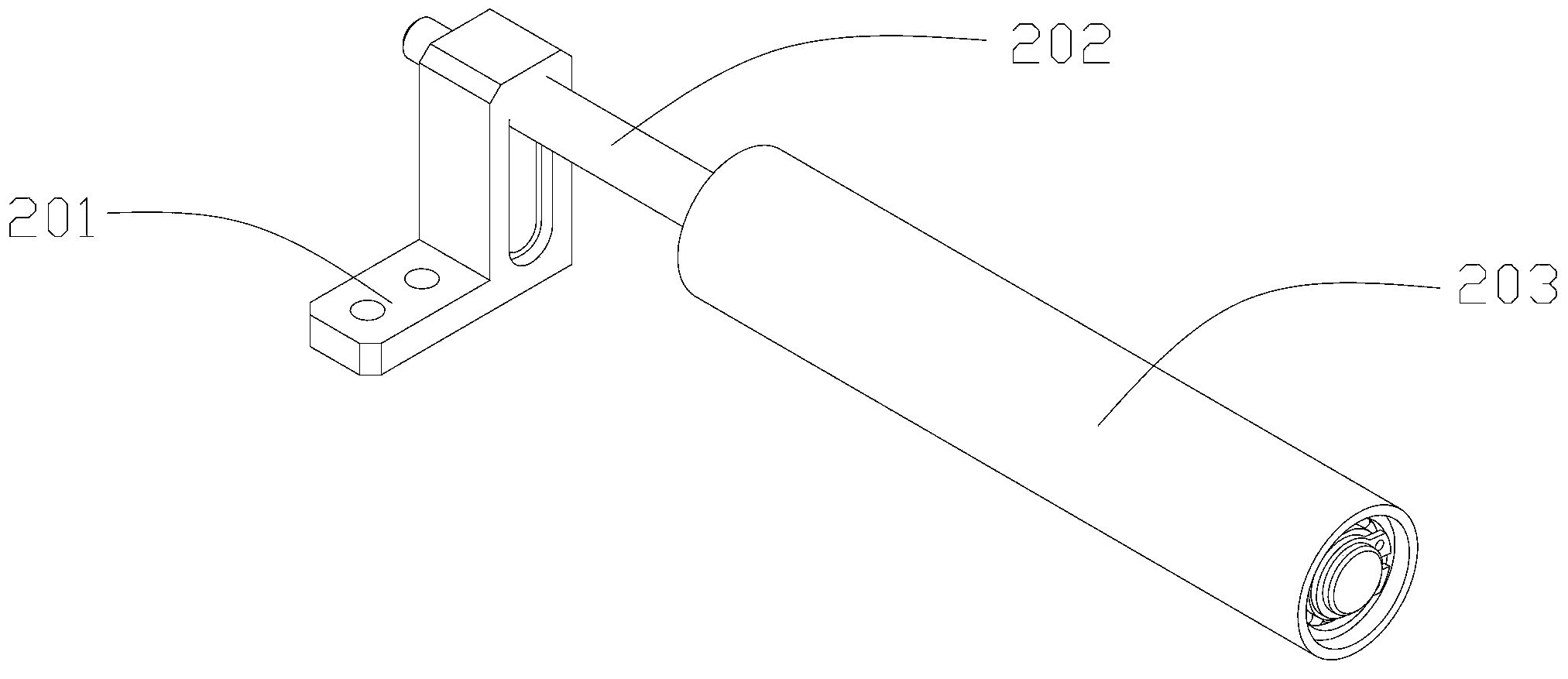

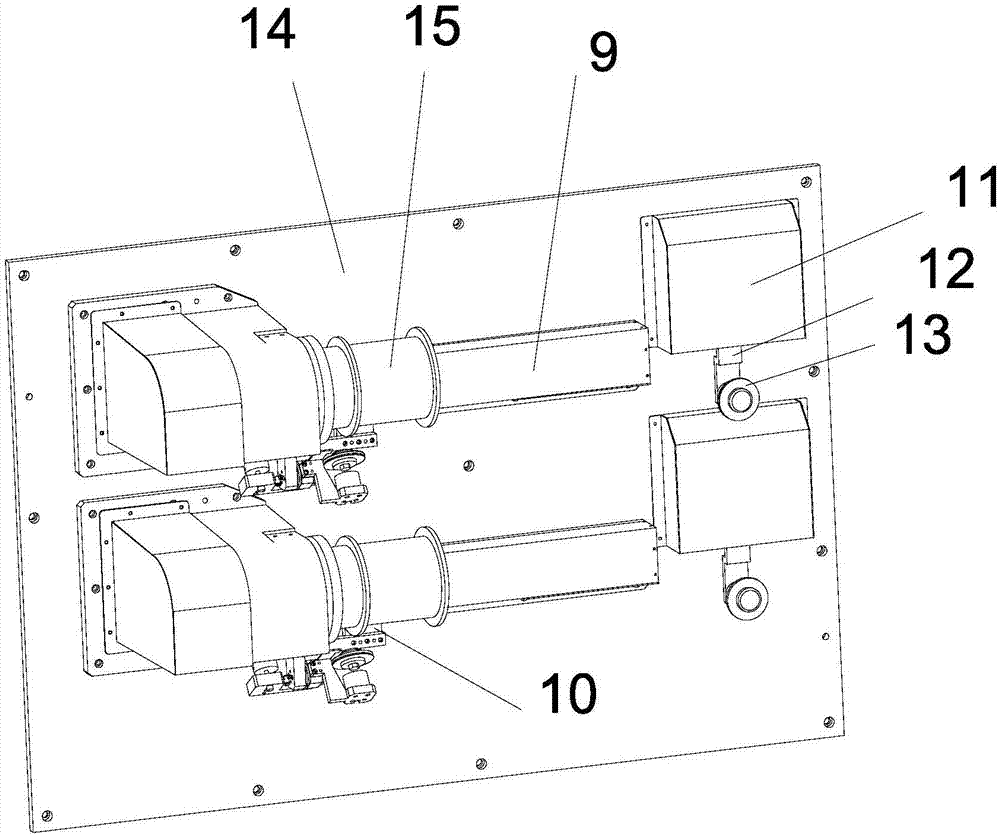

Servo control double-closed-loop tension oscillating roller

InactiveCN103879818AReduce tension fluctuationsRealize tension closed-loop controlWebs handlingMotor driveClosed loop

The invention discloses a servo control double-closed-loop tension oscillating roller. The servo control double-closed-loop tension oscillating roller comprises swing rollers, a servo motor driving the swing rollers to swing and a position detection device for detecting the positions of the swing rollers. A base material tension detection device, a driving roller and a benchmark roller are arranged in front of or behind the position where base materials move forwards and near the swing rollers. The position detection device and the base material tension detection device are electrically connected with a master control device and send detection information to the master control device. The driving roller is controlled by the master control device to carry out rotational speed adjustment. The servo motor is controlled by the master control device to carry out torque adjustment. The servo control double-closed-loop tension oscillating roller has the advantages of being capable of reducing tension fluctuation of the base materials and enhancing the stability of equipment.

Owner:SHENZHEN NEW KATOP AUTOMATION TECH

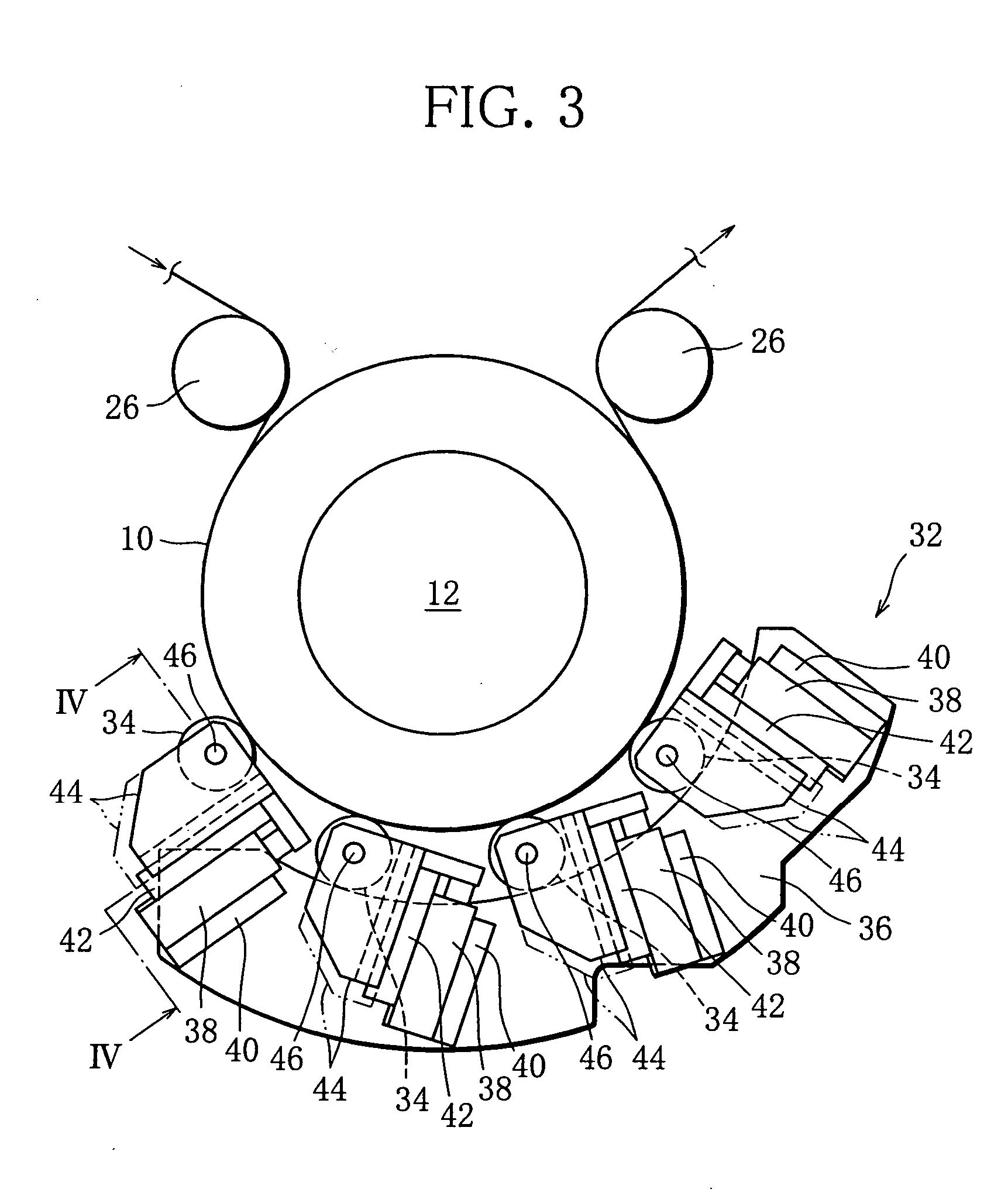

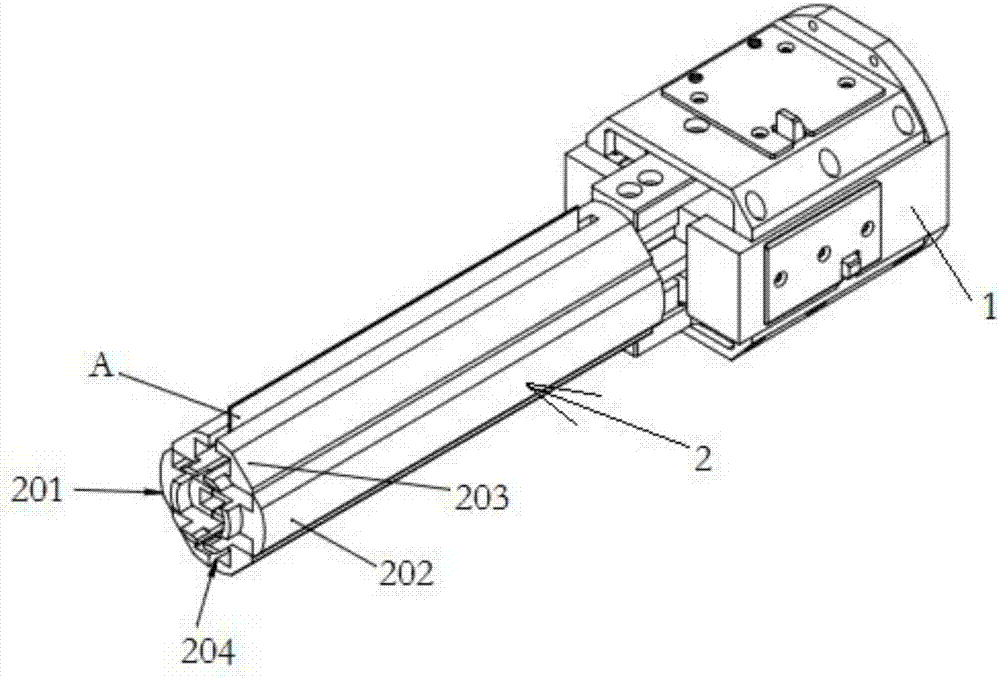

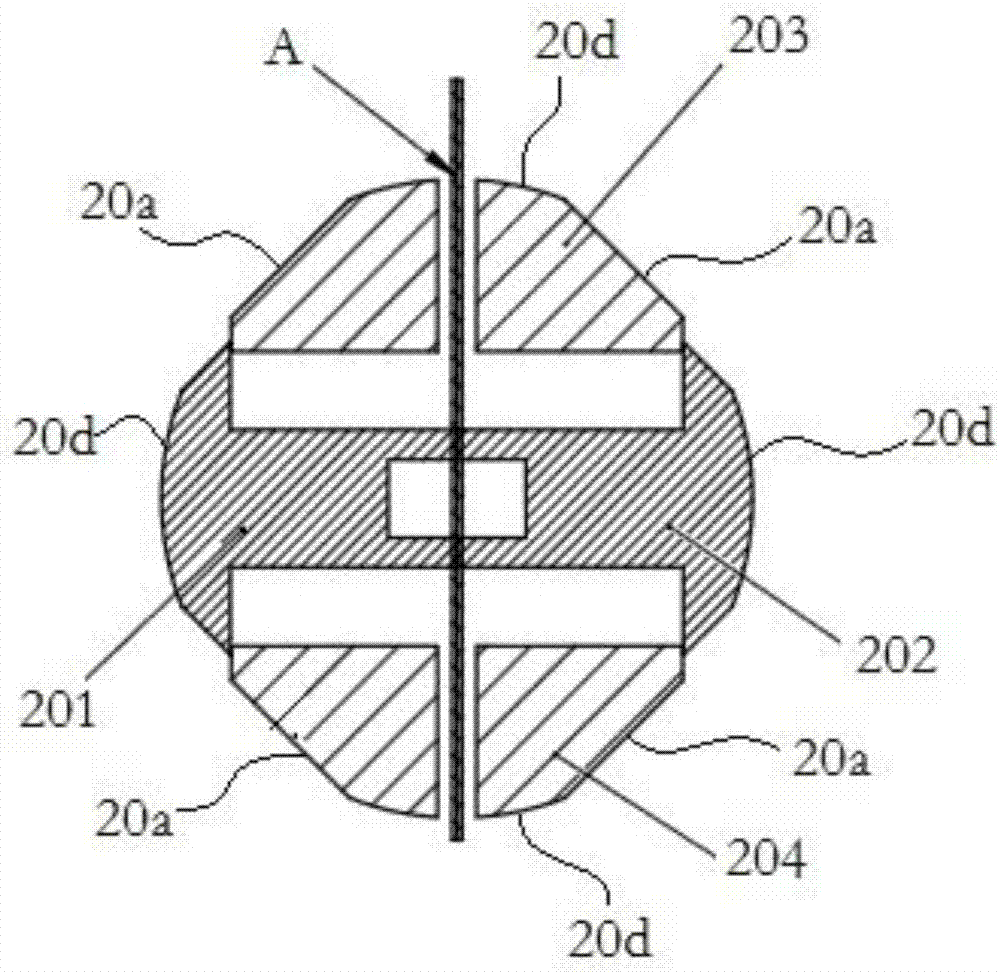

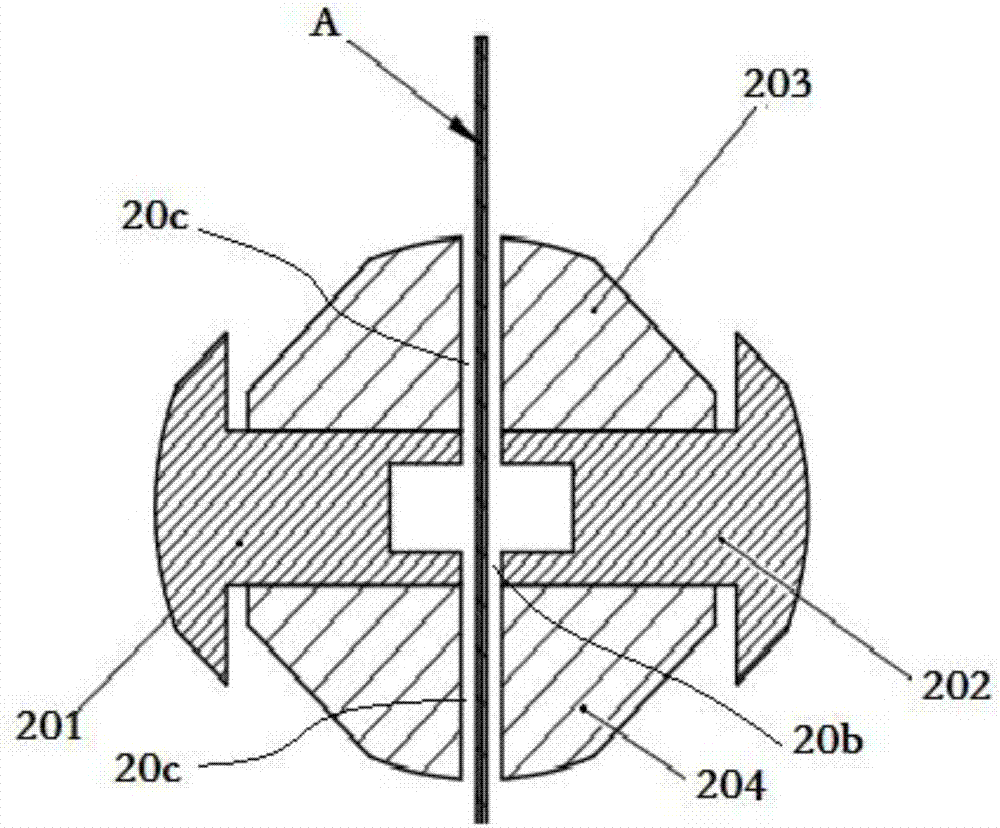

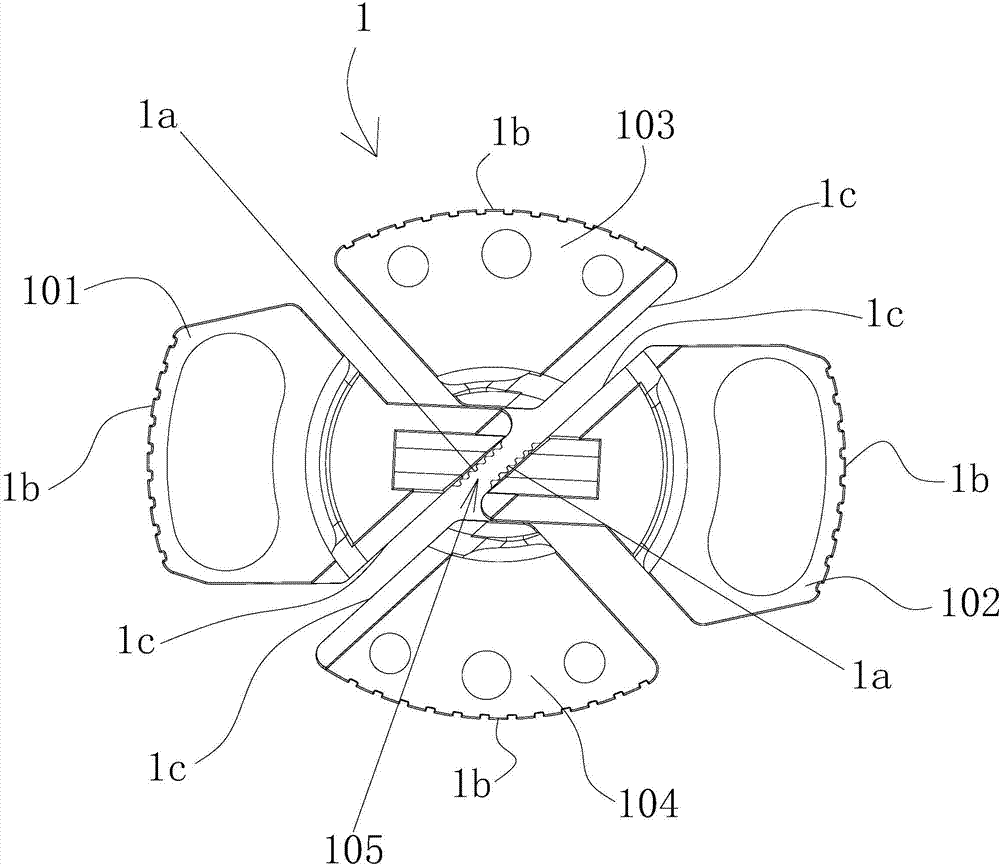

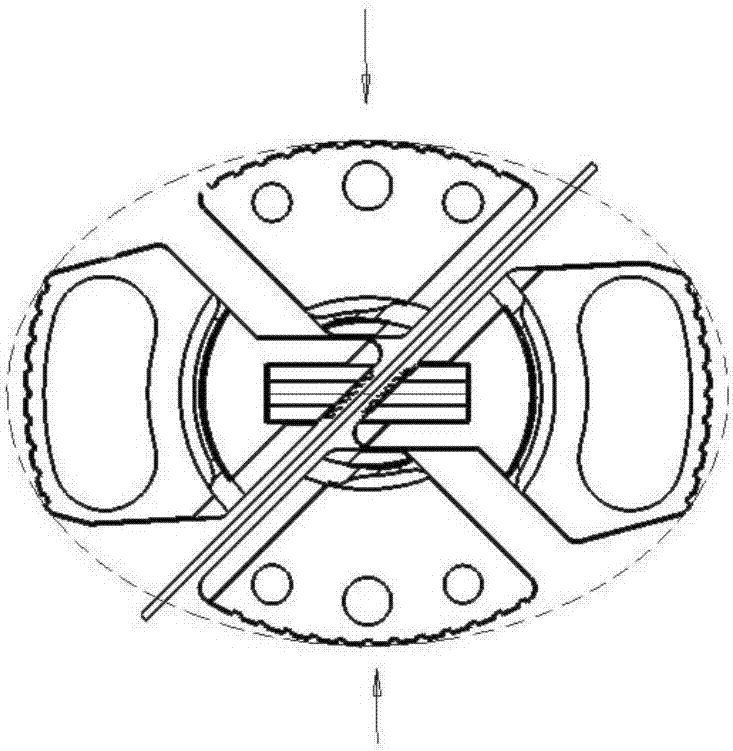

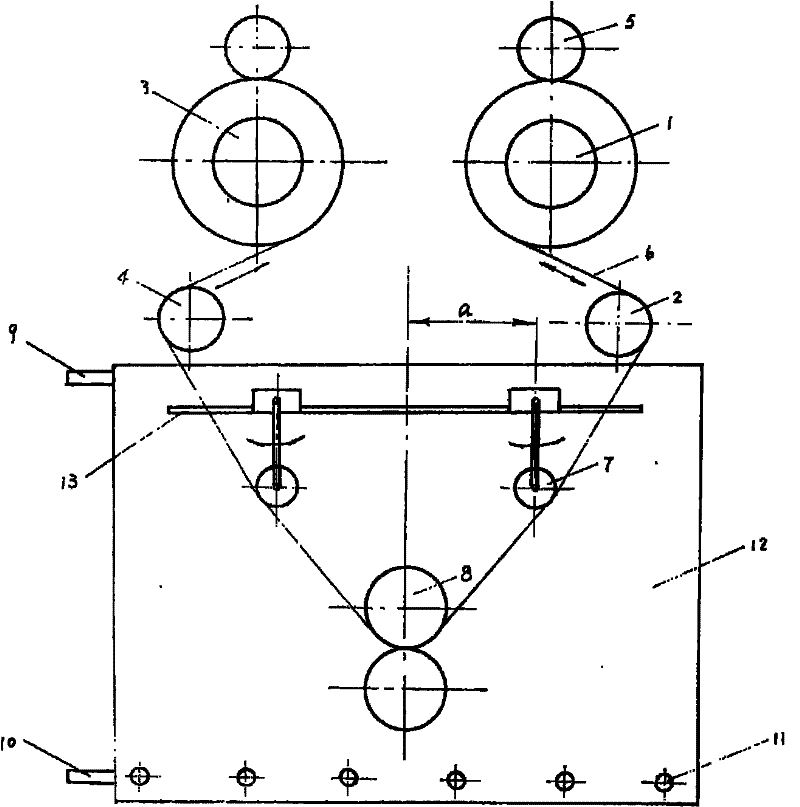

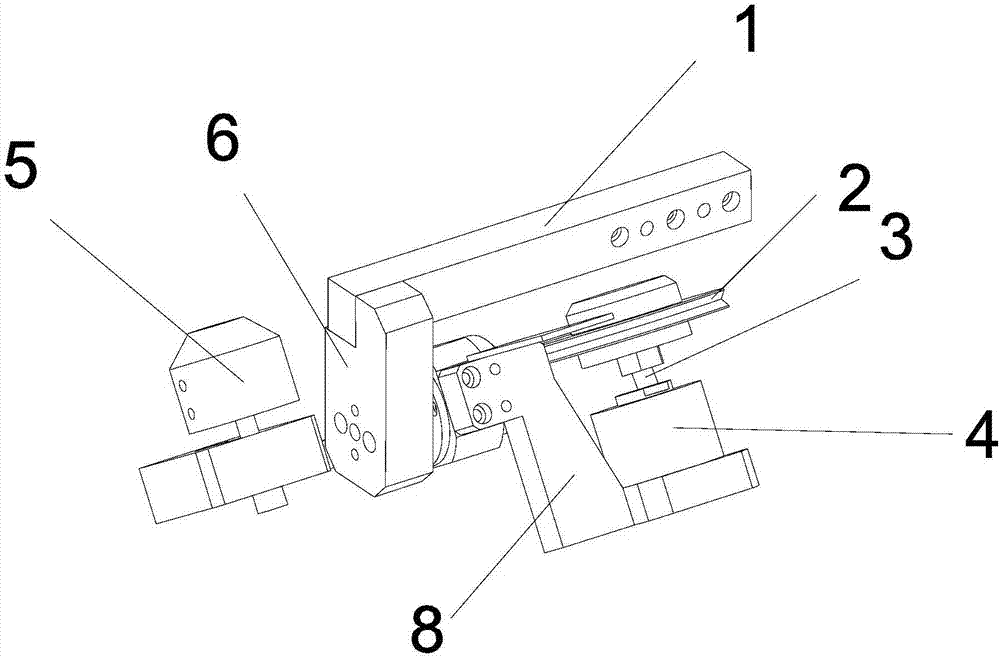

Cell winding needle mechanism and cell winding method

PendingCN106876796AReduce tension fluctuationsSolve the speed problemFinal product manufactureNon-aqueous electrolyte cellsEngineeringPole piece

The invention discloses a cell winding needle mechanism and a cell winding method. The cell winding needle mechanism comprises a winding needling base and a winding needle connected with the winding needling base; a tab positioning plane is arranged on the winding surface of the winding needling; the winding needling comprises a left needle body and a right needle body which are symmetrically arranged left and right, and an upper needle body and a lower needle body which are symmetrically arranged up and down; a clamping slit which can be used for tightly clamping / loosening a diaphragm is formed between the left needle body and the right needle body; an avoidance slit which is connected with the clamping slit is formed in each of the upper needle body and the lower needle body in a run-through manner separately; and the winding needle base is provided with a left and right needle body displacement driving apparatus which drives the left needle body and the right needle body to move in left and right directions to be far from each other / close to each other, and an upper and lower needle body displacement driving apparatus which drives the upper needle body and the low needle body to move in up and down directions to be far from each other / close to each other. When the cell winding needle mechanism is adopted for winding, the tab is tightly attached to the plane of the winding needle, so that the tab is not bent and damaged easily; the long axis and the short axis of the winding needle are low in difference, so that tension fluctuation is relatively low; and therefore, over high shaking on a pole piece can be avoided, and production efficiency is improved.

Owner:GEESUN AUTOMATION TECH

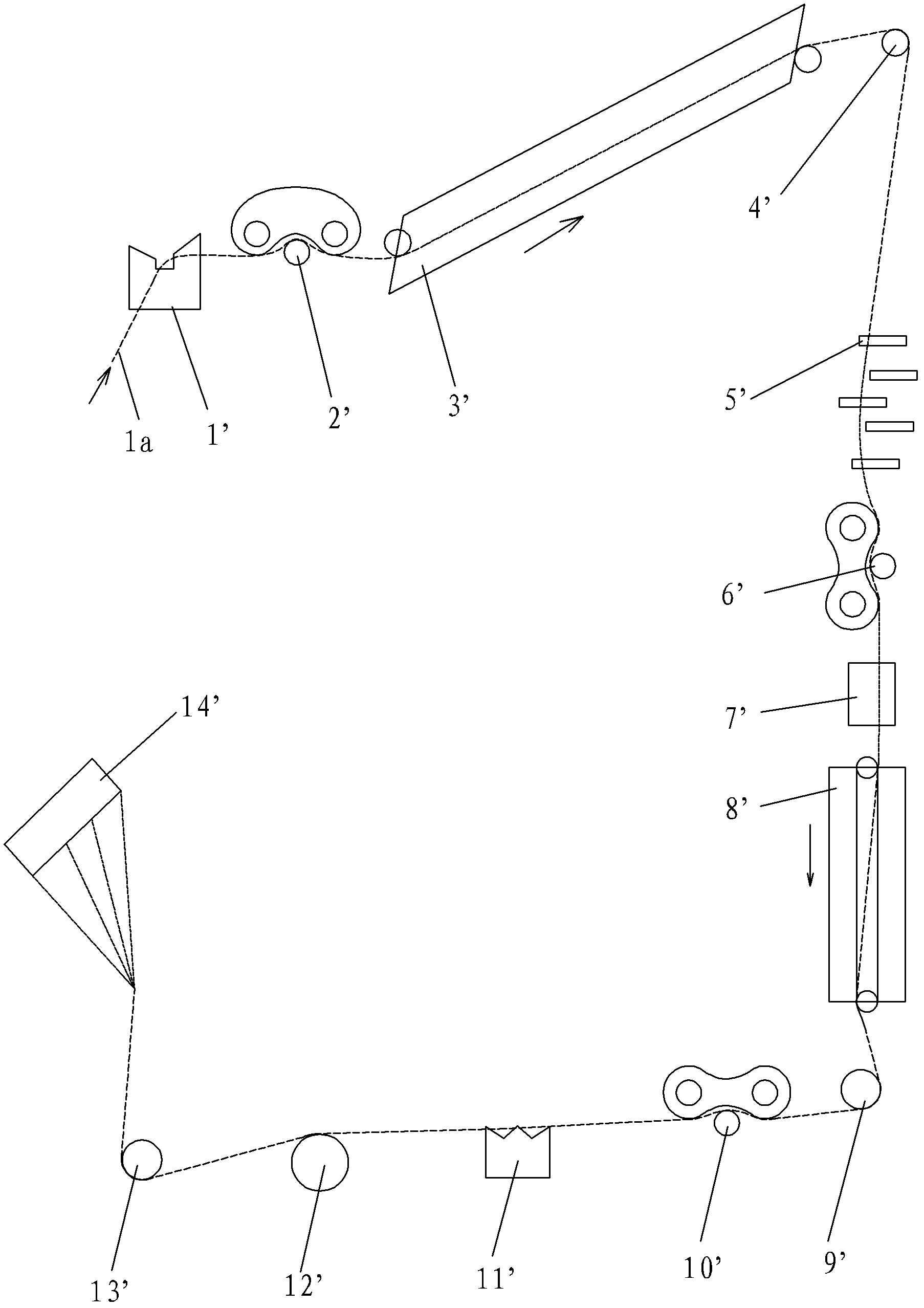

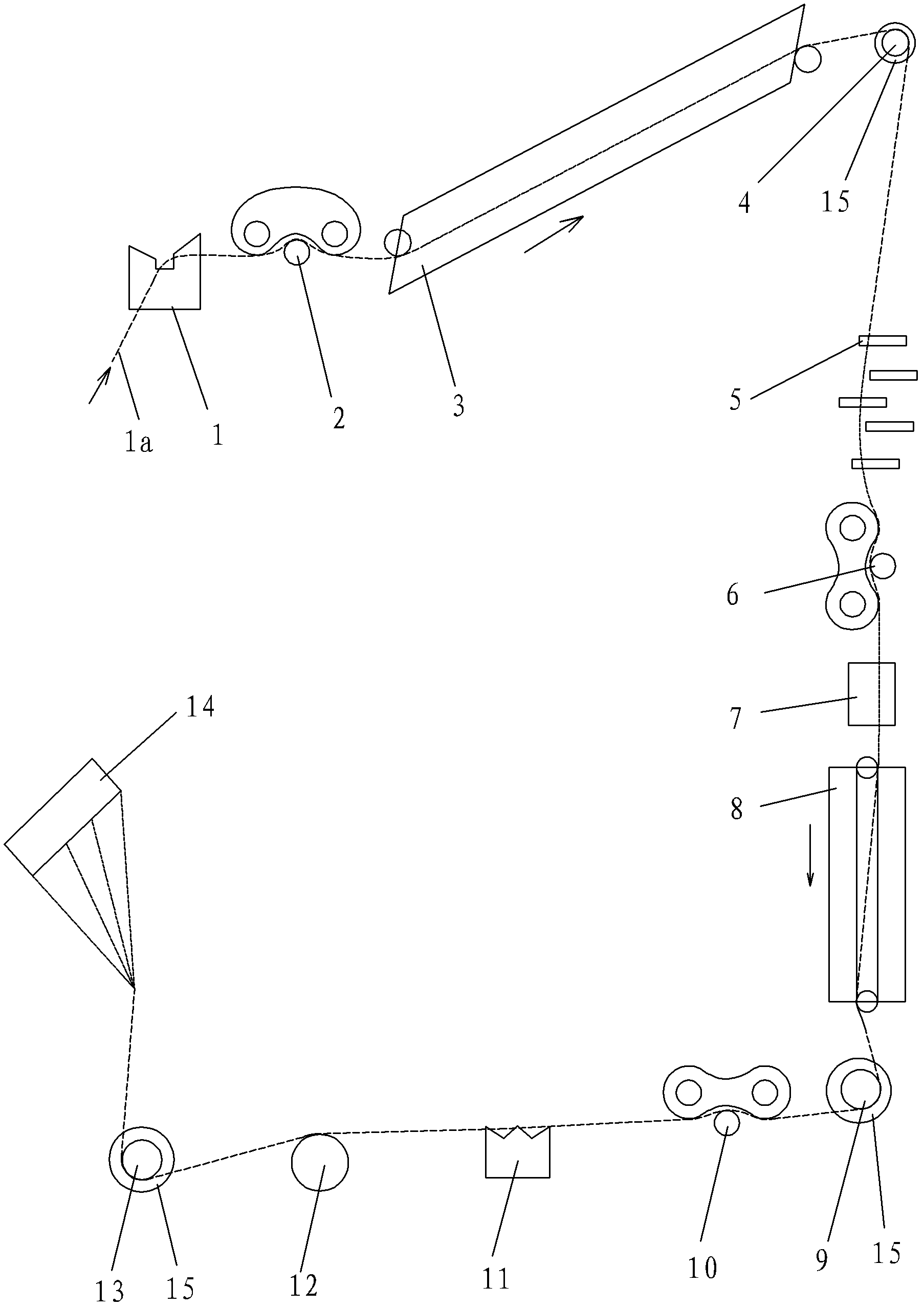

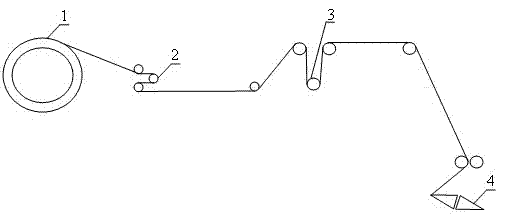

Fiber conduction device for carbon fiber winding machine

The invention discloses a fiber conduction device for a carbon fiber winding machine. The fiber conduction device comprises a tension adjustment device, a front wrap angle adjusting roller, a frictioning device, a driving impregnation roller, a rear wrap angle adjusting roller, a glue extrusion device, a tension measurement device, a frame bottom plate, a left frame and a right frame. Fibers pass though the middle part of each conduction roller; the driving impregnation roller is driven by a servo motor and is arranged on the frame through a bearing block; a gap between a frictioning roller and glue extrusion rollers can be adjusted through a sliding table by the frictioning roller; the positions of the front wrap angle adjusting roller and the rear wrap angle adjusting roller are adjustable; the gap between the glue extrusion rollers can be adjusted through the sliding table by the glue extrusion device; a tension measurement guide roller is arranged on a tension sensor. According to the fiber conduction device, damage in the fiber conduction device can be effectively reduced, problems of fuzziness, line breakage and the like in the processes of winding and molding fibers are reduced, and the glue content and glue uniformity of the fibers are guaranteed, so that the quality of the fiber-wound product is improved.

Owner:BEIHANG UNIV

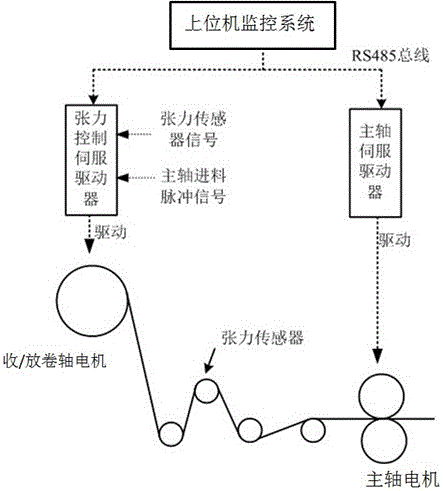

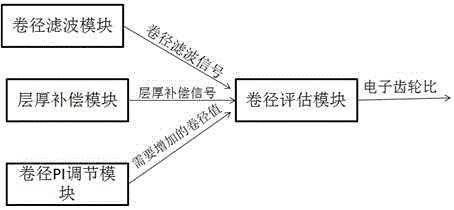

High-precision tension control system and control method

PendingCN106339010ARealize closed-loop controlReduce tension fluctuationsMechanical pressure/force controlComputer control systemLayer thickness

The invention relates to the tension control field, particularly to a high-precision tension control system and control method. The system is composed of an upper computer control system, a tension control servo driver, a spindle servo driver, a spindle motor, a tension sensor and a reeling / unreeling motor. The tension control servo driver consists of a rolling diameter filtering module, a layer thickness compensation module, a rolling diameter PI adjustment module and a rolling diameter evaluation module; and the rolling diameter filtering module, the layer thickness compensation module, and the rolling diameter PI adjustment module output a rolling diameter filter signal, a layer thickness compensation signal, and a rolling diameter value needing to be increased to the rolling diameter evaluation module to carry out rolling diameter evaluation, thereby obtaining an electronic gear ratio. According to the invention, the rolling diameter evaluation function is added and is used for calculating a rolling diameter of a material precisely. Meanwhile, the control capability of the tension adjusting device is weakened; the tension fluctuating range is reduced substantially; and the tension control stability is improved.

Owner:威科达(东莞)智能控制有限公司

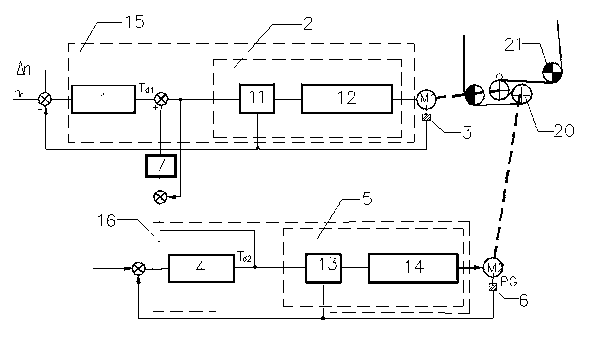

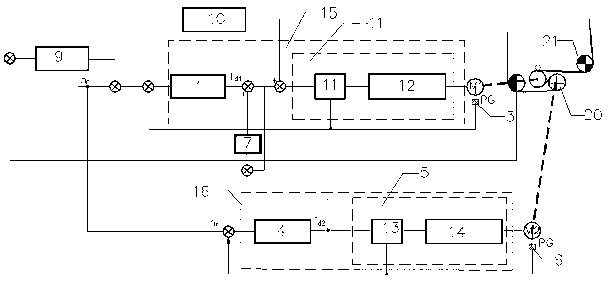

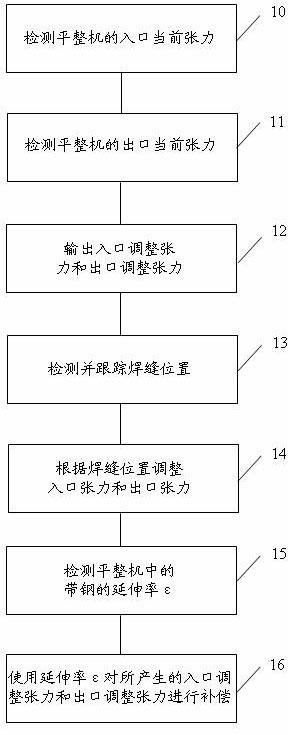

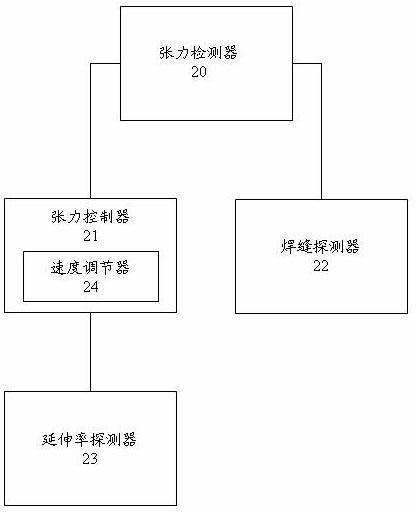

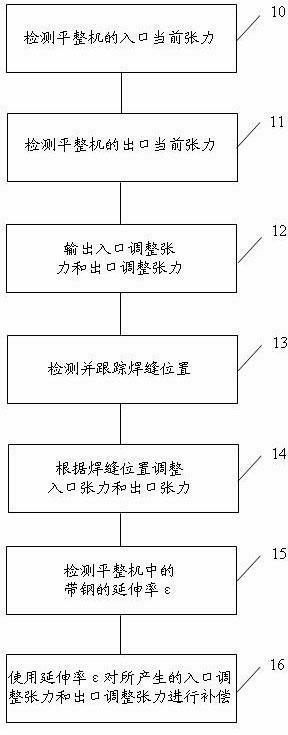

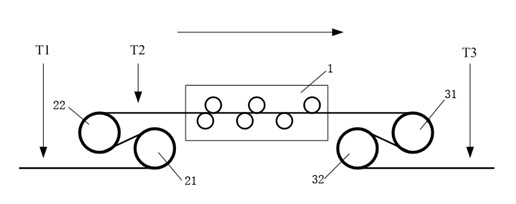

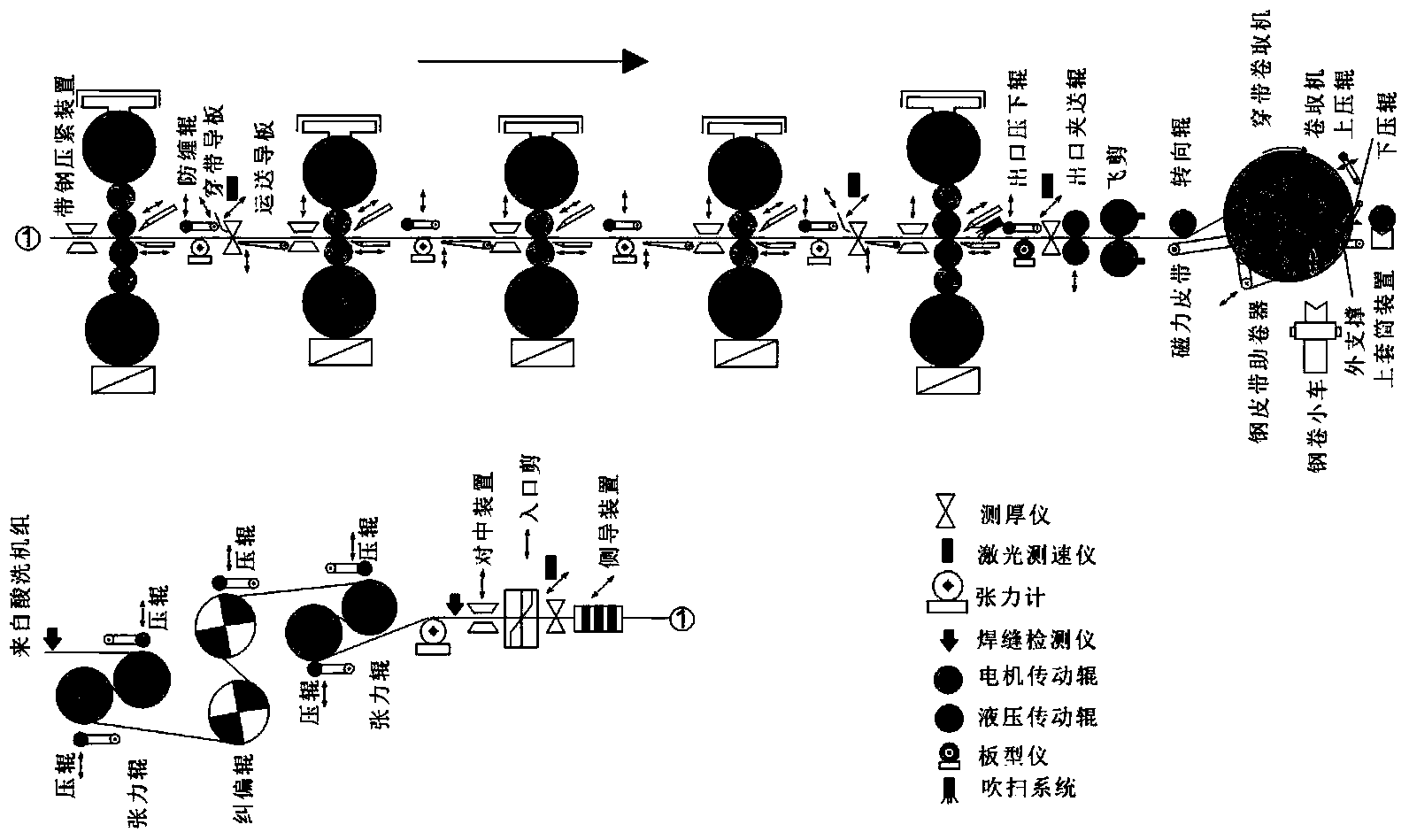

Tension stabilizing control method and device for leveling machine

ActiveCN102485364AReduce tension fluctuationsPrecise tension controlMeasuring devicesTension/compression control deviceEngineeringWeld seam

The invention discloses a tension stabilizing control method for a leveling machine. The method comprises the following steps of detecting current inlet tension of a leveling machine; detecting current outlet tension of the leveling machine; inputting an inlet adjusting tension and an outlet adjusting tension by a tension controller according to the change of the inlet tension and outlet tension; detecting and tracking a welding seam position; when the welding seam position enters the inlet of the leveling machine, adjusting the inlet tension and outlet tension of the leveling machine into an average value of current inlet tension and current outlet tension; when the welding seam position is out of the outlet of the leveling machine, adjusting the inlet tension of the leveling machine into the inlet adjusting tension produced by the tension controller, and adjusting the outlet tension of the leveling machine into the outlet adjusting tension produced by the tension controller. The invention further discloses a tension stabilizing control device for the leveling machine. According to the method and device provided by the invention, the average value of the inlet and outlet tension is used as a transition value for tension switching, and the extension rate of a steel band is further taken into account, so that the tension control is more accurate and steady.

Owner:SHANGHAI BAOSIGHT SOFTWARE CO LTD +1

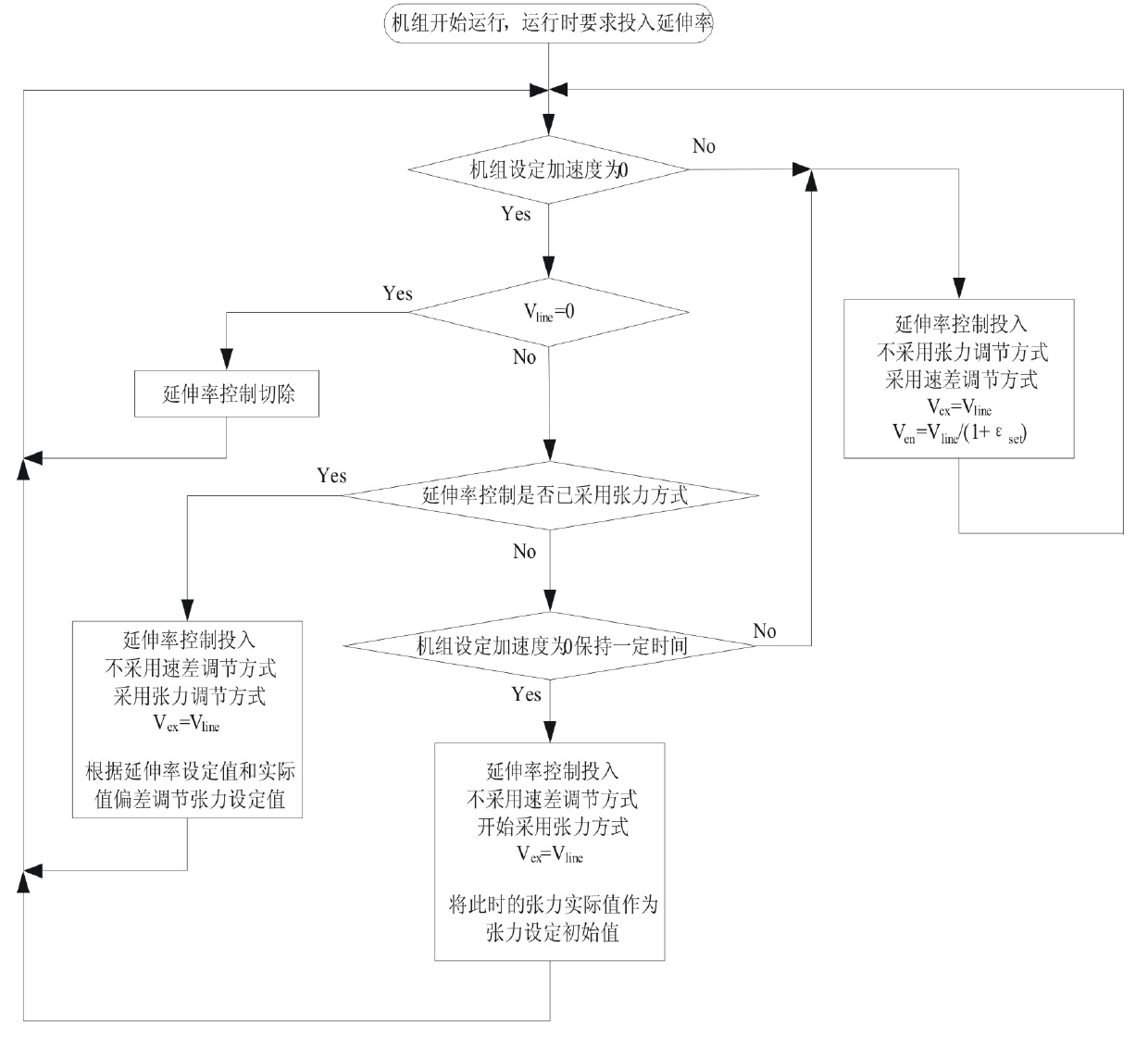

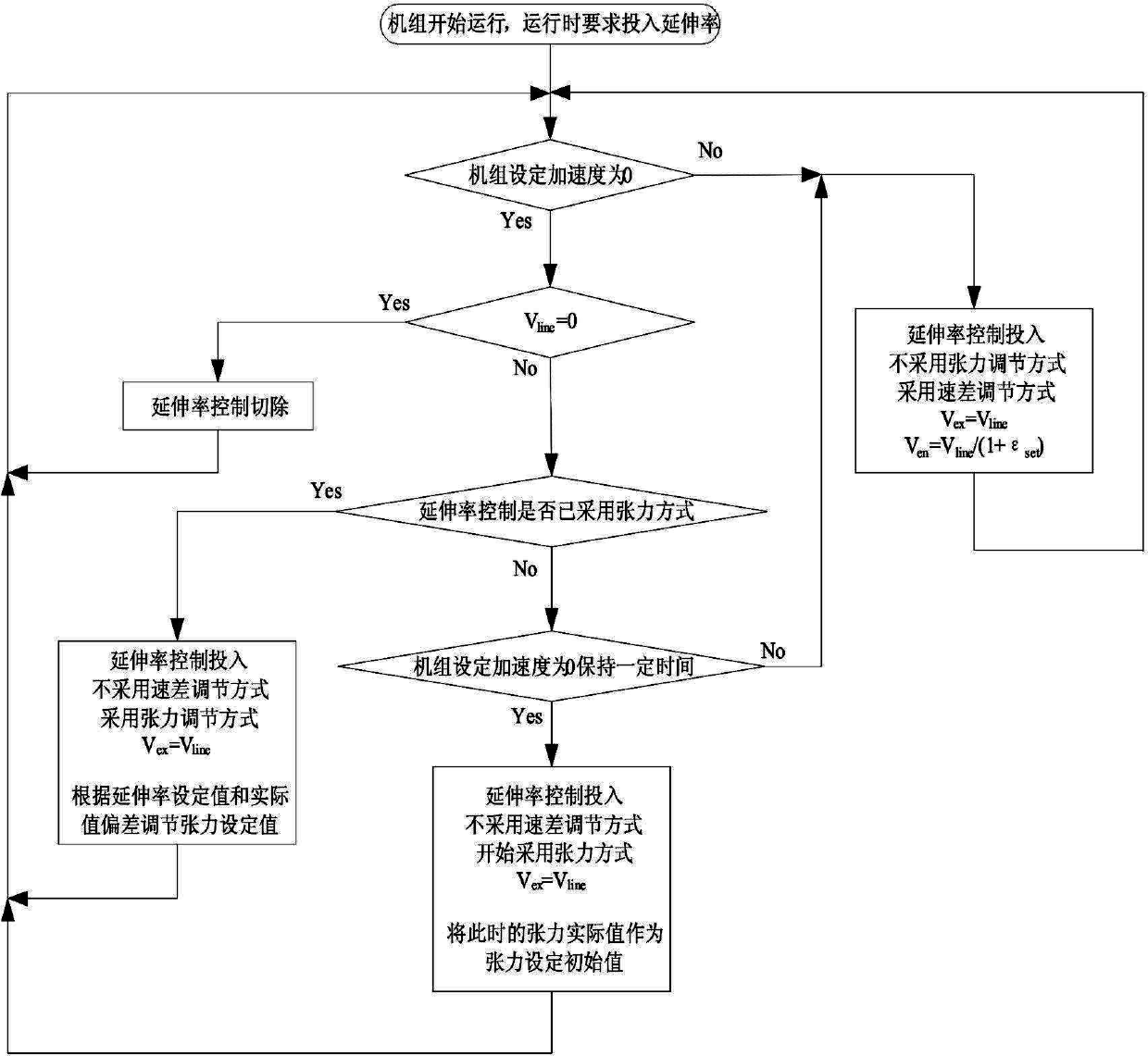

Elongation coefficient control method of rewinding straightening and withdrawal unit

InactiveCN102641901AQuick responseAvoid large tension fluctuationsElongation control deviceControl modeTension control

An elongation coefficient control method of a rewinding straightening and withdrawal unit comprises enabling speed of an exit tension roller unit to serve as a speed standard of the rewinding straightening and withdrawal unit for the exit tension roller unit, and adopting a speed control mode from beginning to end to enable a speed slope setting value Vline of the rewinding straightening and withdrawal unit to serve as the setting speed Vex of the exit tension roller unit; enabling an entrance tension roller unit to adopt the speed control mode in speed-up and speed-down processes of the unit, and achieving elongation coefficient control by adopting a speed difference adjustment mode; enabling the entrance tension roller unit to adopt a tension control mode after the unit enters a constant speed stage, and achieving the elongation coefficient control by adopting a tension adjustment mode; and enabling a tension actual value obtained by feedback at the time to serve as an initial value of the tension setting value when the elongation coefficient is just switched from the speed difference adjustment mode into the tension adjustment mode. The elongation coefficient control method avoids problems of being big in elongation coefficient fluctuation and unstable, and has good dynamic and static state performance.

Owner:WISDRI WUHAN AUTOMATION

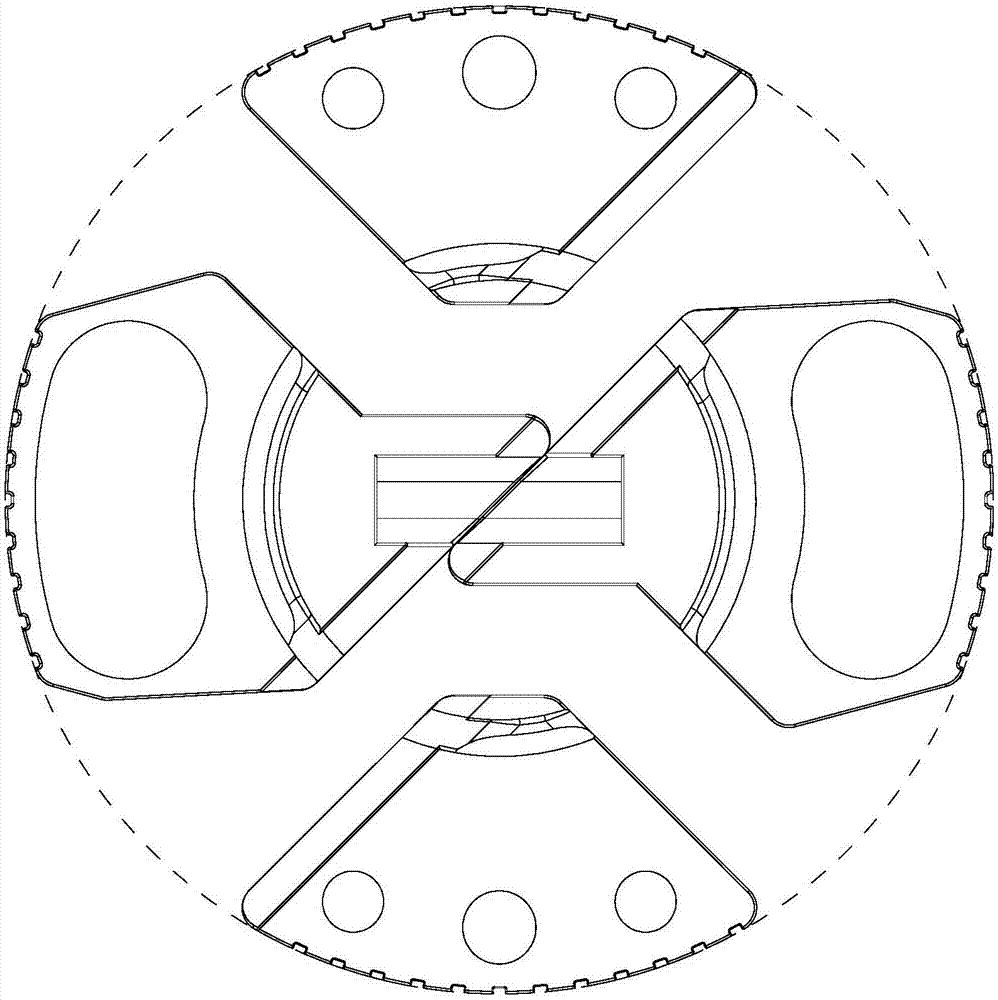

Rolling needle

PendingCN106981688ADoes not cause jitterReduce tension fluctuationsFinal product manufactureSecondary cells manufacturePole pieceTooth position

The invention discloses a rolling needle. The rolling needle comprises a left needle body and a right needle body in parallel arrangement on the left side and the right side, an upper needle body and a lower needle body in parallel arrangement up and down, a clamping gap formed between the left needle body and the right needle body, a left-right needle body displacement driving device for driving the left needle body and the right needle body to move away from each other or close to each other along the left-right direction, and an up-down needle body displacement driving device for driving the upper needle body and the lower needle body to move away from each other or close to each other along the up-down direction; clamping teeth positioned at the position of the clamping gap are arranged on the left needle body and the right needle body respectively; and circular arc-shaped outer surfaces, with the same semi-diameter, which correspond to one another are arranged on the left needle body, the right needle body, the upper needle body and the lower needle body respectively. The rolling needle has a circular outer contour, a membrane and pole pieces are wound according to the circular outer contour respectively during winding, the tension fluctuation is low, too great vibration cannot be caused for the pole pieces, and the production efficiency is greatly improved.

Owner:SHENZHEN GEESUN INTELLIGENT TECHNOLOGY CO LTD

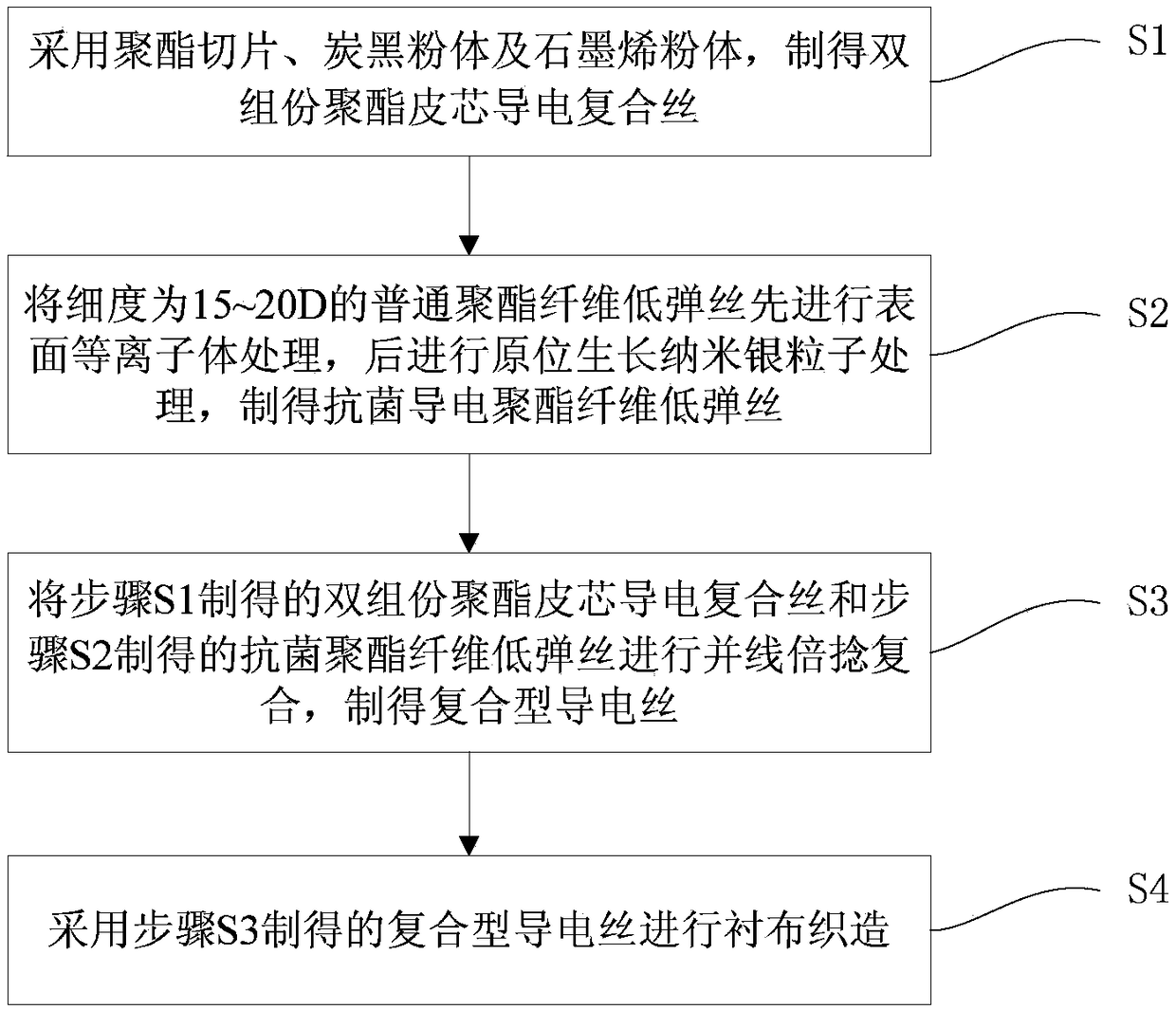

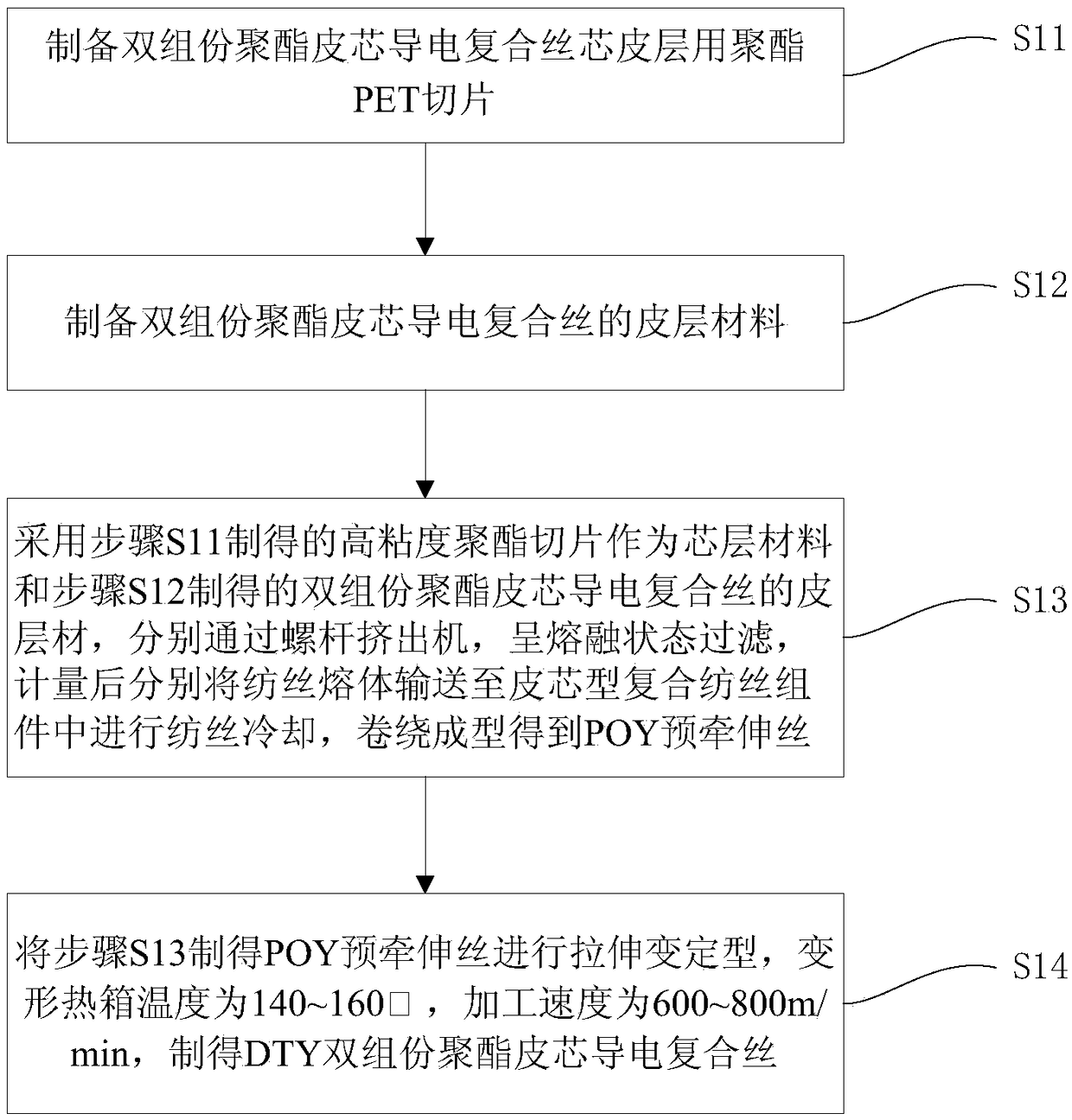

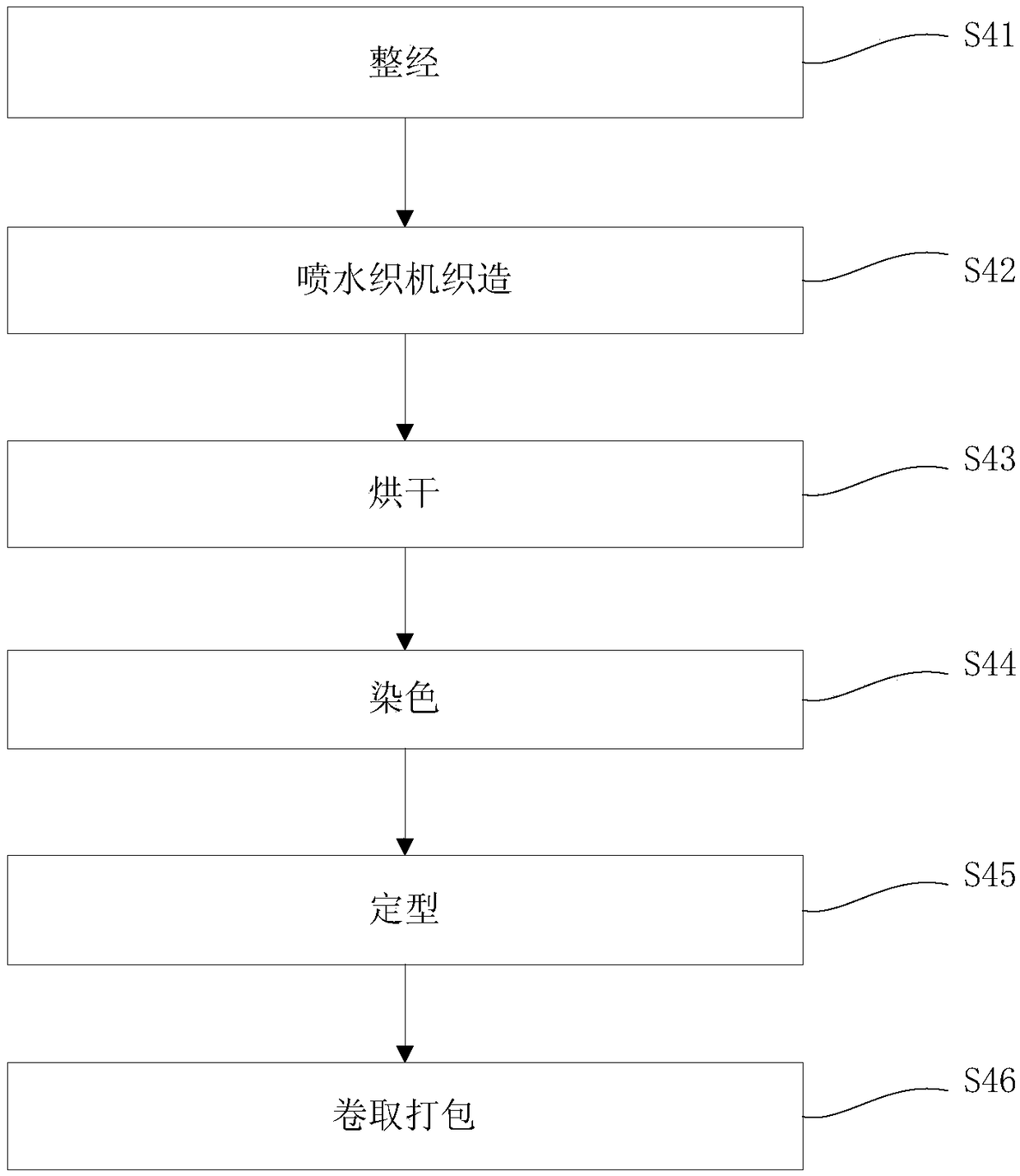

Dacron conductive lining cloth and production process thereof

ActiveCN109371527ASoft touchImprove washing resistanceElectroconductive/antistatic filament manufactureLiquid/gas/vapor treatment of propelled fabricsPolyesterYarn

The invention relates to a dacron conductive lining cloth and a production process thereof. The production process includes the following steps that polyester chips, carbon black powder and graphene powder are adopted, and double-component polyester skin core conductive composite filaments are prepared; common polyester fiber low stretch yarn is subjected to surface treatment, and antibacterial conductive polyester fiber low stretch yarn is prepared; the prepared double-component polyester skin core conductive composite filaments and the prepared antibacterial conductive polyester fiber low stretch yarn are subjected to doubling and double-twisting compounding, and composite conductive filaments are prepared; the composite conductive filaments are used for weaving the lining cloth. The defects such as poor conductivity, poor softness, washing intolerance and the complex processing process of conductive fibers in the prior art are overcome, the dacron conductive lining cloth has excellent washing resistance, dyeing performance and conductivity, is resistant to abrasion and bending and soft in hand feeling, still can keep good conductivity after being machine-washed multiple times, is good in strength, soft and not crispy, and meets the comprehensive requirements of the strength, softness and conductivity of high-grade antistatic clothing on antistatic lining cloths.

Owner:南通源佑纺织科技有限公司

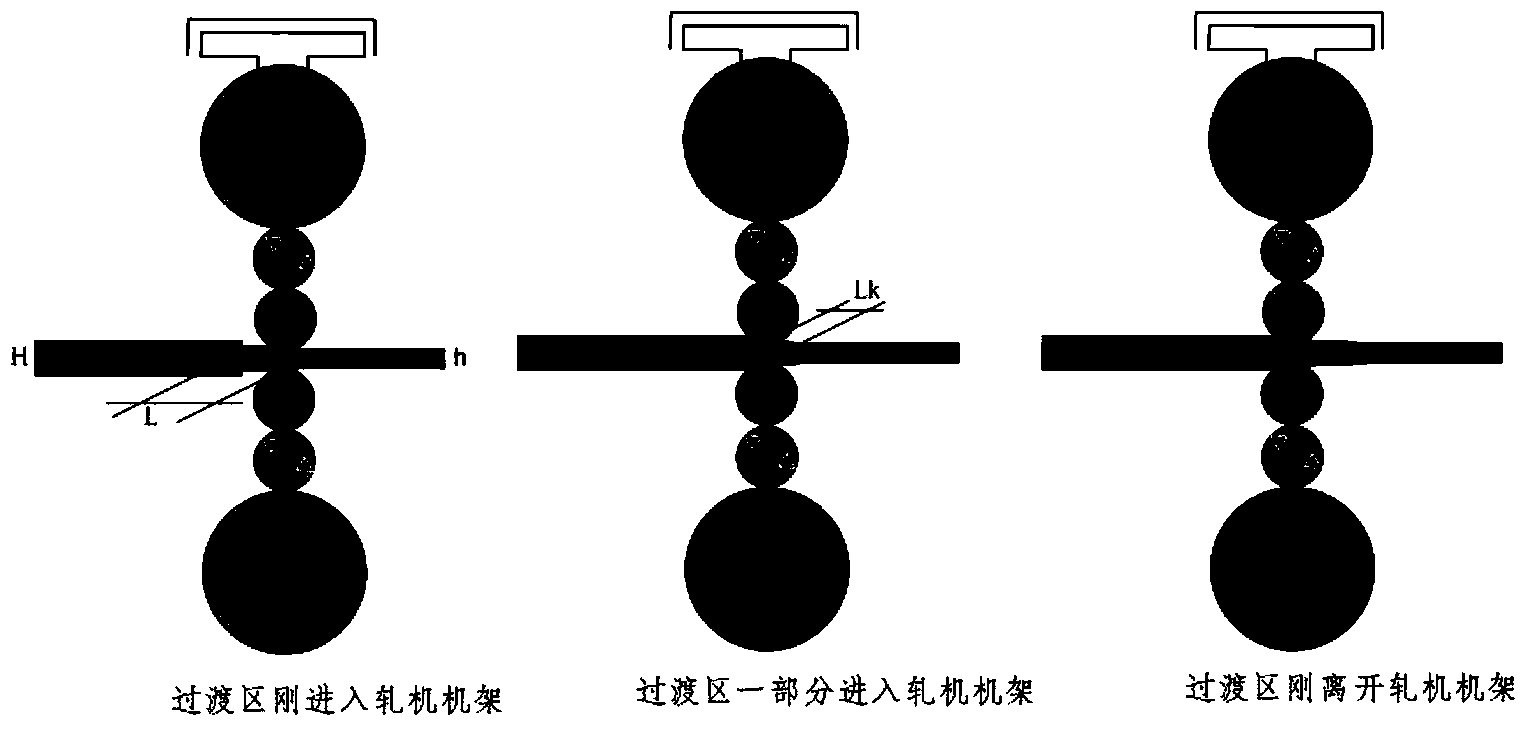

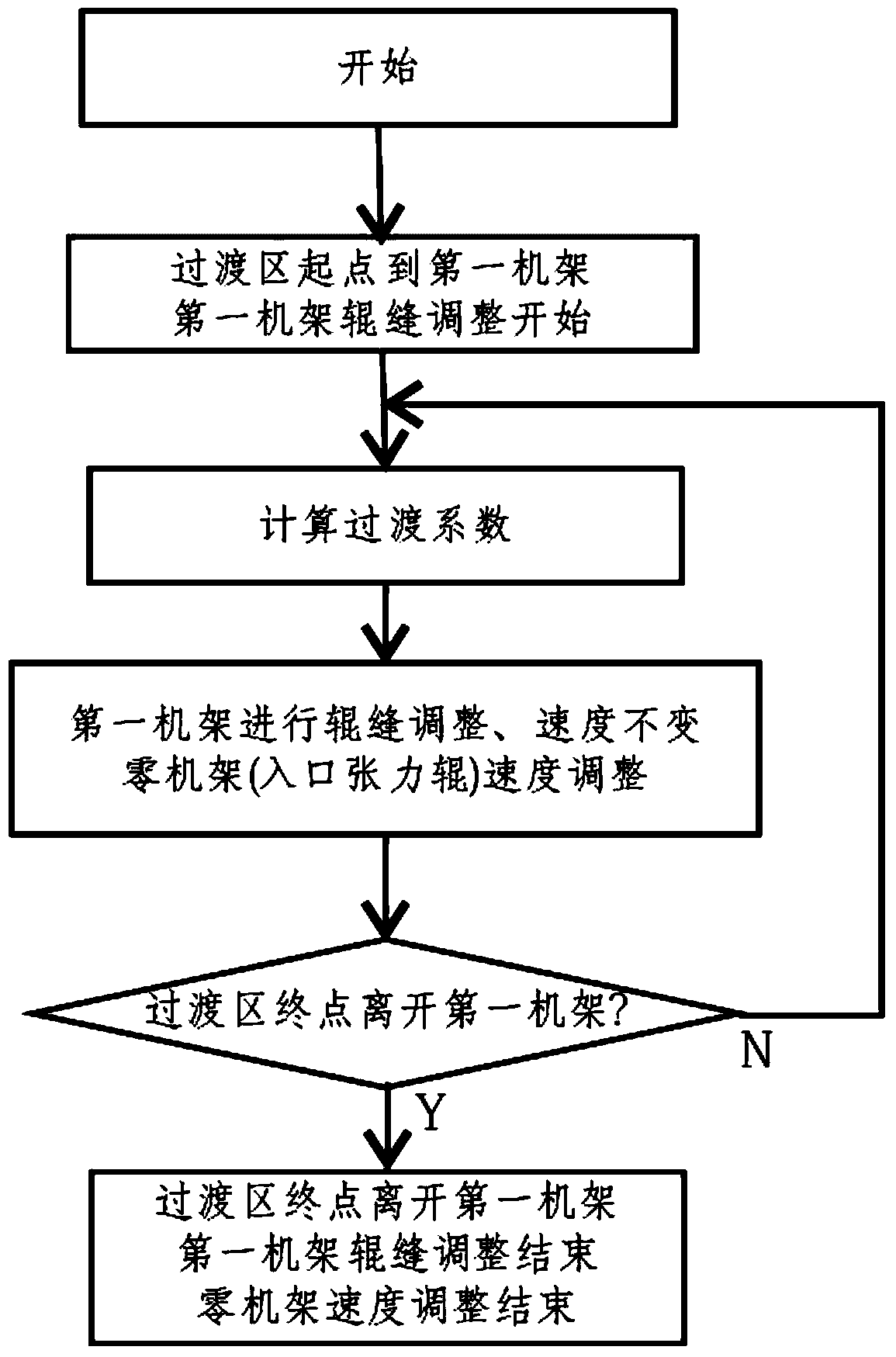

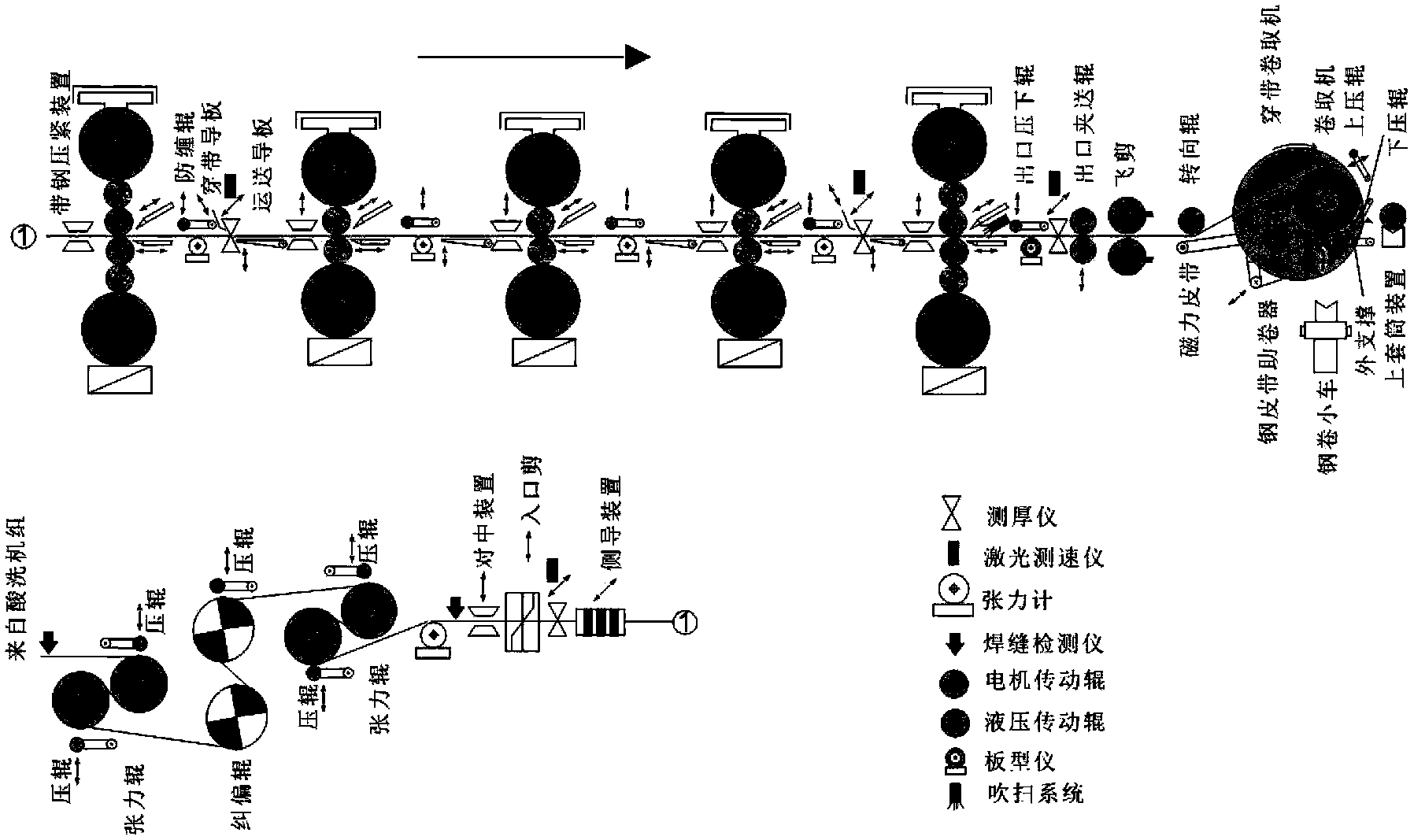

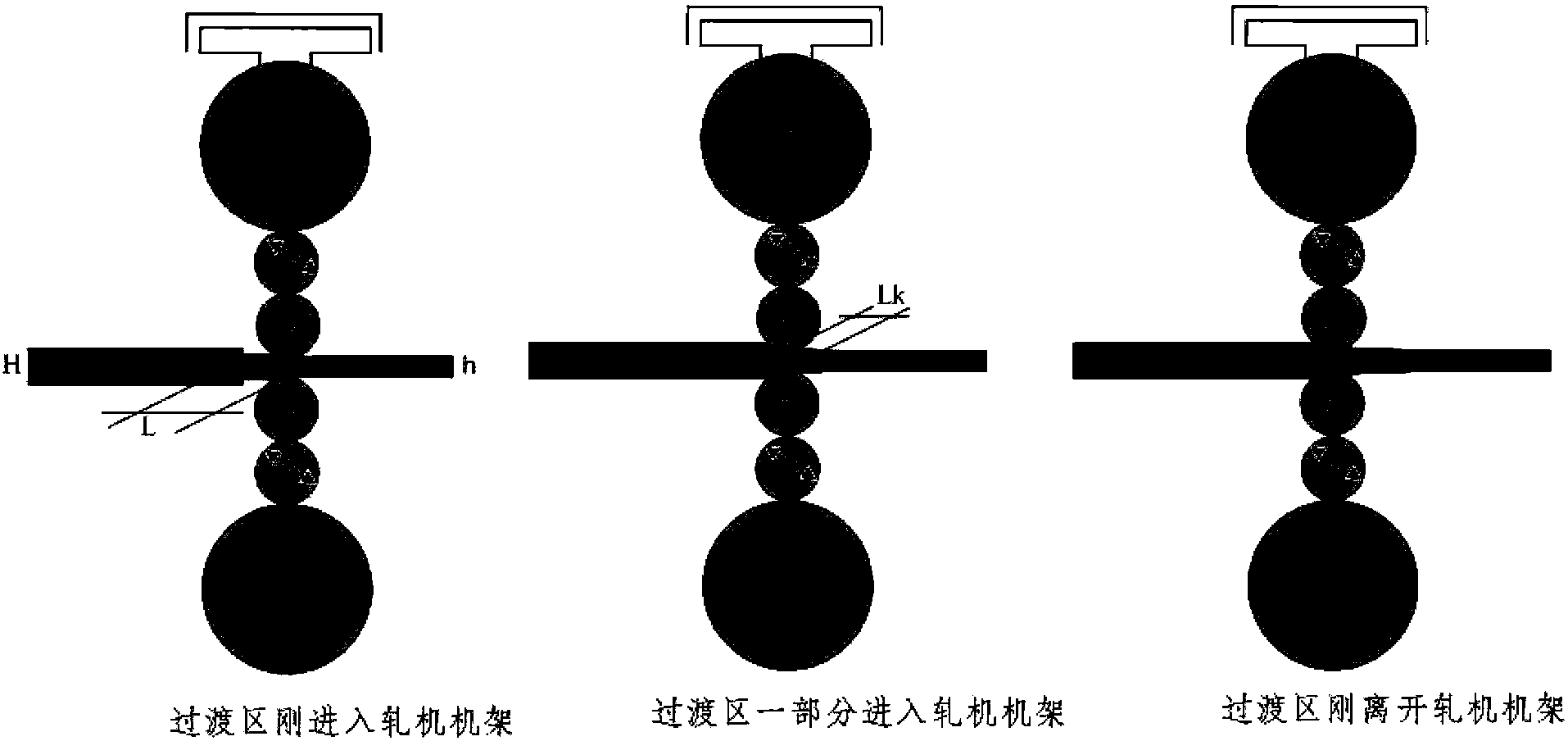

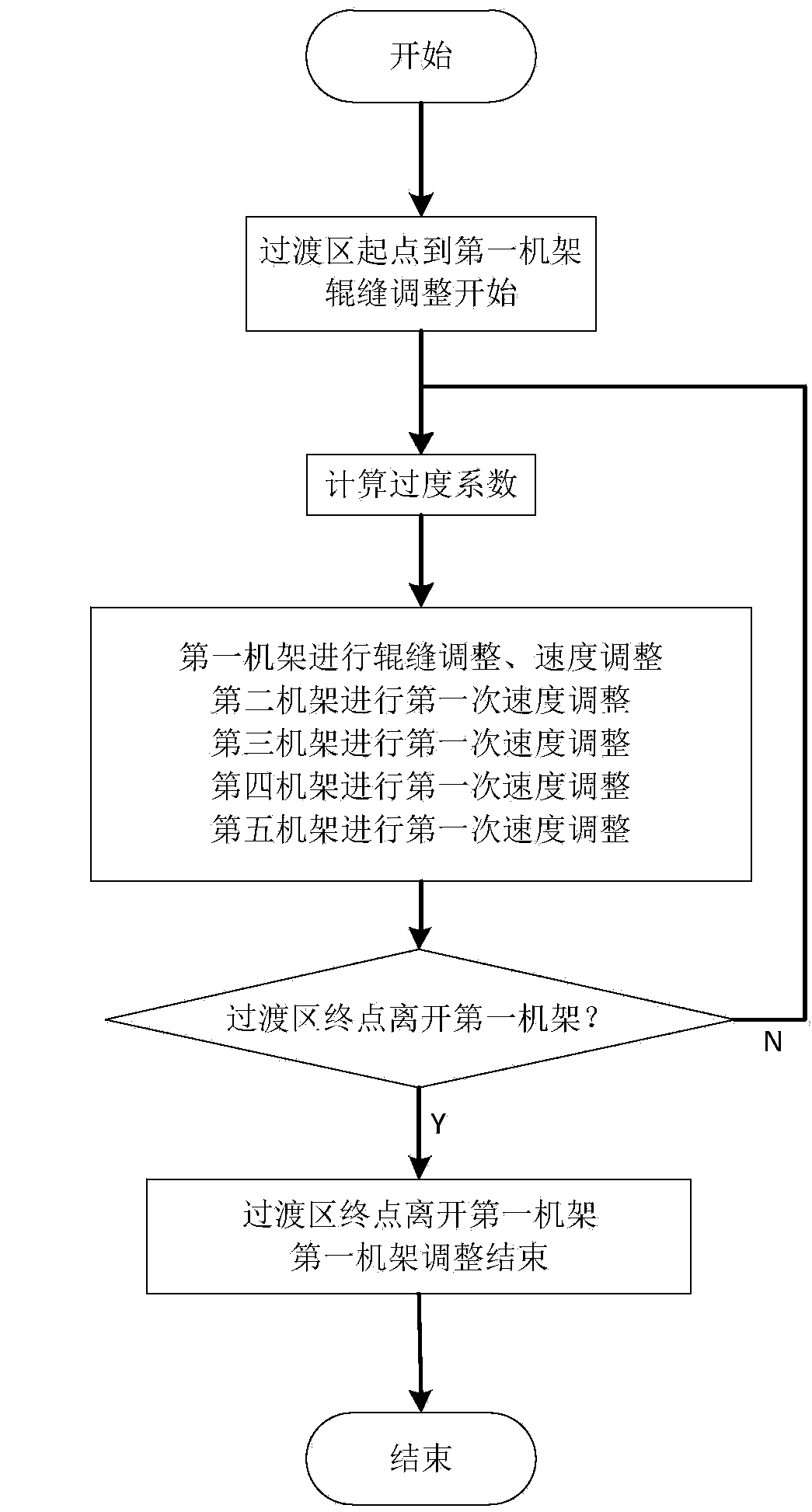

Flying gauge change control method of tandem cold mill

ActiveCN103551389AReduce tension fluctuationsQuality improvementRoll mill control devicesMetal rolling arrangementsEngineeringChange control

The invention discloses a flying gauge change method for a five-rack tandem cold mill. The method comprises the following steps of determining a transition region of flying gauge change; calculating a transition coefficient according to the length of the transition region, the original thickness of band steel before rolling of each rack and the set thickness of the band steel after rolling of each rack; in a transition process, calculating a dynamically adjusted roll gap set value of each rack according to the transition coefficient, and regulating the band steel outlet speed of each rack according to reverse flow. By the adoption of the flying gauge change method, a flying gauge change process of the five-rack tandem cold mill can be optimized, the stability of the flying gauge change is improved, equipment impact is reduced, the out-of-tolerance of the band steel is reduced, the speed of the flying gauge change is increased, and the time of the flying gauge change is shortened.

Owner:WISDRI WUHAN AUTOMATION

Flying gauge change control method of tandem cold mill

ActiveCN104338753AReduce tension fluctuationsQuality improvementRoll mill control devicesMetal rolling arrangementsChange controlStrip steel

The invention discloses a flying gauge change control method of a tandem cold mill. The method comprises the following steps: determining a transition region of flying gauge change, computing transition coefficients according to the length of the transition region, the original thickness of strip steel before the strip steel is rolled by a frame and the set thickness of the strip steel after the strip steel is rolled by the frame, computing a roll gap set value for dynamic adjustment of each frame according to the transition coefficients when a transition process is performed, and adjusting the strip steel discharge speed of each frame according to fair current. By adopting the method, the flying gauge change process of the tandem cold mill can be optimized, the smoothness of flying gauge change is improved, equipment impact is reduced, out-of-tolerance of strip steel is reduced, the speed of flying gauge change is increased, and the time of flying gauge change is shortened.

Owner:WISDRI WUHAN AUTOMATION

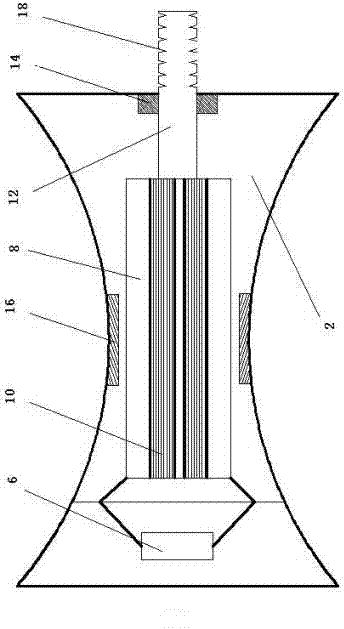

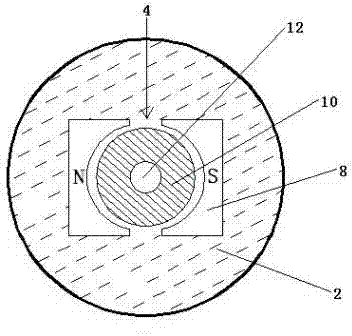

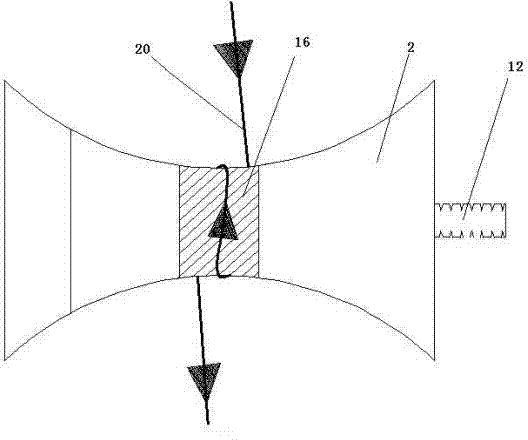

Electromagnetic yarn balance roller

InactiveCN103922191AReduce tension fluctuationsHigh degree of automationFilament handlingElectricityYarn tension

The invention relates to an electromagnetic yarn balance roller which comprises a roller shell, and an electric core and a built-in circuit which are embedded inside the roller shell. The roller shell is coaxial with the electric core. The electromagnetic yarn balance roller is characterized in that the outer layer and the inner layer of the electric core are respectively a magnet group and a coil, a central shaft is fixedly mounted at the axis of the coil, one free end of the central shaft extends out of the roller shell, and the electric core is electrically connected with the built-in circuit. The electromagnetic yarn balance roller has the advantages that defects in the prior art are overcome, yarn tension can be changed instantly by using motor principles, the brake force of the roller is controlled by the electric core embedded inside the roller shell, the faster the yarn moves, the larger the brake force of the roller is, the slower the yarn moves, the smaller the brake force of the roller is, yarn tension fluctuation can be lowered, and high automation level, flexible reaction, instantaneity and quickness are achieved.

Owner:WUJIANG MINGJIA WEAVING

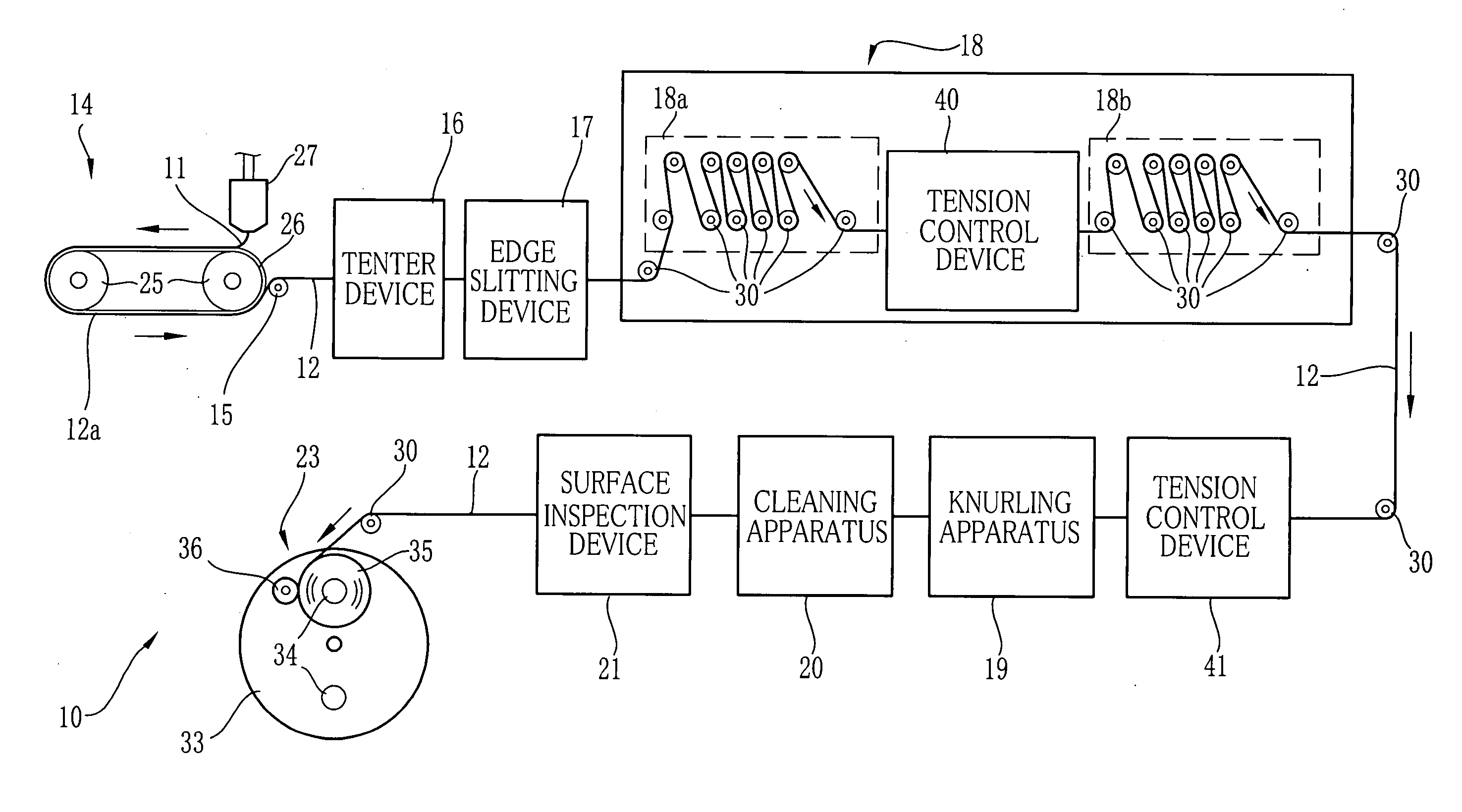

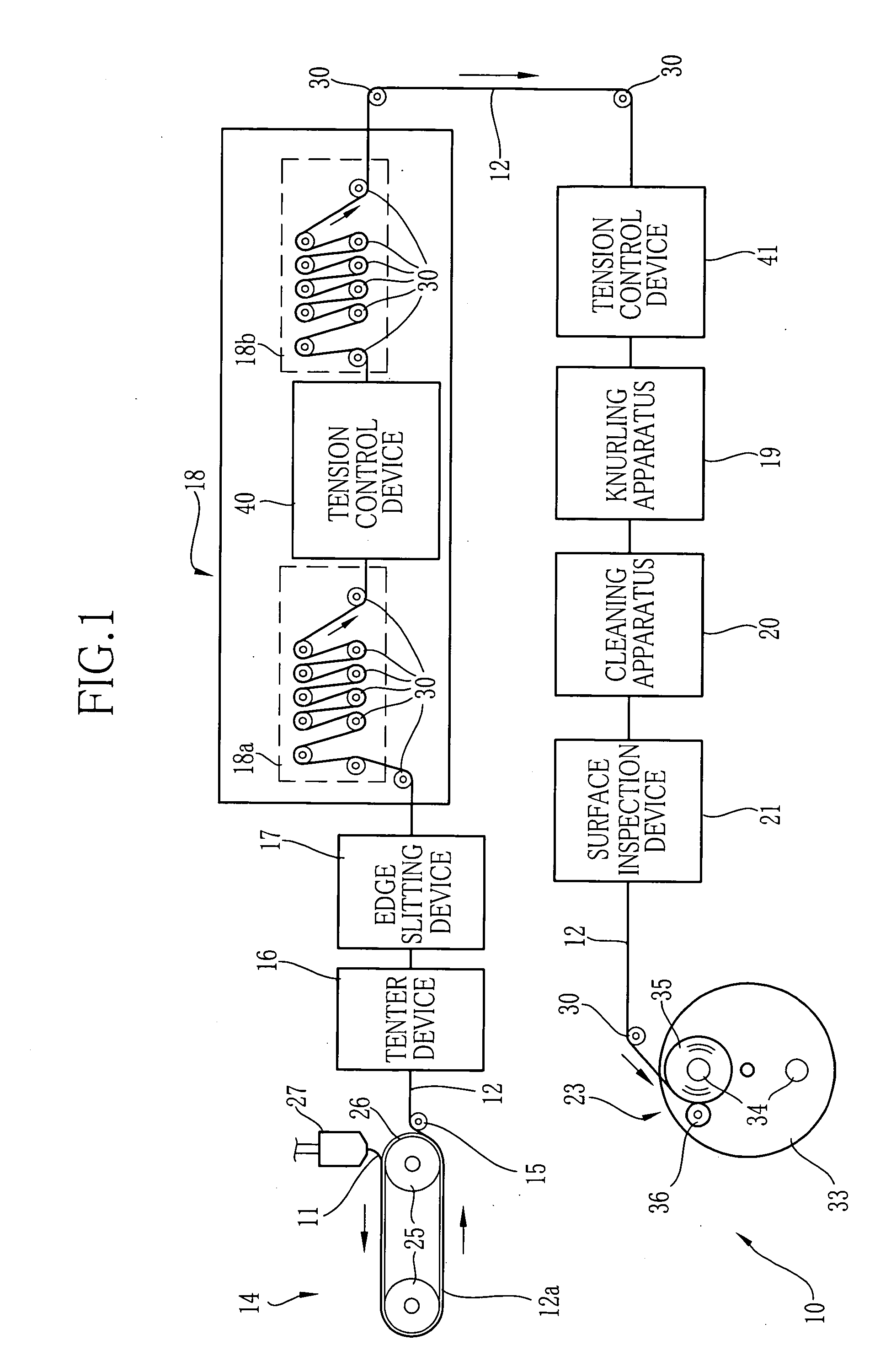

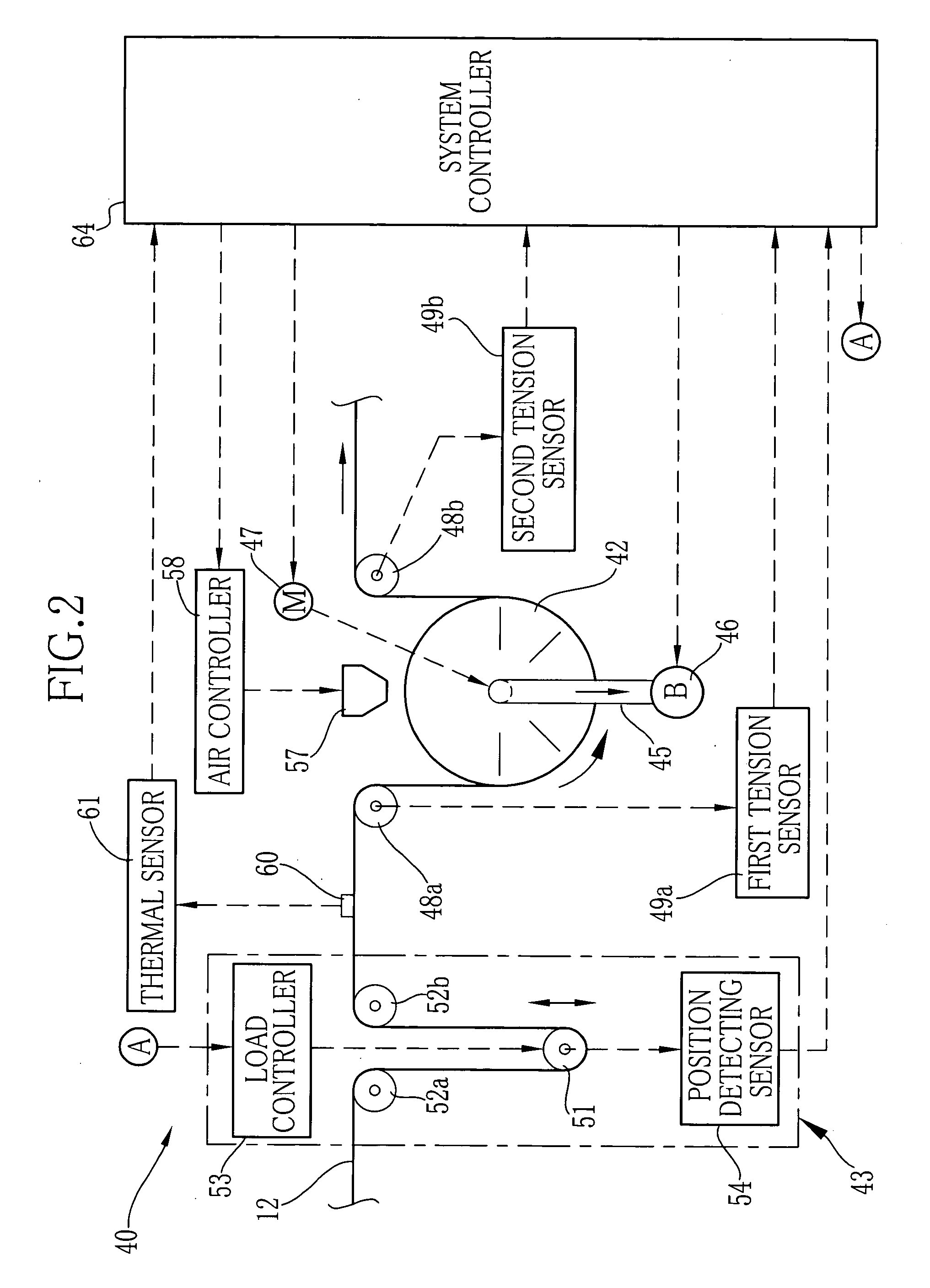

Solution casting method

InactiveUS20050218554A1Constant tensionReduce tension fluctuationsFlat articlesCoatingsEngineeringScratch wound

Owner:FUJIFILM CORP +1

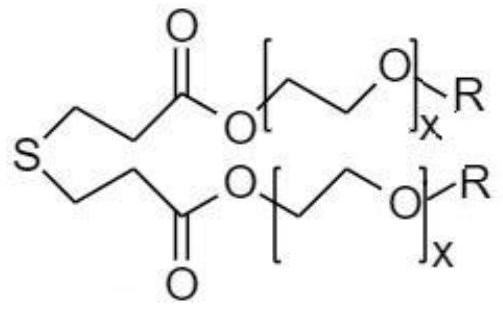

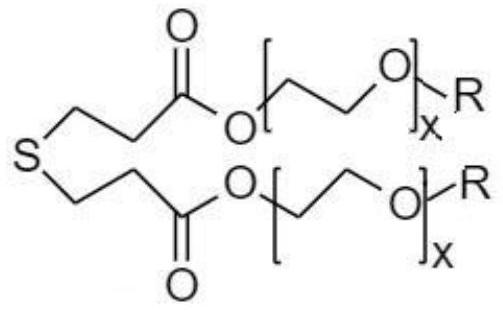

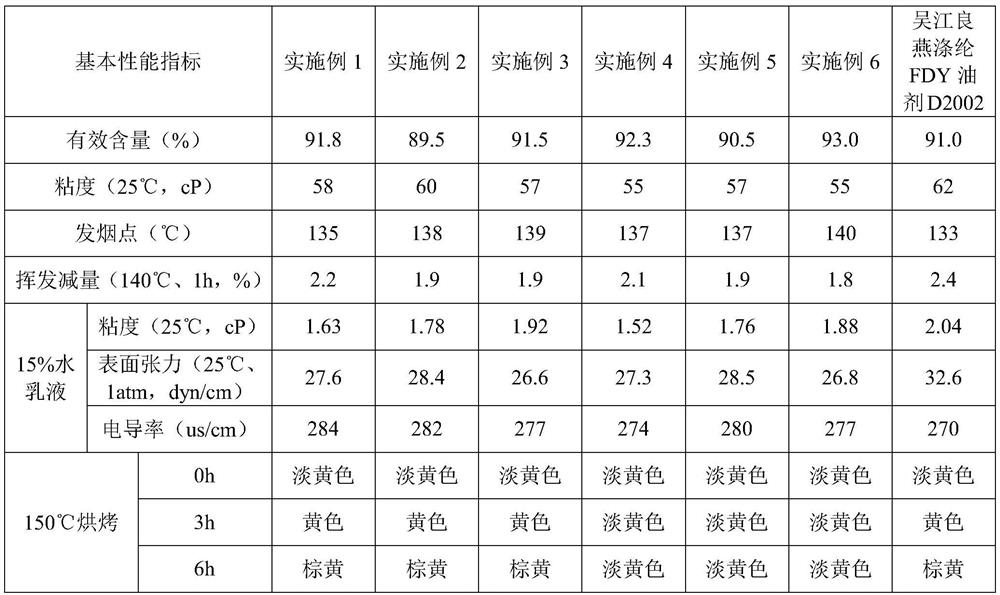

Dacron FDY oiling agent and preparation method thereof

The invention discloses a dacron FDY oiling agent and a preparation method thereof, and relates to the field of dacron spinning oiling agents. The dacron FDY oiling agent is composed of the followingcomponents of, in percentage by weight, 14%-33% of base oil, 24%-38% of a smoothing agent, 7%-11% of a bundling agent, 7%-11% of an emulsifier, 5%-7% of an antistatic agent, 1%-3% of a penetrant, andthe balance additives. According to the dacron FDY oiling agent and the preparation method thereof, through the selection and proportioning of monomers, the prepared FDY oiling agent has good comprehensive properties of smoothness, bundling, static electricity resistance, permeation, heat resistance, sizing and uniform adhesion, is good in spinnability, greatly reduces abnormal broken filaments, broken ends, white powder and tension fluctuation and winding phenomena, and can significantly improve the superior product rate under the same spinning process conditions. In the subsequent printing and dyeing process, dyeing is difficult, the phenomenon of uneven dyeing is reduced, and the fiber dyeing M rate is increased.

Owner:ZHEJIANG HENGYI PETROCHEMICAL RES INST CO LTD

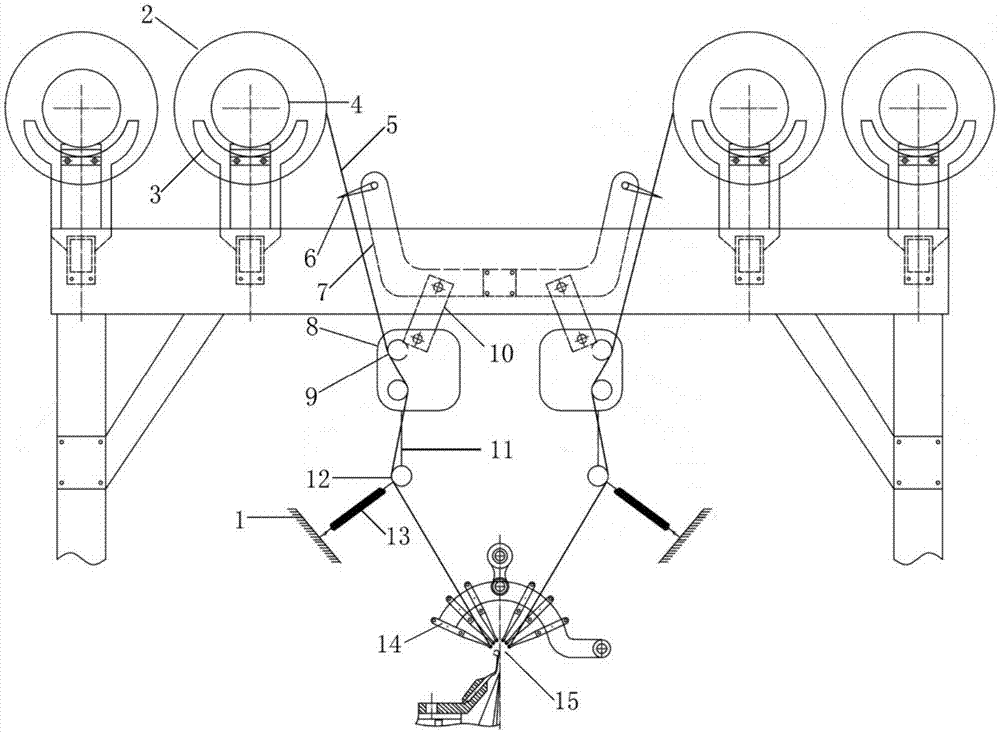

Device and method for compensating warp tension based on stereo loom fabric weave

InactiveCN106854792AImprove the level of intelligent controlSimple mechanical structureLoomsFiberCarbon fibers

The invention provides a device for compensating a warp tension based on stereo loom fabric weave. A stereo loom comprises warp beams, warp yarns from the warp beams penetrate through a heald frame to be interwoven with weft yarns through a layering frame so as to form a fabric. The device for compensating the warp tension comprises tension rollers for vertically moving to perform synchronous compensation on warp extension or shrinkage caused by vertical movement of the heald frame and driving devices of the tension rollers. Each warp beam is correspondingly provided with one tension roller, the warp yarns from the warp beams bypass the tension rollers in a U-shaped mode and then penetrate through the heald frame to be interwoven with weft yarns through the layering frame. The invention further provides a method for compensating the warp tension based on the stereo loom fabric weave. The active compensating method is simple in structure and reliable in performance, can very well adapt to weaving of high performance fiber such as poor-elasticity carbon fiber and can meet the compensating requirement that the stereo loom provided with multiple opening and one heald frame needs frequent stroke change, the loom efficiency and fabric quality are improved.

Owner:DONGHUA UNIV

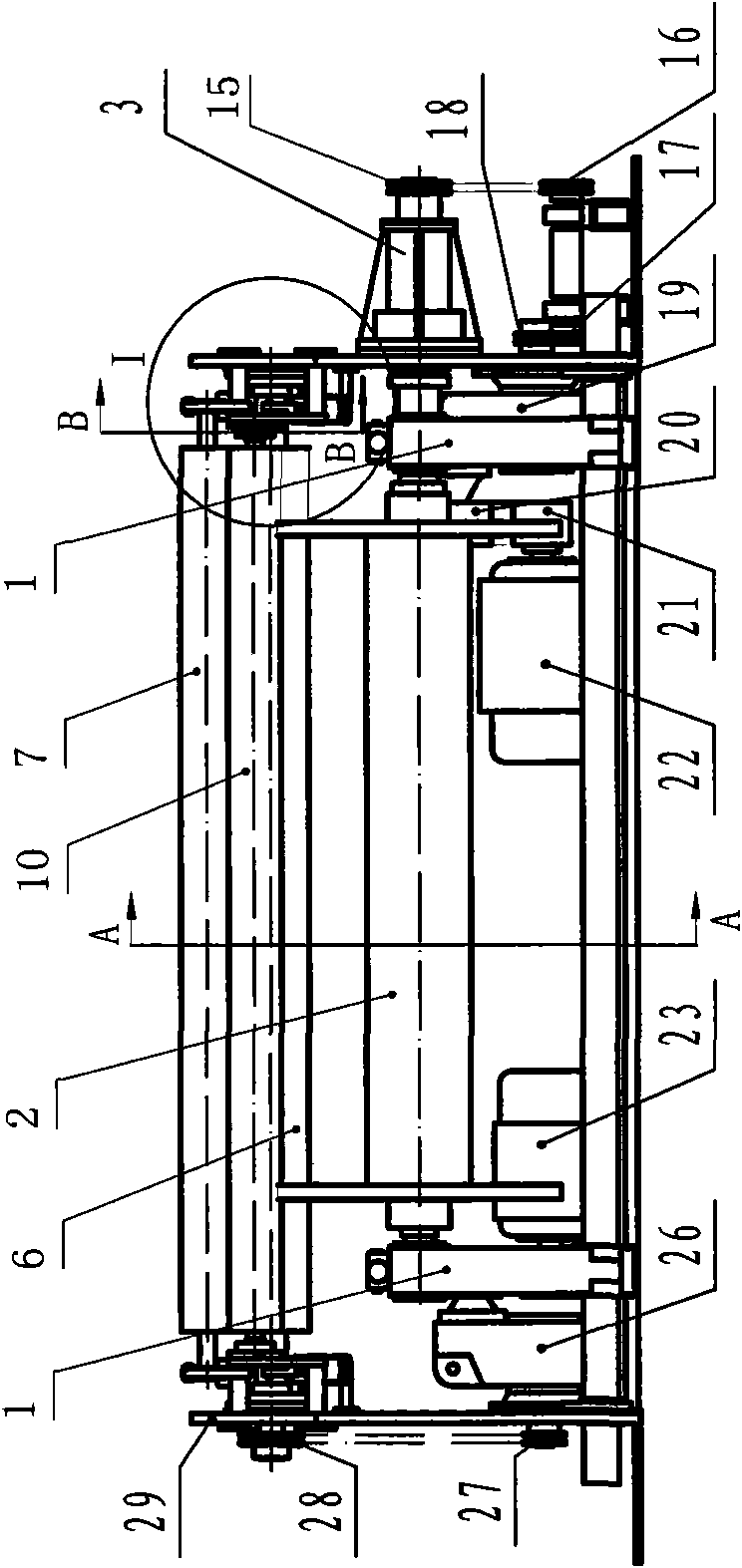

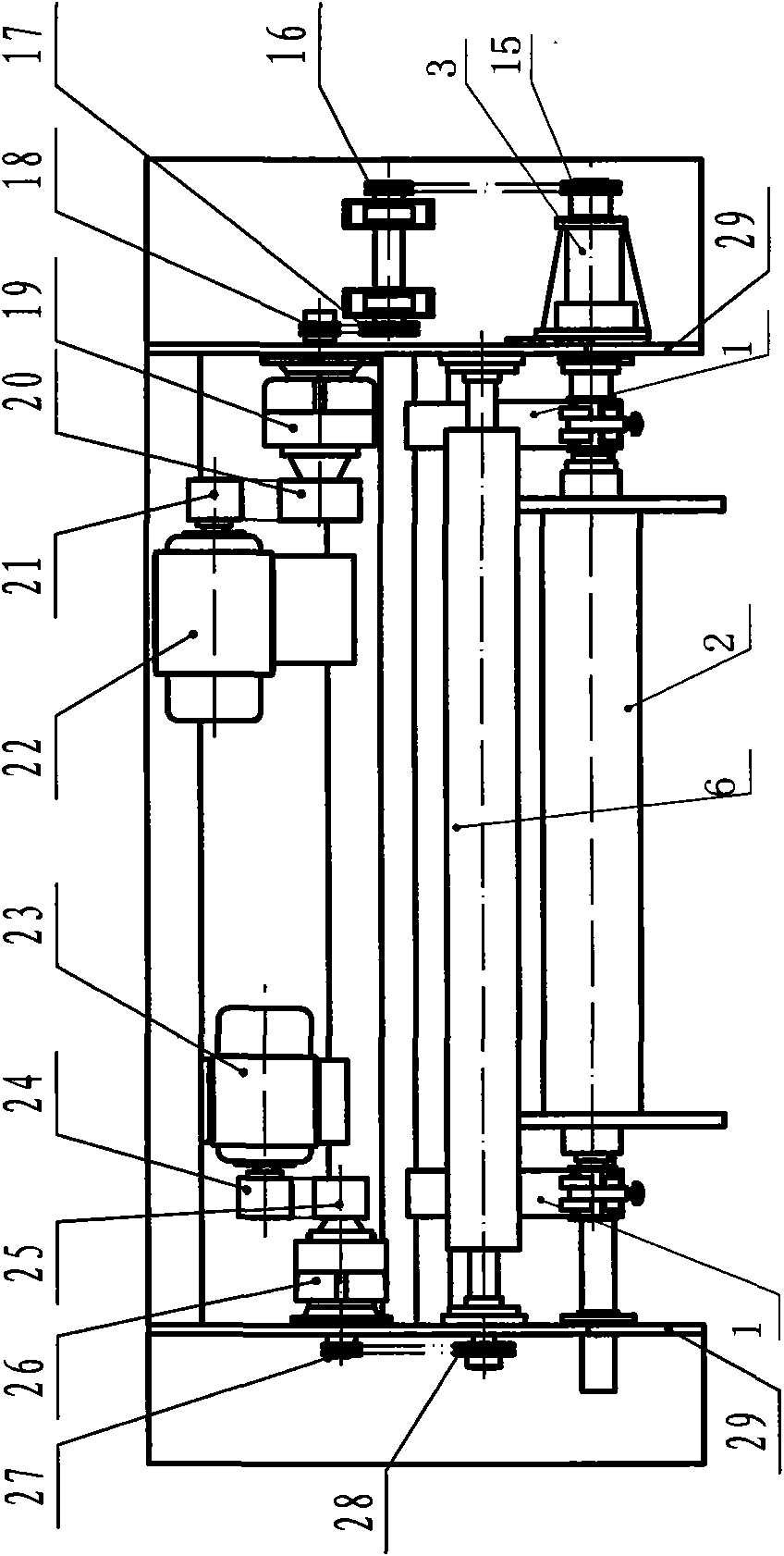

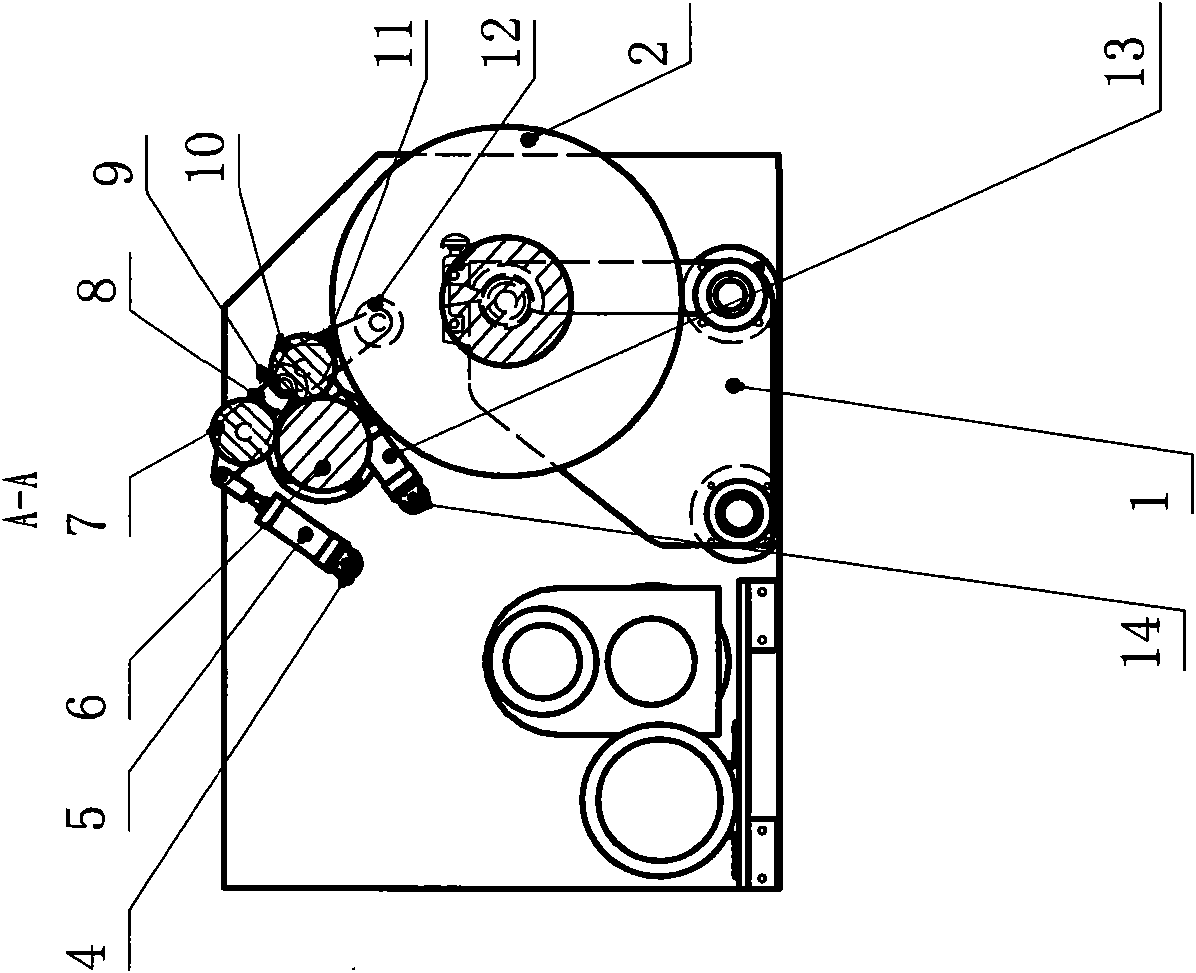

Bi-motor yarn tension control device of disposable warping machine

InactiveCN101555644AHigh control precisionConstant speedOther manufacturing equipments/toolsTextiles and paperElectric machineDrive shaft

The invention relates to a bi-motor yarn tension control device of a disposable warping machine, which is characterized in that a driving shaft (2) and a wrapping roller (6) are respectively driven by a motor; a three-roller delivery device is arranged above the front of the driving shaft (2), two ends of the wrapping roller (6) in the three rollers are respectively arranged in bearing blocks on a wallboard (29), and an upper pressing roller (7) and a side pressing roller (10) in the three rollers can be pressed or loosened on the periphery of the wrapping roller (6). The invention respectively controls the winding of the driving shaft and the yarn delivery of the three-roller delivery device through two motors because of controlling the yarn tension at a machine head, and the driving shaft controls the winding moment through the regulation of a transducer by utilizing the moment control principle so as to lead the driving shaft to realize the constant tension winding; and a three-roller drive motor realizes constant yarn winding speed through the regulation of the transducer by utilizing the speed control principle. The cooperation of the two control methods of the two motors accurately controls the yarn tension.

Owner:射阳东翔纺织机械有限公司

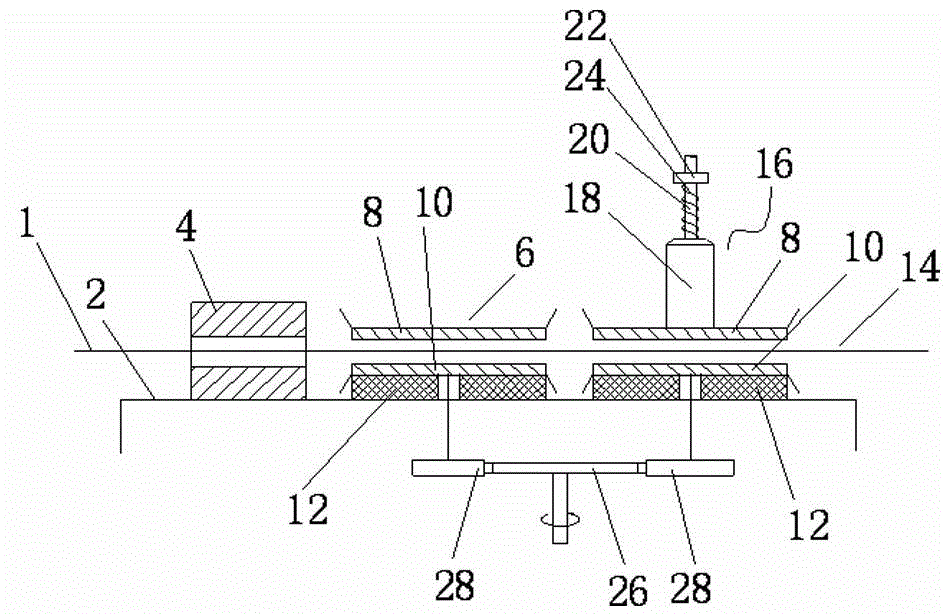

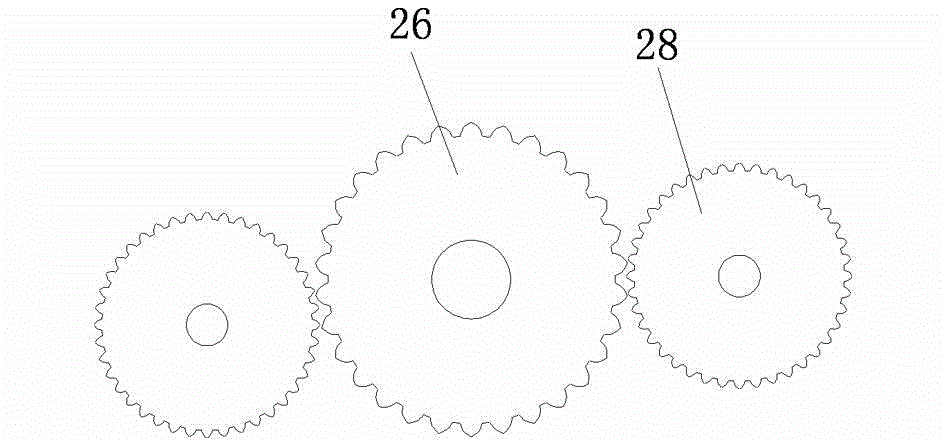

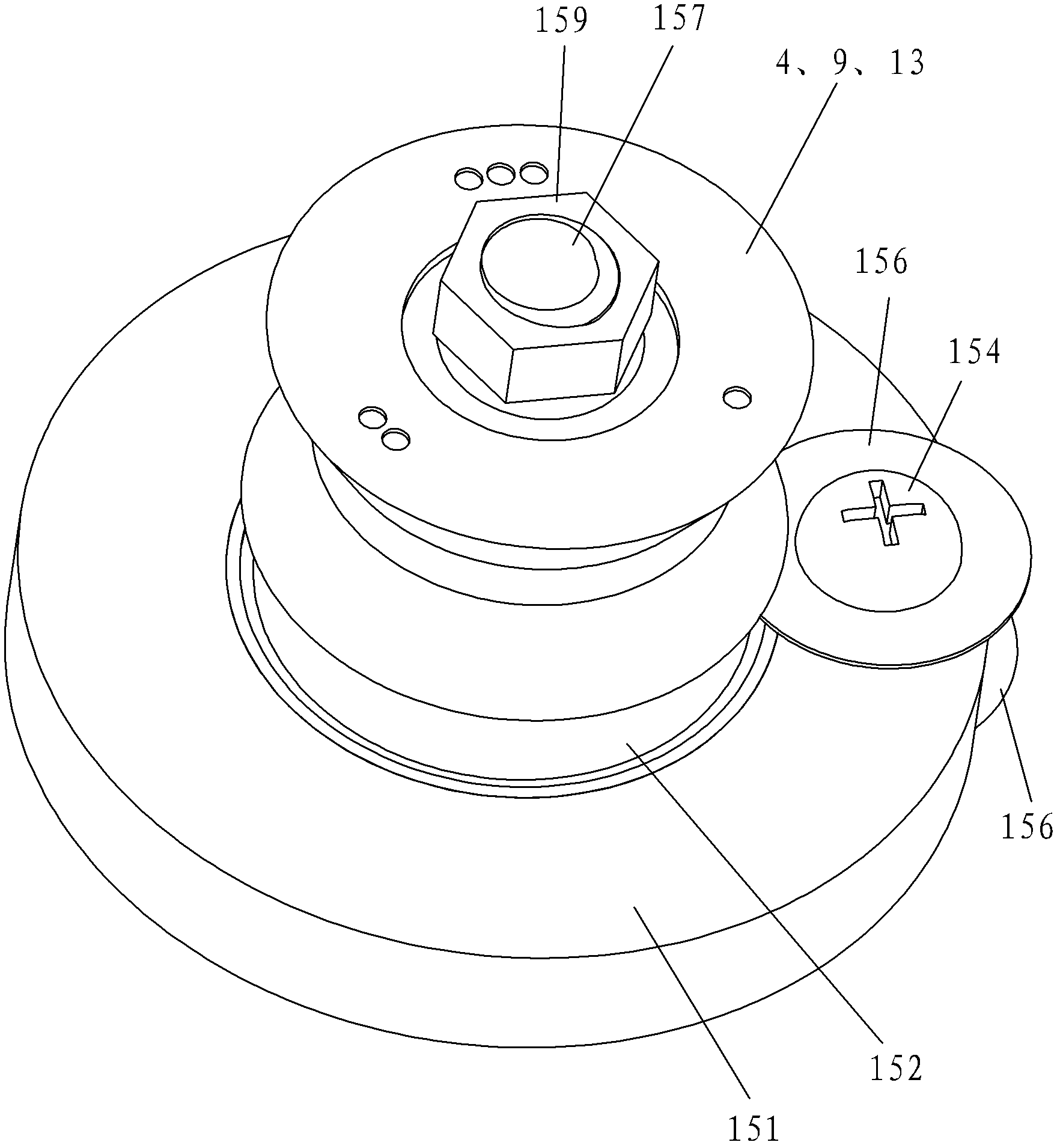

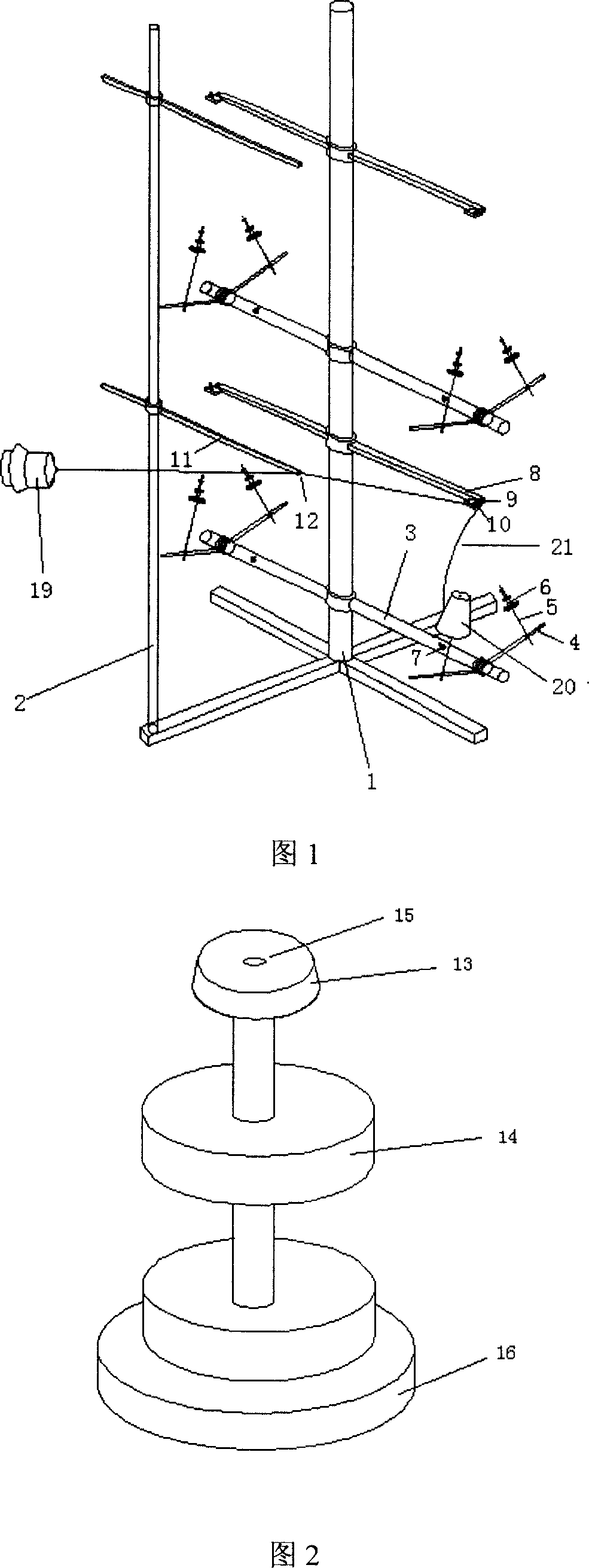

Adjusting device for yarn tension

InactiveCN103950794AAvoid accumulationReduce tension fluctuationsFilament handlingEngineeringYarn tension

The invention provides an adjusting device for yarn tension. The adjusting device comprises a rack, a yarn guiding eye and a primary tension disc set, wherein the yarn guiding eye and the primary tension disc set are sequentially arranged on the rack along the winding direction of yarns; the primary tension disc set is provided with an upper tension disc and a lower tension disc which are oppositely arranged; a clearance for allowing the yarns to penetrate through is formed between the upper tension disc and the lower tension disc; a damping ring is arranged below the lower tension disc. The adjusting device is characterized by further comprising a secondary tension disc set arranged at the rear end of the primary tension disc set along the winding direction of the yarns; the secondary tension disc set is also provided with an upper tension disc, a lower tension disc and a pressurizing mechanism; the upper tension disc set and the lower tension disc set are oppositely arranged; the pressurizing mechanism is arranged above the upper tension disc and can be used for adjusting the downward pressure of the upper tension disc. According to the adjusting device for the yarn tension, which is disclosed by the invention, the fluctuation of output tension is relieved by two-time adjustment; meanwhile, flying sundries generated in the threading process can be automatically cleared and normal work of the tension device is ensured. The adjusting device is suitable for high-speed warping.

Owner:WUJIANG LONGSHENG TEXTILE

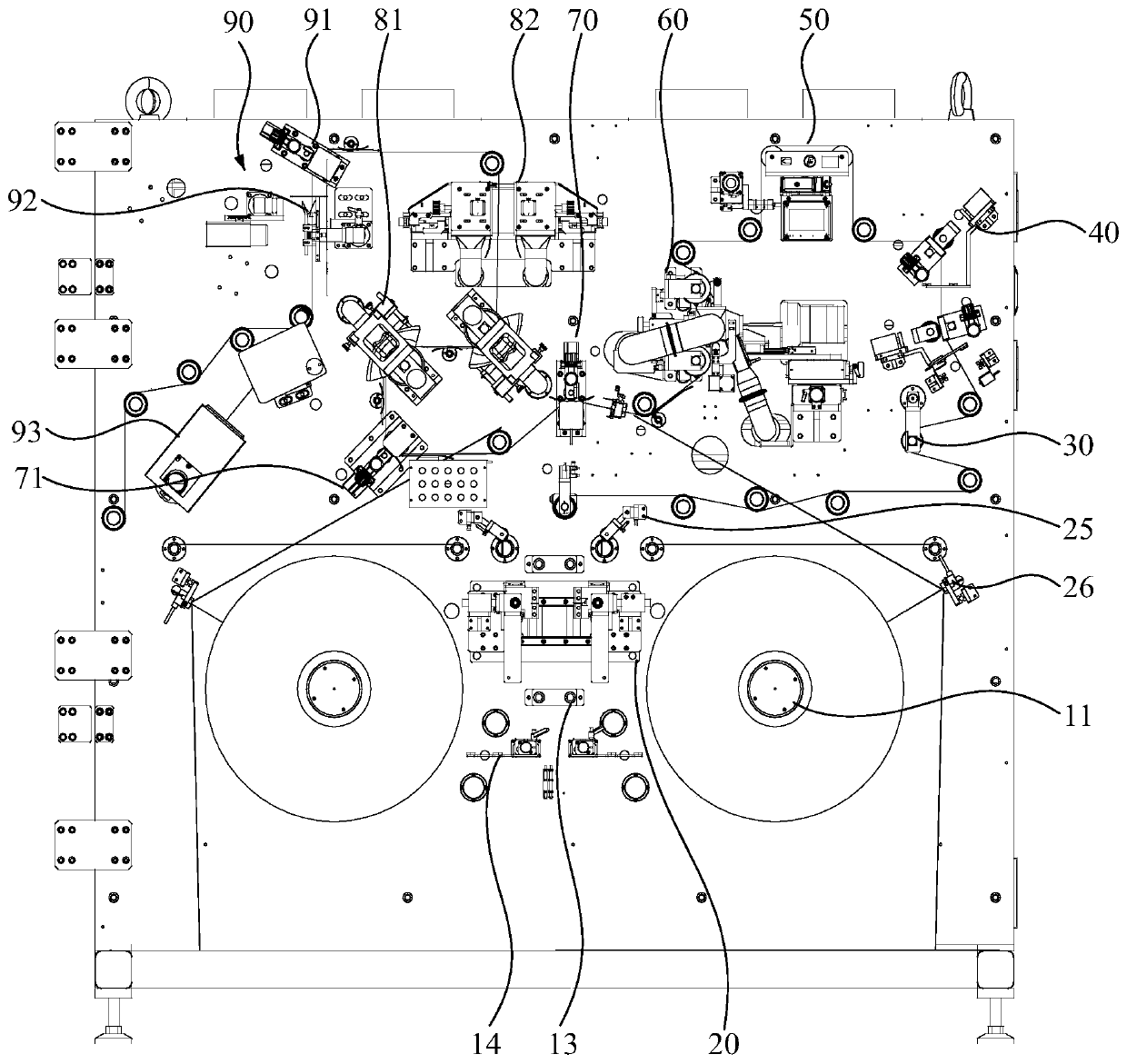

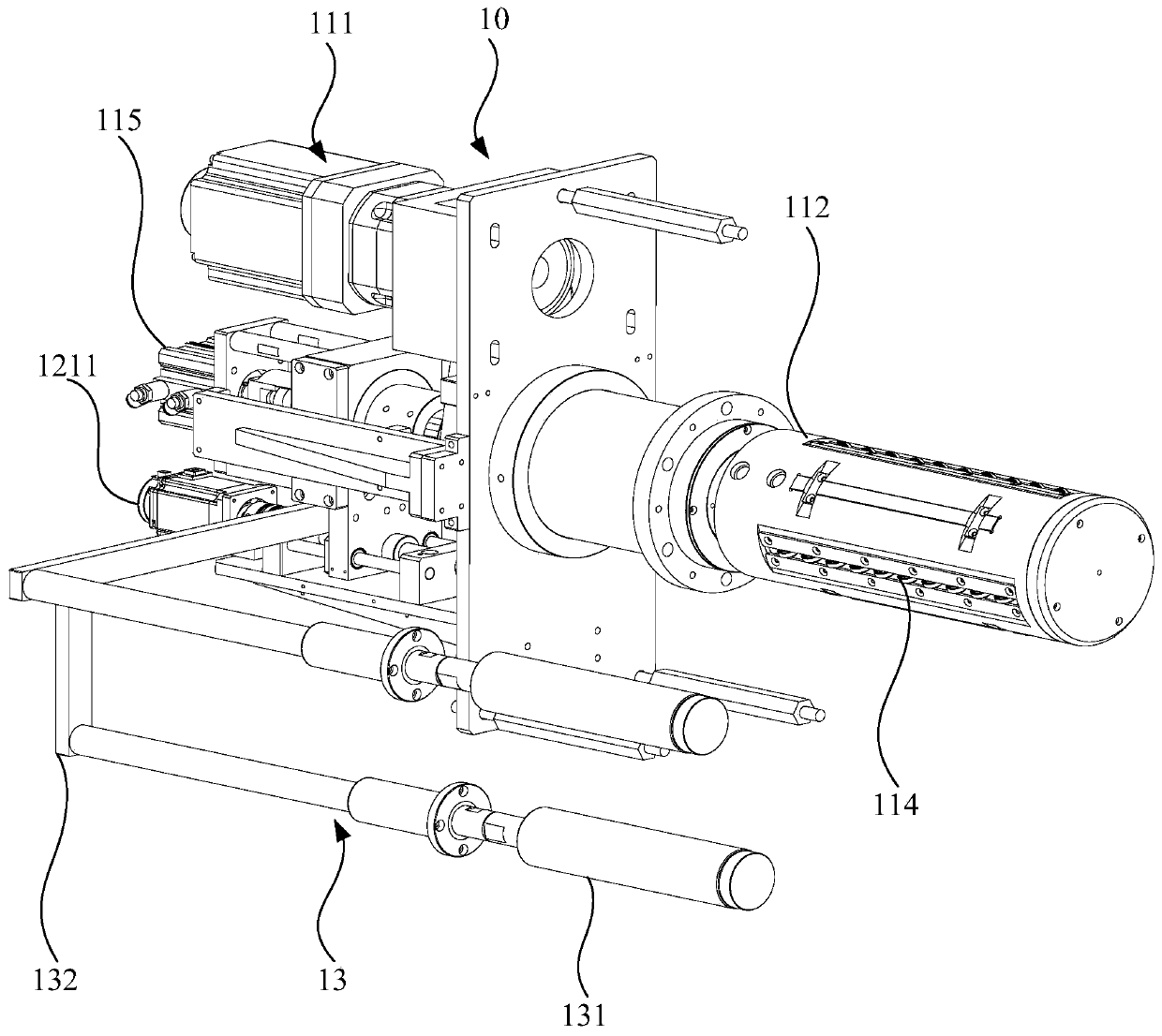

Laser die cutting machine and die cutting method

ActiveCN110977197AGuaranteed cutting accuracyImprove cutting accuracyLaser beam welding apparatusEngineeringLaser cutting

The invention relates to a laser die cutting machine and a die cutting method. The laser die cutting machine comprises an unwinding device, a tension control mechanism and a laser cutting mechanism. The unwinding device comprises an unwinding mechanism, an unwinding rectifying mechanism, a rectifying auxiliary mechanism and a rectifying detecting piece for detecting if materials are deviated; theunwinding rectifying mechanism comprises a first moving module; the unwinding mechanism and the rectifying auxiliary mechanism are connected with the unwinding rectifying mechanism; and the first moving module can drive the unwinding mechanism and the rectifying auxiliary mechanism to move. The tension control mechanism is used for adjusting the tension of the materials to maintain constant tension of the materials. The unwinding device, the tension control mechanism and the laser cutting mechanism are arranged in a material conveying direction. The laser die cutting machine can rectify polarpieces, and meanwhile, reduces the tension fluctuation of the polar pieces in the conveying process to improve the cutting precision of the polar pieces.

Owner:GUANGZHOU EHOLLY MACHINERY CO LTD

Production device and production technology for dacron double-polyester double-splendor Liz silk

The invention aims to provide a production device and a production technology for dacron double-polyester double-splendor Liz silk fabric which have the characteristics that the produced double-polyester double-splendor Liz silk fabric has small bulges on silk after high-temperature dyeing, and is easy in napping and good in style hand feeling. The disclosed production device for dacron double-polyester double-splendor Liz silk comprises a double-protofilamen rack, a protofilament pipe, filament pressing rods, a first roller, a first net mouth, an upper hot box, a cooling plate, a false twisting device, a second roller, a lower hot box, a second net mouth, a third roller, an oil tanker, a silk discharge guide device, a friction roller and a finished product bobbin. The dacron double-polyester double-splendor Liz silk produced by adopting the method is one kind of dacron composition fiber, and specifically used for producing and manufacturing high-grade fabrics such as bag cloth and sofa cloth; the new product has the characteristics that certain variable elasticity is realized, the fabric after single-color dyeing has the bicolor or tricolor effect, napping is easy, rebound resilience is good, and the style hand feeling is good.

Owner:TONGXIANG HENGJI DIFFERENTIAL FIBER

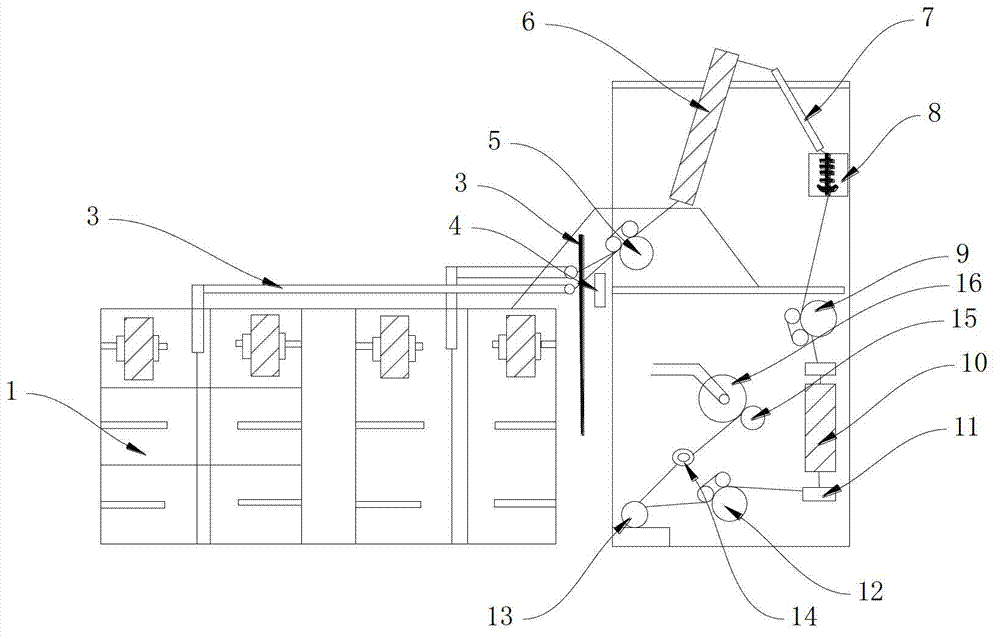

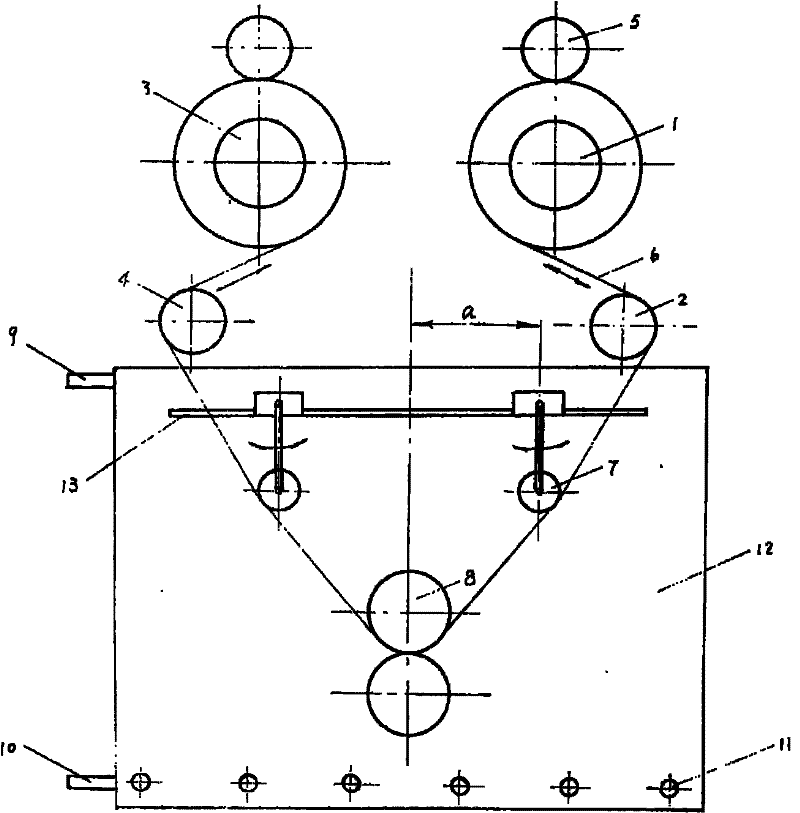

Fabric open-width washing and preshrinking device

InactiveCN102191643AIncrease frictional tractionReduce tension fluctuationsLiquid/gas/vapor removal by squeezing rollersTextile treatment machine arrangementsEngineeringMechanical engineering

The invention relates to an open-width washing device for preshrinking fabric. The open-width washing device comprises two cloth rollers, two overfeed rollers, a sink, two roller oscillating mechanisms and a pair of squeeze roller drums, wherein the two groups of rollers are synchronized by adopting variable-frequency speed regulation to control the cloth rollers A and B and the overfeed rollers C and D, the fabric passes through the sink in a relaxed state by maintaining the overfeed rate of the two overfeed rollers to be 1-4 percent, the two groups of roller oscillating mechanisms are arranged in the sink, the pair of squeeze roller drums externally packed by rubber skin is arranged at the lower part of the sink, therefore, the peripheral contour line of the integrally axial section of the upper roller drum forms a convex radian of 3.85-4.55 degrees, the peripheral contour line of the integrally axial section of the lower roller drum forms a concave radian of 3.86-4.60 degrees, the fabric is properly squeezed by the upper and the lower roller drums, and the pressure between the upper and the lower roller drums is controlled in the range from 5kg to 10kg. The open-width washing device provided by the invention is particularly suitable for preshrinking thin weft-elastic fabric.

Owner:SUZHOU VOCATIONAL UNIV

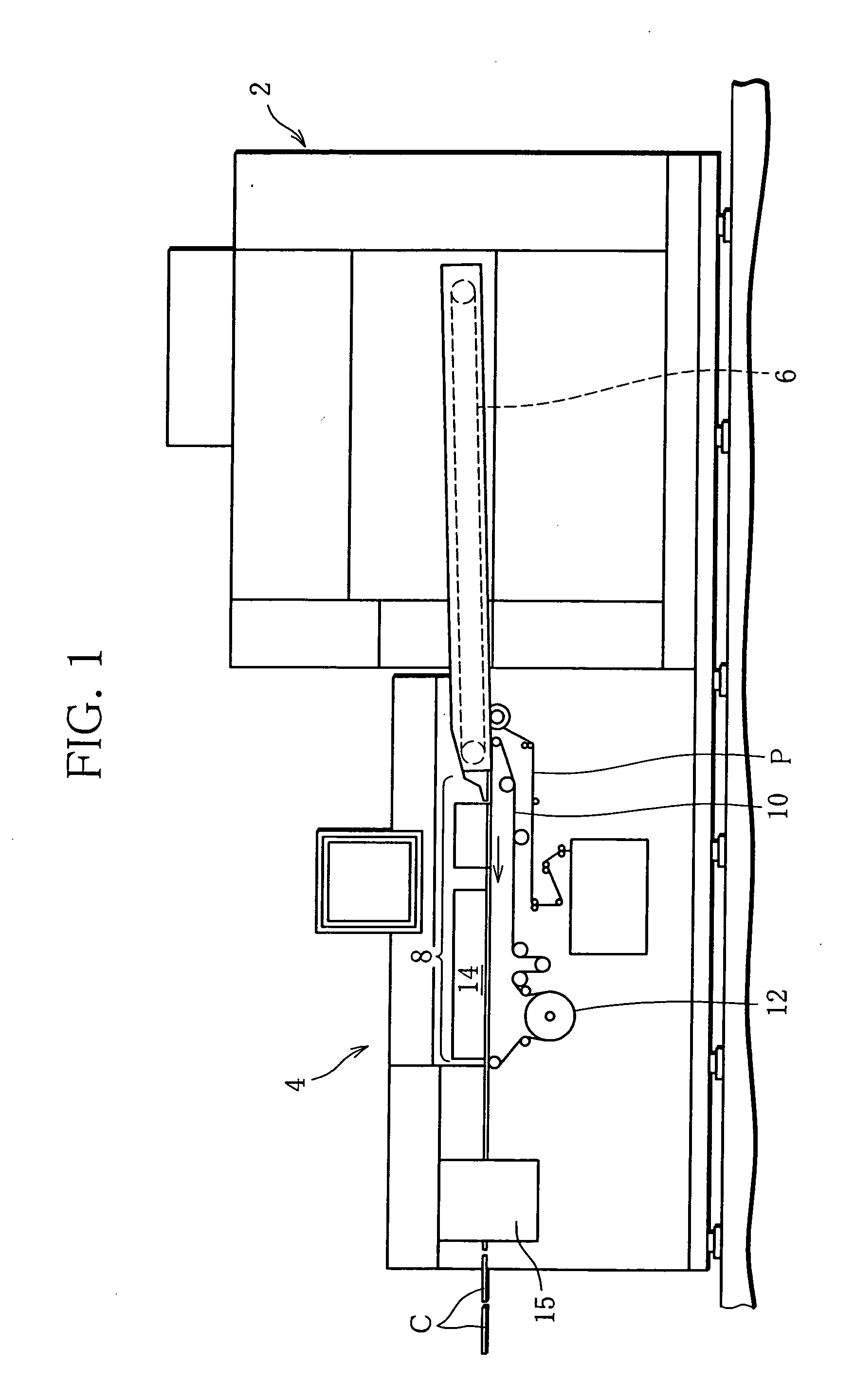

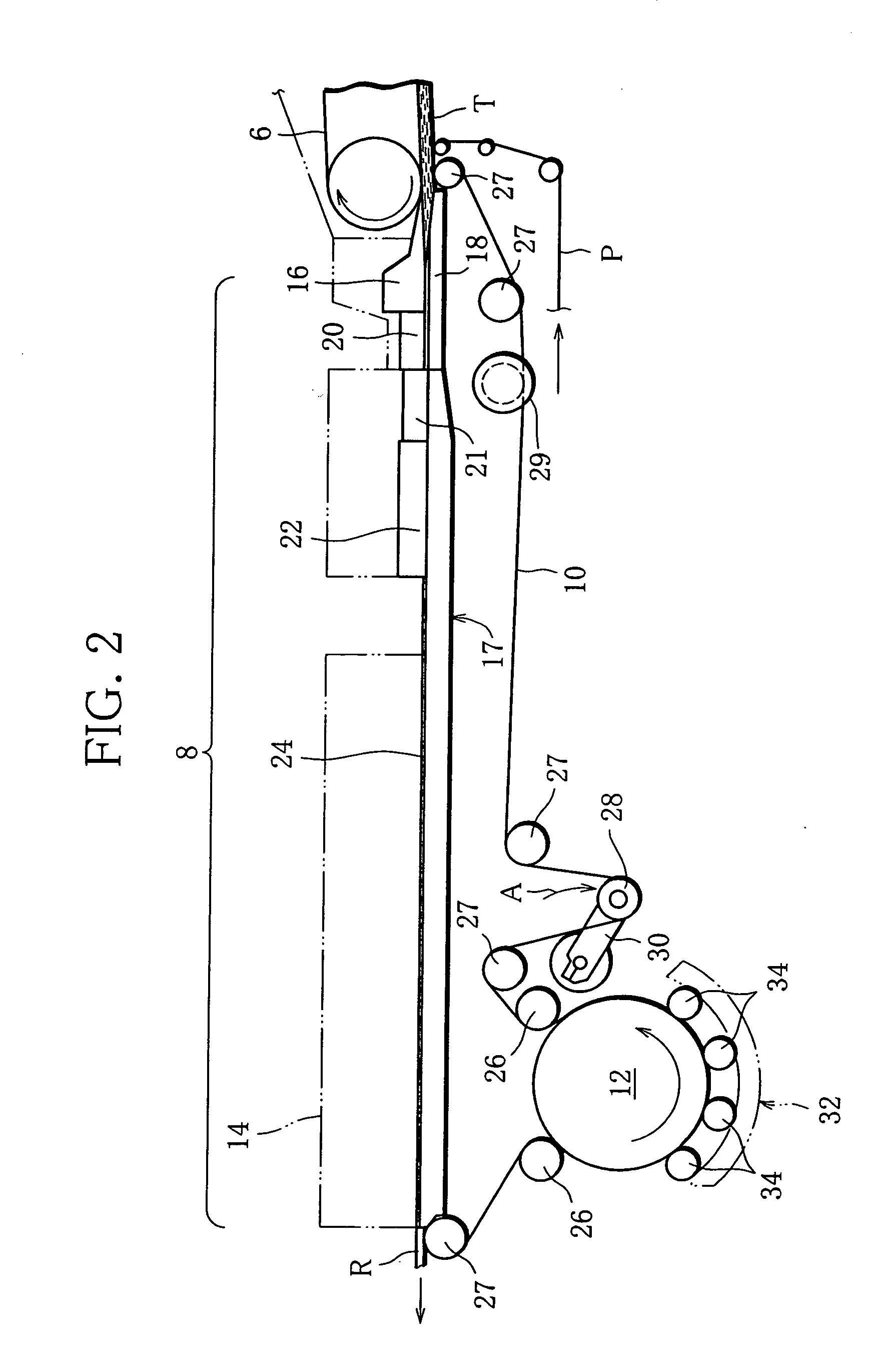

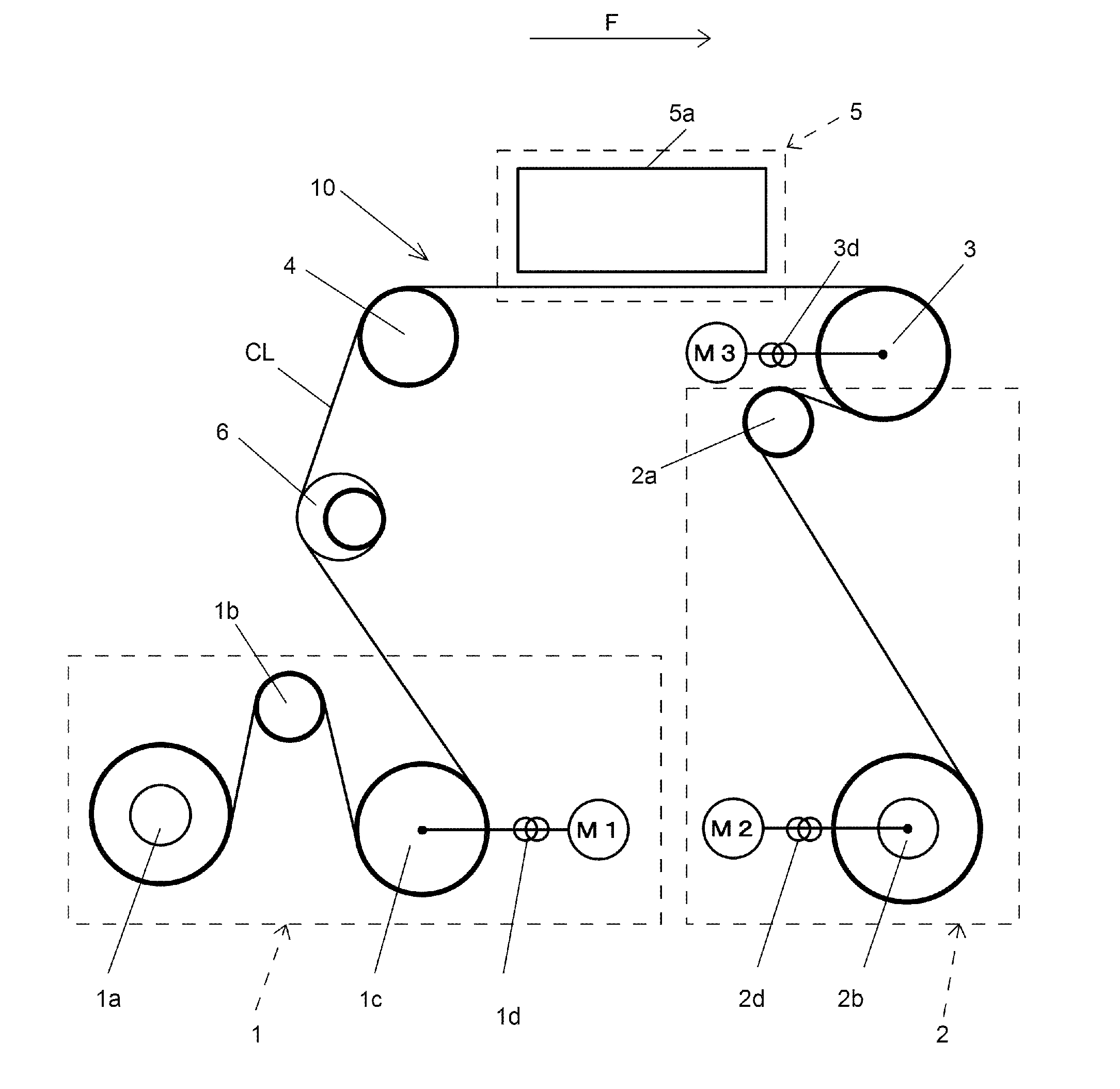

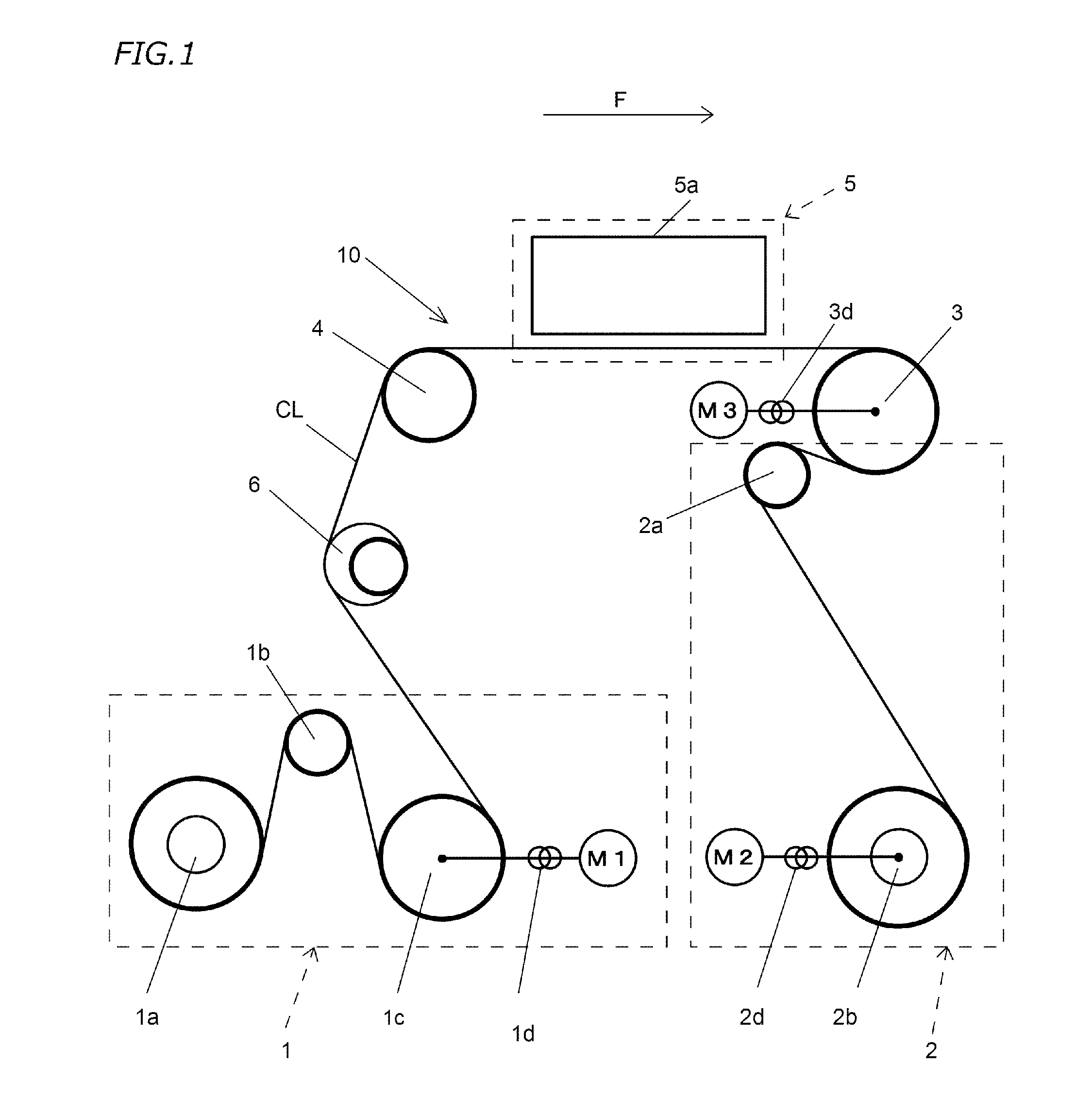

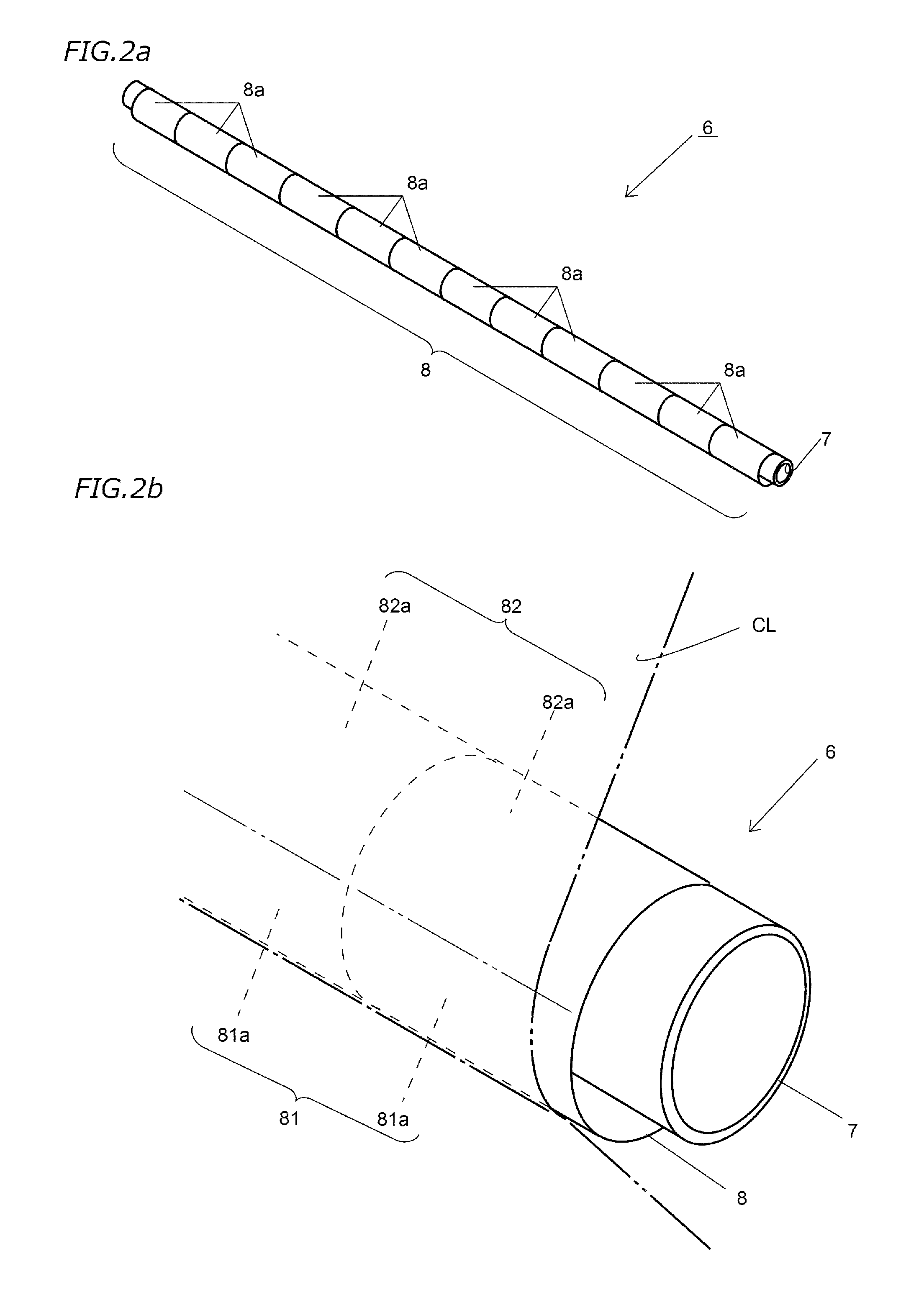

Tension fluctuation alleviating device for use in fabric printing apparatus

ActiveUS20150022606A1Reduce tension fluctuationsHigh resolution printingPattern makingTypewritersMechanical engineering

Owner:ROLAND DG CORP

Improved M type draw texturing machine and hanging type bearing structure thereof

ActiveCN102644135ALower CV valueReduce coefficient of frictionTextiles and paperHot boxCoefficient of variation

The invention discloses an improved M type draw texturing machine which comprises an upper hot box, a lower hot box and a coiling apparatus. The upper hot box and the lower hot box are arranged oppositely, a first godet wheel and a second godet wheel are arranged at the discharging ends of the upper hot box and the lower hot box respectively, and a third godet wheel is arranged between the second godet wheel and the coiling apparatus. The invention also discloses a hanging type bearing structure provided with a bearing seat and a bearing, and the first godet wheel, the second godet wheel and the third godet wheel are arranged on the inner ring of the bearing through a wheel spindle. According to the improved M type draw texturing machine and the hanging type bearing structure thereof, the first godet wheel, the second godet wheel and the third godet wheel are improved from a fixed wheel type to a driven rotating wheel type assembling structure through the hanging type bearing structure, friction coefficient can be greatly reduced and tow tension can be stabilized, broken filament and ossified filament are not easy to generated, nexus and shrinkage can be more even, netting wires are reduced, physical index of coefficient of variation (CV) value of tows is lower and more stable, and can be reduced by 1%, and full-package rate can be improved by 20%.

Owner:FUJIAN BAICHUAN RESOURCES RECYCLING TECH

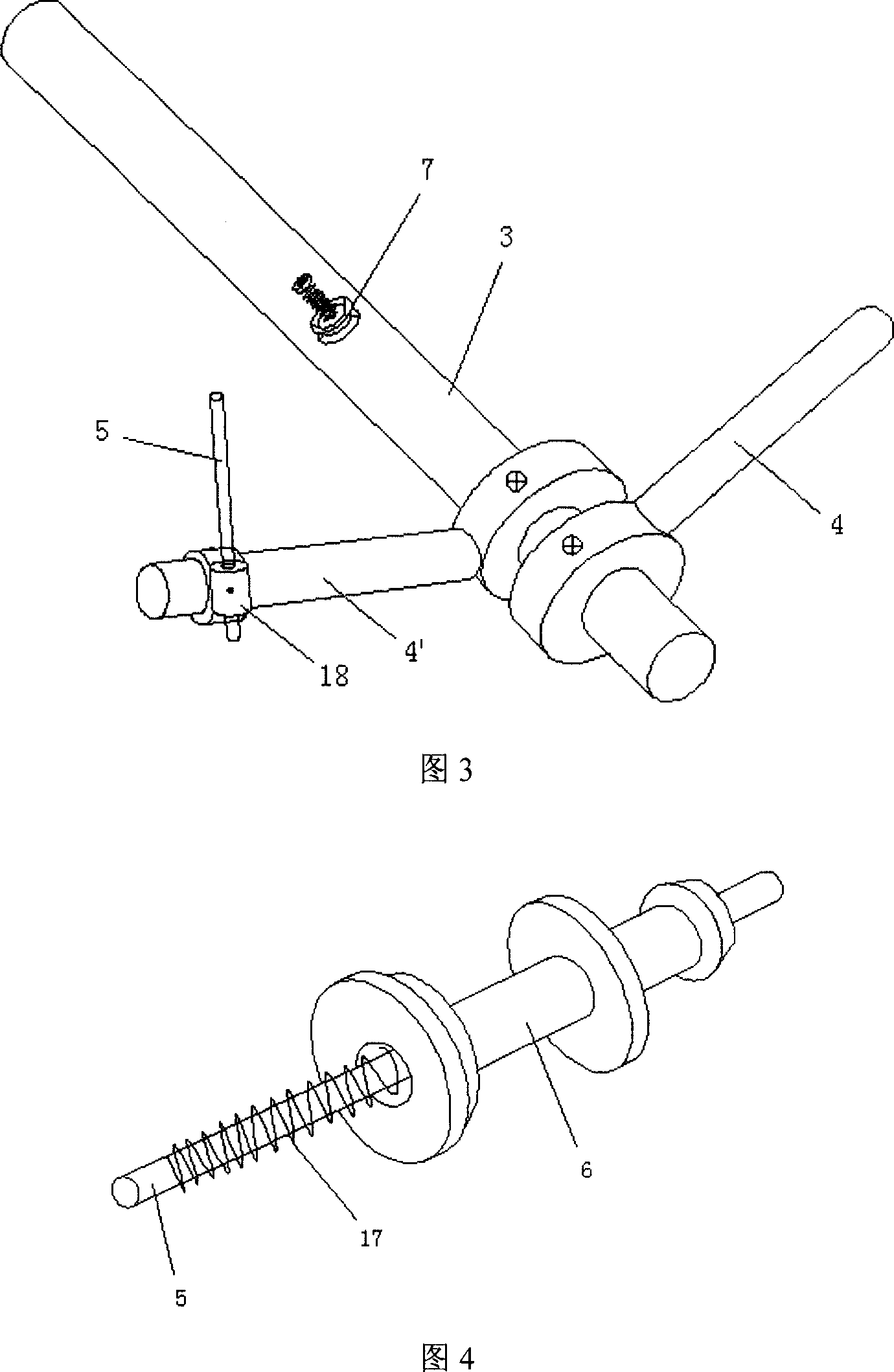

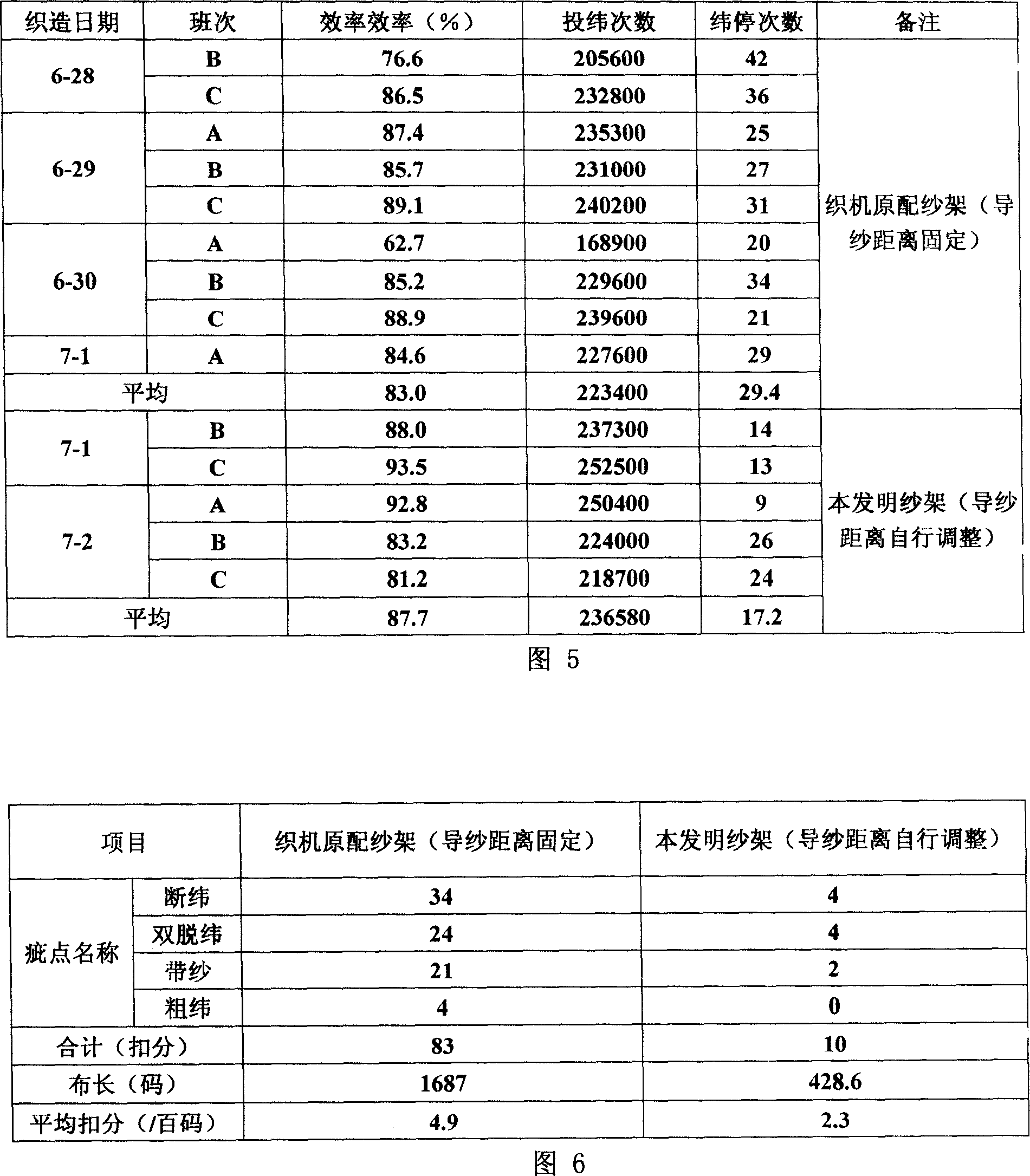

Yarn guide distance automatically regulating method and device therefor

InactiveCN101012594AReduced yarn tension fluctuationsReduce the number of weft stopsLoomsYarnSelf weight

The invention discloses a method for adjusting thread guide distance automatically. It makes a combined support ring body connect with a spring. The self-weight of bobbin is used to compress the spring to achieve long thread guide distance of big bobbin and short thread guide distance of small bobbin. The combined ring body comprises three ring bodies. The combination of the first ring body and the second ring body is used to satisfy the placement of taper bobbin and the combination of the second ring body and the third ring body is used to satisfy the placement of parallel bobbin. Compared with prior technology, merits of the invention is that by adjusting the distance of unwinding thread guide automatically, the diameter of bobbin yarn is corresponding to the optimal thread guide distance; the tension wave of yarn is decreased; the number of weft stop is decreased and the production quality is improved.

Owner:GUANGDONG ESQUEL TEXTILES

Symmetric warp let-off method and device of single needle bed warp knitting machine

ActiveCN107059237AConsistent tensionOvercoming Weaving EffectsWarp knittingYarn tensionWarp knitting

The invention relates to a symmetric warp let-off method and device of a single needle bed warp knitting machine. Yarns are conveyed to a weaving portion from a front side and a back side of a machine body of the single needle bed warp knitting machine respectively; and let-off paths of yarns at two sides of the machine body are mutually symmetrical, i.e., a symmetrical axis of the let-off paths is perpendicular to a central cross beam. The warp let-off device includes an even number of warp let-off systems which are horizontally symmetrical and positioned on the two sides of the machine body of the warp knitting machine; each warp let-off system includes a yarn unfolding mechanism, a yarn tension adjustment mechanism, and a looping mechanism; yarns are unfolded by the yarn unfolding mechanism, the tension of the yarns is adjusted by the yarn tension adjustment mechanism, and the yarns are conveyed to the looping mechanism. The influence of yarn tension difference on knitting can be avoided, the knittability of the yarns can be improved; a plurality of rows of yarn division needles and yarn guide needles can disperse extreme fine metal wires, tangled metal wires can be reduced, broken ends can be reduced, and the quality and the production efficiency of fabrics can be improved.

Owner:DONGHUA UNIV

Silicon wafer wire cutting machine

PendingCN107379297AImprove cutting efficiencyReduce losses such as shortingFine working devicesWire cuttingElectric machinery

The invention discloses a silicon wafer wire cutting machine. The silicon wafer wire cutting machine comprises a frame, a cutting chamber and a wire barrel chamber. The cutting chamber is internally provided with a cutting head and a winding and unwinding wheel tool. The wire barrel chamber comprises a main plate, a winding and unwinding wheel unit, two wire guiding wheel tools arranged below winding and unwinding wheels, wire guiding wheel tool movable bases connected with the wire guiding wheel tools, two transverse movement frames, two tension arm motors, tension arms connected with the tension arm motors, and tension arm guiding wheels arranged at the lower ends of the tension arms, and the transverse movement frames are horizontally arranged. The silicon wafer wire cutting machine has the beneficial effects that the guiding wheel arrangement structure is optimized, the wire barrel installing manner is horizontal installation, the winding displacement load of horizontal installation is uniform, and the number of guiding wheels is reduced; and due to reduction of the number of the wire guiding wheels, the breaking tension of a steel wire is increased firstly, and then fluctuation of tension entering a wire net becomes small; and jumping of the wire barrel is weak, winding displacement is more stable, and arm swinging is stable when the tension arms run. By means of the silicon wafer wire cutting machine, broken wires are effectively monitored, and wire net empty pulling and other losses caused by wire breaking are reduced.

Owner:江阴市展照科技有限公司

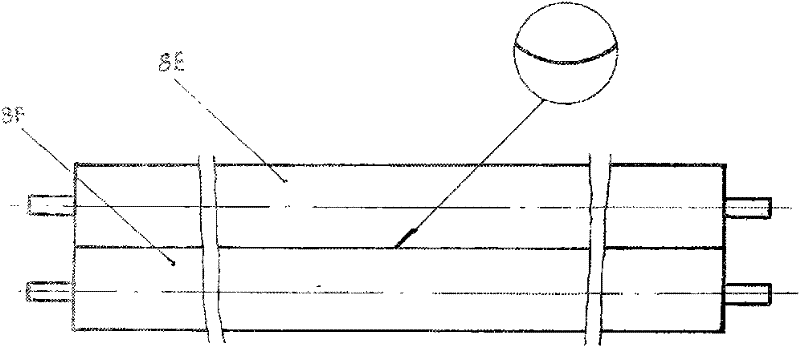

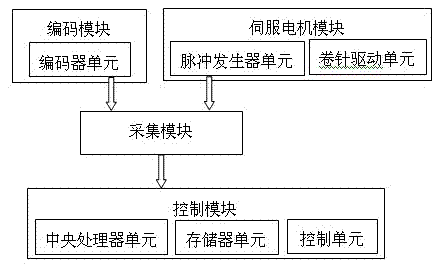

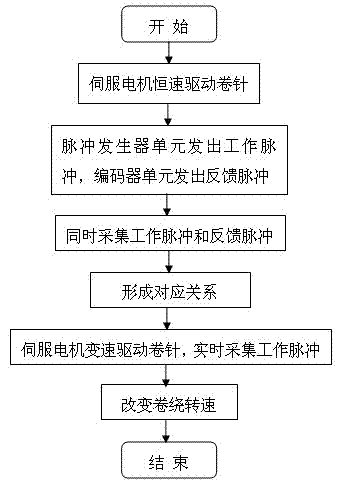

A system and method for variable speed winding of a square winder

ActiveCN102290608AReduce distortionIncrease wind speedFinal product manufactureSecondary cellsEngineeringConductor Coil

The invention provides a square winder variable-speed winding system and a method. The square winder variable-speed winding system comprises a servomotor module, a coding module, an acquisition module and a control module, the servomotor module comprises a winding pin-driving unit and a pulse generator unit, and the pulse generator unit outputs the working pulses of the servomotor module; the coding module adopts a coder unit to periodically interrupt and output feedback pulses; the acquisition module simultaneously acquires the working pulses and the feedback pulses; the control module comprises a central processor unit, a memory unit and a control unit, the central processor unit is used for calculating the winding speed corresponding to the feedback pulses and storing the corresponding relation between the winding speed, the working pulses and the feedback pulses into the memory unit, and the control unit changes the winding speed of the system according to the corresponding relation between the working pulses and the corresponding relation.

Owner:GEESUN AUTOMATION TECH

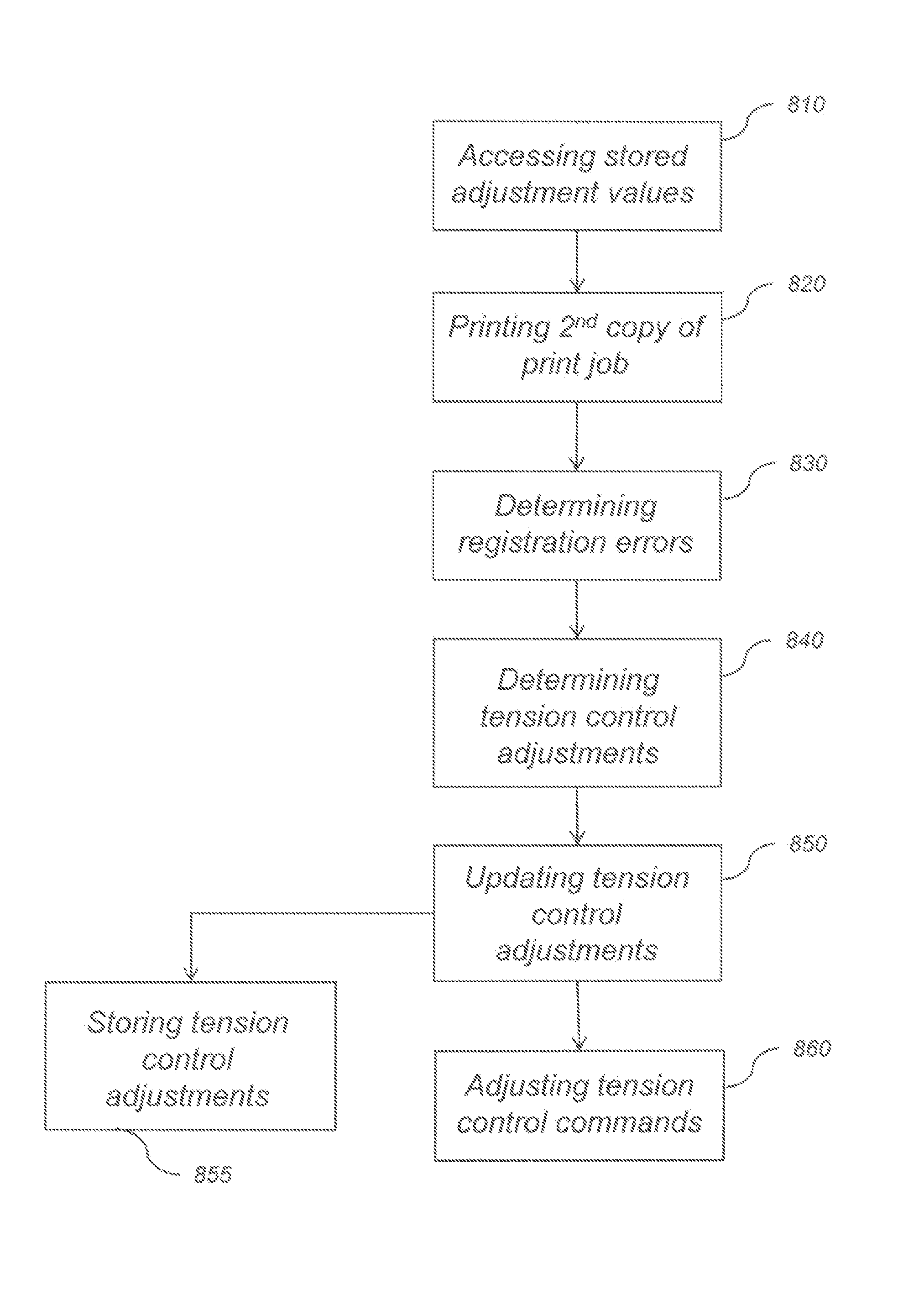

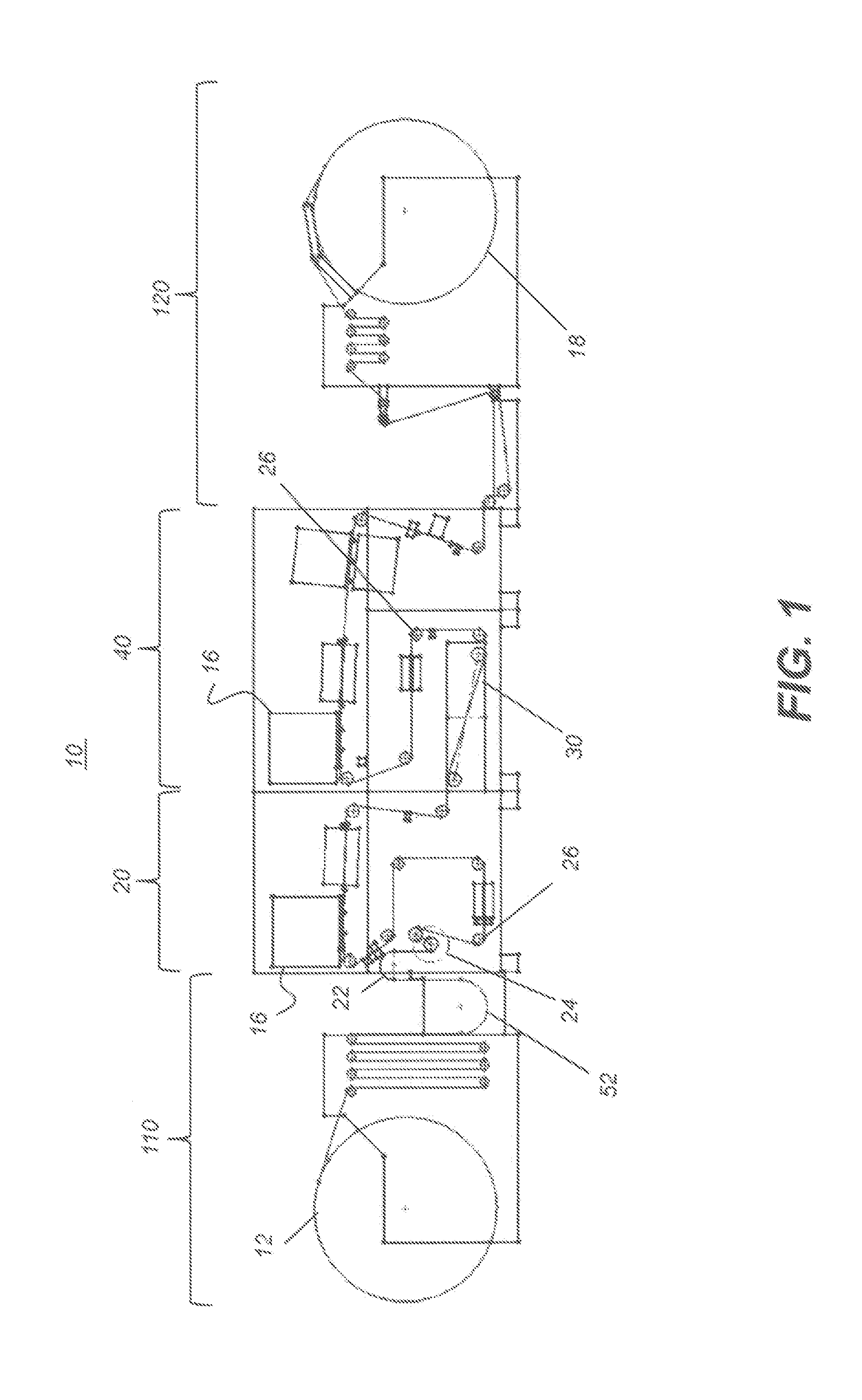

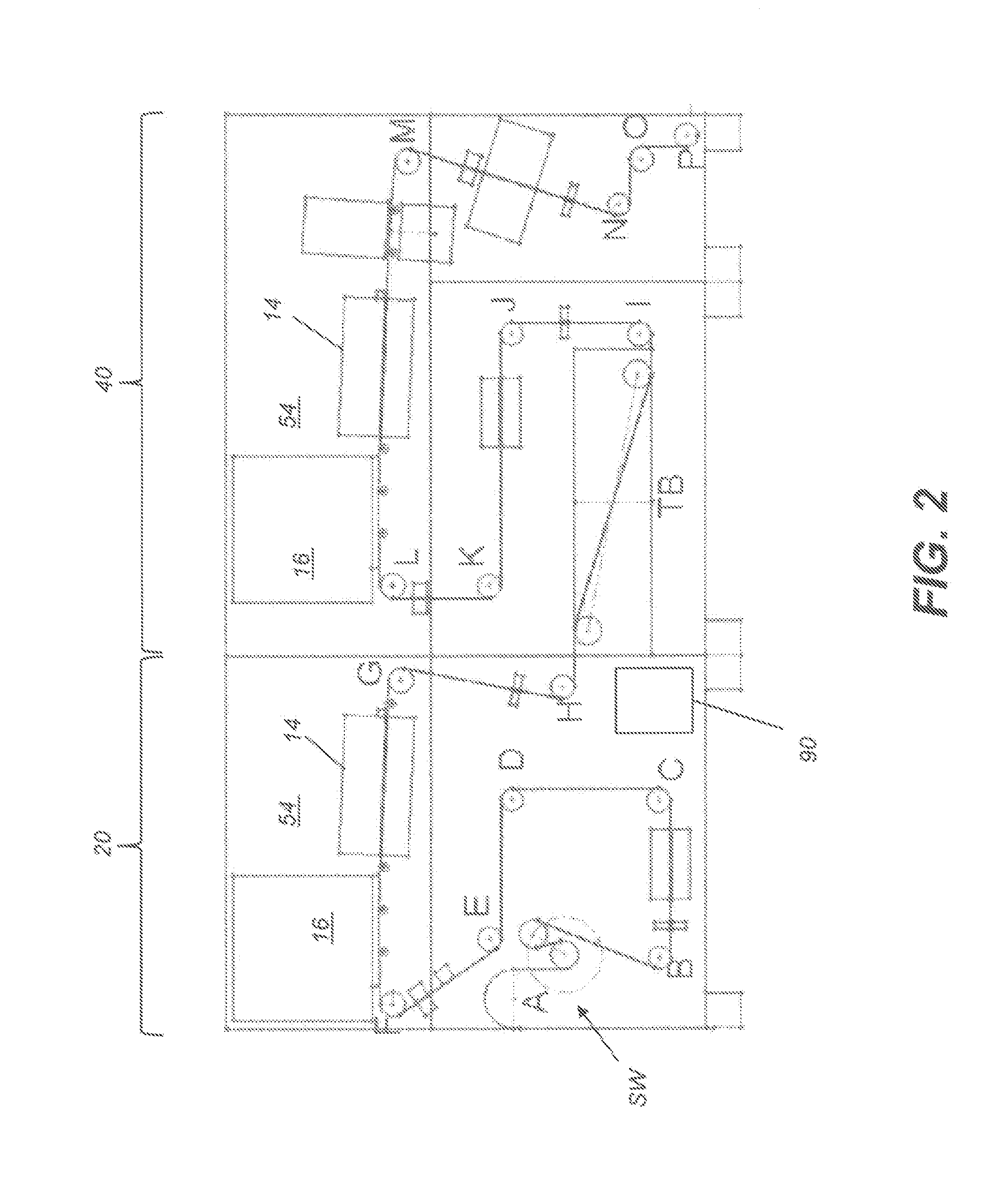

System for reducing tension fluctuations on a web

InactiveUS20150239234A1Reduce registration errorReduce tension fluctuationsCylinder pressesPlaten pressesIndustrial engineeringTension control

A system for reducing tension fluctuations in a web while printing multiple copies of a print job on the web comprises a printing system with a print station disposed opposite a first side of the web and one or more rollers adapted to receive tension control commands, the tension control commands operating on the first rollers to control the amount of tension in the web. A sensor is used to measure tension changes produced during the printing of the first copy of the print job. A processor is used to determine first tension control adjustments based on the measured tension changes and to use the adjustments to adjust the tension control commands to the rollers in the printing system to change the tension in the web when printing a second copy of the print job, thereby reducing tension fluctuations in the web.

Owner:EASTMAN KODAK CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com