Improved M type draw texturing machine and hanging type bearing structure thereof

A texturing machine, an improved technology, used in textiles and papermaking, etc., can solve the problems of low full roll rate, tow jumping, friction coefficient change, etc., and achieves low physical property index CV value, stable tow tension, and reduced friction. The effect of coefficients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

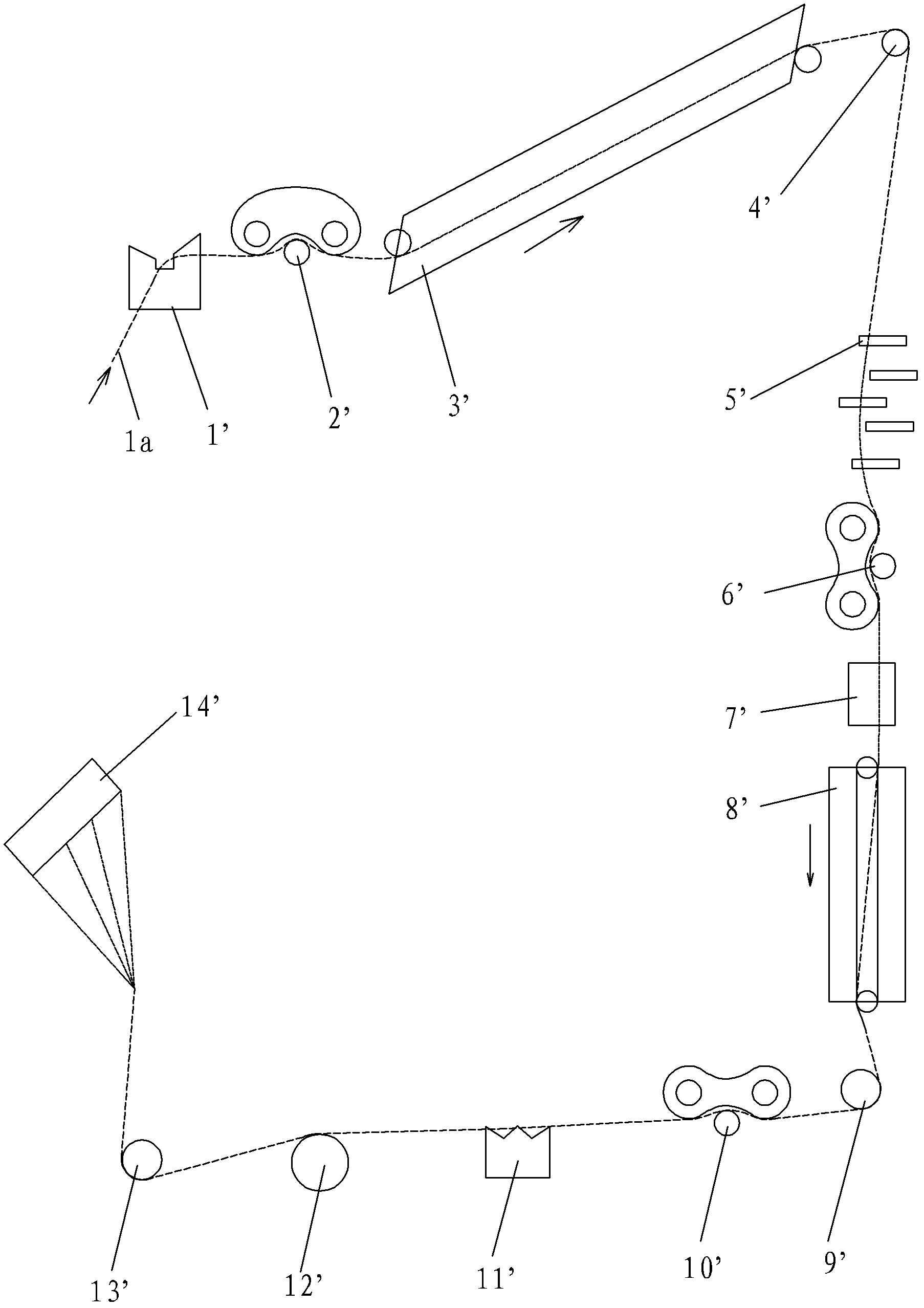

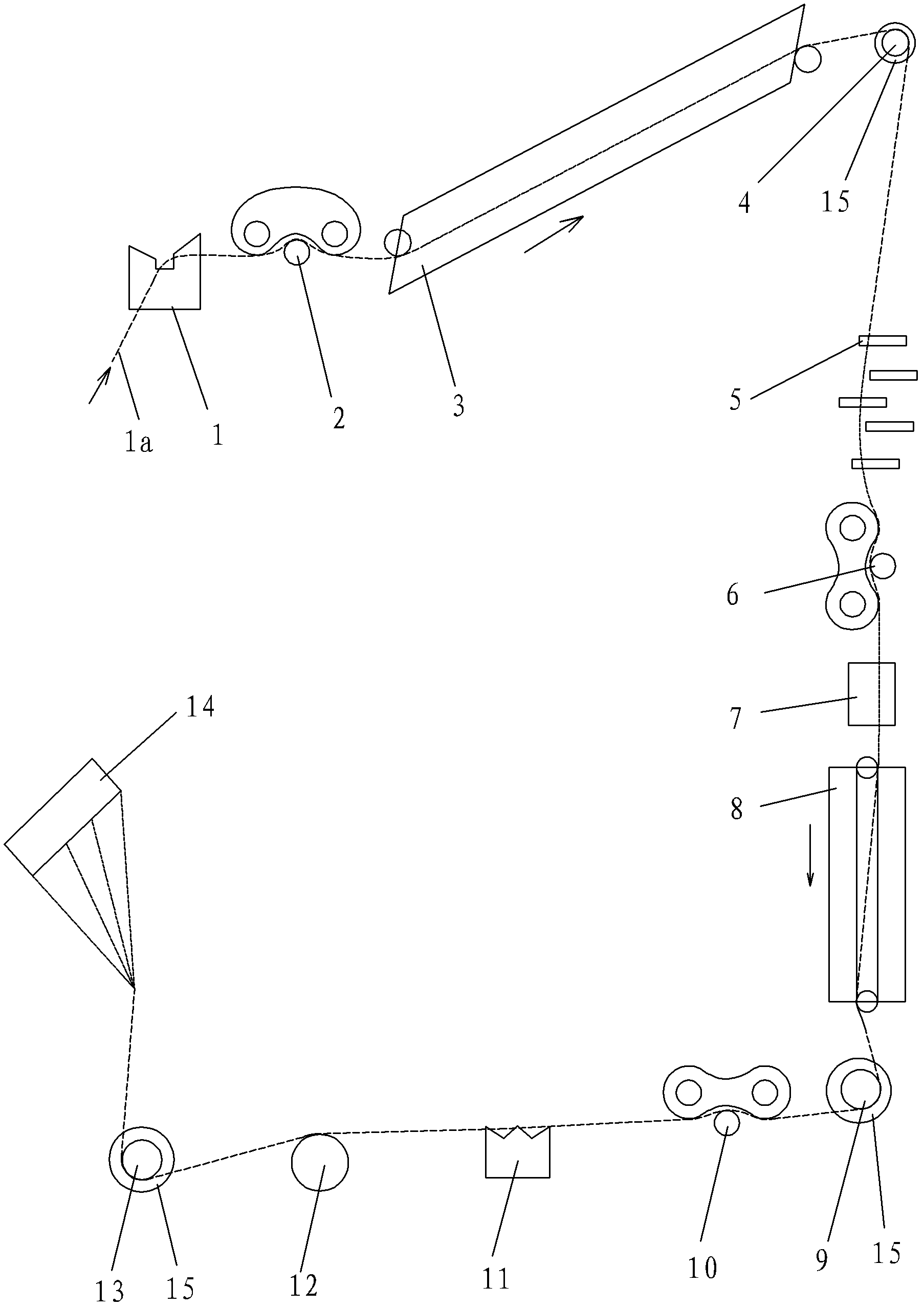

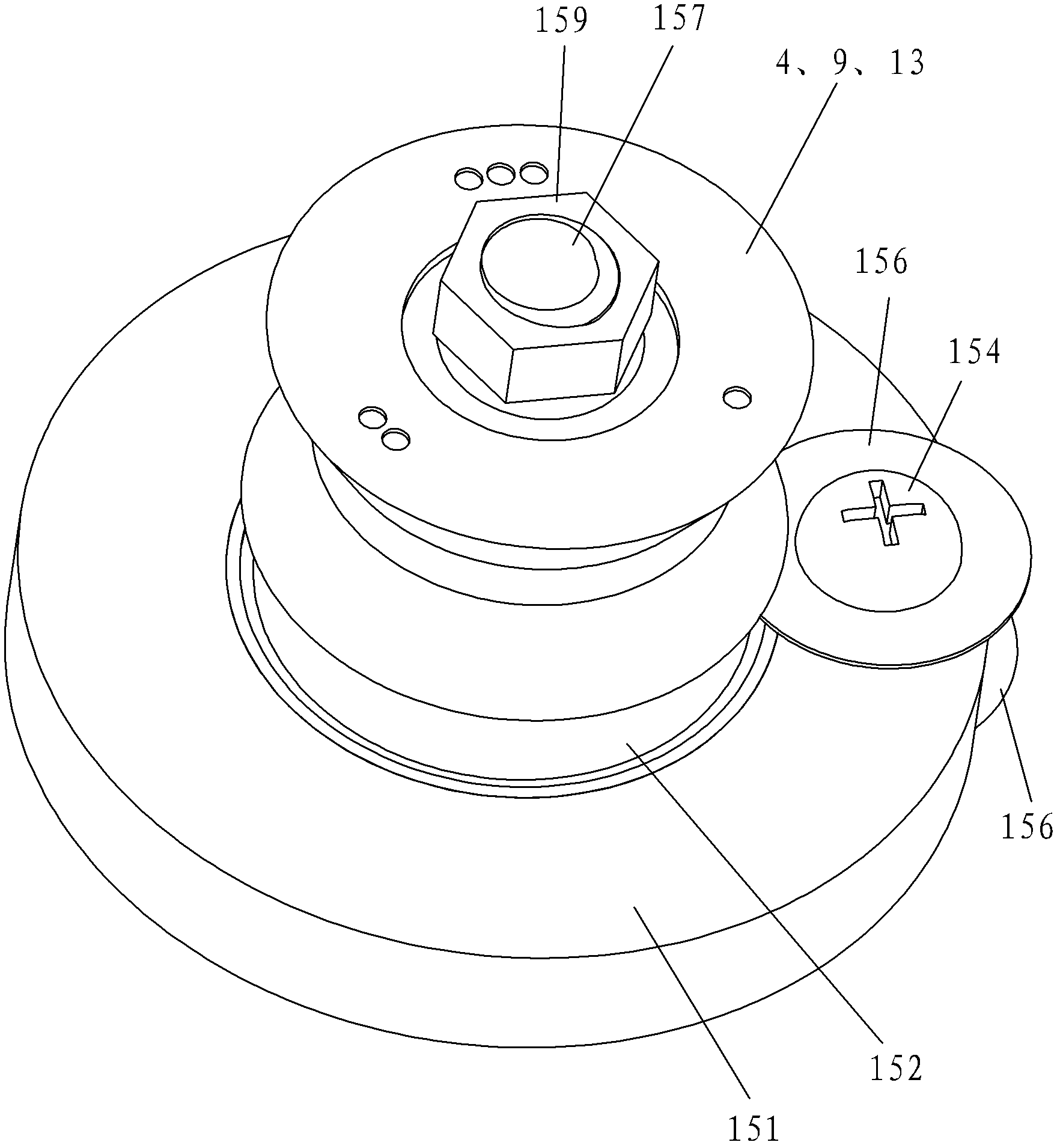

[0052] Such as Figures 2 to 4 As shown, the improved M-type texturing machine of the present invention mainly includes a shredder 1, a first roller 2, an upper heating box 3, a first wire guide wheel 4, a twister 5, The second roller 6, the network nozzle 7, the lower heat box 8, the second godet 9, the third roller 10, the wire sensor 11, the fourth roller 12, the third godet 13, the coiling device 14 and the suspension type Bearing structure15.

[0053] During operation, the tow 1a such as polyester (POY), polypropylene fiber and other untwisted yarns is exported from the cutter 1 and then enters the upper heating box 3 through the first roller 2 for heating; the heated tow 1a passes through the first wire guide wheel 4. After being exported, it enters the twister 5 for twisting; the twisted tow 1a is expo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com