Fabric open-width washing and preshrinking device

An open-width washing and fabric technology, which is used in the processing of textile material equipment configuration, textiles and papermaking, textile processing machine accessories, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

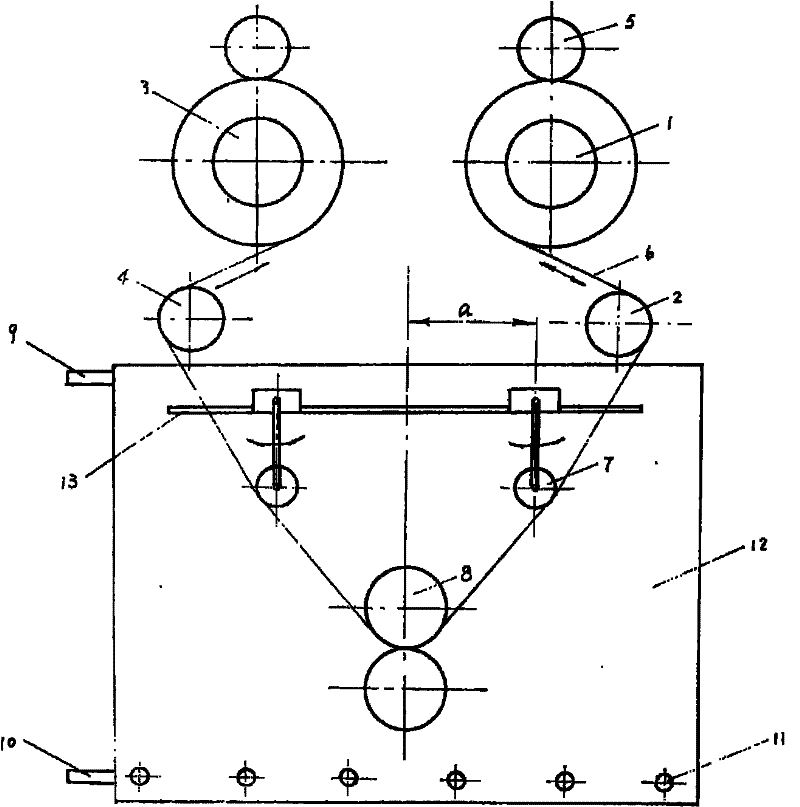

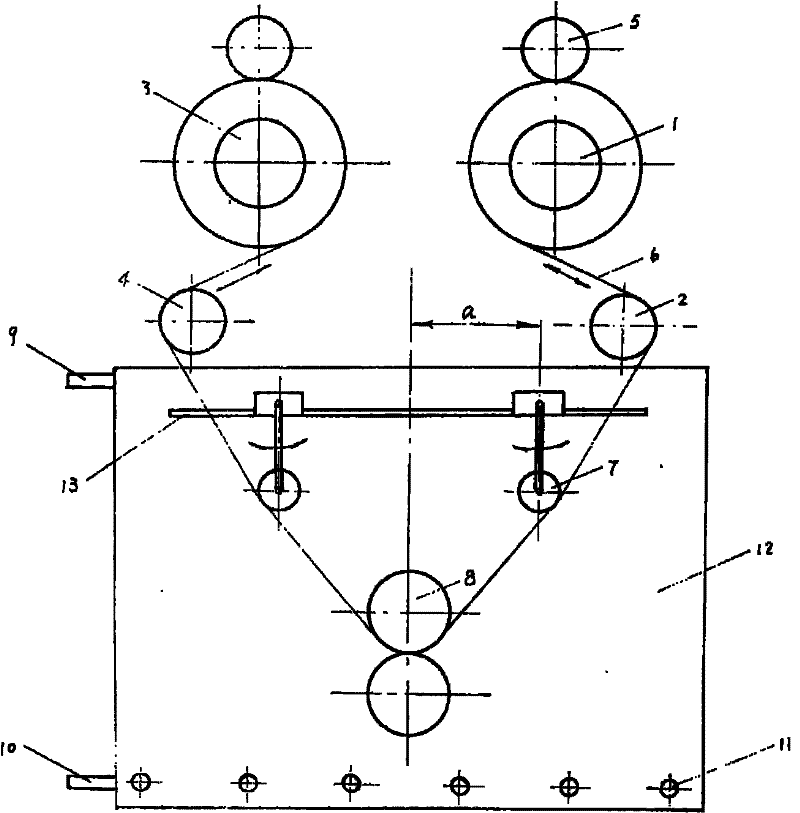

[0006] With warp direction 75D viscose filament, weft elastic fabric of weft direction 40D two-component T400 polyester yarn is used as the typical pre-shrinking gray cloth of the device of the present invention, refer to figure 1 Embodiments of the present invention will be described in detail. The gray cloth has a width of 175cm and a weight of about 75 grams per square meter. The gray cloth is unrolled from the roll roll A (1) and sent into the water tank through the overfeed roll C (2), passes through the right side of the pendulum roll (7) and passes through the rolling surface between the upper and lower extrusion rolls (8) under water, and passes through the pendulum roll (7). The left side of the roll is taken up by the overfeed roll D (4) onto the cloth roll B (3). The linear speed of the gray cloth into the water tank is controlled at 35m / min, the overfeed rate is controlled at 2%, the diameter of the swing roller is 8cm, the axial width is 180cm, the distance betwe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com