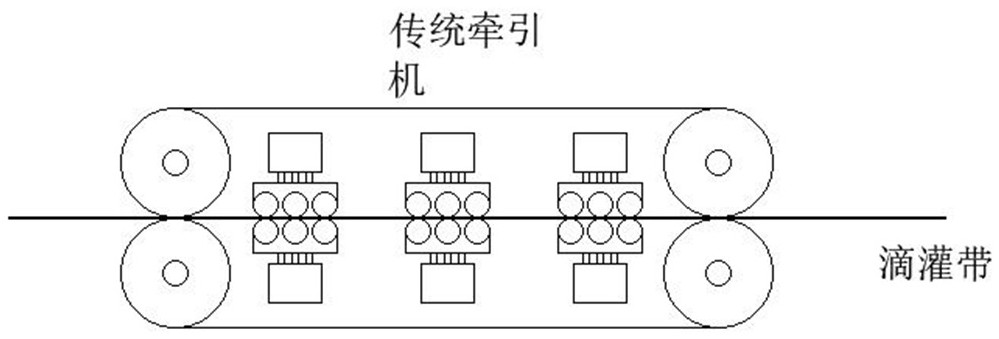

Traction assembly for drip irrigation tape production

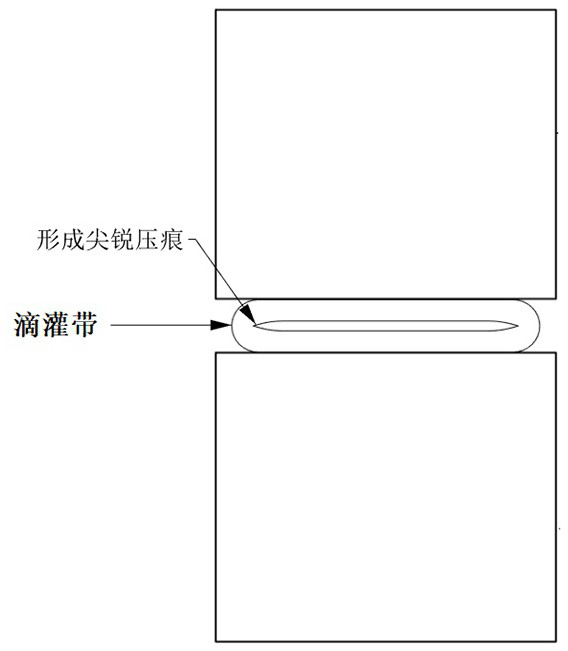

A technology of traction components and drip irrigation belts, applied in metal processing and other directions, to solve cracking, increase frictional traction, and improve yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

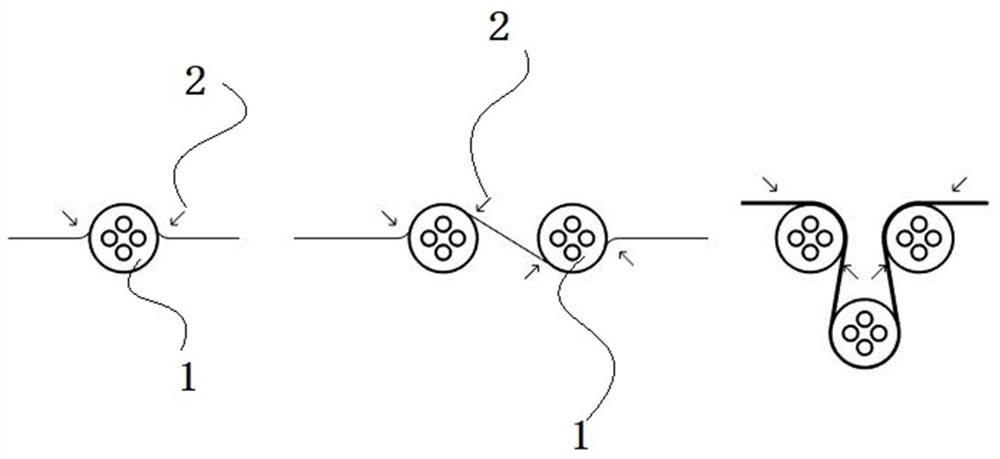

Method used

Image

Examples

Embodiment 1

[0038] Embodiment two

Embodiment 2

[0040] At the same time, the above-mentioned traction pulley 1 is arranged on the same tooling plate through the fixed shaft, and is connected with the driving device 19 after rotating with the tooling plate. The driving device 19 includes a pulley (synchronous pulley) fixedly connected with the fixed shaft. The same belt (the belt with a rack is selected) is wound and connected one by one in a serpentine shape, and is synchronously driven to rotate by a drive motor. At the same time, because the belt has a certain degree of elasticity, there is also a tensioning wheel on the belt. The tension wheel adjusts the tightness of the belt.

[0041] If the fixing method is not separately introduced in the above, the common technical means used by technicians in the industry, such as welding, nesting, or screw fixing, etc. are used.

[0042] In the description of this specification, descriptions with reference to the terms "one embodiment", "example", "specific example" and the like m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com