Patents

Literature

130 results about "Drip tape" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Drip tape is a type of thin walled dripperline used in drip irrigation. The first drip tape, a product known as "Dew Hose", was developed in Watertown, New York, in the 1960s by Richard D. Chapin of Chapin Watermatics in the United States. Drip tape is made of polyethylene and is sold flat, on reels containing several thousand feet. The wall thickness typically ranges from 4 to 25 mils. Thicker walled tapes are commonly used for permanent subsurface drip irrigation and thinner walled tapes for temporary throw-away type systems in high value crops. Water exits the tape through emitters / drippers. Typical emitter spacing ranges from 6 to 24 inches. In some products, the emitters are manufactured simultaneously with the tape and are actually formed as part of the product itself. In others, the emitters are manufactured separately and installed at the time of production. Some of these manufacturers claim that their product is not a tape, but a thin walled dripperline, but in popular parlance, both types of products are called tapes. Typical tape diameters are 5/8", 7/8", and 1-3/8", with the larger diameters more commonly used on permanent installations with longer runs.

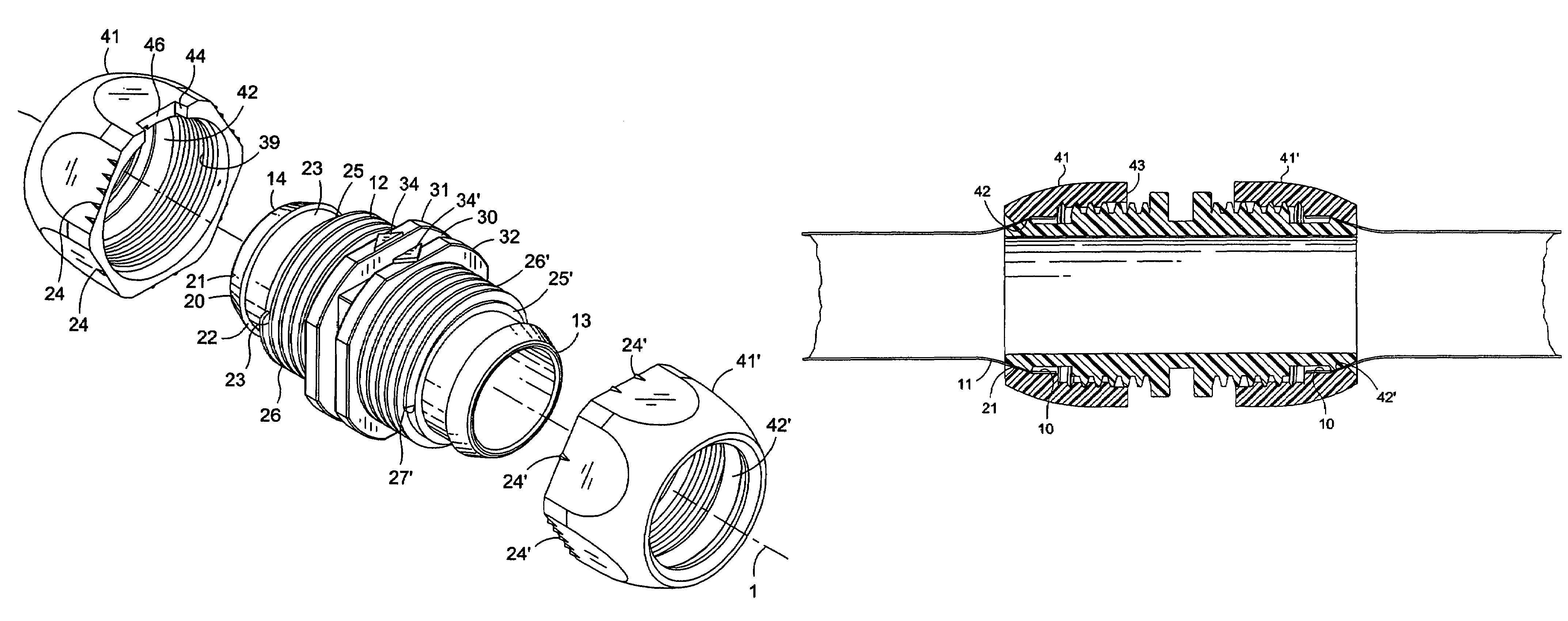

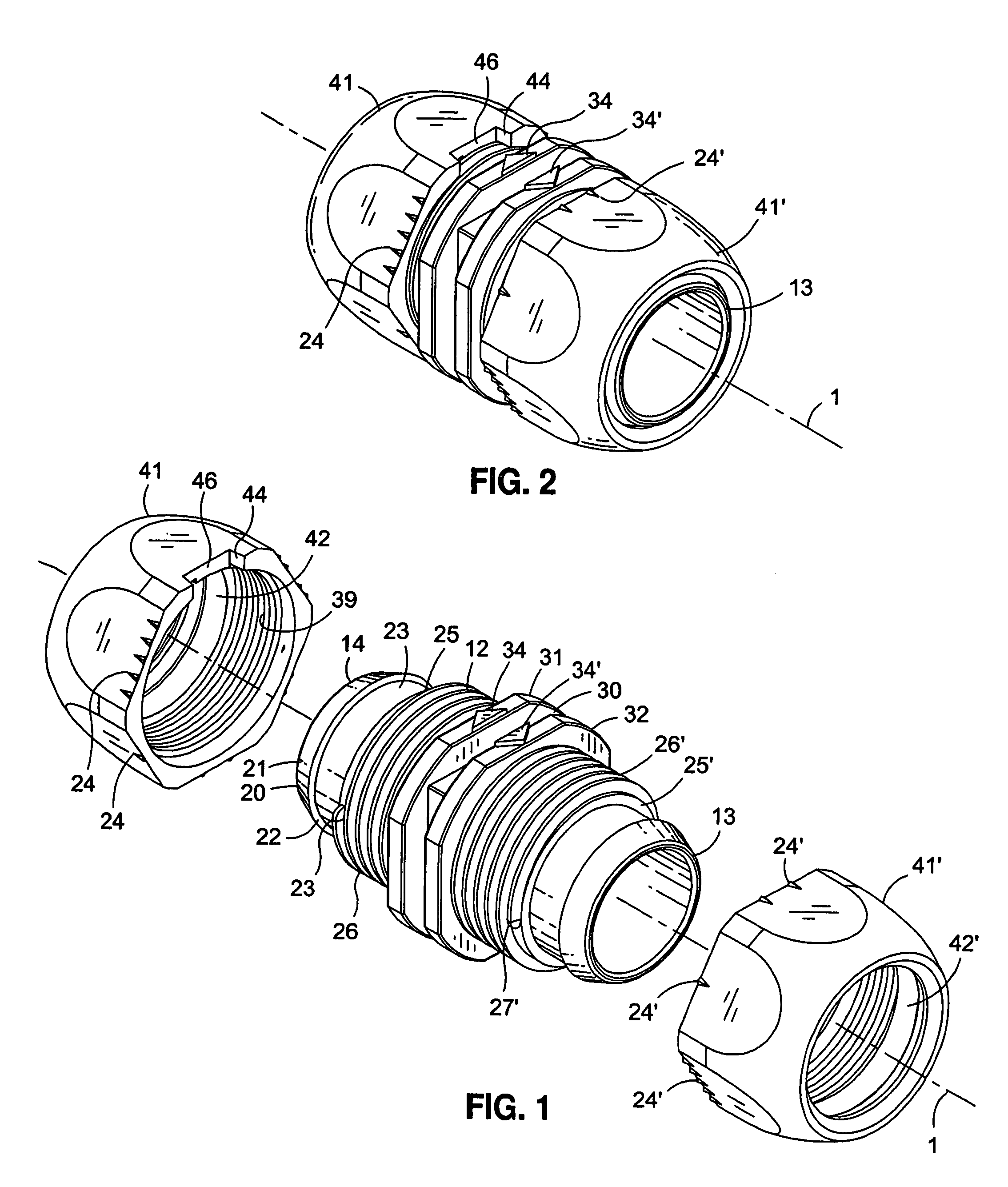

Connector for joining with agricultural drip tape

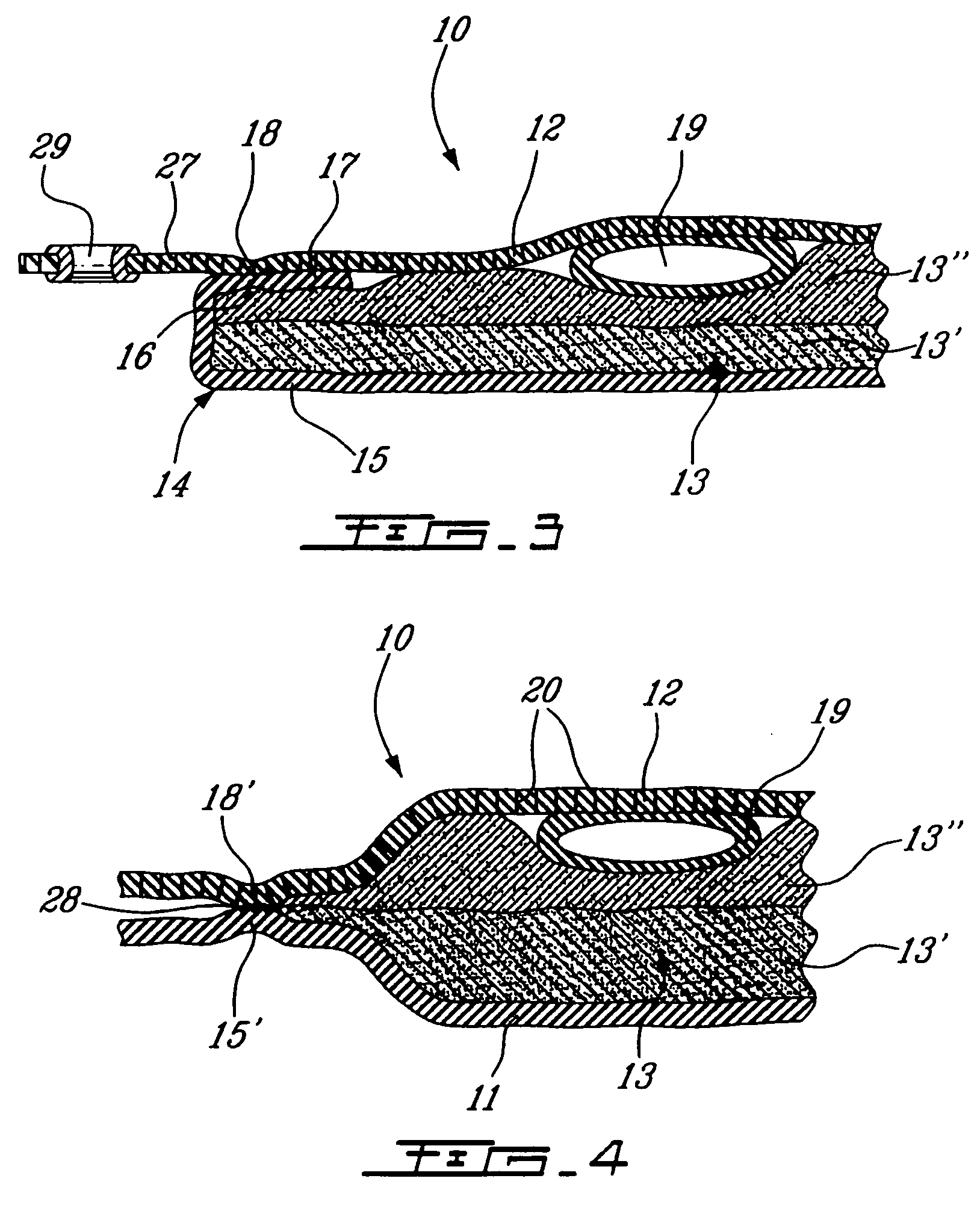

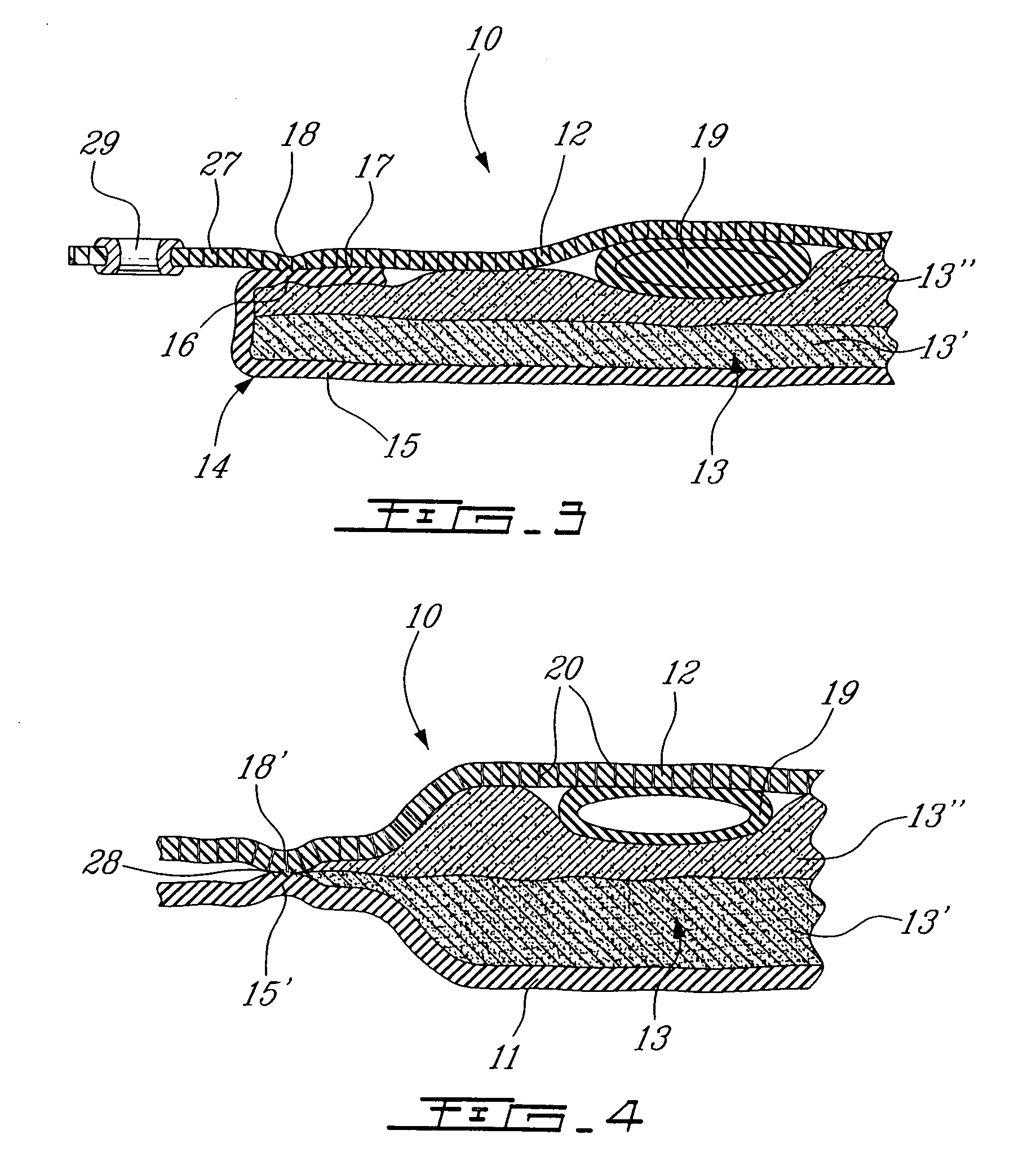

InactiveUS7648178B1Consistently reliable sealPrevent the nut from prematurely jammingPipe elementsHose connectionsDrip tapeWindow opening

A connector for joining agricultural drip tape. The connector includes a rigid tubular body having a tapered trust conical enlargement at its free end over which the free end of the drip tape is pressed and held by an assembly nut having a single entry female thread that threadably engages the tubular body male threads by a pre-determined angular advance of the assembly nut. The environment of use for agricultural drip tape is one of debris and mud consequently; the assembly nut contains a wiper window opening through which debris and mud are expelled from the connection as the assembly nut advances axially along the threads of the tubular body. Indicia on both the assembly nut and on the tubular body may be relatively positioned depending upon the thickness of the tape to form a consistently reliable seal.

Owner:ANDROS MATTHEW J

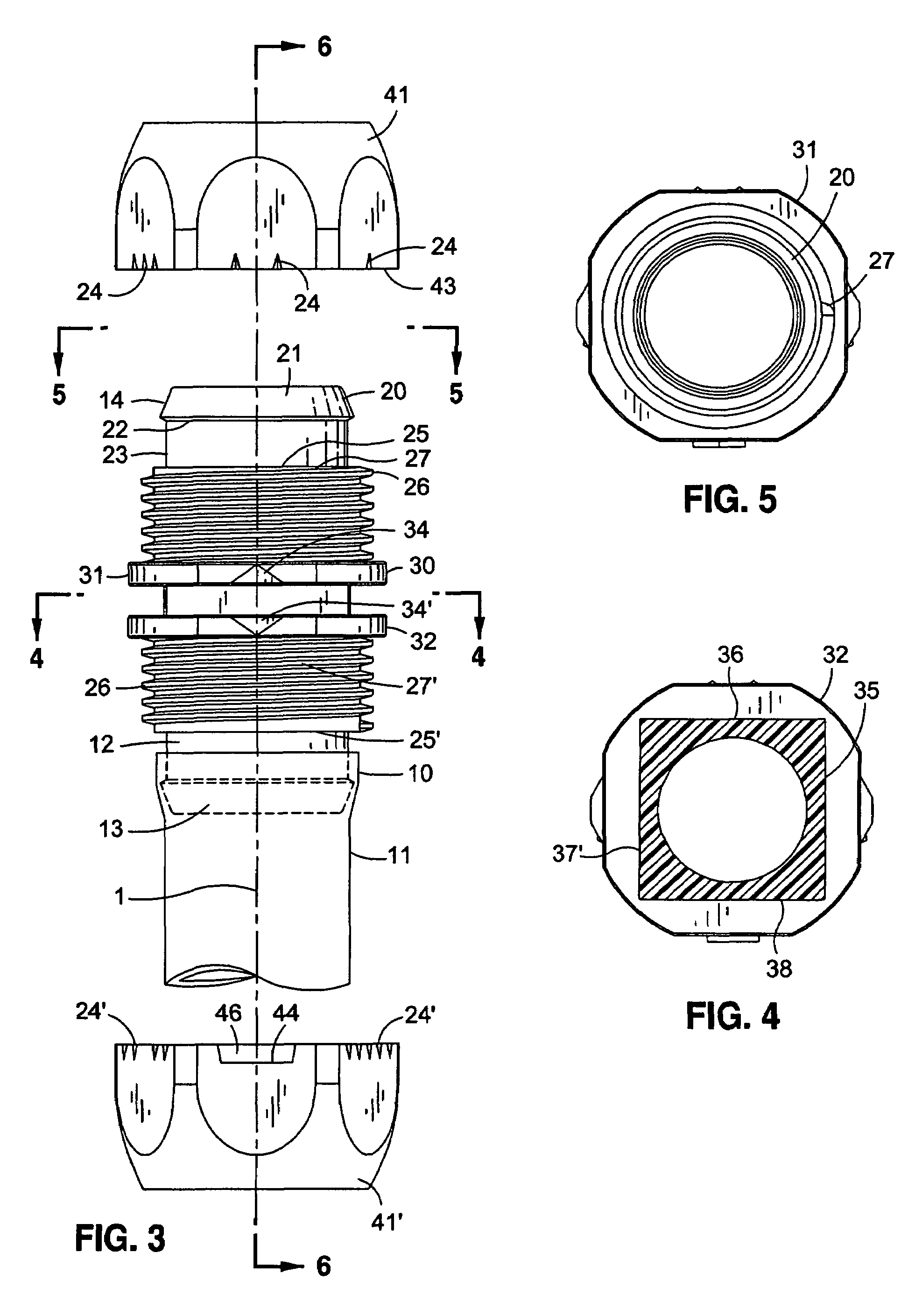

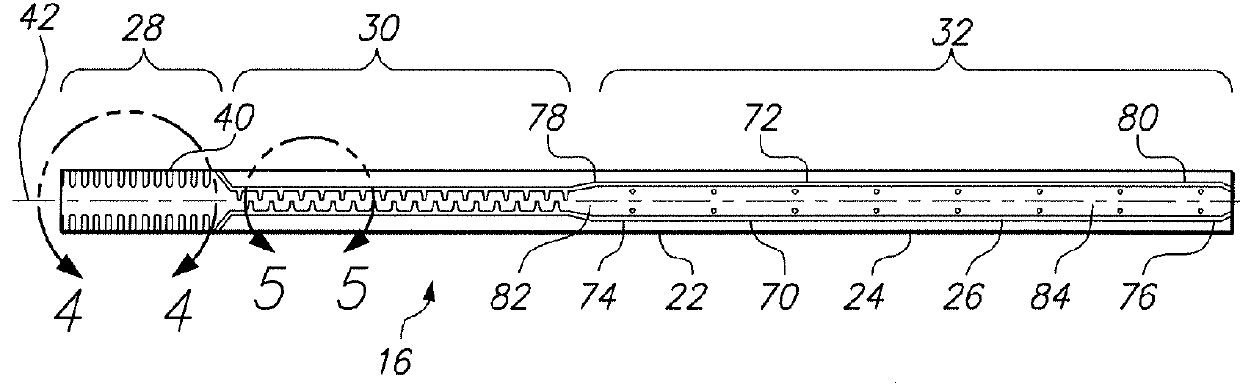

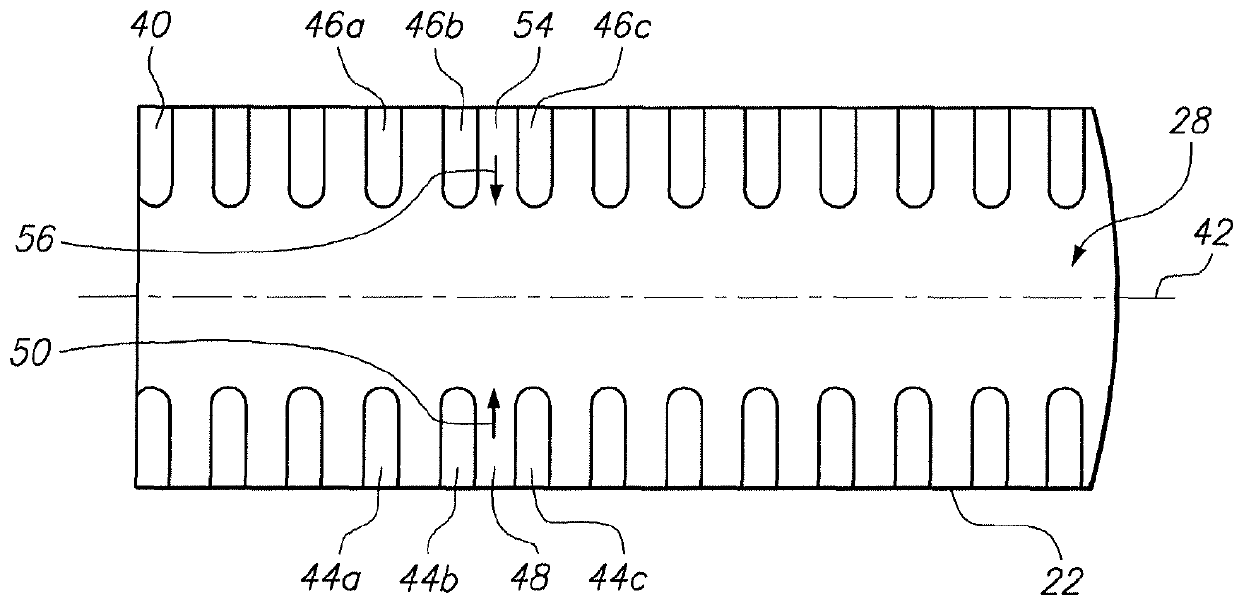

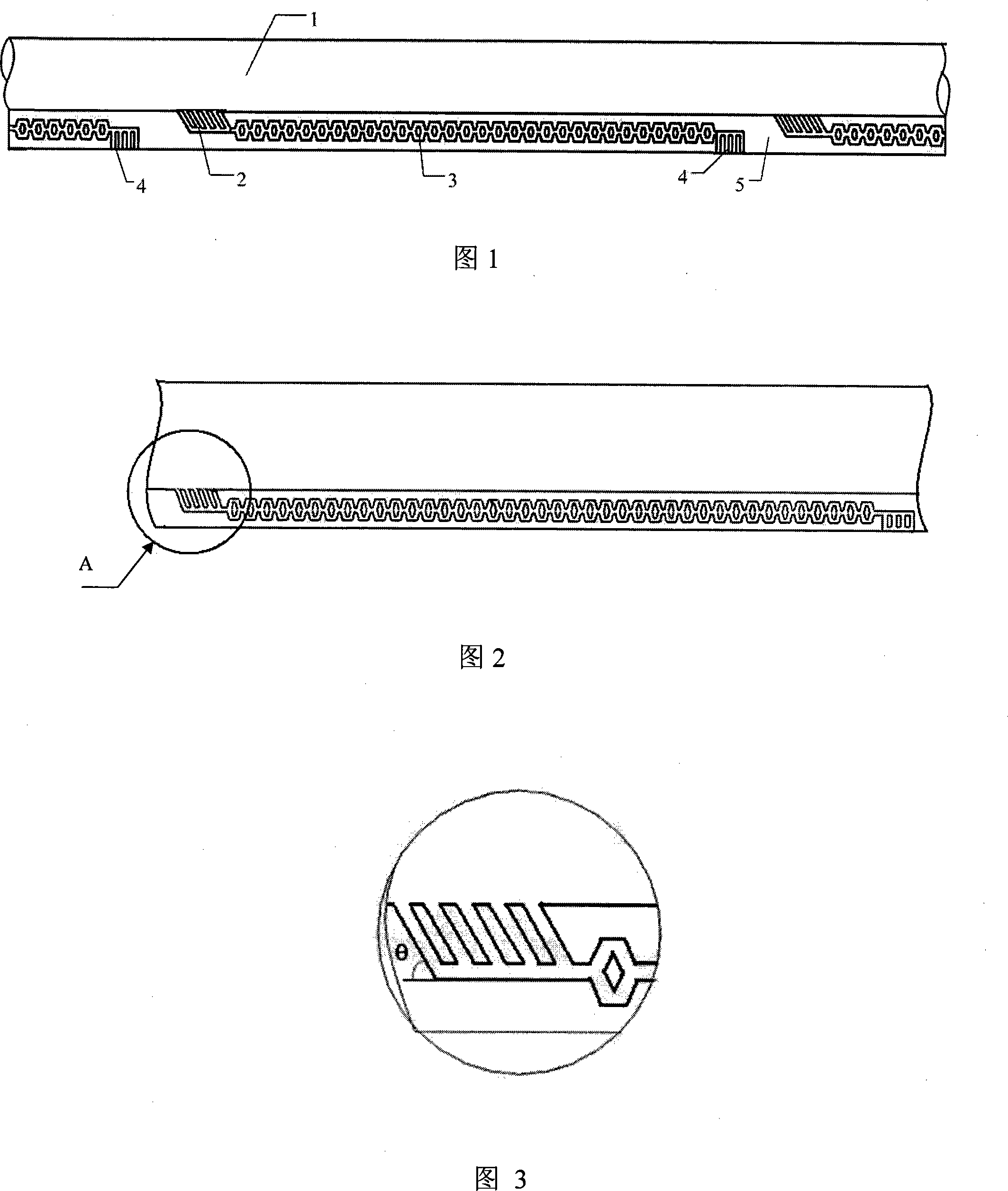

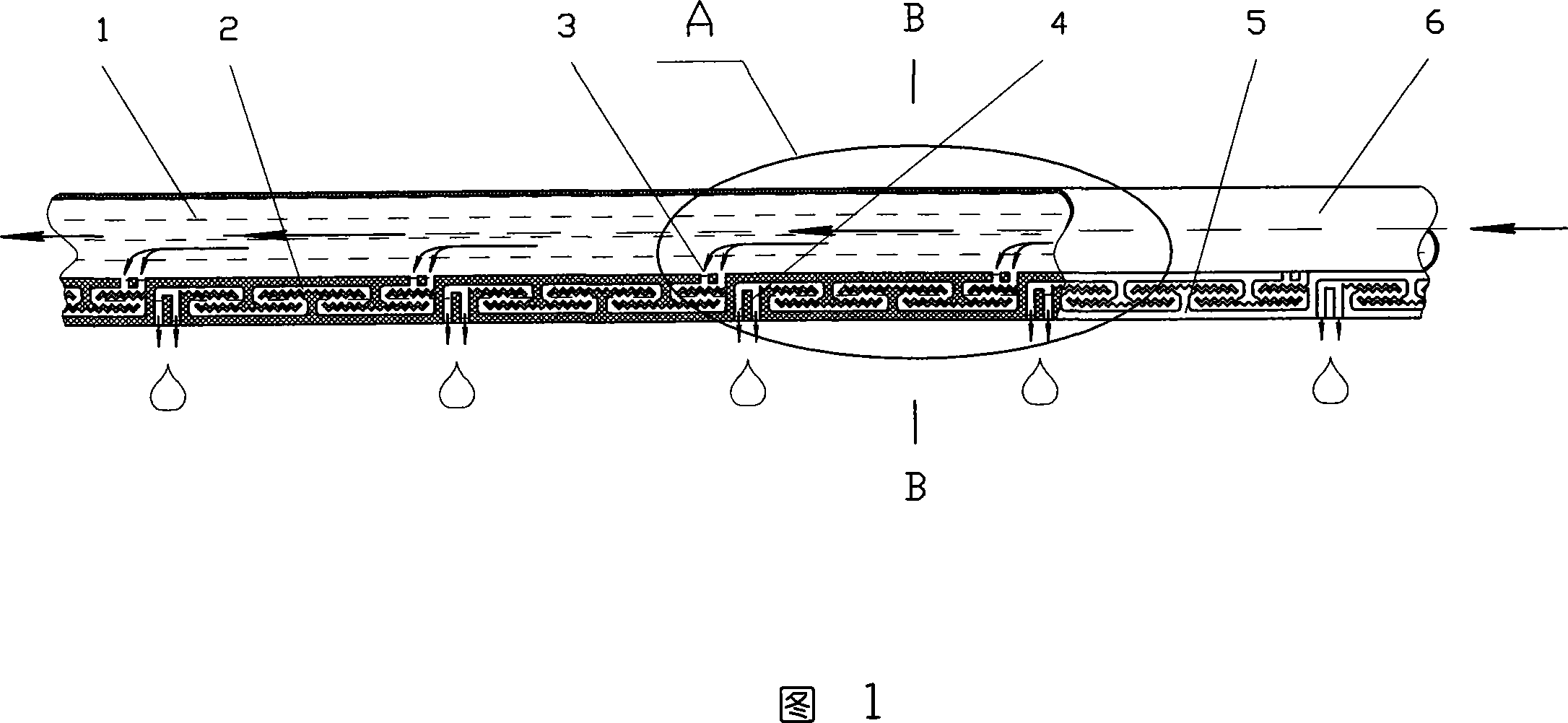

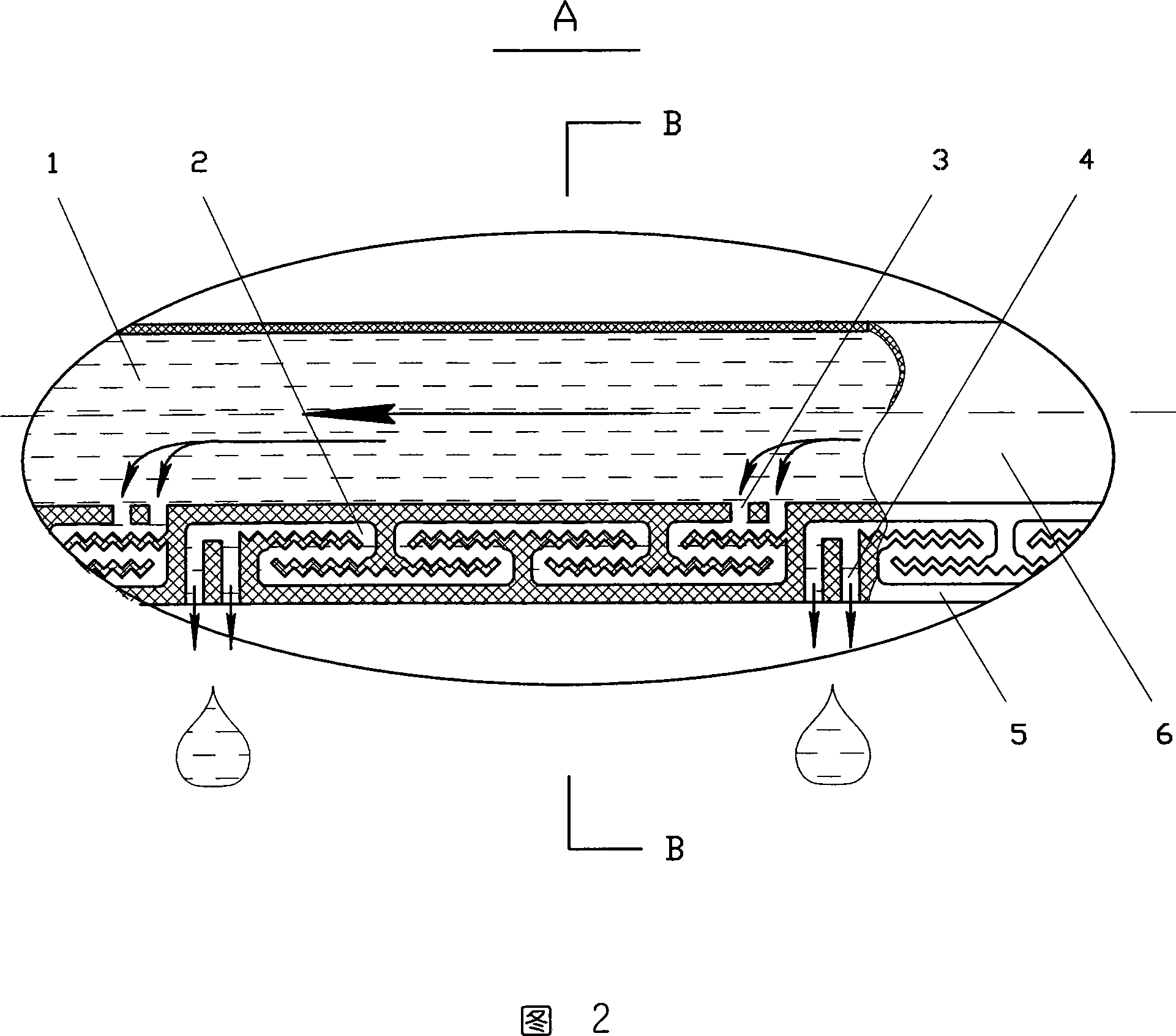

Drip tape irrigation emitter

ActiveUS9380749B2Reduce trafficReduce depositionClimate change adaptationWatering devicesDrip tapeStreamflow

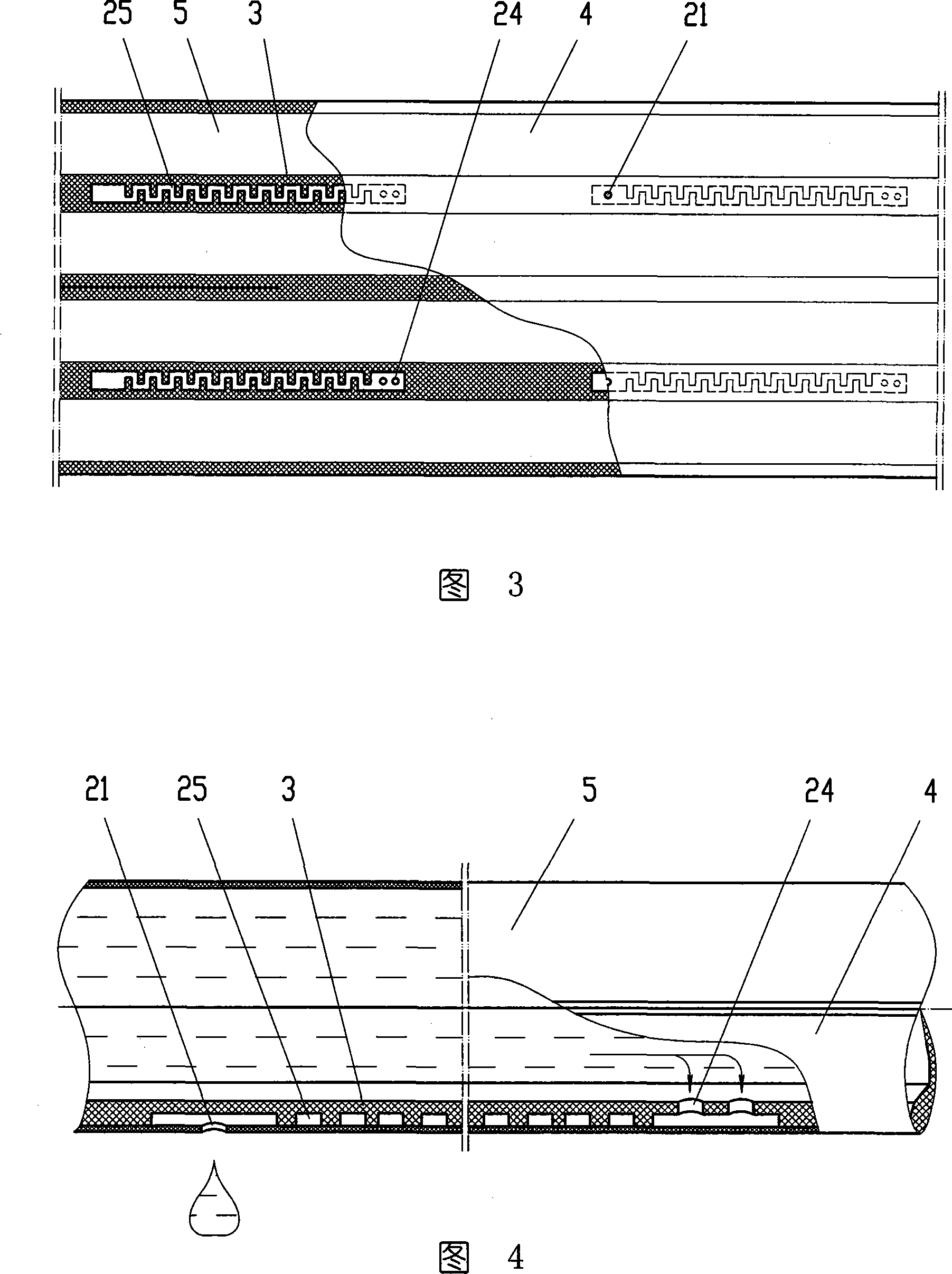

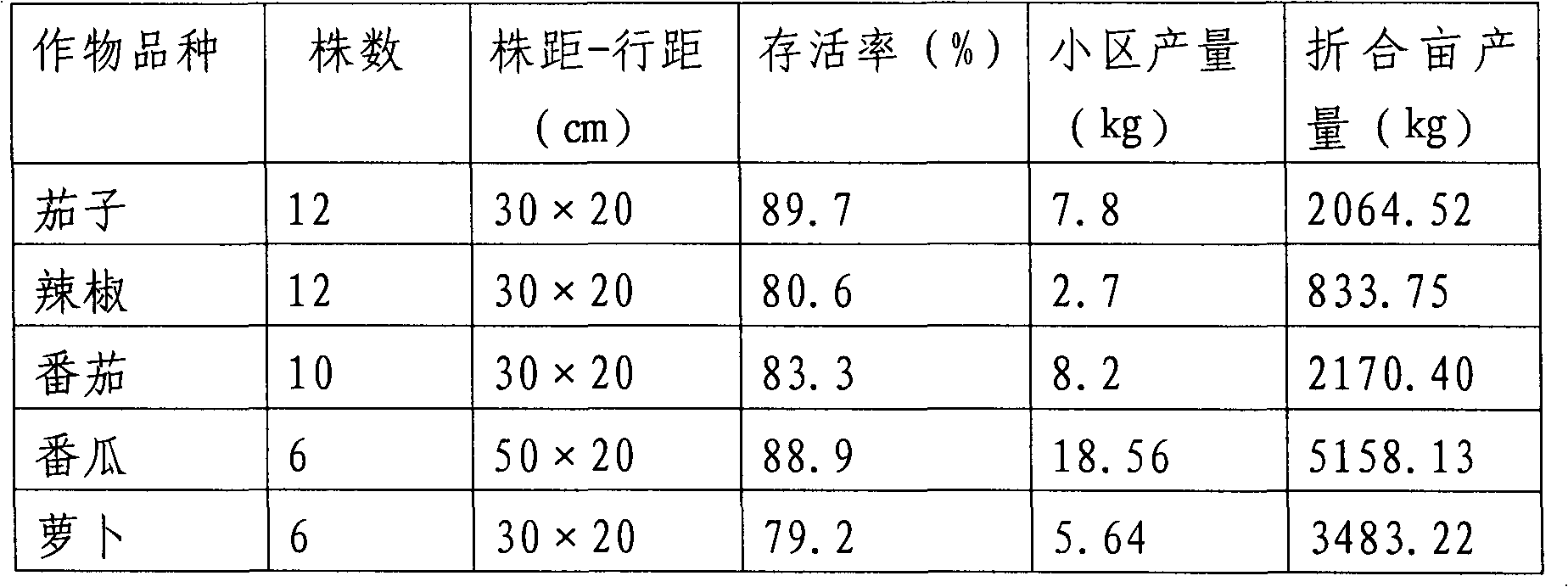

An irrigation system is disclosed having a pipe and a continuous tape of irrigation emitters that is affixed to an inside surface of the pipe and extends along its length. The pipe includes a plurality of fluid outlet ports, with one output port for each emitter in the tape. Each emitter includes a base member that is affixed to the inner surface of the pipe to create an enclosed fluid flow channel between the inner surface of the pipe and the base member. For each emitter, the fluid flow channel extends from a fluid inlet port, though filtering, flow regulation and collection sections, and to one of the fluid outlet ports formed in the pipe. The flow regulation section is formed as a labyrinth path and established which reduces the deposition of particles in the emitter which can reduce flow and / or clog the emitter.

Owner:EURODRIP IND COMML AGRI

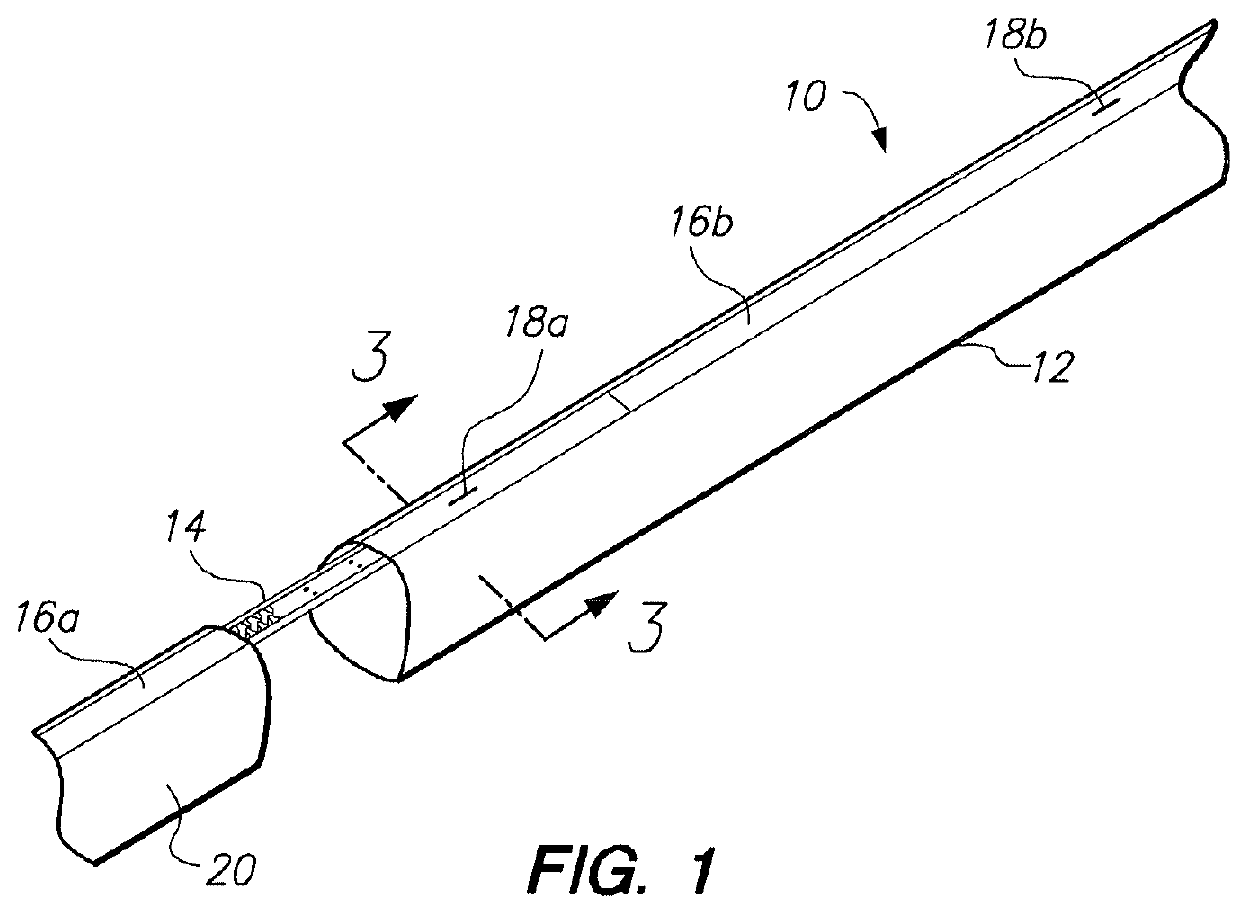

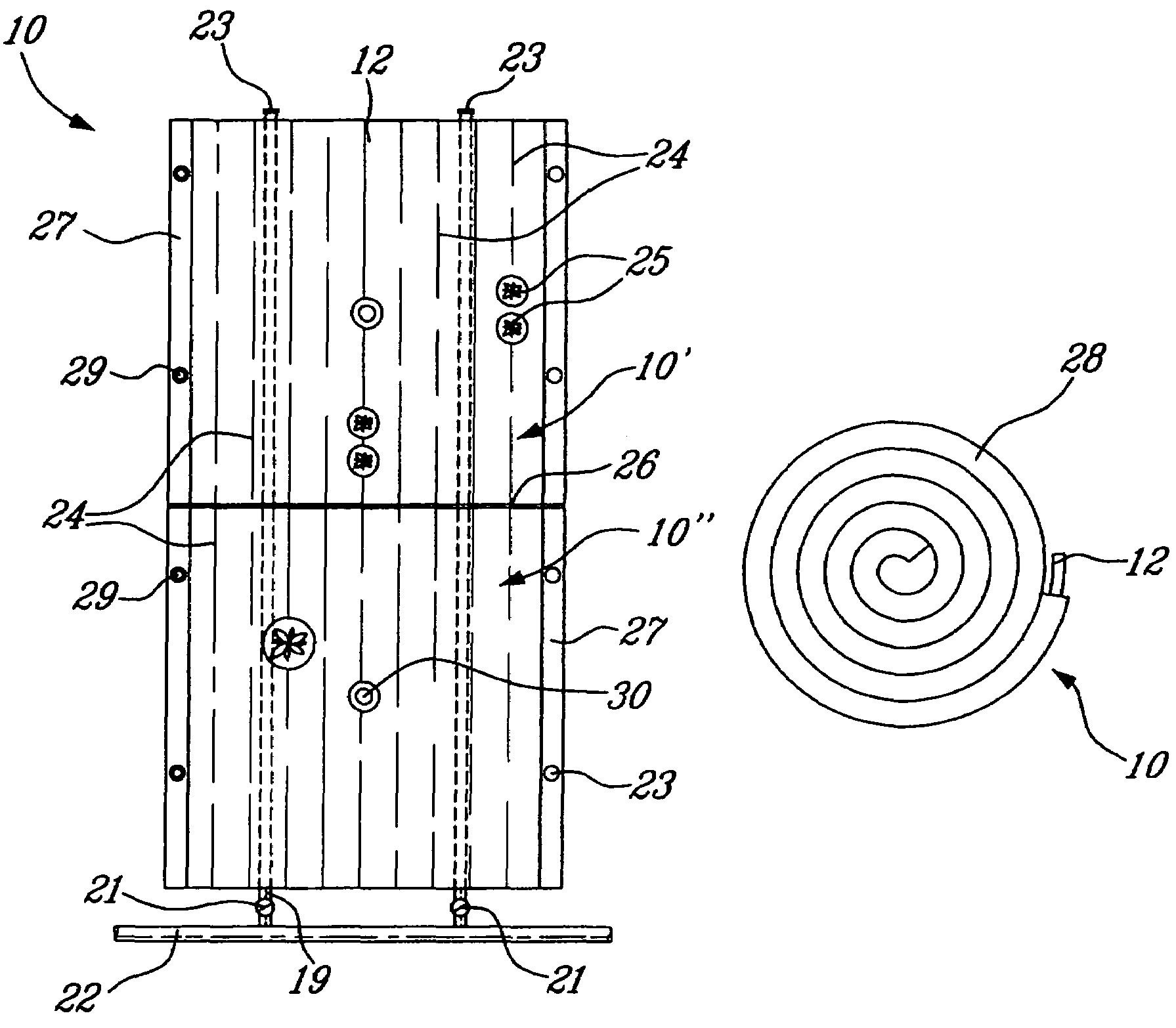

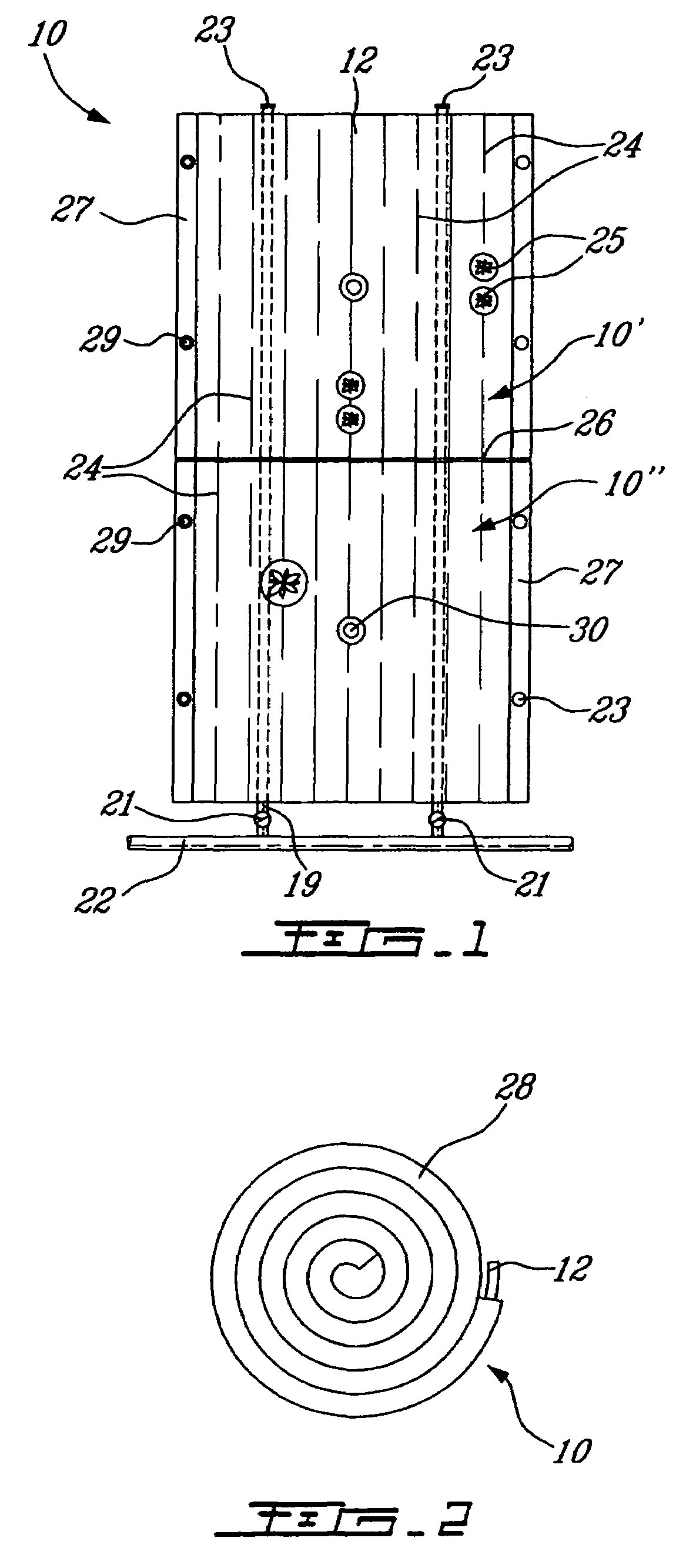

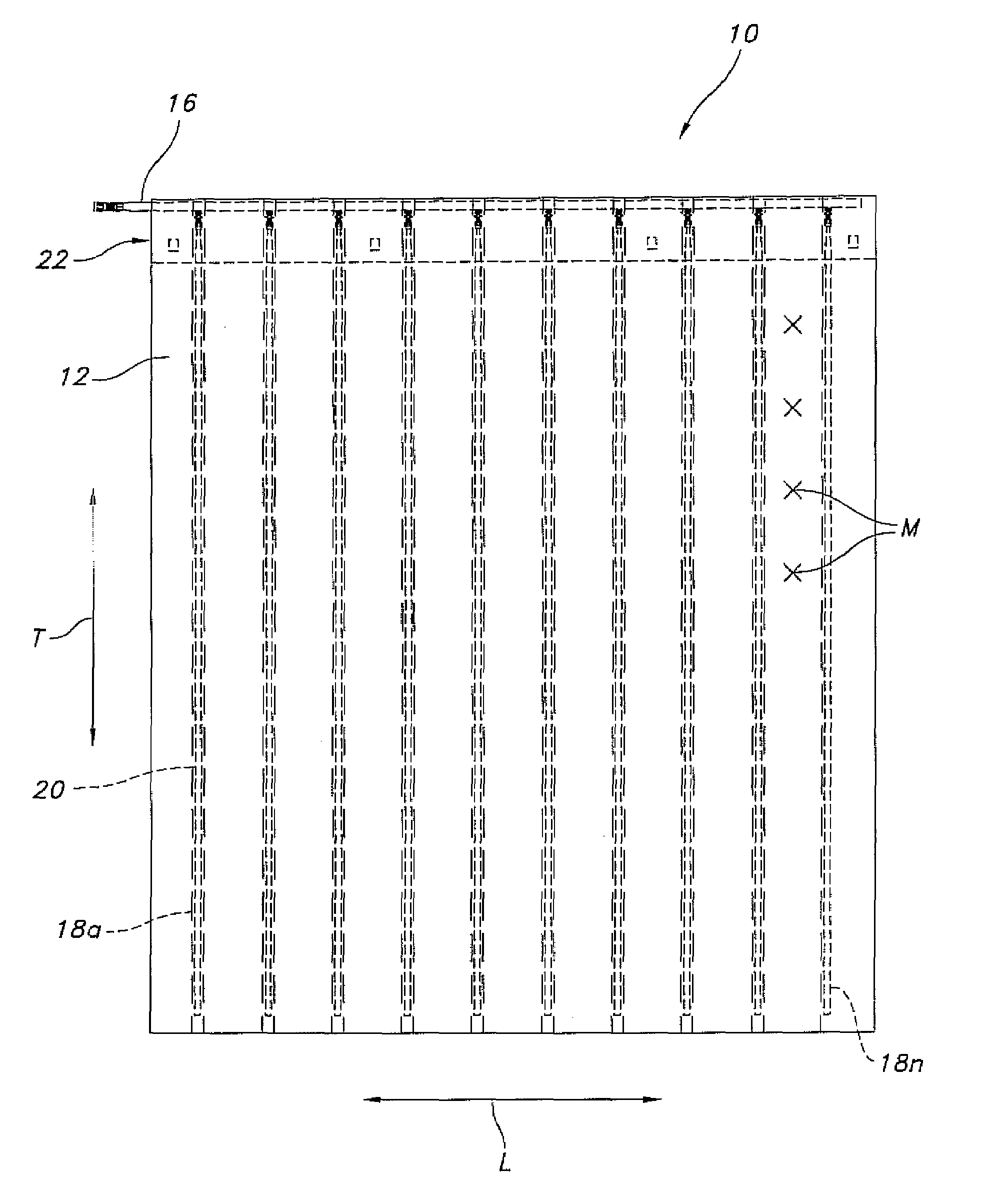

Irrigation mat and method of use

ActiveUS7647724B2Easy to installSelf-acting watering devicesWatering devicesDrip tapePlastic materials

An irrigation mat is comprised of a water impermeable base sheet, a water permeable top sheet and a capillary mat disposed between the base sheet and the top sheet. One or more flat pliable optional drip tapes are loosely disposed between the top sheet and the capillary mat and displaceable therebetween to any desirable position. The drip tape is a hollow flat tube constructed of perforated plastics material and extends at least a full length of the irrigation mat. The irrigation mat with the drip tapes is capable of being rolled up upon itself to form a roll. The top sheet is also heat fused to the folded edges of the back sheet.

Owner:UNIV LAVAL

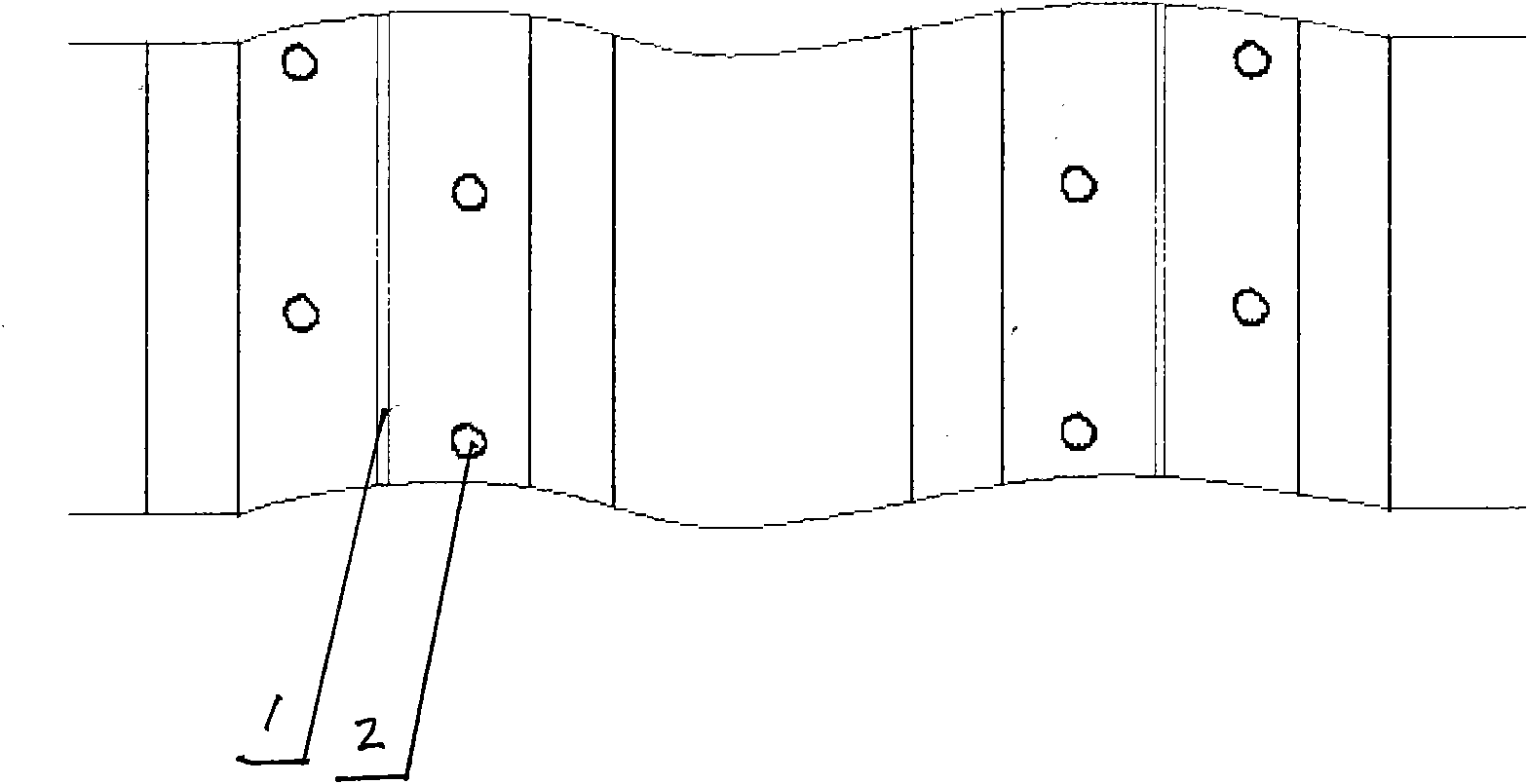

Cold-field corn cultivation method with 1000kg per mu

InactiveCN102657017APromote photosynthesisImprove throughputFertilising methodsHorticultureDrip tapeChemical control

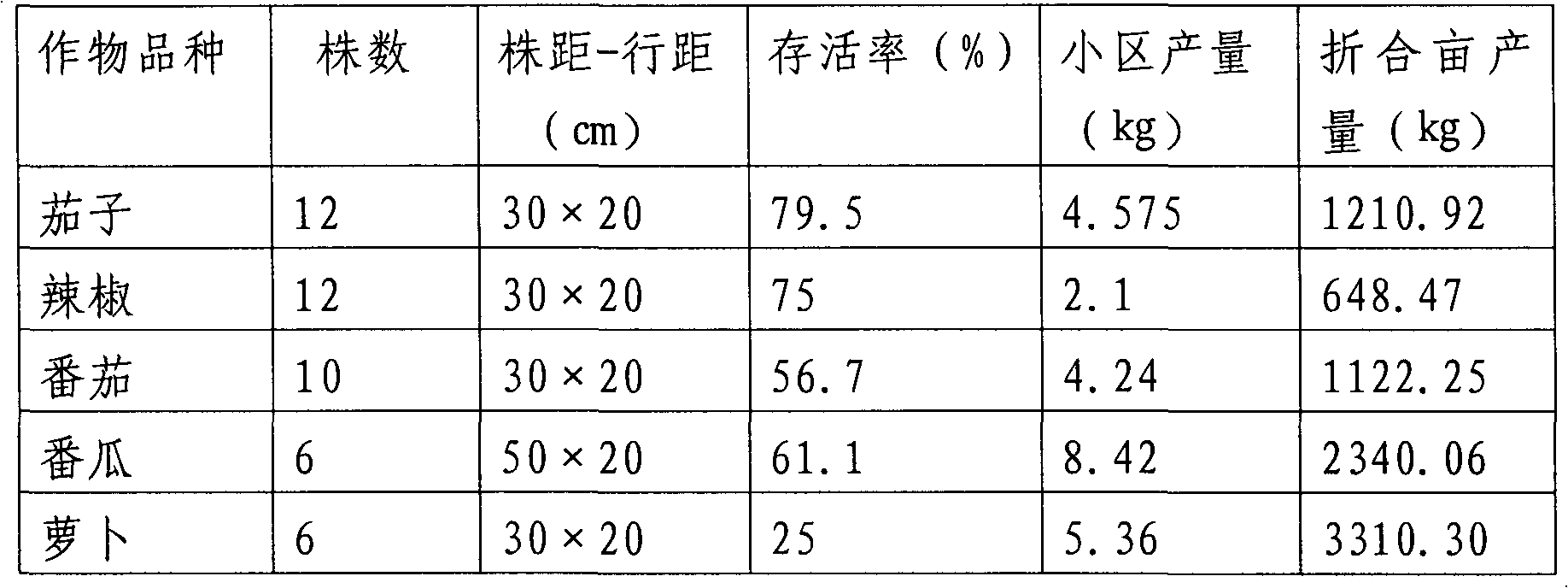

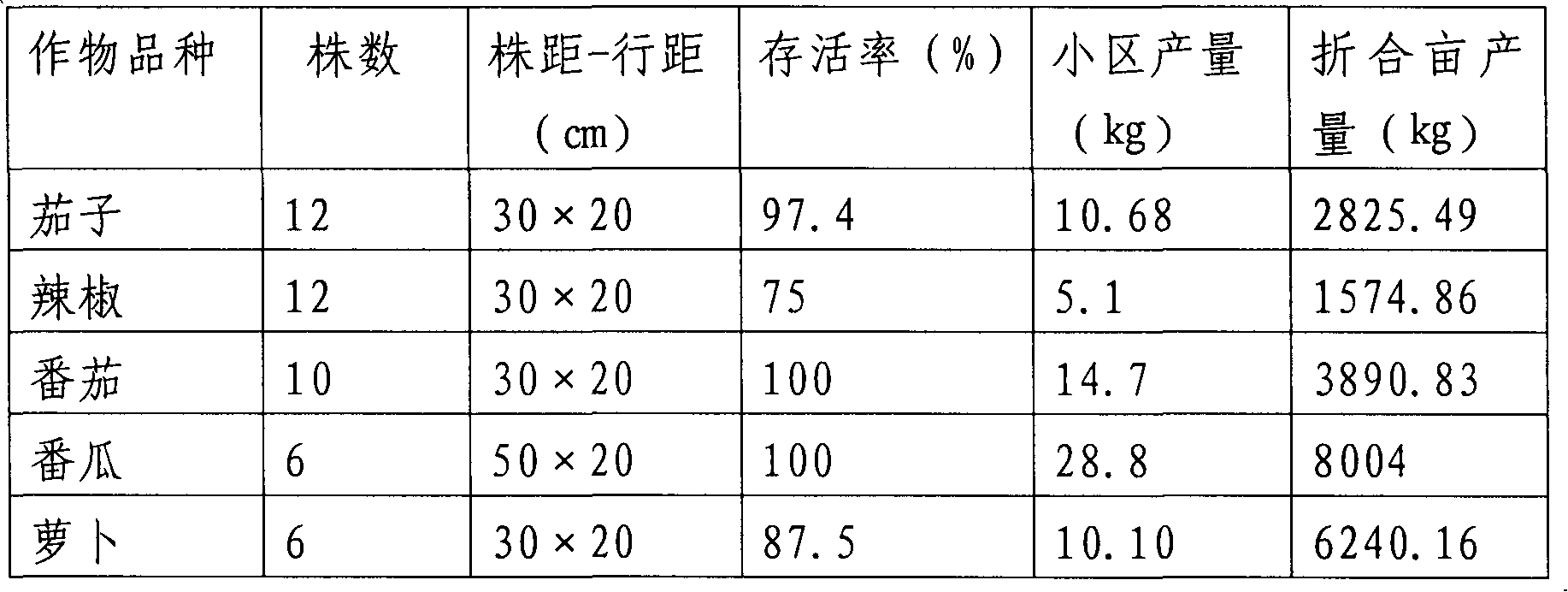

The invention relates to a cold-field corn cultivation method with 1000kg per mu, belongs to the technical field of crop cultivation and solves the technical problem that existing corn cultivation methods in northeast China are low in yield. The methods includes the steps of firstly, before freeze-up in autumn, scattering organic fertilizer, subsoiling to prepare a land, and ridging the land; and secondly, performing double-row sowing of corn seeds and applying base fertilizer the next year in spring, setting a drip tape along the center line of the surface of each ridge, covering the drip tapes with mulch, and performing field water management and chemical control management to complete cold-field cultivation of corn with 1000kg per mu. Double-row 'through' cultivation on a large ridge is performed by the method, so that light and ventilation are improved. Inter-row mulching for the large ridges is adopted, so that effective accumulated temperature is increased. Proper moisture conditions obtained by drip irrigation under mulch are created. Ideal corn plant types are created under adjustment of chemical control technique, and an ultrahigh grown mode is created. By the cold-field corn cultivation method with 1000kg per mu, the cold-field corn yield per unit is increased by 50-100% as compared with that by the traditional methods. The cold-field corn cultivation method with 1000kg per mu is applicable to cold-field corn cultivation.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

Gardening blanket with integral watering system

A blanket with an integral watering system covers the ground associated with a garden and assists in delivering water thereto. The blanket is provided by first and second sheets of material, at least one of said sheets of material being porous. The sheets are interconnected together and form an intermediate space for receiving at least a first conduit for conveying the water to the ground through the porous sheet of material. The first conduit may comprise layflat hose. Preferably, a plurality of channels are formed in the space, each for receiving a second conduit, such as a drip tape or like perforated hose, connected to the first conduit. The first conduit may extend in a first or longitudinal direction of the blanket, and the second conduits may extend in a second, transverse direction.

Owner:BAKER RICHARD L

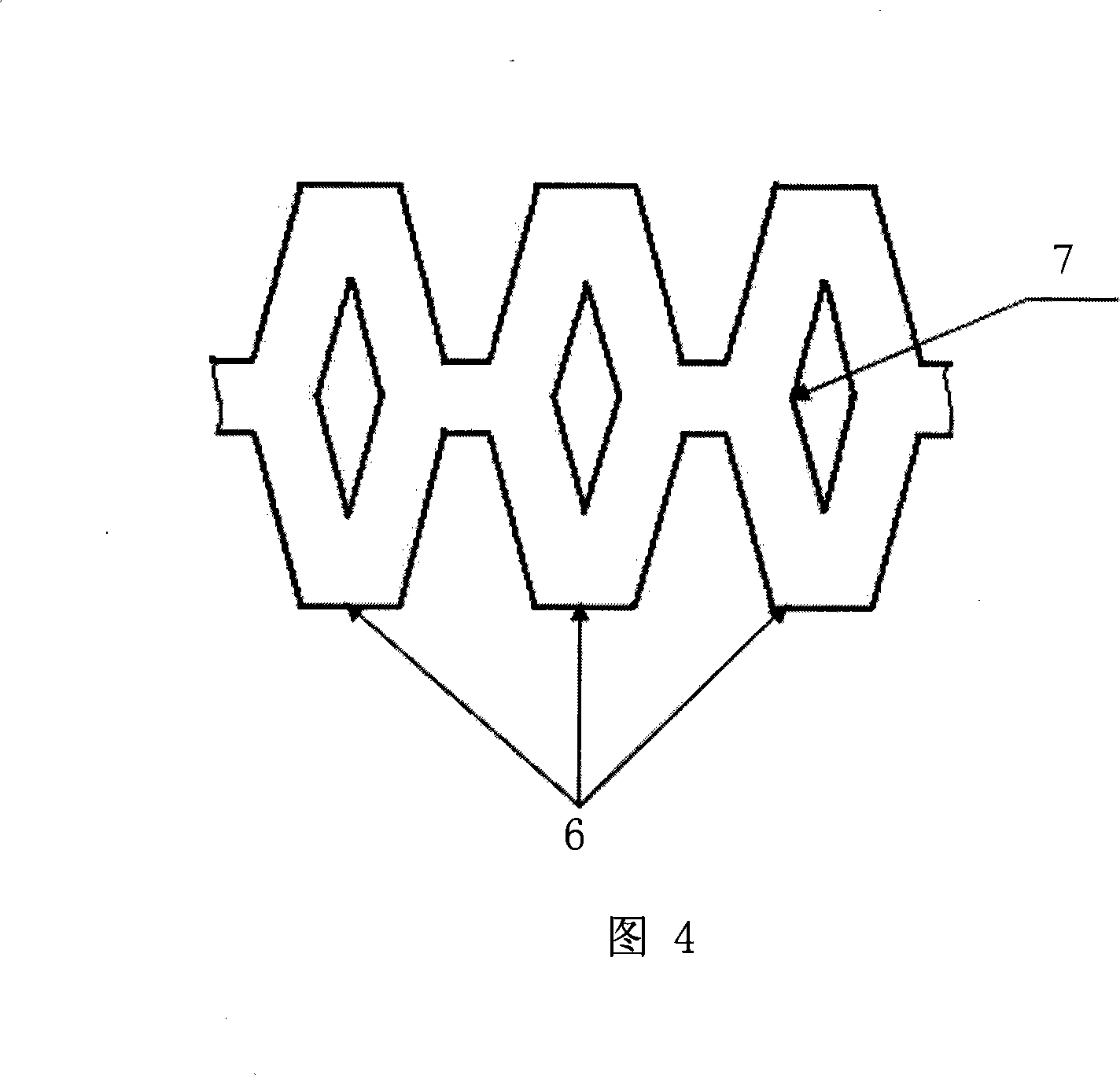

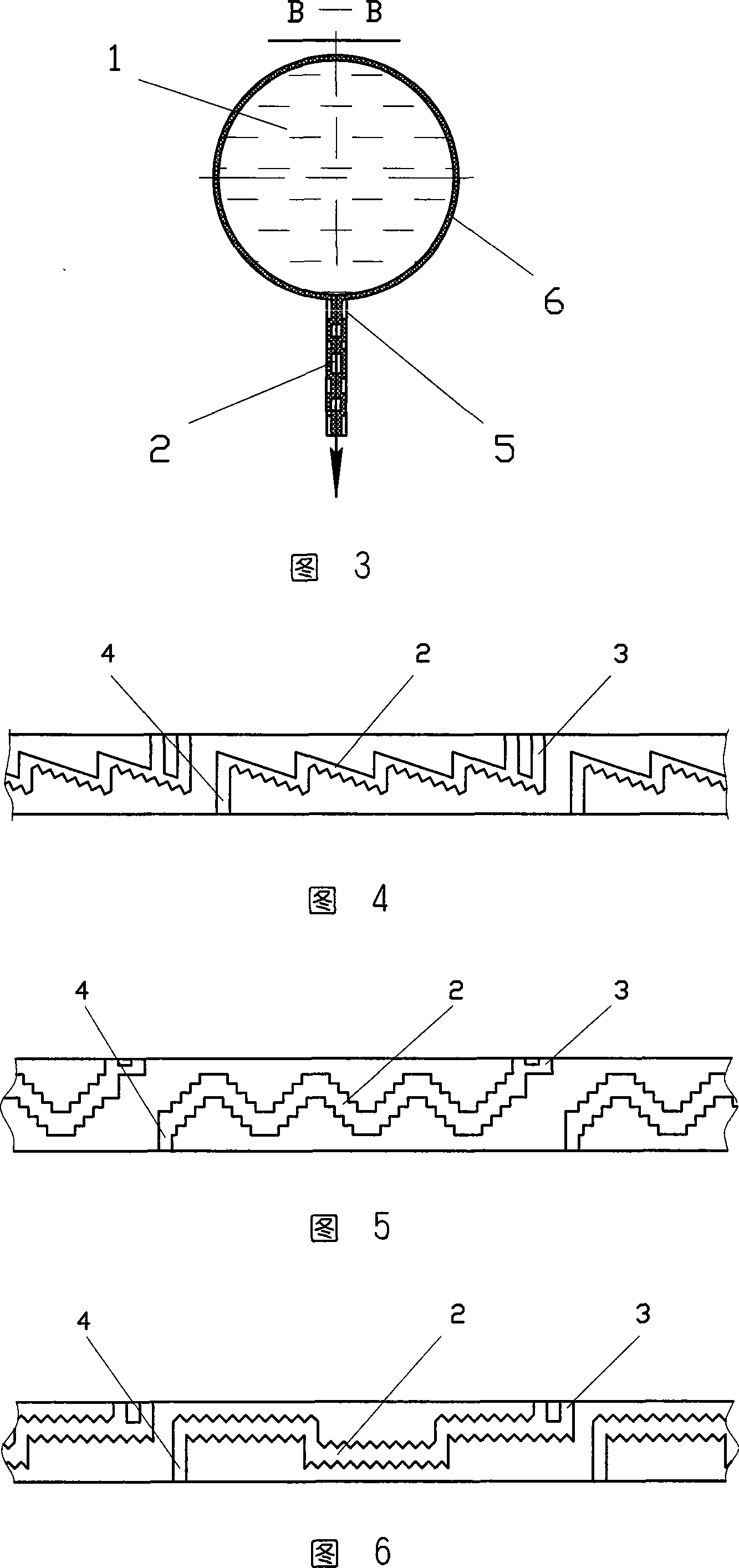

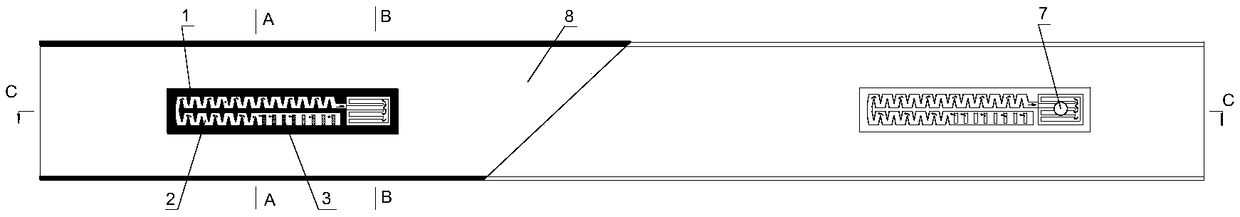

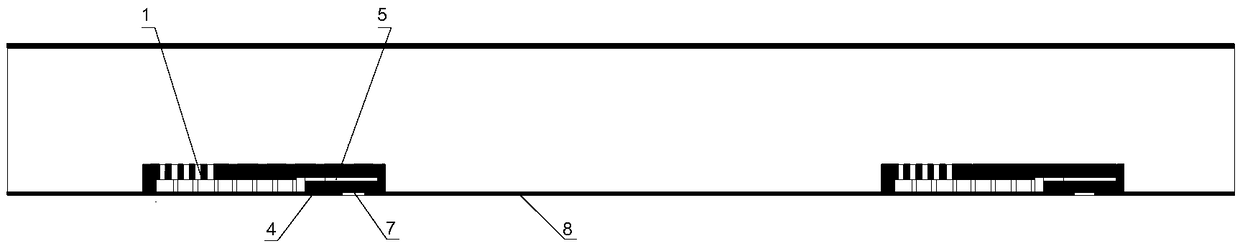

Paster type maze flow passage drip irrigation belt and production process

InactiveCN101234369AReduce wall thicknessReduce manufacturing costClimate change adaptationSpray nozzlesDrip tapeProduction line

The invention provides a patch-type labyrinth channel drip tape and a production method thereof. The invention is made by thermally attaching a labyrinth channel patch in the middle of plastic film, and is characterized in that a layer of plastic film continuously thermally attaches a plurality of groups of patches which are provided with labyrinth channels under horizontal draft; another synchronous tract layer of plastic film is covered, forms a plurality of channels with a plurality of groups of sandwich patches after be separated and heat pressed and is cut into a plurality of strips of patch type drip tapes. The patch-type labyrinth channel drip tape and the production method thereof can directly take the blown film which is widely used in packaging industry as the base material of channel drips; the width of the wall of a channel drip is reduced obviously; 3 to 8 channel drips can be formed simultaneously on a production line, thereby greatly increasing the production efficiency, reducing the production cost of drip tapes, effectively avoiding the problem of deformation and intensity reduction owing to extending labyrinth channels, simplifying the processing equipment and controlling the quality of products more easily.

Owner:NORTHWEST A & F UNIV +1

Method for reusing saline-alkali waste cultivated land to grow plants

InactiveCN102523779AReduce the impactNormal emergenceHorticultureSoil-working methodsTerrainWater discharge

The invention discloses a method for reusing saline-alkali waste cultivated land to grow plants, comprising the following steps of: (1) digging grooves and holes, ensuring length according to terrain, setting slight gradient at the bottom of the grooves, and arranging a water outlet at a lower place; (2) building a water discharge groove at the end of the water outlet; (3) digging a water return pool at the head of the land, reflowing redundant water in the grooves and holes, and storing the water in the water return pool; (4) isolating the saline-alkali waste cultivated land from the matrix by an agricultural greenhouses film at the bottom and the periphery of the grooves and holes, or paving furnace clinker at the bottom of the grooves and holes, and isolating the periphery of the grooves and holes by the agricultural greenhouses film; (5) the proper matrix has mixture of pearlstone, vermiculite and silver sand, mixture of furnace clinker, danty and coal ash, mixture of exotic soil and straw fermented substrate and exotic soil of the mixture, respectively filling the matrix into the different grooves and holes; (6) applying compound fertilizer and diamine with fixed quantity before the plants are grown, and topdressing urea and diamine with fixed quantity at twice at the fruiting period of the plants; (7) irrigating by means of trickle irrigation by a drip tape; (8) ridging, film paving and growing when the plants are grown; and (9) leading the grooves and holes to have a certain gap, and replacing the surfaces of the grooves and holes with the straw fermented substrate, so that the influence of the saline alkali to the matrix is reduced.

Owner:BAIYIN AGRI SCI RES INST

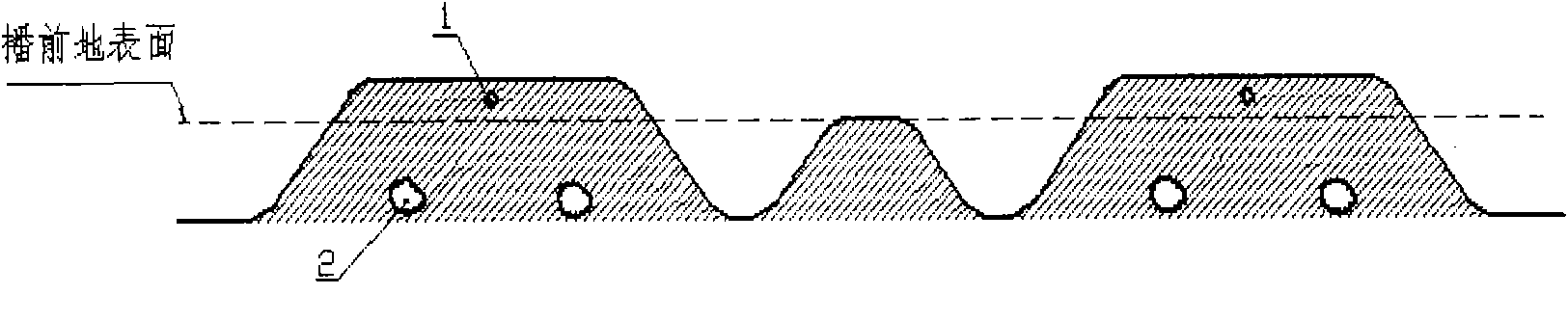

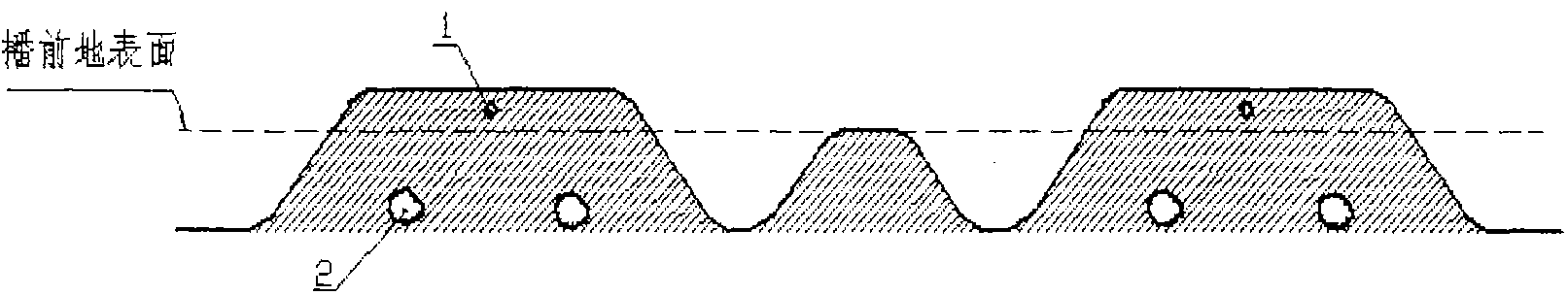

Potato infiltrating irrigation growing method

The invention discloses a potato infiltrating irrigation growing method. The growing process comprises the following steps: firstly ditching, wherein the ditch width is 19-23cm and the ditch depth is 6-10cm; sowing two lines of potatoes in the ditches alternately, wherein the line width is 18-22cm and the plant spacing is 23-42cm; earthing, forming low ridges, wherein two lines form one ridge and the ridging spacing is 87-93cm; shallowly paving underground drip tapes on the ridges between the two lines and 2-5cm under the earthed ground surface; and earthing up and ridging, 10 days after seedling emergence. By using the growing method of the invention, water resource can be saved, pouring of fertilizer can be lowered, occurrence of pests and diseases can be reduced, the yield can be increased and the environment can be protected.

Owner:INNER MONGOLIA AGRICULTURAL UNIVERSITY +1

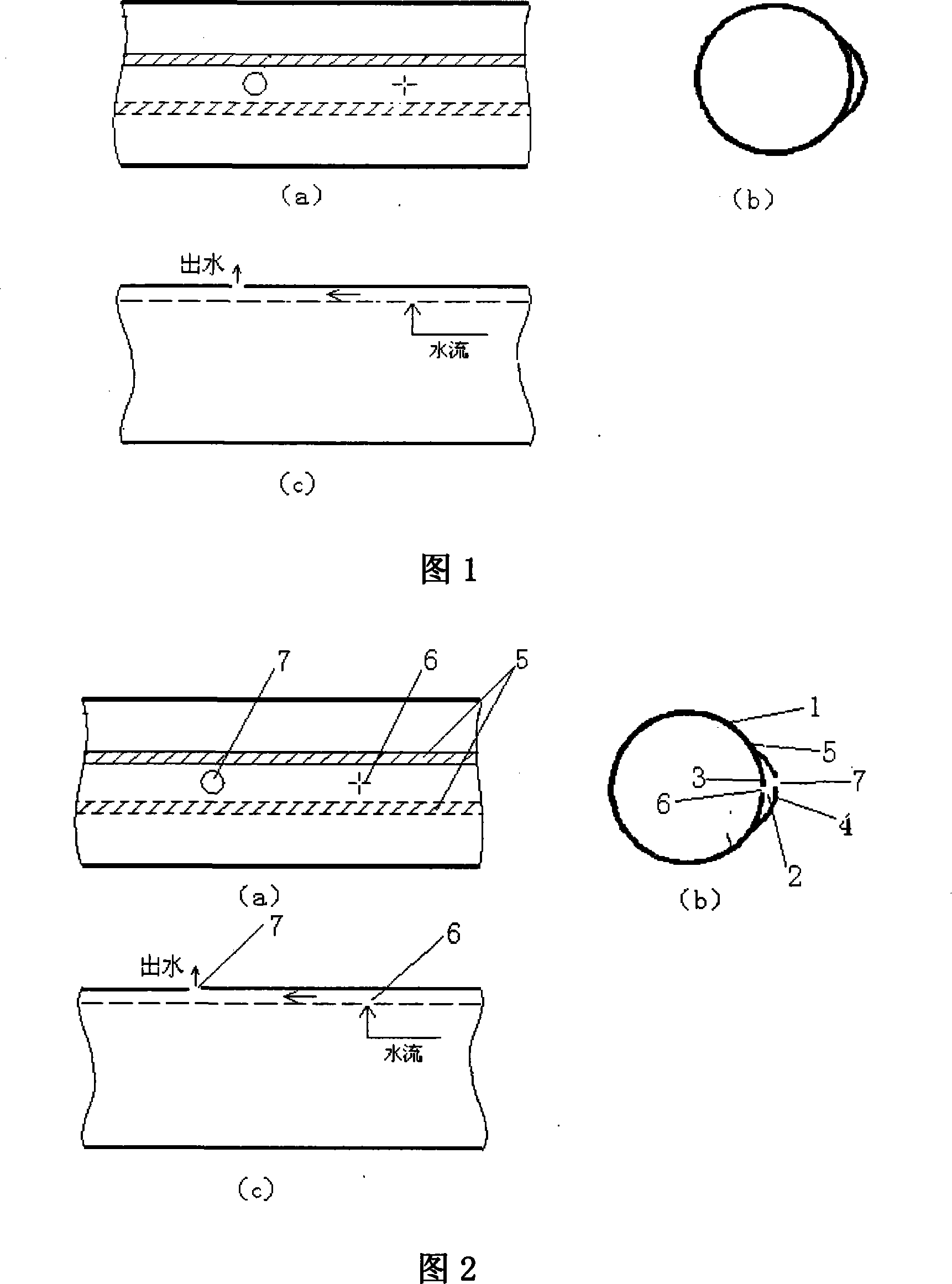

Anti-clogging drop irrigator with stable flow and low pressure

InactiveCN101223856ASimple structureStable outflowClimate change adaptationWatering devicesDrip tapeTransmission channel

The invention discloses a low-pressure douche with steady flow and blockage resistance. A douche on a drip tape is a continuous channel composed of a double-layered tube wall which is respectively a douche inner wall and a douche outer wall, two sides of the double-layered wall of the douche continuous channel are adhered with the drip tape, and the douche inner wall and the douche outer wall are in natural tangency; furthermore, a douche water-passing channel is arranged between the inner wall and the outer wall, the douche inner wall is a part of the drip tape, a water transmission channel is arranged inside the inner wall, the outer wall covers the inner wall; a crosswise or chuan-shaped water inlet orifice that is communicated with a water output channel is arranged on the wall surface of the douche inner wall, and a circular or crosswise water outlet orifice is arranged on the wall surface of the douche outer wall. The invention has the effect of preventing channel blockage, and under different inner tube pressure, the invention has different combination closeness between the inner wall and the outer wall, as well as different water-passing channel section area; the water-passing section area is in inverse proportion to pressure, the flow speed is in positive correlation with the pressure difference between the water inlet and the water outlet, and pressure change has little influence on flow output amount, therefore, the flow output amount is very steady.

Owner:INST OF SOIL & WATER CONVERVATION CHINESE ACAD OF SCI +2

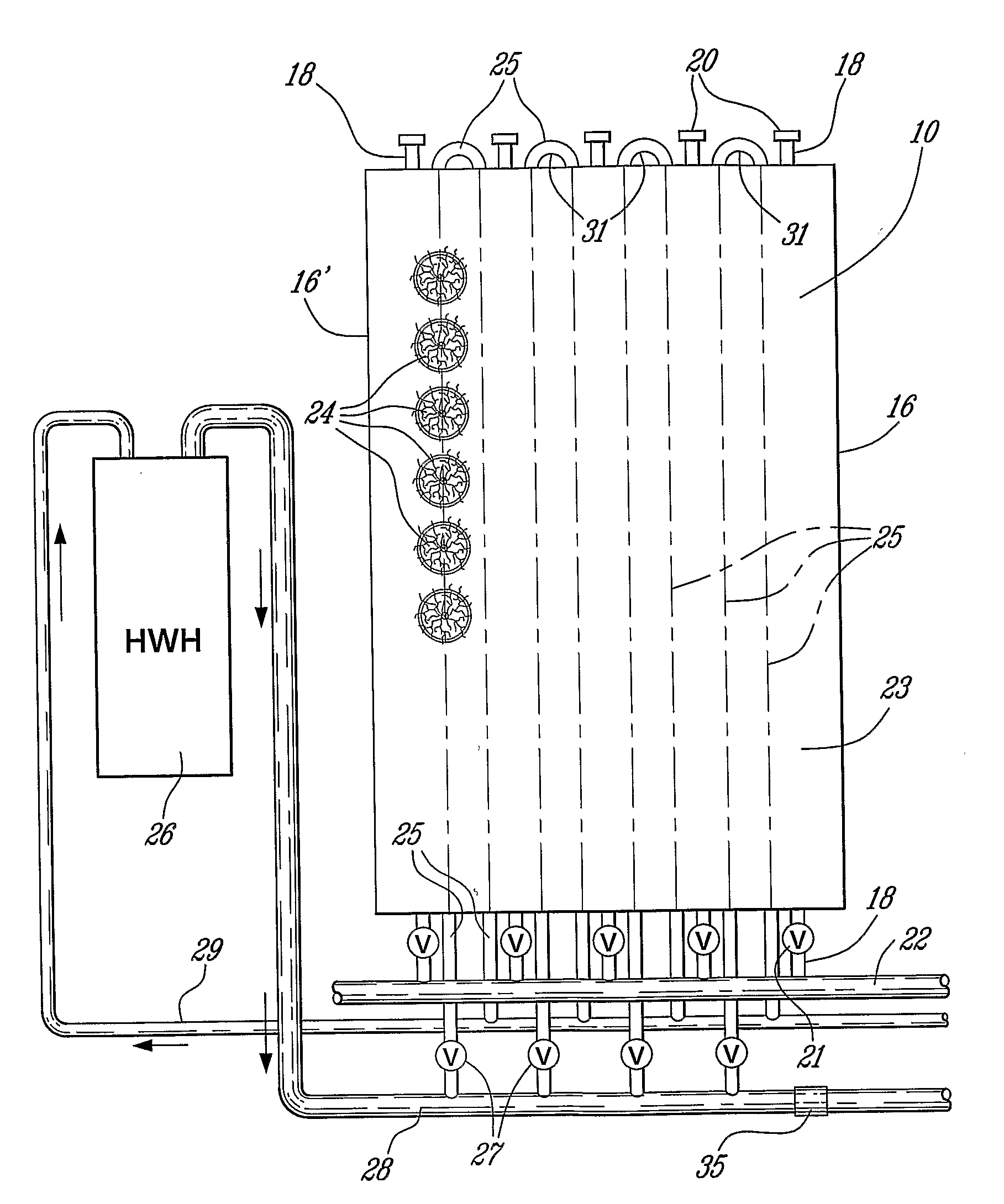

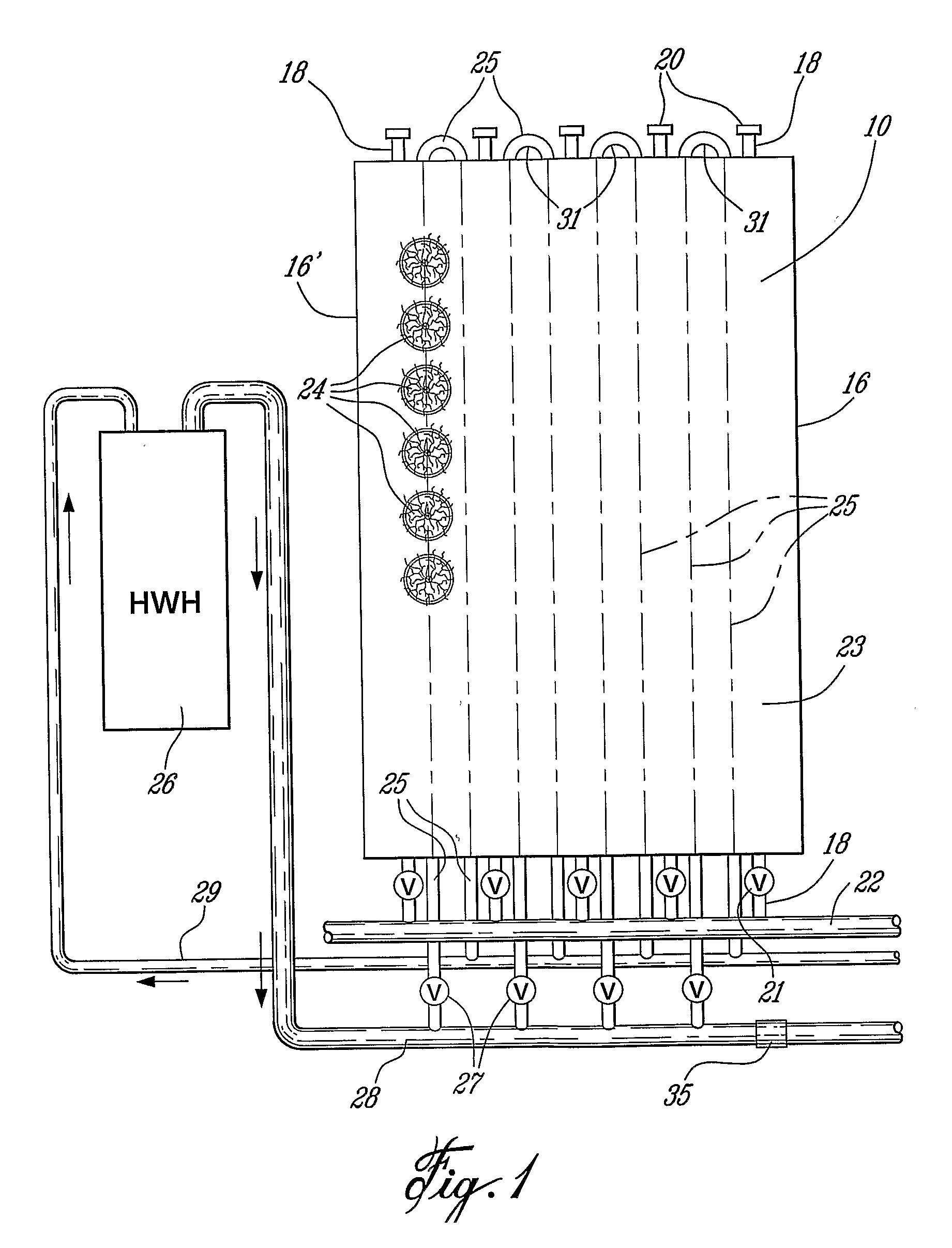

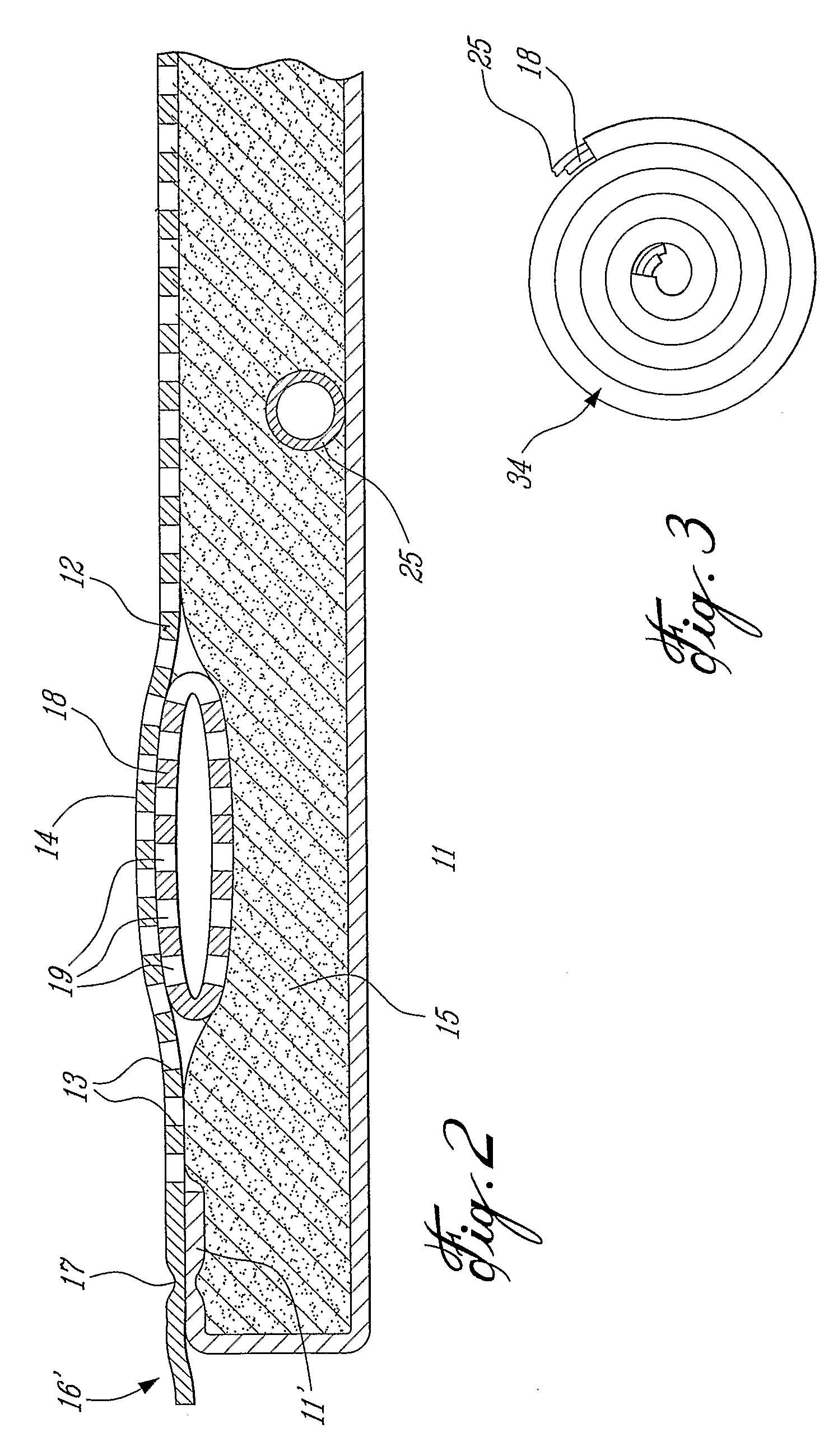

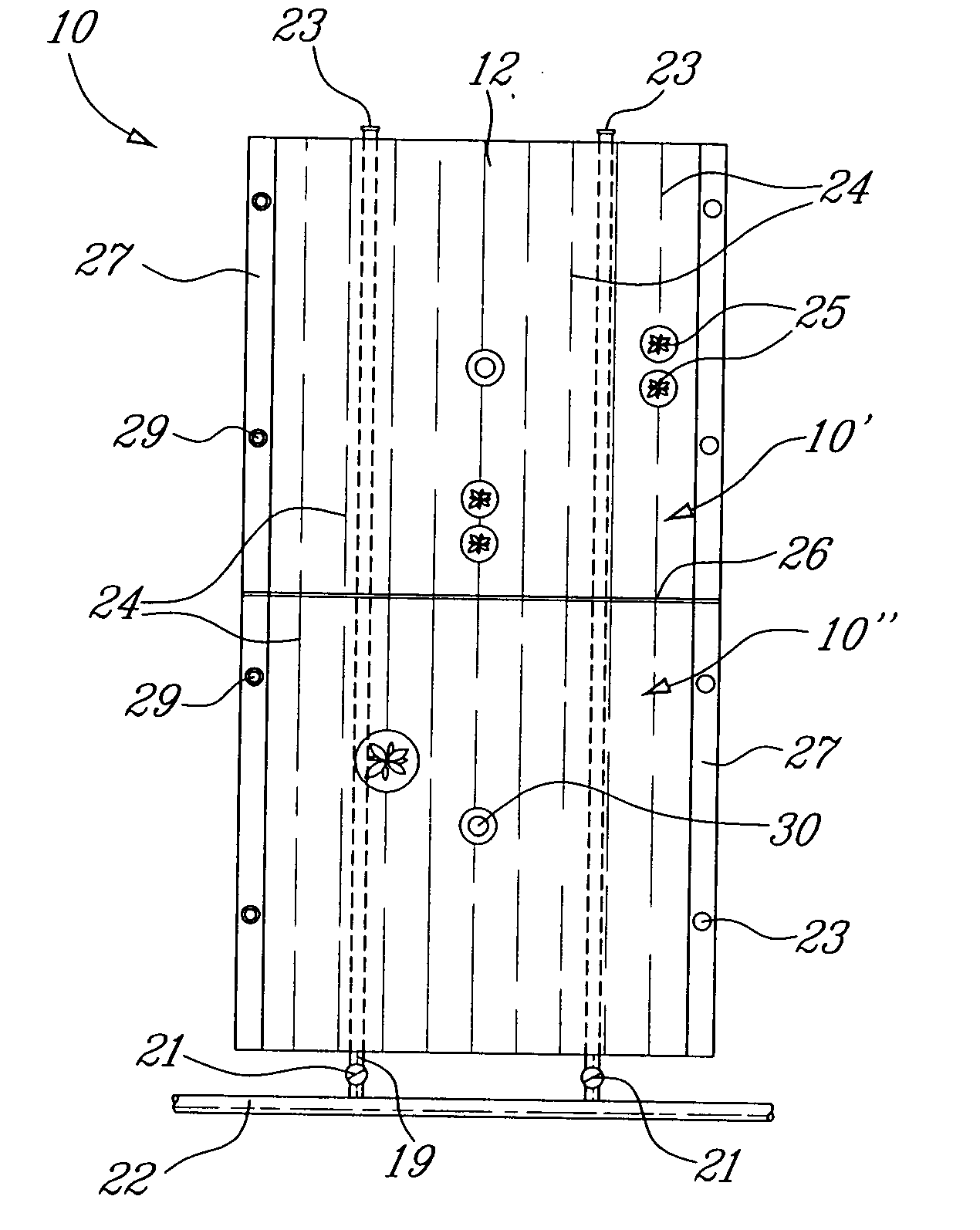

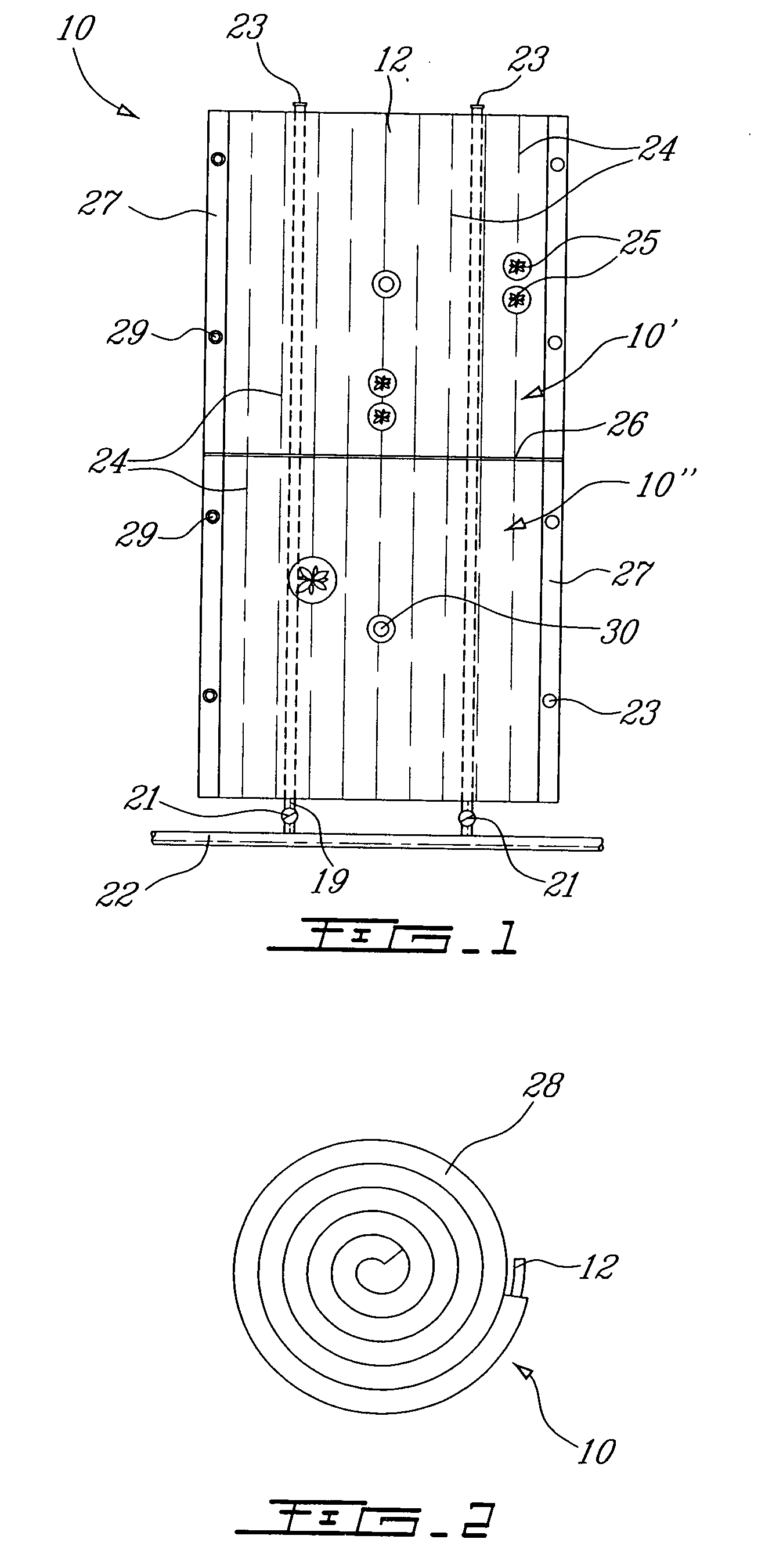

Hydro-thermo irrigation mat

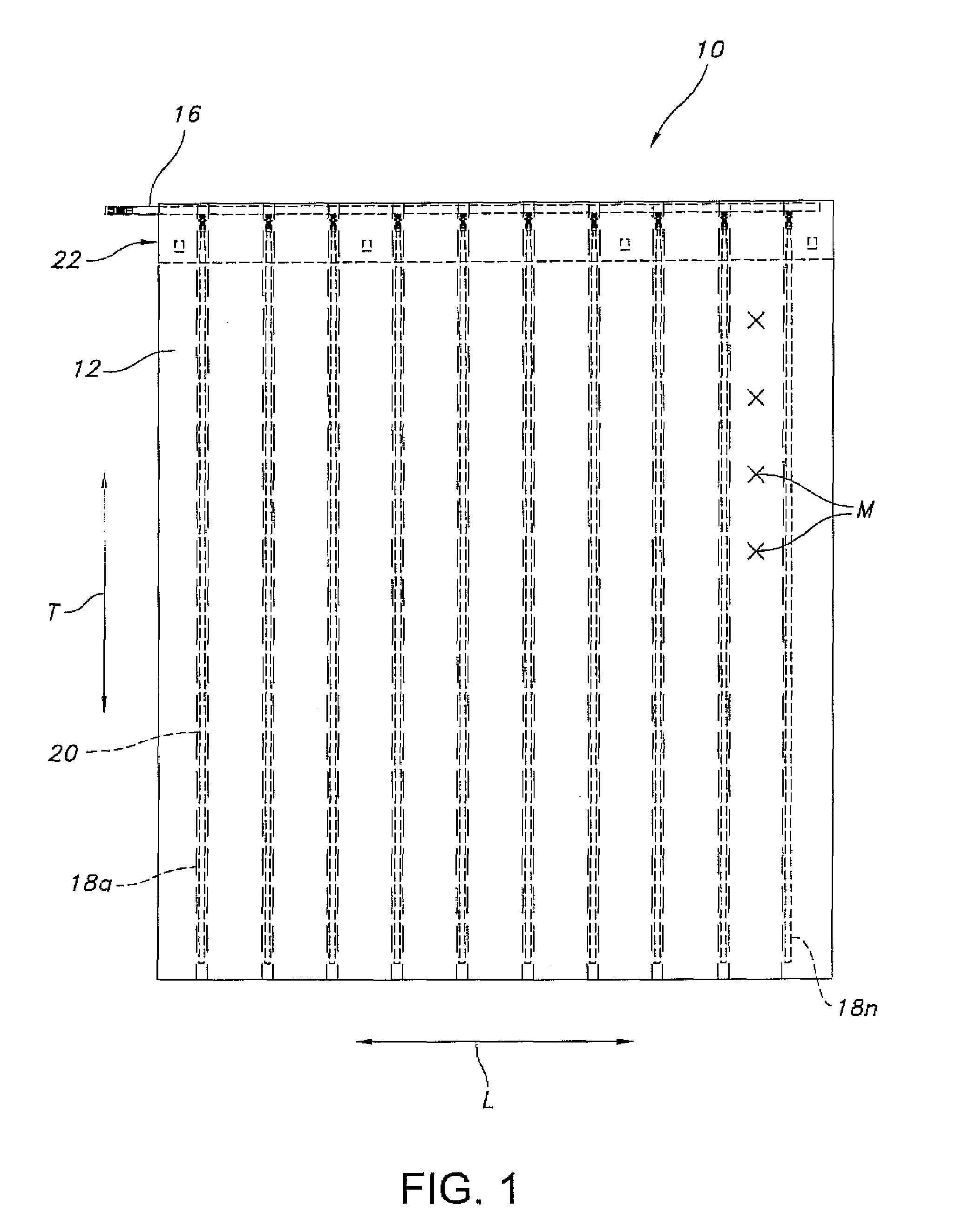

A hydro-thermo irrigation mat (10) is comprised of a base sheet (11), a water-permeable root-shielding top sheet (12), and a capillary mat (15) of absorbent material therebetween. One or more flat pliable drip tapes (18) are loosely disposed in spaced-apart relationship between the top sheet (12) and the capillary mat (15). Hot water convection tubes (25) are disposed co-axially with the drip tapes (18) but between the base sheet (11) and the capillary mat (15). The drip tapes (18) are connected to a water supply line (22) and the hot water convection tubes (25) are secured to a hot water supply line (28). Water within the mat is heated and distributes heat from the hot water convection tubes (25) substantially throughout the mat.

Owner:UNIV LAVAL

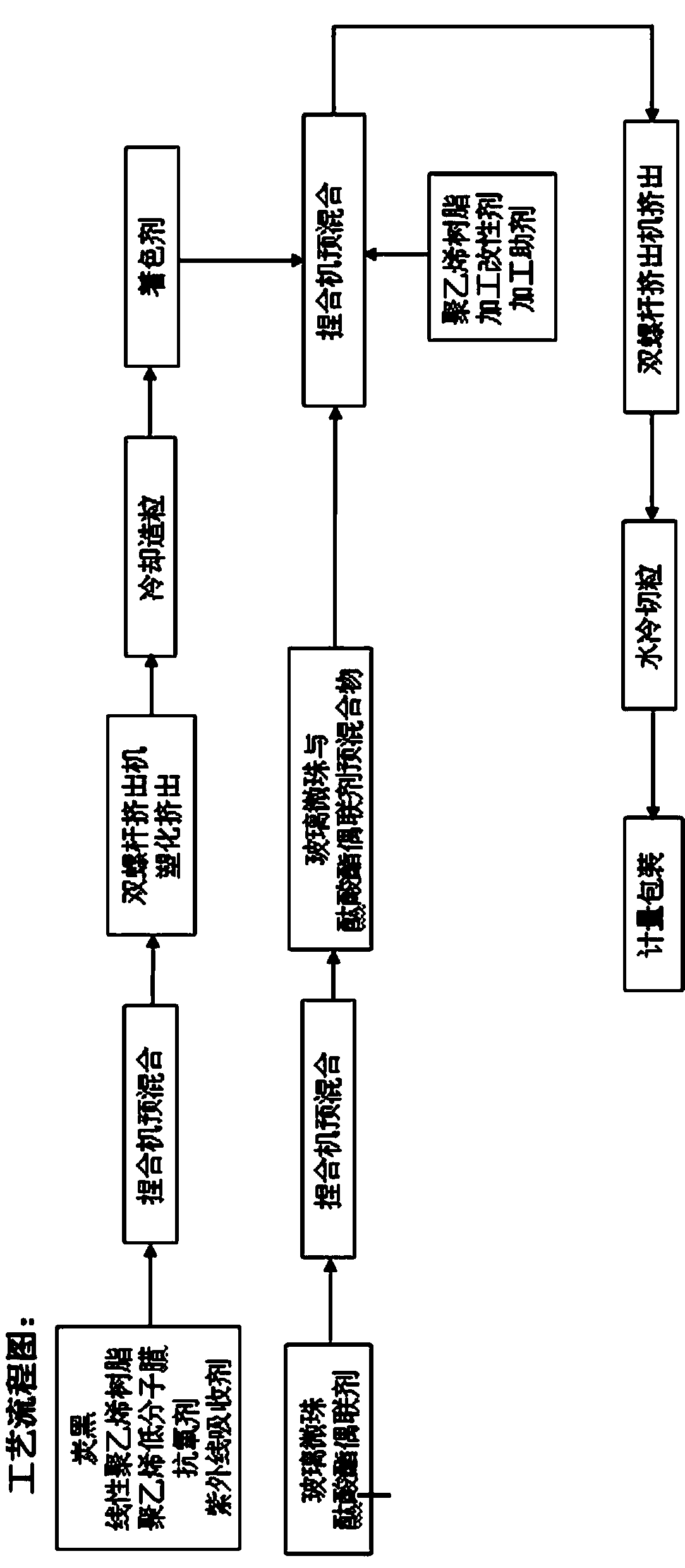

Modified polychloroethylene drip irrigation tape

InactiveCN101434733AIdea novel scienceImprove performanceSpray nozzlesProcedure AgentsPolyvinyl chloride

The invention relates to a modified polyvinyl chloride (PVC) drip tape applied to the filed of agricultural water-saving irrigation facilities. The formula of the PVC drip tape comprises carbon black, a plasticizer, a high molecular plasticizer (GZ), an anti-impact modifier, a lubricant, a processing accessory agent, a heat stabilizer, calcium carbonate (CaCO3), a coupler and PVC; the carbon black comprises medium color black and common color black; the PVC comprises the types of PVC-SG2, PVC-SG3, PVC-SG4 and PVC-SG5; the plasticizer comprises dibutyl phthalate (DBP) and dioctyl sebacate (DOS); the lubricant comprises a compound lubricant, i.e., a stearic acid, calcium stearate, chlorinated paraffin or oxidized polyethylene wax (OPE). The modified PVC drip tape has scientific and novel conception; the PVC drip tape has excellent comprehensive performance after modification treatment by using various modification accessory agents; and compared with the common PVC drip tape, the modified PVC drip tape has relatively low production cost and more remarkable advantages in price and performance, can reduce the consumption of gasoline resource and is more beneficial to the agricultural water-saving irrigation technology of China.

Owner:SHENYANG HUADE MACHINERY MFG

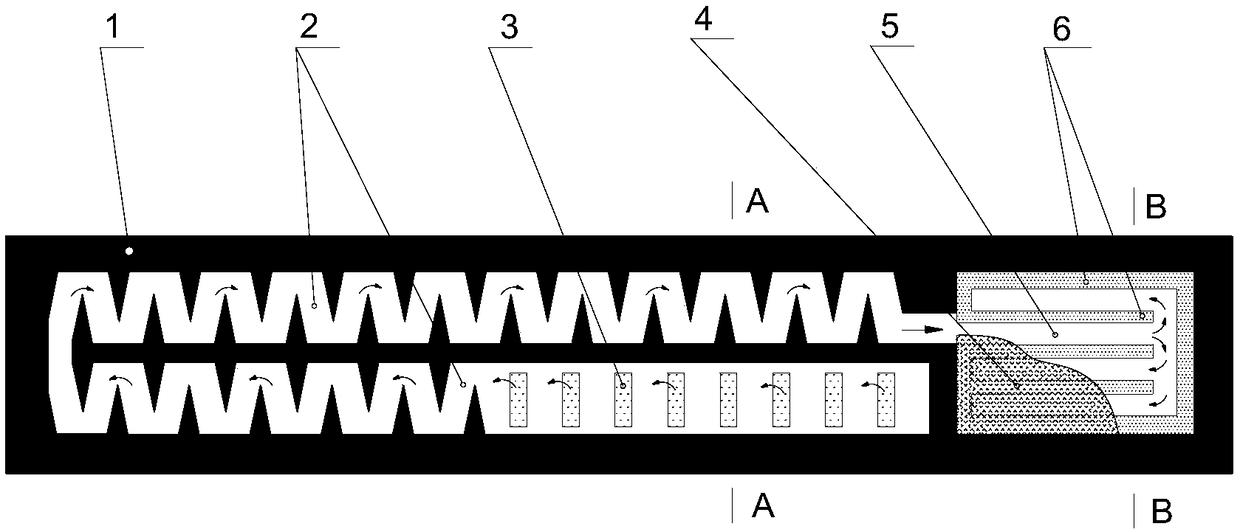

Single-wing twin channel circumferential motion micropressure drip tape

InactiveCN101229532AImprove anti-clogging performanceIncrease the lengthWatering devicesSpray nozzlesDrip tapeTerrain

The invention discloses a flow micro-pressure drip irrigation tape with a single wing and double channels, which comprises a water pipeline, a drip irrigation tape wing and n working units; the drip tape wing is adhered to the water pipeline; the n working units are distributed on the drip tape wing alternatively. The working units comprise a water inlet, a double-channel flow passage and a water outlet; the water inlet is communicated with the water pipeline; the water inlet and the water outlet are communicated through the double-channel flow passage; the double-channel flow passage consists of continuously distributed serrated passage units. The part passage surface of the drip irrigation tape of the invention is a labyrinth-type serrated flow passage; the mutual erosions of the continuous serrated structure and water flow cause local energy dissipation to be more outstanding and ensure an emitter to have more efficient energy dissipation effect. The invention has better effluent evenness, anti-clogging performance and economy. The drip irrigation tape is suitable for irrigation under low water pressure and is applied to irrigation under the conditions of complex terrain and simple equipment.

Owner:HUAZHONG UNIV OF SCI & TECH

Method and apparatus for the production of an irrigation mat

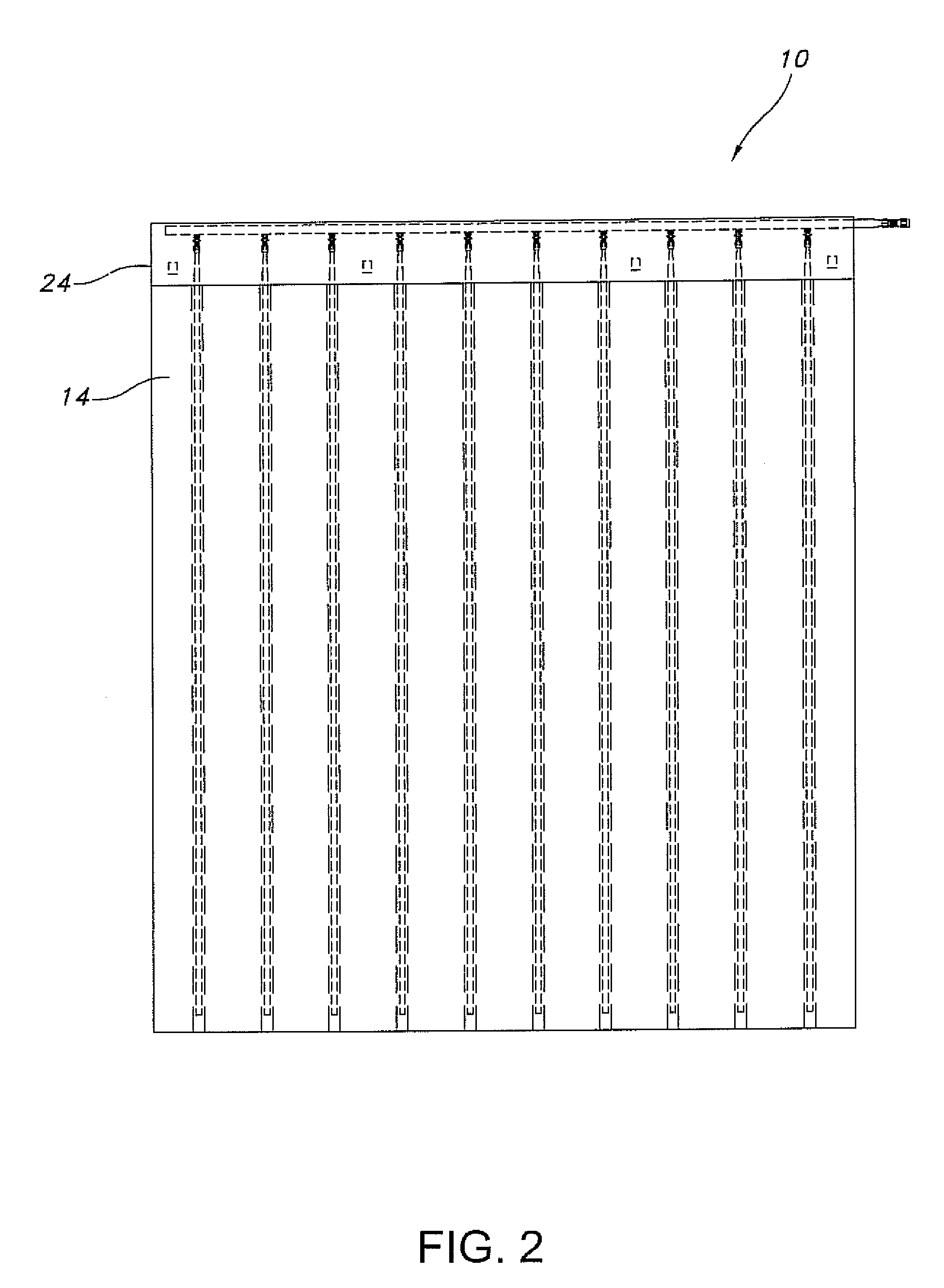

A method and apparatus for producing an irrigation mat comprised of a water impermeable base sheet, a water permeable top sheet and a capillary mat disposed between the base sheet and the top sheet. One or more flat pliable drip tapes are loosely disposed between the top sheet and the capillary mat and displaceable therebetween to any desirable position. The drip tape is a hollow flat tube constructed of perforated plastics material and extends at least a full length of the irrigation mat. The irrigation mat with the drip tapes is capable of being rolled up upon itself to form a roll. The method and apparatus for fabricating same provide for the base sheet to be folded upon opposed elongated side edges thereof to overlap the capillary mat and to be heat fused thereto. The top sheet is also heat fused to the folded edges of the back sheet.

Owner:ALTER INVEST II FUND

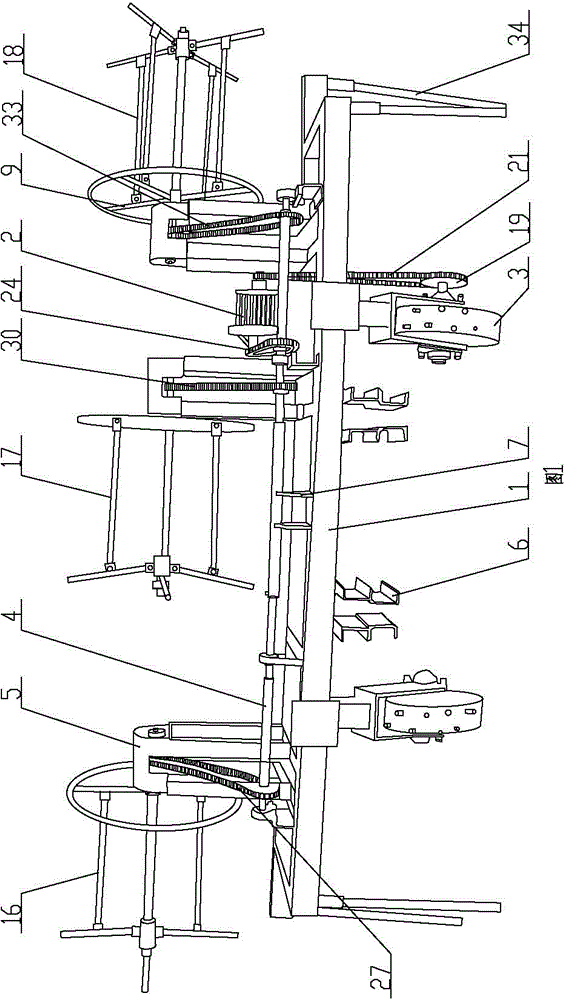

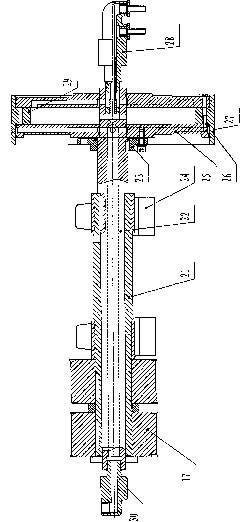

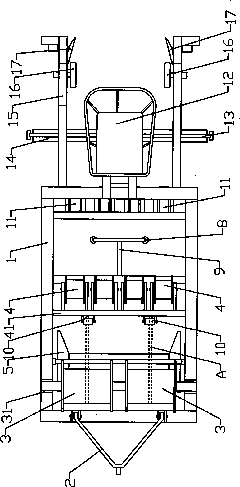

Device for automatically recycling drip irrigation tape

The invention relates to the technical field of agricultural machinery, in particular to a device for automatically recycling a drip irrigation tape. The device for automatically recycling the drip irrigation tape comprises a stander and a stepless gearbox, wherein travelling wheels are mounted at a lower side of the stander in a fixed manner, a transmission shaft is mounted at top of the stander along a left- right direction, a roller is mounted above the stander through a bearing block, the stepless gearbox is mounted above the stander in a fixed manner, a rotating shaft of each travelling wheel is connected to a power input end of the stepless gearbox through a first transmission mechanism, a power output end of the stepless gearbox is connected to a power input end of the transmission shaft through a second transmission mechanism, and a power output end of the transmission shaft is connected to a power input end of the roller through a third transmission mechanism. According to the invention, as the stepless gearbox is mounted, a transmission ratio of the stepless gearbox can be regulated according to operational requirements to ensure a more uniform recycling speed of the drip irrigation tape and an appropriate and uniform tension for the drip irrigation tape, so that the drip irrigation tape is prevented from being broken easily, and moreover the continuity and stability of automatically recycling the drip irrigation tap can be ensured.

Owner:新疆千里良驹农业科技有限公司

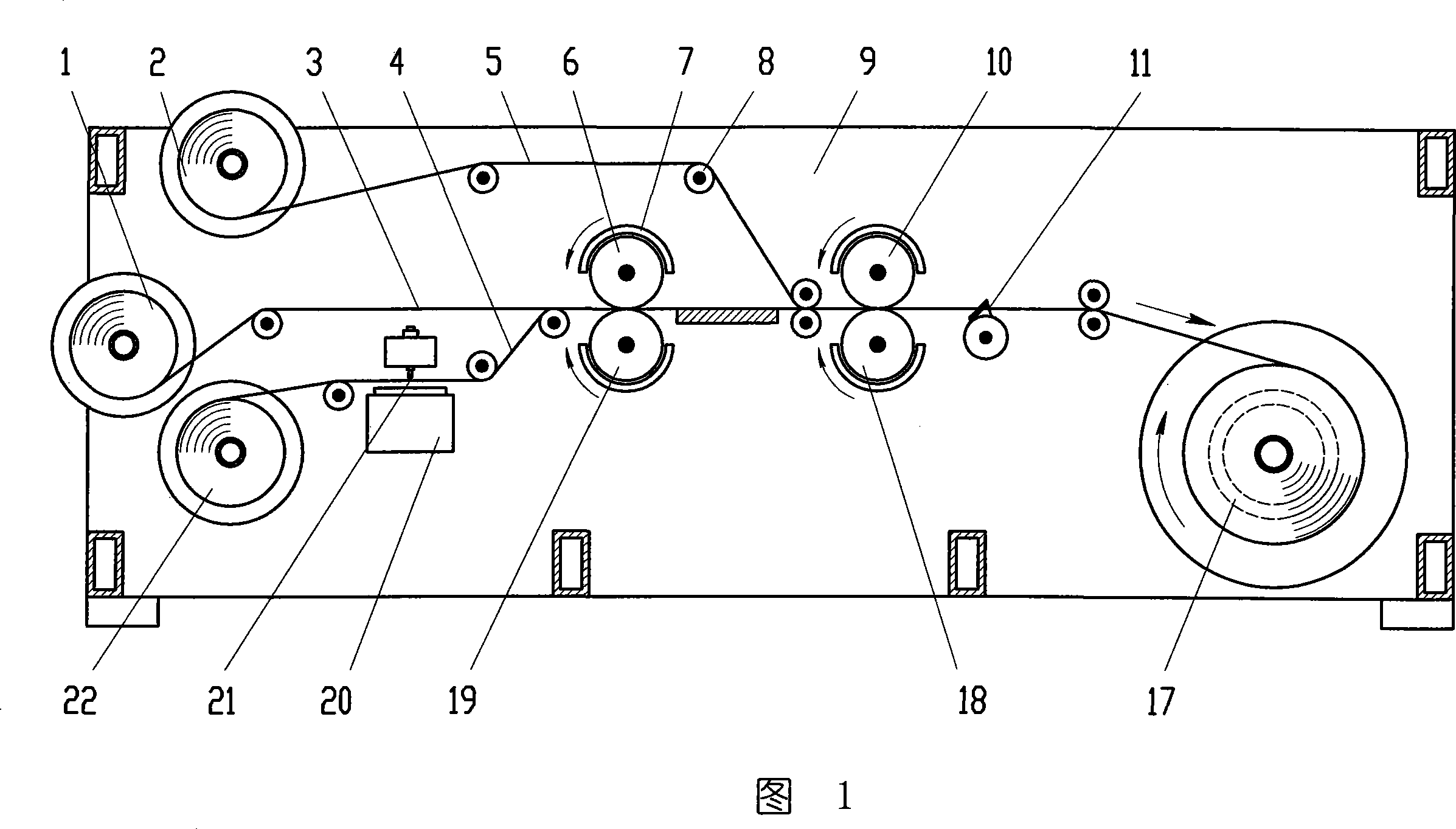

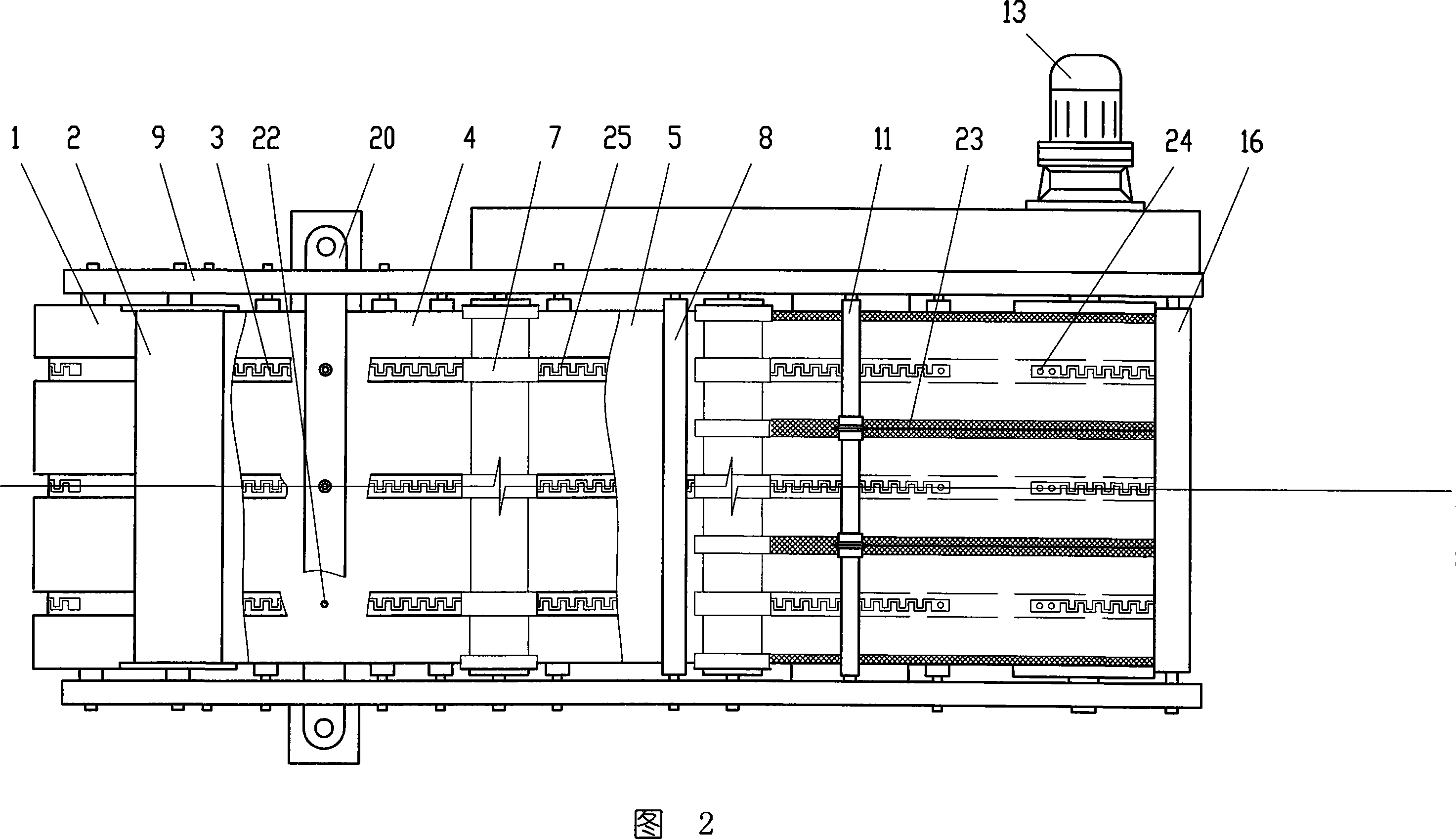

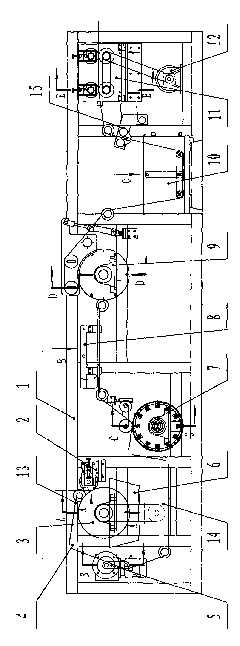

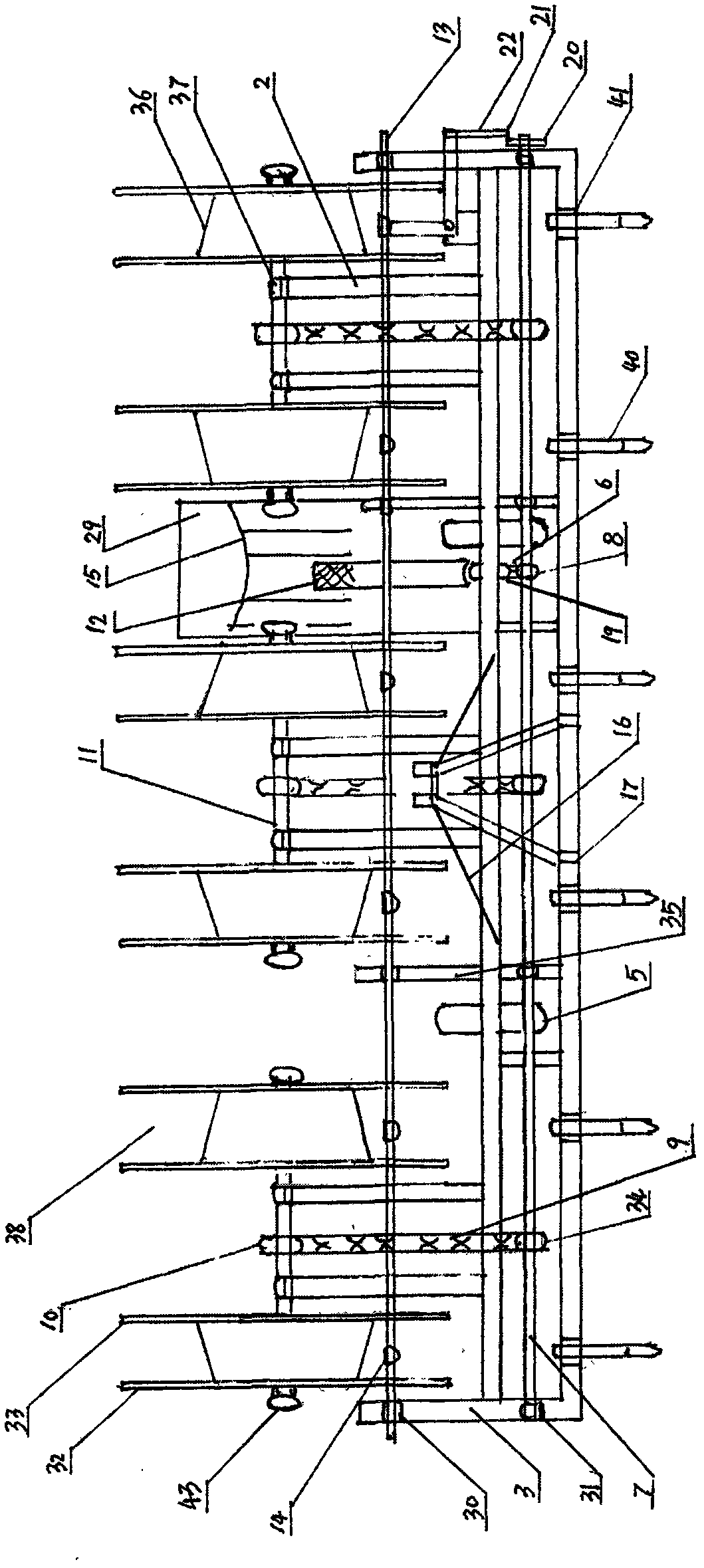

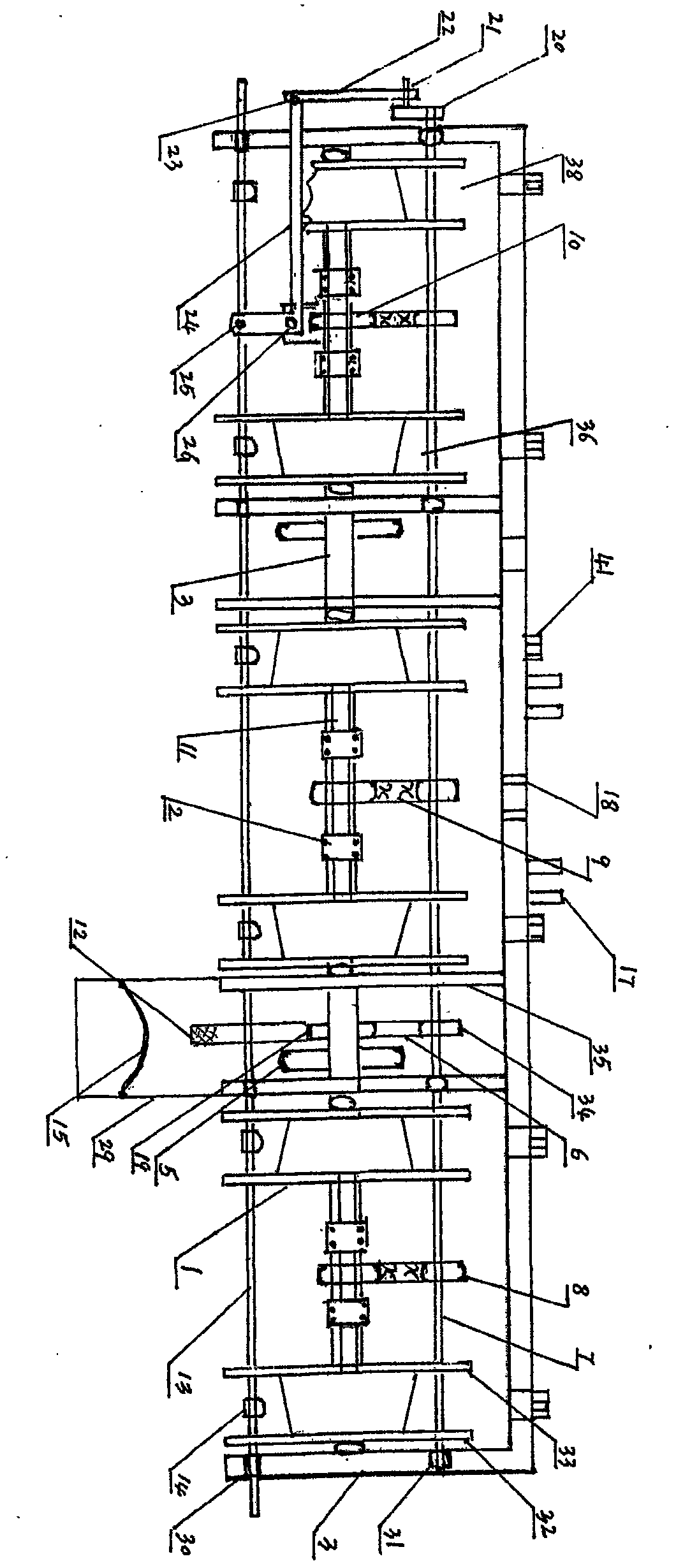

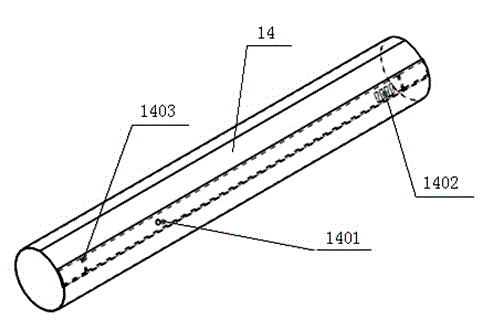

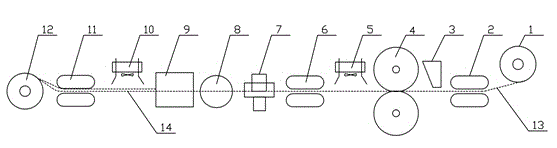

Forming tractor for producing casting type drip tape

The invention relates to manufacturing equipment of a drip tape, in particular to a forming tractor specially used for producing a casting type drip tape. The forming tractor of the invention comprises a pinch roller mechanism, a forming wheel mechanism, a knife flywheel mechanism, a folding mechanism, a heat-sealing wheel mechanism, a cooling device and a traction device, wherein the forming wheel mechanism completes labyrinth vacuum forming and plastic sheet cooling; the knife flywheel mechanism completes cutting of a labyrinth water outlet; the folding mechanism folds plastic sheets together and adjusts folding allowance; the heat-sealing wheel mechanism can adjust the relative position between a heat-sealing line and a drip tape labyrinth to ensure that the position of the heat-sealing line is not changed in the production process; after being bonded by the heat-sealing wheel, the plastic sheets are further cooled and shaped by the cooling device; and the traction device delivers the plastic sheets at a uniform speed into a follow-up winder. The invention continuously carries out the processes of labyrinth vacuum forming of the casting type drip tape, cutting of the water outlet, heat-sealing bonding, and the like, and greatly improves the production speed of the casting type drip tape, and the action of each mechanism can be accurately controlled by a PLC, thereby improving the automation performance of the equipment.

Owner:TANGSHAN ZHIFU PLASTIC MACHINERY

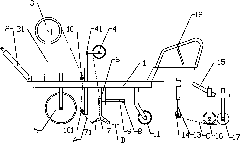

Carrot seeding and film laminating machine

InactiveCN101822143ASave manpower and material resourcesIncrease productivityClimate change adaptationWatering devicesDrip tapeAgricultural engineering

The invention discloses a carrot seeding and film laminating machine which comprises a main machine frame. A drip tape laying device and a seed tape laying device are arranged on the main machine frame and a film laminating device is connected with the rear end of the main machine frame. The carrot seeding and film laminating machine can complete drip tape laying, seed tape laying and burying, drug praying and film laminating and compaction simultaneously, which not only saves labor or materials, but also improves the production efficiency. The carrot seeding and film laminating machine is quite suitable for seeding in a large scale.

Owner:刘学军

Special drip tape material

ActiveCN103665509AImprove scratch resistanceEasy to processWatering devicesCultivating equipmentsDrip tapeProcedure Agents

The invention relates to a special drip tape material. The special drip tape material is made from the following raw materials in parts by weight: 100 parts of polyethylene resin, 5 parts of colorant, 5-25 parts of toughening agent, 0.5-2 parts of processing modifier and 0.01-1 part of processing agent, wherein the raw materials are mixed according to a proportion, plasticized and extruded by a double screw extruder and are cooled and granulated to prepare the special drip tape material. The special drip tape material provided by the invention has the advantages that the toughening agent is added in the polyethylene resin to reduce the density of a filled drip tape product; meanwhile, the toughness of the drip tape product is improved on the condition of not reducing the rigidity of the polyethylene resin and the scratch resistance of the product is improved, since the toughening agent is added, a scorching phenomenon of the drip tape in an application process can be effectively avoided or alleviated; the processing properties of the polyethylene resin are enhanced, and the special drip tape material provided by the invention has the advantages of good scratch resistance, excellent weatherability, easy processing, etc.

Owner:吉林喜丰节水科技股份有限公司

Drip irrigation band for printing labyrinth flow-path and processing method

InactiveCN101069477AReduce wall thicknessReduce extrusionClimate change adaptationWatering devicesDrip irrigationEngineering

The present invention provides a drip-irrigation band with printed labyrinth flow channel. It is composed of water-conveying channel, hot-pressed edge with several groups of labyrinth flow channel units, labyrinth flow channel water inlet and water outlet. It is characterized by that the described labyrinth flow channel is the hot-pressed gap formed from heat-resisting layer printed on the plastic.

Owner:INST OF GENETICS & DEVELOPMENTAL BIOLOGY CHINESE ACAD OF SCI

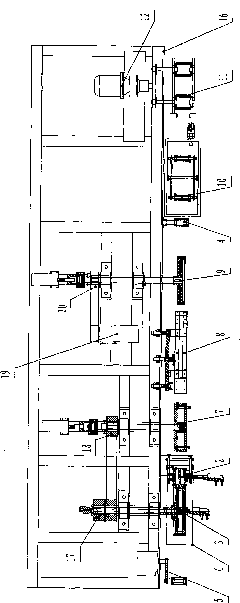

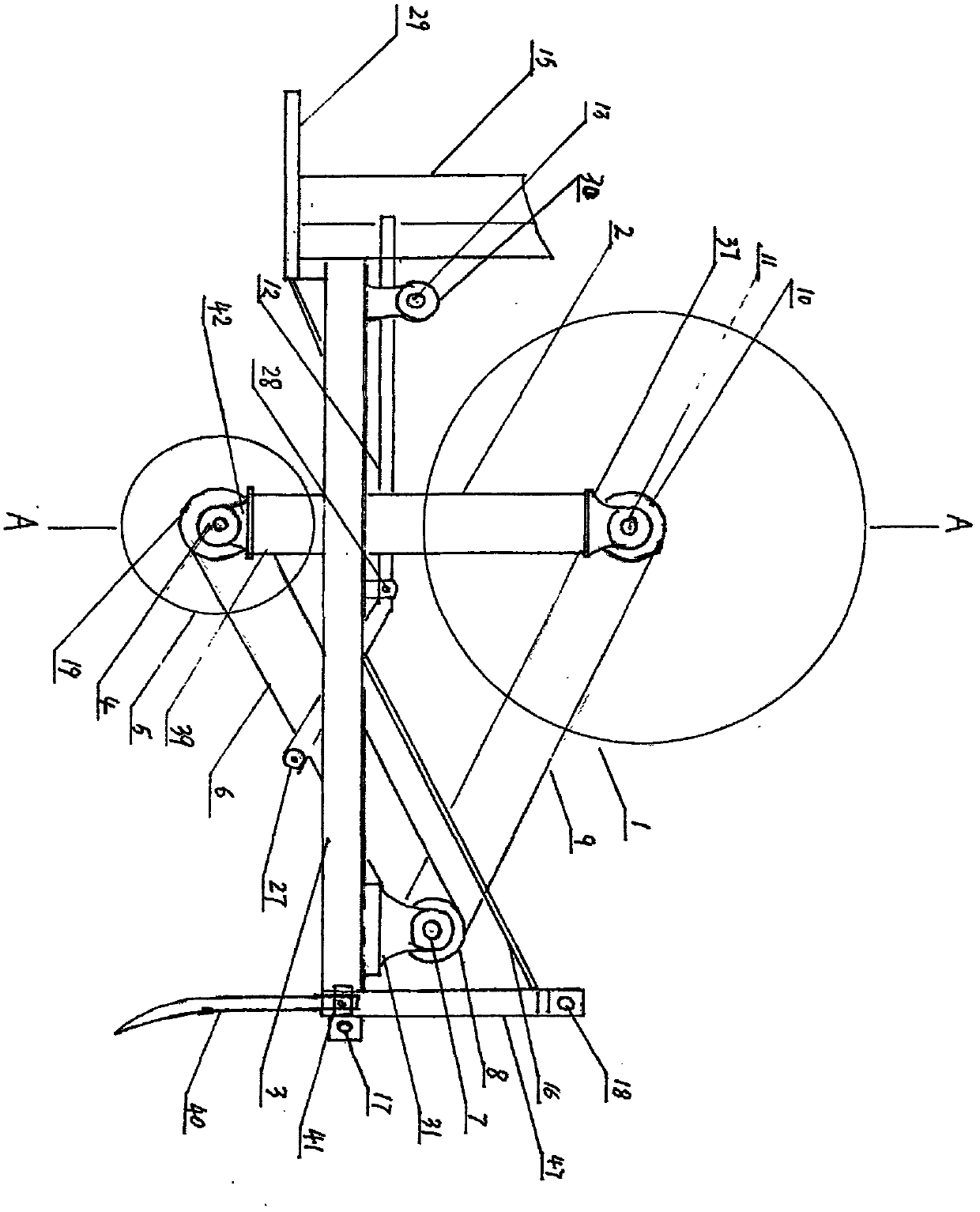

Waste drip tape recycling machine

InactiveCN103292034AEasy to load and transportLabor savingPipe laying and repairWebs handlingDrip tapeAgricultural engineering

The invention relates to agricultural machinery, in particular to a waste drip tape recycling machine which can roll and pick up waste drip tapes laid on the ground, and can roll the waste drip tapes into bundles for recycling and conveyance. The waste drip tape recycling machine comprises a machine frame body, a tape feed roller body and a land wheel body. Front, back, left and right longitudinal beams and a diagonal draw bar of a machine frame of the waste drip tape recycling machine are welded with one another; a trifilar suspension frame is welded in the middle of the frame on the front side of the machine; an upper suspension hole and a lower suspension hole are formed in the trifilar suspension frame; a lever tooth clamp is fixed on a front cross beam of the frame by a screw; and a lever tooth is arranged on the lever tooth clamp; a long shaft is horizontally mounted on the front side of the frame; four sets of long bearing pedestals are respectively mounted at two ends and the middle of the long shaft; and the long bearing pedestals are fixed on the frame by screws. Six seat posts are respectively welded on a cross beam in the middle of the frame; a roll wheel bearing pedestal is fixed at a plane, facing upwards, of each seat post by a screw; a roll wheel shaft penetrates the bearing of the roll wheel bearing pedestal; an inner plate of the tape feed roller is welded at one external diameter end of a shaft sleeve; and a cone ring is welded at the middle part of the inner plate. A hole matched with a coaxial screw rod is drilled in the middle of an outer plate; and an outer plate hole is formed in the shaft screw rod in a through manner. One end of a turning plate is tightly connected to a long shaft head by a key, and the other end is welded with a turning plate pin; the two land wheel brackets are welded at the lower part of the middle section of the cross beam of the machine frame; and a land wheel bearing pedestal is tightly connected to a plane, facing downwards, of the bracket by a screw. The waste drip tape recycling machine can roll up drip tapes laid on the ground and then bundle the drip tapes laid on the ground to facilitate the loading and conveying, the working efficiency is a hundred times of the manual operation, labor is saved, and the cost is reduced.

Owner:蒋毅蕾

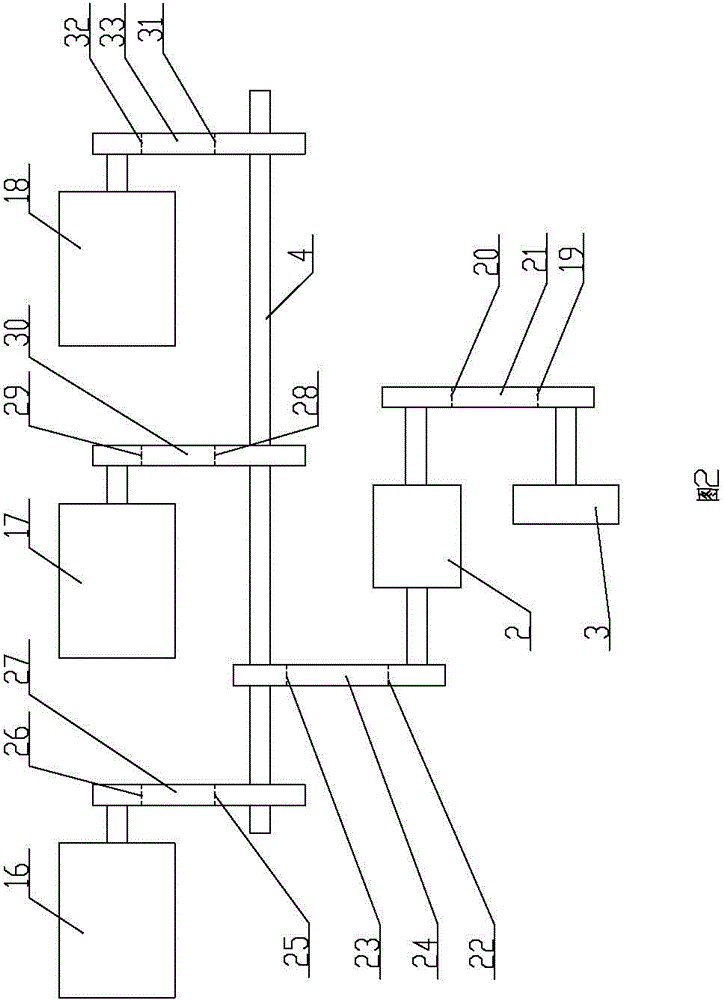

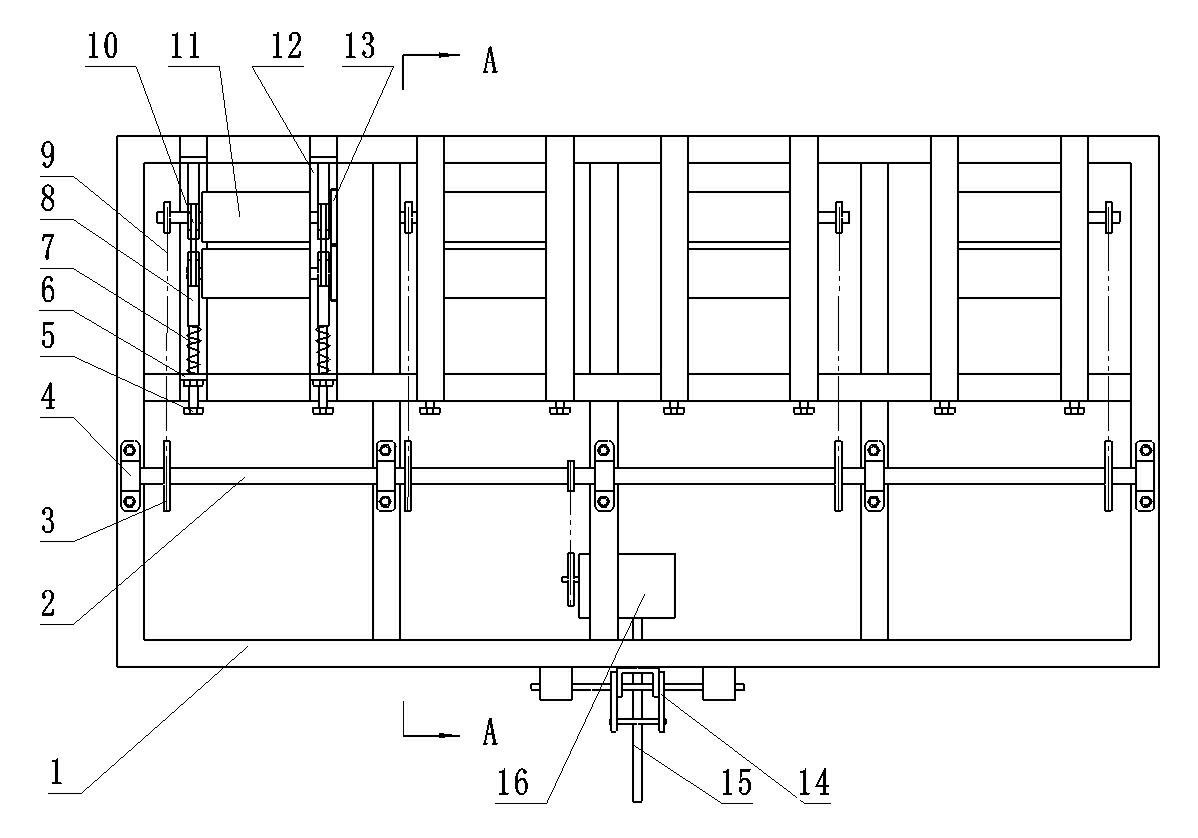

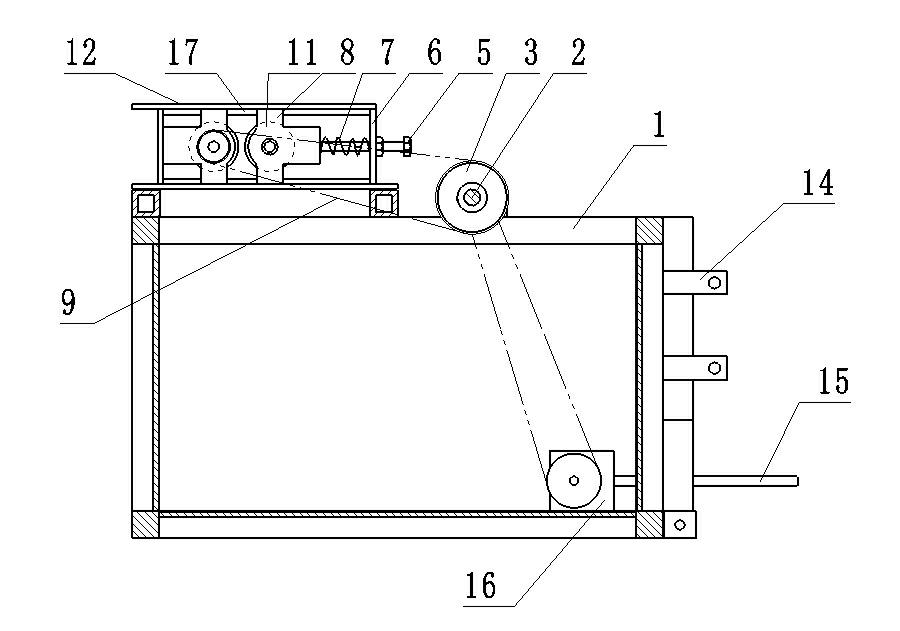

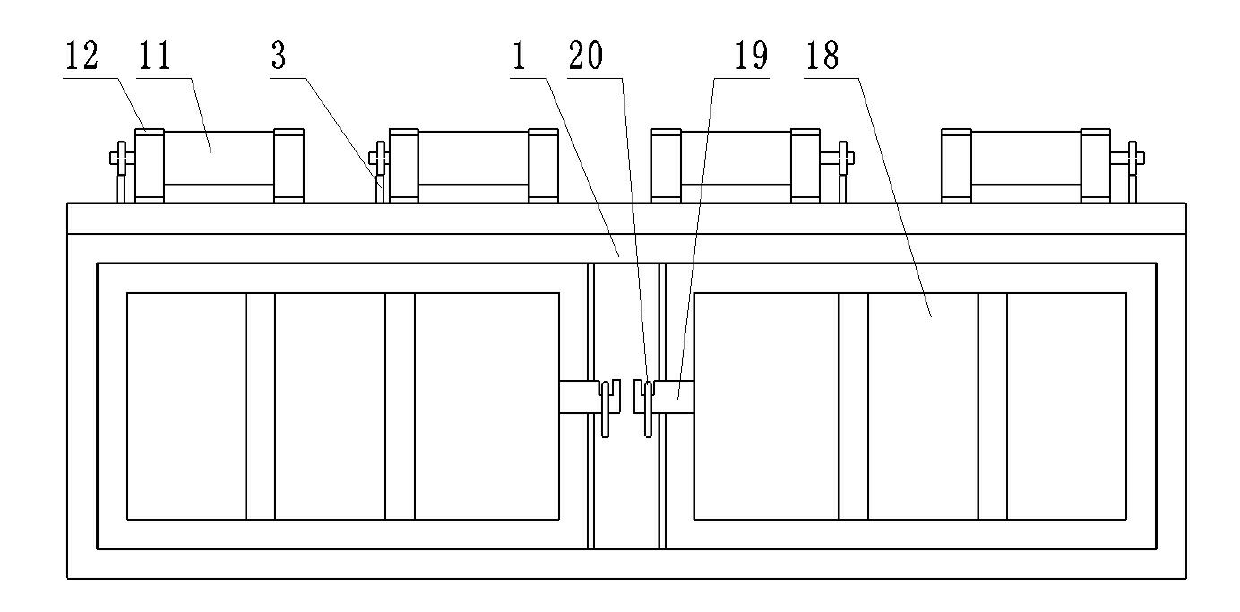

Drip irrigation tape withdrawing machine

The invention discloses a drip irrigation tape withdrawing machine, which comprises a framework (1), a suspension bracket (14), a gearbox (16), a transmission shaft (15) and a crankshaft (2). A roller support (12) is arranged on the framework (1), rollers (11) are disposed in the roller support (12), each group of rollers includes two rollers, and at least one roller (11) in each group can move on the roller support (12) and is provided with a spring (7) used for pushing the roller (11) to the other roller (11) in the group. The distance between the two rollers in each group can be automatically adjusted, squeezing force between the two rollers in each group can also be adjusted, and accordingly a drip irrigation tape cannot be broken when withdrawn. Compared with the prior art, the drip irrigation tape withdrawing machine can replace a manual drip irrigation tape withdrawing mode, and withdrawing efficiency of drip irrigation tapes can also be improved greatly.

Owner:袁庆龙

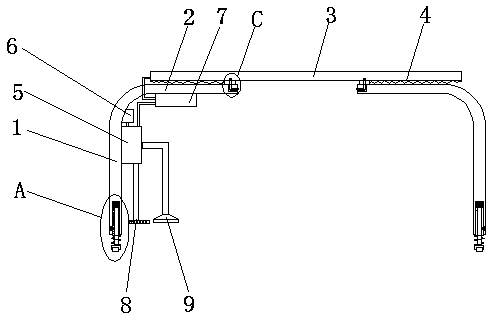

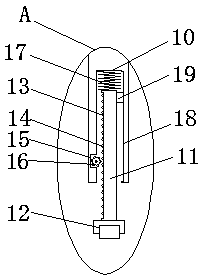

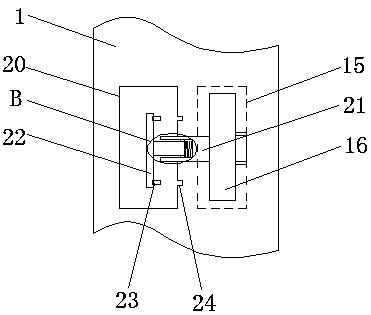

Irrigation system based on micro-nano bubble technique

InactiveCN107691046APosition for stable adjustmentStable position adjustmentClimate change adaptationGreenhouse cultivationDrip tapeMicro nano

The invention discloses an irrigation system based on a micro-nano bubble technique, comprising two support posts arranged in parallel; close sides of the two support posts are fixedly provided with transverse plates respectively, a same drip tape duct for irrigation is arranged above the two transverse plates, a plurality of nozzles are mounted at the bottom of the drip tape duct at equal intervals, and a positioning adjusting mechanism for adjusting irrigation area of the drip tape duct is arranged between the drip tape duct and the transverse plates; one side of each support post is fixedlyprovided with a gas supply device and a micro-nano bubble generator. The irrigation system of the invention has the advantages that vegetation in a greenhouse can be irrigated in movable manner, theheight of the drip tape duct can be adjusted conveniently, the positon of the drip tape duct is convenient to adjust, and the irrigation area of the drip tape duct is convenient to adjust.

Owner:陕西猕林果业有限公司

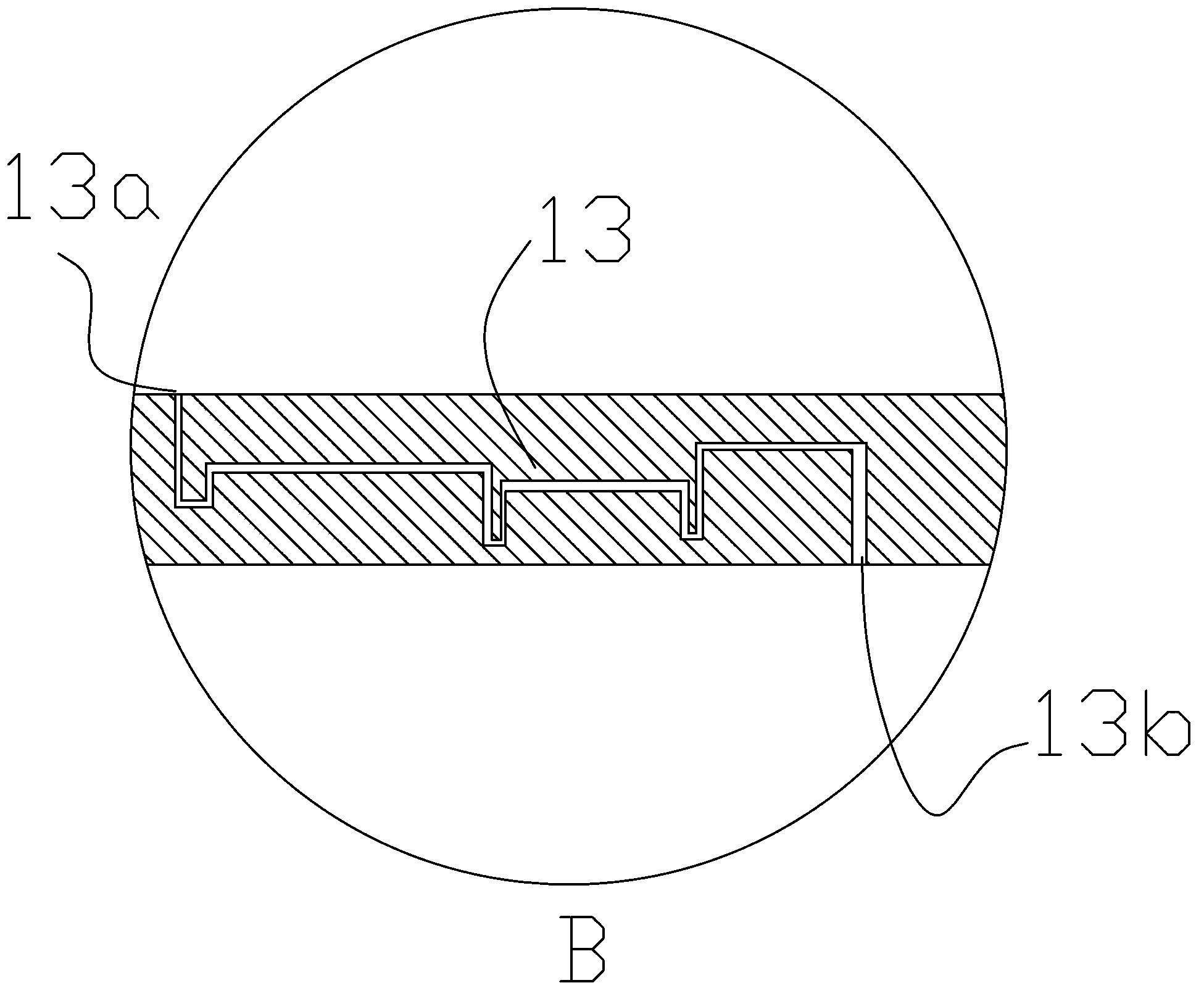

Double-dropper inlaid patch drip irrigation belt and preparation method thereof

InactiveCN106117759AAvoid the disadvantage that the water output cannot meet the water demand of a large number of cropsImprove anti-clogging performanceClimate change adaptationWatering devicesLow-density polyethyleneLinear low-density polyethylene

The invention discloses a double-dropper inlaid patch drip irrigation belt and a preparation method thereof. The double-dropper inlaid patch drip irrigation belt comprises a drip irrigation belt body, wherein droppers are arranged on two sides of the drip irrigation belt body, wherein the droppers on the two sides are arranged in parallel in a staggered manner; and the distance between the droppers on the same side is 300-600mm. The preparation method comprises the following steps: mixing 44-48 parts of high density polyethylene, 23-27 parts of low density polyethylene, 25-26 parts of linear low density polyethylene, 2-3 parts of carbon black, and 0.3-0.8 part of PPA multifunctional master batch, extruding by using an extruder, thermally adhering to an inner wall of the drip irrigation belt, sizing, cooling, setting, pulling, and punching, thereby obtaining the final product. According to the invention, the droppers are arranged on two opposite sides of the drip irrigation belt, and the droppers are arranged in parallel in the staggered manner, so that the drip irrigation belt has a good irrigation effect on an area in which intensive crops are planted, and is wide in application range. Moreover, the drip irrigation belt has high anti-blockage capability in long-term using process.

Owner:大禹节水(天津)有限公司

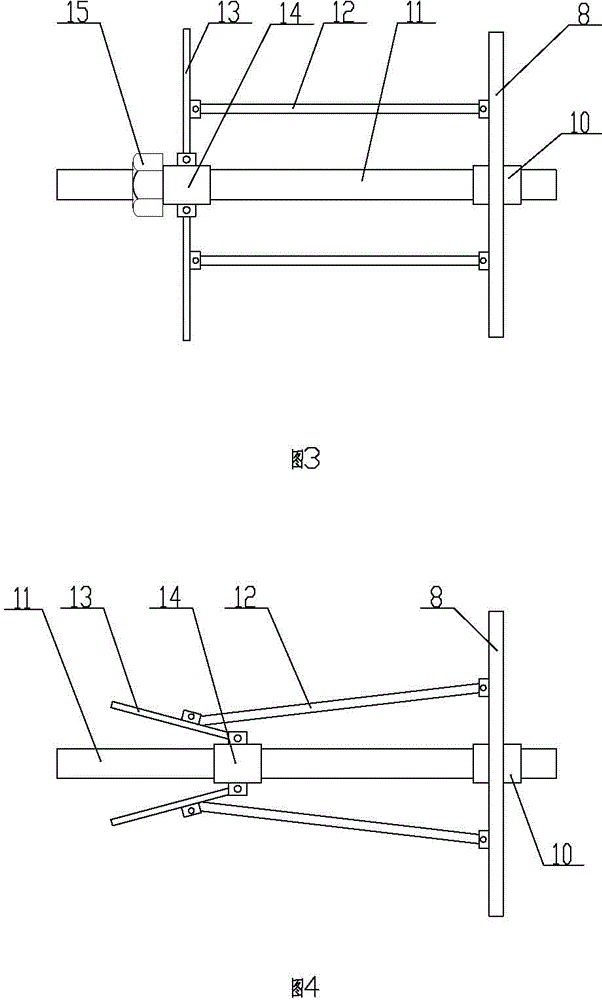

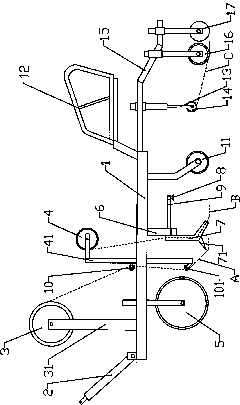

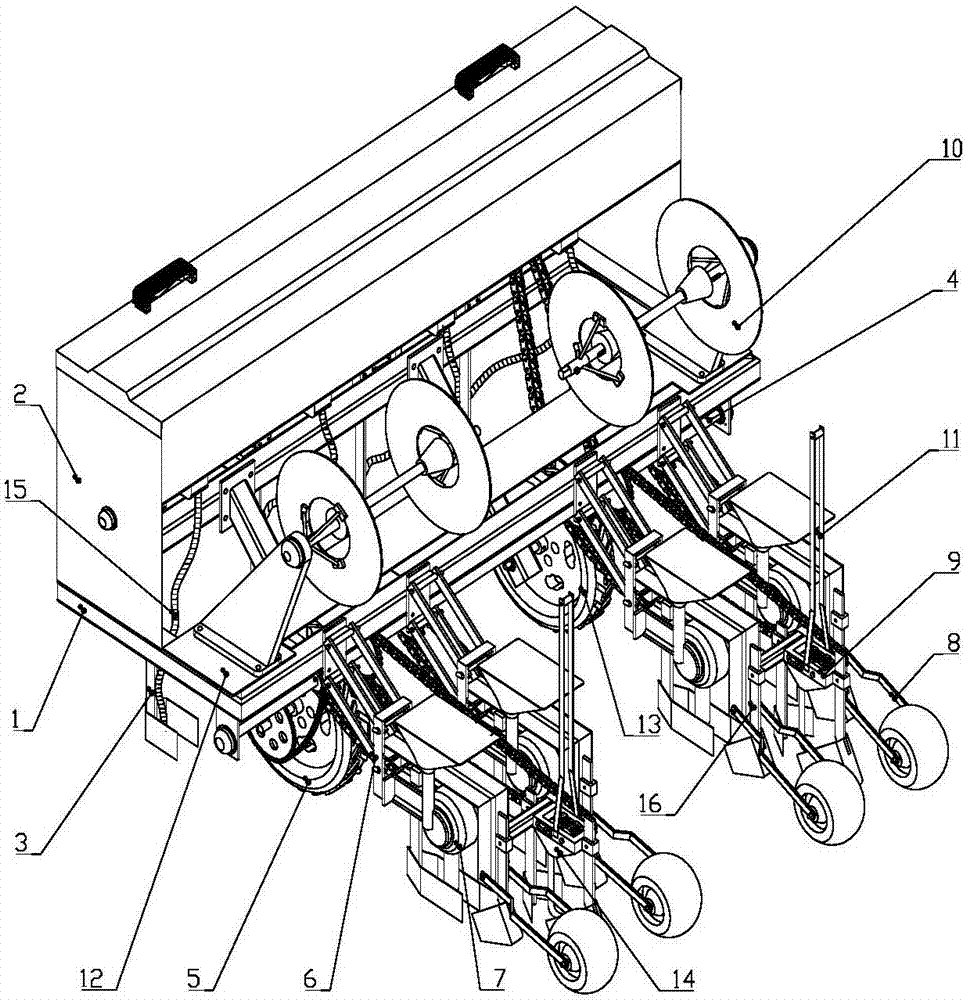

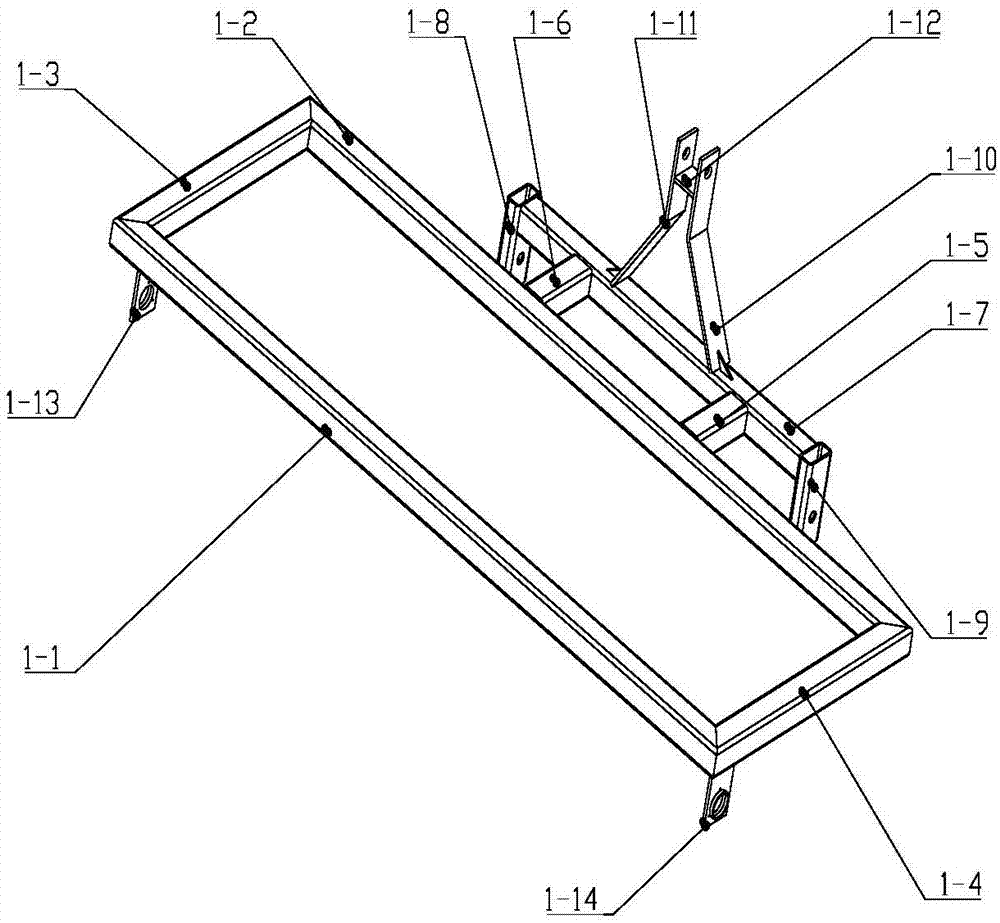

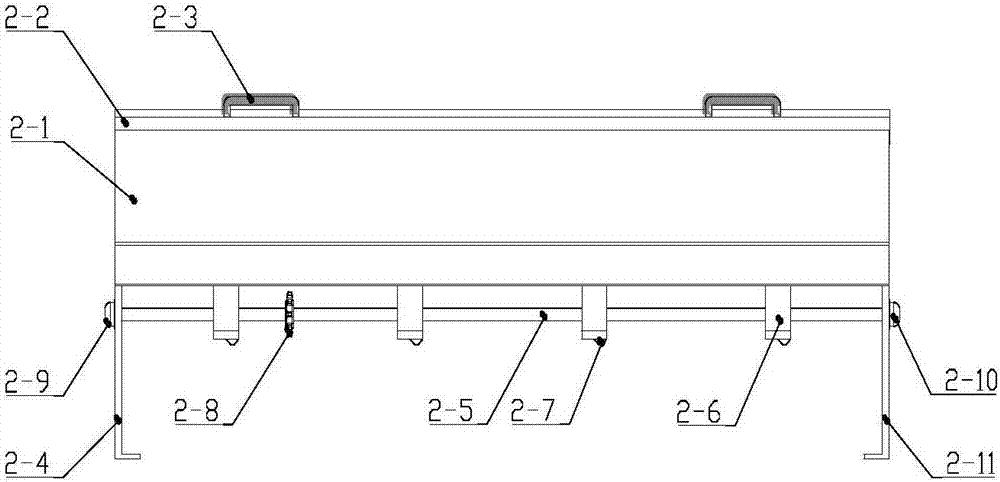

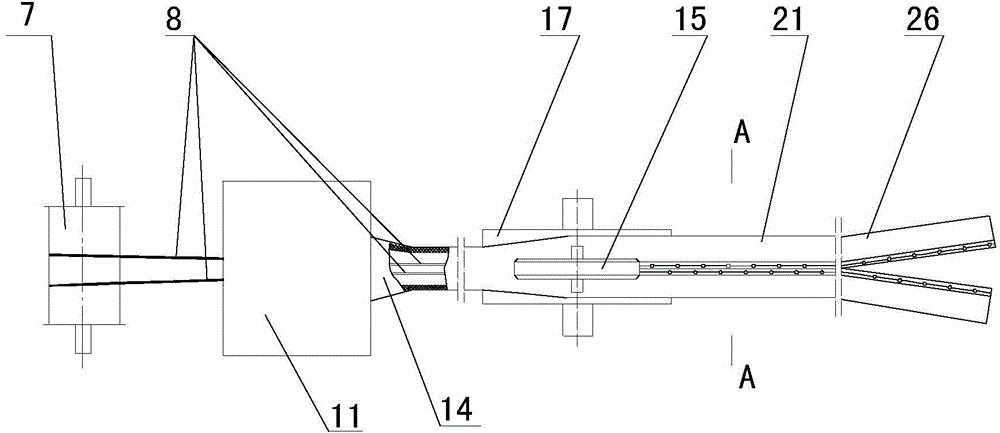

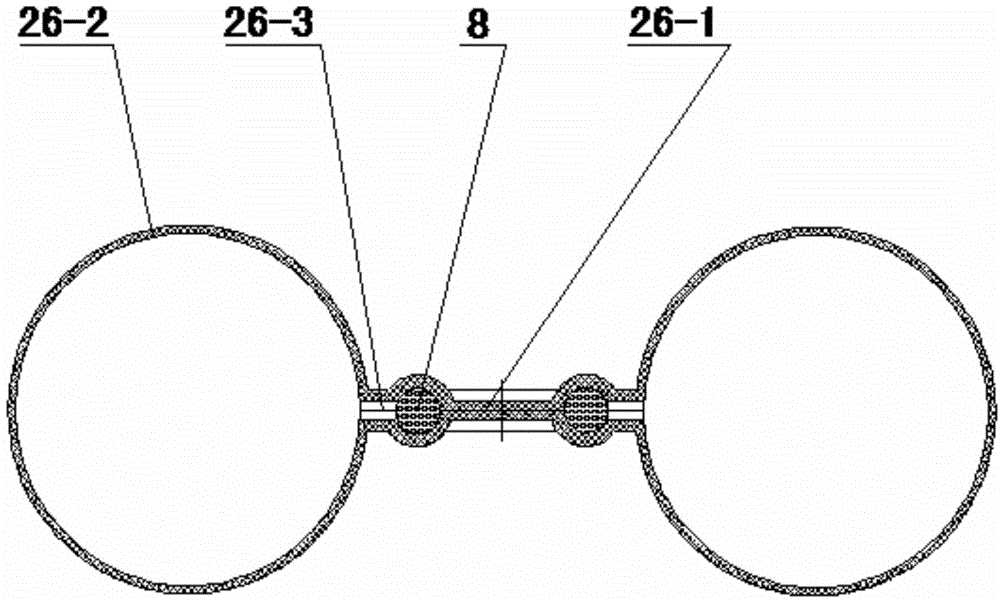

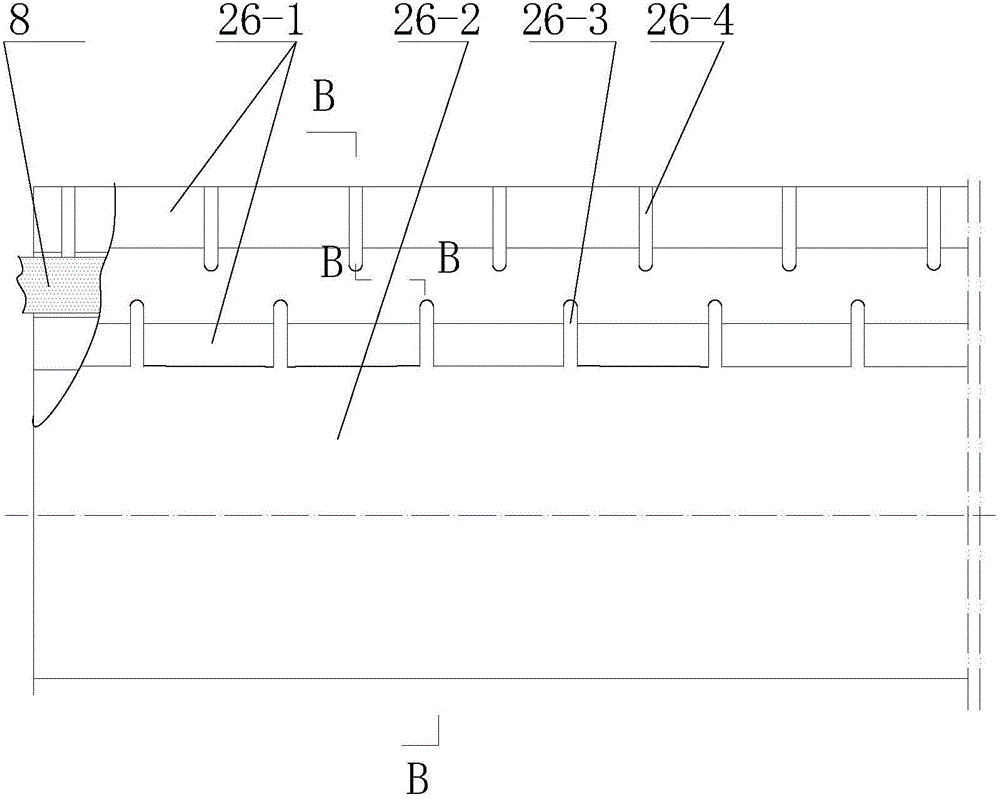

Corn large-small ridge shallow-buried drip irrigation sowing-fertilization-tape laying all-in-one machine and tape laying mechanism for agricultural machinery

ActiveCN107371494AEffective clampingAvoid entanglementPlantingClimate change adaptationSeederDrip tape

The invention discloses a corn large-small ridge shallow-buried drip irrigation sowing-fertilization-tape laying all-in-one machine and a tape laying mechanism for agricultural machinery. The machine solves the problem that the existing machine cannot realize drip irrigation tape smooth laying, has the characteristic of integration of sowing, fertilization and drip irrigation tape laying and prevents drip irrigation tape winding. The all-in-one machine is characterized in that the machine comprises a fertilization mechanism assembly which is arranged on a frame, a ground wheel assembly which is arranged at the bottom of the frame, a drip irrigation tape reel installation mechanism assembly which is arranged in one side of the fertilization mechanism assembly through the frame, a profiling mechanism assembly which has one end connected to the front side of the frame and is arranged below the drip irrigation tape reel installation mechanism assembly, a sowing mechanism assembly which is connected to the profiling mechanism assembly, and a tape laying mechanism of which a roller support is fixedly connected to the profiling mechanism assembly.

Owner:INNER MONGOLIA UNIV FOR THE NATITIES +1

Method for testing environmental stress cracking resistance (ESCR) of drip tape

InactiveCN101900652ATest environmental stress cracking resistanceGuaranteed reasonablenessMaterial strength using tensile/compressive forcesChinese charactersRoom temperature

The invention relates to a method for testing the environmental stress cracking resistance (ESCR) of a drip tape, which comprises the following steps of: (1) sampling; (2) cleaning, drying, cooling to be room temperature, and keeping the drying status for later use after adjusting the status of a plurality of samples; (3) preparing active solution with volume concentration of 20%; (4) evenly coating active solution on the two sides of each sample, and folding each sample to be four layers in a shape like Chinese character 'ZHI'; (5) putting the five folded samples into a sample clamp in parallel and screwing; (6) putting the sample clamp with the samples into an oven with the temperature of 60+ / -20 DEG C and timing; (7) drying under constant temperature for 8h, withdrawing the clamp, naturally cooling to the room temperature, withdrawing the samples, wiping solvent, and visually observing whether the side edge of each sample has crackle under natural light; and (8) judging a result. The method is easy to operate, practical and convenient, and is an effective method for testing the environmental stress cracking resistance (ESCR) of the drip tape currently after being verified with repeated experiments.

Owner:GANSU DAYU WATER SAVING

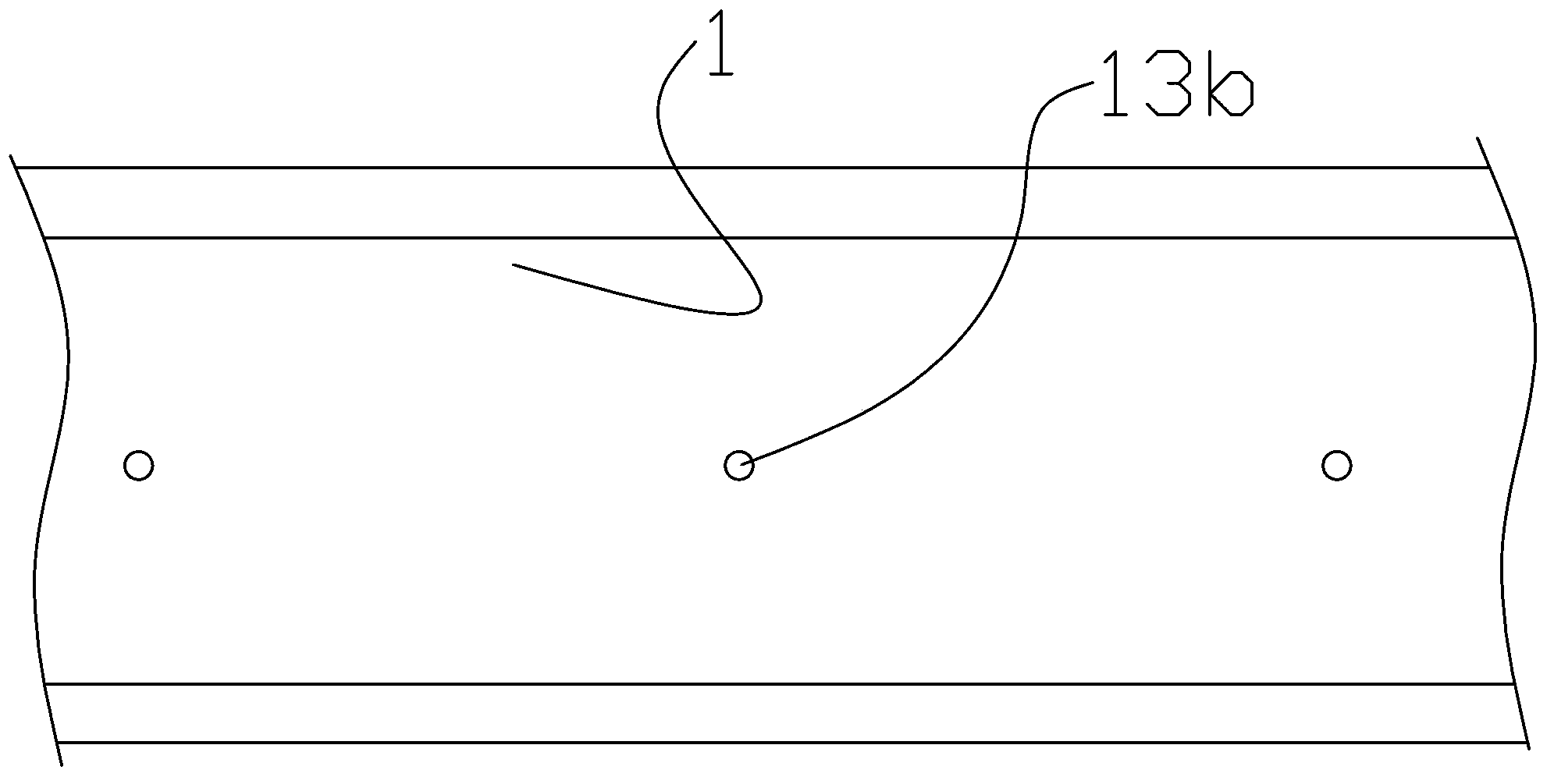

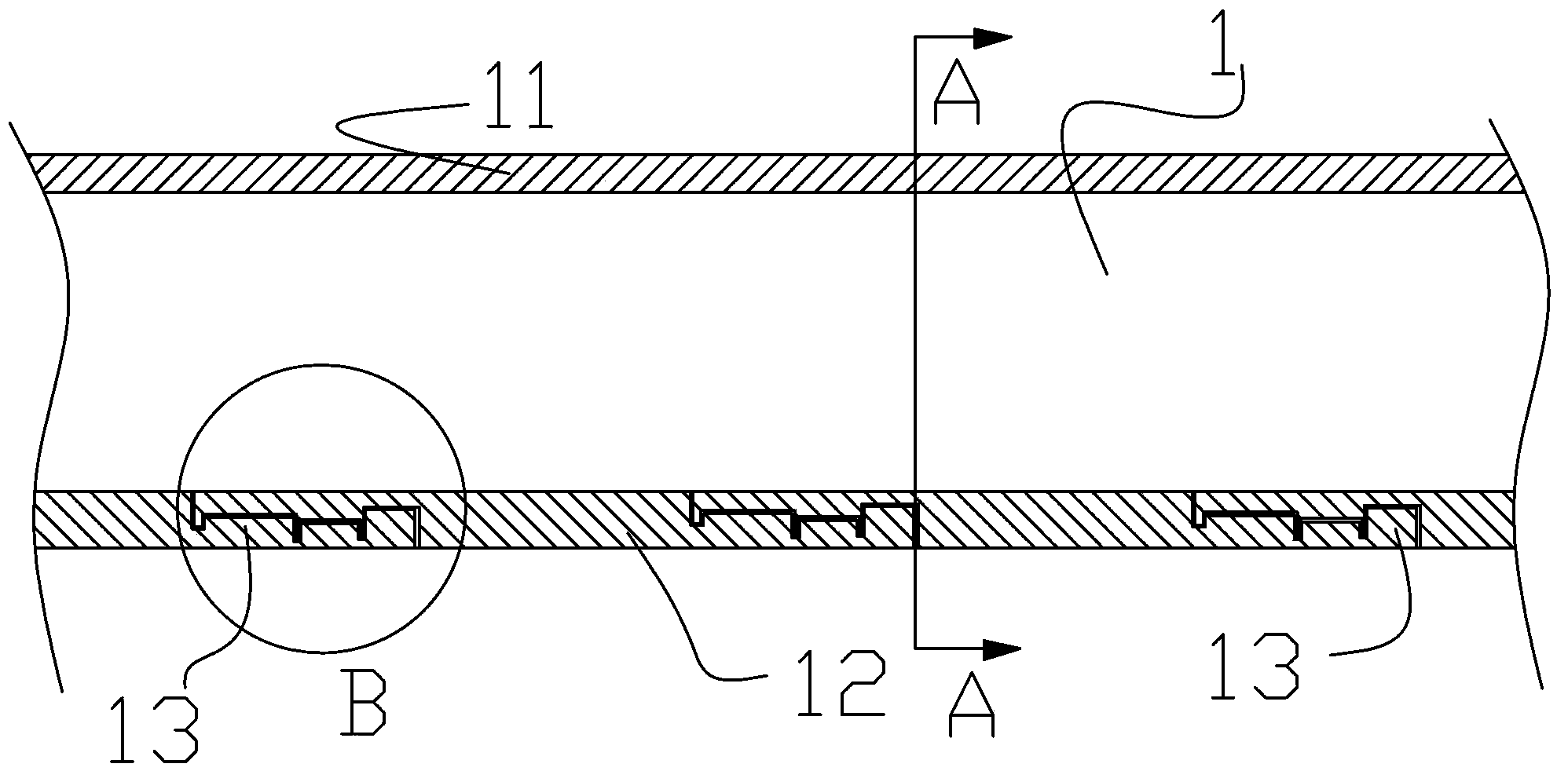

Drip tape

ActiveCN103782871AExtended service lifeReduce cloggingWatering devicesCultivating equipmentsDrip tapeEngineering

The invention discloses a drip tape comprising an upper tape and a lower tape. The lower tape is provided with water pressure reducers. A filter is disposed between the upper tape and the lower tape, so that irrigation water which is filtered before entering the drip tape is filtered again by the filter before entering the water pressure reducers, and the irrigation water which is filtered again can drop from the water pressure reducers. A filter layer is added to the drip tape, so that before the irrigation water enters the water pressure reducers of the drip tape, various particles such as sand in the irrigation water can be further filtered, chances of pores of the pressure reducers being blocked are slimmed, the service life of the drip tape is prolonged and service efficiency is improved.

Owner:SHANGHAI JIAO TONG UNIV

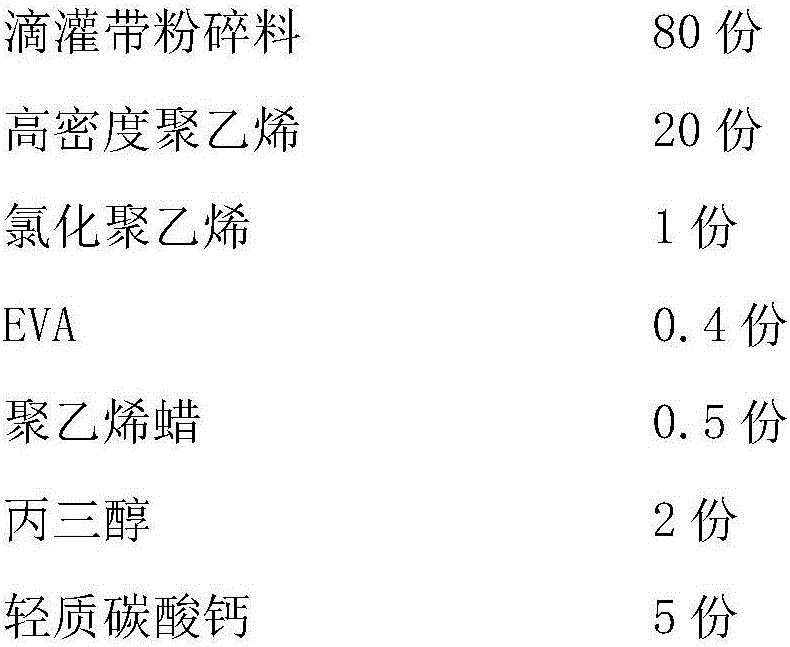

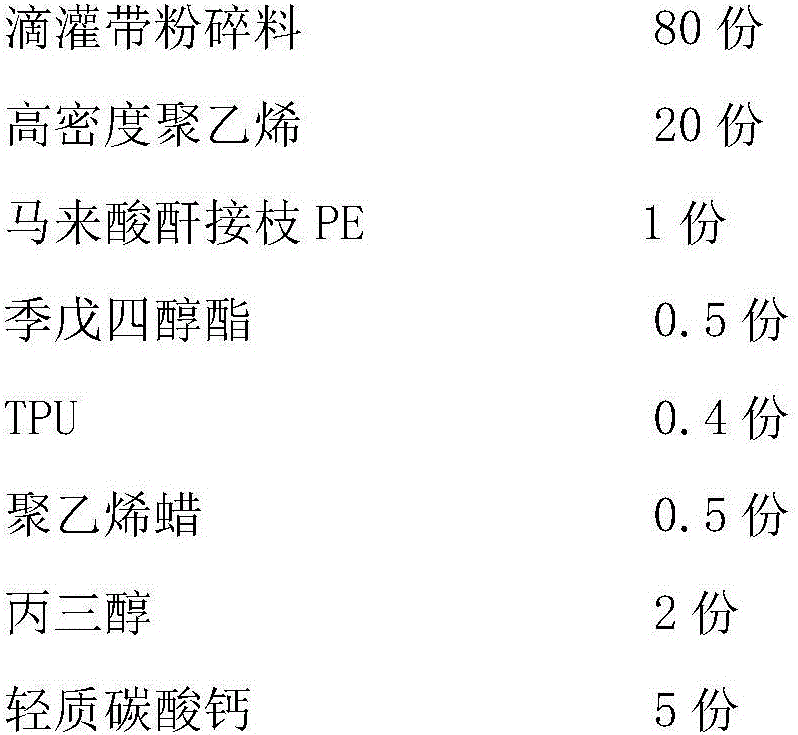

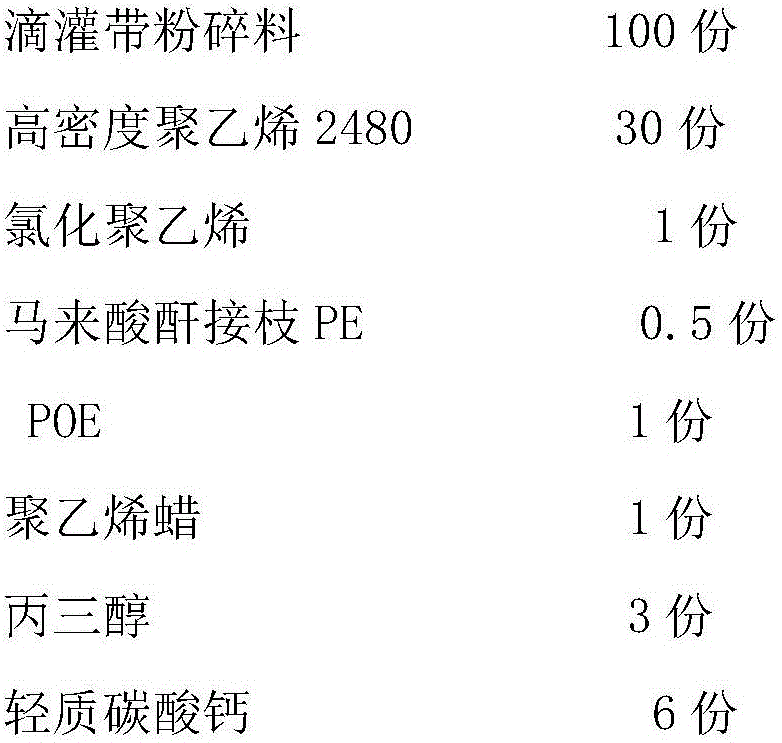

Recycled modified material of waste drip-irrigation tape and preparation method thereof

The invention discloses a recycled modified material of a waste drip-irrigation tape and a preparation method thereof. The recycled modified material comprises the following components: a drip-irrigation tape crushed material, high-density polyethylene 2480, a compatibilizer, an elastomer, polyethylene wax, glycerol and light calcium carbonate. The recycled modified material of the waste drip-irrigation tape is prepared from the following raw material components in parts by mass: 50 to 100 parts of the drip-irrigation tape crushed material, 10 to 30 parts of the high-density polyethylene 2480, 0.5 to 2 parts of the compatibilizer, 0.2 to 1 part of the elastomer, 0.3 to 1 part of the polyethylene wax, 2 to 3 parts of glycerol and 4 to 6 parts of the light calcium carbonate. The recycled modified material of the drip-irrigation tape is prepared through the following steps: recycling the waste drip-irrigation tape, and carrying out cutting, cleaning, air drying, crushing, melting, plasticizing and extrusion. The recycled modified material has the following beneficial effects: the waste drip-irrigation tape is recycled, so waste is prevented, and pollution of the drip-irrigation tape to the environment is reduced; in addition, the production cost can be reduced in the process of recycling; and the produced drip-irrigation tape by the invention has good tensile strength and elongation at break.

Owner:大禹节水(天津)有限公司

Cylindrical micro-porous labyrinth drip irrigation tape as well as machining method and equipment

InactiveCN104082102ASmall water seepage gapSimplify Filtration EquipmentClimate change adaptationWatering devicesProduction lineDrip irrigation

The invention provides a cylindrical micro-porous labyrinth drip irrigation tape as well as a machining method and equipment. The drip irrigation tape consists of a drip irrigation tape water delivery channel and a labyrinth channel, wherein a micro-porous labyrinth channel consisting of filling cotton ropes is formed in the water delivery channel side surface of the drip irrigation tape, inner water outlets are radially and evenly arranged in the micro-porous labyrinth channel and adjacent to the water delivery channel, and outer water outlets staggered with the inner water outlets extend to edges of the drip irrigation tape. The machining method comprises the steps as follows: two cotton ropes penetrate through an extrusion die head to be used as cylindrical labyrinth filler while the drip irrigation tape water delivery channel is extruded, the cotton ropes are sleeved with an extruded thin-walled cylinder, inner and outer 8 shapes are extruded, the 8 shape on the outer side forms the drip irrigation tape water delivery channel, and the small 8 shape on the inner side wraps the two cotton ropes in a plastic film respectively to form a cylindrical micro-porous labyrinth. By means of the drip irrigation tape as well as the machining method and equipment, the anti-blocking performance can be improved substantially, filter equipment of a drip irrigation system can be simplified, and the running energy consumption of the drip irrigation system can be reduced. When the irrigation specification of the drip irrigation tape is required to be changed, all that is required is to select the cotton ropes with proper diameters or the number of the water outlets instead of changing production line hardware.

Owner:HEBEI YUYAN IRRIGATION EQUIP

Anti-root intrusion and rat and insect bite resistant subsurface drip irrigation tape

InactiveCN107629302AImprove anti-clogging performancePrevent intrusion cloggingBiocideClimate change adaptationLinear low-density polyethyleneDrip irrigation

The invention discloses an anti-root intrusion and rat and insect bite resistant subsurface drip irrigation tape. The subsurface drip irrigation tape includes an irrigation emitter and a drip irrigation tape. Specifically, the raw materials for preparation of the irrigation emitter include linear low density polyethylene, a herbicide microcapsule and a dispersing lubricant, and the raw materials for preparation of the drip irrigation tape pipe wall include synthetic capsaicin microcapsule and deltamethrin microcapsule. The drip irrigation tape provided by the invention integrates root intrusion prevention, rat and insect bite resistance and the like, has significantly improved performance, covers up the peculiar smell of the core material, lowers the product toxicity, reduces the pollutionof underground water and soil, and at the same time reduces the influence on users' personal safety to a certain extent,.

Owner:CHINA AGRI UNIV

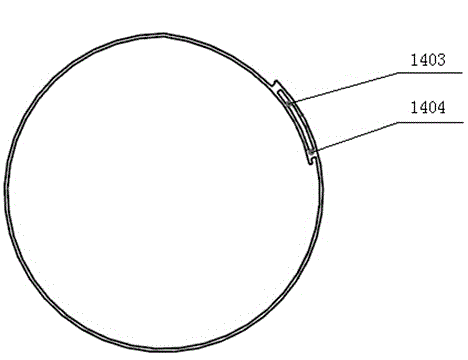

Drip tape production equipment and production process thereof

The invention discloses drip tape production equipment and a production process thereof. The equipment comprises first traction equipment, a heater, a molding roller group, first cooling equipment, second traction equipment, a U-shaped rolling frame, an O-shaped rolling frame, welding equipment, second cooling equipment and third traction equipment which are arranged in sequence, wherein the U-shaped rolling frame comprises a bracket and a limiting cover plate; the bracket comprises an air charging pipe communicated with compressed air; a U-shaped supporting plate is fixed above of the air inlet pipe; a cavity communicated with the air inlet pipe is formed in the U-shaped supporting plate; a plurality rows of air outlets are uniformly distributed along the radial circumference in the inner wall of the U-shaped supporting plate; the O-shaped rolling frame comprises a hollow through pipe which is internally provided with a cavity communicated with the compressed air; a plurality of air holes communicated with the cavity are formed in the inner wall of the through pipe. The process is used for producing a drip tape by forming holes, forming a flow passage in a pressing manner, rolling and welding based on a plastic film; a two-step process including pipe blank base material manufacturing and drip tape molding is realized; the reliability and thin-wall property of molding of the drip tape are improved; the product quality is improved, and the product cost is effectively lowered as well.

Owner:HEBEI RUNNONG WATER SAVING TECH

Drip irrigation tape with anti-blocking inlaid patches

PendingCN108812226ASmall water seepage gapSimplify Filtration EquipmentWatering devicesCultivating equipmentsDrip tapeEngineering

The invention provides a drip irrigation tape with anti-blocking inlaid patches. The invention is to solve the problem of blockage of a water outlet for a buried drip irrigation pipe. The drip irrigation tape with the anti-blocking inlaid patches provided by the invention is composed of a drip irrigation tape and patches, wherein each patch is provided with a curved labyrinth flow channel and a comb-like water inlet hole to communicate with the inner wall of the drip irrigation tape; each patch is provided with a water outlet to communicate with the outer wall of the drip irrigation tape; theposition of the drip irrigation tape corresponding to the water outlet of each patch is provided with a confluence chamber to communicate with a labyrinth flow channel; and an anti-blocking filter piece is inlaid in each confluence chamber. The drip irrigation tape with the anti-blocking inlaid patches provided by the invention has the following technical progress effects: crop root hairs are prevented from piercing into water dripping holes of the drip irrigation tape; muddy water located outside the drip irrigation tape is prevented from recharging the confluence chamber and the labyrinth flow channel through the water dripping holes under the action of negative pressure during intermissions of water irrigation; thus, blockage caused by the crop root hairs and the muddy water is completely eliminated.

Owner:HEBEI YUYAN IRRIGATION EQUIP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com