Recycled modified material of waste drip-irrigation tape and preparation method thereof

A drip irrigation belt and modification technology, applied in the field of waste drip irrigation belt recycling modified material and its preparation, can solve the problems of environmental pollution, poor compatibility, performance discount of drip irrigation belt, etc., and achieve lower production cost, good tensile strength and fracture The effect of elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

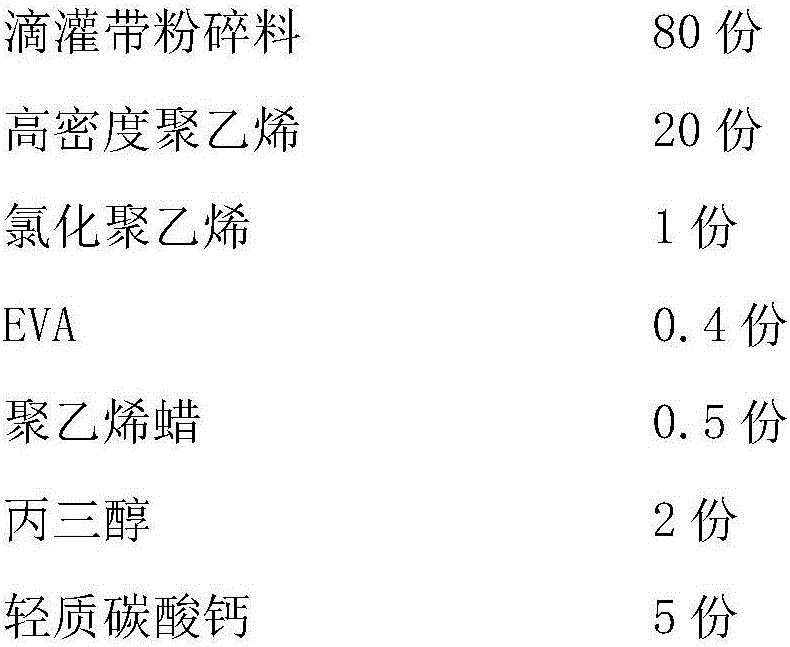

[0020] The formula for recycling and modifying the drip irrigation belt consists of the following raw materials in parts by mass:

[0021]

[0022] Put the above-mentioned raw materials in a blender and stir them evenly according to parts by weight to obtain a blend; introduce the blend into an extruder, granulate at 190-210°C, and then filter through a 100-mesh filter to obtain a recycled modified material.

Embodiment 2

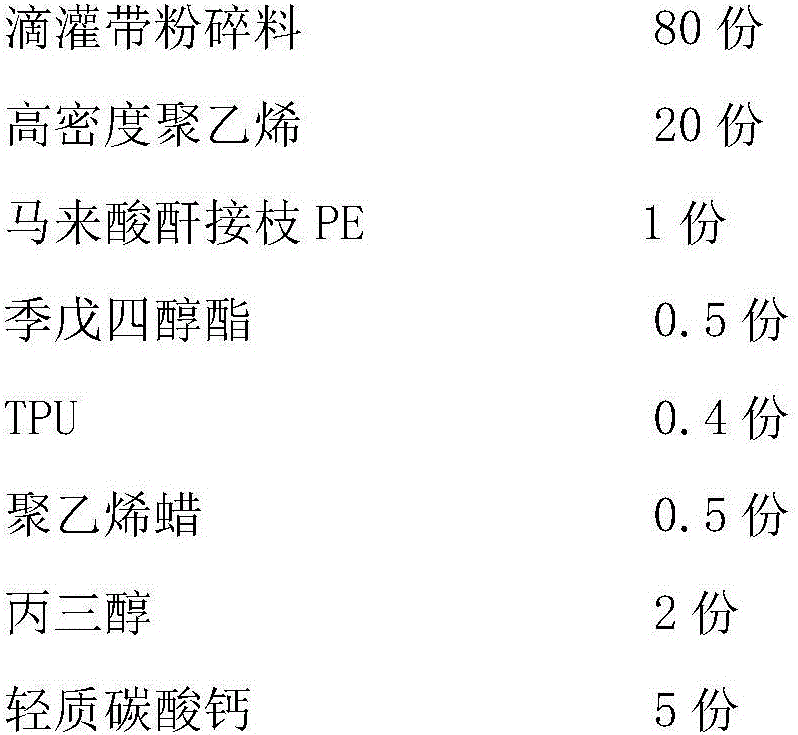

[0024] The formula for recycling and modifying the drip irrigation belt consists of the following raw materials in parts by mass:

[0025]

[0026] Put the above-mentioned raw materials in a blender and stir them evenly according to parts by weight to obtain a blend; introduce the blend into an extruder, granulate at 190-210°C, and then filter through a 100-mesh filter to obtain a recycled modified material.

[0027] Among them, after maleic anhydride grafted PE and pentaerythritol ester are compounded, the compatibility between recycled materials and additives can be further improved. Among them, pentaerythritol ester is also a multi-component hindered phenol antioxidant, which has a good effect of preventing discoloration caused by light and heat, and can increase the aging resistance of recycled materials.

Embodiment 3

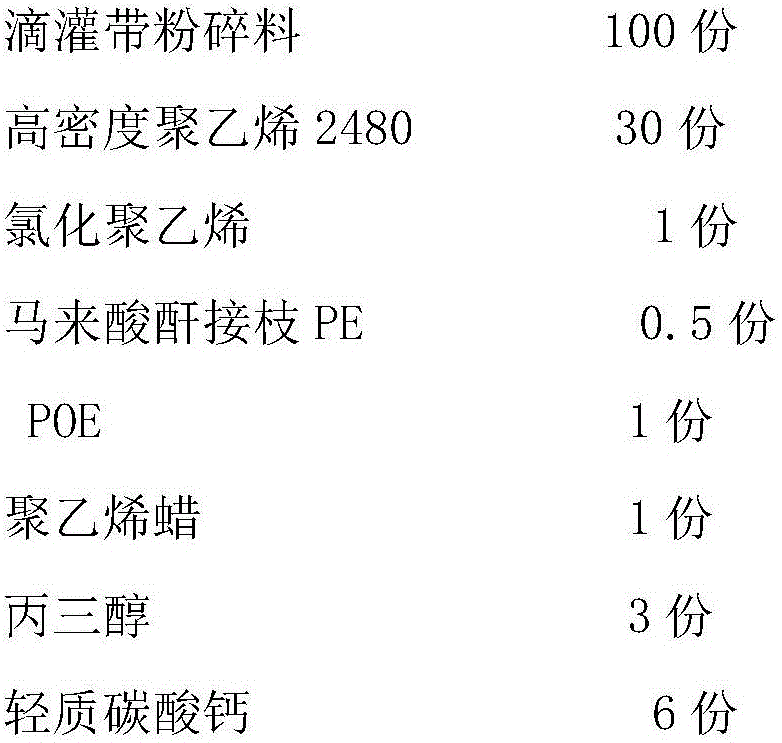

[0029]

[0030] Put the above-mentioned raw materials in a blender and stir them evenly according to parts by weight to obtain a blend; introduce the blend into an extruder, granulate at 190-210°C, and then filter through a 100-mesh filter to obtain a recycled modified material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com