Drip irrigation tape withdrawing machine

A technology of recycling machine and drip irrigation belt, applied in the field of drip irrigation belt recycling machine, can solve the problems of time-consuming, troublesome, laborious, etc., and achieve the effect of improving recycling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

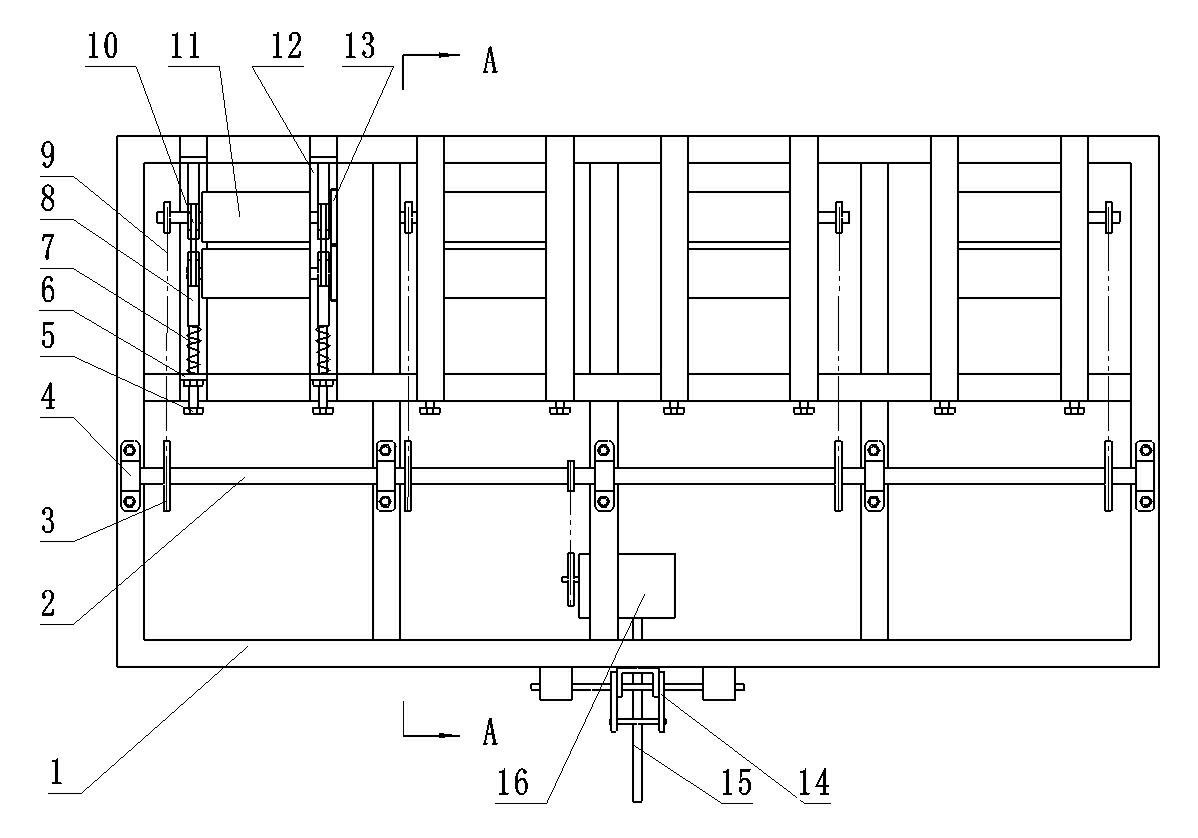

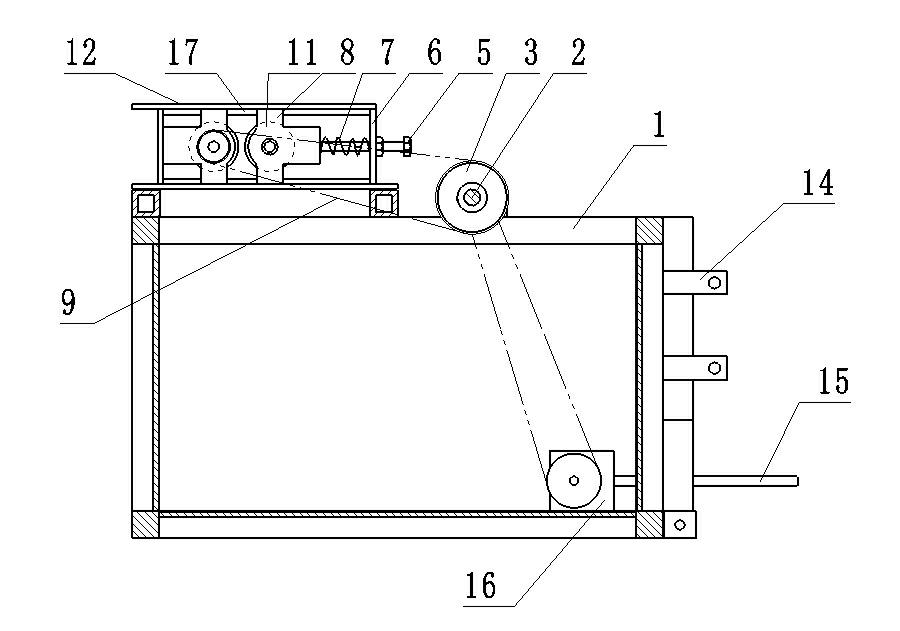

[0021] Example 1: Refer to Figure 1 ~ Figure 3 In order to invent the structural diagram of the implementation example 1, the lower part of the rack 1 forms a box, and there is a suspension frame 14 at the front end of the rack 1.The drive shaft 15 is connected to the power connection of the tractor. At the upper end of the rack 1, there is an organic shaft 2. The axis 2 connects to the gearbox 16 through a chain.There are also roller bracket 12. There are 4 groups in the roller brackets in this embodiment. There are two roller wheels 11 on each group of roller brackets. There is a rolling wheel bearing seat 8 at both ends of the roller 11.There are skating 10, sliding 10 cards on the sliding rail 17 on the roller bracket 12, can be moved around the slide rail 17, and there is a baffle 6 on the roller bracket 12 on the rolling wheel 11.There is a bolt 5 on the Board 6, and there is a spring 7 between the bolt 5 and the roller wheel bearing seat 8. Adjust the bolt 5 to adjust the s...

Embodiment 2

[0022] Example 2: Refer to Figure 4 ~ Figure 5 For the structural diagram of the embodiment 2 of the invention 2, compared with the embodiment 1, the difference between the embodiment 2 and the embodiment 1 is that the embodiment 2 sets the front scrape 25 and the back scraping on the front and rear sides of the roller.The end of the mud board 24, the end of the rear scraper 24 is fixed on the roller bracket 12, the other end is bent down the edge of the wheel, one end of the front scrape 25 is also bent down to the edge of the other roller, the front scrape 25 25On the other end of the nail ring 23, the nail 21 is set on the adjustment board 27, and there is a regulating slot 28 in the middle of the adjustment board 27. The fastener bolt 22 is connected to the roller bracket 12 in the adjustment slot 28.The position of the adjustment board 27 makes the front scrape 25 close to the edge of the roller. There is a tape spring 26 at the front end of the front mud 25, which can make t...

Embodiment 3

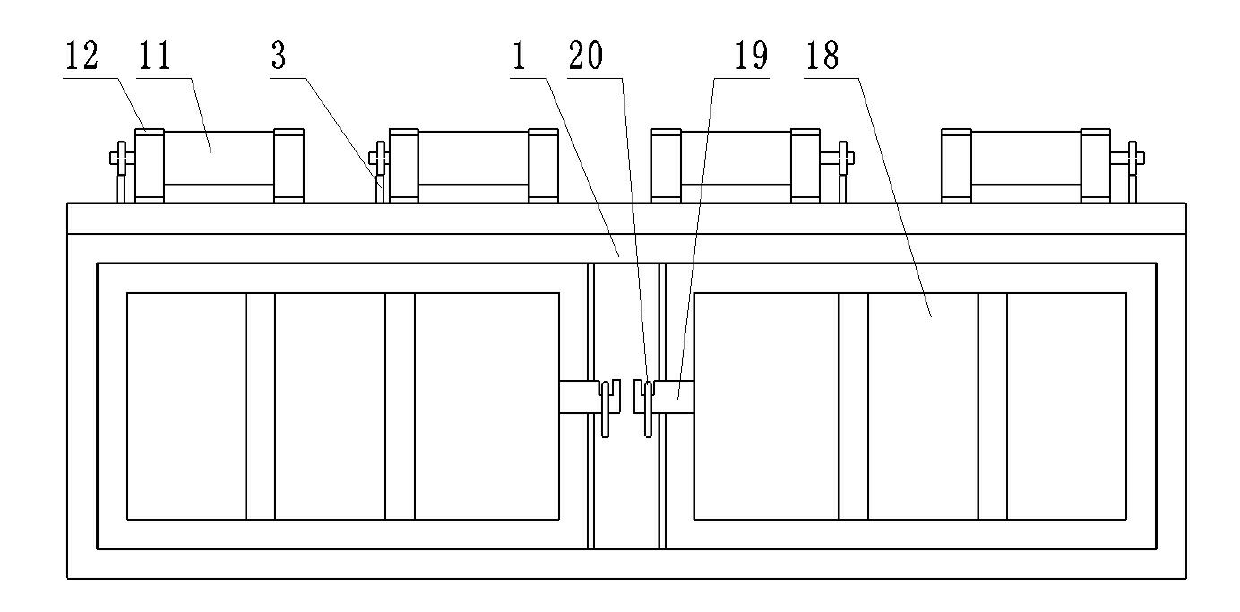

[0023] Example 3: Refer to Figure 6 ~ Figure 8 For the structural diagram of the embodiment 3 of the present invention, compared with the embodiment 2, the difference between the embodiment 3 and the embodiment 2 is that in the embodiment 3 set the guide band 33 at the back end of the rack 1, at the back end of the rack 1, at the back end of the rack 1, at the back end of the rack 1, at the back endThe guide strap 33 is connected with a tube 31, and the tube 31 has a guide band ring 32. You can guide the drip irrigation band into the box through the roller. In order to adjust the position of the tube 31, it is also set on the tube 31 and also set it on the tube 31.There are screws 34. There are skids 29 at the front and rear ends of each group of roller brackets, and 29 slide 29 sets are on the rack 1. A adjustable bolt 30 is also set on the sliding cover 29, which can adjust the position of the roller bracket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com