Patents

Literature

55results about How to "Idea novel science" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

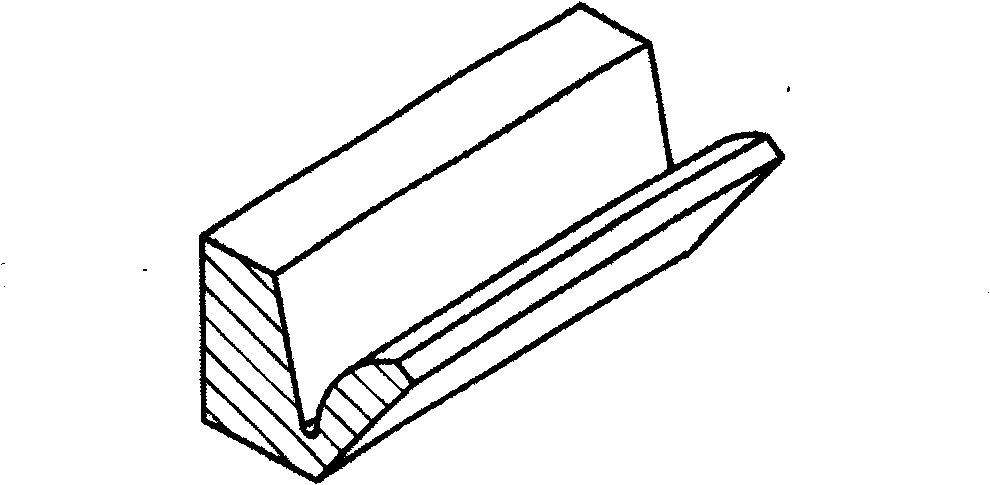

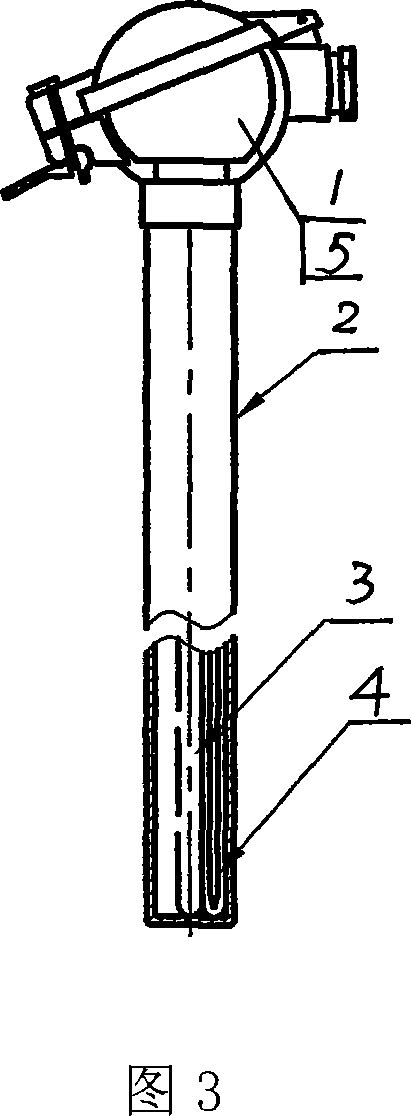

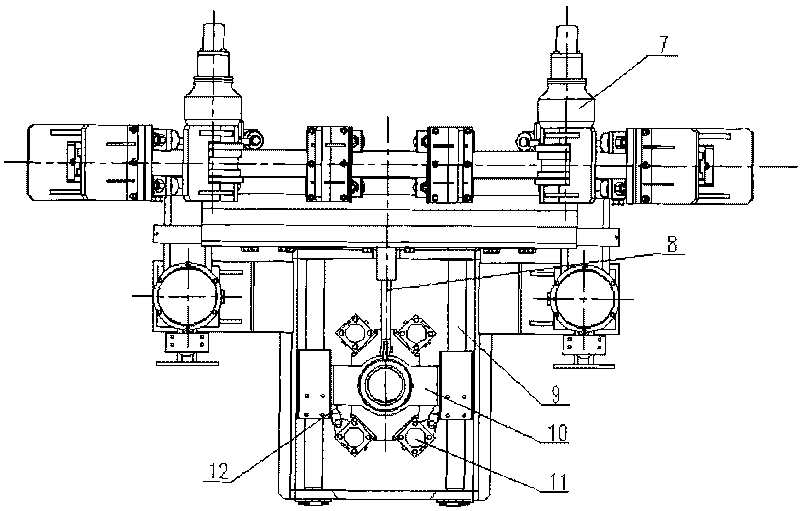

Tool bit rock breaking mechanism and abrasion tester

InactiveCN101299013AIdea novel scienceFunction increaseInvestigating abrasion/wear resistanceInvestigating machinabilityTool bitHydraulic cylinder

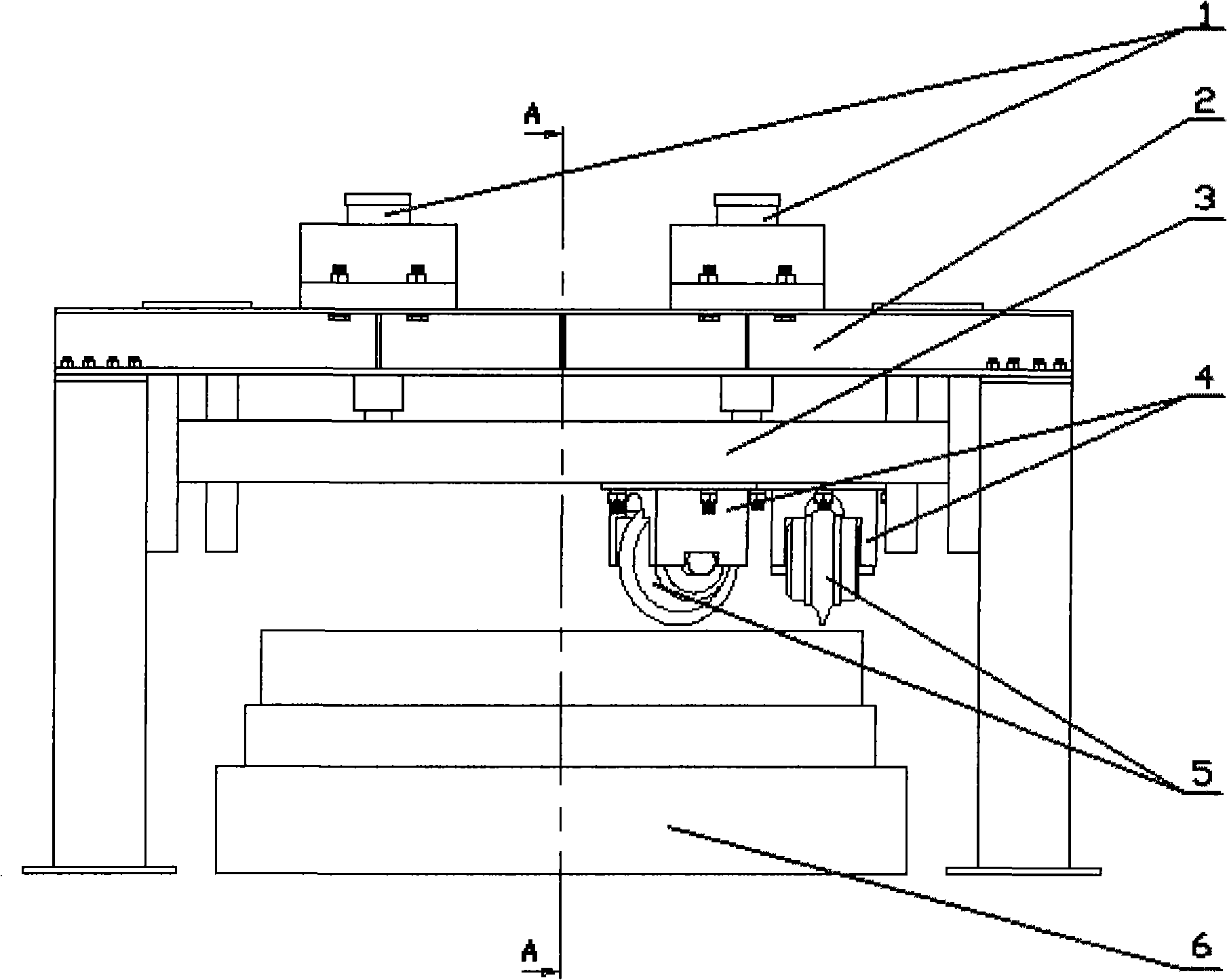

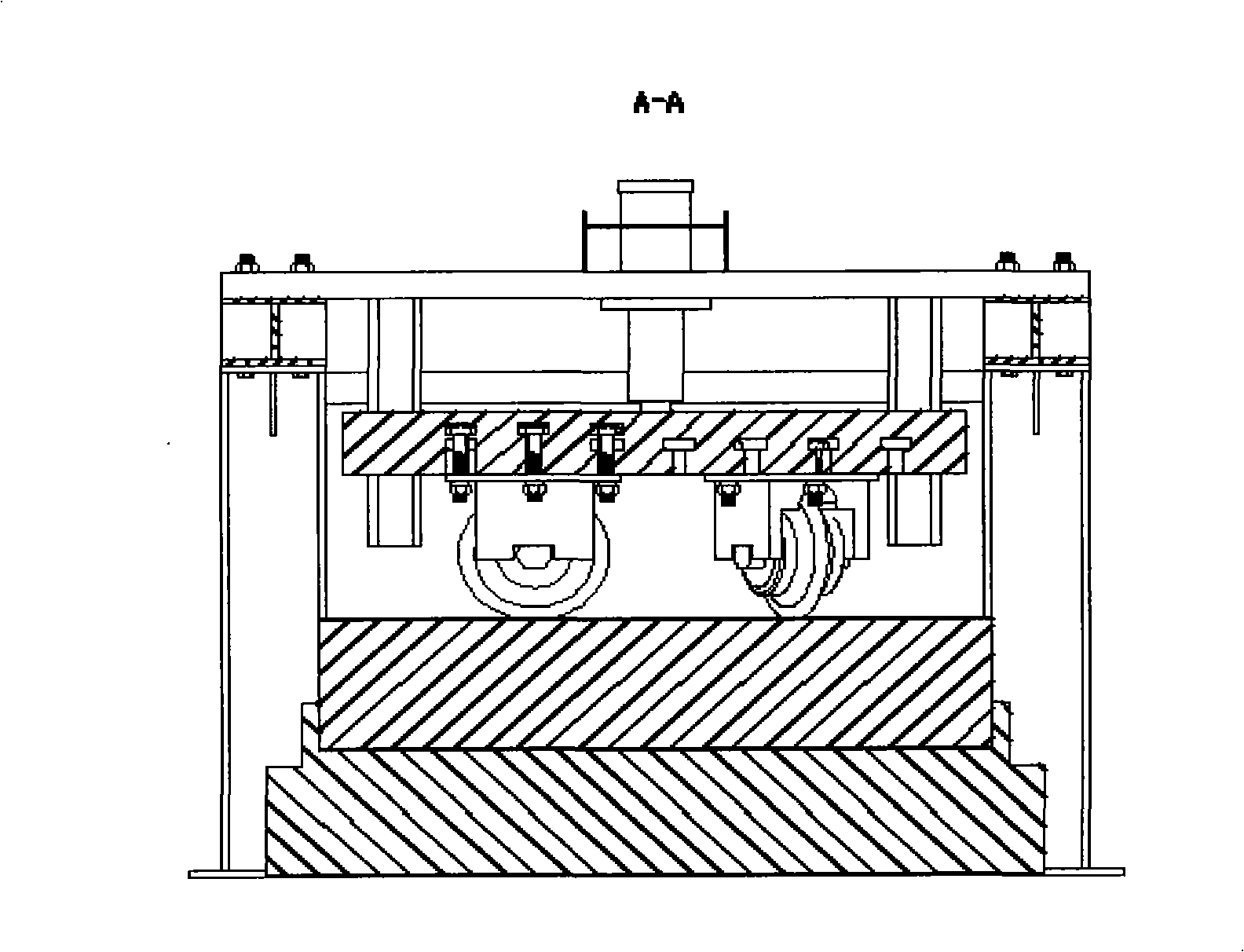

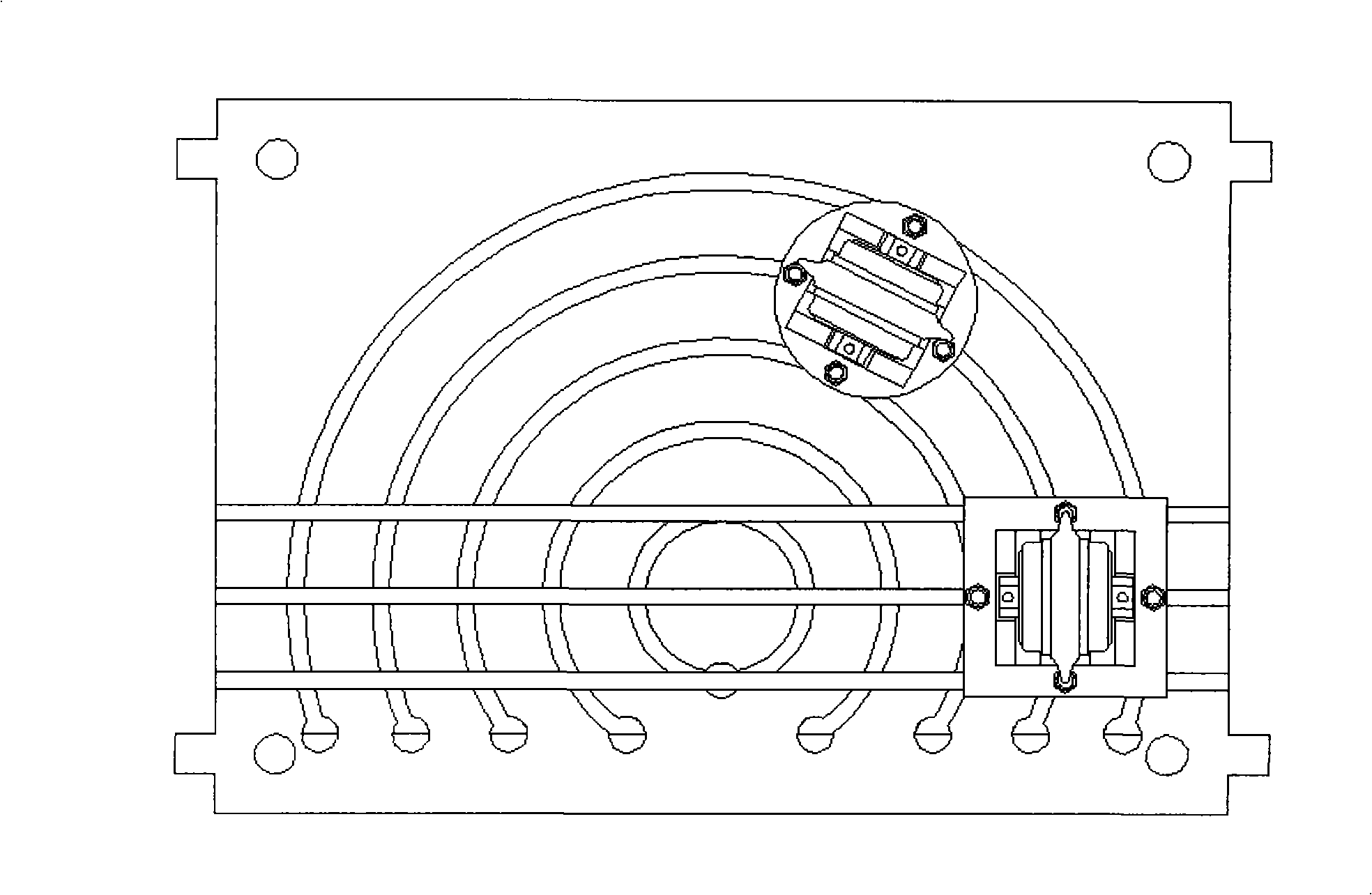

The present invention provides a cutter rock-breaking mechanism which is applied in the technical field of the cutter experiment and an abrasion resistant tester thereof. The abrasion resistant tester comprises a hydraulic cylinder, a structural frame, a bearing plate, a cutter support, a disc-shaped hob and a rotation worktable. When the cutter rock-breaking mechanism and the abrasion resistant tester work, the disc-shaped hob is connected with the cutter support through a bolt. The cutter support is jointed and fixed on the bearing plate through the bolts. The hydraulic cylinder exerts a certain load to impact the disc-shaped hob to the rock sample on the worktable and generate a certain penetration. Afterwards the worktable is rotated through a power system to execute cutting test to the rock passively. The cutter rock-breaking mechanism and the abrasion resistant tester execute cutting with a single cutter to do the abrasion resistance test of the cutter. The bearing plate is provided with a groove. The regulation to the cutter space and the phase angle is realized through the variation of the jointing position of the cutter support on the bearing plate. The regulation to the inner deflection angle of the cutter is realized by changing the cutter supports with different angles. The positioning and rotation of the rock are realized through the rotating worktable. The designing of the device is novel and scientific. The knife angle, phase angle and inner deflection angle which affect larger to the rock breaking and abrasion of cutter are researched. The device settles the problem that two hob cutters simultaneously cut the rock.

Owner:NORTHERN HEAVY IND GRP CO LTD

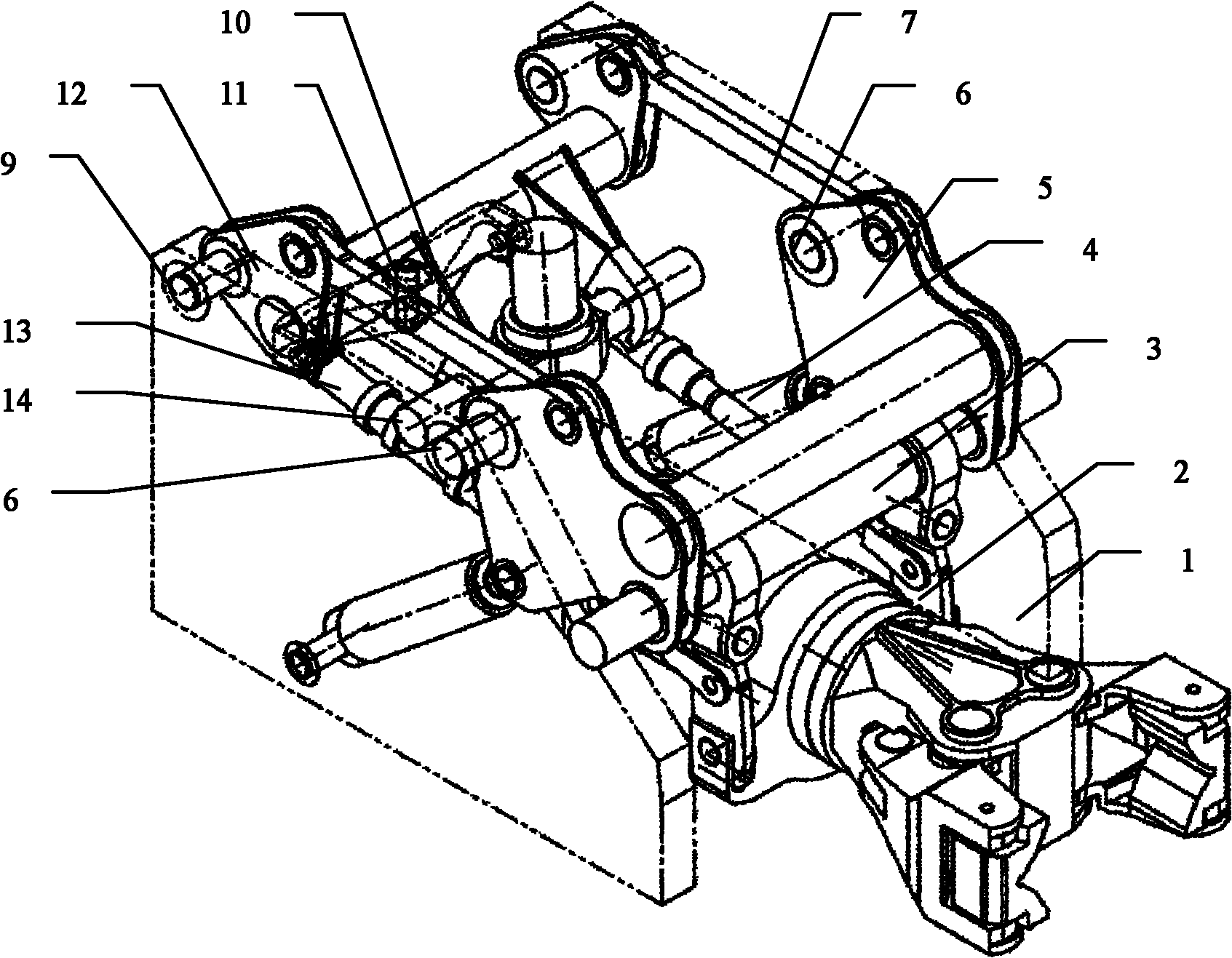

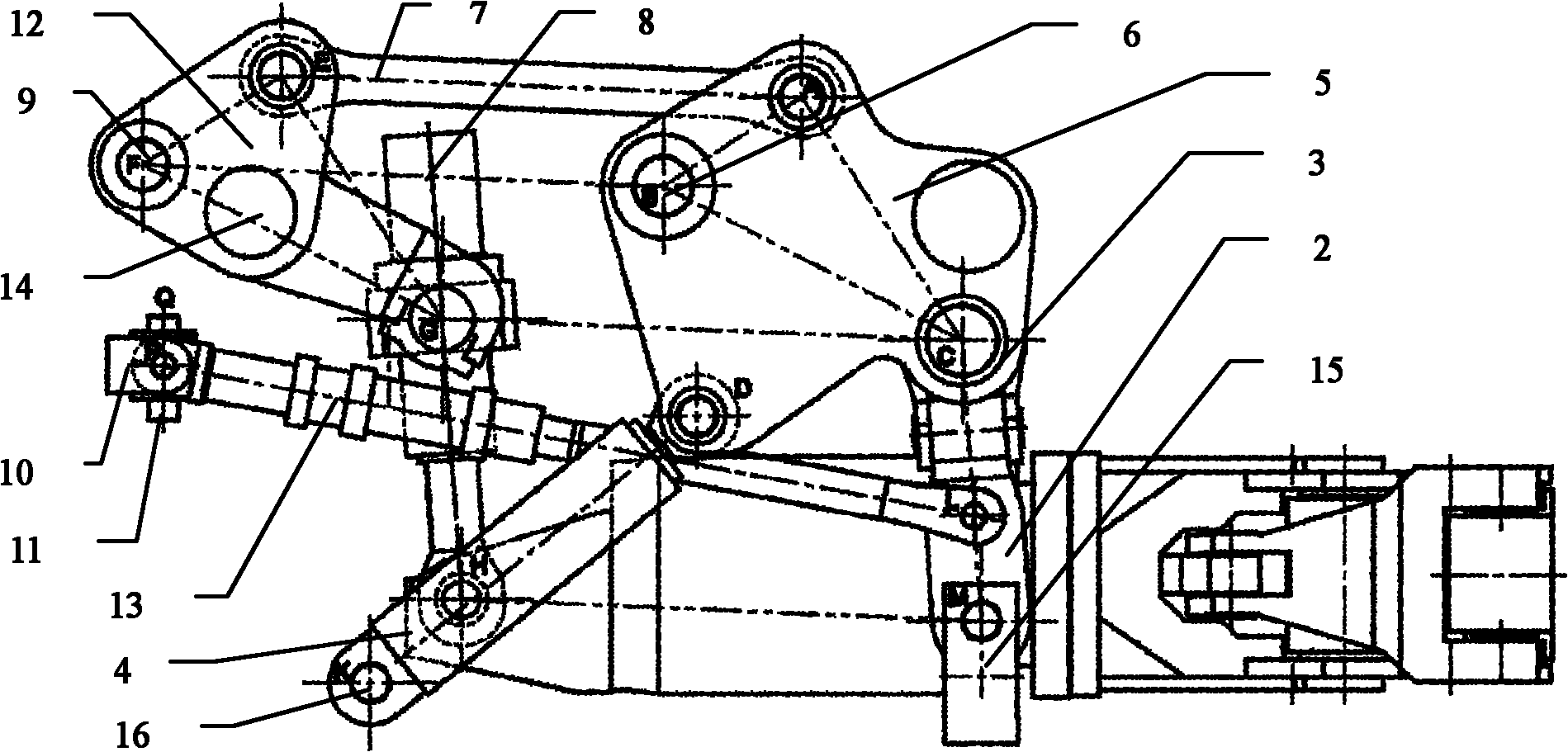

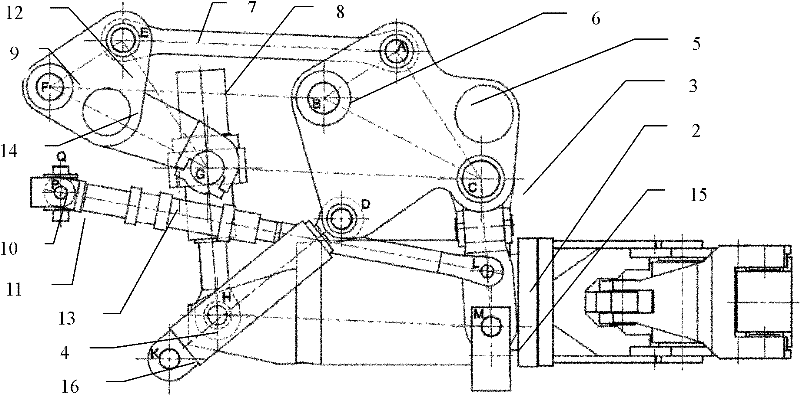

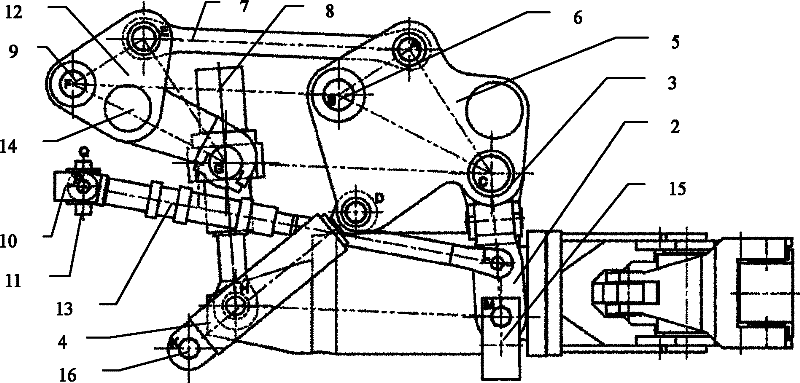

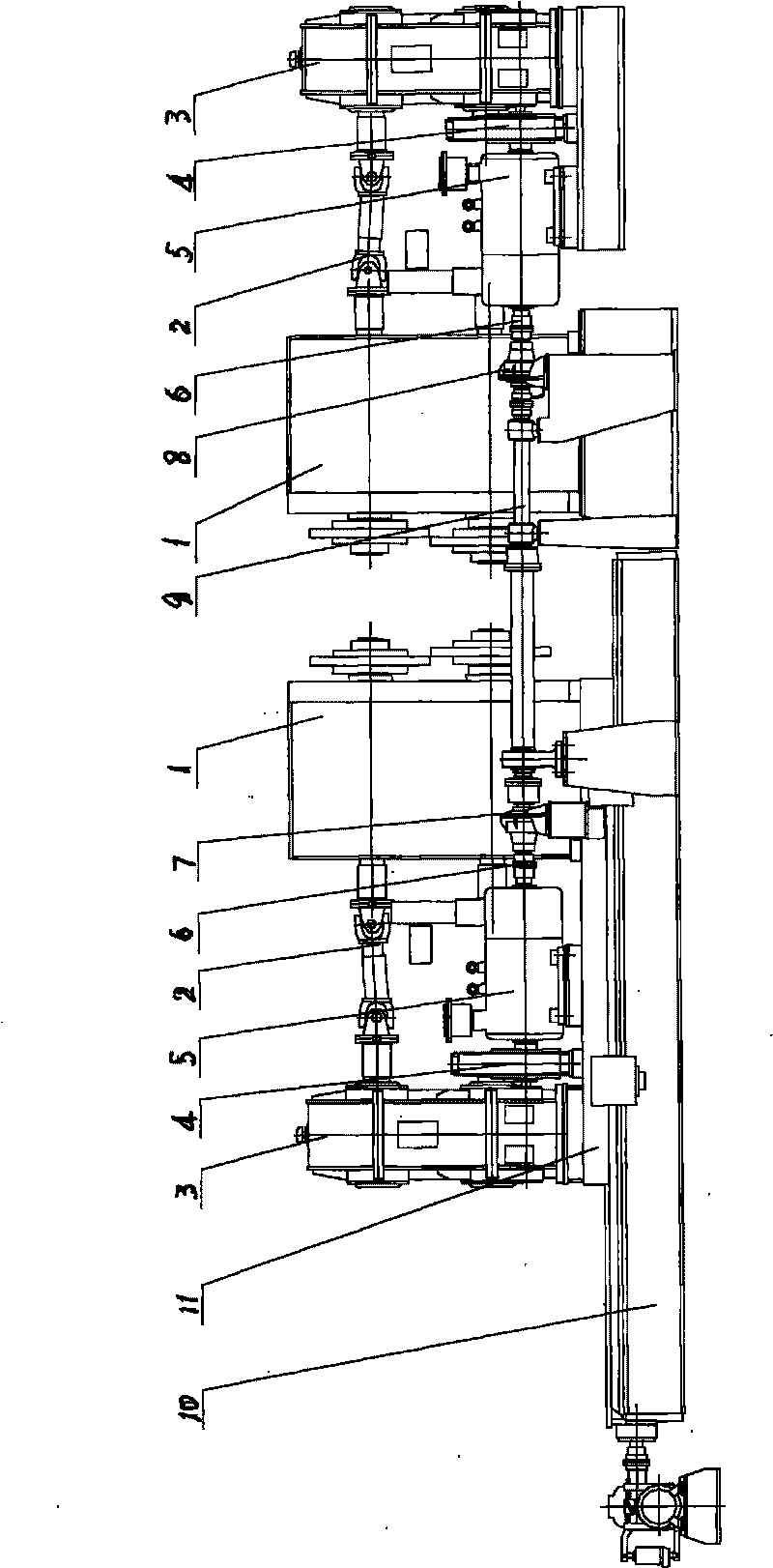

Claw beam lifting mechanism for forging manipulator

InactiveCN102019340AHigh movement precisionGuaranteed motion accuracyForging/hammering/pressing machinesVehicle frameRange of motion

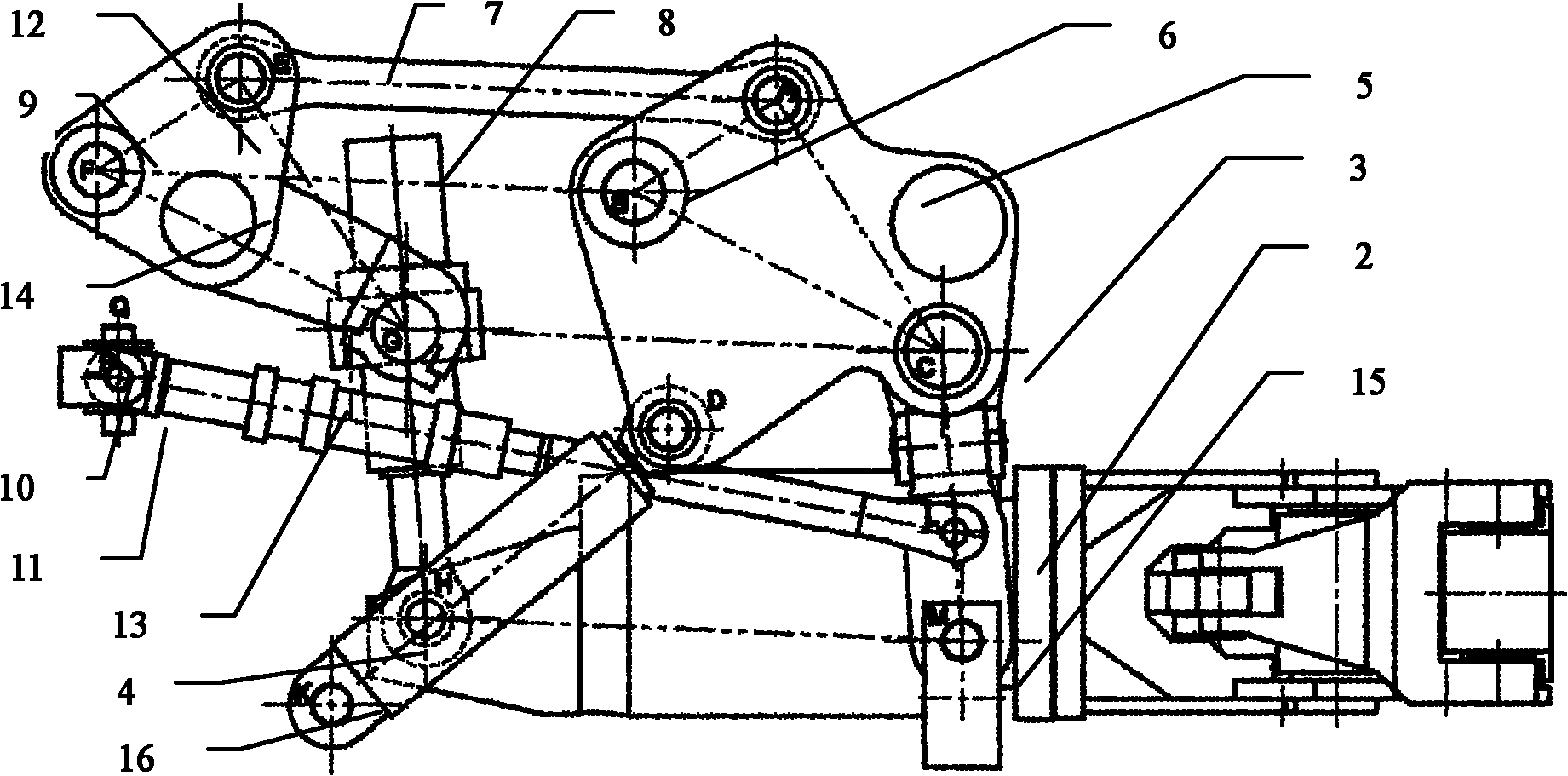

The invention discloses a claw beam lifting mechanism for a forging manipulator, applied to forging industry. The claw beam lifting mechanism mainly comprises a front lifting part, a rear lifting part, a synchronous connector rod, a lifting cylinder, a pitching cylinder and a buffering part, a front fixing shaft in the front lifting part, a rear fixing shaft in the rear lifting part and the lower end of the lifting cylinder are respectively connected with a large machine frame through hinges, the synchronous connecting rod is arranged overhead and always moves in a range above a connecting line of a front fixing hinge point and a rear fixing hinge point of a claw beam lifting and pitching mechanism and the large machine frame, front ends of two buffering cylinders are respectively connected with tow front lifting connecting rods through hinges, the rear ends of the two buffering cylinders are respectively articulated with two ends of a compensating beam, and the middle part of the compensating beam is connected with the middle part of the large machine frame by a hinge through a beam fixing shaft. The claw beam lifting mechanism has novel and scientific design concept, reasonable stress application, high movement precision, simple structure, low manufacturing cost and is convenient to install, adjust and maintain. The invention not only reduces the manufacturing cost of the lifting mechanism under the condition of ensuring the movement precision, but also thoroughly solves the problems that the front fixing shaft and a shaft sleeve matched with the front fixing shaft are worn easily and a side plate of a machine needs to be thickened specifically.

Owner:SHENYANG HEAVY MACHINERY GROUP

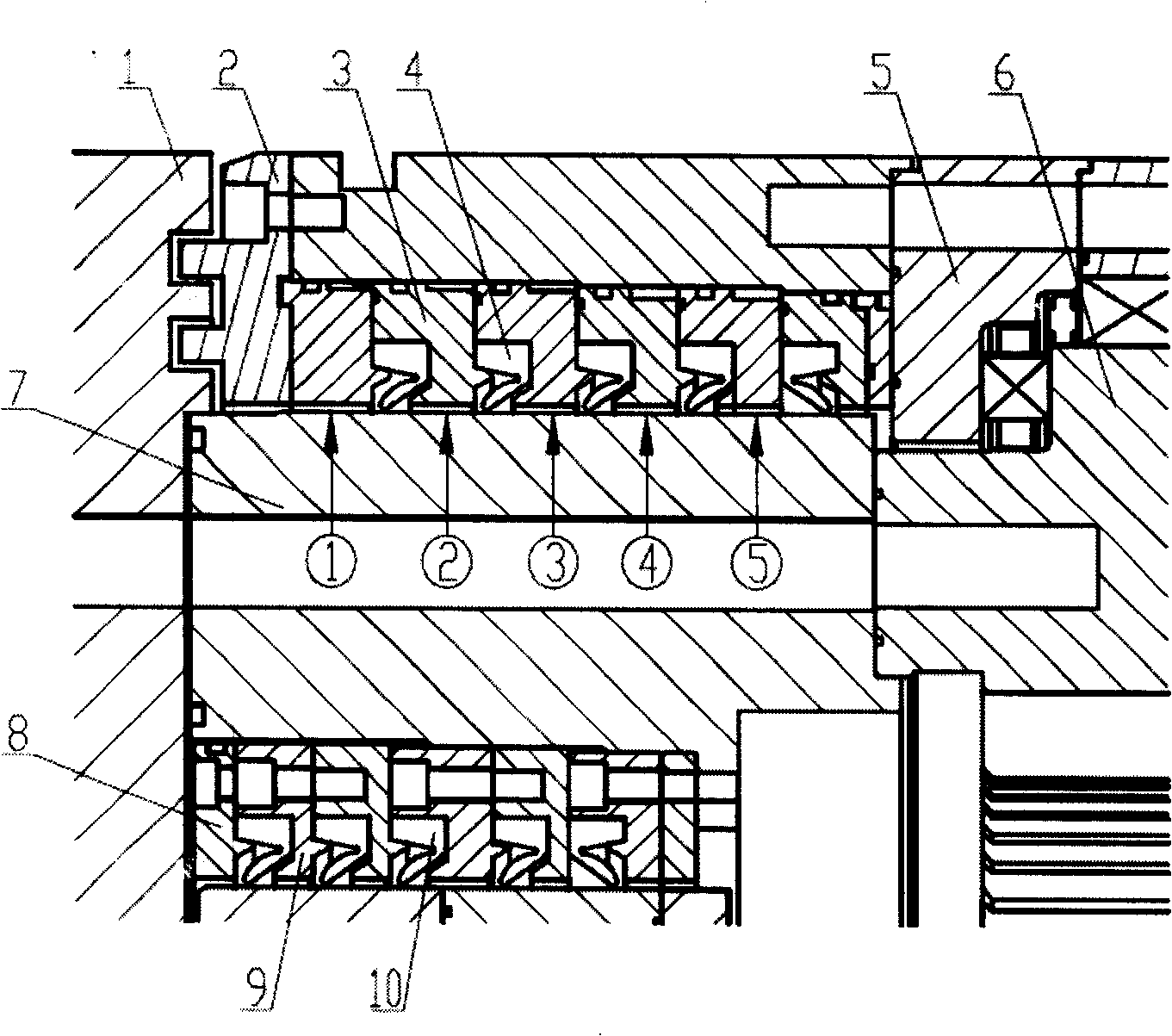

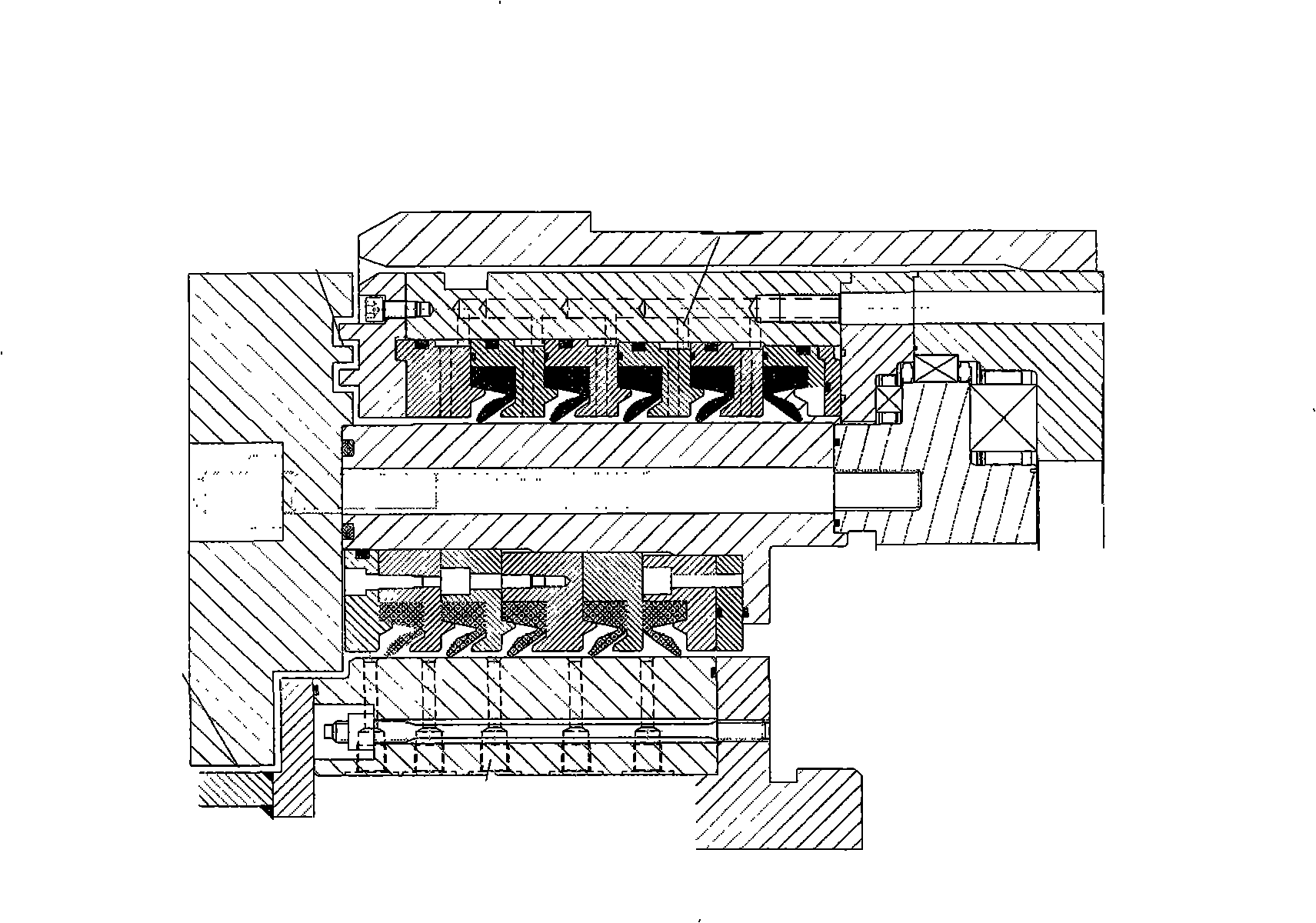

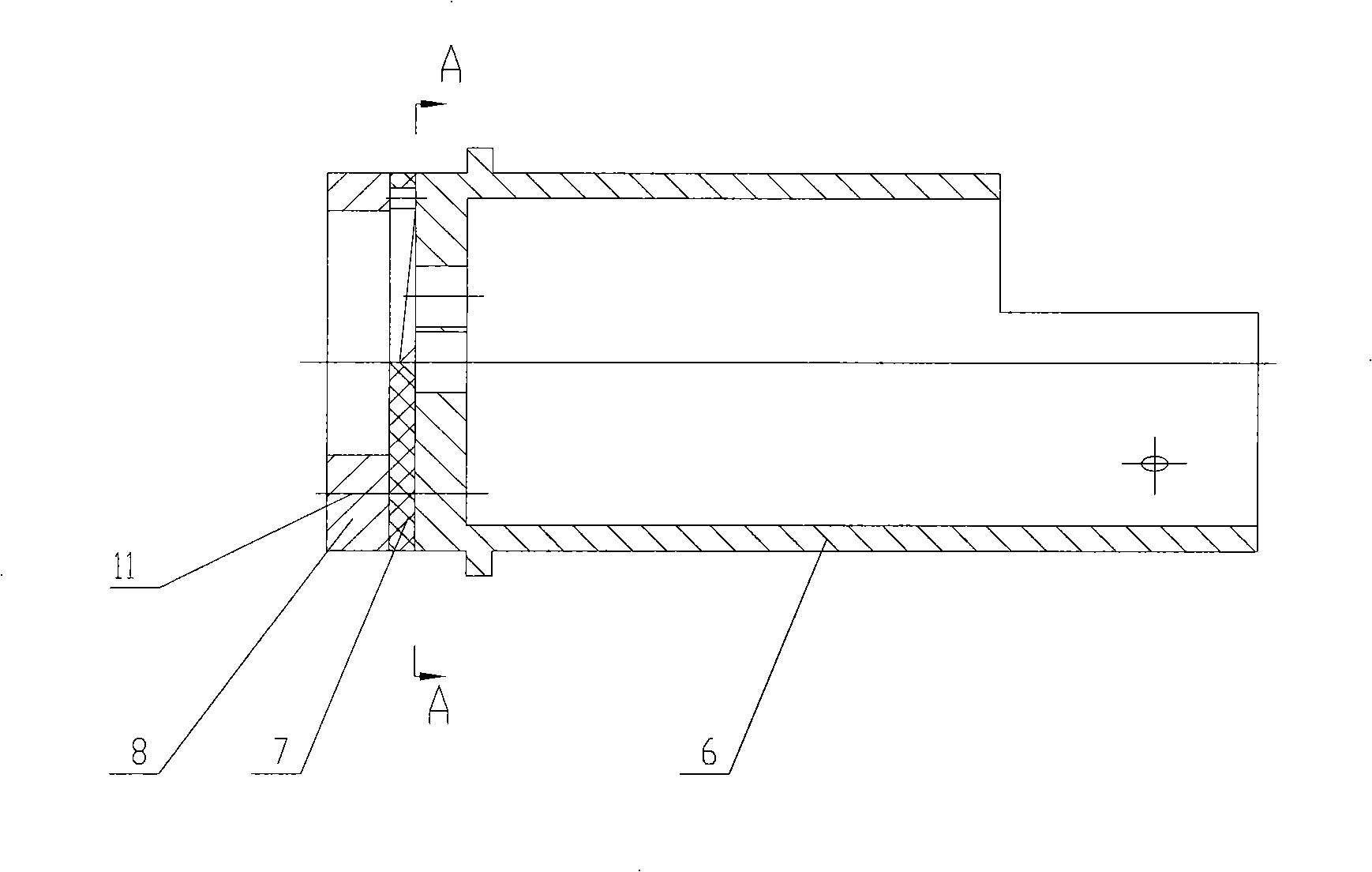

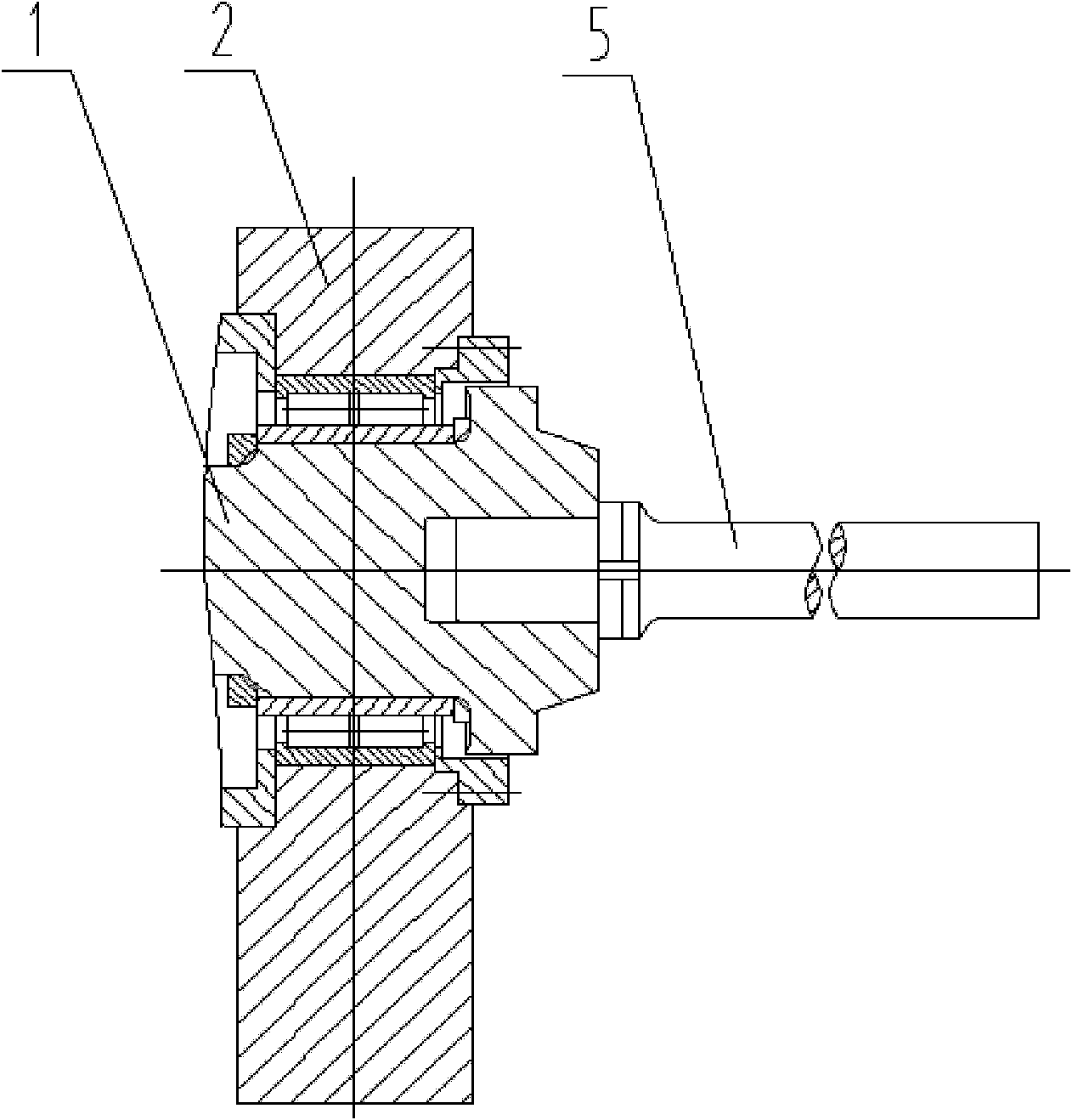

Main bearing multi-layer sealing structure of complete section tunnel boring machine

InactiveCN101280847AIdea novel scienceSimple manufacturing processEngine sealsTunnelsShield machineTunnel boring machine

The invention provides a multi-layer sealing structure for full section earth boring machine main bearing in shield construction machine engineering machinery technique field in electric power plant industry, comprising a blade disc support ring, an external seal ring compression ring, an external seal ring partition sleeve, a lip shaped external seal ring, a main bearing external ring, a main bearing intenal gear ring, a barrate, an internal seal ring compression ring, a internal seal ring partition sleeve, a lip shaped internal seal ring. The main bearing has a main bearing external ring, a main bearing internal gear ring in structure, the barrate is provided between the main bearing external ring and the main bearing internal gear ring, the gear from structure of the main bearing internal gear ring has engaging transmission with a pinion in main drive, a layer of seal is separately arranged on internal and external side of the barrate, each layer is separated in to five sealing chambers by using the lip shaped external sealing ring, the lip shaped sealing ring through the external sealing ring partition sleeve, the internal sealing ring partition sleeve. labyrinth type conjunction is processed between the blade disc support ring and the external seal ring compression ring, internal seal ring compression ring.

Owner:SHENYANG HEAVY MACHINERY GROUP

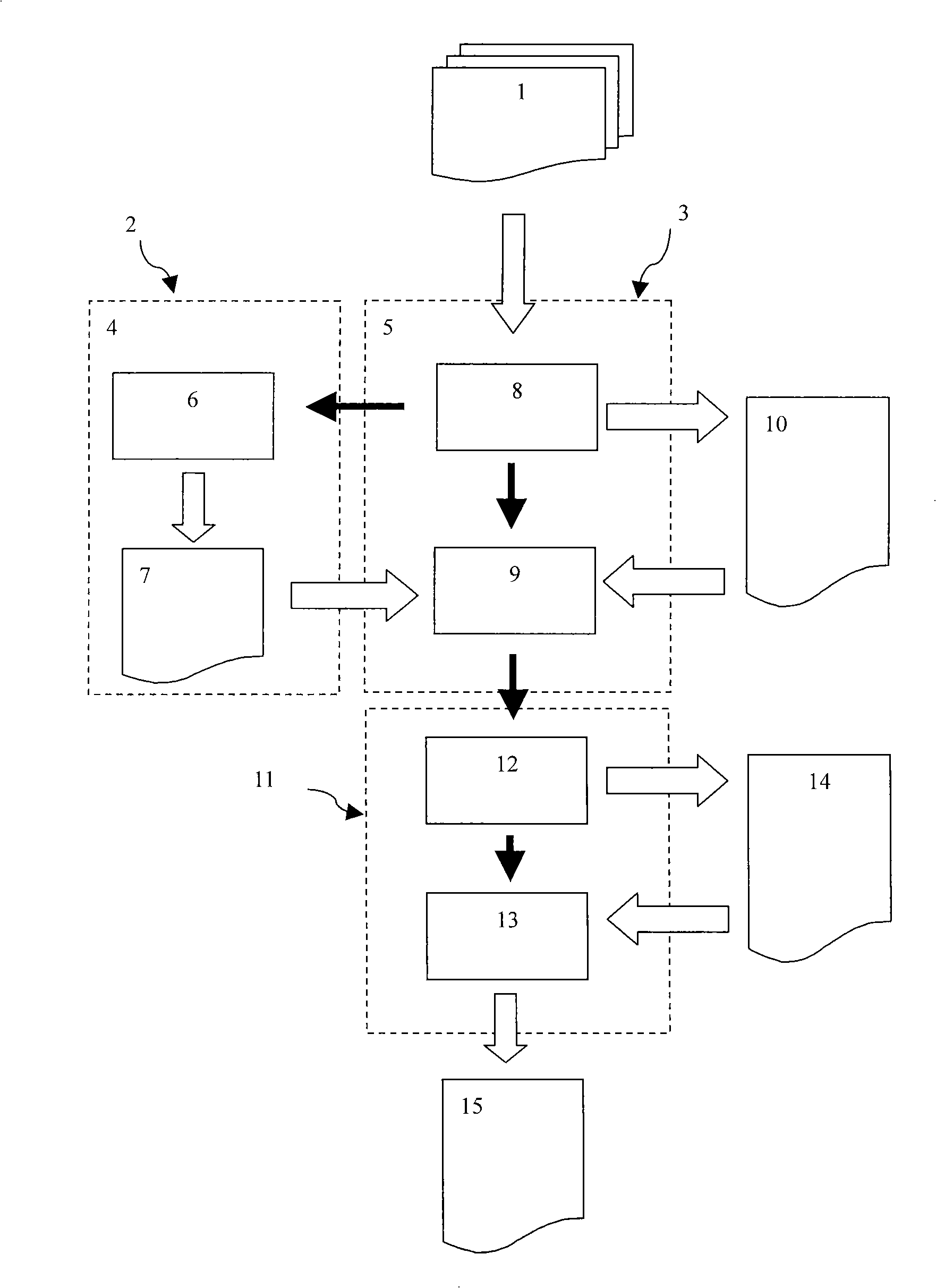

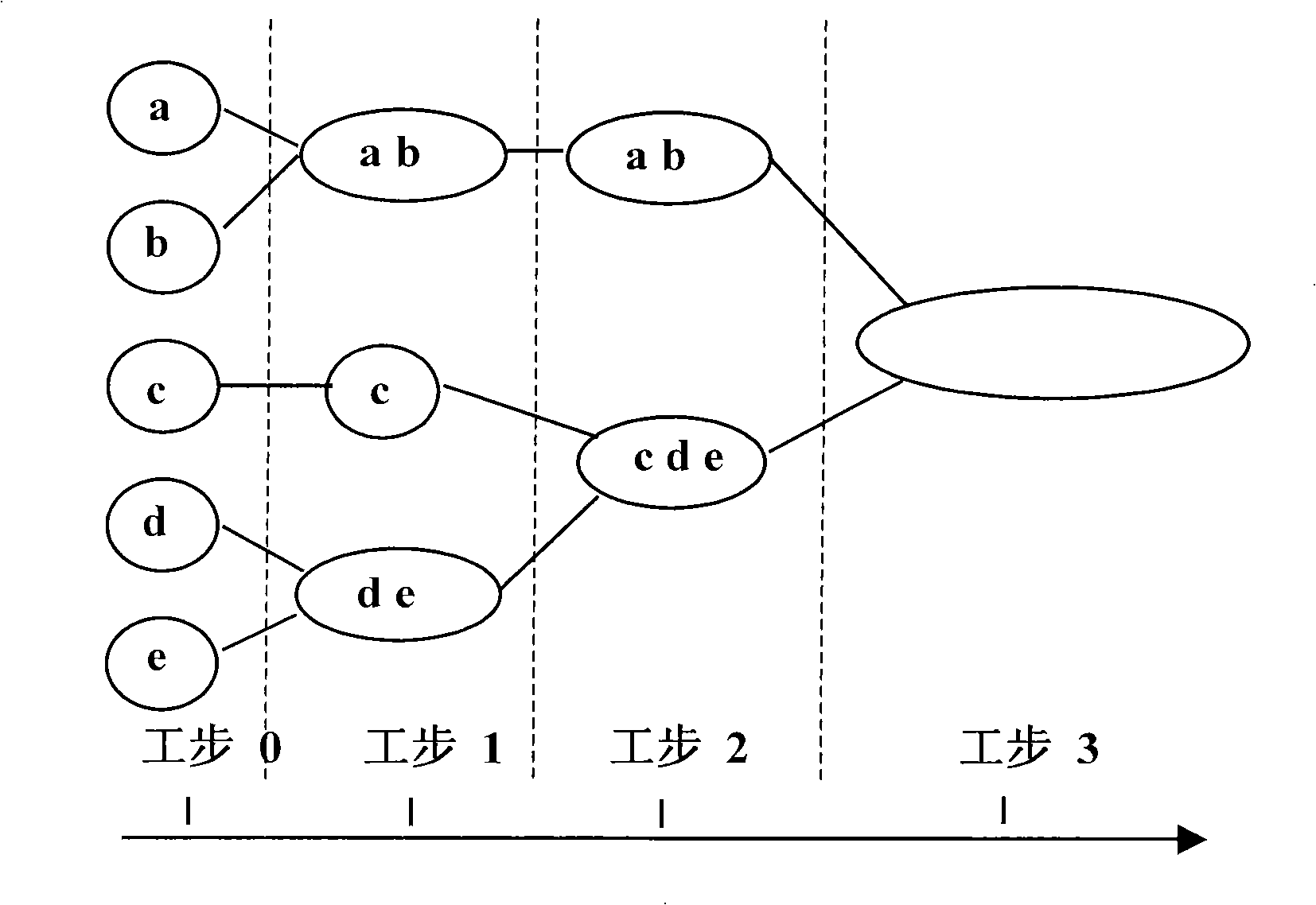

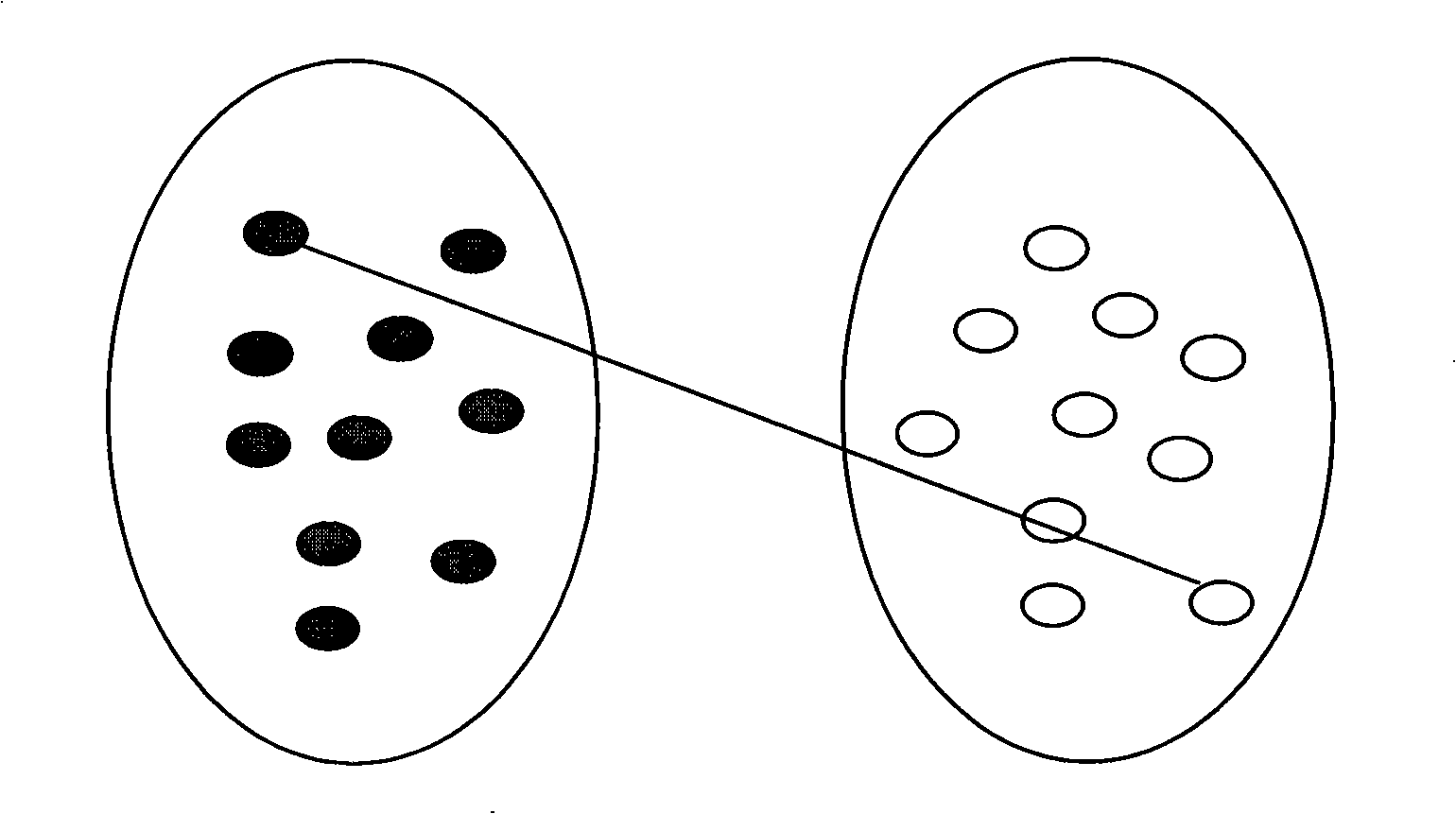

Large scale text data external clustering method and system

InactiveCN101308496ALarge capacityReduce use costSpecial data processing applicationsFeature vectorCluster algorithm

Disclosed are an external clustering method and a system for large-scale text data, applied to the information technical field; the designed clustering system comprises a candidate analyzer, a relationship generator, a relationship selection component and a clustering component; each sample point serves as a cluster; a candidate related candidate point cluster is selected for each sample through search technology; the relationship between the sample and the candidate relationship sample is calculated by the relationship generator and outputted to the external storage space by an increasing or decreasing order. The method mainly comprises the following steps: to pre-process the input text set and generate the inverted index and the eigenvector of the text set; to use the search technology to retrieve the candidate relationship set of each file; to calculate the relations of the files with candidate relationship through a relation calculation method; to orderly output the calculated results which are greater than a certain threshold value; then according to the orderly outputted results, the clustering algorithm repeatedly and iteratively combines a text pair with a first direct relationship, so as to eventually achieve the text set clustering output. The device has novel and scientific design, occupies small space in the clustering process and uses large-capacity external memories to make differentiated treatment to the treatment process.

Owner:沈阳格微软件有限责任公司

Method utilizing wormcast to manufacture biological organic fertilizer

The invention provides biological organic fertilizer made from wormcast, which is applied in the fields of agriculture and flower industry. Nitrogen, phosphorus, potassium and the wormcast are included in the product formula of the biological organic fertilizer. In a production method for the biological organic fertilizer, earthworms with great appetite and vigorous metabolism are selected and cultivated in the environment with the temperature of 15 to 28 DEG C and the humidity of 50 to 70%, and the cultivating density is 10,000 to 20,000 pcs / m2; adult earthworms are separated from the wormcast after being cultivated for 7 days, and the collected wormcast is dried and crushed to form the black, granular and uniform organic fertilizer with the grain diameter of 0.3 to 1.0cm. The characteristics of the provided biological organic fertilizer with the wormcast as raw materials are as follows: the product design is novel and scientific; the undernutrition of the present biological organic fertilizer is overcome; the biological organic fertilizer not only maintains the advantages of traditional agricultural fertilizer, but also has the function and effect of total nutrition of modern fertilizer; therefore, the biological organic fertilizer can cultivate high-quality / yield grains and other crops.

Owner:沈阳尊龙生物技术有限公司

Mashed potato and preparation process thereof

InactiveCN1961735AIdea novel scienceGood workmanshipCheese manufactureFood preparationFood sectorDry bean

The invention relates to a mashed potatoes and relative production, wherein it comprises that using the potatoes, to be boiled, skin remove, dried, and broken into potato powder; adding chickens' extract, plant oil, iodized salt, dried onion, dried particles, to be mixed; packing into package box; when eating, opening the package, adding boiled water, eating after 3-5mins; the particles are chicken, beef, pork, tomato, bread, and dry bean curd. The invention has high nourishment content.

Owner:金大顺

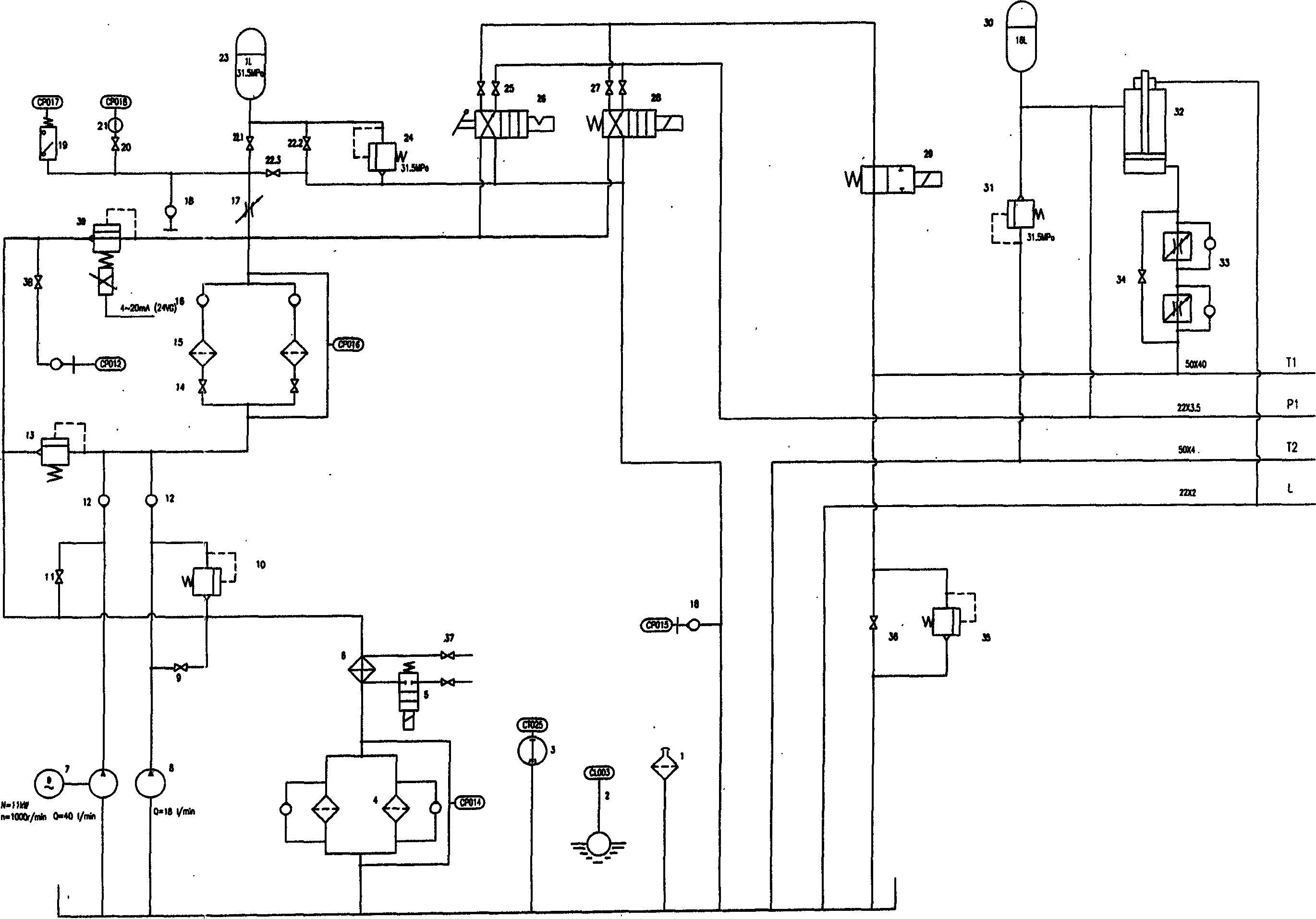

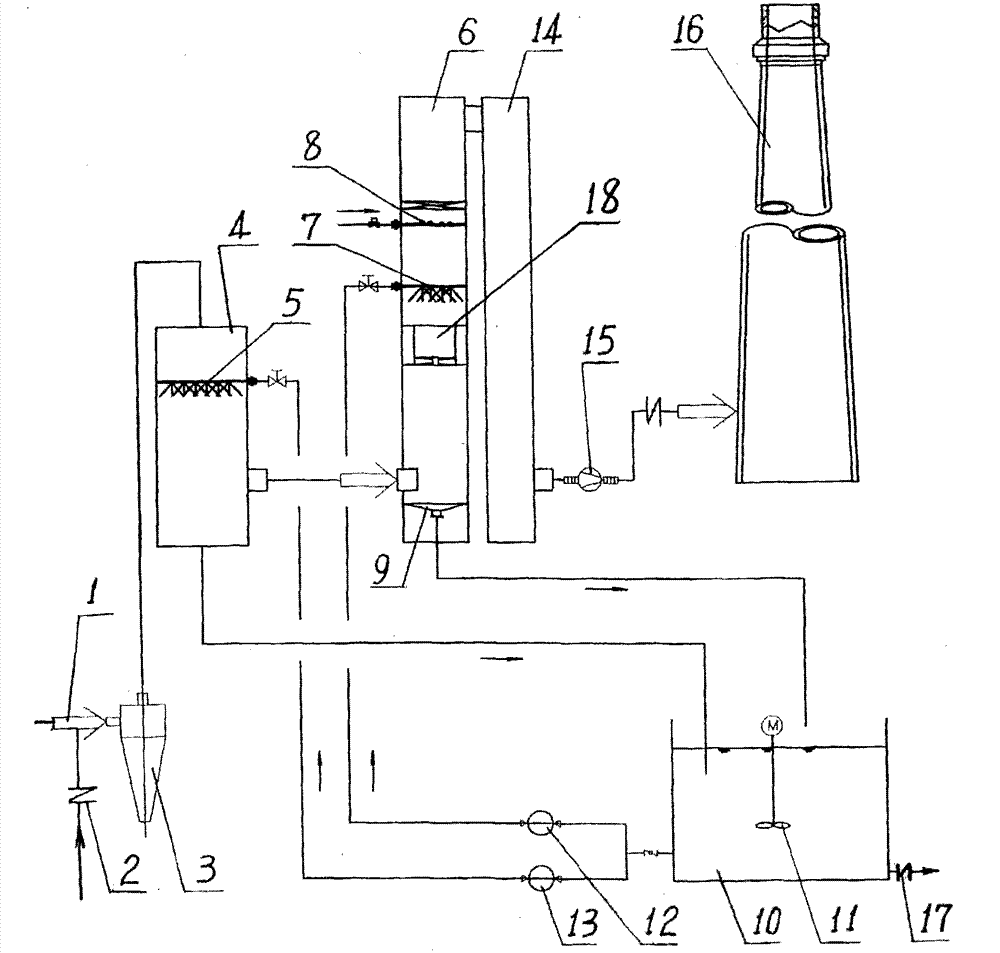

Hydraulic variable loading system for roller-plate coal mill

InactiveCN1672800AGrinding force to matchReduce operating load power consumptionCement productionGrain treatmentsSolenoid valveLow load

The hydraulic variable loading system for roller-plate coal mill in power station, cement mill, etc. consists of filter, motor, two-gang pump, high pressure bi-directional filter, pressure speed variator, energy accumulator, two-position four-way solenoid valve, hydraulic cylinder, proportional overflow valve, etc. The motor drives the two-gang pump to provide the hydraulic kinetic energy, and under the control in the central control room via the pressure speed variator, proportional overflow valve and the hydraulic variable loading system, the work pressure is applied to the hydraulic cylinder cavity. The system of the present invention is novel, safe and reliable, and makes the coal mill operate stably at low load.

Owner:SHENYANG HEAVY MACHINERY GROUP

Production technique of vinegar sauce and product thereof

InactiveCN101361534ASolve the pollution of the environmentIdea novel scienceVinegar preparationFood preparationPolyolFood technology

A vinegar jam preparation process and a correspond product belong to the food technique field. The preparation process includes the following steps: fruit is washed well; pericarps, cores and stalks are respectively isolated after the fruit is crashed; the thickness of isolated pericarps is crushed into the thickness about 1mm and then the hot water of 100 DEG C is added to heat the isolated pericarps for 5 to 10 seconds; a certain amount of citric acid is added onto the processed pericarps and then the pericarps are steamed under a high pressure till the pectin is released to obtain the pericarp paste; the juice and flesh are steamed under the high pressure and are mixed with the pericarp paste and then the mixture is stirred equally to obtain the semi-manufactured jam; and then the vinegar and sugar polyol are respectively added into the semi-manufactured jam and then constant stirring, homogenizing, degassing and sterilizing are carried out sequentially to obtain the vinegar jam. The idea of the invention is novel and scientific and the prepared vinegar jam is provided with the harmonious and balanced acidity, sweetness and a little bitterness; the combination between vinegar and jam brings out the double health-preserving effects of both vinegar and fruit so as to enrich the nutrition and lead the sugar polyol to replace the maltose and granulated sugar adopted by the traditional jam.

Owner:沈阳麦金利食品制造有限公司

Modified polychloroethylene drip irrigation tape

InactiveCN101434733AIdea novel scienceImprove performanceSpray nozzlesProcedure AgentsPolyvinyl chloride

The invention relates to a modified polyvinyl chloride (PVC) drip tape applied to the filed of agricultural water-saving irrigation facilities. The formula of the PVC drip tape comprises carbon black, a plasticizer, a high molecular plasticizer (GZ), an anti-impact modifier, a lubricant, a processing accessory agent, a heat stabilizer, calcium carbonate (CaCO3), a coupler and PVC; the carbon black comprises medium color black and common color black; the PVC comprises the types of PVC-SG2, PVC-SG3, PVC-SG4 and PVC-SG5; the plasticizer comprises dibutyl phthalate (DBP) and dioctyl sebacate (DOS); the lubricant comprises a compound lubricant, i.e., a stearic acid, calcium stearate, chlorinated paraffin or oxidized polyethylene wax (OPE). The modified PVC drip tape has scientific and novel conception; the PVC drip tape has excellent comprehensive performance after modification treatment by using various modification accessory agents; and compared with the common PVC drip tape, the modified PVC drip tape has relatively low production cost and more remarkable advantages in price and performance, can reduce the consumption of gasoline resource and is more beneficial to the agricultural water-saving irrigation technology of China.

Owner:SHENYANG HUADE MACHINERY MFG

Fruit vinegar capsules and preparation method

The invention provides fruit vinegar capsules and a preparation method applied in the technical field of food. A product formulation comprises fruit vinegar powder, rice bran dietary fiber, inulin, soy peptide, barley seedling leaf powder, lotus leaf powder and grape pip proanthocyanidins. The preparation method comprises: taking high-quality fresh fruits or concentrate juice thereof as main raw material; obtaining fruit vinegar through alcohol microbial fermentation and acetic acid microbial fermentation; concentrating the fruit vinegar through membrane concentration, spray-drying and grinding the obtained product to prepare the fruit vinegar into titratable total acid; washing barley seedling leaves and lotus leaves clean respectively and then preparing the two into dry powder after drying, grinding and sieving; weighing rice bran dietary fiber, inulin, soy peptide and grape pip proanthocyanidins according to the weight in the formulation; mixing the materials well by use of a high-speed mixer; drying and sterilizing the mixture under vacuum through microwave; and obtaining the fruit vinegar capsules through the filling of an full-automatic capsule filling machine. The preparation method has the advantage of novel scientific conception, and the capsules prepared by concentrating and drying the fruit vinegar are safe, effective, incapable of causing gastrointestinal discomfort or dependency, suitable for long-term eating and capable of rapidly clearing free radicals and superfluous fat in human bodies, neutralizing acidic constitution and increasing satiety so as to achieve the aim of losing weight.

Owner:沈阳麦金利食品制造有限公司

Airplane engine heat exchanger guiding-tube bend filling and technique

InactiveCN101058708AImprove bending qualityStable performance of filling processOther chemical processesHollow article cleaningSodium bicarbonateJet aeroplane

The invention discloses a bending filler and technique of heat exchanger conduit of airplane motor in the machine making domain, which comprises the following steps: allocating raw material proportionally; putting disodium phosphate and sodium bicarbonate in the autoclave; blending 2h; adding stablizier and reinforcer; packing the allocated fill; sealing to reserve. The filling technique of conduit product comprises the following steps: weighing the filler; controlling the temperature after the filler is fused; entering into the working condition; filling the conduit. The cleaning technique is characterized by the following: placing the moulded conduit into cleaning groove; injecting the tap water to heat and stir; controlling the water temperature between 80 and 90 deg. c for 20-30 min; fetching the conduit; draining the solution; repeating 5 times; fetching the conduit to dry; finishing the cleaning process.

Owner:沈阳华铁异型材有限公司 +1

Manufacturing method for producing artificial board with branch strip or shrub tress

InactiveCN101130258AIdea novel scienceSimple processDomestic articlesFlat articlesFiberSocial benefits

The invention relates to a method of fabricating artificial board made of tree branch or shrub branch in the fabrication industry of artificial board. Tree branch or shrub branch with the diameter smaller than 20mm is cut into small segments with the length of 40-50mm by trimming machine. Those segments are sent to the thread rolling machine by air-sending system. Water content of small segment of tree branch or shrub branch becomes into 20%-30% and the temperature is 70-80deg.C after heating and moistening by heat. After thread rolling and polishing big material is returned into thread rolling machine again and fiber broken material with satisfaction with process requirement is sent into drying pipe to be dried by hot wind. Namely, fiber preparation segment adopts secondary rolling polishing wind-selecting technology of heating-moistening, rolling-polishing, selecting and rolling-polishing and there is no need of heat polishing. Fiber is separated under normal state. Then artificial board is fabricated by procedures of drying, selecting, sizing, paving, preloading, slab transporting, hot pressing, cooling, edging and sanding so on. The invention makes use of non-forest resource and solves the lack of wood resource. The invention also increases peasant income and possesses huge social benefit. The invention conforms to saving society, cycling economy and sustainable development.

Owner:SHENYANG HEAVY MACHINERY GROUP

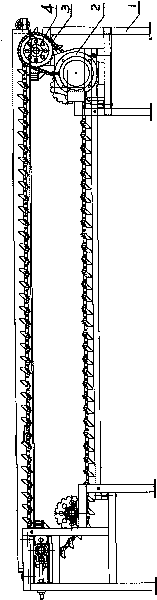

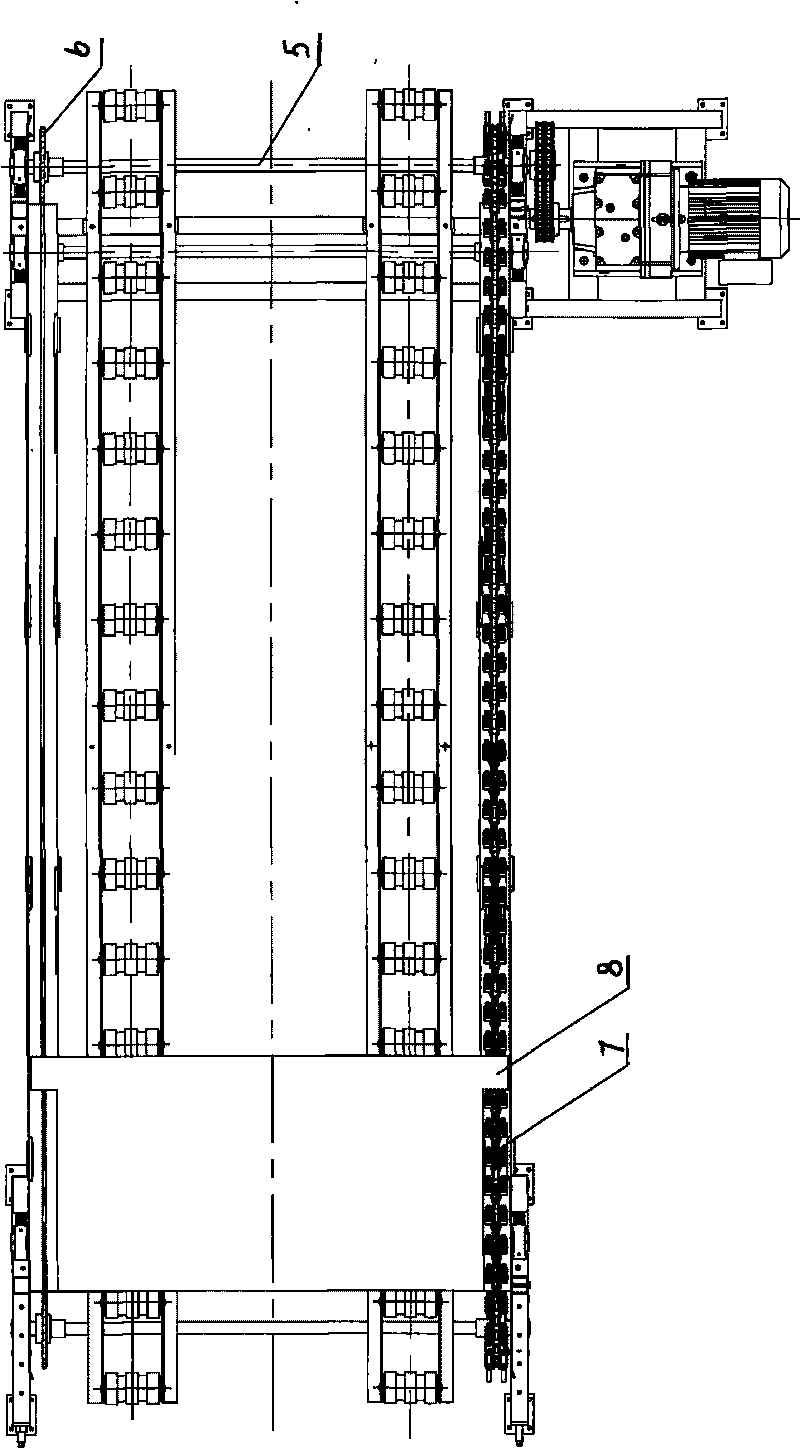

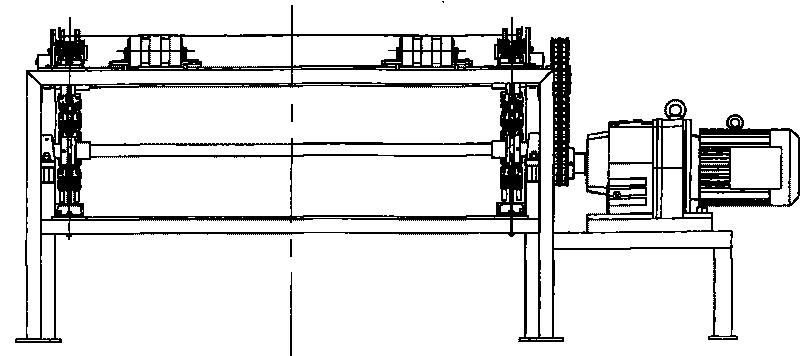

Movable chain-hook chain type conveyer

The invention relates to a movable chain-hook chain type conveyer which comprises a bracket, a power part, a transmission chain, chain wheels, a shaft, a chain wheel set and a double-pitch chain with a movable chain-hook, wherein the chain wheels and the chain wheel set are assembled on the shaft, and the shaft and a power system are both assembled on the bracket; the chain is used for connecting chain wheels of the power system; and the chain wheel set and the double-pitch chain with the movable chain-hook form engagement transmission. The movable chain-hook chain type conveyer is formed by changing the chain-hook of a normal fixed chain-hook chain type conveyer with other parts same as that of the fixed chain-hook chain type conveyer. When the movable chain-hook chain type conveyer is normally operated, the power system drives the chain wheels to rotate through the transmission chain, and the chain wheel set arranged on the shaft also rotates along with chain wheels. The double-pitch chain with the movable chain-hook, which is engaged with the chain wheel set, runs forwards along with the rotation of the chain wheel set, and a material carrier also runs forwards under the driving of the chain-hook. The movable chain-hook chain type conveyer has novel and scientific conception, delicate and compact structure, stable operation and reliable performance, greatly shortens the length of the chain type conveyer, reduces the power consumption of the chain type conveyer and provides powerful guarantees for the chain type conveyer.

Owner:SHENYANG HEAVY MACHINERY GROUP

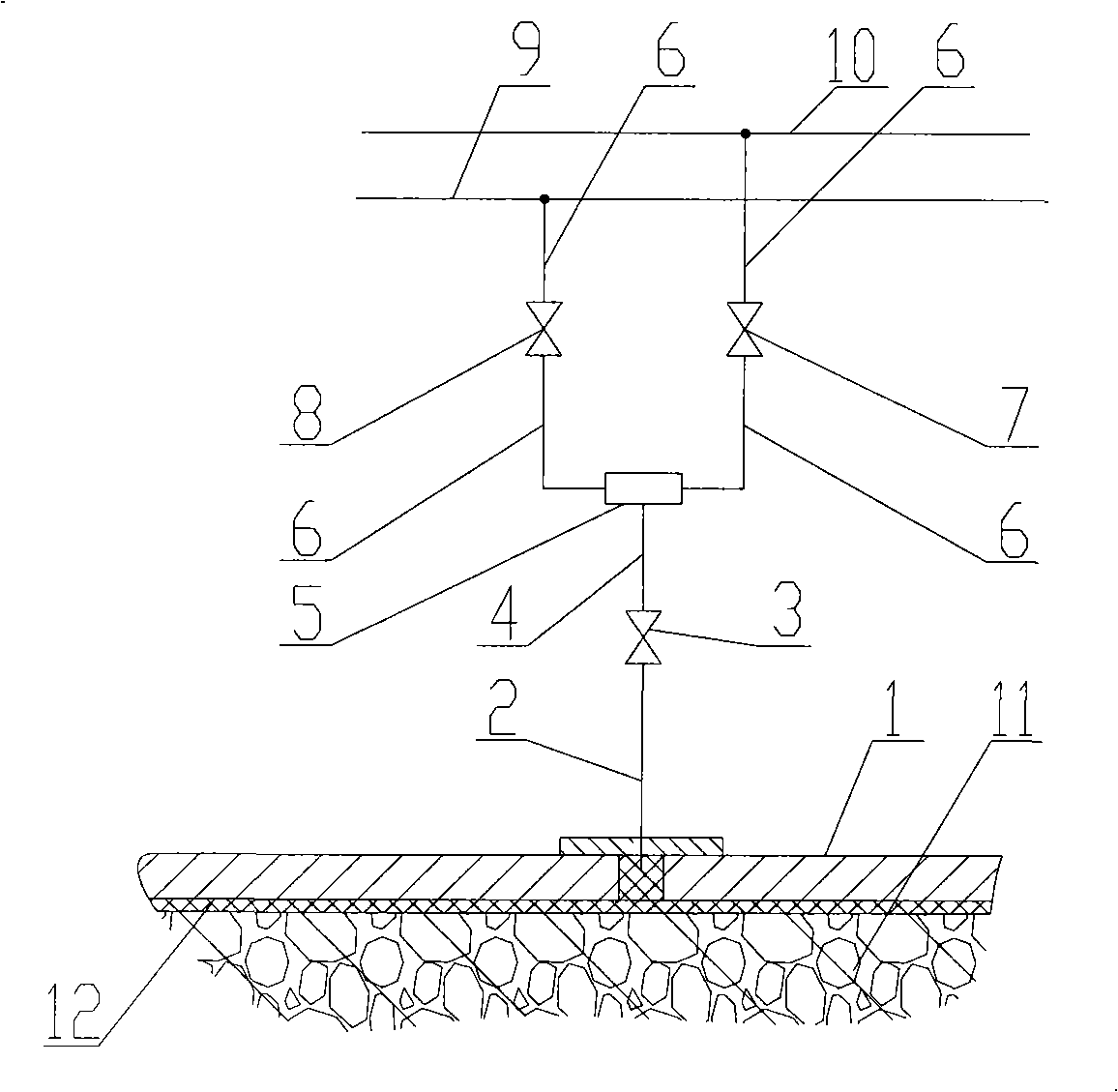

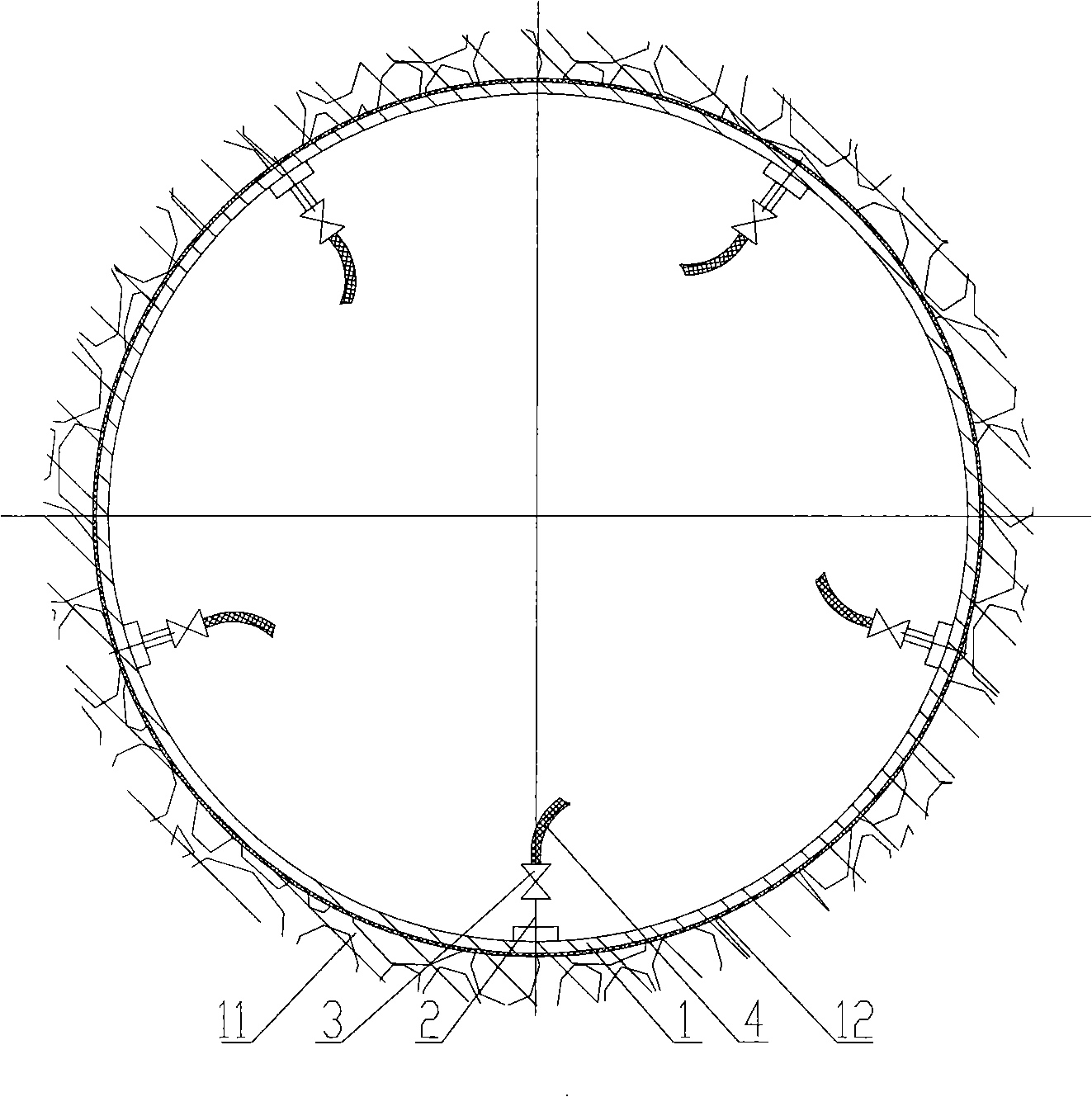

Apparatus for reducing friction resistance between shield machine shield body and tunneling wall

InactiveCN101298837AReduce frictional resistanceReduce sliding frictional resistanceTunnelsTunnel wallEngineering

A device for reducing the frictional resistance between the shield machine shield body and tunneling wall applied in the technical field of tunnel driving; the device comprises shield body, steel pipe, valve, lubricant pipeline, distributor, pipeline, first control valve, second control valve, foam system pipeline, bentonite slurry system pipeline, tunnel wall and lubricant; one end of the valve is connected with the steel pile welded in the inside of the shield body and communicated with the tunneling wall; the other end of connected with the lubricant pipeline; the lubricant pipeline is communicated with the foam system pipeline and bentonite slurry system pipeline of the shield machine through the distributor, pipeline, first control valve and second control valve; the steel pipe is communicated with the tunneling wall through the hole of the shield body; the lubricant is injected between the tunnel wall and the shield body; when needs to injecting the lubricant, the valve is opened to inject the lubricant between the shield body and the tunneling wall. The conception of the device is novel and scientific; the device for injecting the lubricant between the shield body and the tunneling wall is able to effectively reduce the sliding friction resistance between the shield body and tunneling wall.

Owner:SHENYANG HEAVY MACHINERY GROUP

Asphalt additive for cold repair of road surface

InactiveCN1810885AImprove road performanceImprove anti-aging propertiesIn situ pavingsBuilding insulationsPetroleum resinPolyamide

The asphalt additive material for cold repair of road surface consists of: styrene-butadiene-styreene block copolymer 2-5 weight portions, petroleum resin 1-3 weight portions, terpene resin 1-3 weight portions, polyamide 0.3-0.7 weight portions, N-cyclohexyl-Níõ-phenyl-phenylenediamine 0.3-0.7 weight portions, mineral oil 1-3 weight portions, styrene 3-7 weight portions, diesel oil 3-7 weight portions and asphalt 70-90 weight portions. It is prepared through mixing the materials at 170- 200 deg.c via high speed stirring for mutual reaction. The present invention has reasonable preparation process, and the asphalt additive material for cold repair of road surface has simple application, long storage period, high repair quality, wide use, environment friendship and low cost.

Owner:SHENYANG URBAN CONSTR ASPHALT CONCRETE FACTORY

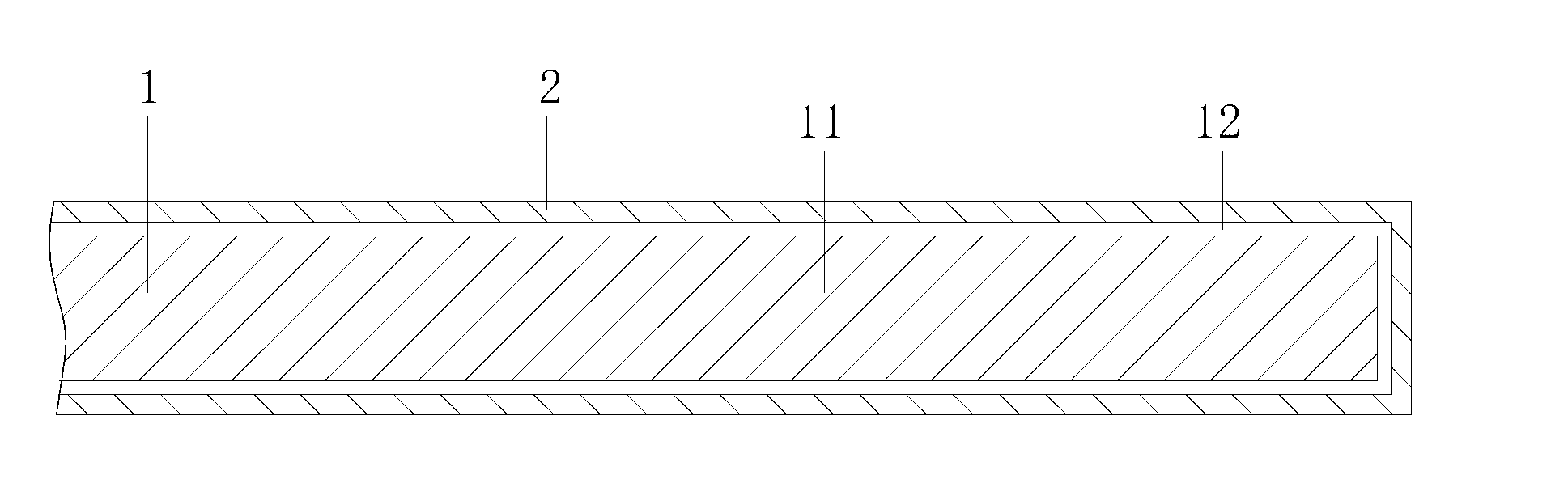

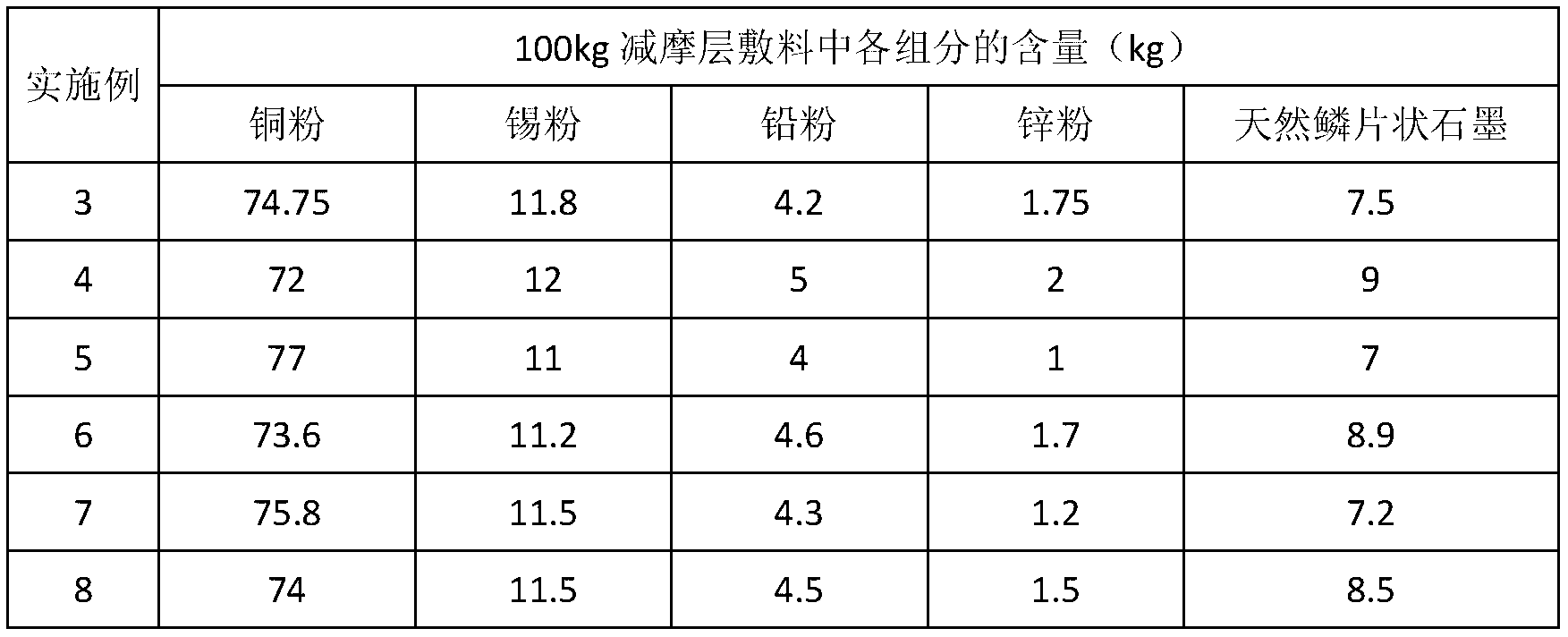

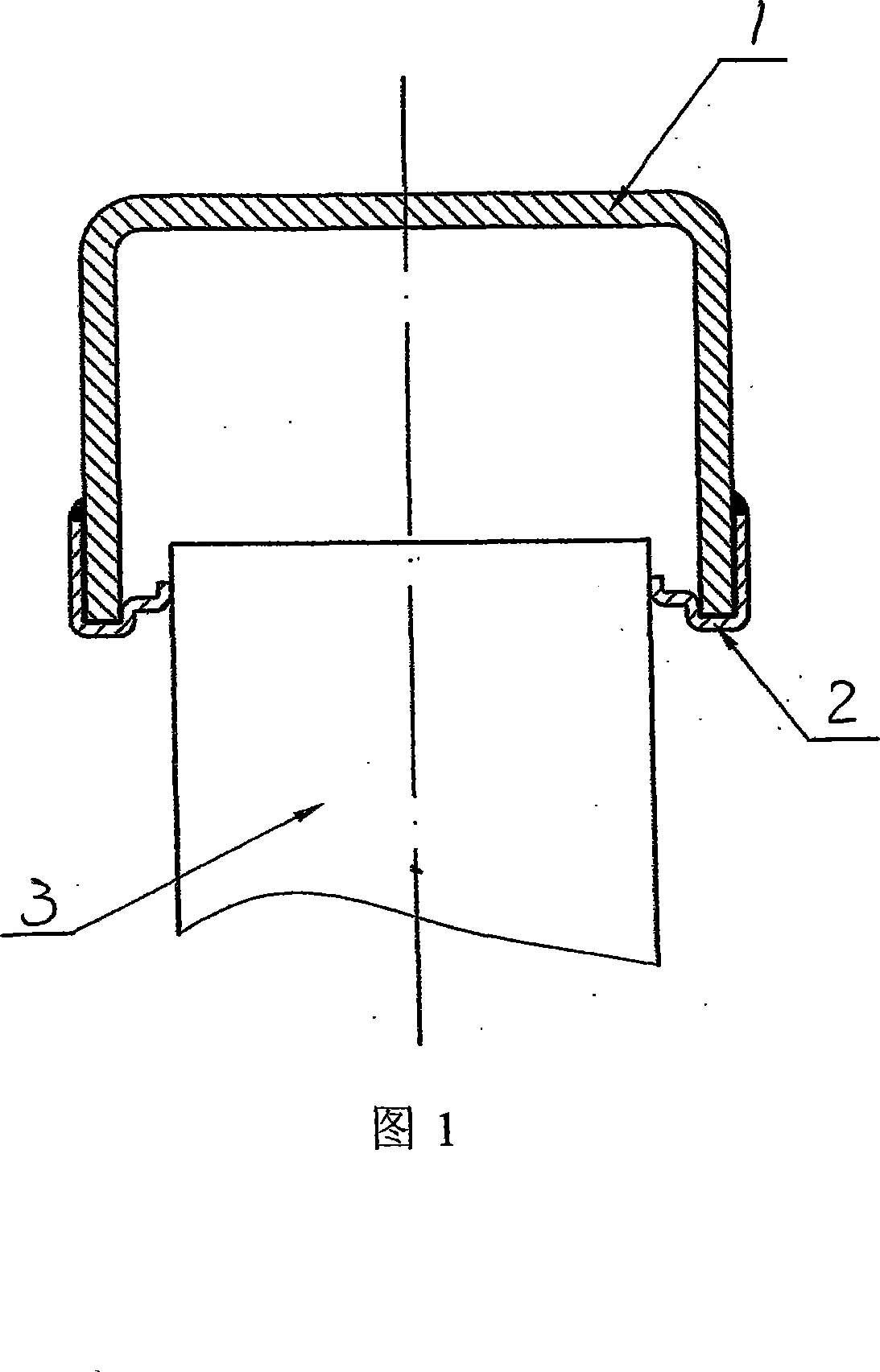

Long-service-life multi-face self-lubricating antifriction plate and manufacture method thereof

The invention relates to a long-service-life multi-face self-lubricating antifriction plate in rubber tire mould manufacture industries and a manufacture method thereof. The antifriction plate comprises a steel base plate and an antifriction layer dressing. The manufacture method comprises applying the antifriction layer coating on the surface of the base plate, placing the base plate in a sintering furnace protected by decomposition ammonia for sintering at the temperature in a range of 800 DEG C to 900 DEG C for 20 minutes to 30 minutes, performing cold rolling and annealing treatment, and sending the base plate into a finishing roller for rolling. A copper alloy coating with the thickness larger than or equal to 0.1mm is coated after the base plate is subjected to planning processing and sand blasting, and the antifriction dressing layer is formed by mixing and preparing, by weight, 72% to 77% of copper powder, 11% to 12% of tin powder, 4% to 5% of lead powder, 1% to 2% of zinc powder and 7% to 9% of natural flaky graphite. The multi-face self-lubricating antifriction plate manufactured through the method has the advantages of being low in frictional coefficient, high in antifriction performance, few in maintenance time, long in service life and the like.

Owner:沈阳思莱德模具有限公司

Manufacturing technique and products of adopting casted hydroecium radiator

InactiveCN101229604AMeet the needs of useEliminate long-term use aging failure problemsWelding/cutting auxillary devicesArc welding apparatusHeavy dutyControllability

The invention relates to a production technology adopting a casting water chamber radiator in technology field of the traffic conveyance and a product thereof, as well as a technique connecting a cast aluminum water box with a main leaf by an adopting argon-arc welding technique. The production process is that a cast aluminum water chamber is buckled at the inner edge of the main leaf of a core assembly and the upper part and the lower part of the cast aluminum water chamber is fixed with welding jigs in certain positions; 2-3 welding points exist between the cast aluminum water chamber and the main leaf; every weld length is 10mm to ensure the total size of the core assembly; workpieces are taken down after correcting and fixing the size of the assembly; a welding carried out is carried out for the long edge and the short edge of the main leaf respectively. The welding process is that AL-Si welding wires with Phi3.0 of diameter are adopted as welding rods. During the working process, AC welding arc with better controllability and aluminum alloy with a better carrying capability is adopted; the technological parameters needed to be controlled during welding are current, voltage and argon flow. The device of the invention is novel and scientific in design; the invention adopts the production technology in which the cast aluminum water chamber replaces an original plastic water chamber and argon-arc welding is used; therefore, the structural strength of product is obviously improved, thus meeting the using needs of heavy duty vehicles and motorbuses, having more reliable and stable sealing performance and reducing the production cost.

Owner:沈阳华铁异型材有限公司 +1

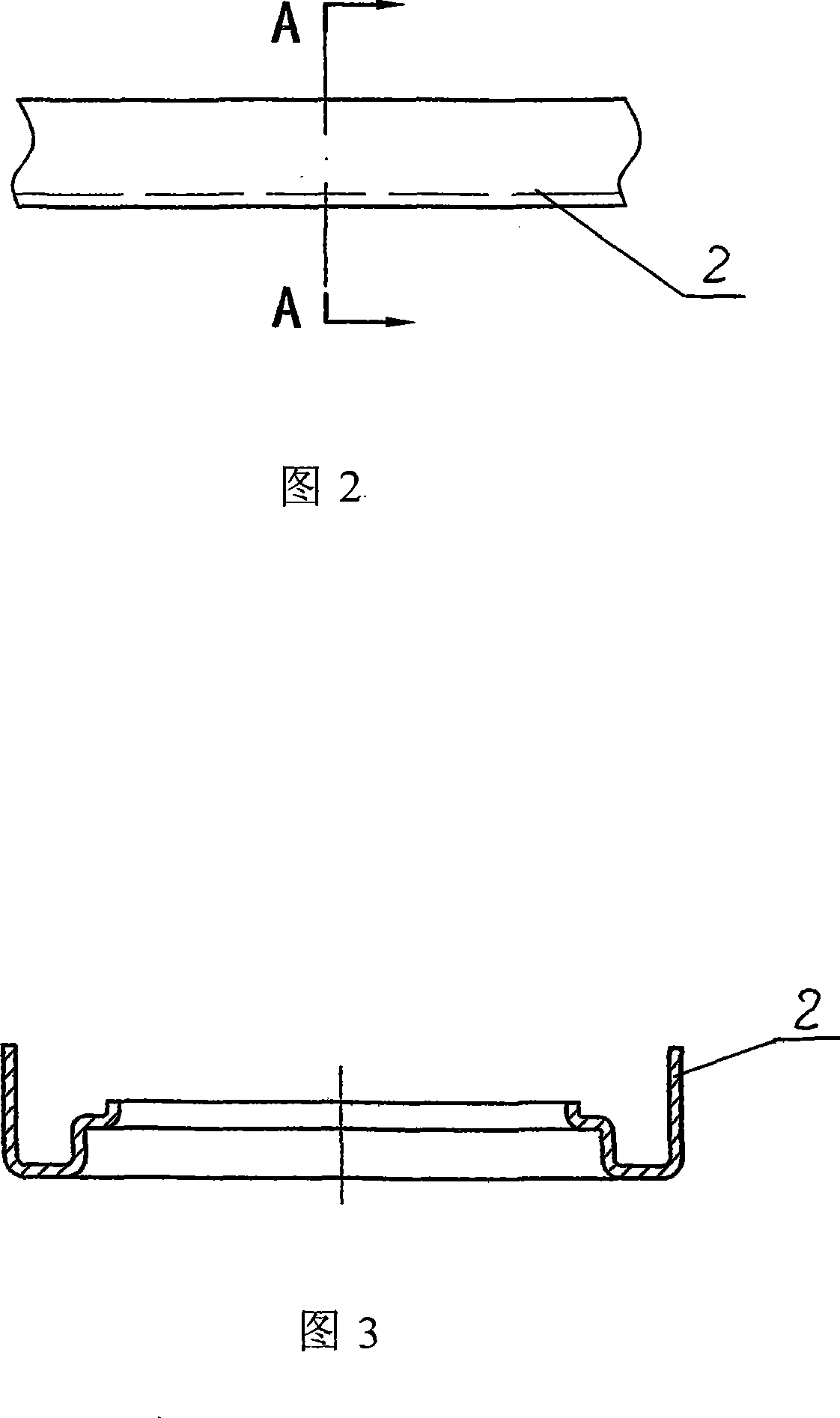

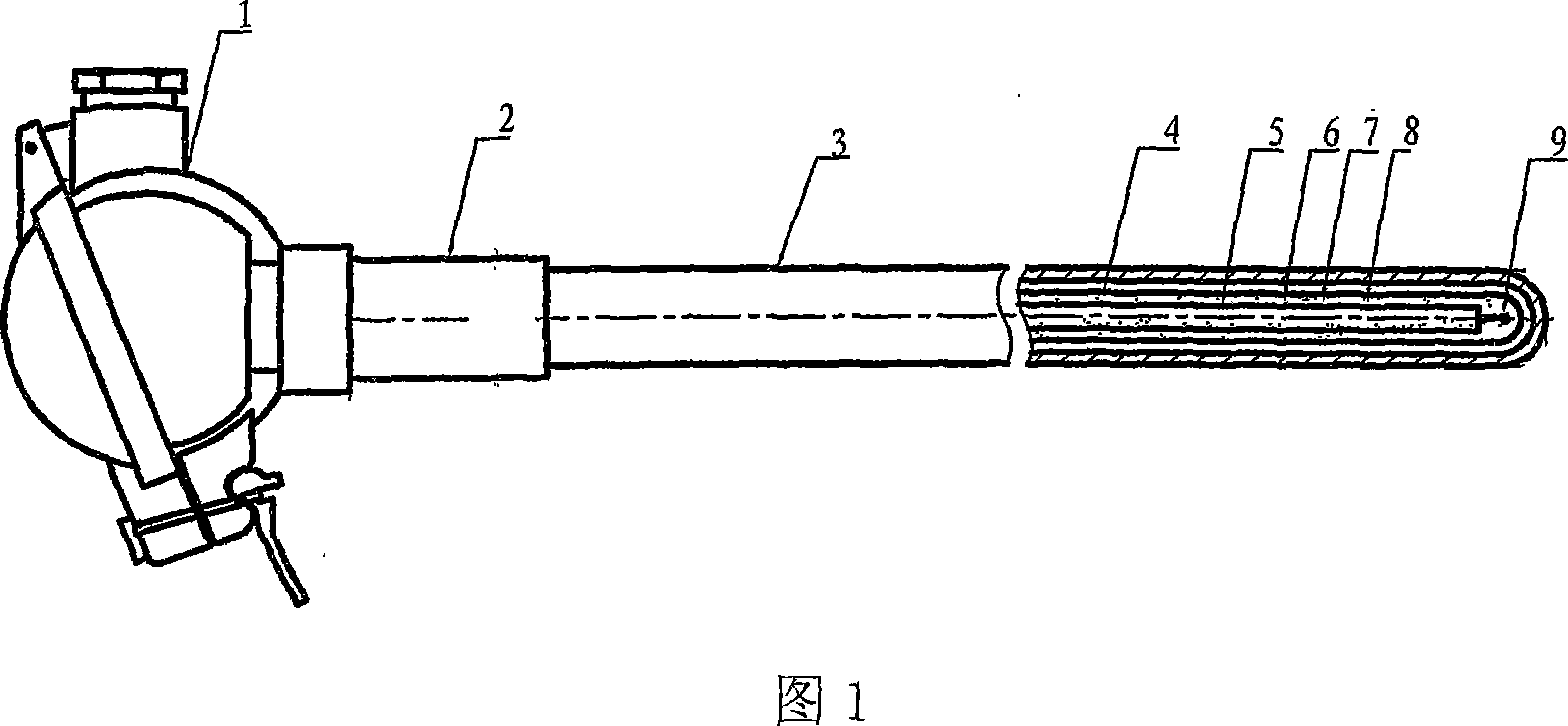

Thermocouple with temperature correcting and monitoring holes

InactiveCN101034017AIdea novel scienceSimple manufacturing processThermometers using electric/magnetic elementsUsing electrical meansMonitoring temperatureCermet

A kind of tungsten-rhenium thermocouple with regulating and monitoring tap, apply to measurement testing region. The invention is composed by junction box, protecting tube, regulating-monitoring tap, thermocouple, patch board. junction box connect with protecting tube, built thermocouple in protecting tube and connect with patch board of junction box internal. Protecting tube inside has regulating- monitoring tap, the tap position is at protecting tube center line; Protecting tube inside has regulating- monitoring tap, the tap position at one side of protecting tube; stuff protecting tube are metal, ceramics cermets; thermocouple are noble metal S, R, B; thermocouple are cheap metal K, E, N, J, T, C, D; thermocouple is single branch; Thermocouple is two branches. The invention obligate regulating- monitoring temperature hub in thermocouple, extraordinary convenience; because thermocouple's environment and condition is same, just insert gagged thermocouple into preformed hole to reach thermal balance, then can process regulating or monitoring to original system, thereby solve accuracy problem of scene's thermometric bumber.

Owner:沈阳东大传感技术有限公司

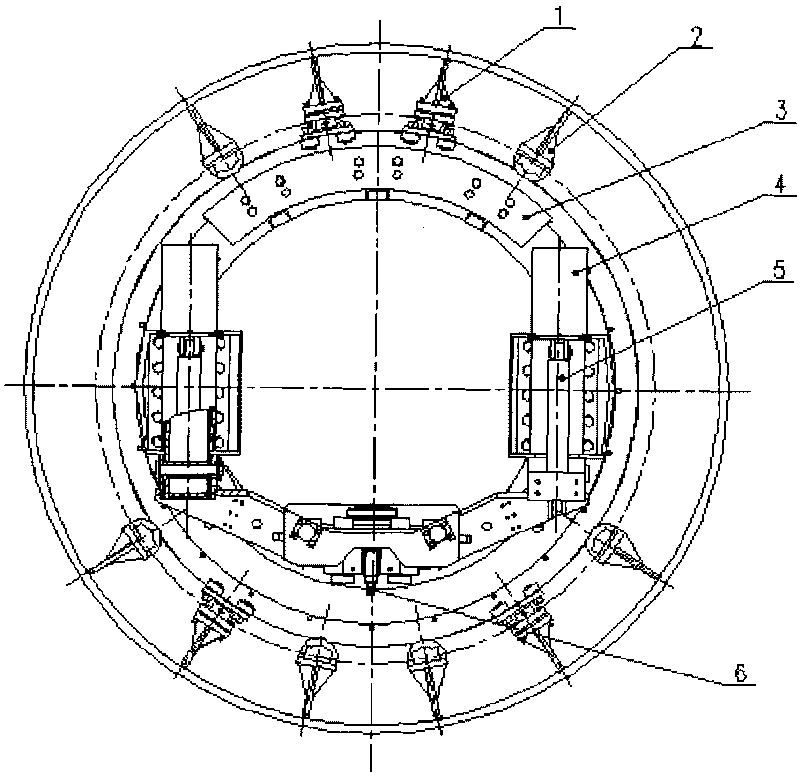

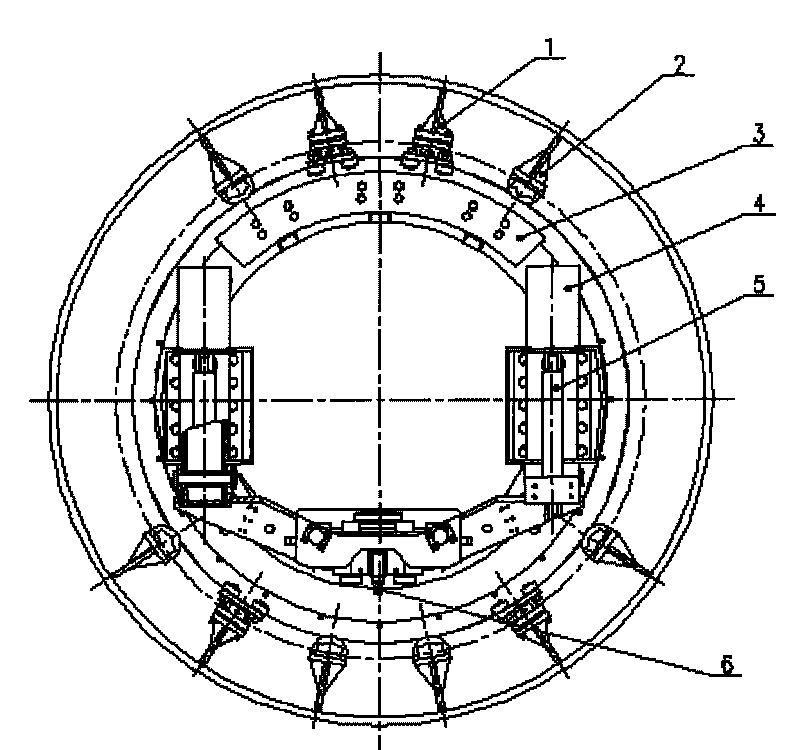

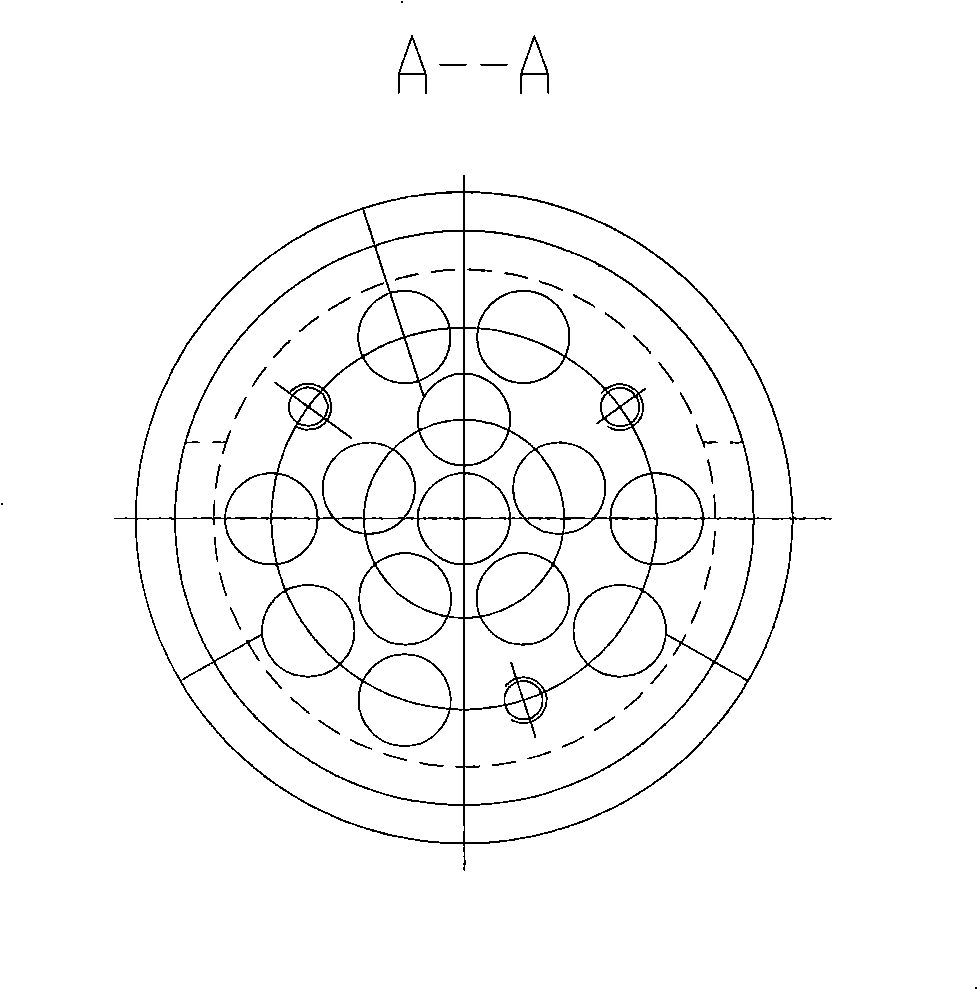

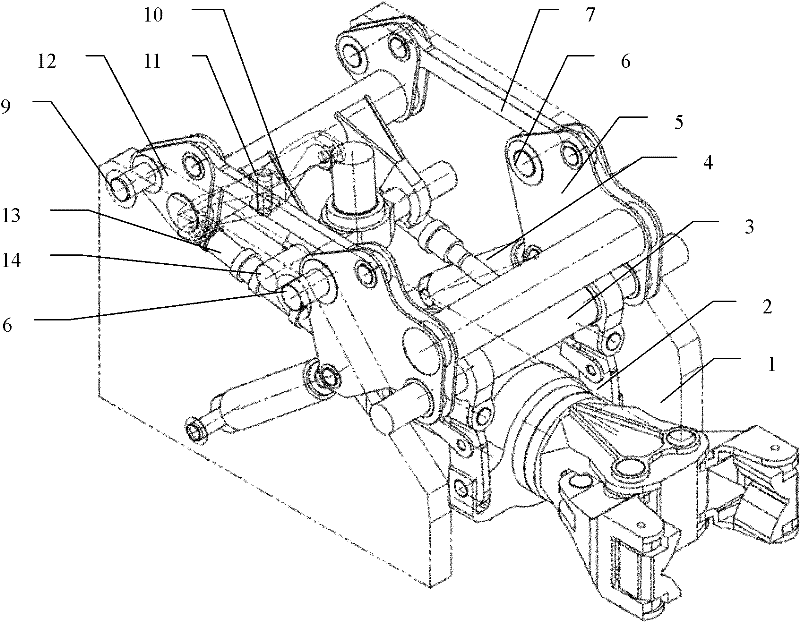

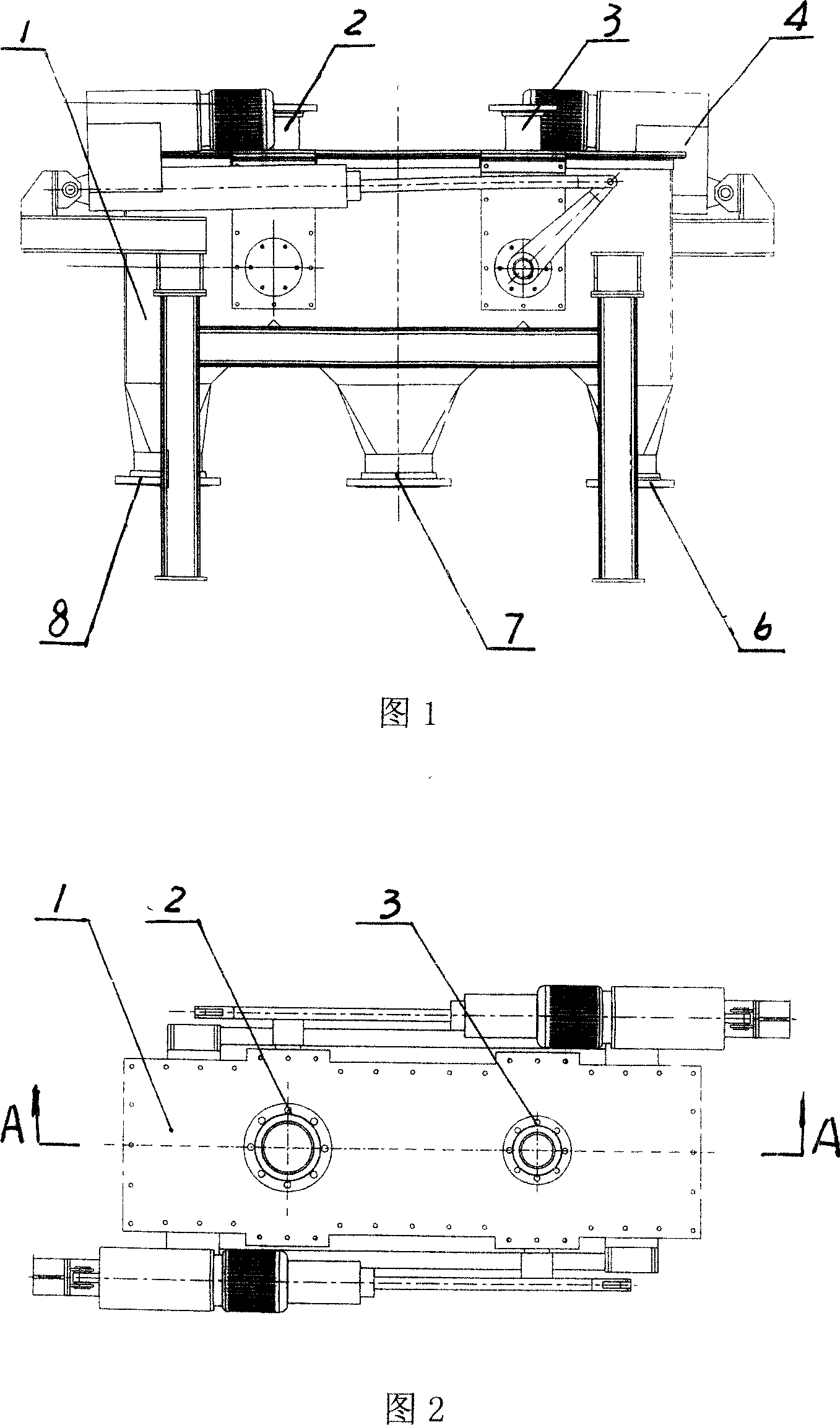

Segment assembly robot for miniature shield machine

InactiveCN101737062AIdea novel scienceCompact structureUnderground chambersTunnel liningEngineeringPinion

The invention provides a segment assembly robot for a miniature shield machine, which is applied to the shield machine industry. The robot comprises a guide wheel, a lifting guide rod, a lifting oil cylinder, a driving device, a translation oil cylinder, a horizontal guide rail, an oscillating oil cylinder and the like, wherein, the guide wheel and a thrust wheel are respectively welded on the inner wall of a shield body and also serve as a supporting track for the segment assembly robot to rotate along an X axis; the driving device is fixed on a shield body bracket, and a pinion in the driving device is meshed with a bull gear in a rotating ring; the cylinder body part of the lifting oil cylinder is connected with the lifting guide rod, the piston rod end of the lifting oil cylinder is connected with the horizontal guide rail through a mechanism, and a fixed end of the lifting guide rod is fixed on the rotating ring; a grabbing head is connected with a segment through a segment lifting pin; and four groups of fine adjustment oil cylinders are supported on four points of the segment to fix the segment. The device has unique and scientific conception and exquisite and compact structure, meets the special requirement of spatial arrangement structurally, provides sufficient installation space for related components such as a spiral conveyer and the like, and meets the precision requirements of various actions and positioning in each direction in the segment assembly process.

Owner:SHENYANG HEAVY MACHINERY GROUP

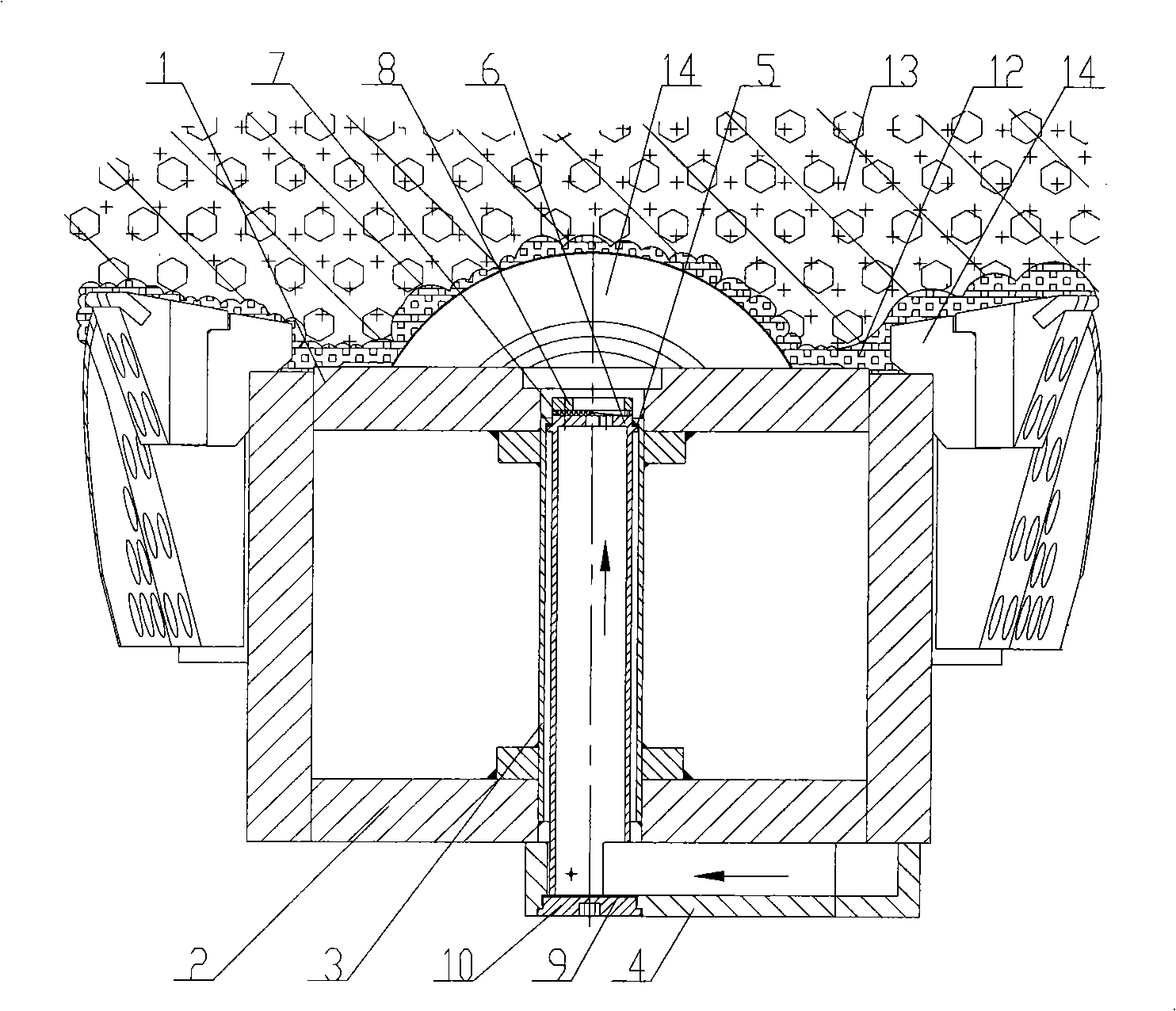

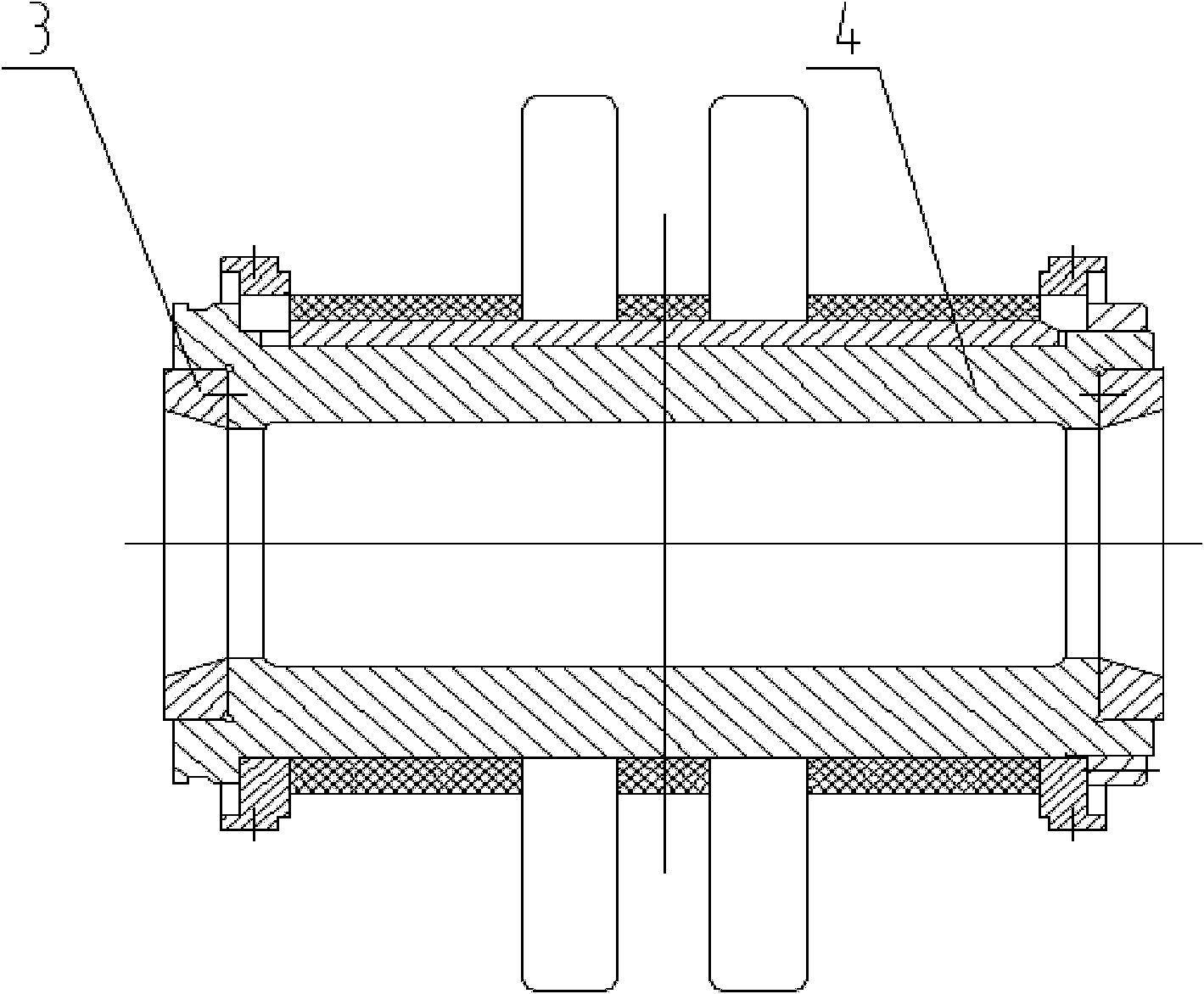

Soil pressure balance shield machine back loading type cutter head foam spraying device

A dorsal-loading-type cutter head foam injection device of soil pressure balance shield machine in the technical field of tunnel driving, the dorsal-loading-type cutter head foam injection device of soil pressure balance shield machine is composed of cutter head front panel, steel pipe with spigot flange at inner hole, cutter head back panel, foam pipeline box with sealing threaded hole, sealing ring, sleeve with foam nozzle end opening, diaphragm, flange, gasket, sealing fixed plug, screw, foam, excavation tunnel face and tool; the spigot flange end of the steel pipe with spigot flange at inner hole is connected with the cutter head front panel; the other end is connected with the cutter head back panel; the foam pipeline box with sealing threaded hole is connected with the cutter head back panel; when they are connected, the steel pipe with spigot flange at inner hole is concentric with the foam pipeline box with sealing threaded hole and is enclosed in the steel pipe with spigot flange at inner hole with the sealing ring; when assembles, the opening position of the sleeve with foam nozzle end opening is alignment to the hole of the foam pipeline box with sealing threaded hole. The conception of the device is novel and scientific and detaches at the back of the cutter head and is able to clean and maintain.

Owner:NORTHERN HEAVY IND GRP CO LTD

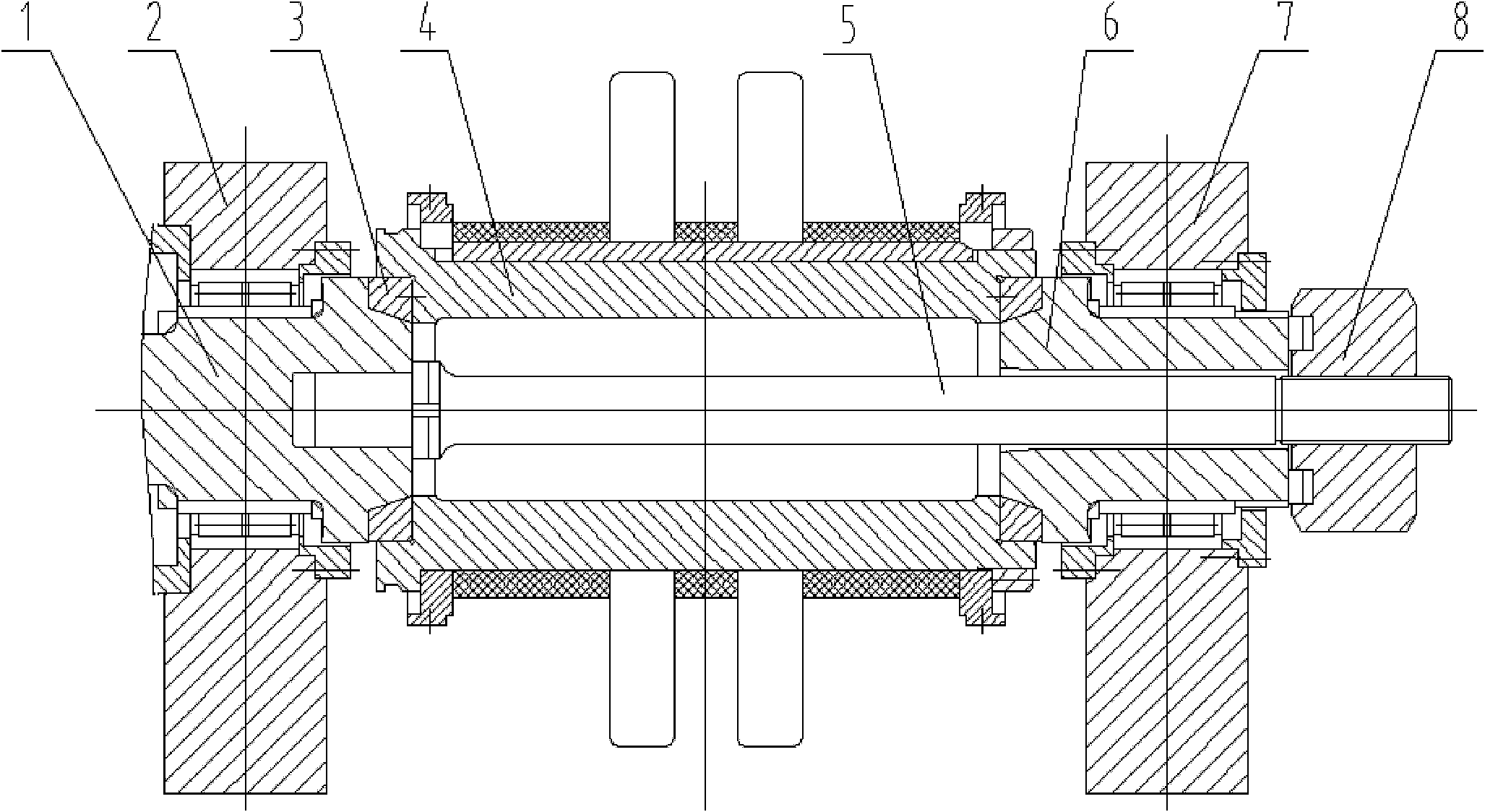

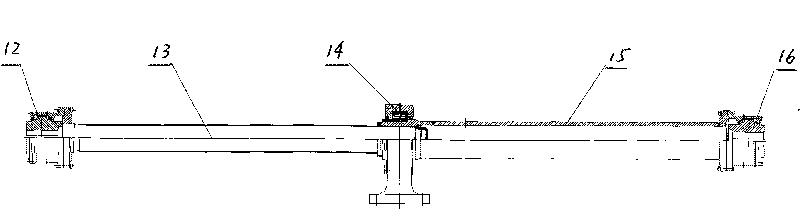

Simultaneous and quick aligning and locking device for multi-roll ring of section steel straightener

The invention relates to a simultaneous and quick aligning and locking device for a multi-roll ring of a section steel straightener applied in the metallurgical machinery industry. The device consists of a fixed side cone shaft, a fixed side bearing pedestal, cone hole rings, a combined roll ring, a roll shaft, a movable side cone shaft, a movable side bearing pedestal and a hydraulic nut, wherein the fixed side cone shaft is installed on the fixed side bearing pedestal, and the conical surface end of the fixed side cone shaft is in threaded connection with one end of the roll shaft; the other end of the roll shaft passes through the combined roll ring and the movable side cone shaft; the cone hole rings are screwed at two ends of the combined roll ring by bolts; the movable side cone shaft is installed on the movable side bearing pedestal; a cone hole and a guide device are arranged at the end part of the conical surface of the movable side cone shaft; the roll shaft can pass through the movable side cone shaft along the guide device to be connected with the hydraulic nut, so that the combined roll ring is clamped between the fixed side cone shaft and the movable side cone shaft; and the combined roll ring is aligned and quickly locked through the fixed side cone shaft and the movable side cone shaft. The device has novel and scientific concept, long service life and high hydraulic control precision, is convenient to adjust and disassemble and is stable and safe to run synchronously.

Owner:SHENYANG HEAVY MACHINERY GROUP

Airplane engine fuel oil total pipe bend filling and technique

InactiveCN101054506AStable performance of filling processImprove bending qualityOther chemical processesHollow article cleaningJet aeroplaneSodium bicarbonate

An airplane engine fuel manager bending filling and its craft in machinery manufacturing field are provided. The product preparing craft is correctly weighing material weight by proportion, adding the disodium hydrogen phosphate, trisodium phosphate, sodium bicarbonate by proportion into the material preparing vessel, fully mixing for two hours, adding stabiliser, seal preserving the prepared filling packing. The filling craft of the conduit product is weighing the fillings, enterring the working state after the filling melting achieves the controlling temperature, performing the conduit filling craft. The cleaning craft of the bending conduit product is putting the moulded conduit into the cleaning groove, emitting tap water, heating and stirring, controlling water temperature of 80-90 DEG C for 20-30 minutes, taking out conduit, discharging the water solution, repeating 5 times, taking out conduit and drying. The product and the craft is scientific and novel and has a low cost, a stability to the alloy conduit material non-erosion, alloy conduit bending filling easily being cleaned, and alloy conduit bending filling packing craft.

Owner:沈阳华铁异型材有限公司 +1

Method for treating domestic garbage by establishing bioreactor through earthworms

InactiveCN102247978AIdea novel scienceSolid waste disposalClimate change adaptationBiotechnologyEngineering

The invention relates to a method for treating domestic garbage by establishing a bioreactor through earthworms, which is applied to the field of domestic garbage treatment. A production method of the product comprises the following steps of: establishing the bioreactor according to the life habit of the earthworms, arranging 20,000 to 80,000 earthworms in each square meter of bioreactor, and culturing; sorting the domestic garbage, treating parts which can eaten by the earthworms, and mixing the domestic garbage, sludge and biological bacteria in a ratio to form an earthworm feed; putting 60 kilograms of prepared earthworm feed in each square meter of a culture bed of the earthworm bioreactor, and controlling the temperature of the earthworm feed on the culture bed to be between 15 and 25 DEG C, the humidity to be between 50 and 70 percent and the pH value to be between 6 and 8; and adding 60 kilograms of earthworm feed every other 6 to 10 hours, culturing for 50 to 60 days, and taking the mature earthworms out of the bioreactor. The earthworms are used for producing Chinese medicinal materials, health care products and agriculture, animal husbandry and fishery feeds, and earthworm excrement generated by the earthworms through metabolism is used for processing organic fertilizers. The method is novel and scientific in concept, a large-scale modernized earthworm bioreactor is established according to the life habit and growth characteristic of the earthworms, and the available parts of the earthworms are treated to form feeds for culturing the earthworms.

Owner:沈阳尊龙生物技术有限公司

Special type WRe temperature sensor

InactiveCN101034016AIdea novel scienceSuitable working environmentThermometer detailsThermometers using electric/magnetic elementsRheniumThermocouple Wire

A special WRe temperature sensor apply to temperature measuring region, composed by junction box, gripping tube, plumbago outer protecting tube, corundum inner tube, corundum insulating tube, antioxidant, hydride function stuff, stuffing, and tungsten- rhenium thermocouple. The structure: outer layer is special plumbago protecting tube; inner layer is alundum tube multiunit tube type oxidation protection WRe thermocouple. The invention can take temperature measurement under below 1600 degree, alcali molten erode and reducing atmosphere. fill antioxidant, hydride function stuff, stuffing into around of tungsten- rhenium thermocouple wire in corundum insulating tube inside of alundum tube inside; adopt stuffing at high temperatures release hydrogen gas on tungsten- rhenium thermocouple wire surface and powder particle interstice, and adopt organic- inorganic binder pressurize exactly, isolate contact between environment and tube insides, thereby to make thermometric condition for tungsten- rhenium thermocouple working.

Owner:沈阳东大传感技术有限公司

Plant fiber finished goods

The invention relates to a plant fiber product with wide application in articles for daily use, artware, finishing material and package article, which formula contains plant fiber, corn starch material, powder composite macromolecule material, additive and modifying agent. the preparation method comprises selecting materials, while the plant fiber contains at most 1% of soil, removing dote part, drying, breaking, selecting and determining the broken degrees according to demands, mixing materials via a high-speed mixer for at least 20min at 3000r / min uniformly, shaping at high pressure via a presser of 200t or more, wherein dishware, flower bowl, small package and artware need 50s of shaping time, two ventilations of 1-2s each time, and the shaping machine works at 145-210 DEG C, the product mould is made from high-strength speical steel, product is glazed, colored, edged, disinfected and packed germ-free. The product has better glossness, strength and flexibility, which is hard to break, crack and deform, with better waterproof, oil-proof and fungus-proof properties and wide application.

Owner:辽宁新加源环保科技有限公司

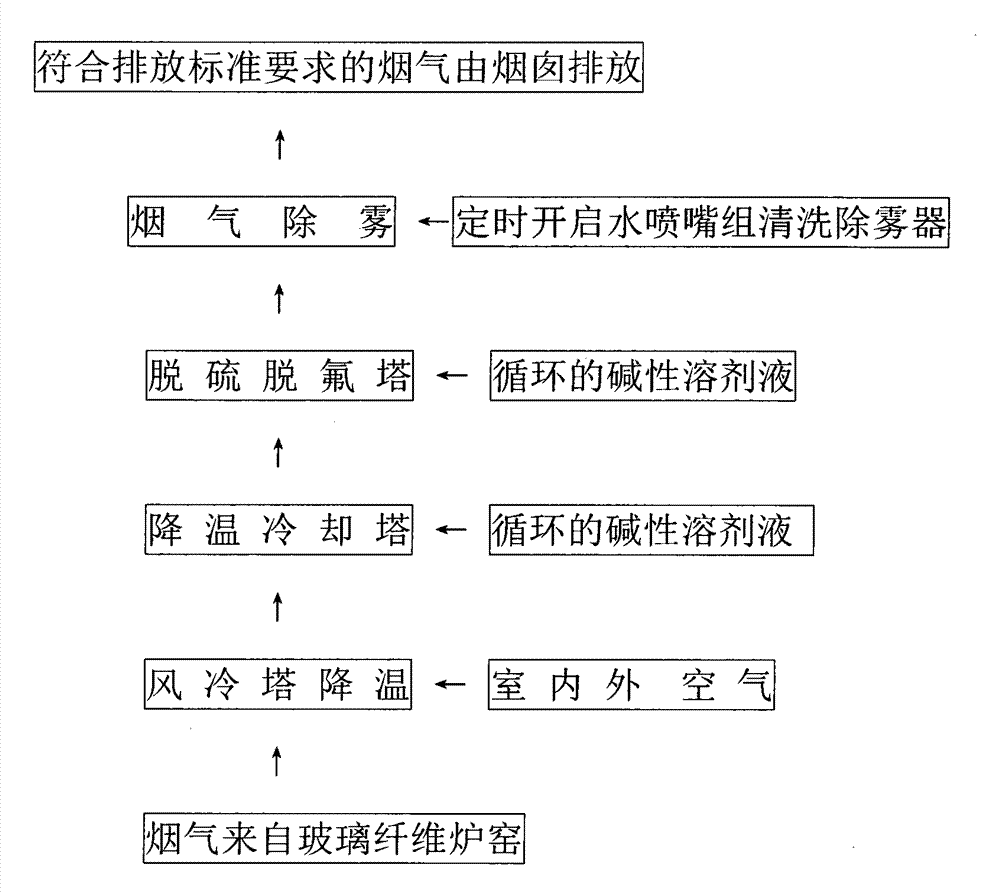

Glass fiber furnace kiln waste gas desulfurization device with turbo-charging turbulator and process

InactiveCN104841263APromote mutual mixingFull chemical reactionDispersed particle separationGlass fiberEngineering

The invention discloses a glass fiber furnace kiln waste gas desulfurization device with a turbo-charging turbulator, and a process, belonging to the technical field of environment protection. According to the glass fiber furnace kiln waste gas desulfurization device, a furnace kiln fume tube and an air supplement valve, an air cooling tower and a cooling tower, the cooling tower and a desulfurization tower are fixed by using pipelines; the furnace kiln fume tube is fixed with the air cooling tower, and the cooling tower is fixed with an atomization nozzle group; the cooling tower and a receiving tank are fixed with a pipeline inserting into a circulation tank; the inner wall of the desulfurization tower is fixed with a water nozzle group, a desulfurization nozzle group, the turbo-charging turbulator and the receiving tank in sequence; a stirrer is arranged inside the circulation tank; the circulation tank is fixed with a desulfurization pump as well as an atomization pump by pipelines; the desulfurization pump is fixed with the desulfurization nozzle group by a pipeline, and the atomization is fixed with and the atomization nozzle group by a pipeline; the desulfurization tower is fixed with a secondary tower flue by a pipeline, the secondary tower flue is fixed with a draft fan by a pipeline, the draft fan is fixed with a chimney by a pipeline, and the circulation tank is fixed with a blow-down valve by a pipeline. The process comprises the steps that fume is subjected to air cooling, temperature reduction, desulfurization, defluorination, demisting and discharge and the liquid is refluxed, the overall operation is organic, automatic and continuous, and thus sewage can be discharged in appropriate time. The glass fiber furnace kiln waste gas desulfurization device is applied to fume desulfurization and defluorination. The device is smart and simple in process, and stable in effect.

Owner:刘启杰

Asphalt additive for cold repair of road surface

InactiveCN100386386CImprove road performanceImprove anti-aging propertiesIn situ pavingsBuilding insulationsPolyamideRoad surface

Owner:SHENYANG URBAN CONSTR ASPHALT CONCRETE FACTORY

Claw beam lifting mechanism for forging manipulator

InactiveCN102019340BHigh movement precisionGuaranteed motion accuracyForging/hammering/pressing machinesVehicle frameRange of motion

Owner:SHENYANG HEAVY MACHINERY GROUP

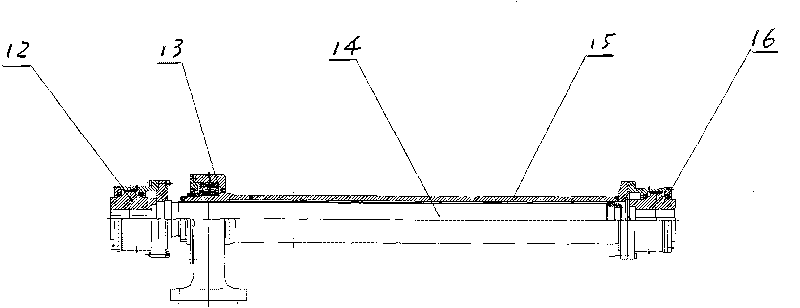

Mechanical synchronizer for main driving motor of disc shear

InactiveCN101702605AImprove cutting accuracyExtended service lifeElectric motor speed/torque regulationCouplingSynchronous control

The invention provides a mechanical synchronizer for the main driving motor of a disc shear, applied to the metallurgical machinery industry. The overall mechanical synchronizer comprises a shear body, a main driving reducer, a main driving motor, a first crown gear coupling, a fixed-side rigid synchronizing shaft, a second crown gear coupling, a spline shaft, a spline housing and a third crown gear coupling, wherein the other end of the fixed-side rigid synchronizing shaft is connected with the third crown gear coupling; the output end of a moving-side cycloidal pinwheel reducer is connected with the second crown gear coupling; the second crown gear coupling is connected with the spline shaft, a middle supporting seat, the spline housing and the third crown gear coupling; the middle supporting seat adopts rolling bearings to support the spline housing; a guiding device which can be extracted or retracted in the spline housing is arranged at the head part of the spline shaft. The mechanical synchronizer has the advantages of novel and scientific design, convenient adjustment, assembly and disassembly, stable and safe synchronous operation, long service life, high motor synchronous control accuracy and high shearing precision of disc shear.

Owner:SHENYANG HEAVY MACHINERY GROUP

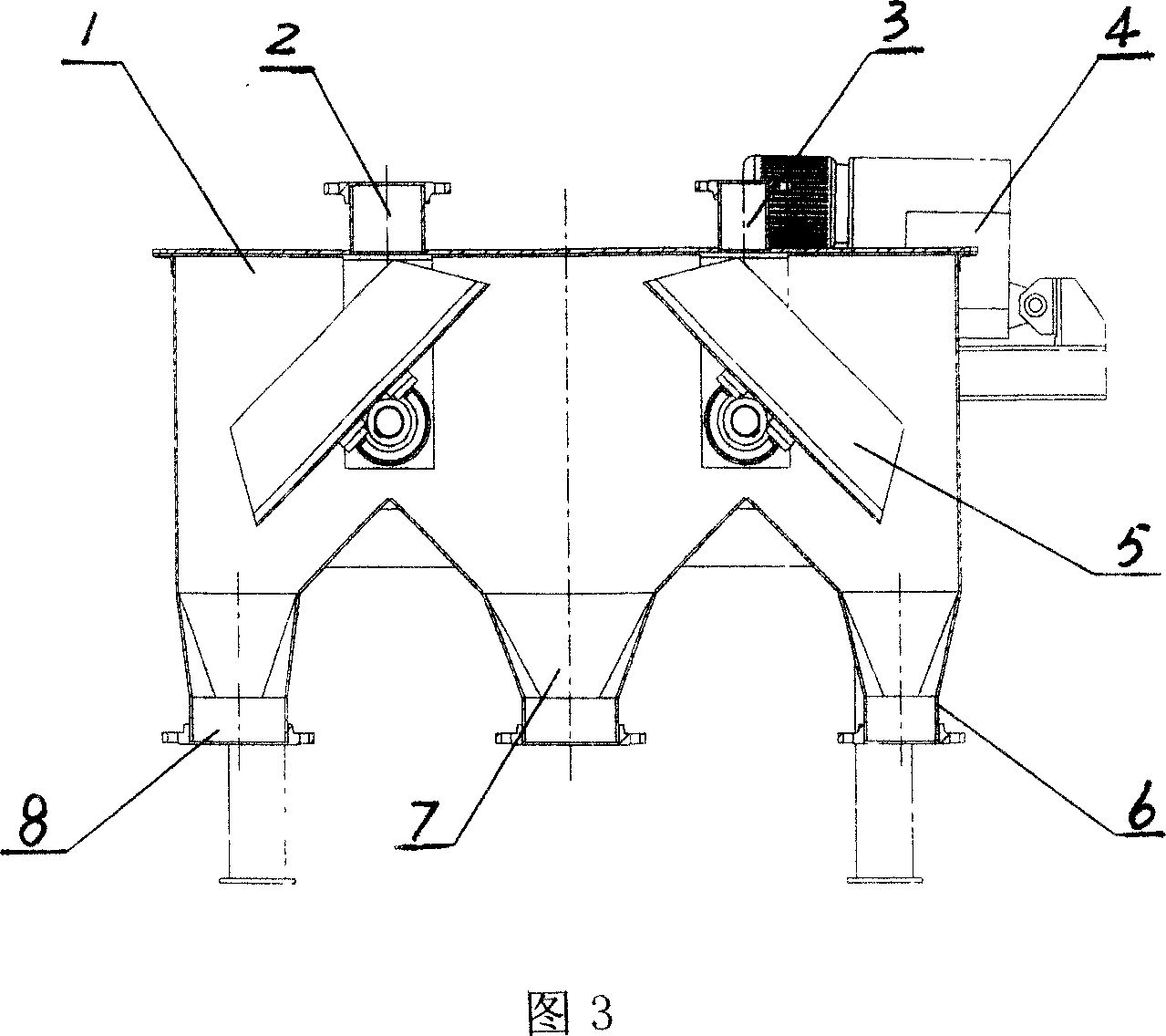

Serous fluid distributor

InactiveCN101012892AIdea novel scienceSimple manufacturing processDispersed particle separationMultiple way valvesAutomatic controlEngineering

A slurry distributor used in electric industry comprises a box, a first flange, a second flange, an electric executor, a turnover plate, a third flange, a fourth flange, and a fifth flange. The third, fourth and fifth flanges are arranged under the box. The operation comprises that the electric executor controls the turnover plate to feed the slurry to the liquid pot of the desulfuration tower, the inlet of abrading machine and the circulator. The first and second flanges above the box are connected to the flanges of slurry separator. The box is mounted with two inner turnover plates, to change the direction of slurry. The executor via the pressure and density signals of checker controls the turnover plates, to realize automation. The invention has simple structure and easy control.

Owner:SHENYANG HEAVY MACHINERY GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com