Thermocouple with temperature correcting and monitoring holes

A technology for thermocouples and calibration systems, applied in thermometer testing/calibration, thermometers, heat measurement, etc., can solve problems such as not providing temperature measuring holes, unable to achieve calibration or monitoring, and difficult to fully comply with the environment and conditions of the temperature measuring system, etc. Achieve the effect of novel and scientific conception, easy process manufacturing, and accuracy problem solving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

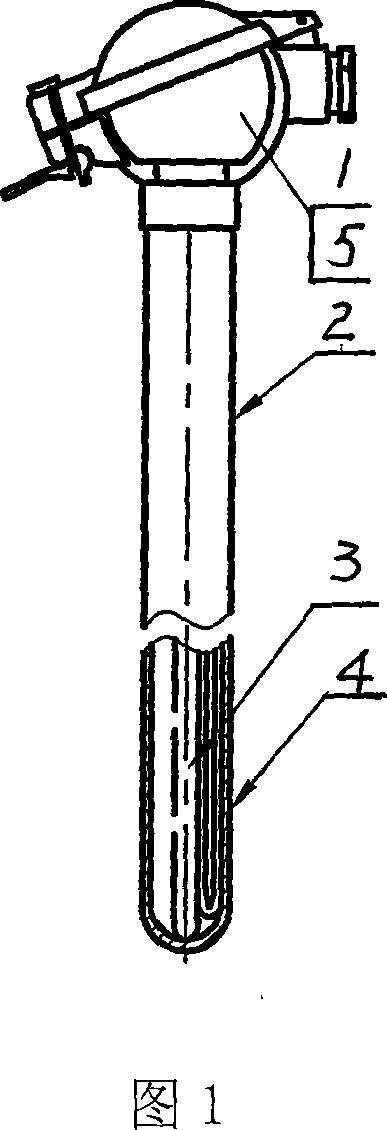

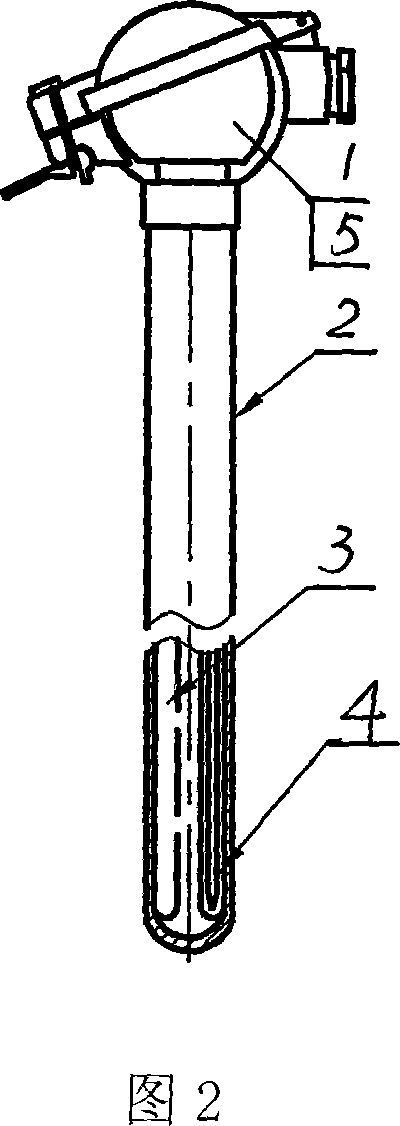

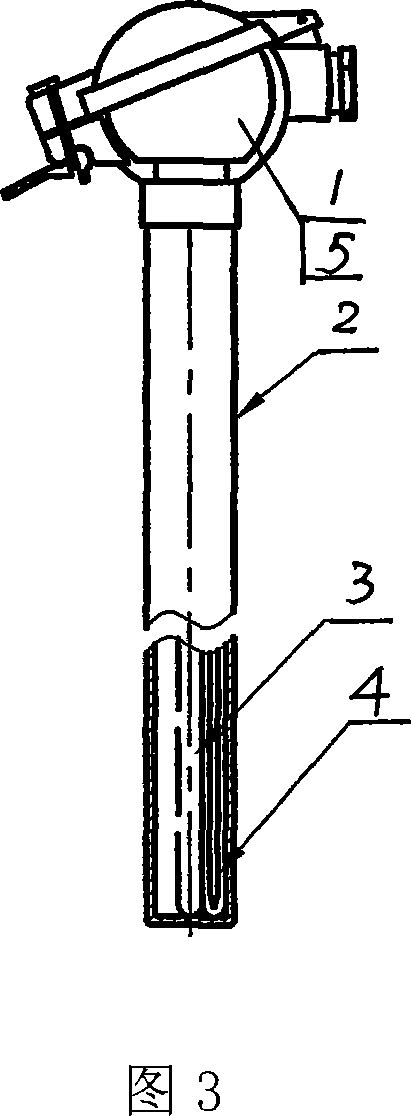

[0018] Thermocouple with temperature calibration and monitoring holes, composed of junction box 1, protection tube 2, calibration and monitoring hole 3, thermocouple 4, terminal board 5, junction box 1 is connected with protection tube 2, and thermoelectricity is installed in protection tube 2 The pair 4 is also connected to the wiring board 5 in the junction box 1, and there is a hole 3 for calibration and monitoring in the protection tube 2, and the position of the hole is on the center line of the protection tube 2; there is a hole 3 for calibration and monitoring in the protection tube 2 , the position of the hole is on one side of the protection tube 2; the material of the protection tube 2 is metal; the material of the protection tube 2 is ceramic; the material of the protection tube 2 is cermet; the thermocouple 4 is precious metal S, R, B; Metal K, E, N, J, T, C, D; thermocouple 4 is a single piece; When the on-site temperature measurement system performs online calibr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com