Serous fluid distributor

A distributor and slurry technology, applied in the field of slurry distribution devices, can solve the problems of difficult sulfur dioxide emissions, large differences, and small capacity of a single machine, etc., and achieve the effects of easy process manufacturing, novel and scientific conception, and convenient control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

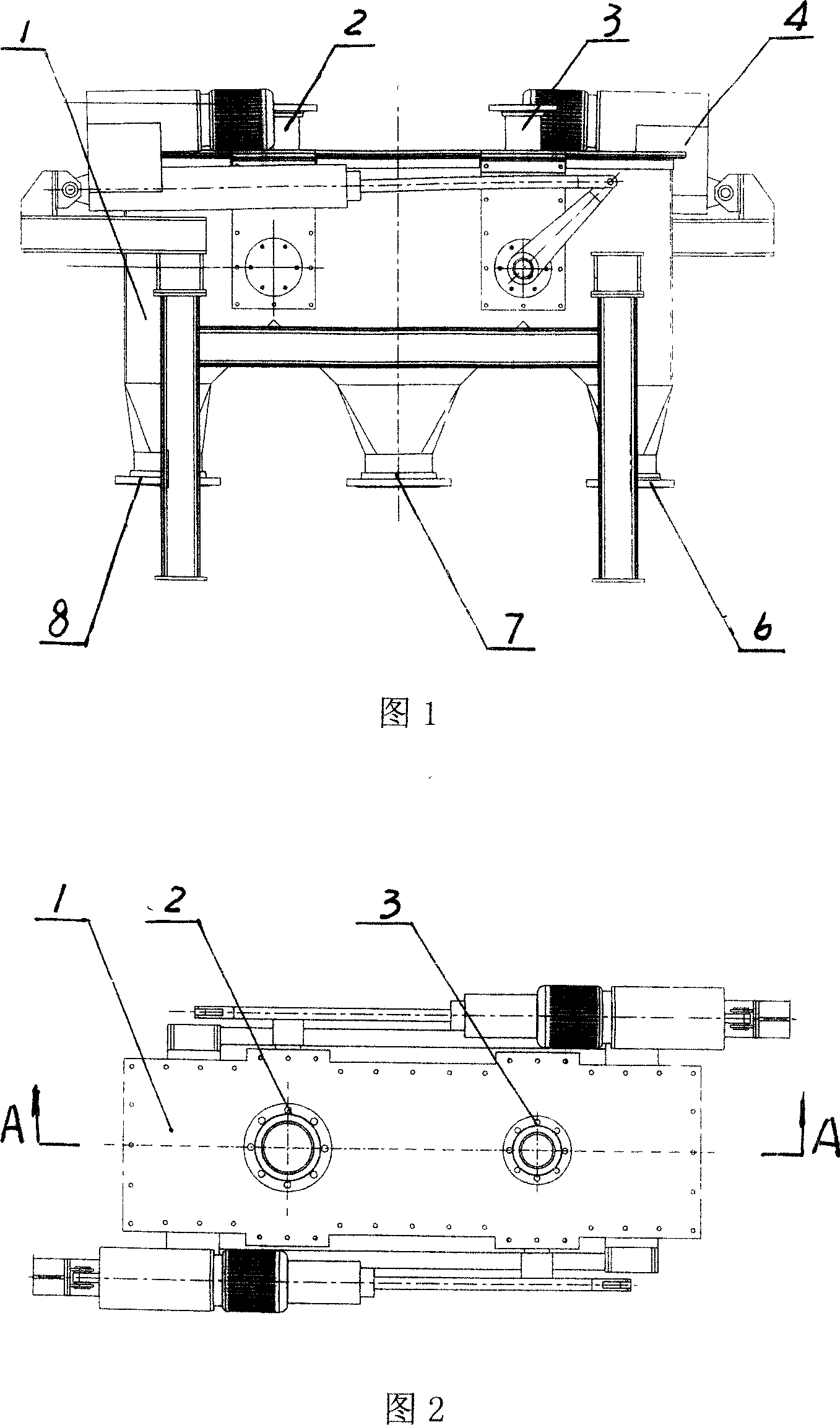

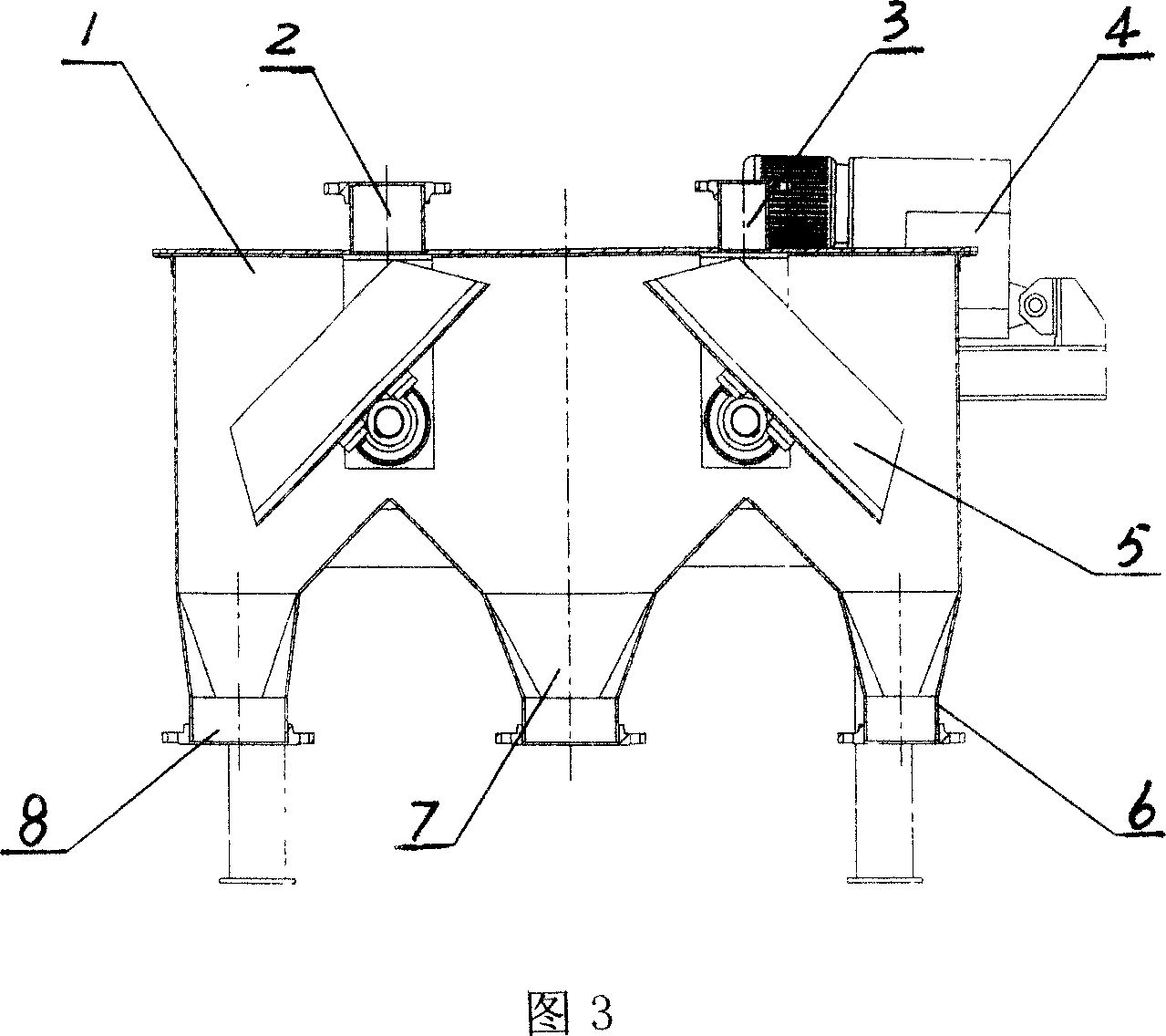

[0012] The slurry distributor is composed of a box body 1, a first flange 2, a second flange 3, an electric actuator 4, a flap device 5, a third flange 6, a fourth flange 7, and a fifth flange 8. The first flange 2 and the second flange 3 are arranged on the upper side of the box body 1, electric actuators 4 are respectively installed on both sides of the upper side of the box body 1, two flap devices 5 are installed in the box body 1, and a The third flange 6 , the fourth flange 7 , and the fifth flange 8 . The operation mode of the slurry distributor is to control the action of the turnover device 5 through the electric actuator 4, and send the slurry to the liquid storage tank of the desulfurization tower, the entrance of the mill and the recirculation device, and the first flange 2 above the box body 1 and the second flange 3 are respectively connected to the corresponding flanges of the slurry separation device. Two flap devices 5 are installed in the box body 1. Accordin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com