Manufacturing technique and products of adopting casted hydroecium radiator

A production process and radiator technology, applied in manufacturing tools, heat exchanger shells, heat exchange equipment, etc., can solve the problems of anti-vibration, low anti-pulse pressure performance, unsatisfactory press-fit bonding strength, and large radiator volume , to achieve the effect of eliminating long-term use aging failure problems, simplifying the production process, and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

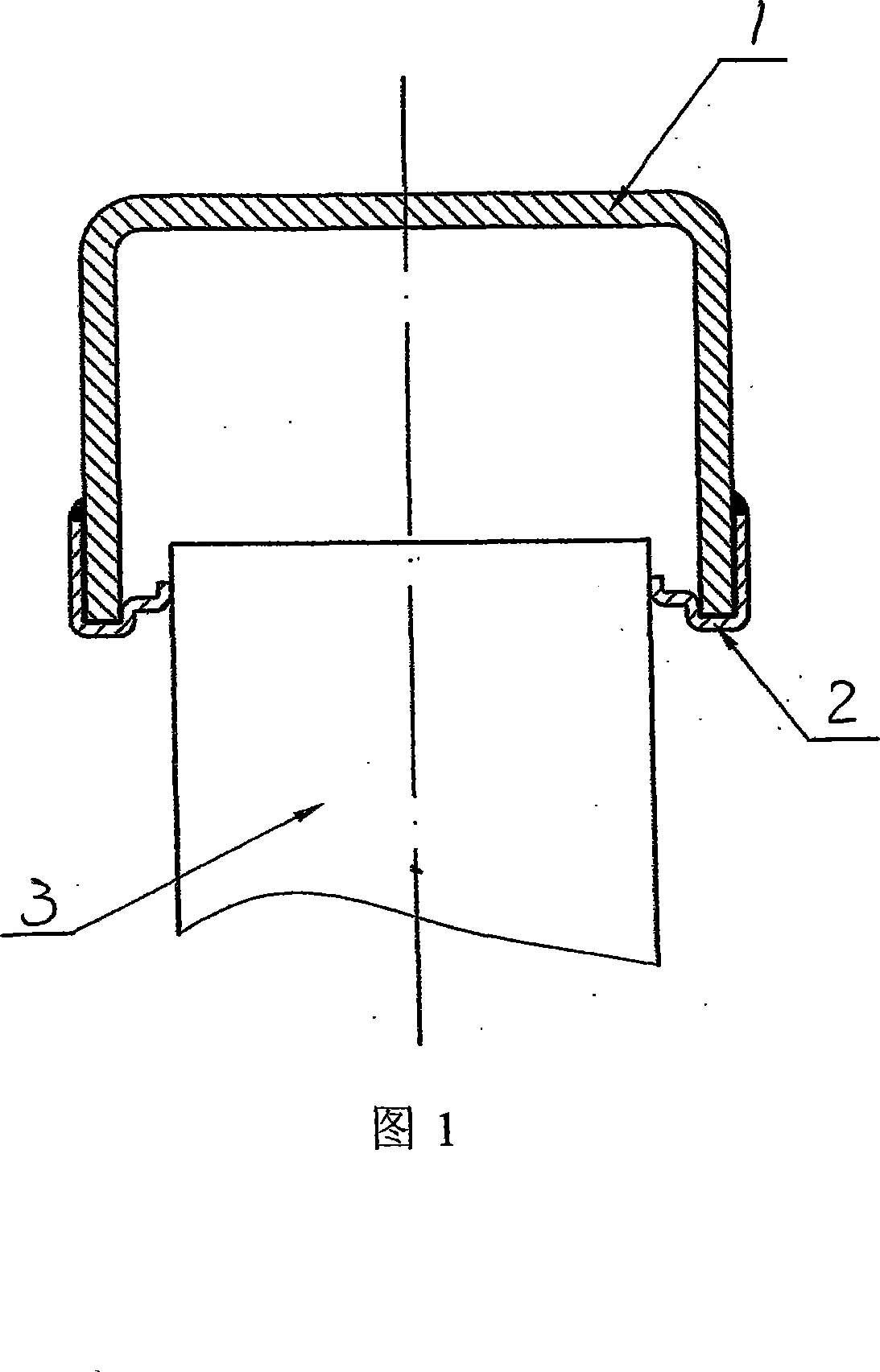

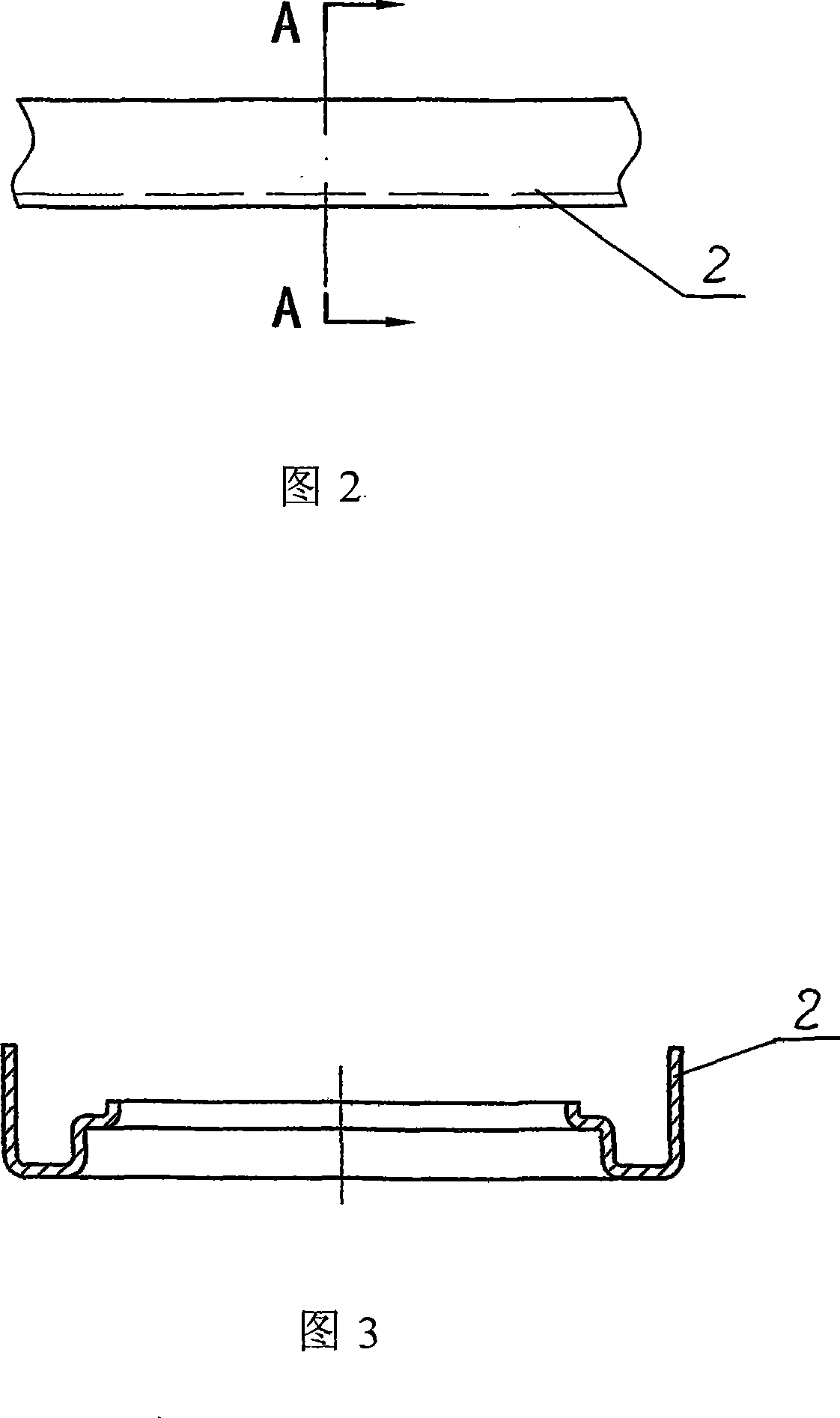

[0011] Referring to the accompanying drawings, adopt the production process of the cast water chamber radiator, and use the argon arc welding process to connect the cast aluminum water chamber 1 and the main piece 2. The production process is as follows: buckle the cast aluminum water chamber 1 on the core The inner edge of the main piece 2 of the assembly 3, and use the welding fixture to position the upper and lower water chambers to ensure the assembly size requirements, and then manually correct the matching gap between the inner edge of the main piece 2 and the cast aluminum water chamber 1 to ensure the fit to meet the welding needs. After sizing, there are 2-3 points at the welding place between the cast aluminum water chamber 1 and the main piece 2, and the length of each welding is 10mm to ensure the size of the assembly. 2 The long side and the short side are welded. The welding process is that the welding rod adopts AL-Si welding wire with a diameter of Φ3.0. The pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com