Patents

Literature

208 results about "Crown gear" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A crown gear (or a contrate gear) is a gear which has teeth that project at right angles to the face of the wheel. In particular, a crown gear is a type of bevel gear where the pitch cone angle is 90 degrees. A pitch cone of any other angle is simply called a bevel gear. Crown gears normally mesh with other bevel gears, or sometimes spur gears, a typical use being a crown gear and pinion system which allows a rotary motion to be shifted 90 degrees.

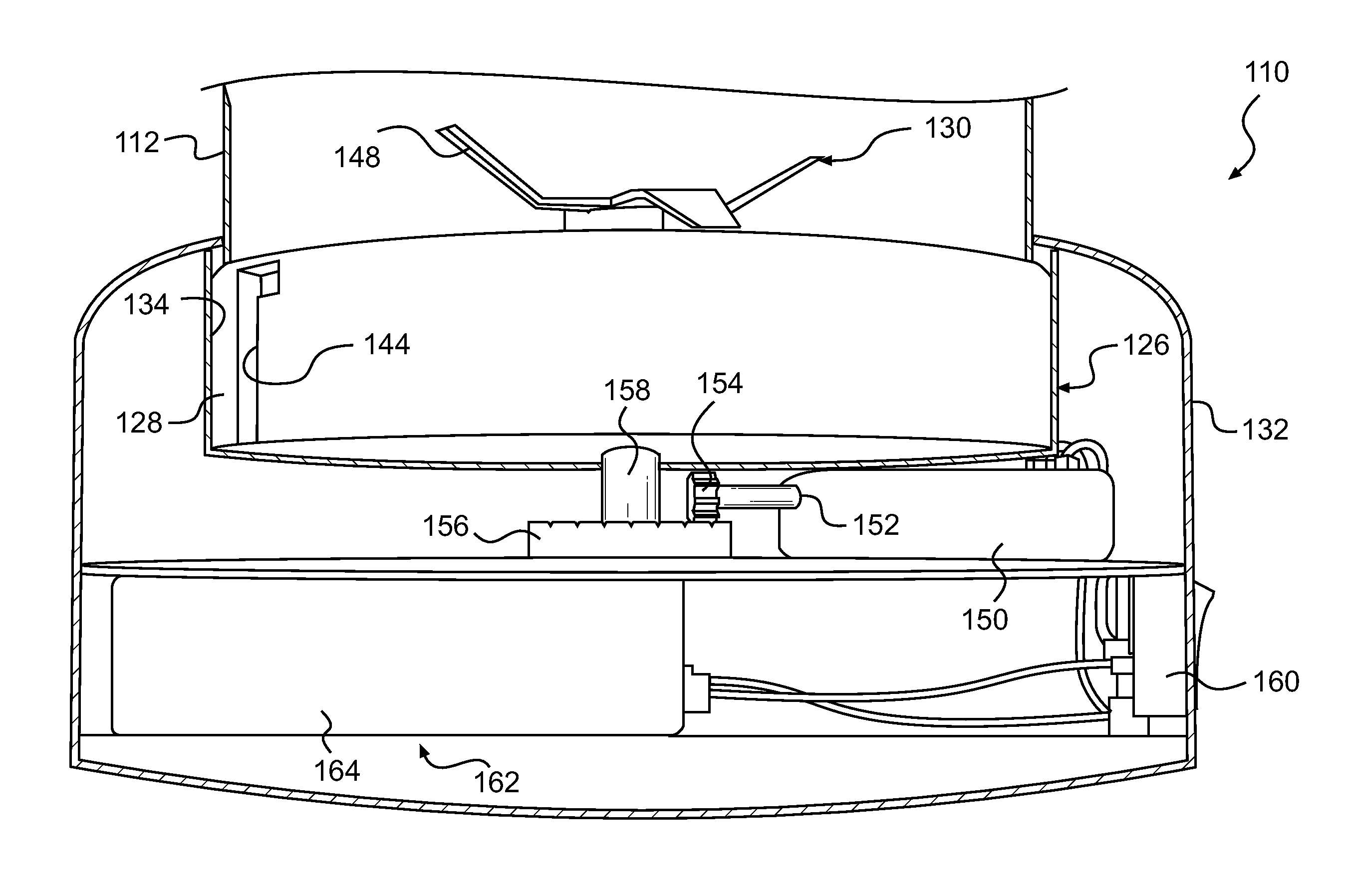

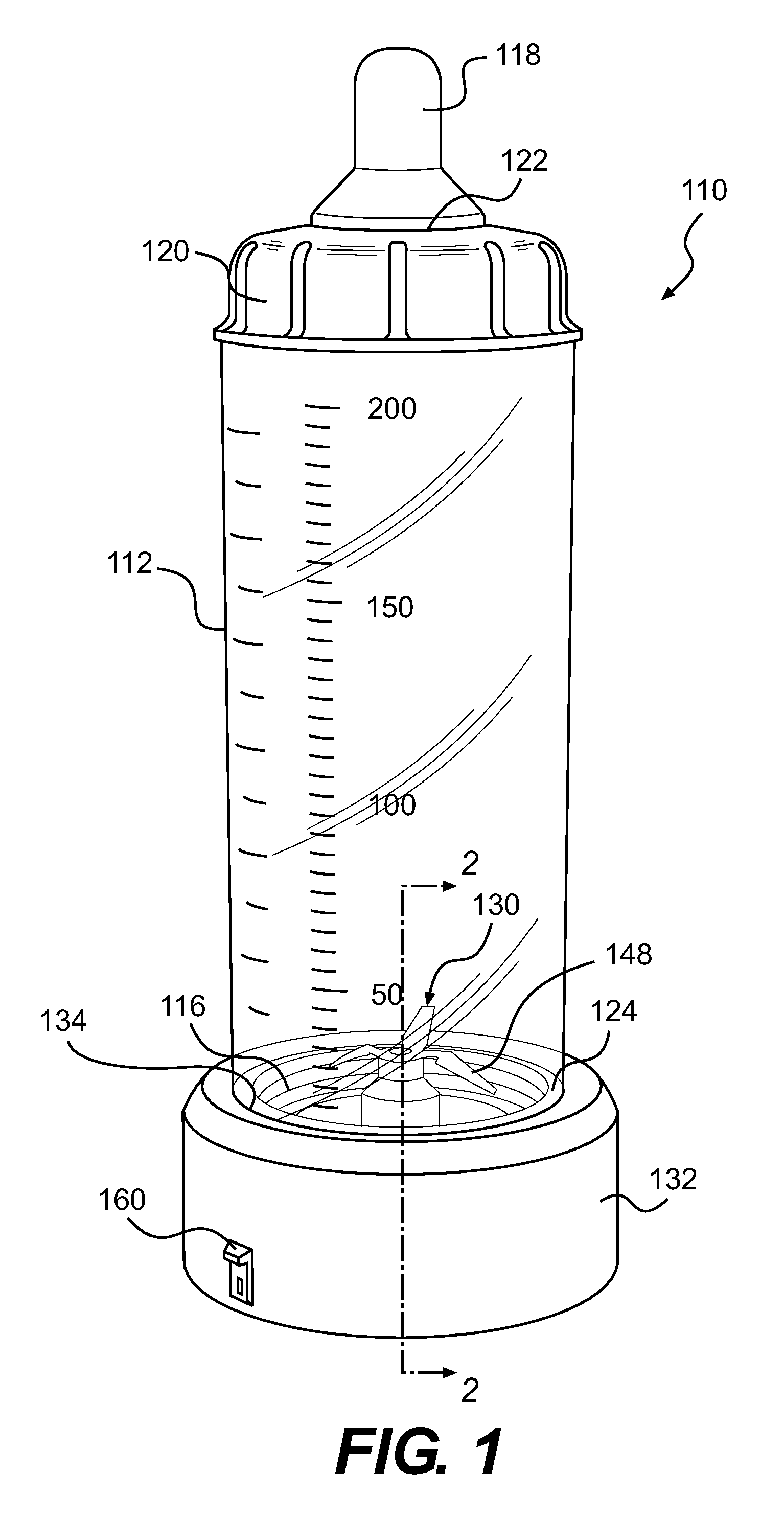

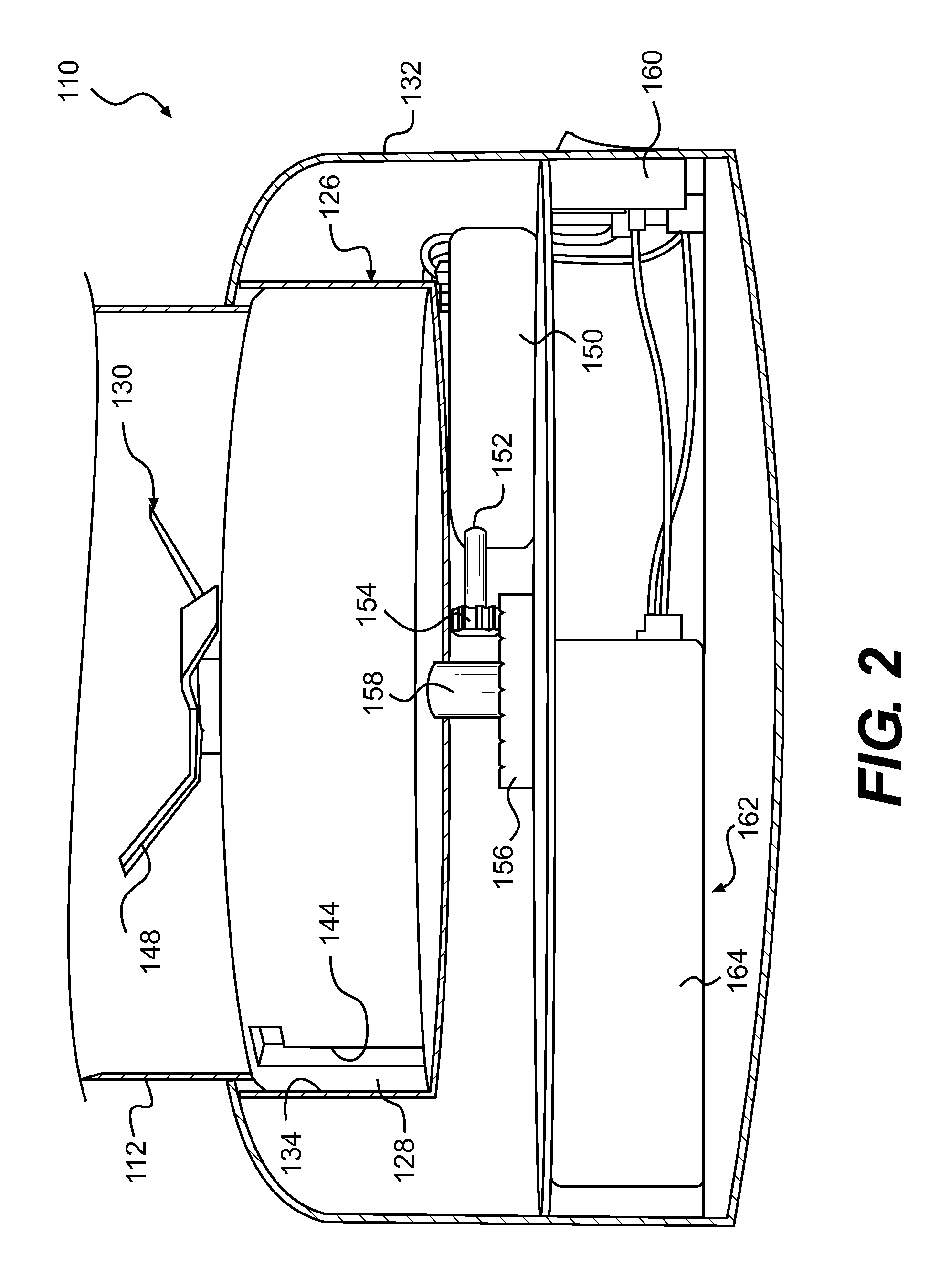

Portable baby bottle blender

ActiveUS8851739B2Simple and inexpensive to manufactureEasy to useRotary stirring mixersFeeding-bottlesCouplingEngineering

Owner:EASY PARENTS

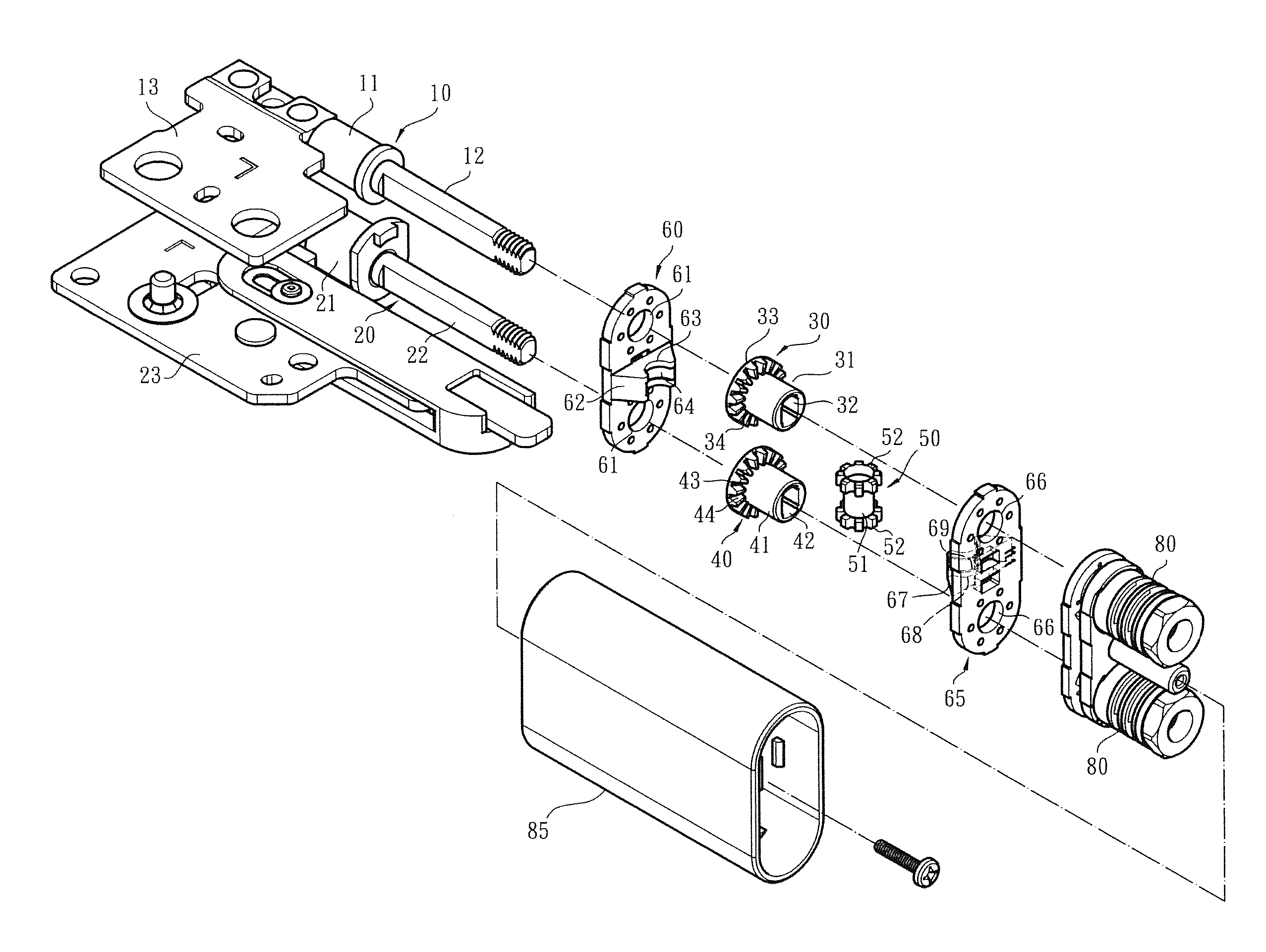

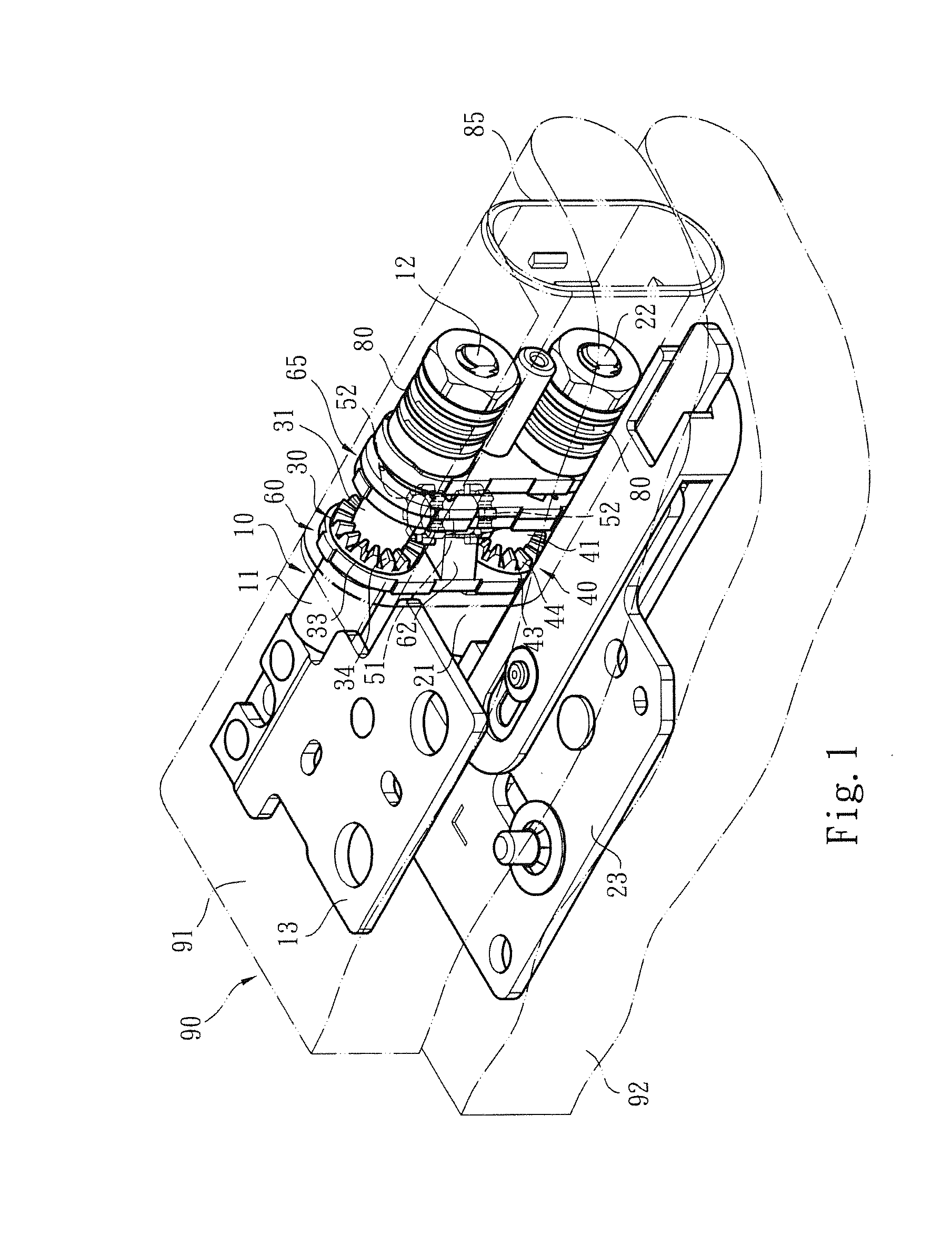

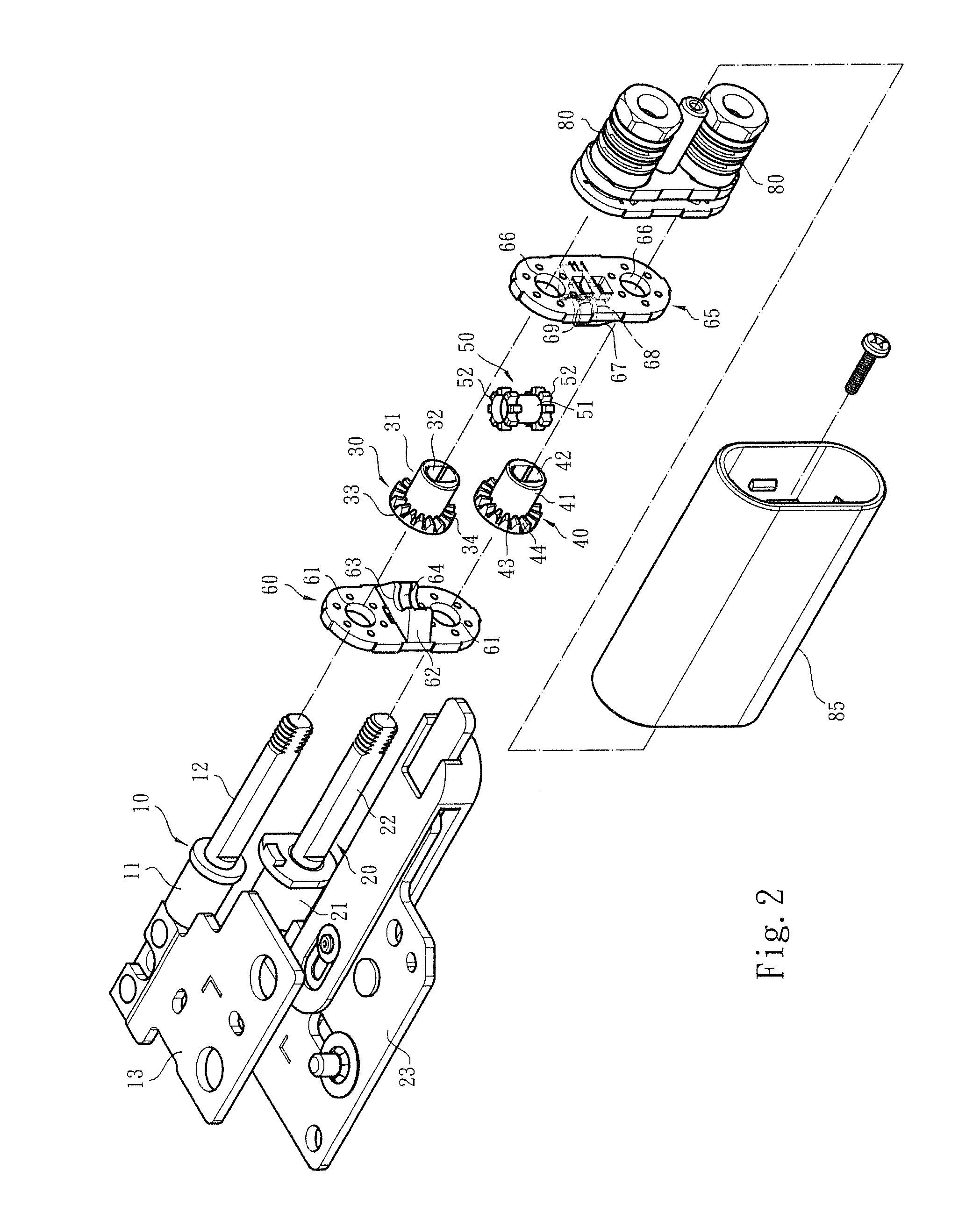

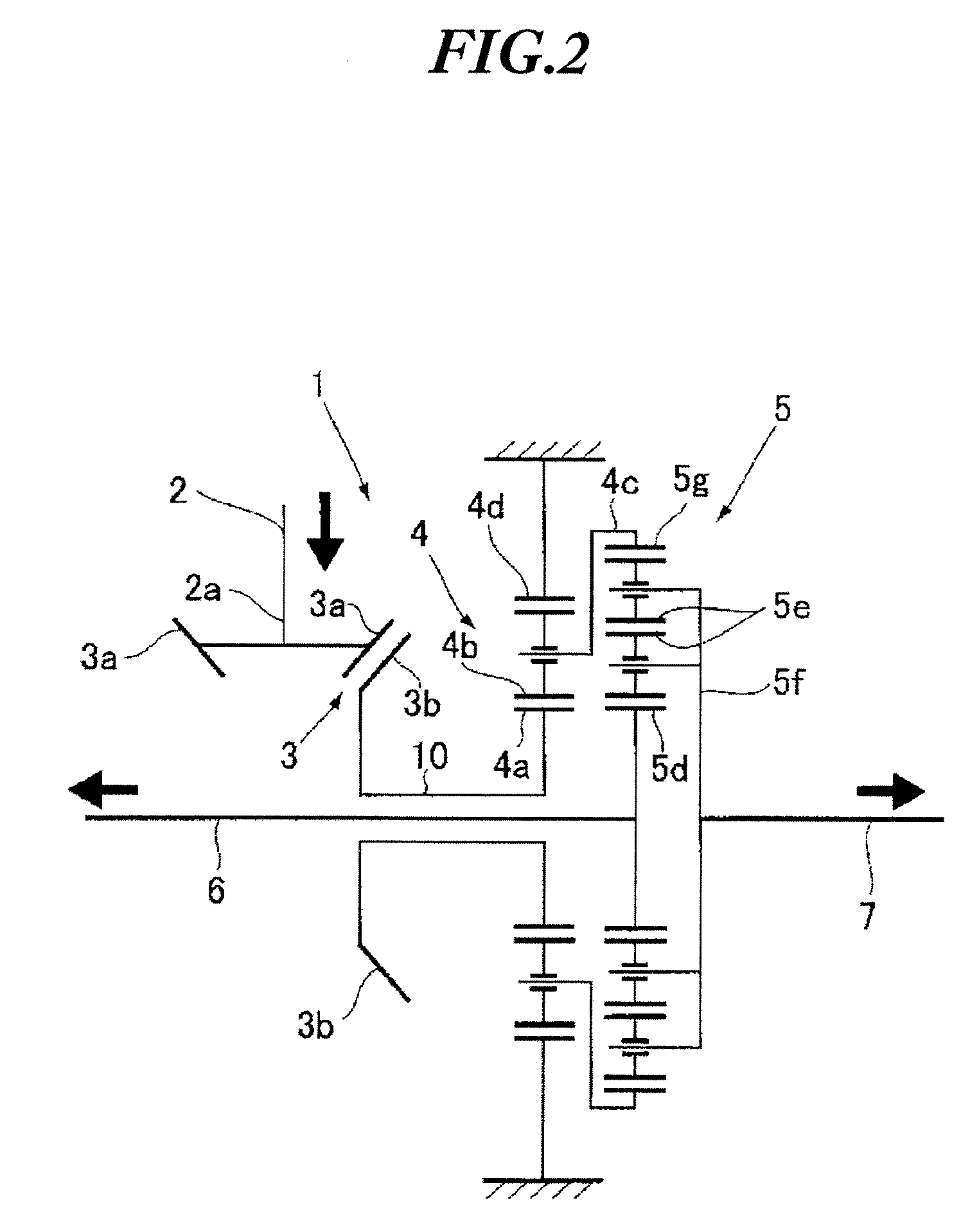

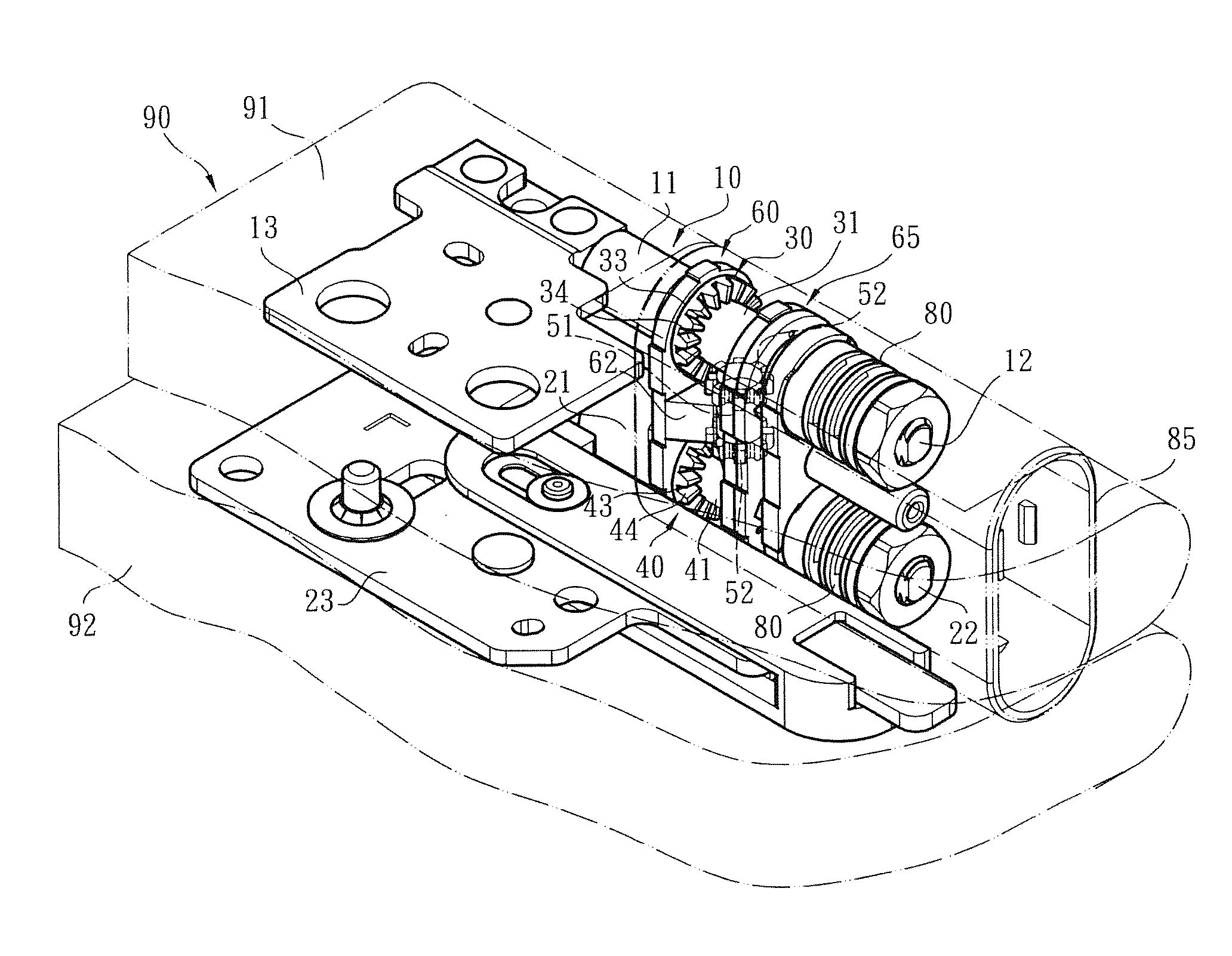

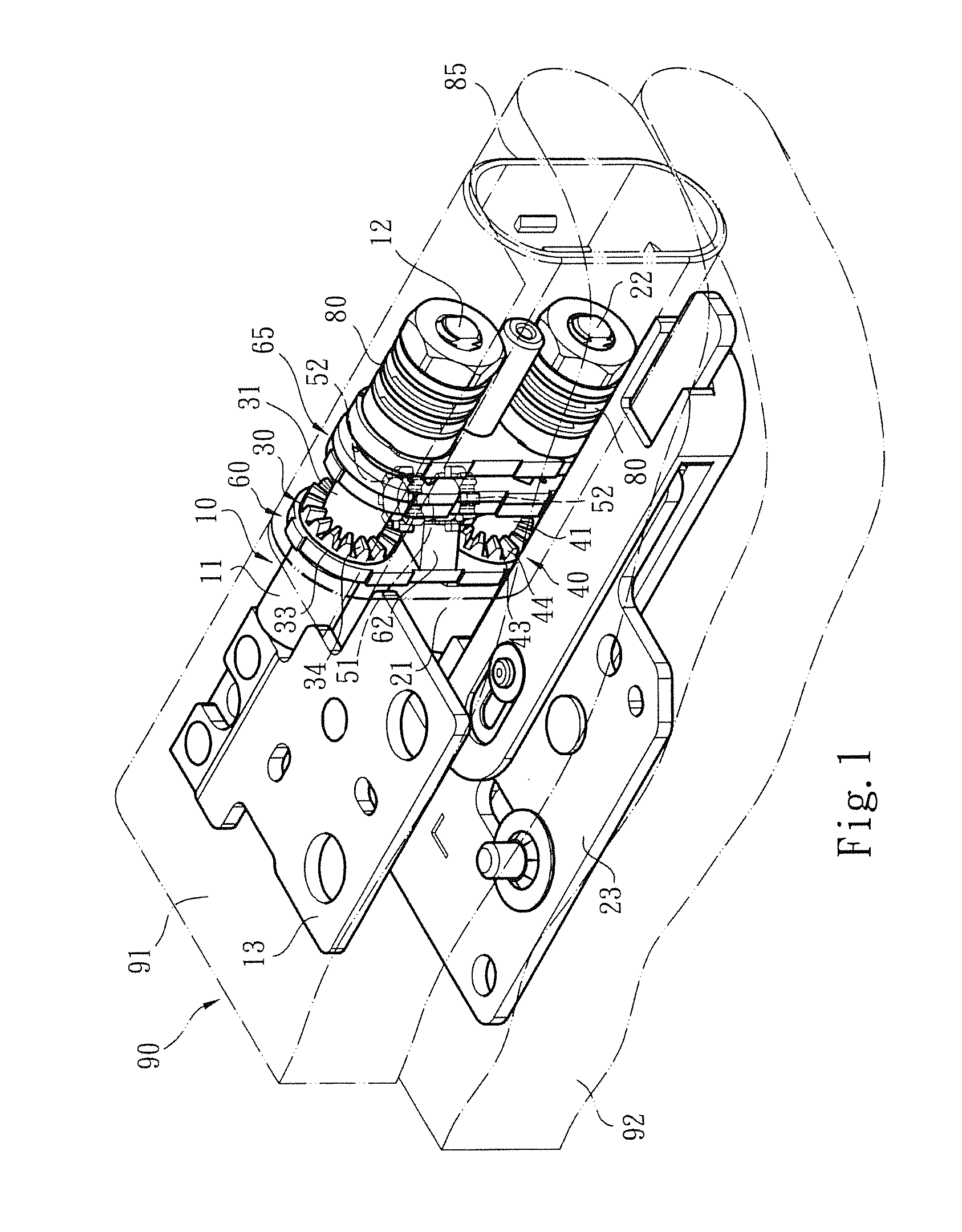

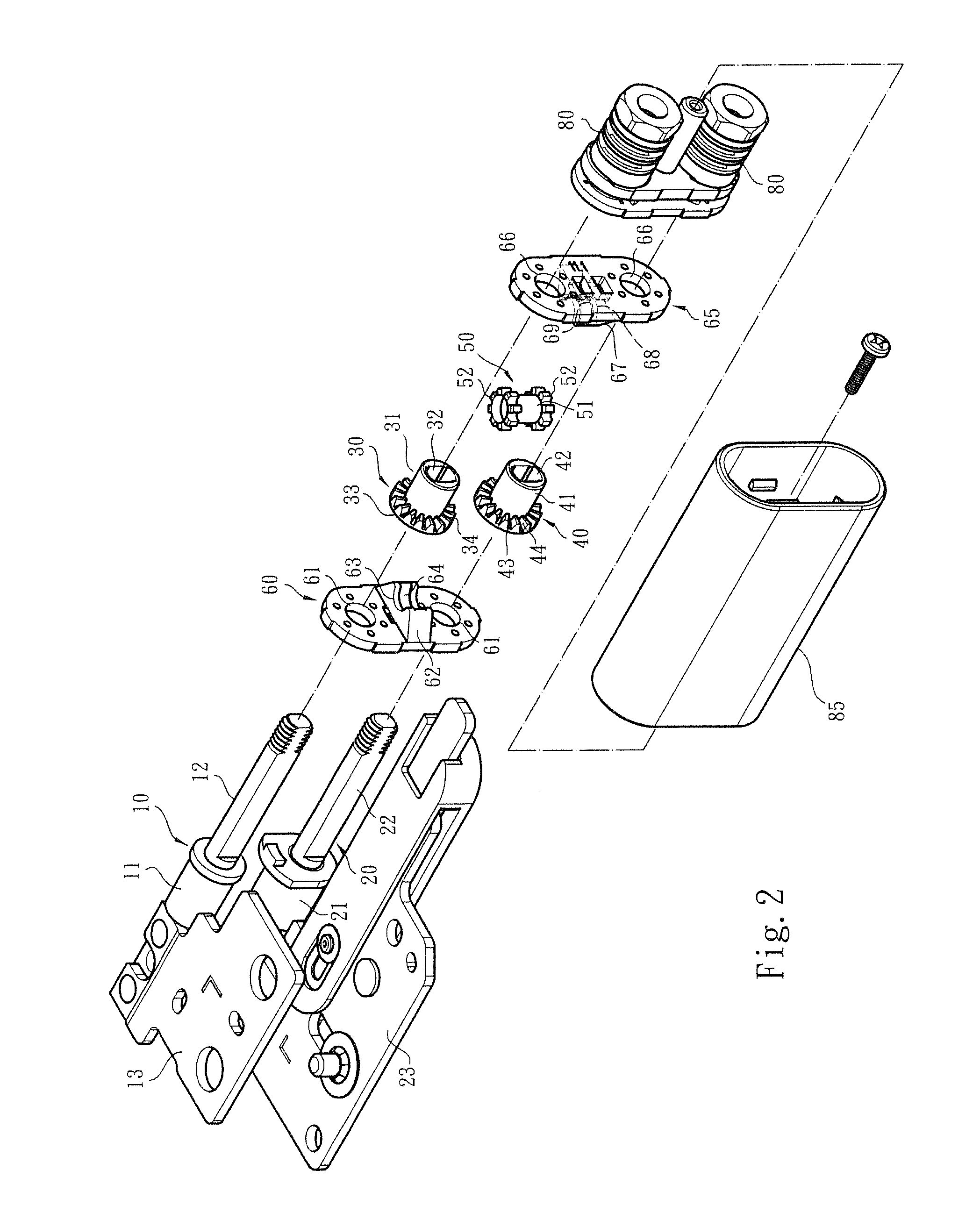

Dual-shaft synchronous transmission device

ActiveUS20160011632A1Reduce distanceSmooth rotationDigital data processing detailsWing accessoriesSpur gearCrown gear

A dual-shaft synchronous transmission device is applied to an electronic apparatus. The distance between the two shafts of the dual-shaft synchronous transmission device is shortened so that the electronic device can be thinned and lightweight. The dual-shaft synchronous transmission device includes a driver and a reactor respectively disposed on a first shaft and a second shaft and a link unit. Spur gear structures or crown gear structures are respectively disposed on the driver and the reactor. Crown gear structures or spur gear structures are respectively disposed at two ends of the link unit correspondingly engaged with the spur gear structures or crown gear structures of the driver and the reactor. When the first shaft and the driver are rotated, the driver rotates the link unit to drive the reactor and the second shaft to synchronously rotate in a direction reverse to the rotational direction of the driver.

Owner:FIRST DOME

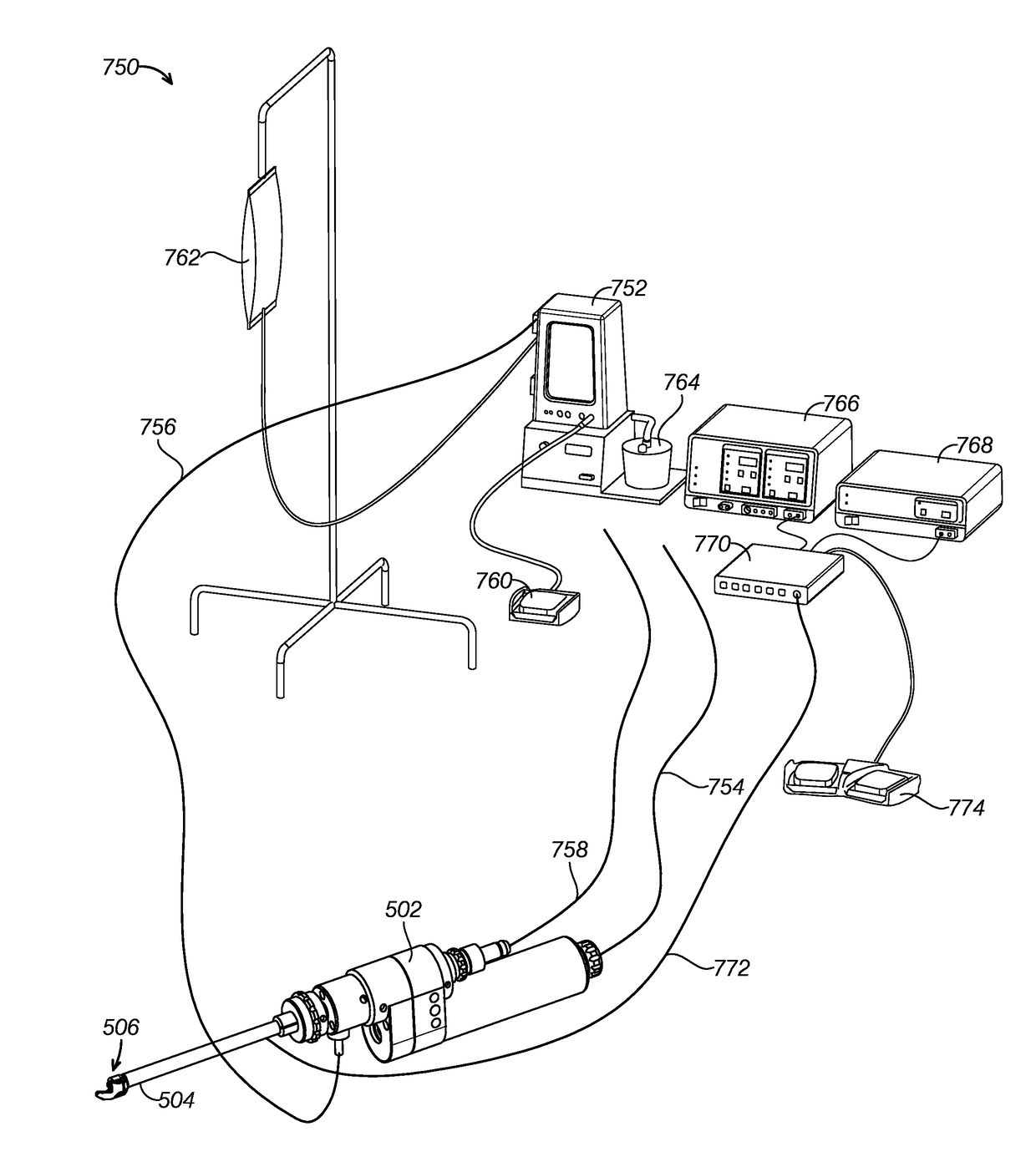

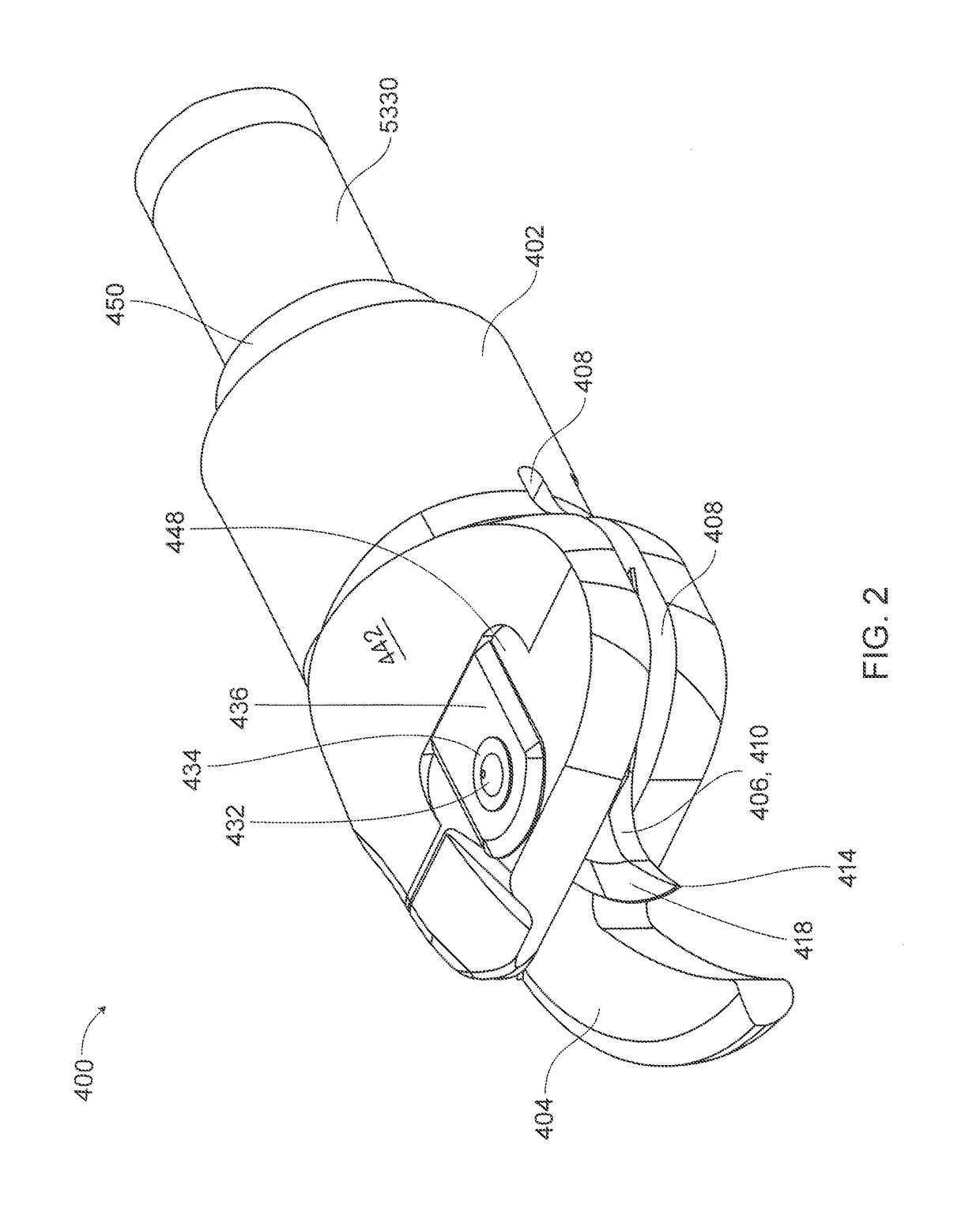

Nutating Gear Drive Mechanism for Surgical Devices

InactiveUS20090090201A1Reduce speedIncrease rotational forceToothed gearingsWobble plate gearingsLow speedGear drive

A drive mechanism for transmitting rotation force in surgical devices comprises a nutating gear reduction drive having an input and an output. The input is configured to be driven at high speed, low torque by a proximal drive shaft of a surgical device. The output is configured to transmit a low speed, high torque rotational force. The proximal drive shaft can be flexible. In one embodiment, the nutating gear reduction drive includes a wobble plate. This nutating gear reduction drive may include at least one crown gear. In an alternative embodiment, the nutating gear drive includes at least one ring gear. The ring gear is fixed in place. This embodiment can also include at least one spur gear.

Owner:TYCO HEALTHCARE GRP LP

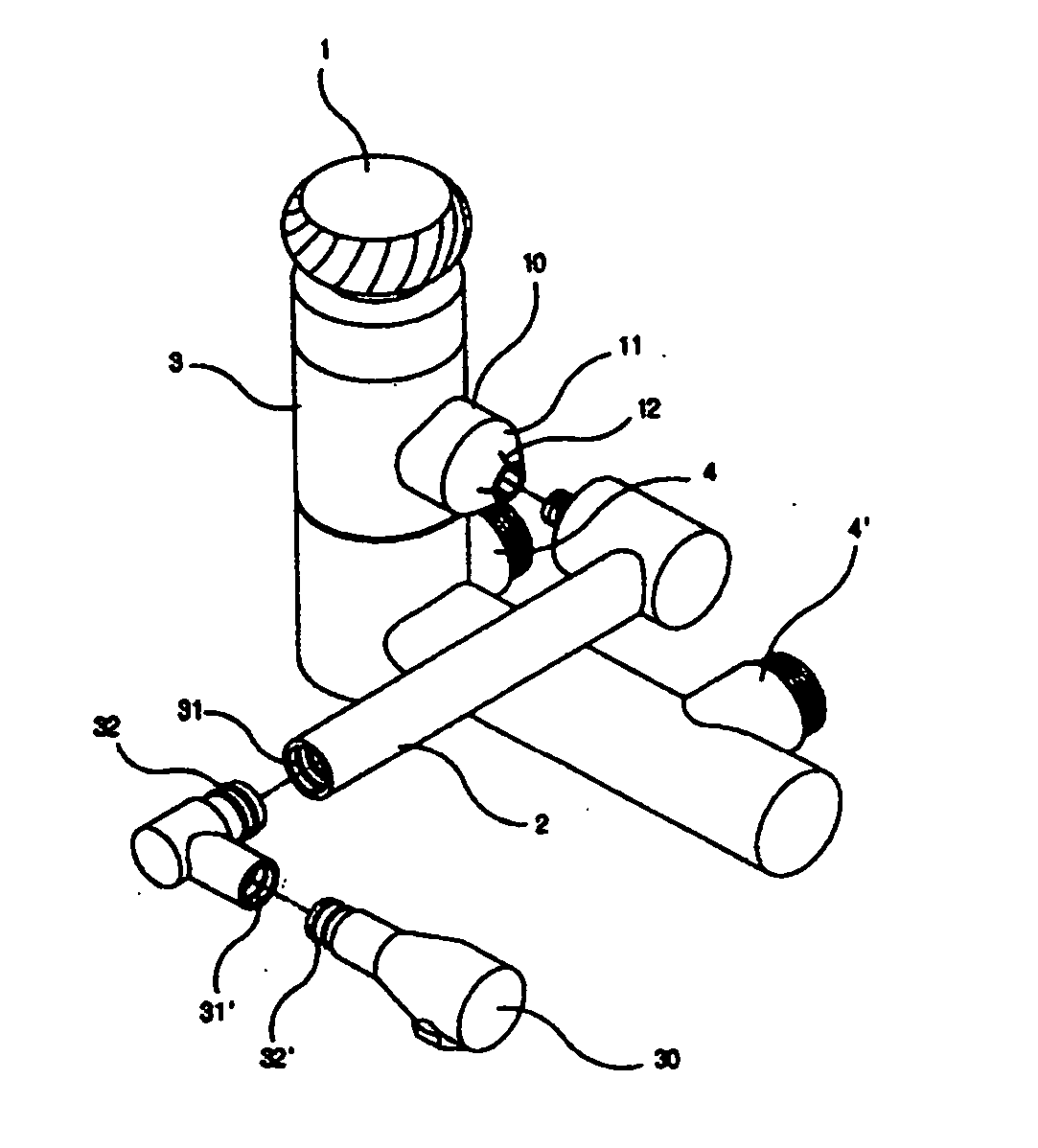

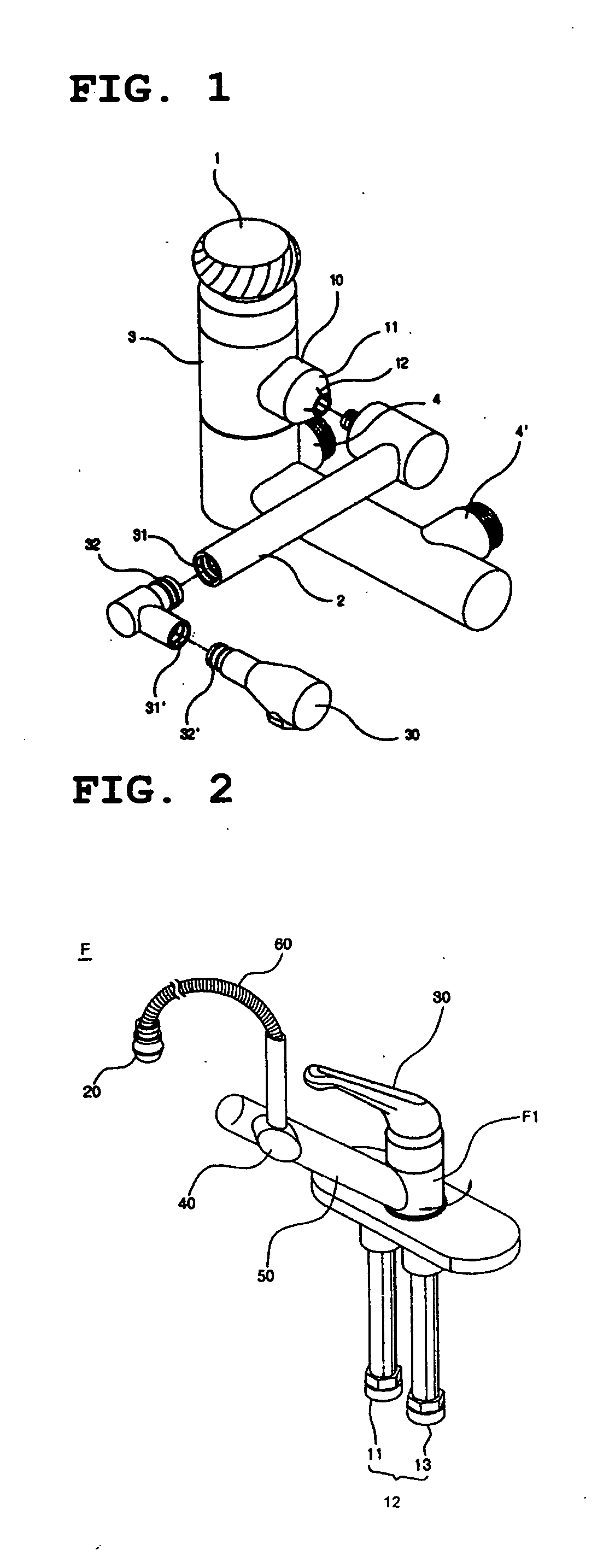

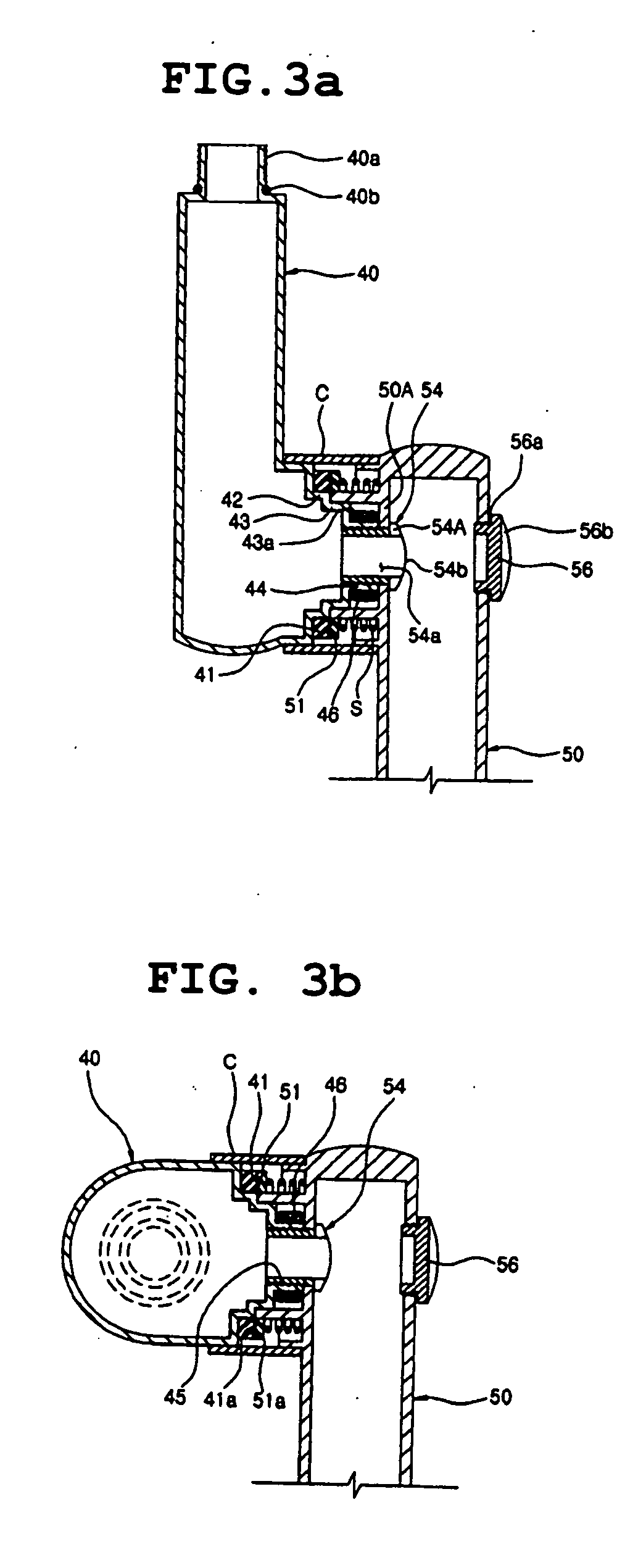

Mesh-type angle-adjustable faucet

InactiveUS20060180222A1Preventing drooping of the tubesPreventing a trouble of the faucetServomotor componentsDomestic plumbingGear wheelMechanics

Disclosed is a mesh-type angle-adjustable faucet for a kitchen sink, which can control the angle stepwisely by crown gears arranged at contact surfaces of two tubes. The faucet includes: a raw water pipe; a water tap; flow rate controlling means; a first tube connected with the water tap and having a first crown gear fixed at an end portion of the water tap via fixing means for preventing an idle rotation; a second tube having a second crown gear engaged with the first crown gear of the first tube at an end thereof via fixing means for preventing the idle rotation, the other end of the second crown gear being connected with the raw water pipe; an elastic member for allowing the first and second crown gears to be in close contact with each other; and a watertight member arranged at the contact surfaces of the first and second tubes.

Owner:JEUNG HYON JIN

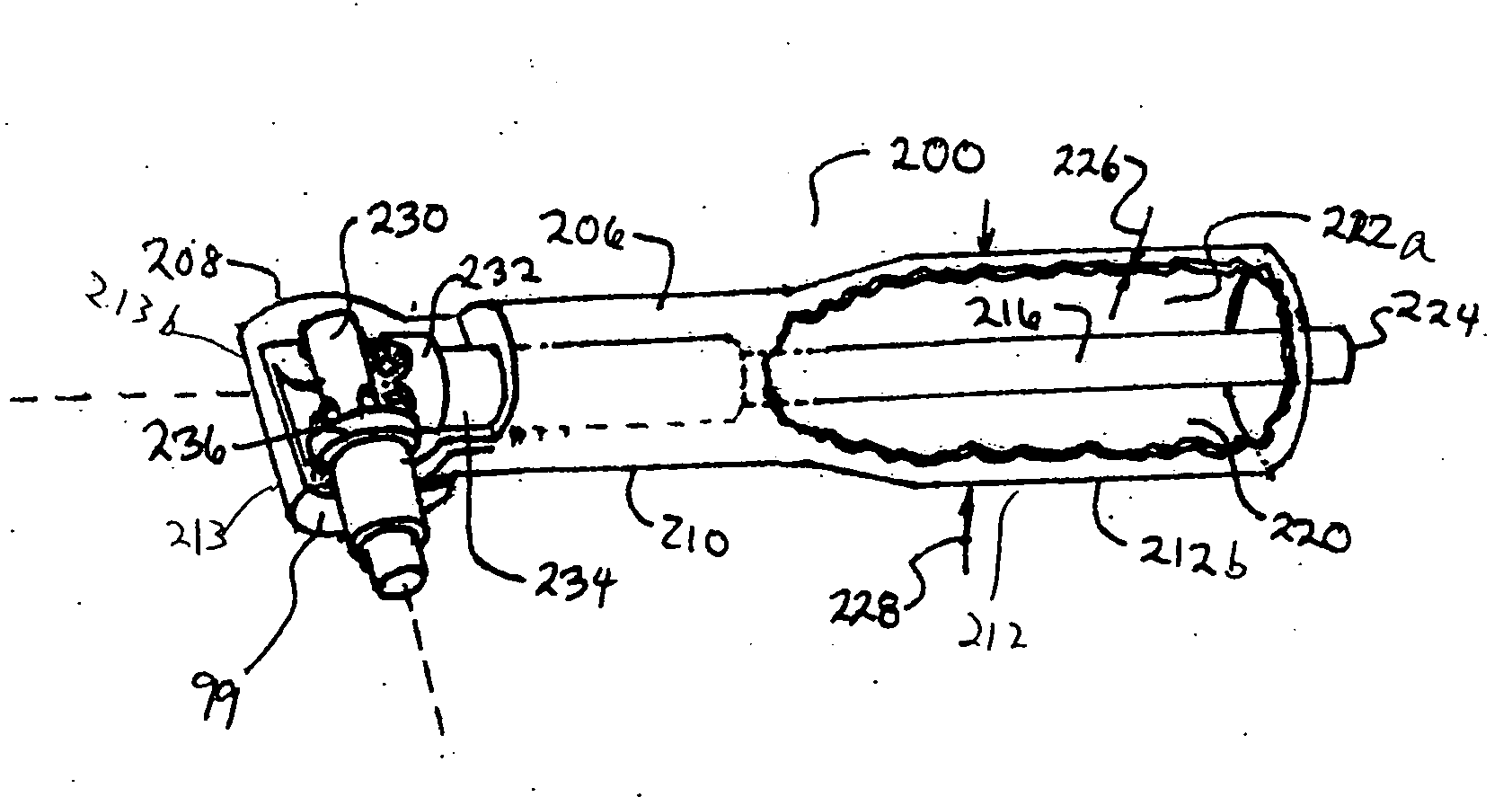

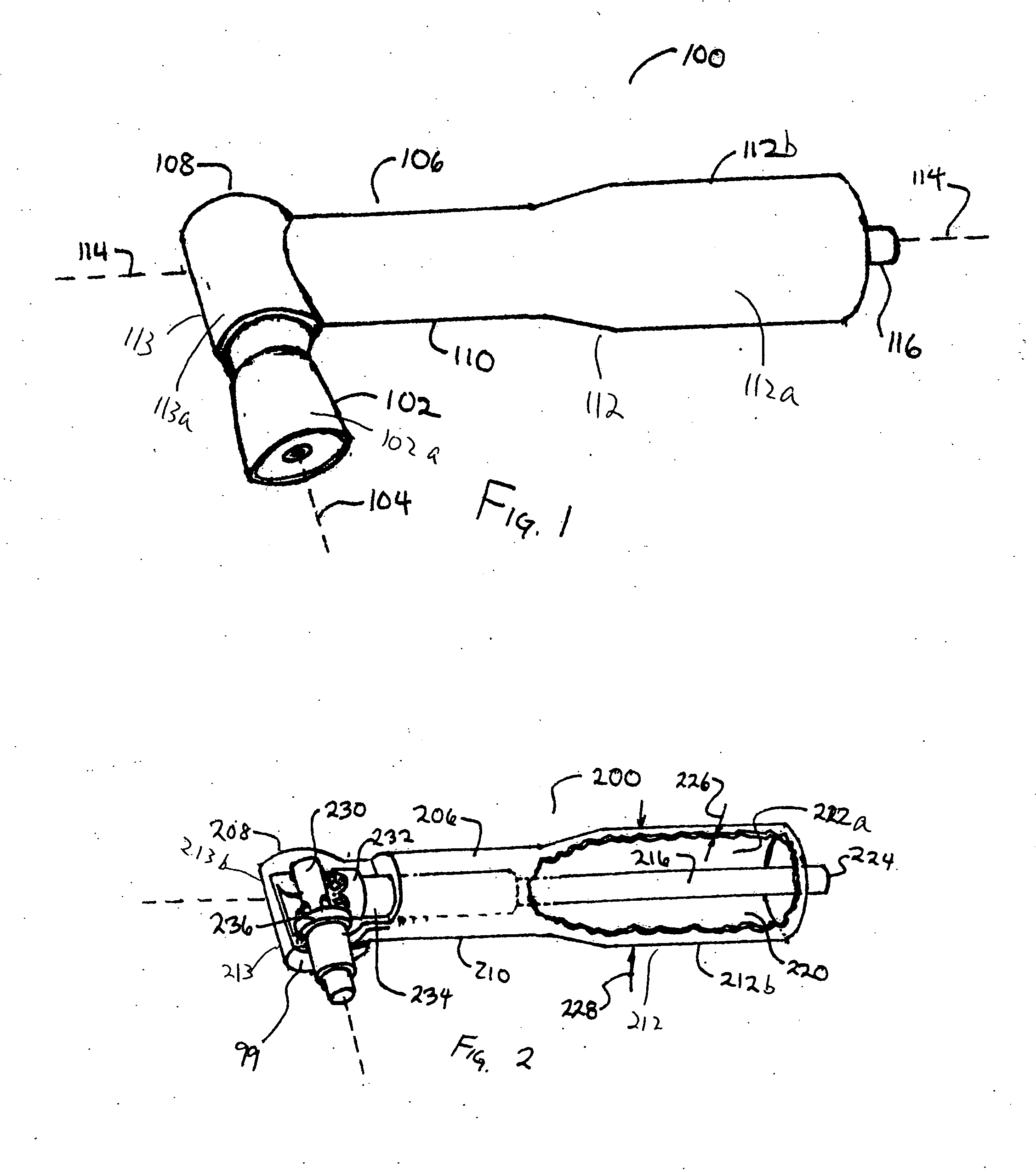

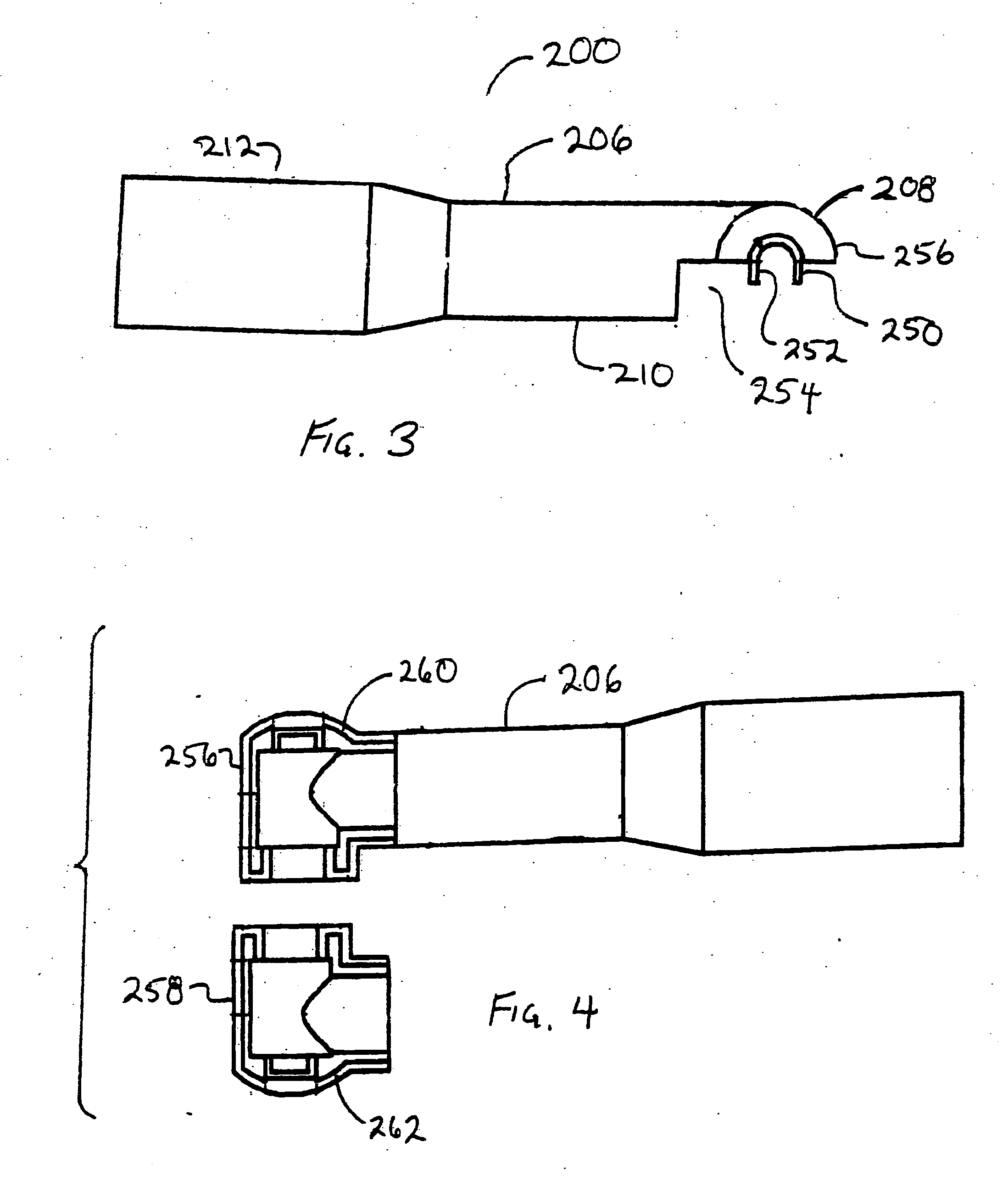

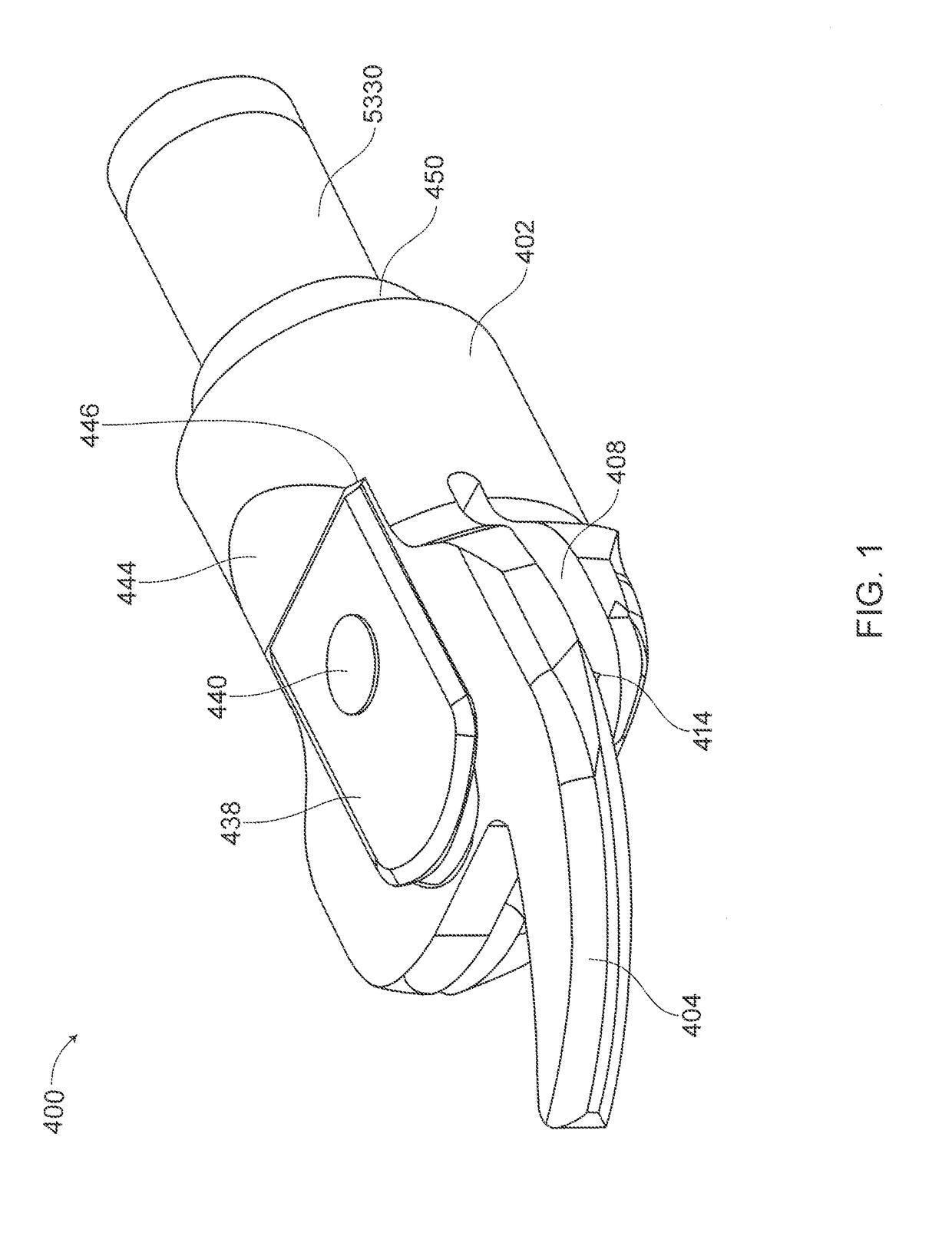

Prophylaxis angles and cups

A prophy angle includes a driven shaft and a driving shaft. The driving shaft as an integrally molded crown gear disposed coaxially thereon. The driven shaft as a carousel gear including a plurality of pins, each pin having a longitudinal axis parallel to a longitudinal axis of the driving shaft. Each pin is coupled to the driving shaft by a fillet. The prophy angle includes a housing that has a major part and a minor part. The driving shaft is inserted into the housing from an open distal end of the major part. The driven shaft is also inserted into the housing at the open distal end of the major part. Thereafter, the minor part of the housing is connected to the major part of the housing to close the open distal end of the major part of the housing.

Owner:ZILA INC

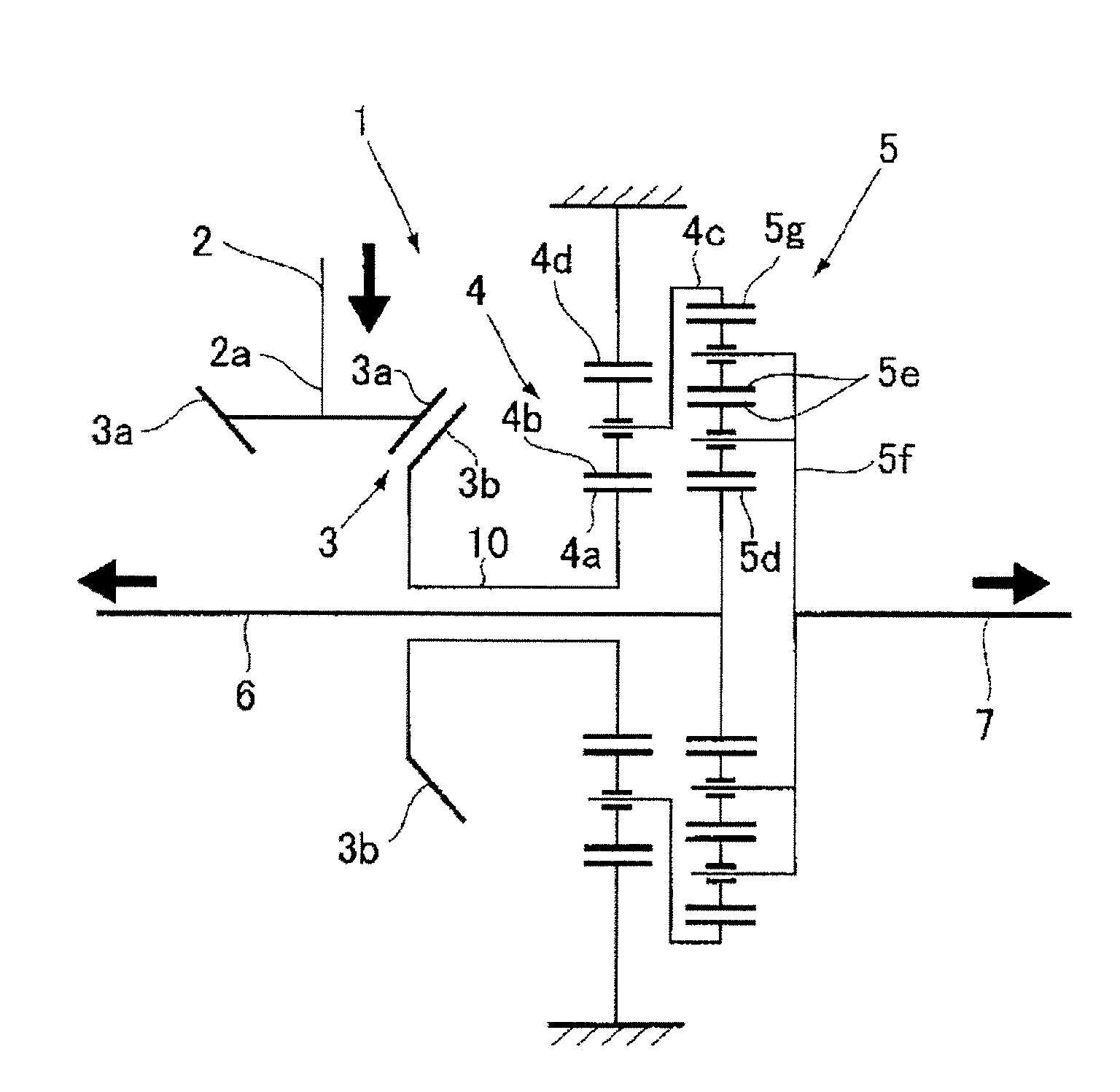

Crown gear deceleration mechanism

A crown gear deceleration mechanism provided by the present invention includes: a stator including a crown gear; a rotor including another crown gear; and an output shaft coupled to the rotor. Stator includes a stator tooth row in which N1S stator teeth are circularly arranged. Rotor includes: a first rotor tooth row in which N1 teeth are arranged; and a second rotor tooth row in which N2 teeth are arranged. Output shaft includes an output tooth row in which N2S teeth are arranged. Rotor performs a precession while engaging the first rotor tooth row with the stator tooth row at places existing at both sides between which a devotion central line intervenes. Rotor transmits rotation to the output shaft while engaging the second rotor tooth row with the output tooth row at the places existing at both sides between which the devotion central line intervenes.

Owner:FUKUSHIMA UNIVERSITY

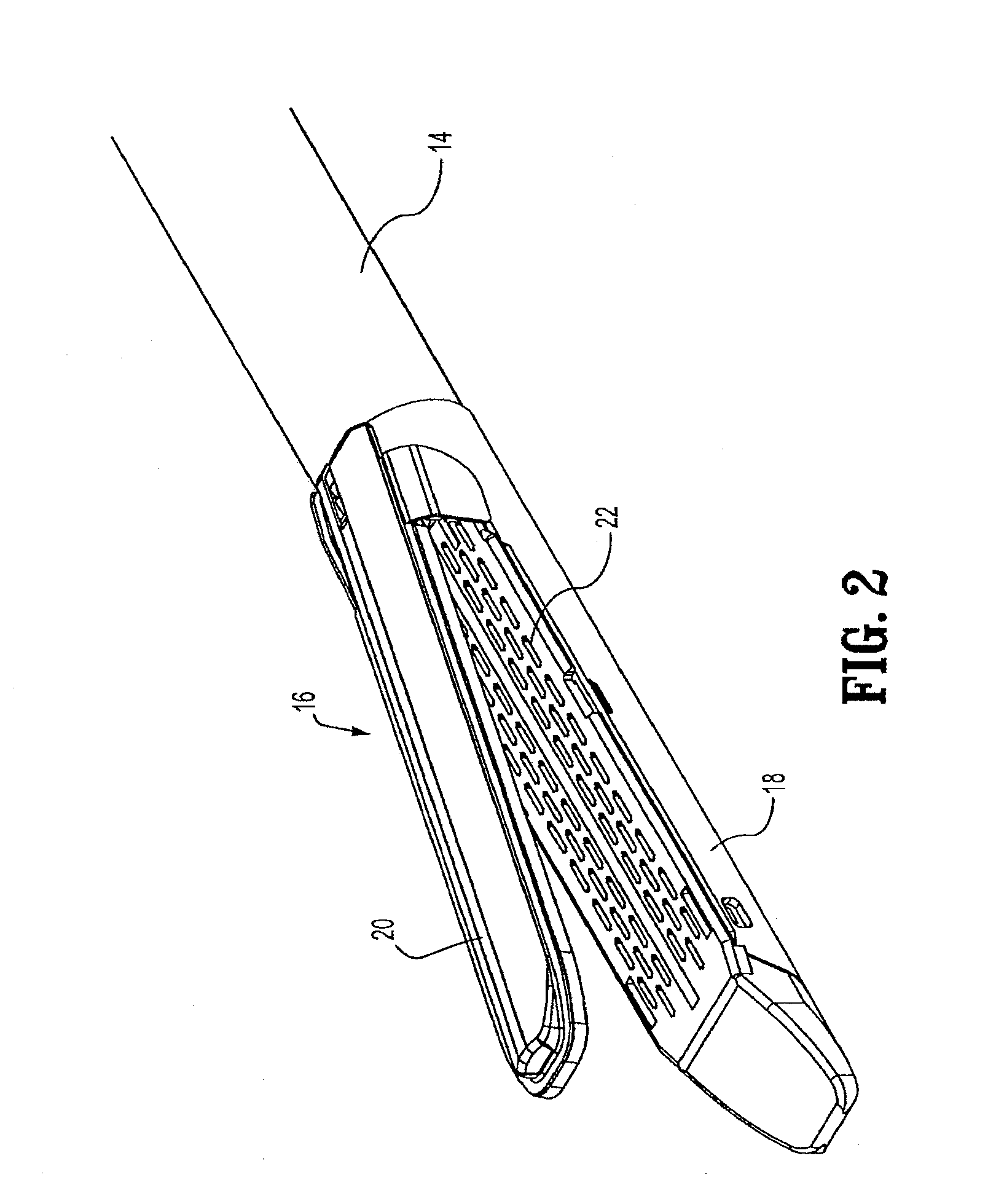

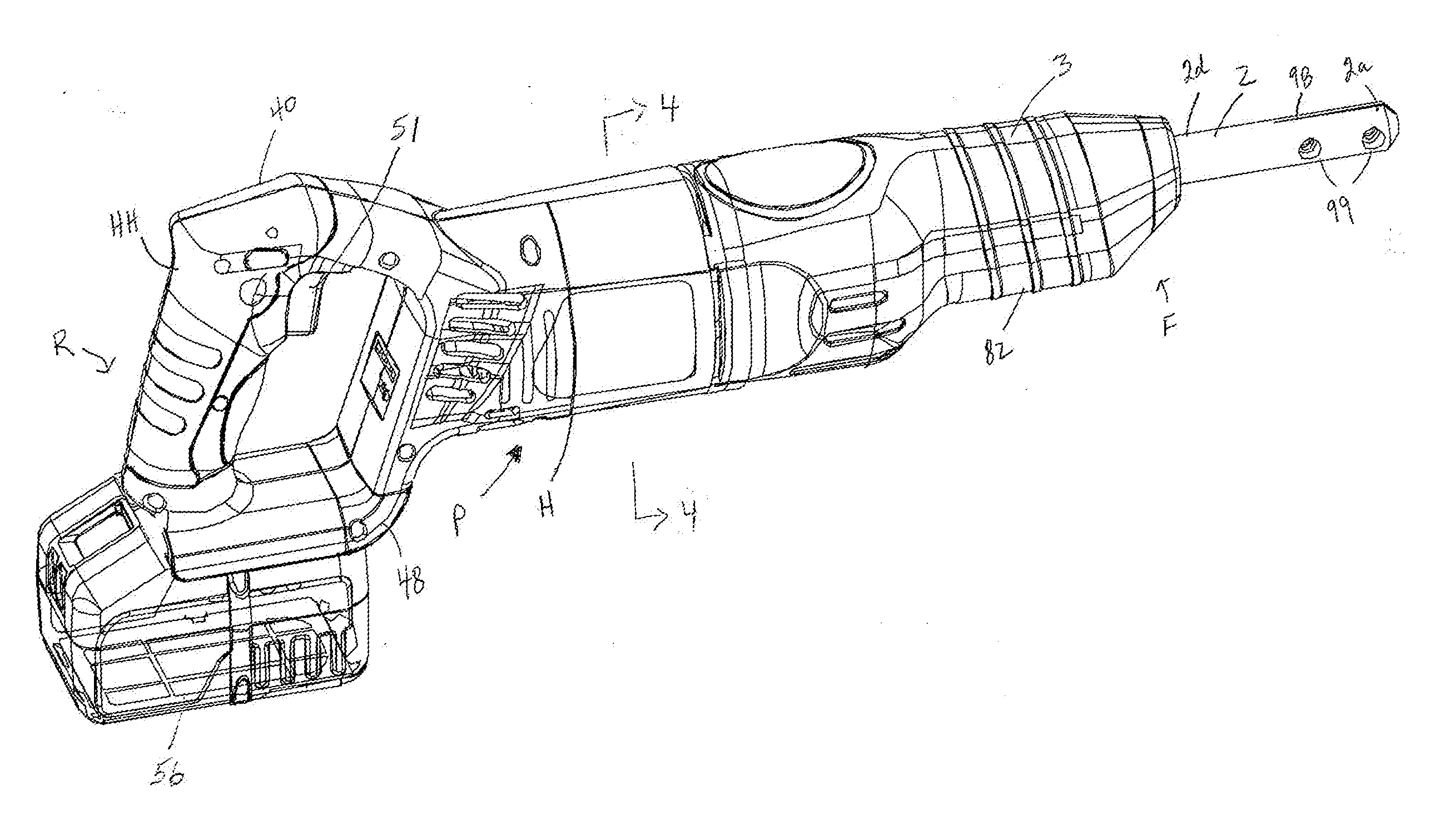

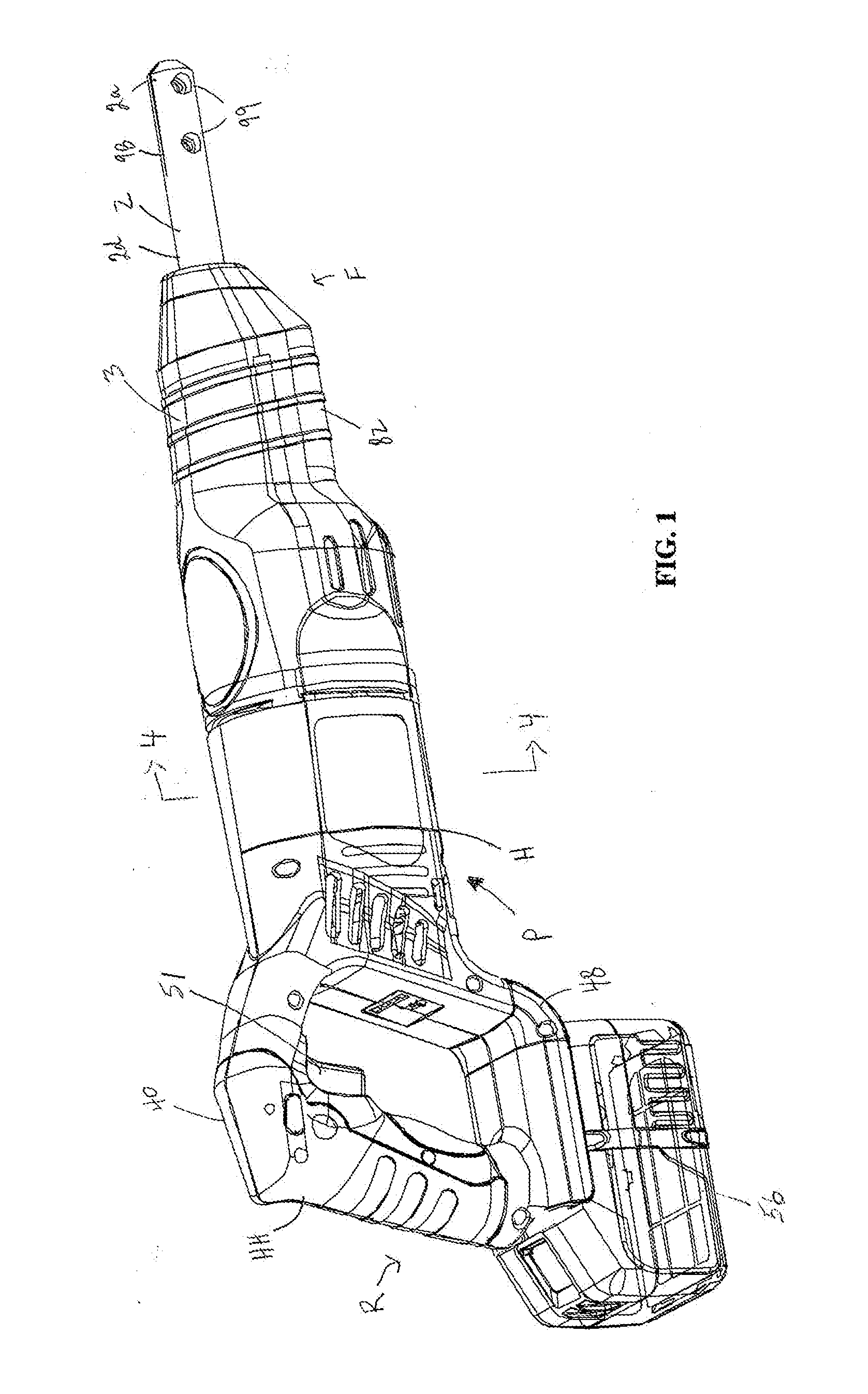

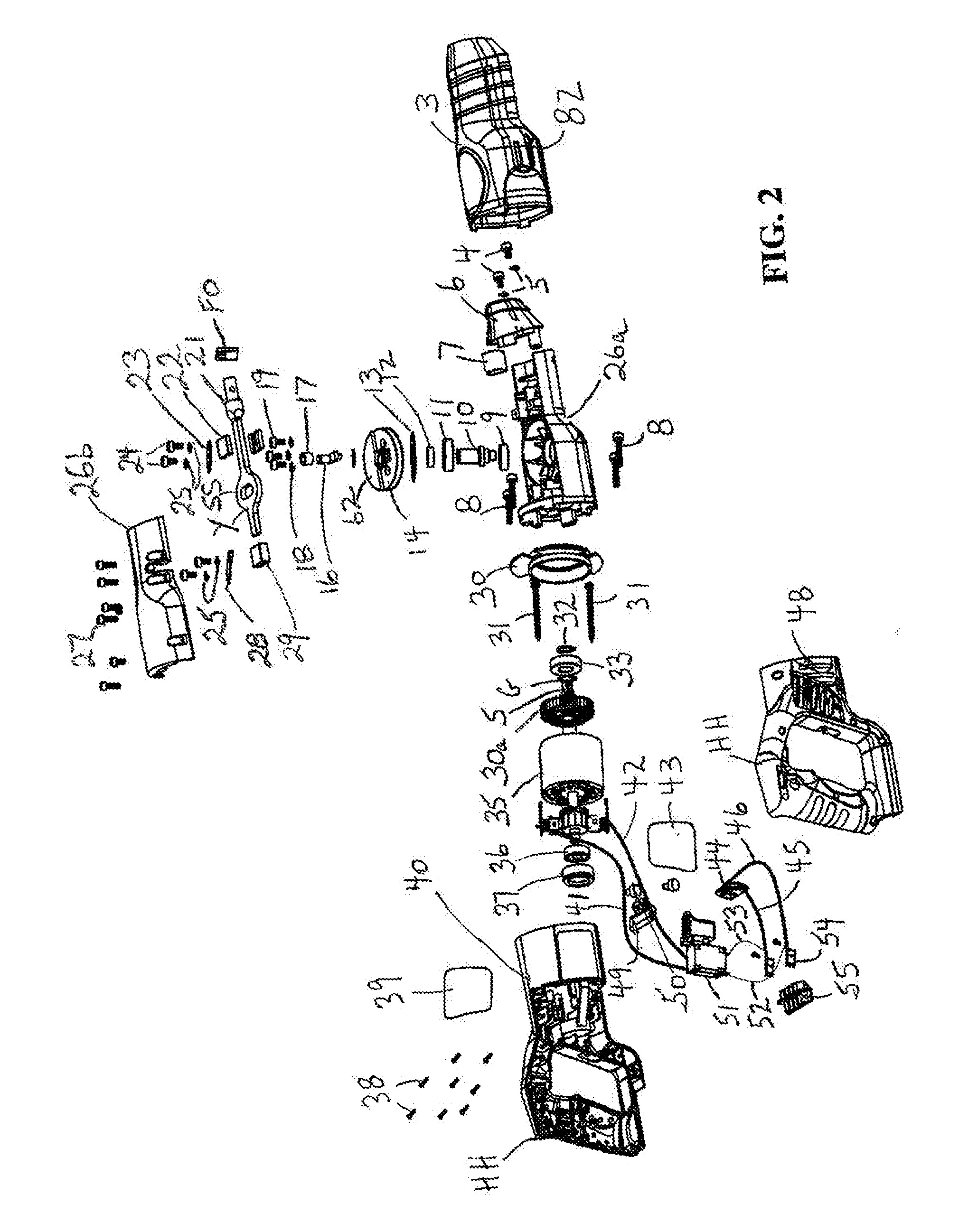

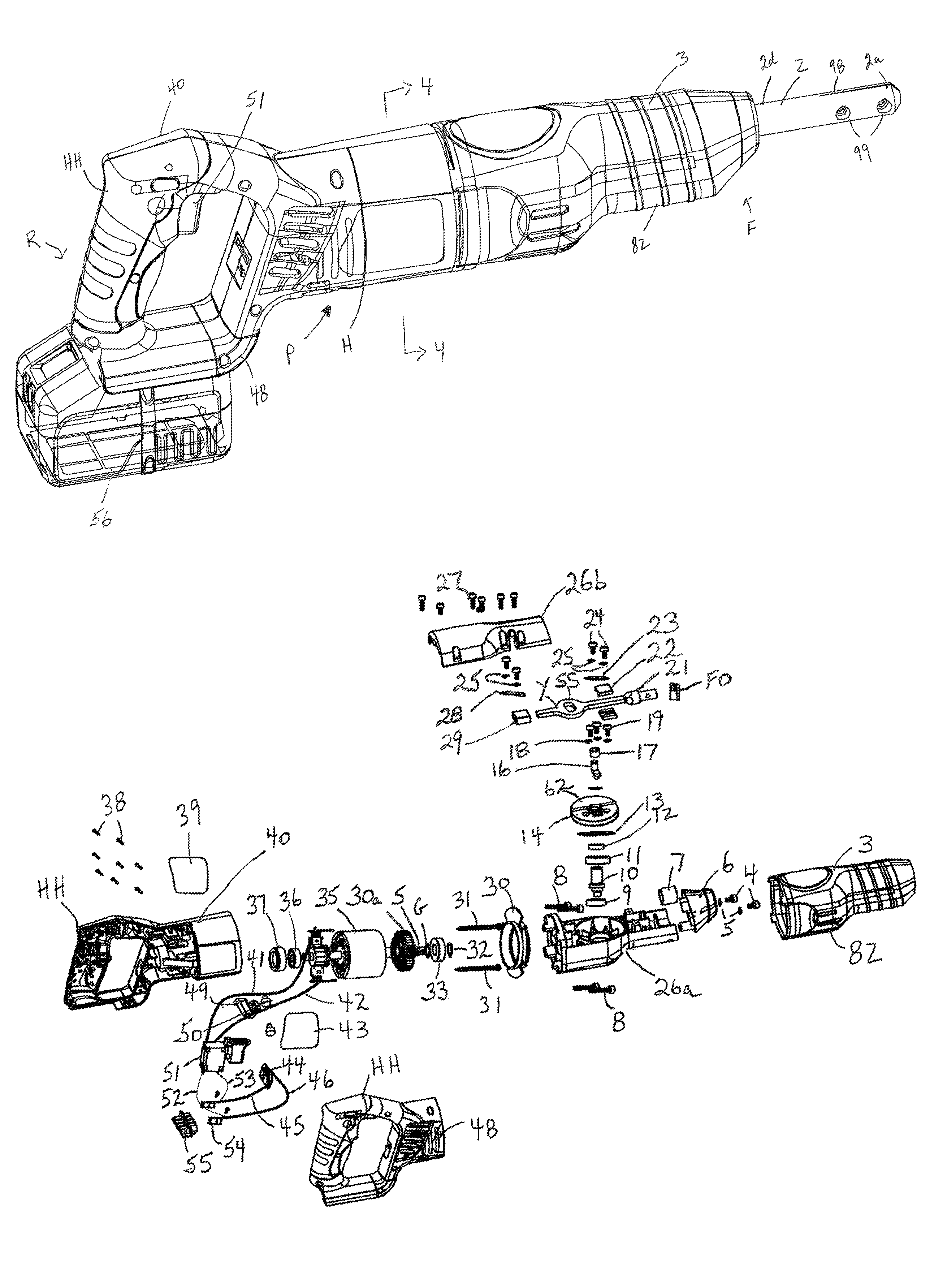

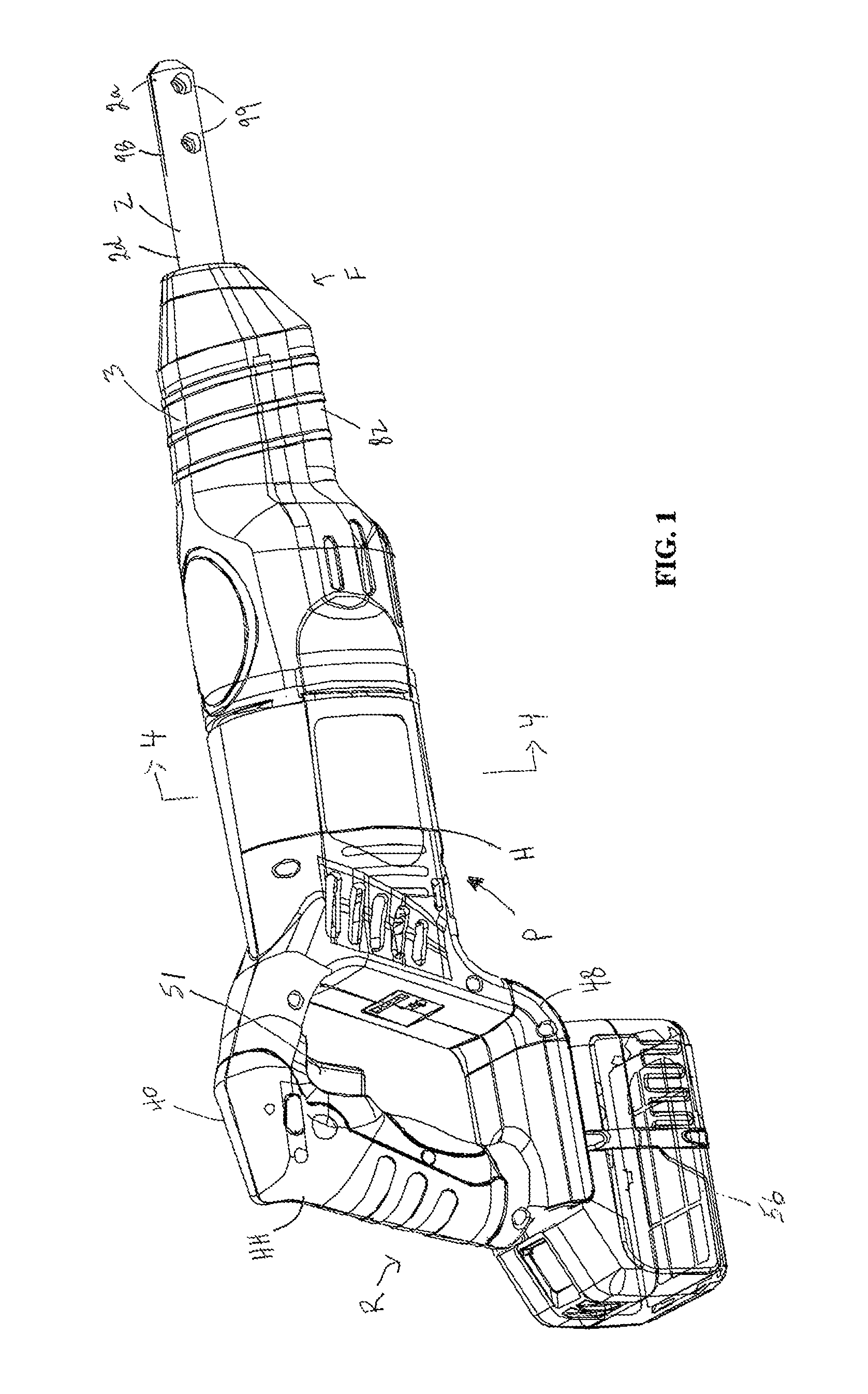

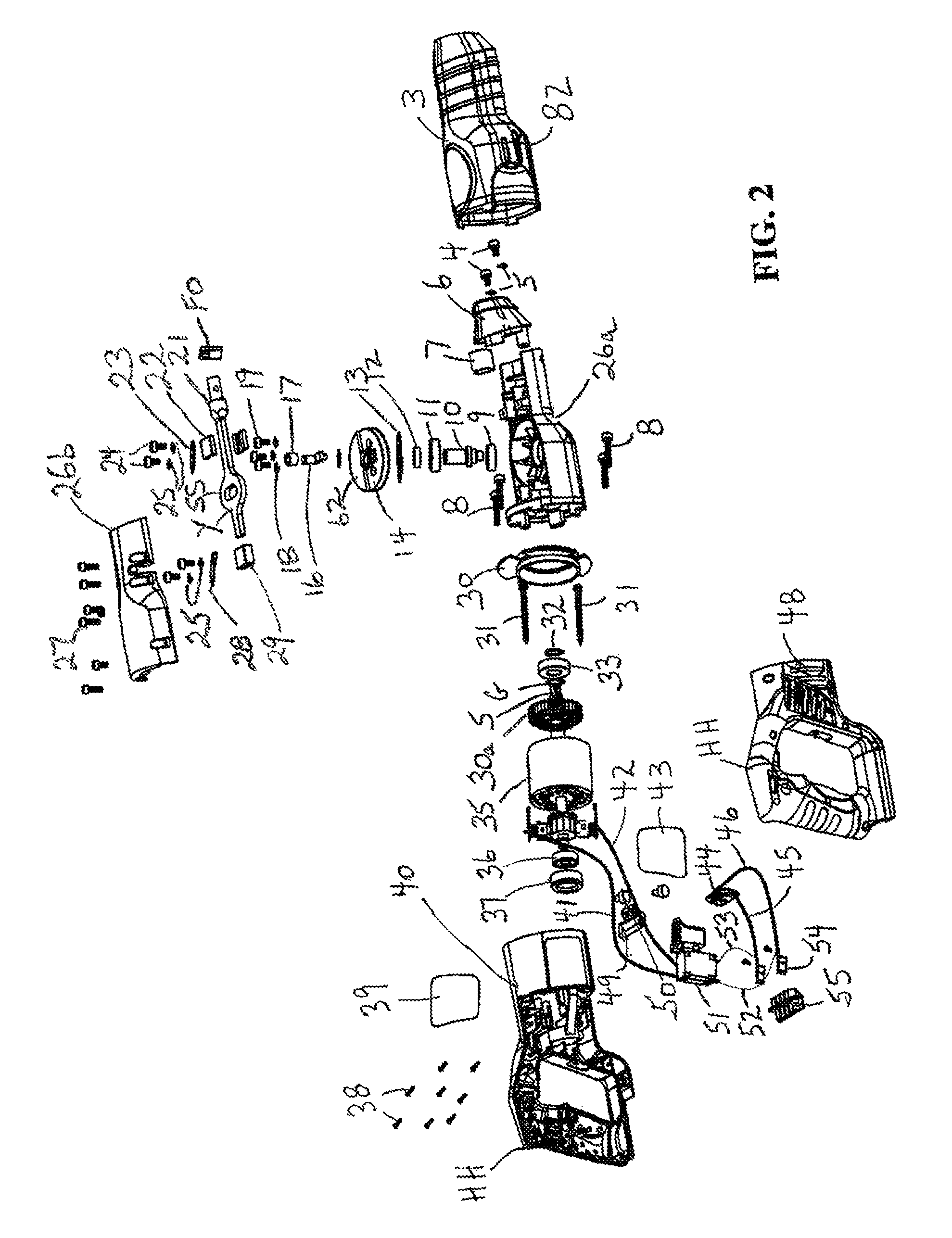

Reciprocating power tool

ActiveUS20120291294A1Reliable lockingReduce forceMetal sawing devicesOperator-supported drilling machinesReciprocating motionDrive shaft

A reciprocating power tool and drive mechanism with a drive shaft mounted for reciprocating movement relative to a housing along a center longitudinal axis of the drive shaft. The drive shaft has a front end adapted to attach to an external shaft or tool attachment, a rear end, and a slot oriented perpendicular to the center longitudinal axis of the drive shaft between the front and rear ends. A motor driven shaft imparts rotary movement to a pinion gear, which meshes with a crown gear to impart rotary motion to the crown gear about its center axis. A drive pin connected to the crown gear has an eccentric pin eccentrically offset relative to the center axis of the crown gear for engagement in the slot of the drive shaft so as to impart the reciprocating movement to the drive shaft on rotation of the crown gear.

Owner:CRYSTAL GLASS CANADA

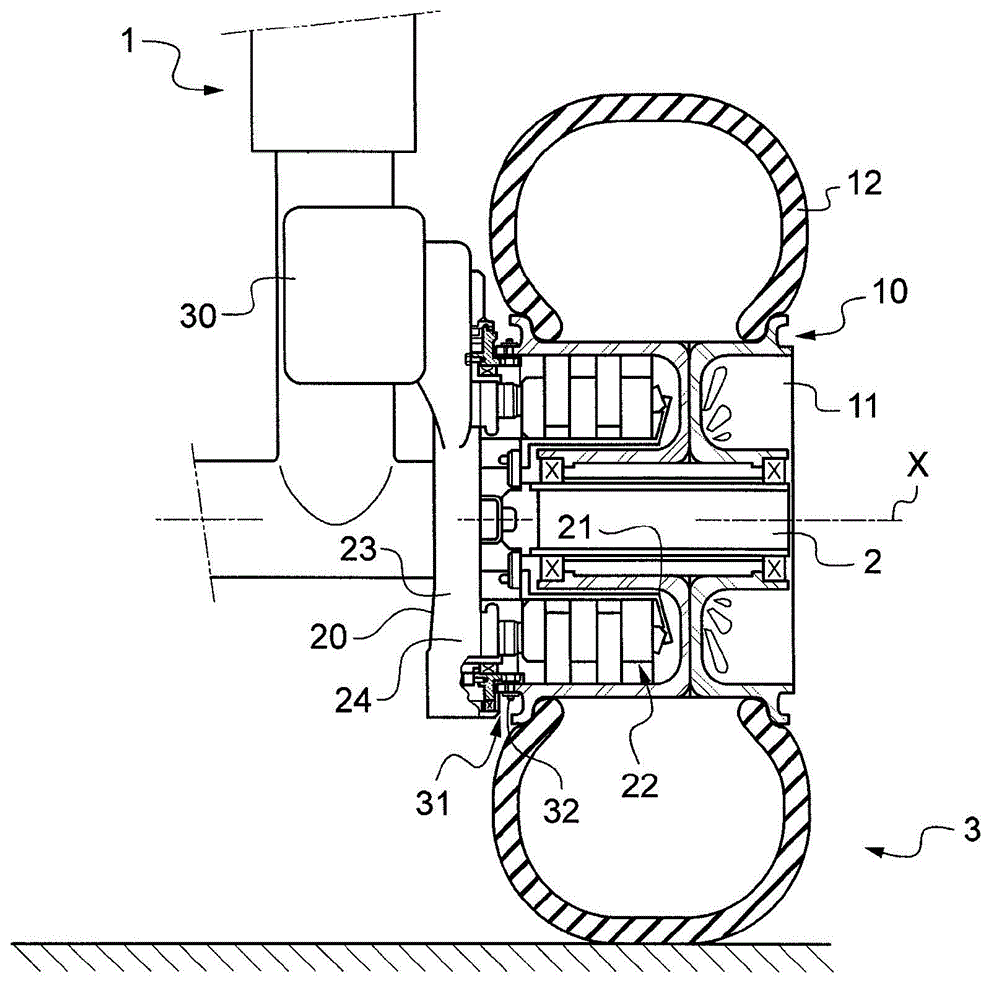

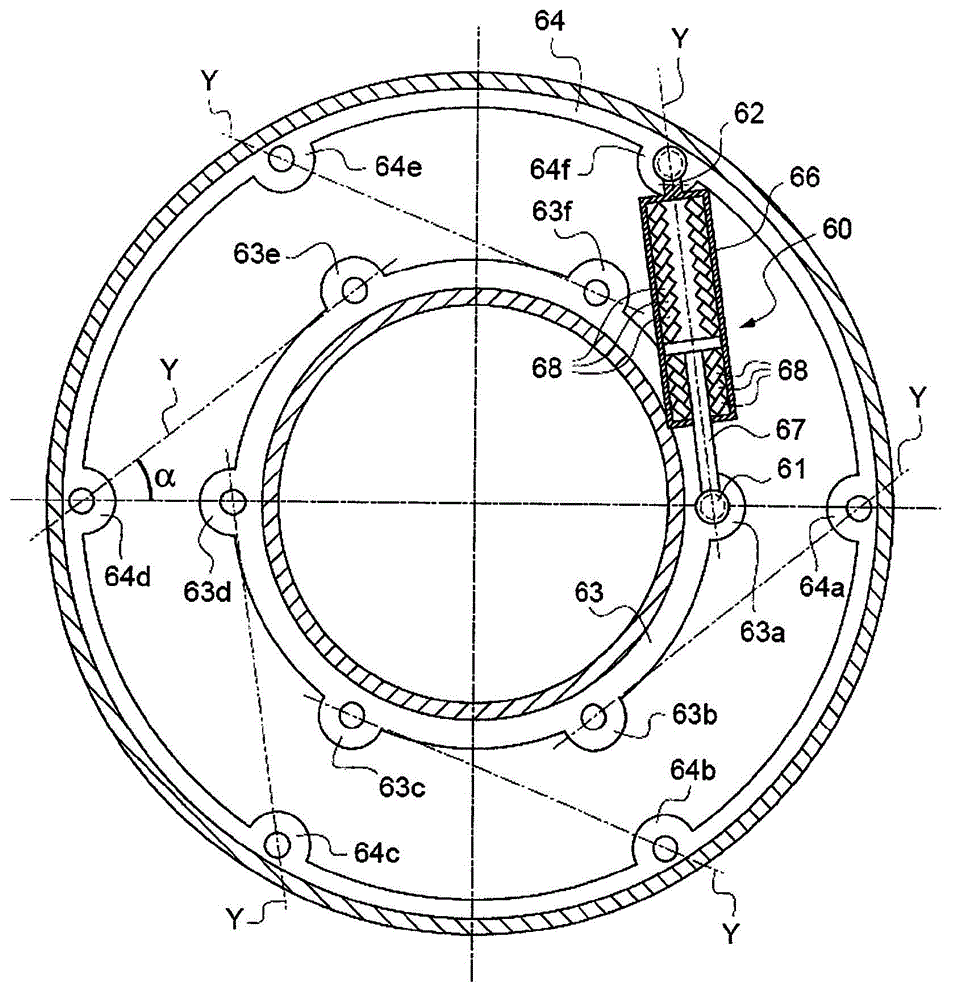

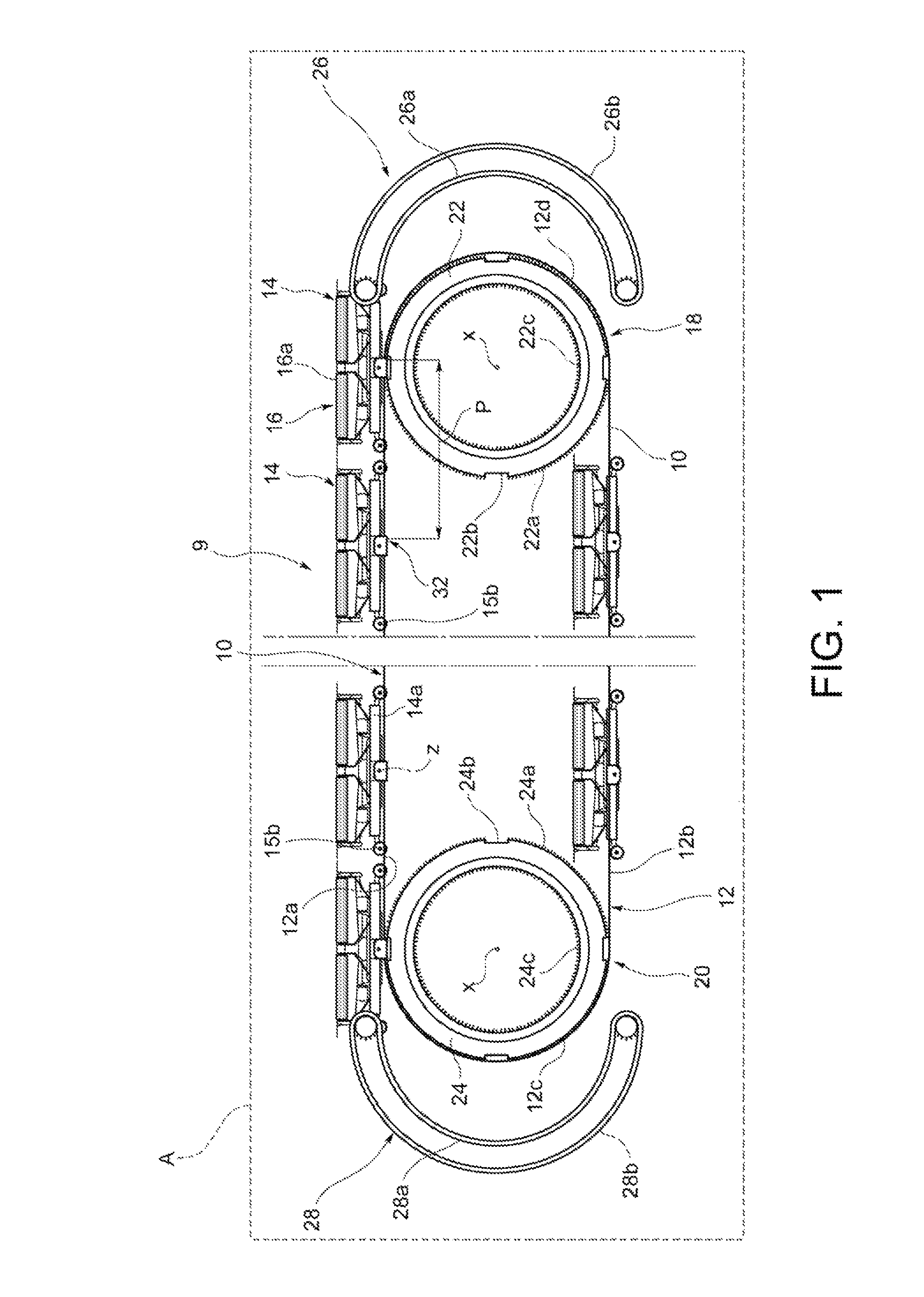

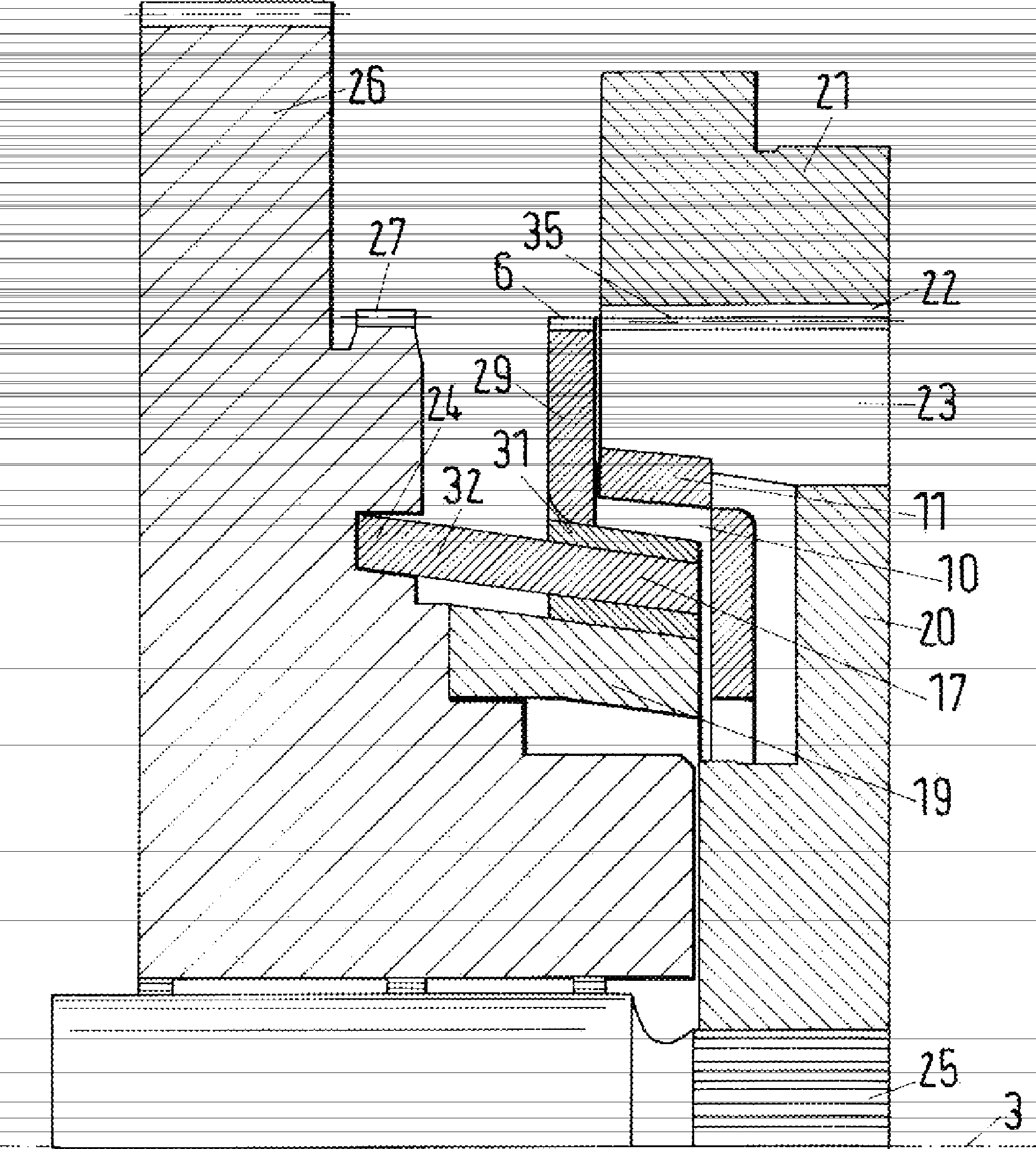

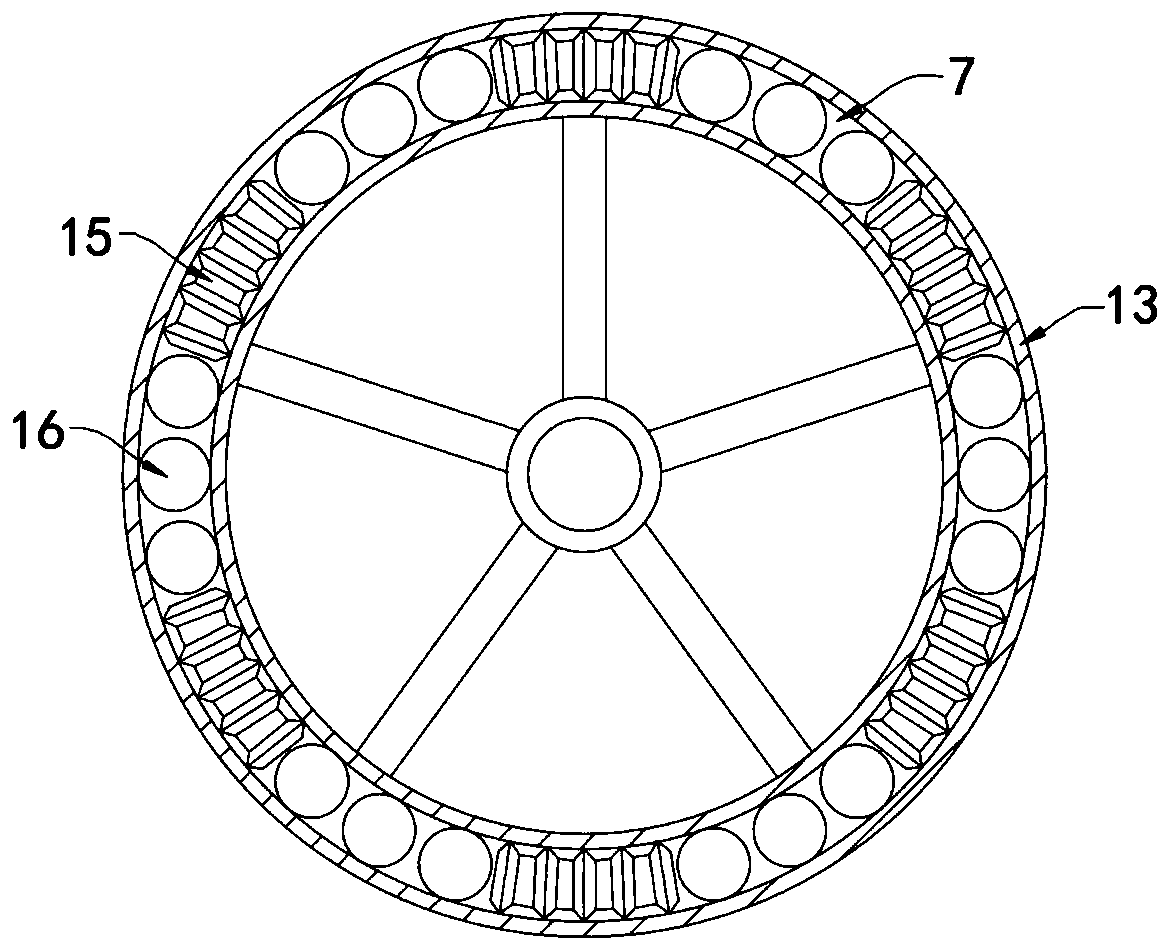

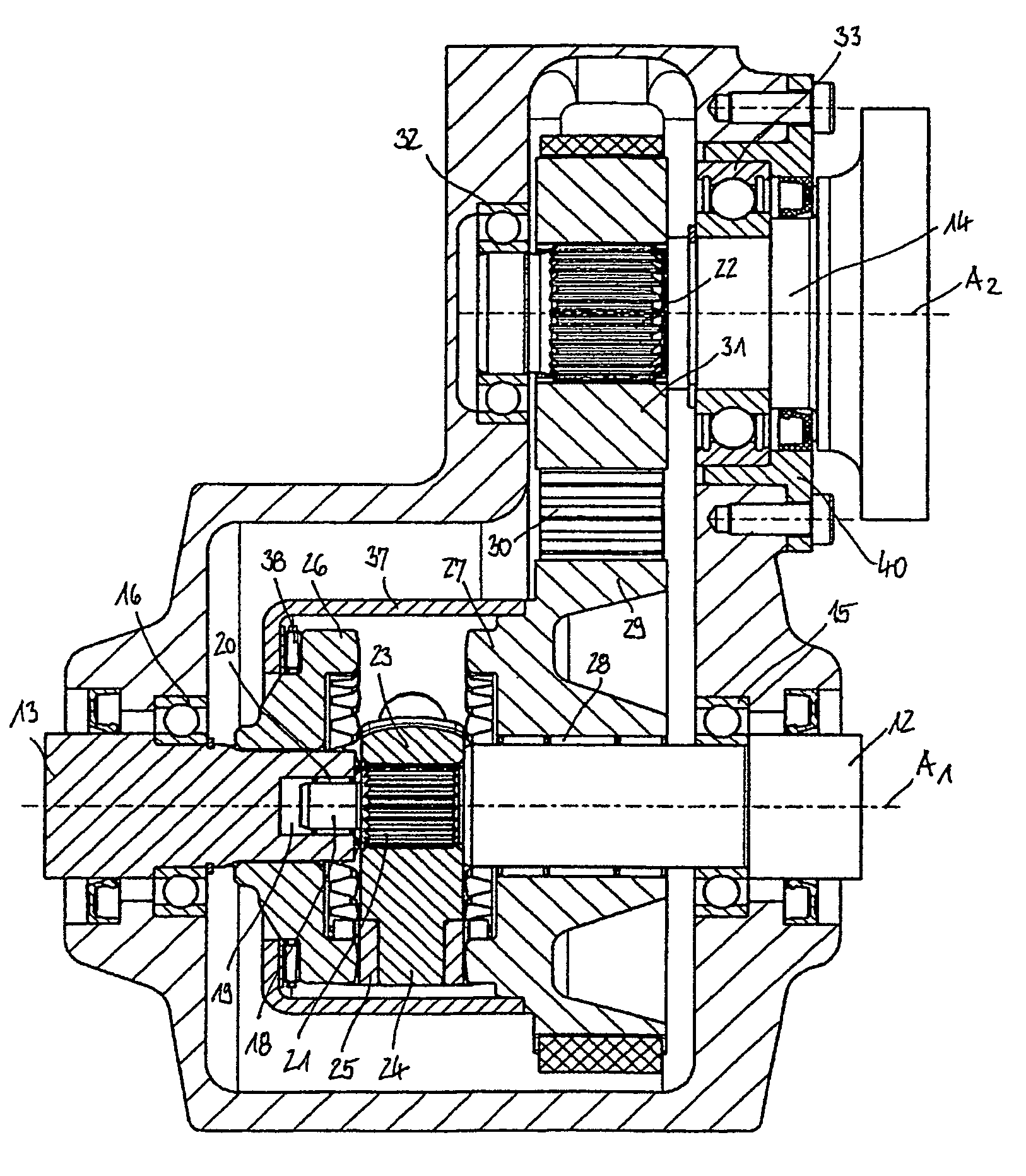

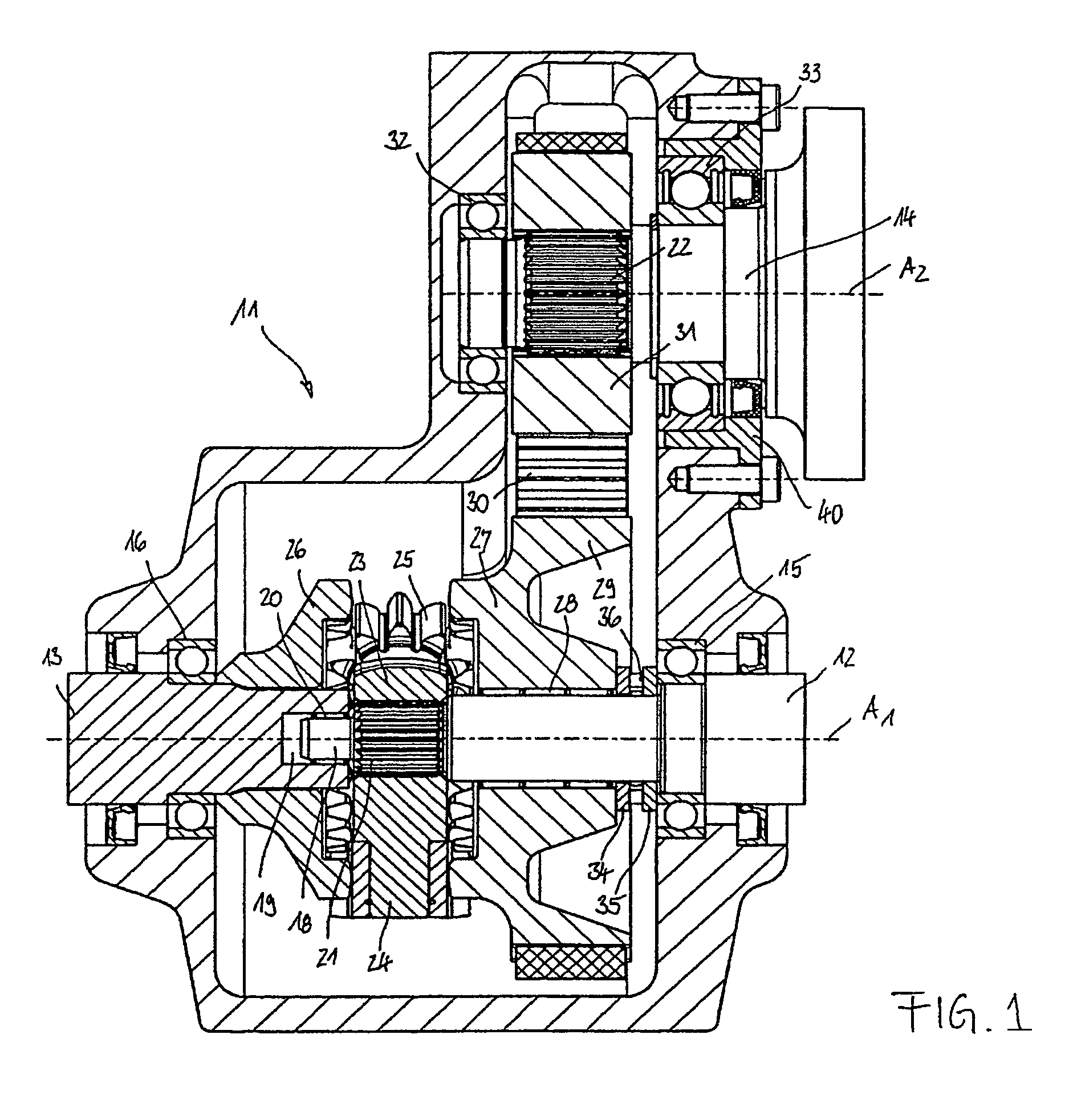

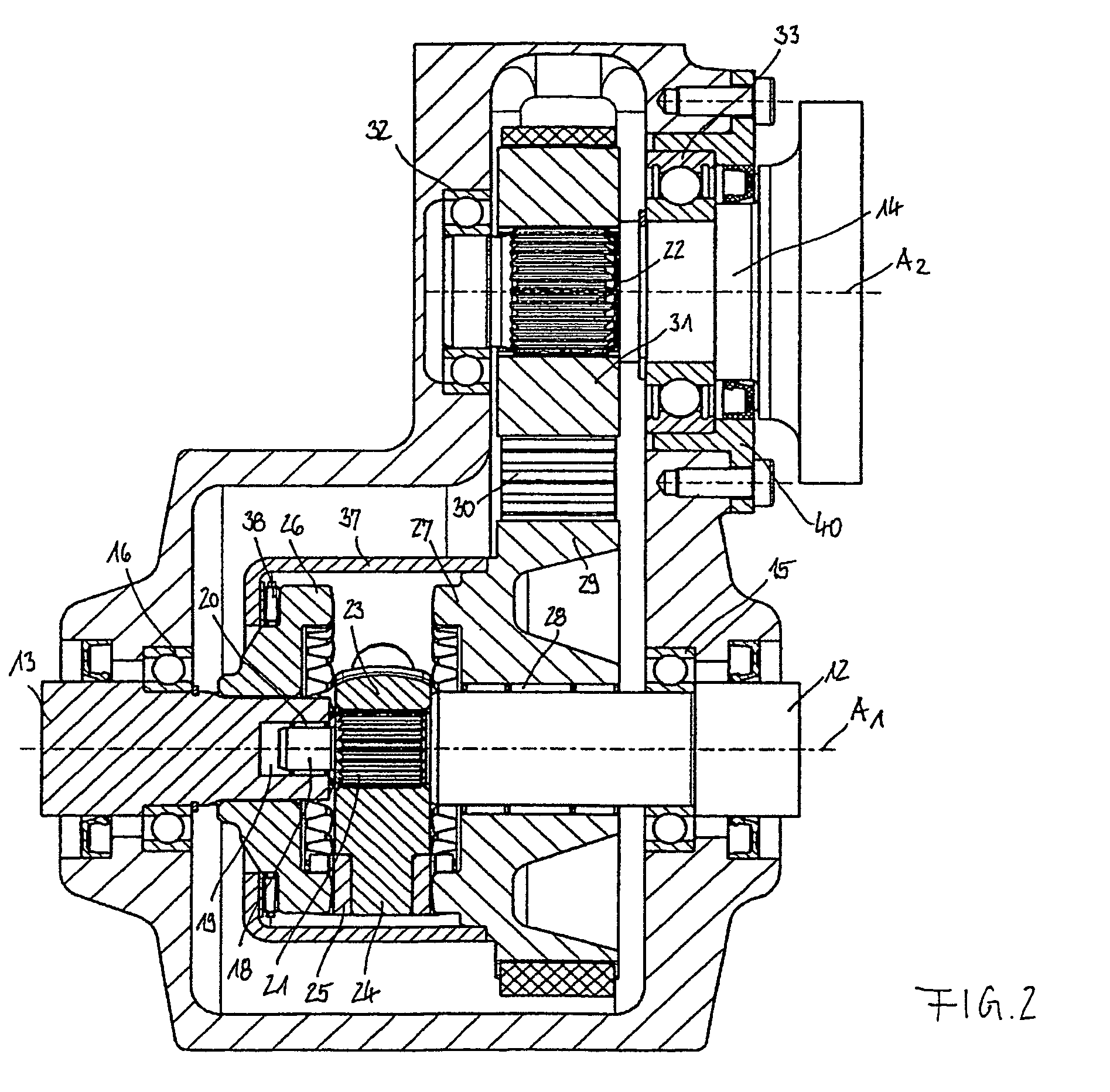

Device for rotational coupling of a crown gear to a wheel and aircraft landing gear provided with such a device

The invention relates to a device (32) for rotationally coupling a wheel (10) with a ring (31) for driving the wheel (10) mounted so as to rotate coaxially with the wheel (10). According to the invention, the device (32) comprises a plurality of connecting members (60) each extending in a direction contained in a plane perpendicular to the axis of rotation and forming an angle with a radial direction, the connecting members (60) being pivotably mounted on the one hand on the wheel (10) and on the other hand on the ring (31).

Owner:SAFRAN LANDING SYSTEMS

Planetary gear

InactiveUS20110009232A1Reduce in quantityIncrease gear ratioToothed gearingsGearing detailsGear driveGear wheel

A planetary gear drive comprises two stages. Each of two stages comprises a central sun gear, a crown gear, several satellites located on a carrier between the sun gear and the crown gear, input and output shafts. The sun gear of the first and second stages is rigidly connected to each other. The input shaft is rigidly connected with the sun gear of the first stage. The carriers of the first and the second stages are rigidly connected to each other and, the output shaft is rigidly connected with the crown gear of the second stage (first embodiment). The crown gears of the first and the second stages are rigidly connected to each other, and the output shaft is rigidly connected with the carrier of the second stage (second embodiment).The satellites are at least at one stage are unevenly distributed around.

Owner:KAPELEVICH ALEXANDER

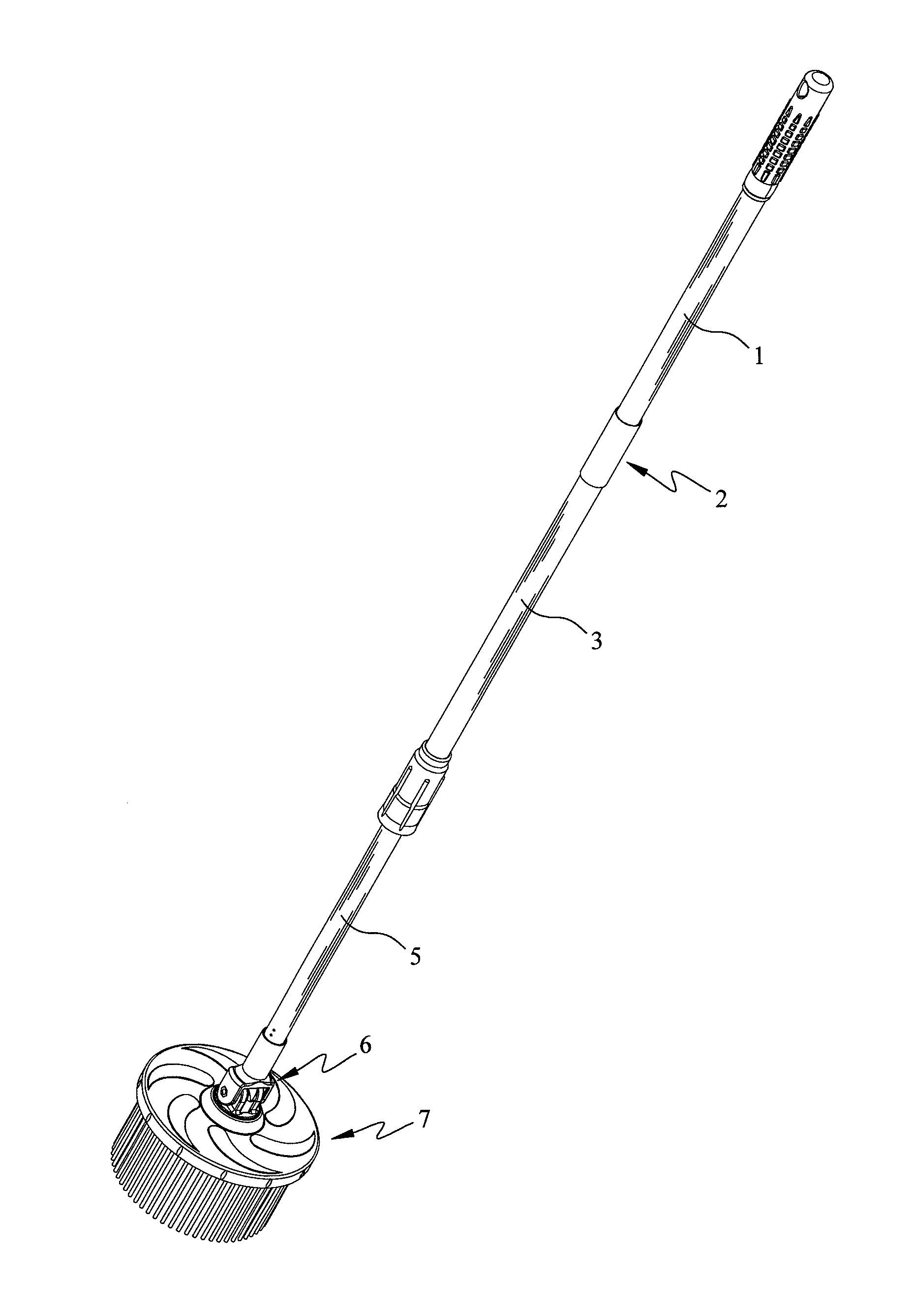

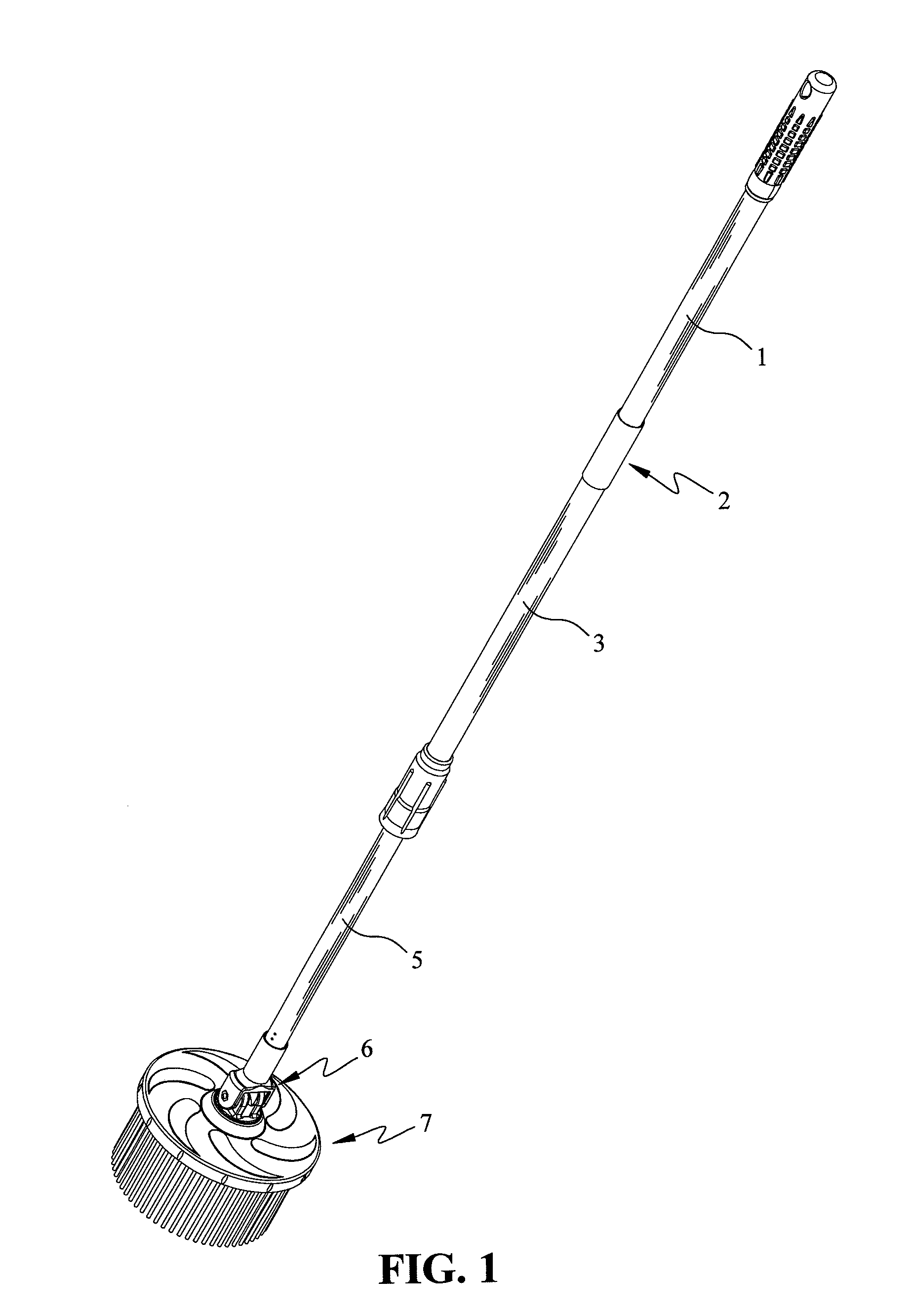

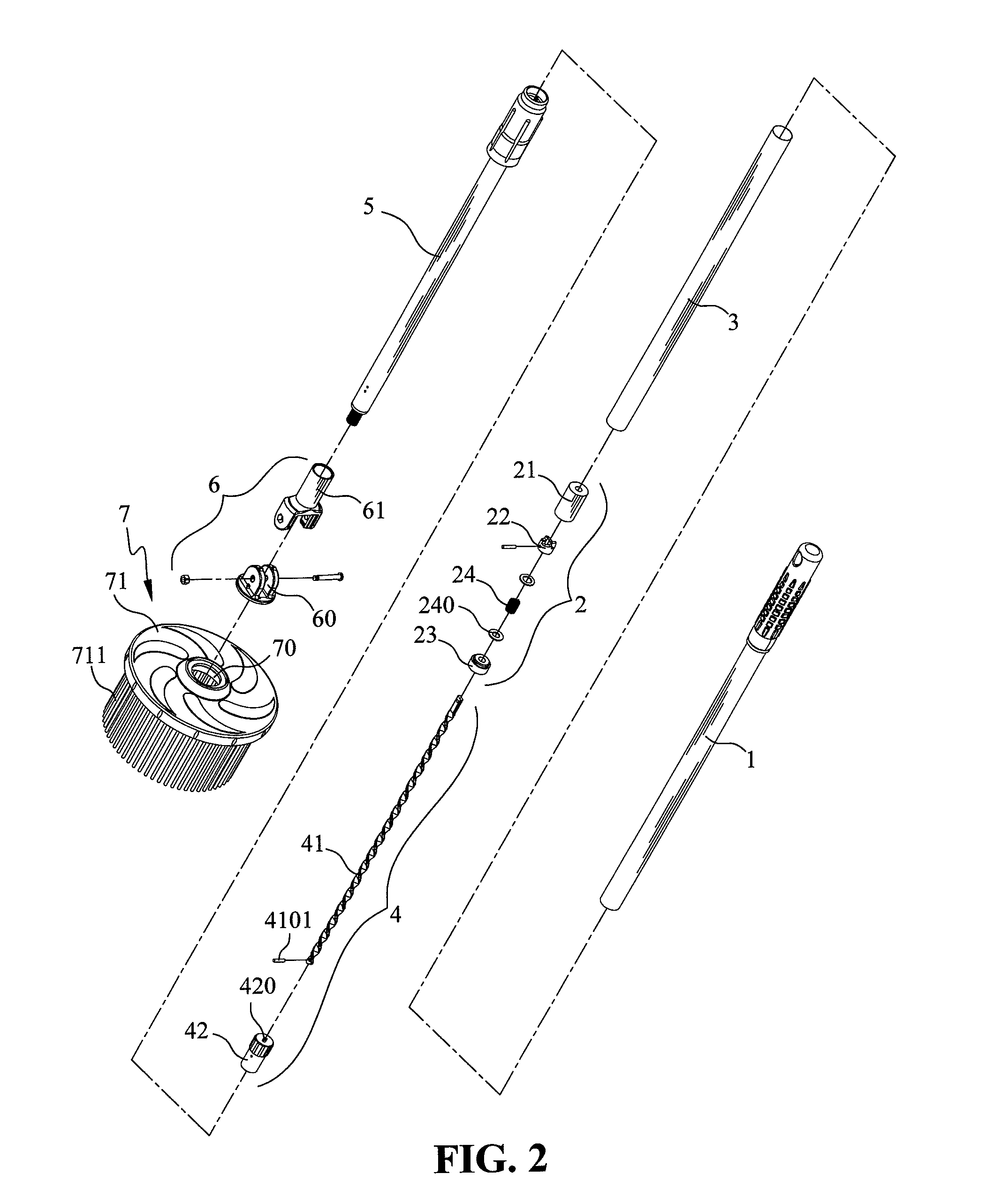

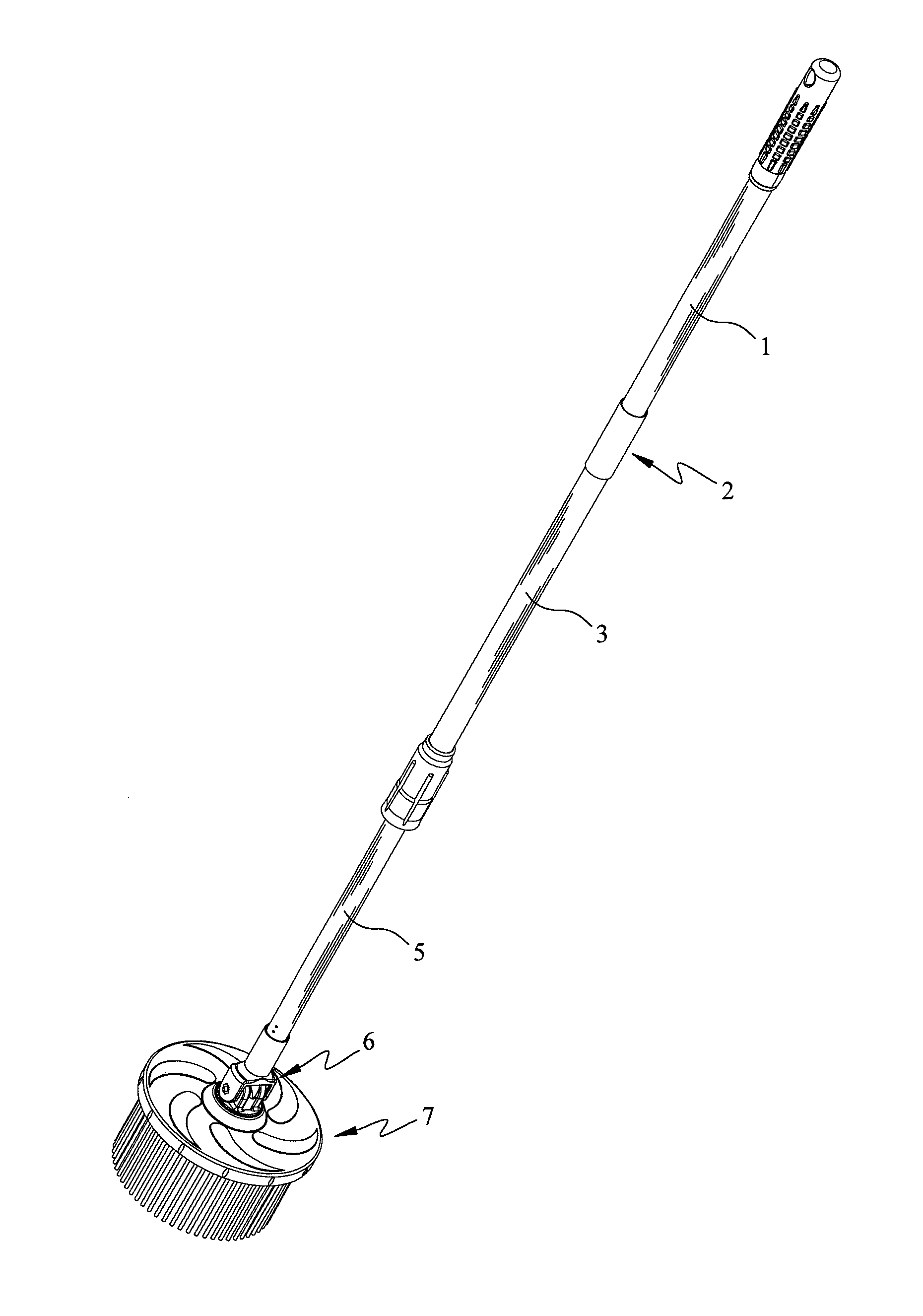

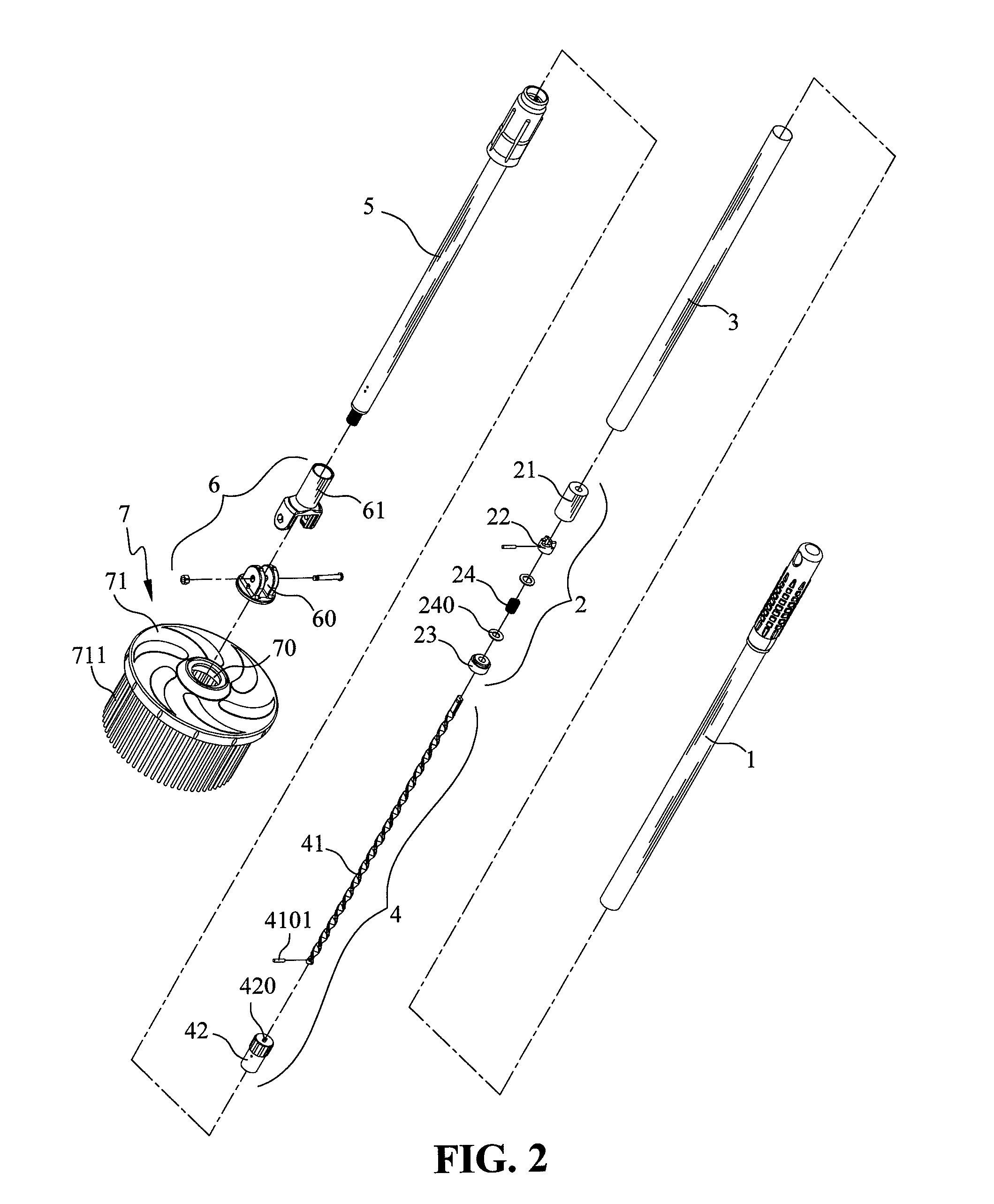

Mop with spinning device

A mop includes a handle connected to one end of a first rod. The other end of the first rod is connected to a second rod. A driving unit includes a spiral member disposed in one end of the second rod. A clutch unit is disposed in the first rod. A mopping unit is pivotably connected to the other end of the second rod. The clutch unit includes a sleeve disposed in the first rod and having a crown teeth defined in a lower end thereof. A bearing is connected to an opening of the sleeve, which is rotatable relative to the bearing. A crown gear is disposed in the sleeve and separably engaged with the crown teeth. A spring is disposed between the crown gear and the bearing. The spiral rod inserts through the bearing and the spring and is fixed to the crown gear.

Owner:YU TSUNG MOU

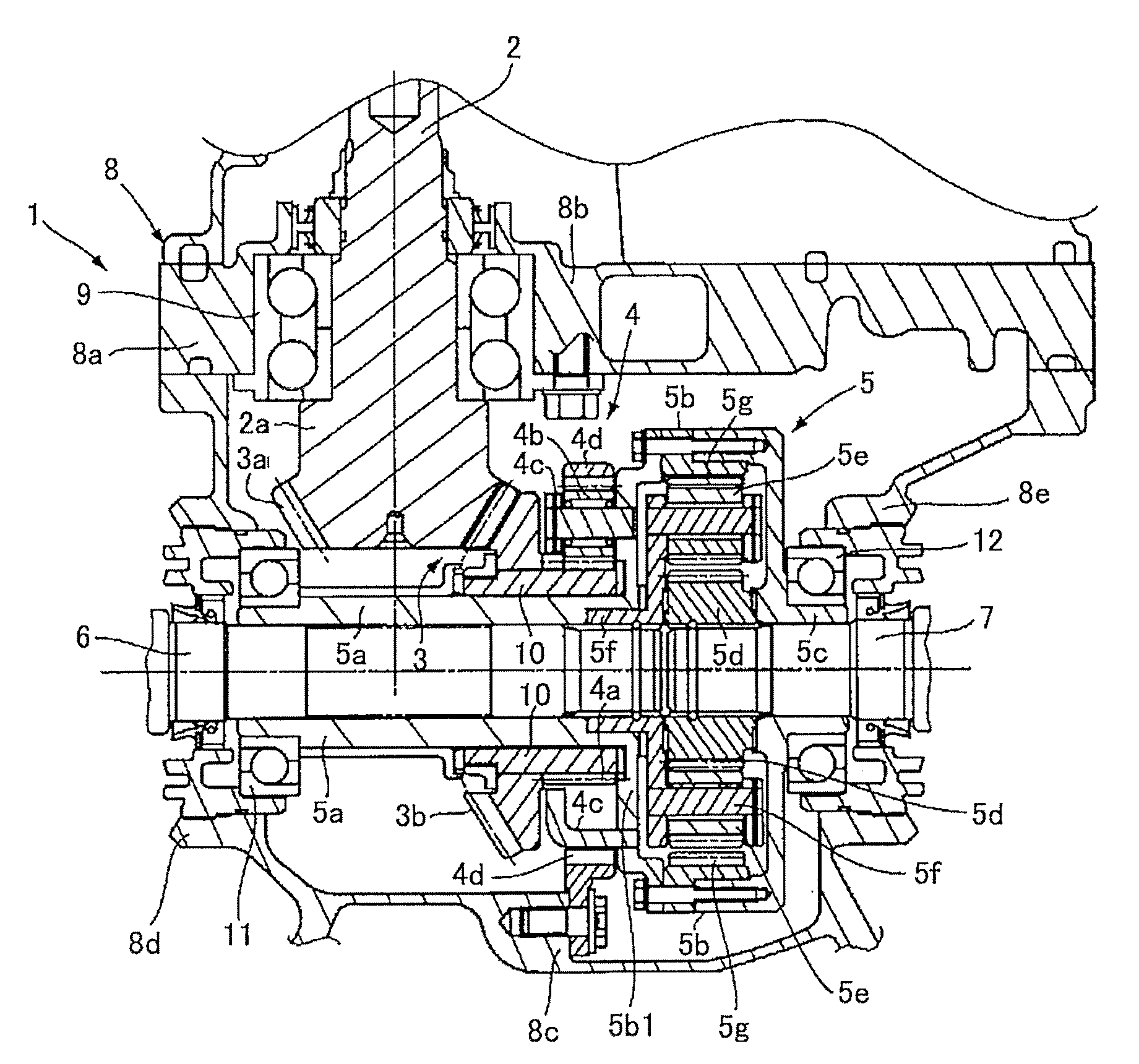

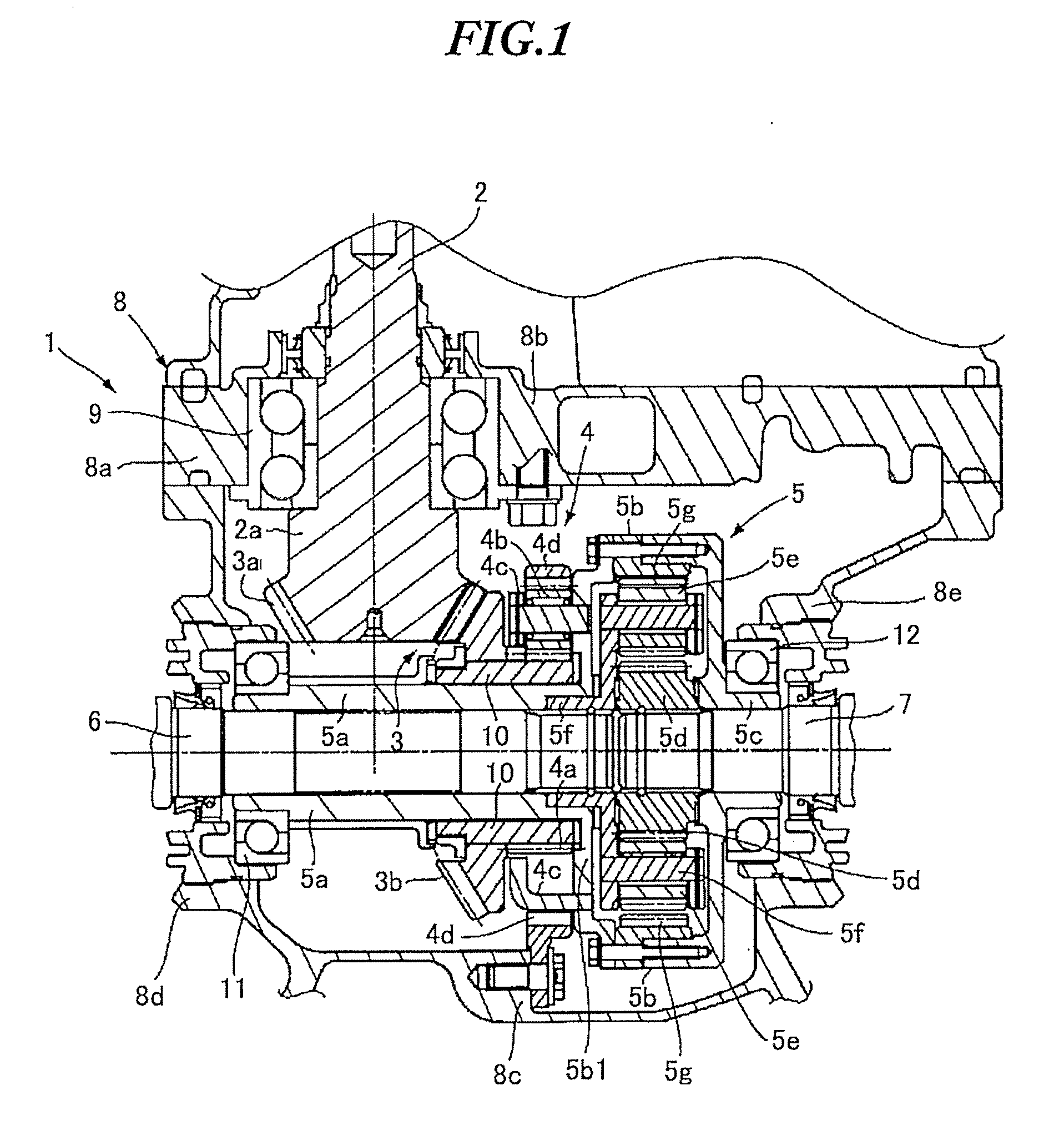

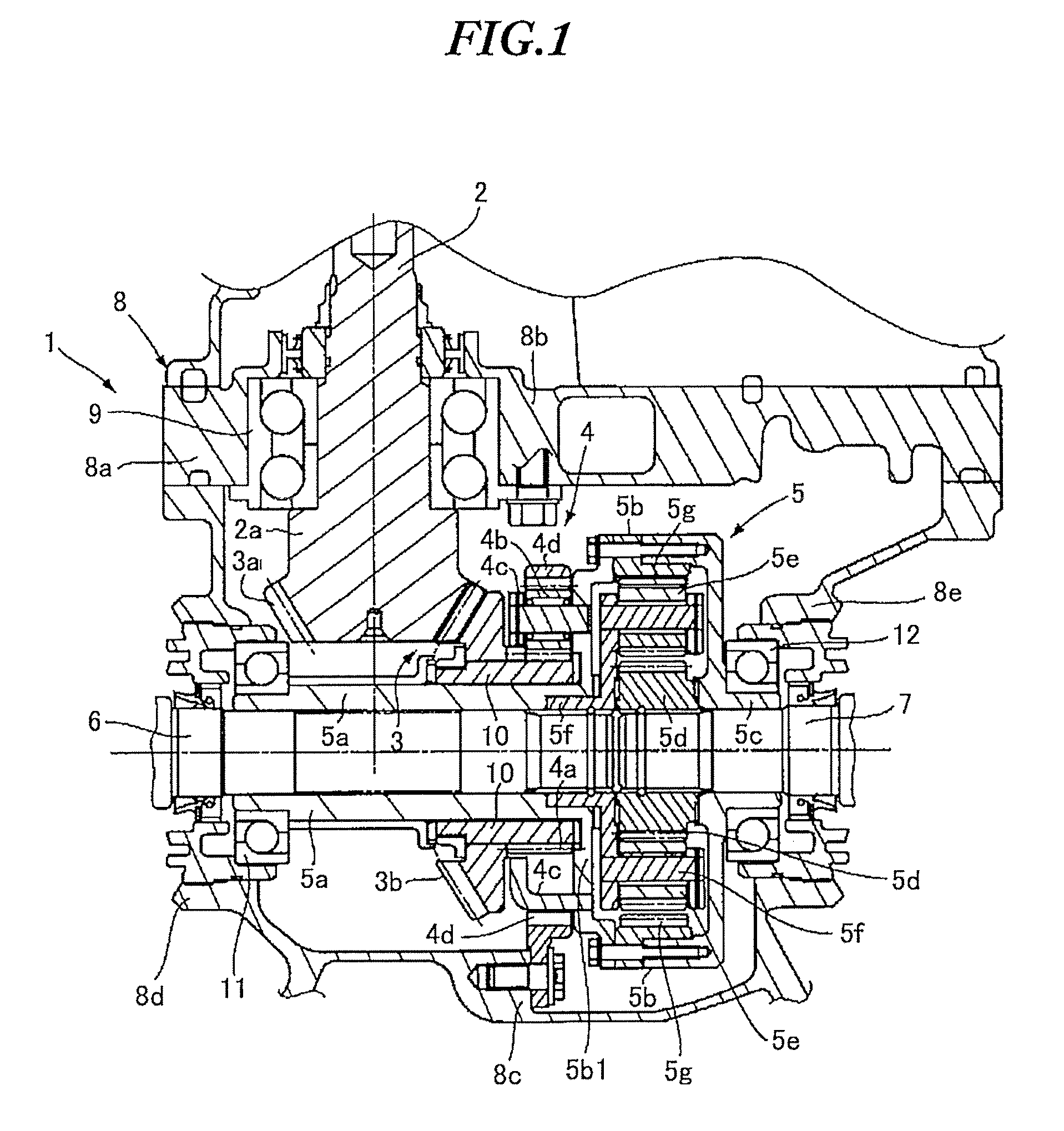

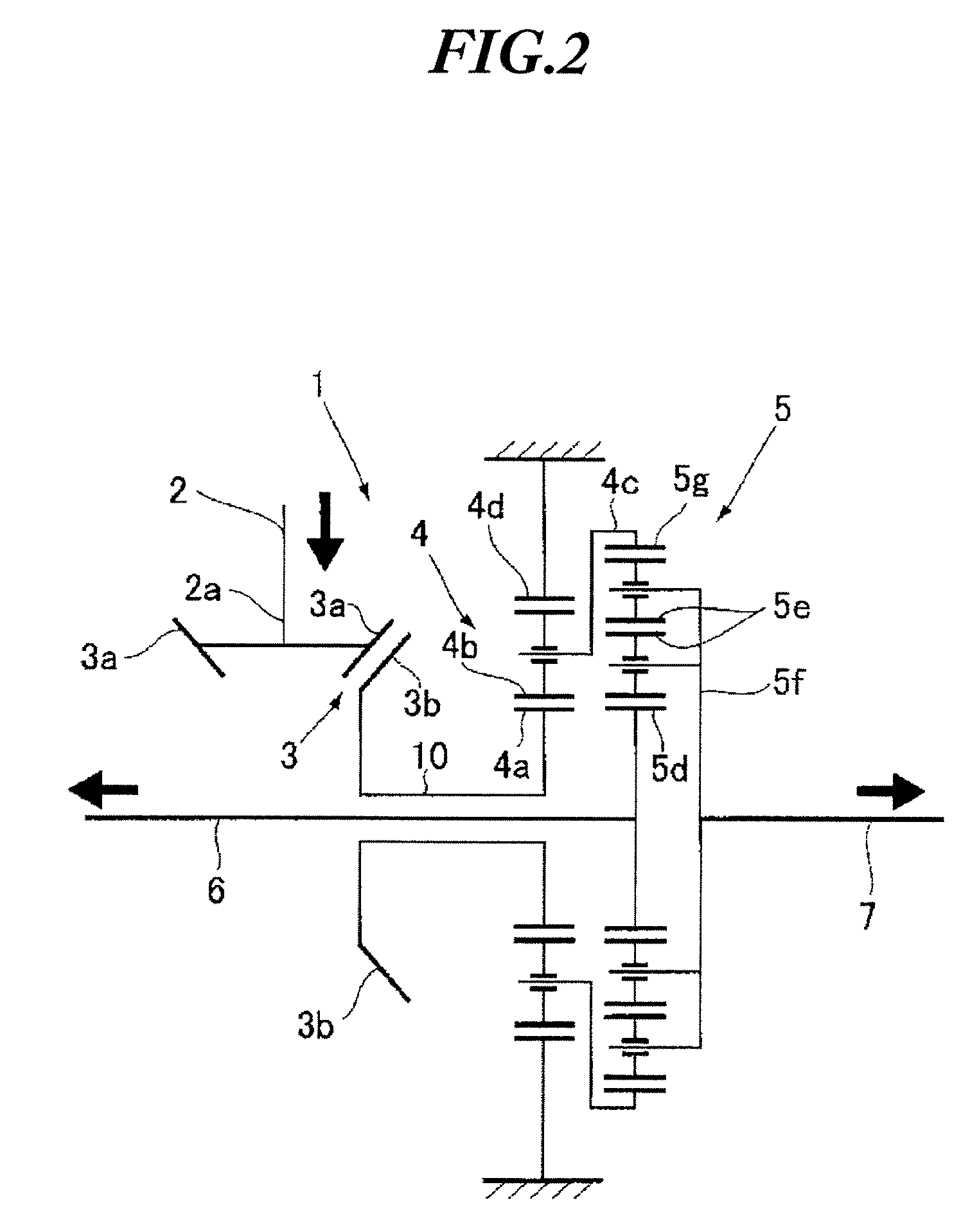

Differential apparatus for vehicle

InactiveUS20080287245A1Reduce the overall diameterEliminate needRoad transportDifferential gearingsSpur gearCrown gear

An orthogonal axis gear, a planetary gear reduction mechanism portion, and a differential gear mechanism portion are arranged along an axial center direction of left and right output shafts. The planetary gear reduction mechanism portion is constituted such that a sun gear thereof is provided as a continuation of a crown gear of the orthogonal axis gear, a ring gear thereof is fixed to a differential case, and a planetary carrier thereof serves as an output. Further, the differential gear mechanism portion employs a planetary gear mechanism and is constituted such that a ring gear of the planetary gear mechanism is provided as a continuation of the planetary carrier of the planetary gear reduction mechanism portion, a planetary carrier thereof is provided as a continuation of the left side output shaft, and a sun gear thereof is provided as a continuation of the right side output shaft.

Owner:SUBARU CORP

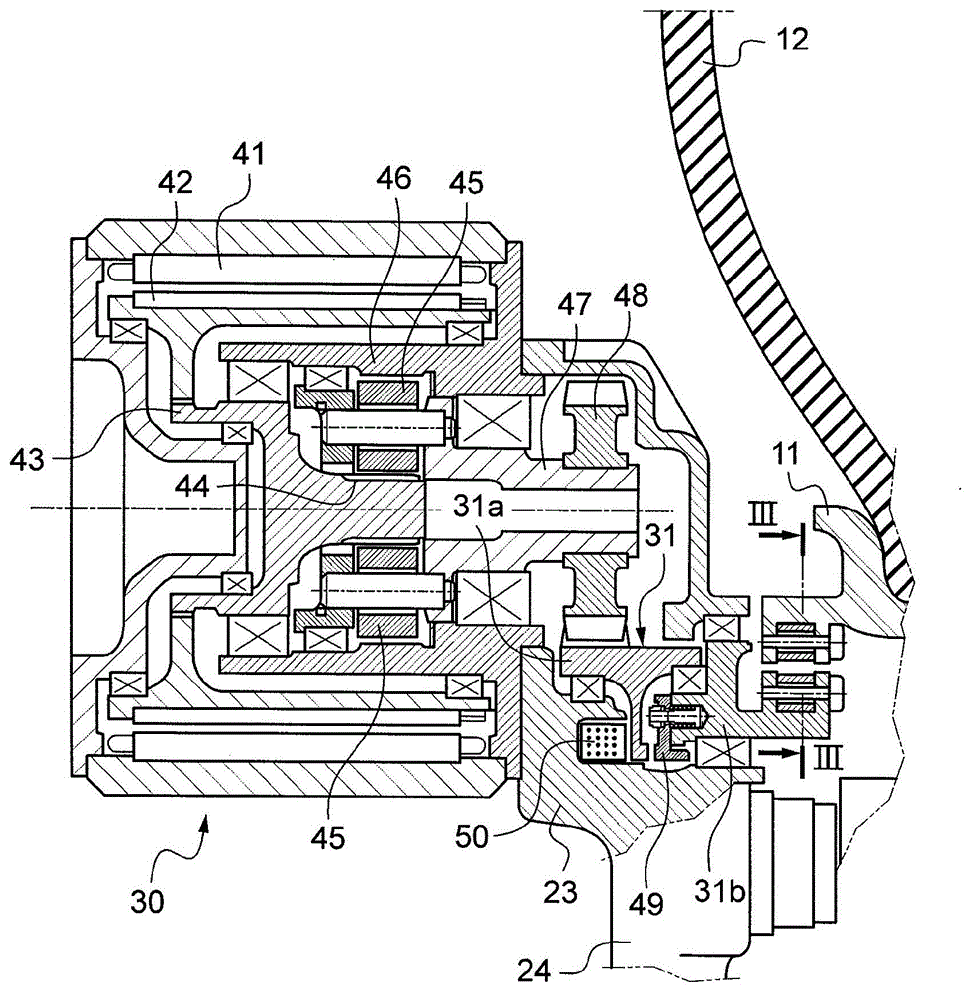

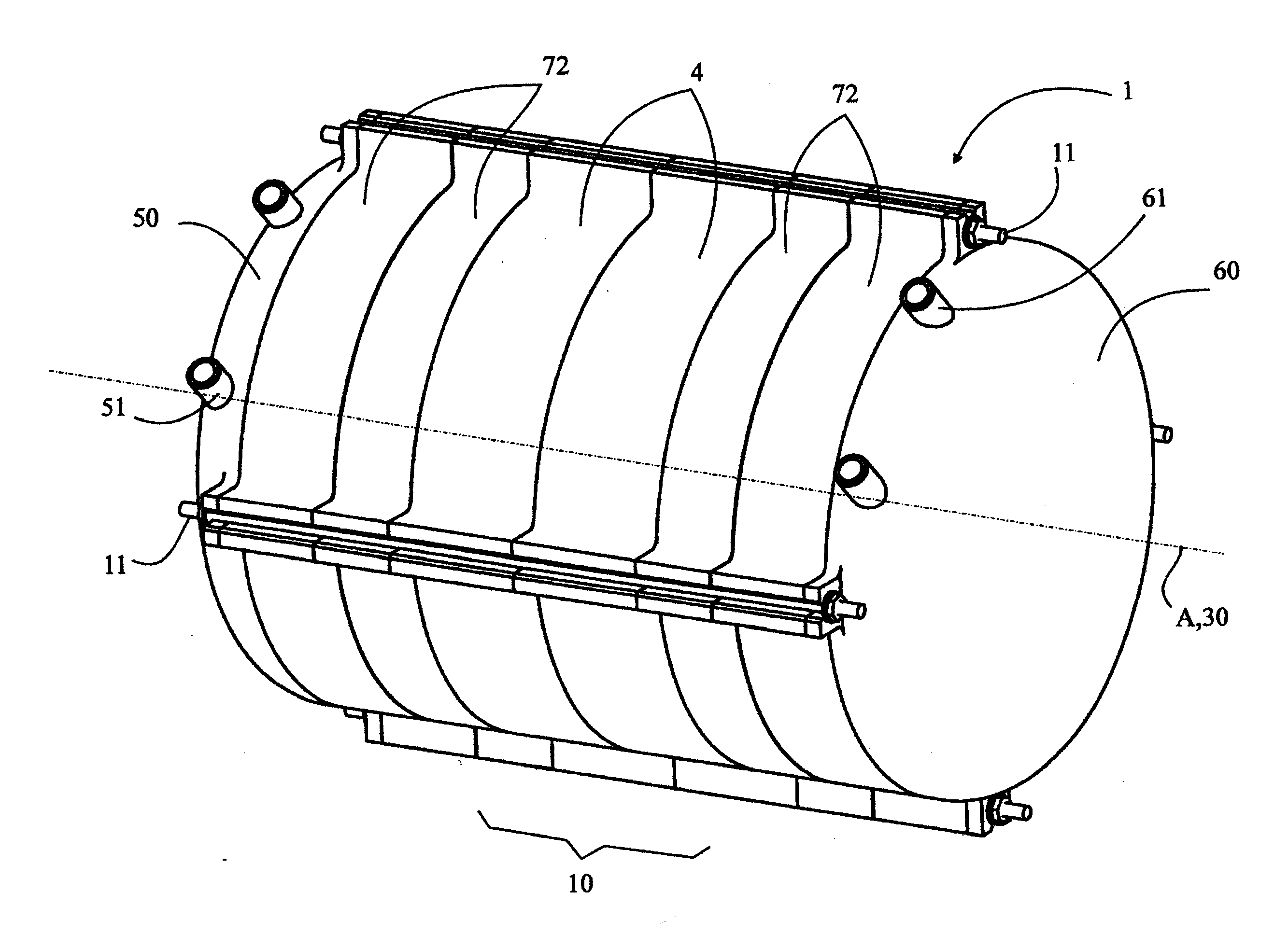

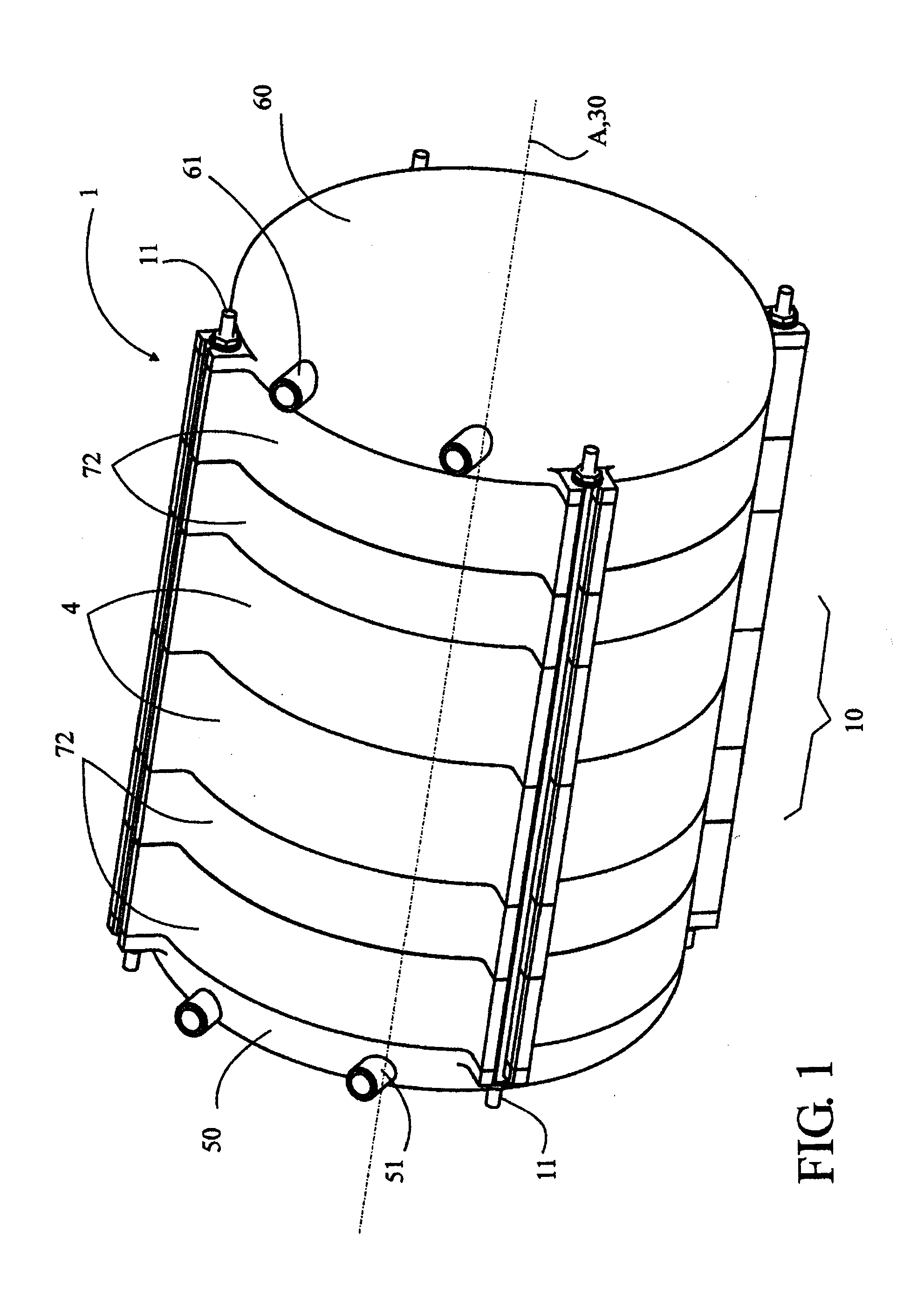

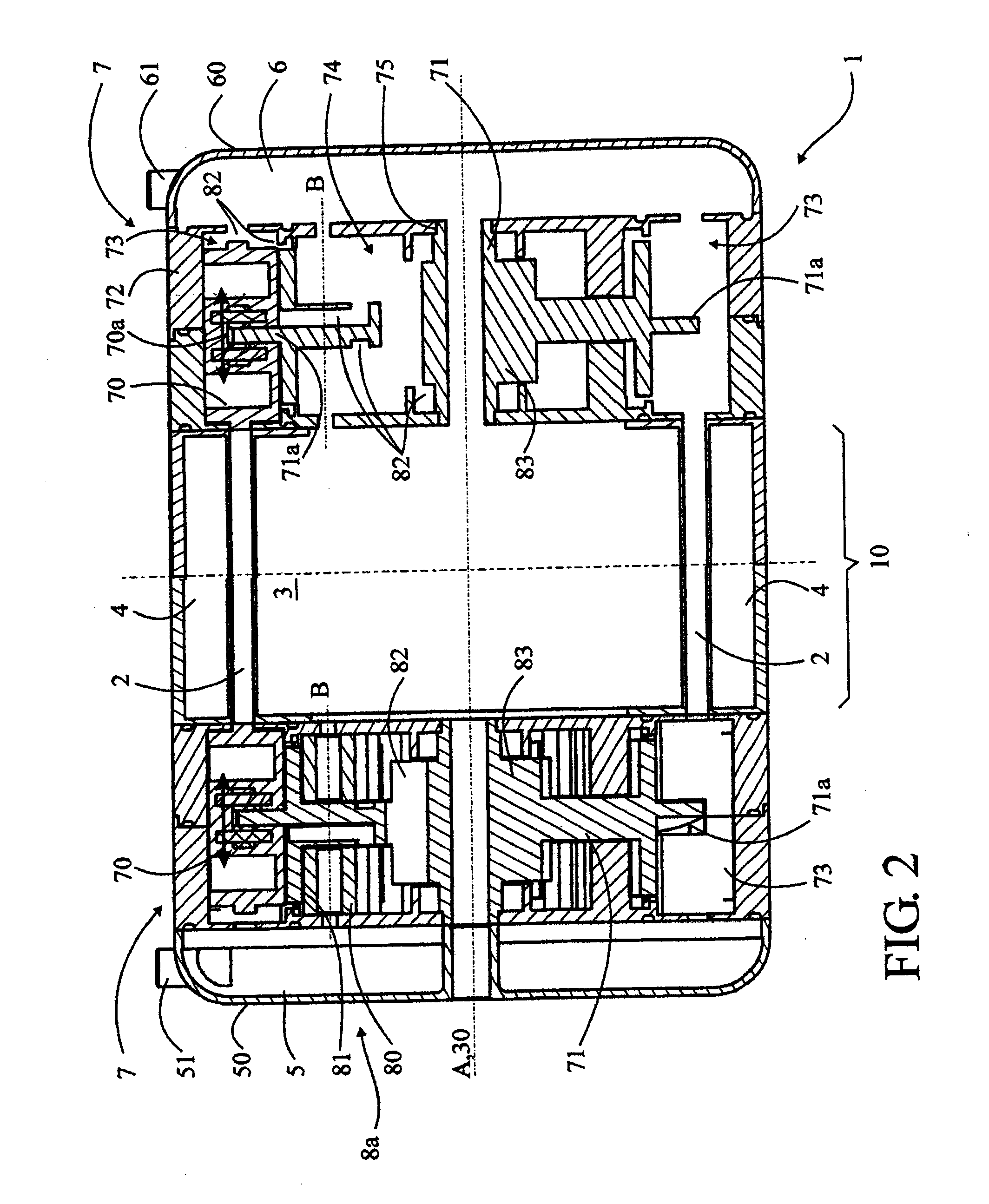

Magnetocaloric generator

InactiveUS20100300118A1Improve efficiencyIncrease calorific powerEnergy efficient heating/coolingMachines using electric/magnetic effectsGear pumpDrive shaft

A generator comprising at least one thermal stage having magnetocaloric elements (2) arranged around an axis and a magnetic arrangement (3) supported by a drive shaft (30) that rotates about the axis to subject the elements to a variation in magnetic field. The generator comprises pistons (70) to force heat transfer fluid through the elements with the pistons being driven in reciprocating translation within chambers (73) by at least one cam (71) that is rotationally driven the drive shaft (30). The generator comprises a forced circulation unit (8a) having planet gears (80) arranged around the central axis, supported by the body (72) of the generator and meshing with an inner crown gear (81) integral with the cam (71). Each gear (80) forms a gear pump that mixes the heat transfer fluid and places the fluid in forced circulation in the tanks (74) and the chambers (73).

Owner:COOLTECH APPL S

Reciprocating power tool

ActiveUS9073563B2Reliable lockingReduce forceMetal sawing devicesOperator-supported drilling machinesMotor driveDrive shaft

Owner:CRYSTAL GLASS CANADA

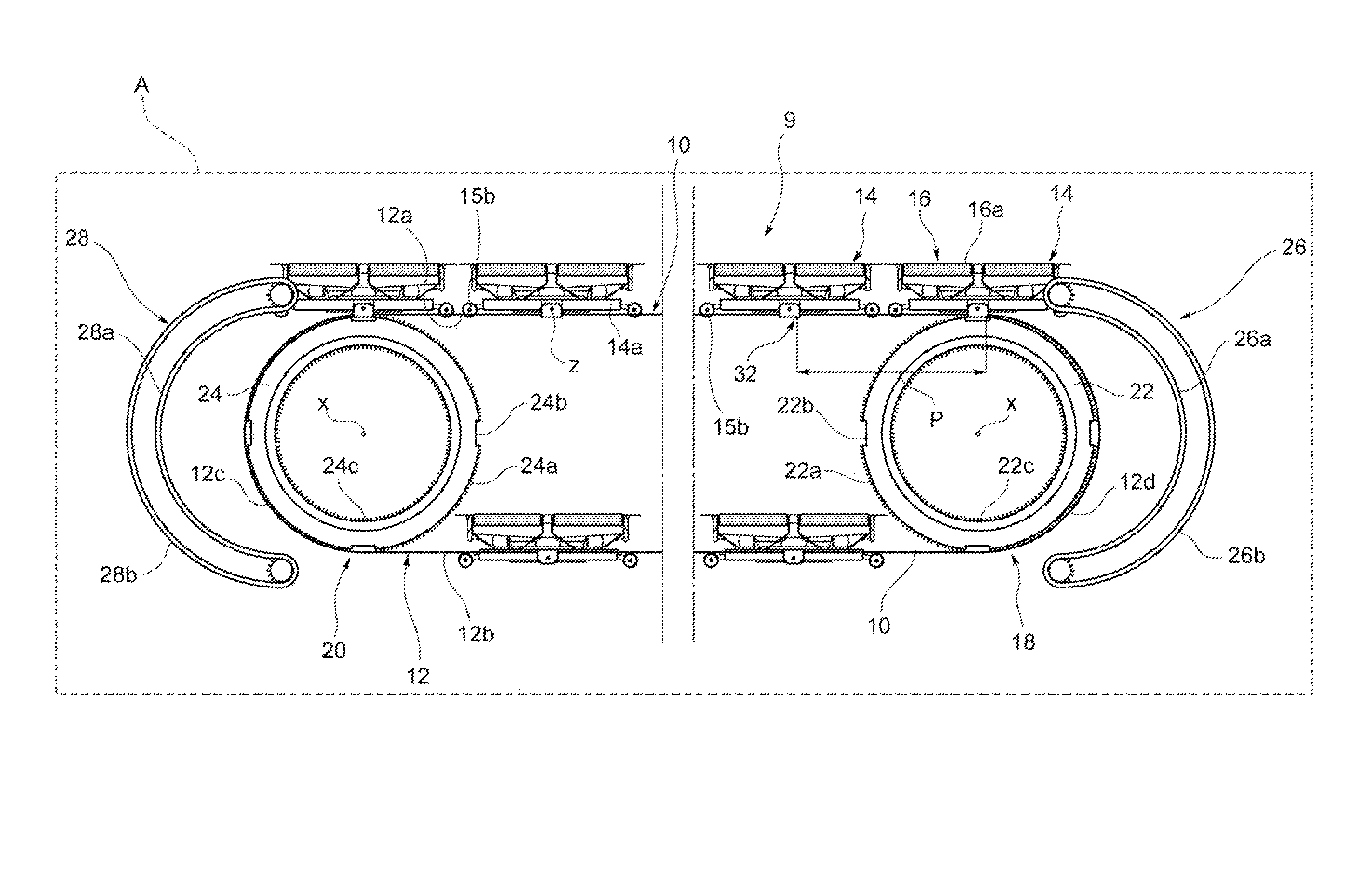

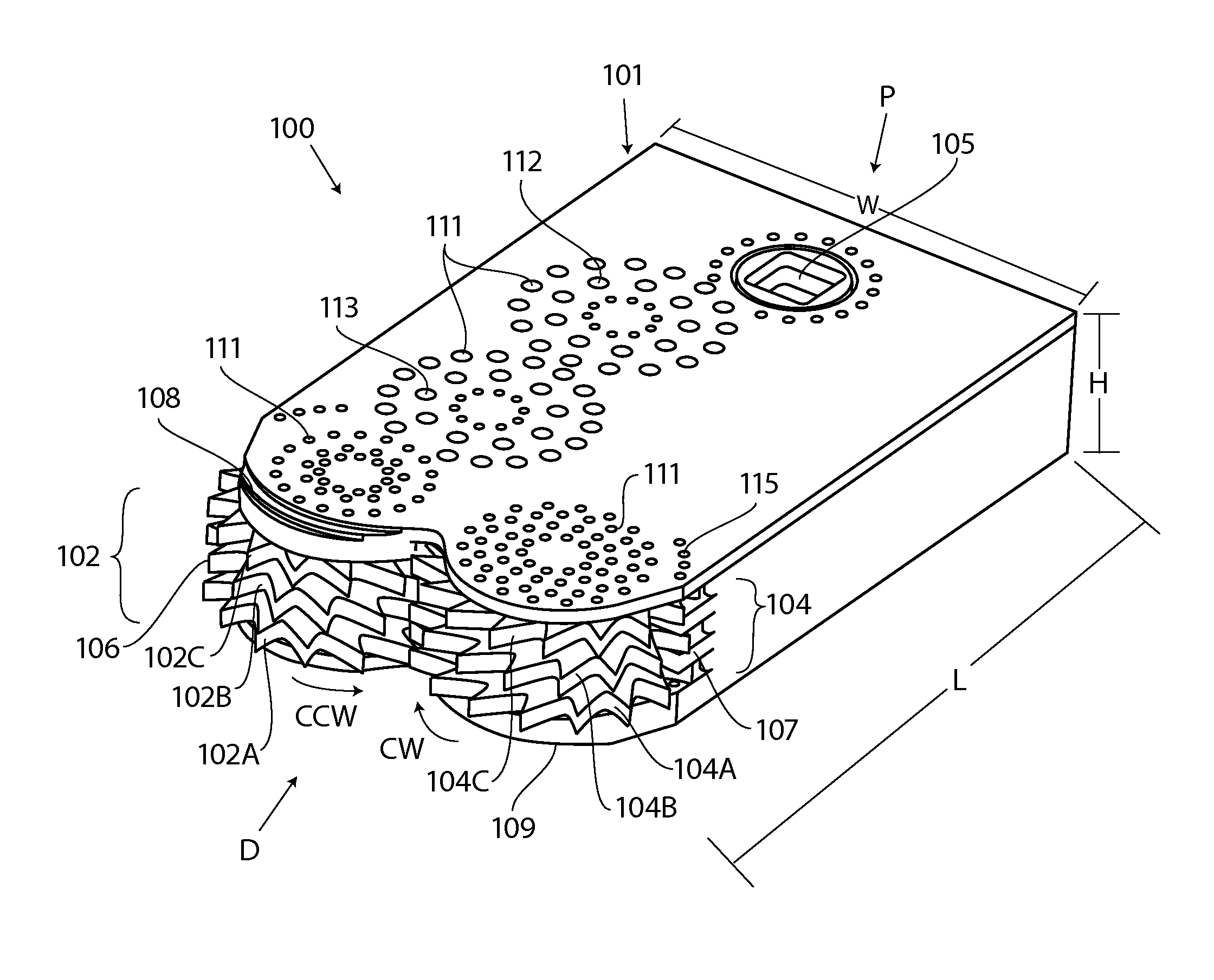

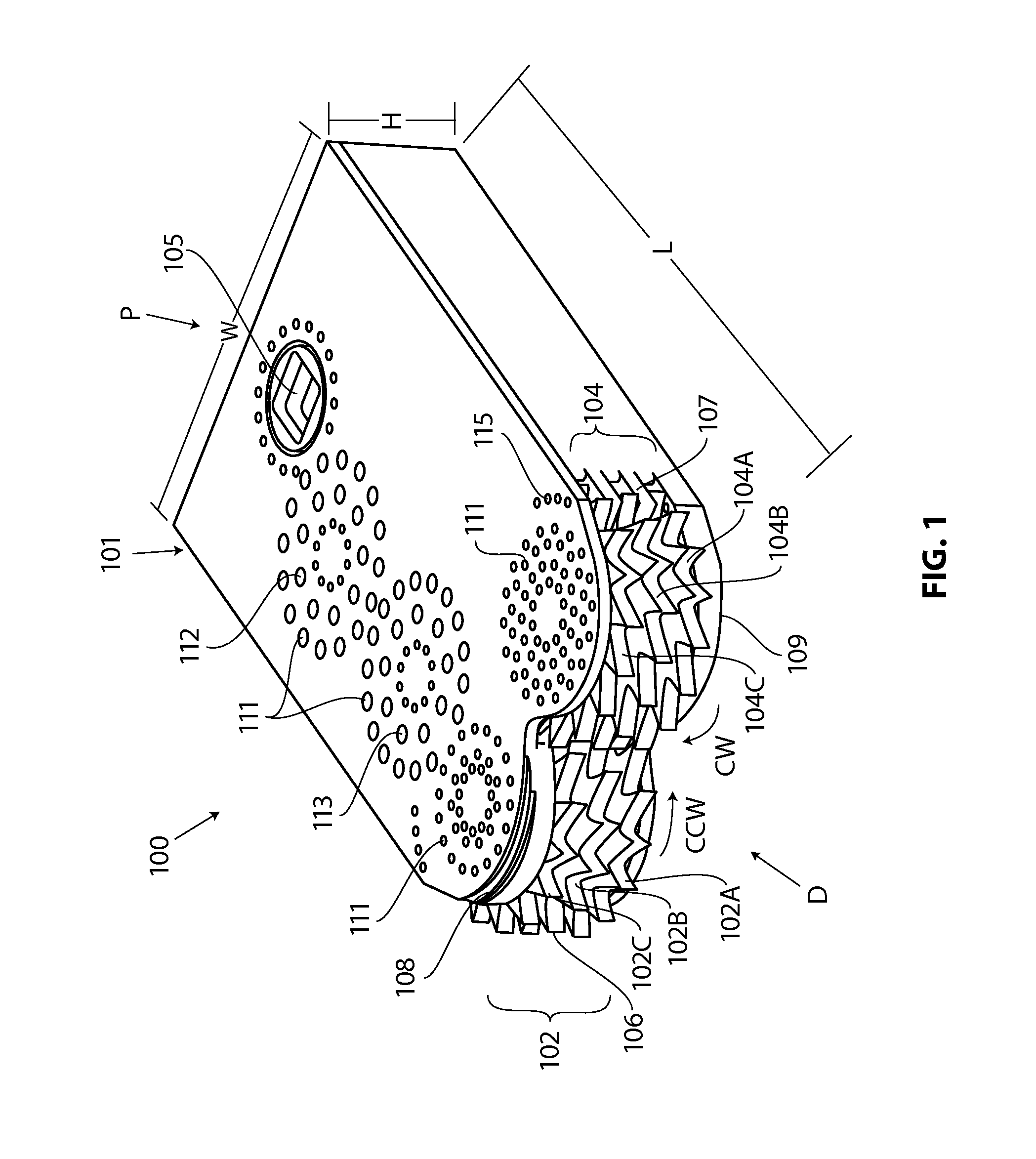

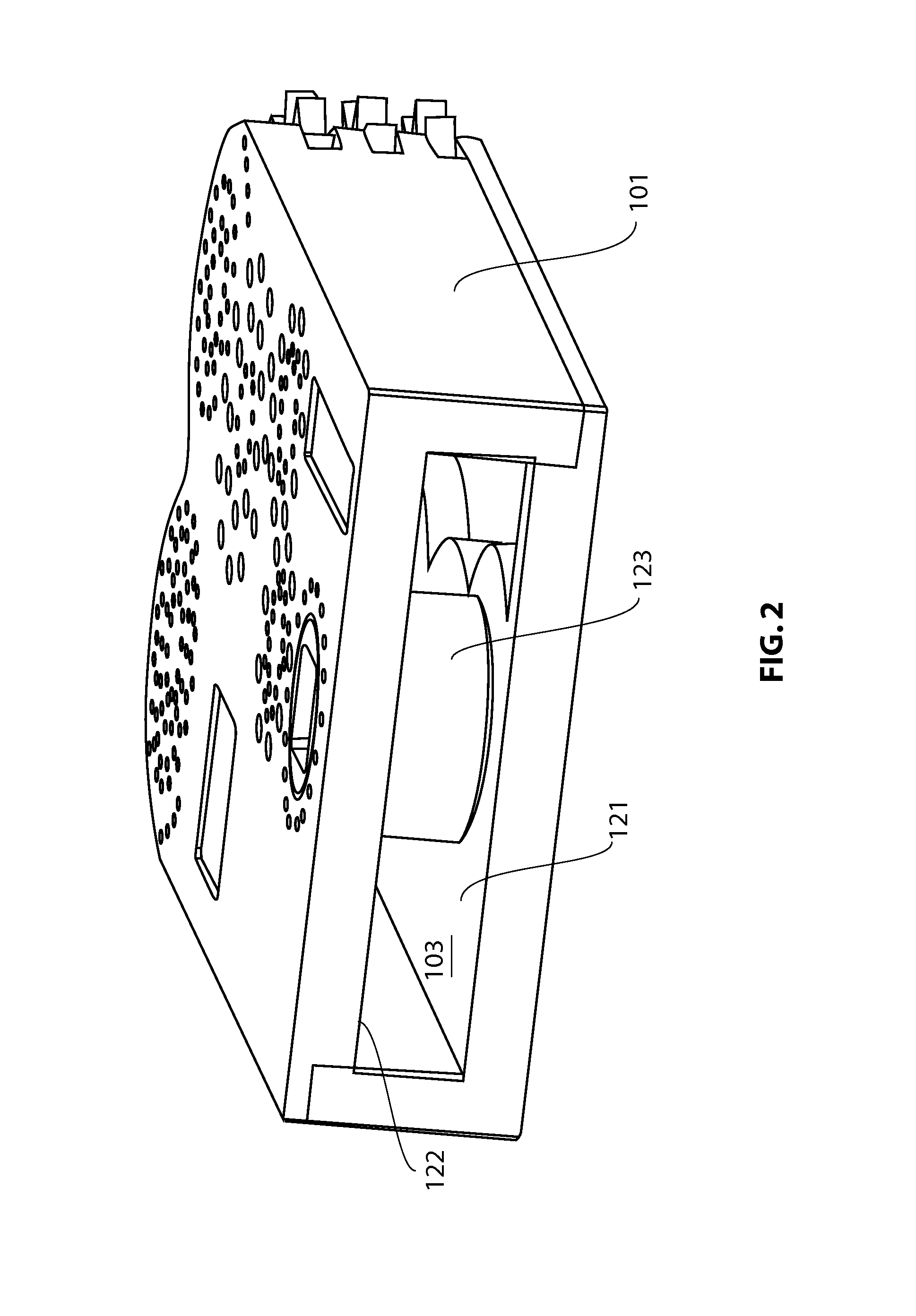

Machines for sorting objects

Machines for sorting objects having a series of carriages fixed at a given interval (P) to two drive belts configured to move along closed-loop paths in two parallel vertical planes are provided. Each path may include a top horizontal section and a bottom horizontal section joined together by two curved connecting end sections. Two end assemblies may be arranged at the curved end sections of the path. Each assembly may include crown gears which are configured to engage with the belts and a series of sliders which are configured to retain the carriages along a semicircular section close to the crown gears. The carriages are thus able to perform a rotary / translational movement along the end connecting sections and keep their support surface horizontally oriented.

Owner:LEONARDO

Mop with spinning device

InactiveUS8959697B2Reduce wearExtended service lifeLiquid processingCarpet cleanersEngineeringCrown gear

Owner:YU TSUNG MOU

Synchronizer ring

InactiveCN103511497APrecisely synchronized process assuranceSimplify the placement processMechanical actuated clutchesShortest distanceEngineering

A synchronizer ring for a synchronizer of a switchable gear changing transmission, includes a ring body having a synchronizer ring axis, which ring body has an inner friction surface and an outer installation surface, wherein the inner friction surface and the outer installation surface bound the ring body as jacket surfaces. The ring body has an end face and a gear surface opposite the end face, wherein the synchronizer ring has a width (15) which corresponds to the shortest distance between the end face and the gear surface and the jacket surfaces extend between the end face and the gear surface, wherein the ring body has a toothed arrangement which extends radially outwardly from the outer installation surface, wherein the toothed arrangement has a crown gear which extends from the gear surface via a part of the width of the ring body in the direction of the end face, characterized by a recess which is arranged at the inner friction surface of the ring body, so that the radius of the inner friction surface in the region of the recess is larger than the radius of the inner friction surface; at the end face, and wherein a bulge is provided at the outer installation surface which is arranged in the radial direction over the recess.

Owner:SULZER FRICTION SYST GERMANY

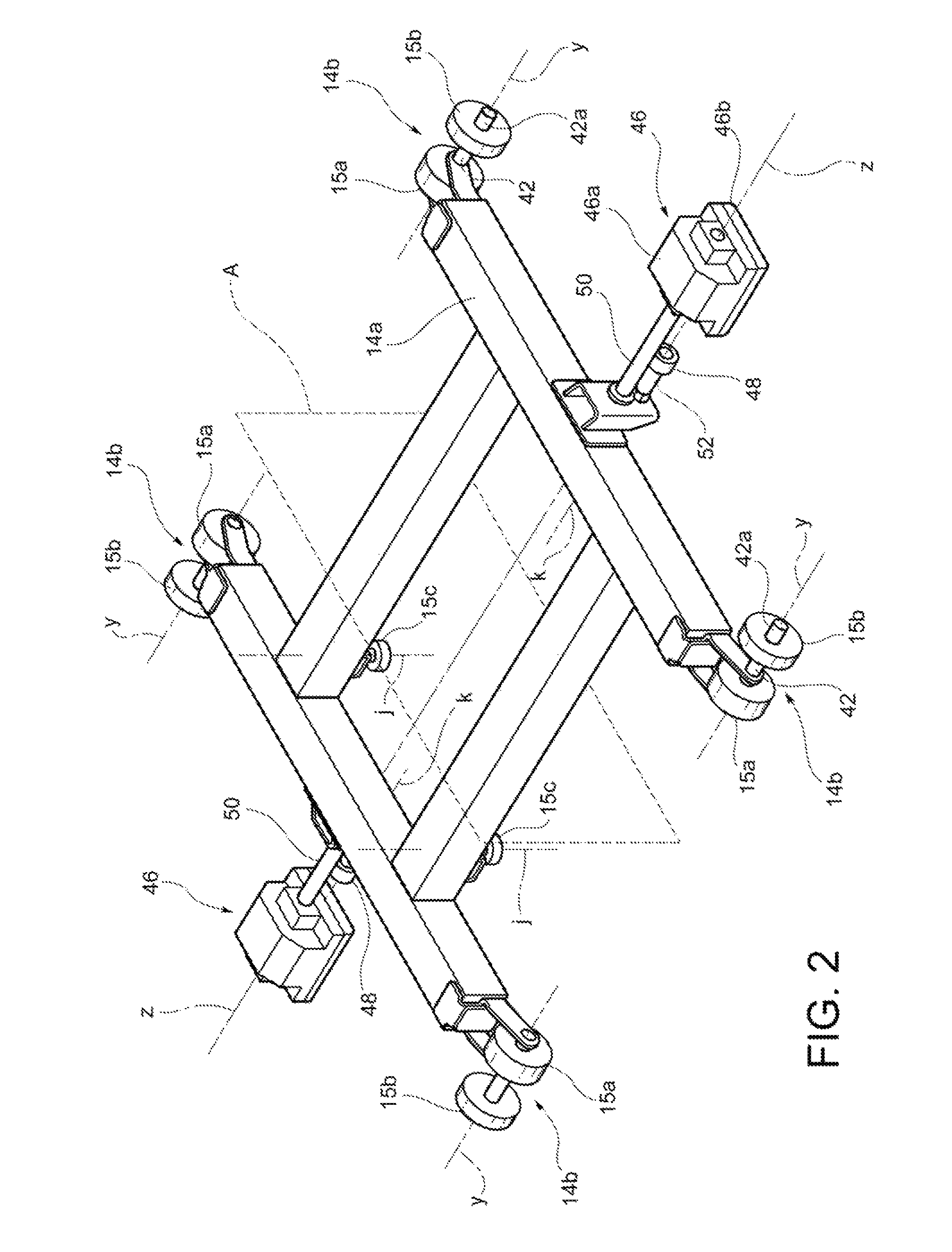

Dual-shaft synchronous transmission device

ActiveUS9310849B2Smooth rotationDigital data processing detailsWing accessoriesGear wheelEngineering

A dual-shaft synchronous transmission device is applied to an electronic apparatus. The distance between the two shafts of the dual-shaft synchronous transmission device is shortened so that the electronic device can be thinned and lightweight. The dual-shaft synchronous transmission device includes a driver and a reactor respectively disposed on a first shaft and a second shaft and a link unit. Spur gear structures or crown gear structures are respectively disposed on the driver and the reactor. Crown gear structures or spur gear structures are respectively disposed at two ends of the link unit correspondingly engaged with the spur gear structures or crown gear structures of the driver and the reactor. When the first shaft and the driver are rotated, the driver rotates the link unit to drive the reactor and the second shaft to synchronously rotate in a direction reverse to the rotational direction of the driver.

Owner:FIRST DOME

Differential apparatus for vehicle

InactiveUS8007391B2Reduce the overall diameterEliminate needDifferential gearingsControl devicesContinuationMechanical engineering

An orthogonal axis gear, a planetary gear reduction mechanism portion, and a differential gear mechanism portion are arranged along an axial center direction of left and right output shafts. The planetary gear reduction mechanism portion is constituted such that a sun gear thereof is provided as a continuation of a crown gear of the orthogonal axis gear, a ring gear thereof is fixed to a differential case, and a planetary carrier thereof serves as an output. Further, the differential gear mechanism portion employs a planetary gear mechanism and is constituted such that a ring gear of the planetary gear mechanism is provided as a continuation of the planetary carrier of the planetary gear reduction mechanism portion, a planetary carrier thereof is provided as a continuation of the left side output shaft, and a sun gear thereof is provided as a continuation of the right side output shaft.

Owner:SUBARU CORP

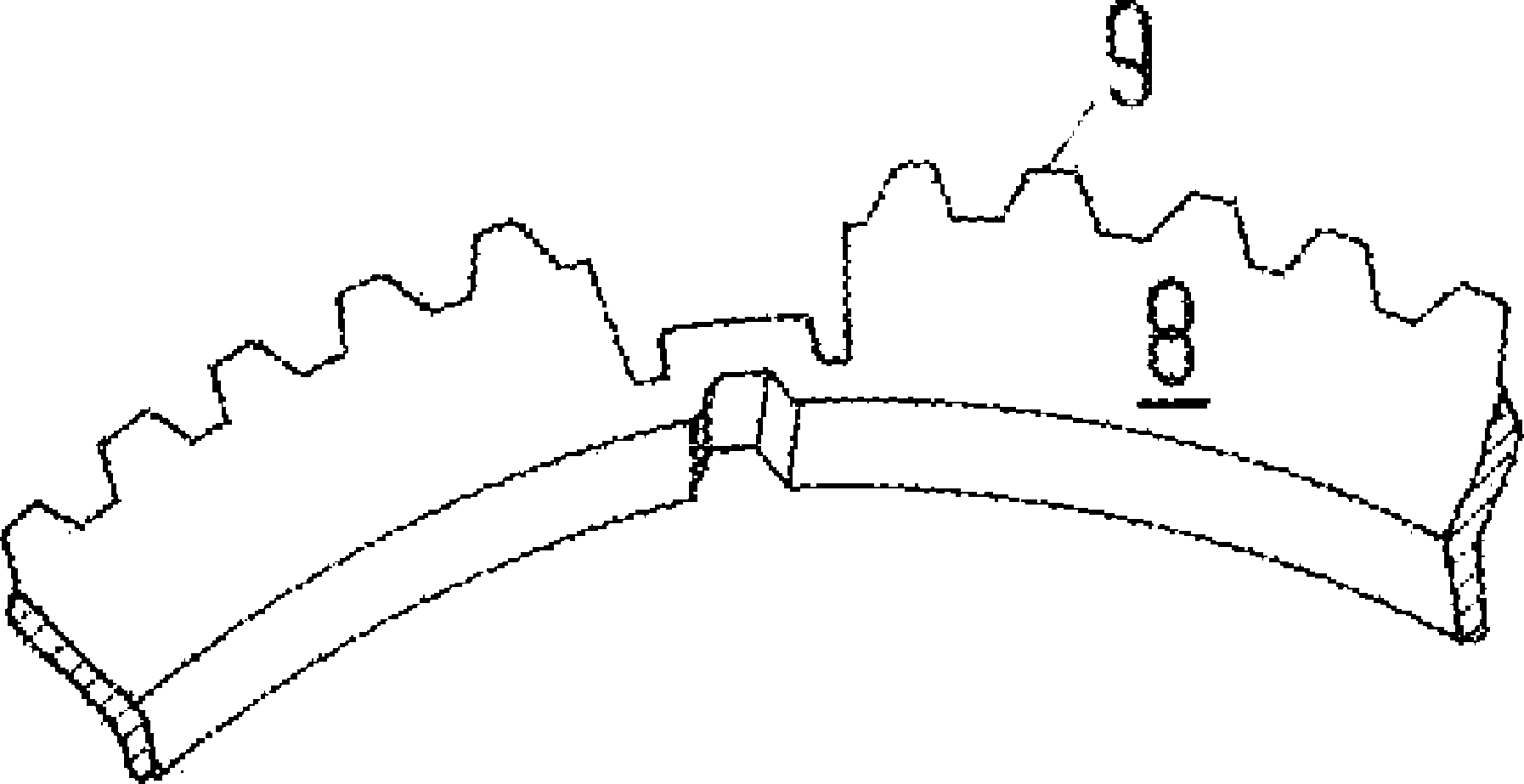

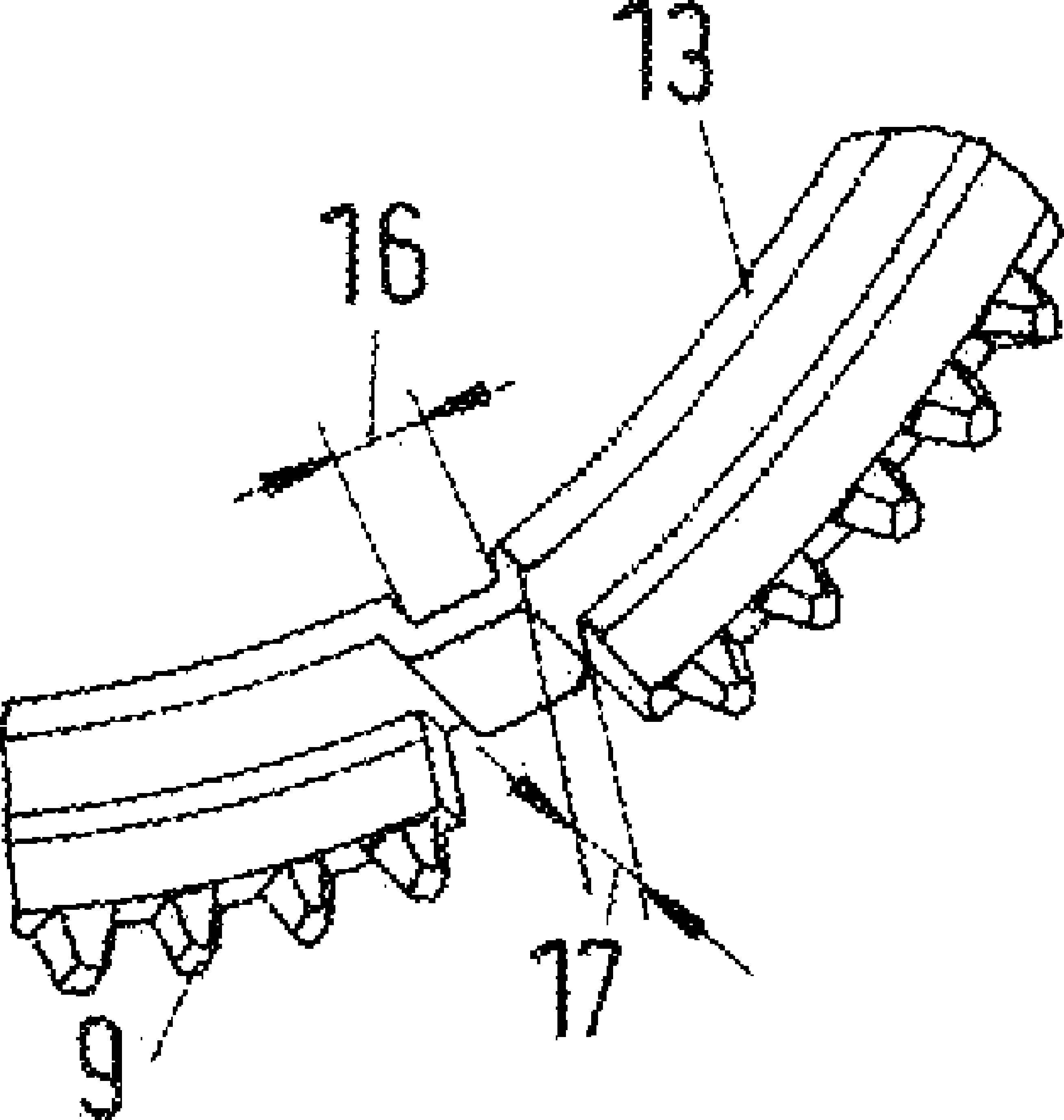

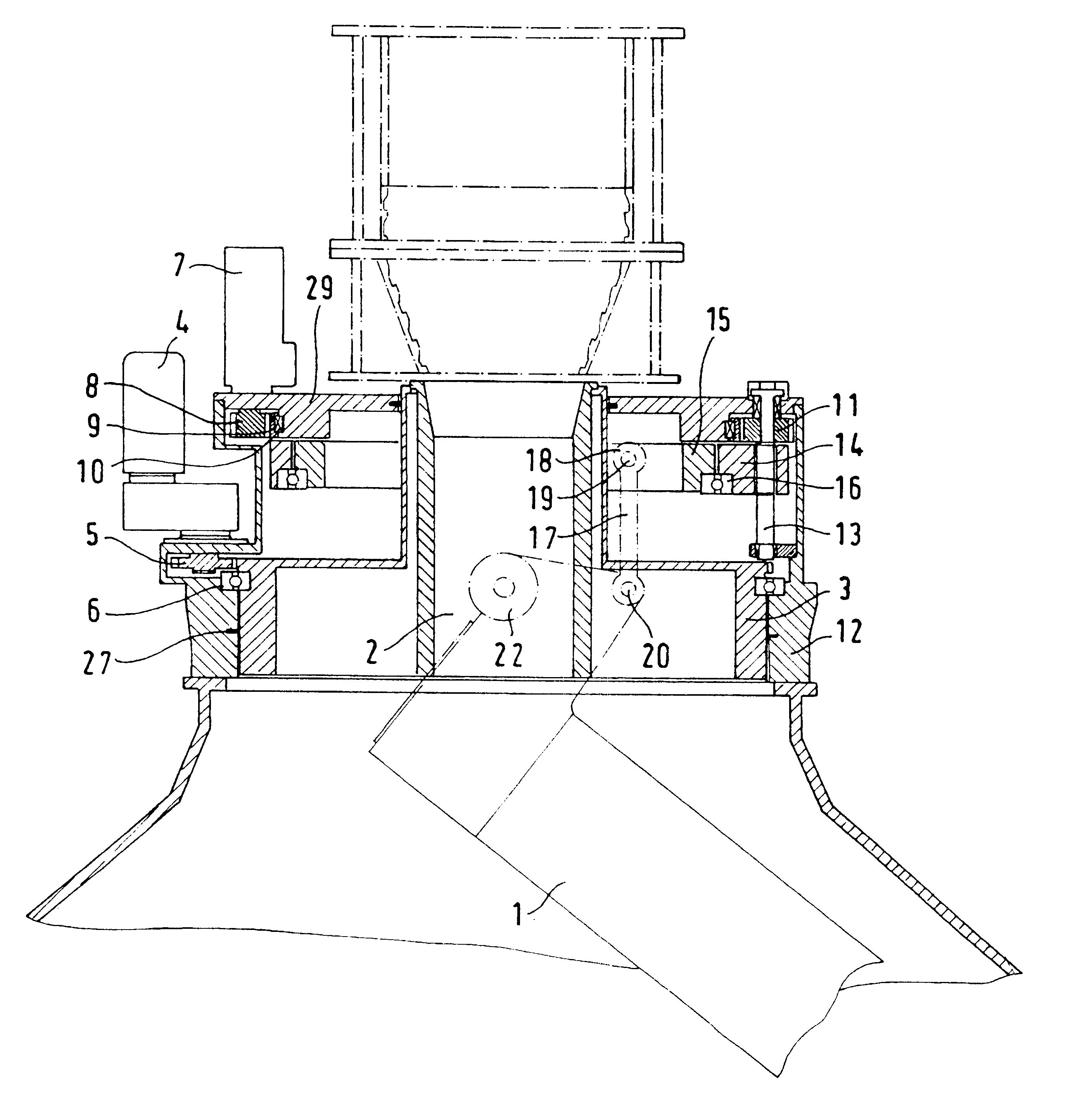

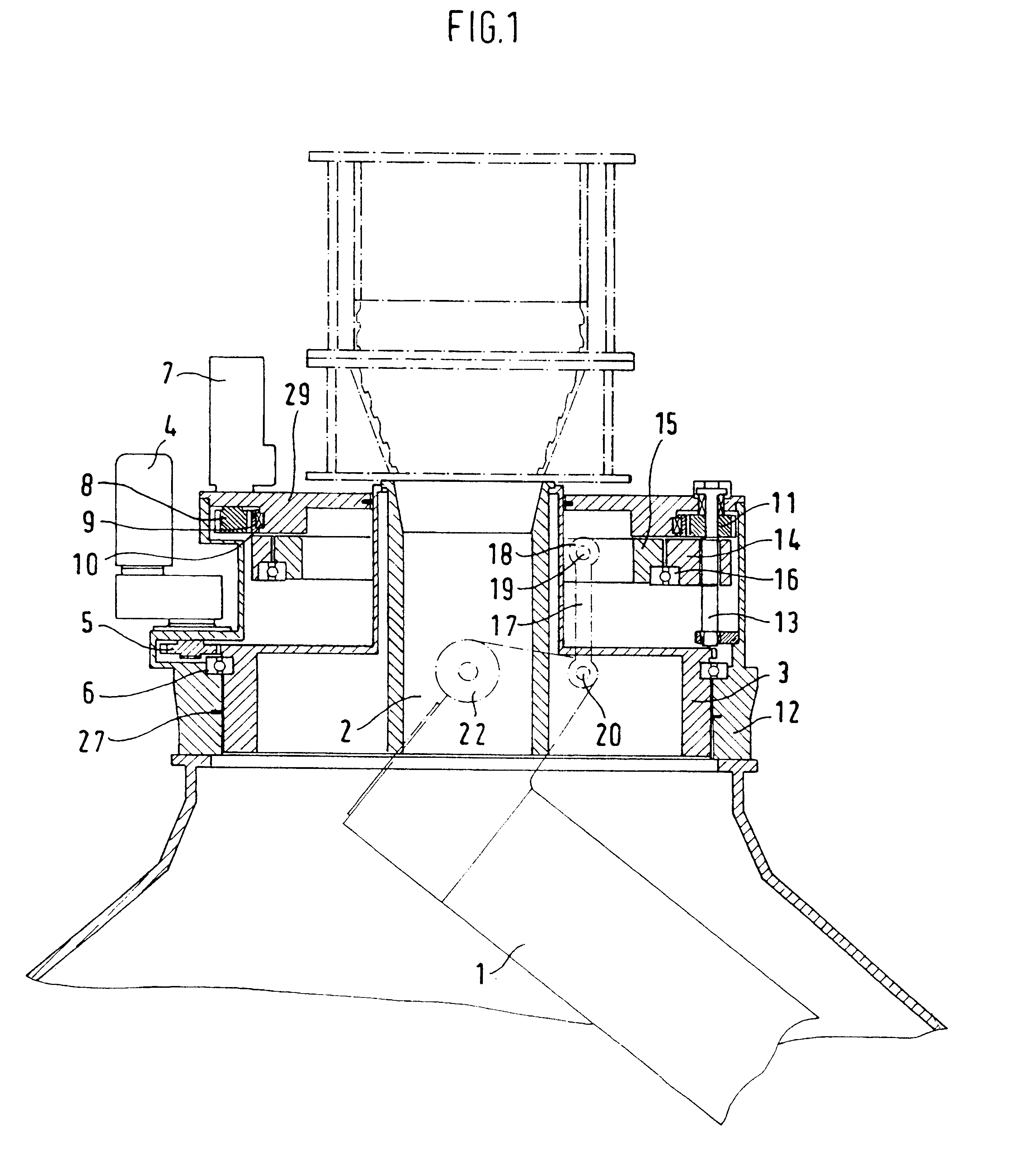

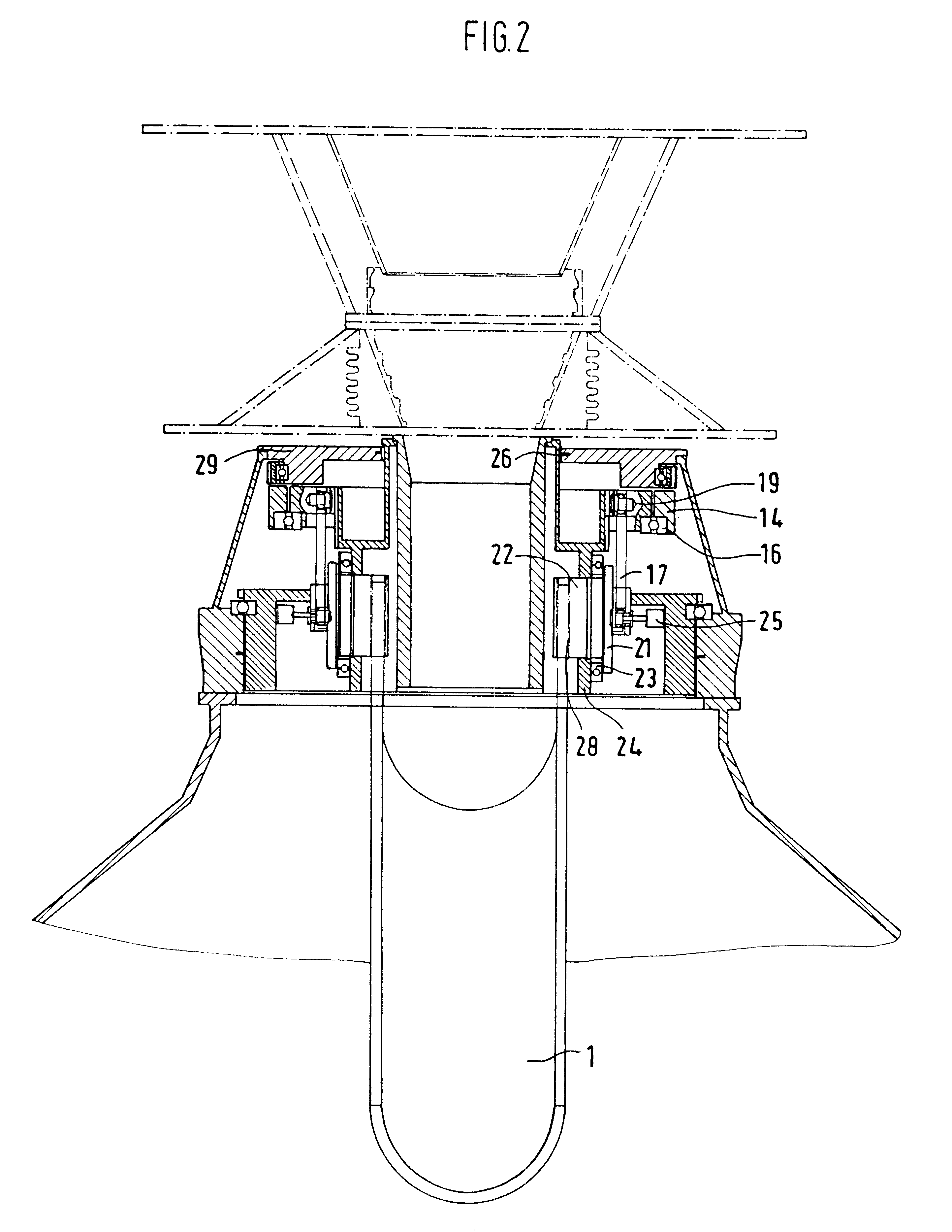

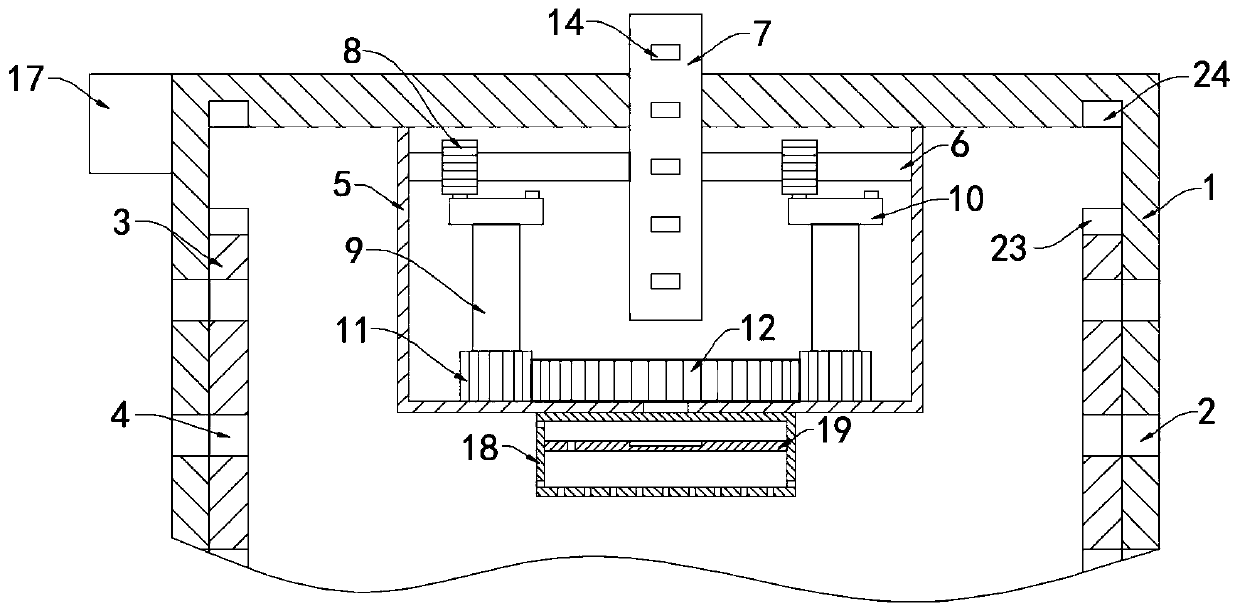

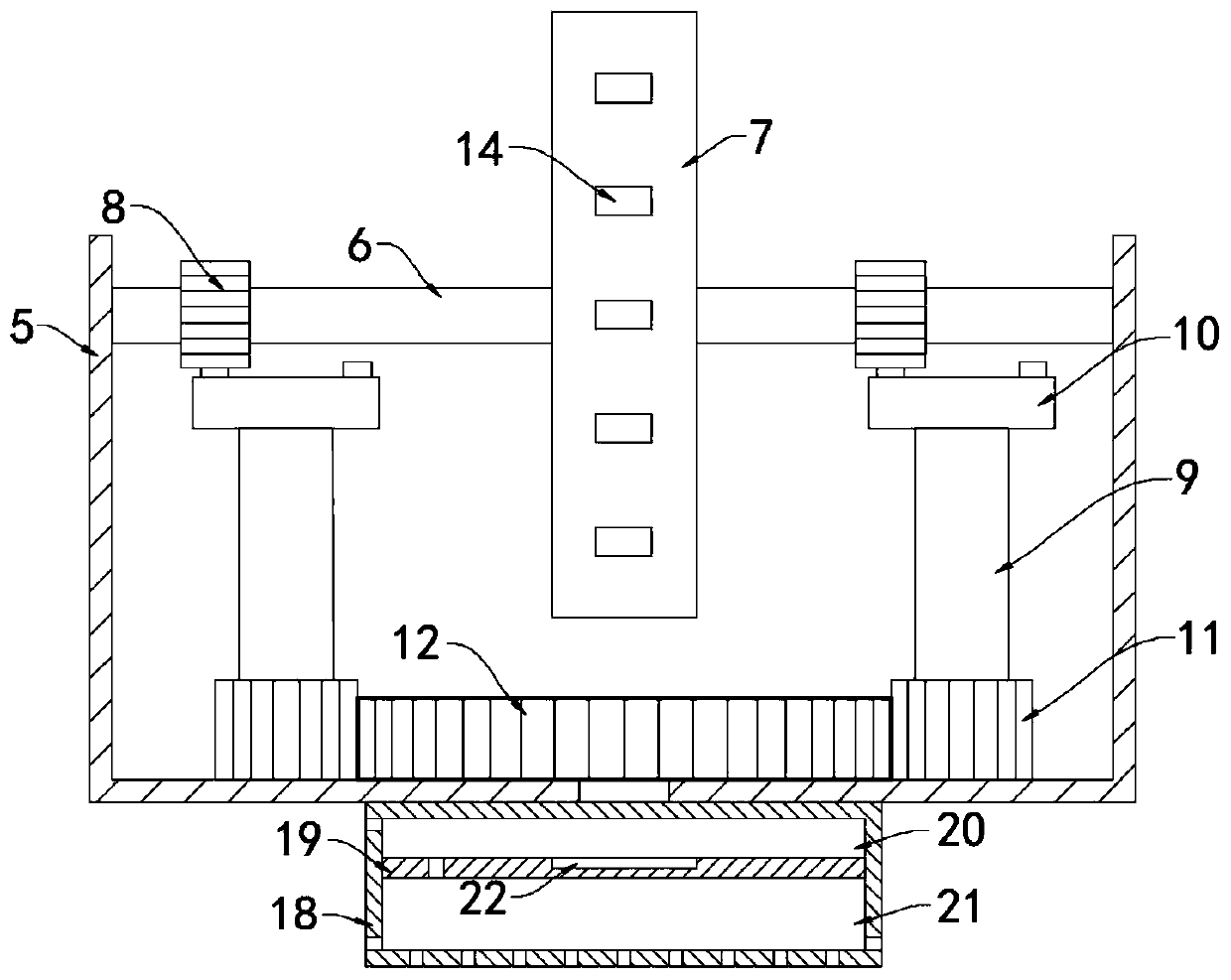

Bell and hopper for shaft furnaces

InactiveUS6540958B1Overcome disadvantagesCanting-free driveConveyorsBell-and-hopper arrangementWear resistantGear wheel

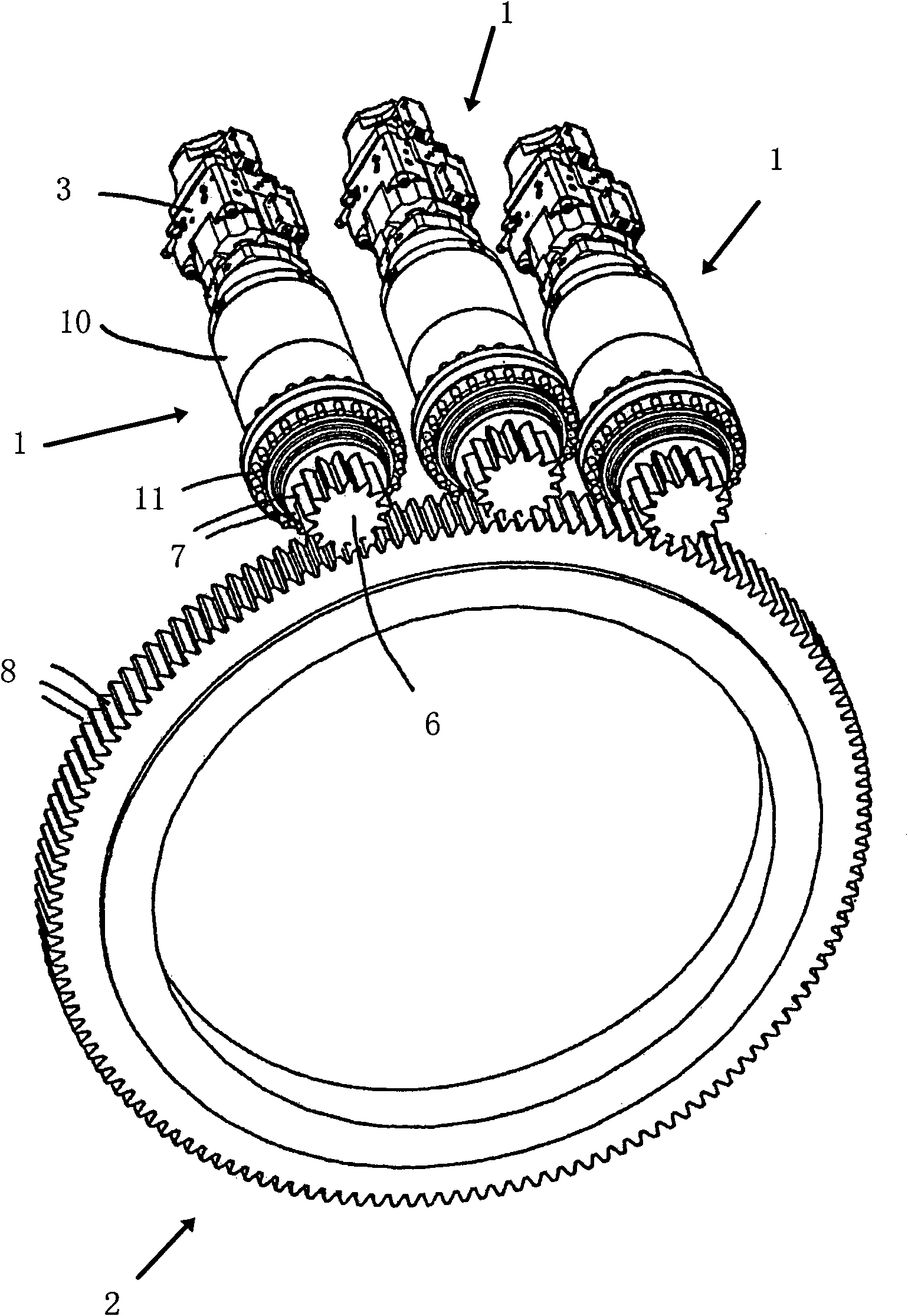

In order to configure a bell and hopper for shaft furnaces, in particular, blast furnaces, comprising a charging bin with a feed tube, a rotating chute carrier with rotary drive, a swiveling chute in the interior of the furnace with drive means arranged external to a housing, in a less failure-prone and a wear resistant way, the drive means for the swivel movement of the chute are to comprise: at least one motor (7) which drives by a respective pinion (8) a crown gear (9), wherein the crown gear (9) engages the spindle gear wheels (11) of at least two spindles (13) distributed about the periphery of the bell and hopper external to the rotating chute carrier (3) for generating a lifting and lowering movement of the spindles, as well as means (14, 15, 17, 21) for transmitting this vertical movement of the spindles onto the tilting shafts (22), which penetrate the inner wall (24) of the chute carrier (3) and from which the chute can be suspended, for generating a swivel and tilting movement of the chute.

Owner:PAUL WURTH SA

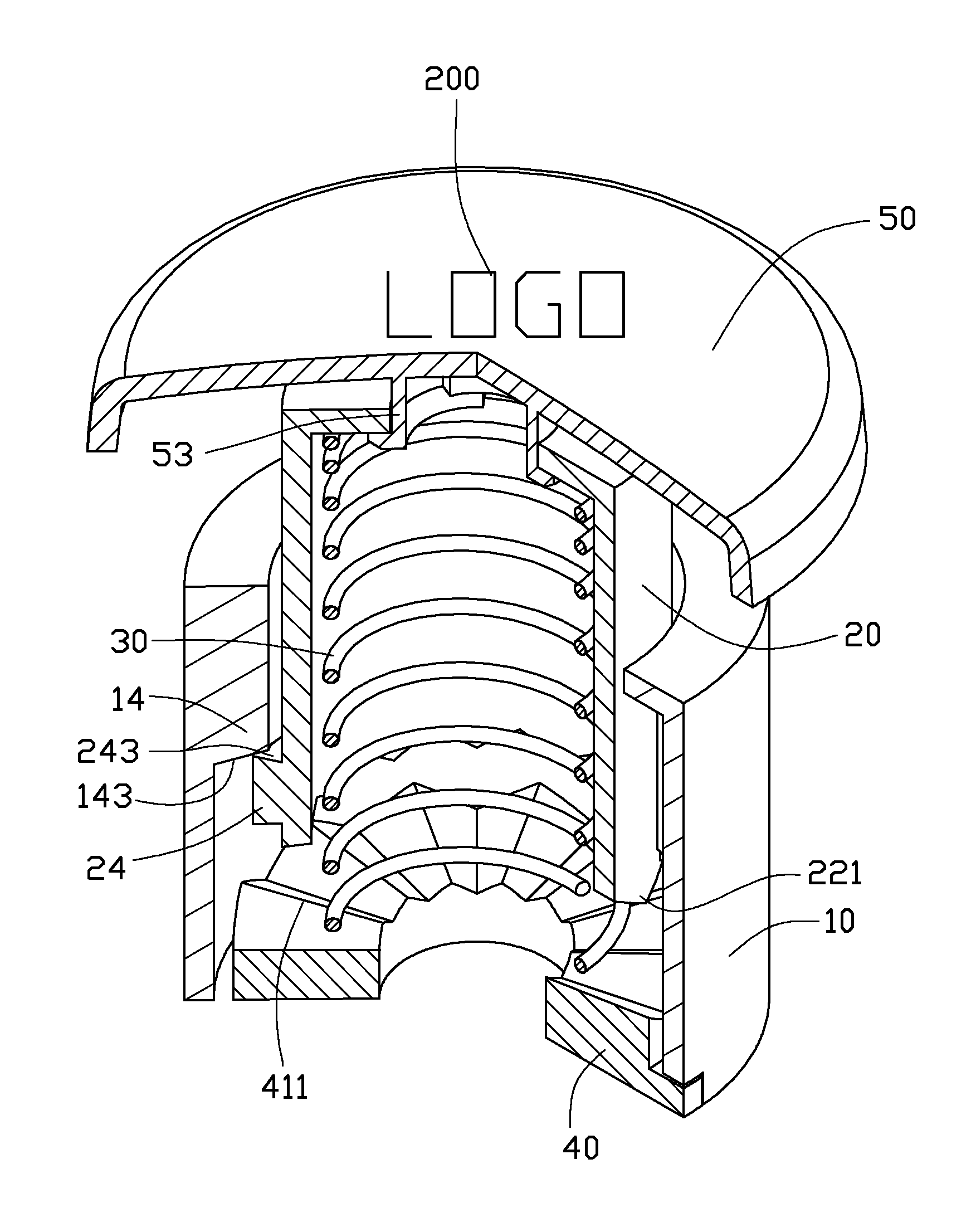

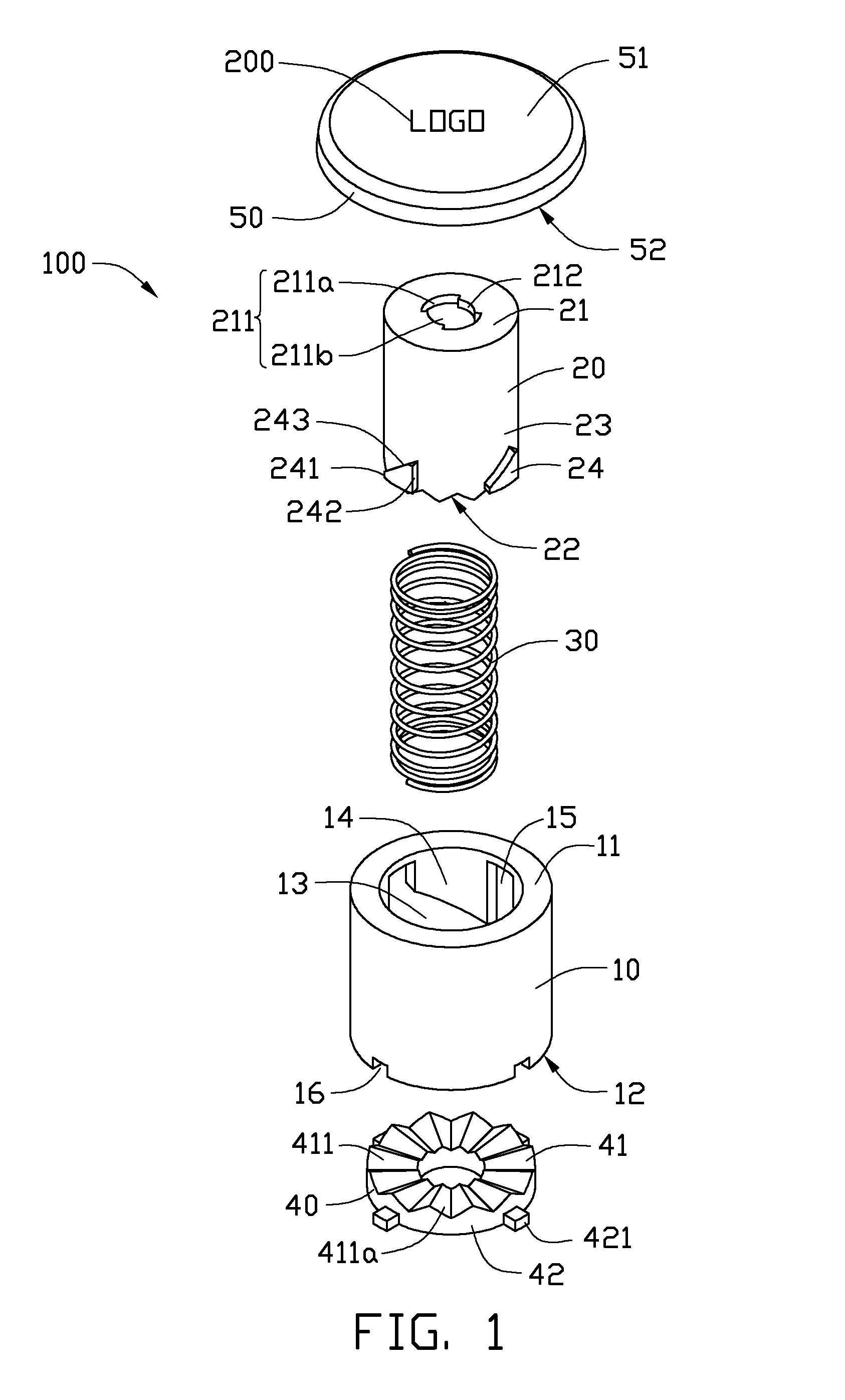

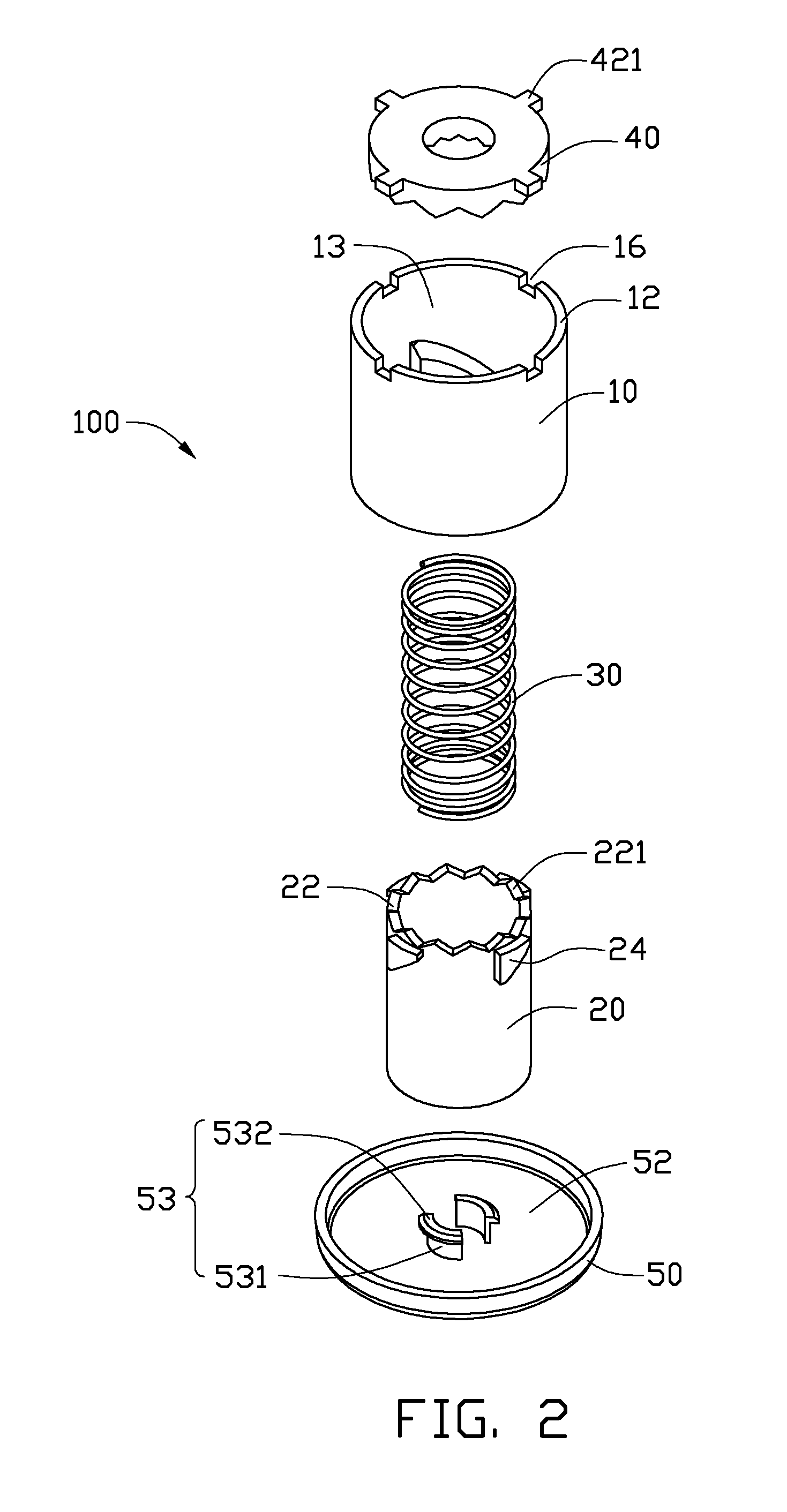

Rotatable graphic assembly

A rotatable graphic assembly includes an outer barrel including an inner surface and a plurality of inner teeth formed thereon with an inner bevel formed at an end of each inner tooth; an inner barrel received within the outer barrel, the inner barrel including an outer surface and a plurality of outer teeth formed on the outer surface with an outer bevel formed at an end of each outer tooth and movably engaged with the inner teeth, the inner barrel defining a first crown gear portion at one end thereof; a spring sleeved in the inner barrel; a base sealing one end of the outer barrel, and the spring biased between the other end of the outer barrel away from the base and the base; and the base defines a second crown gear facing the first crown gear portion; and a button disposed on the end of the second barrel away from the base and showing a graphic.

Owner:HON HAI PRECISION IND CO LTD

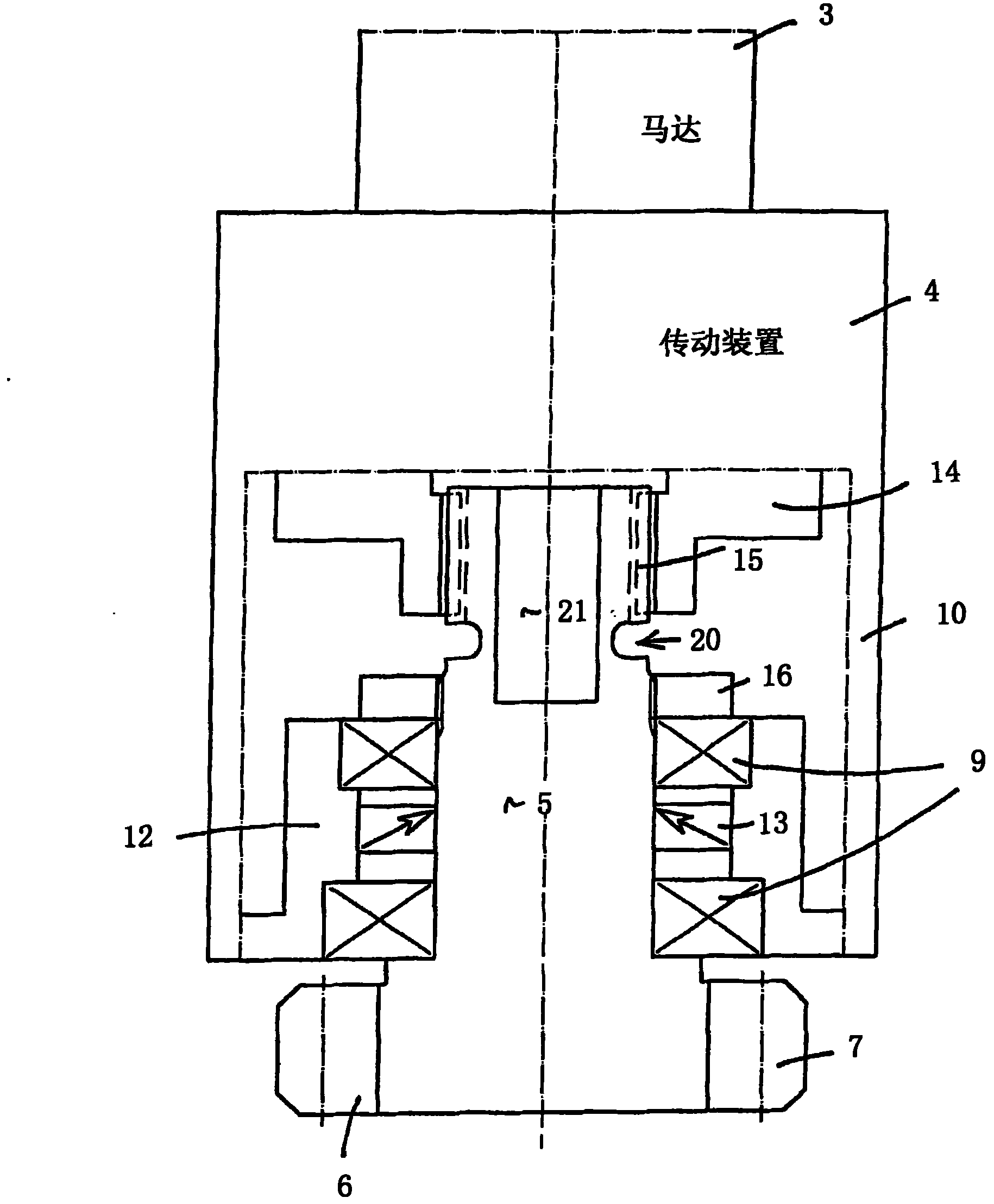

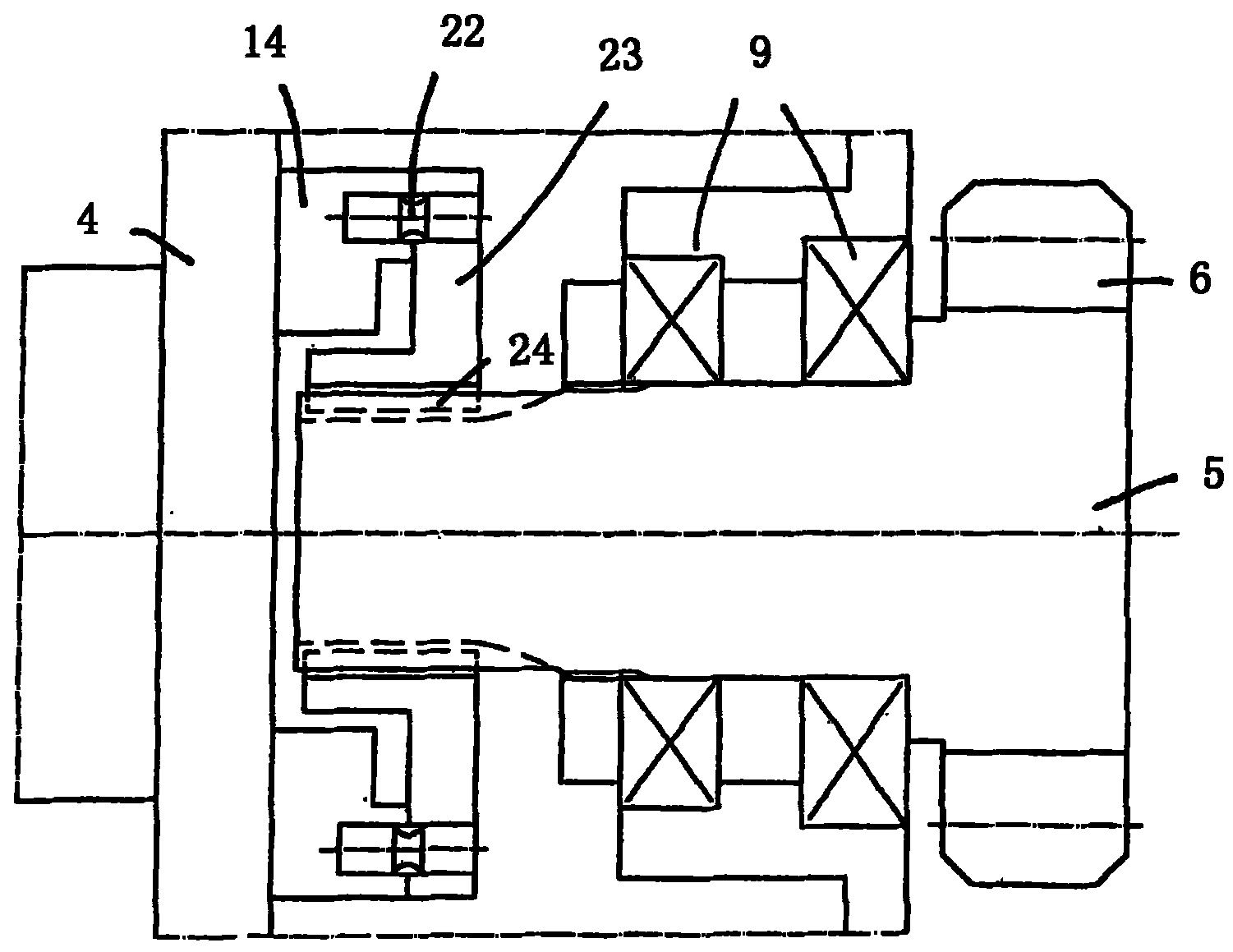

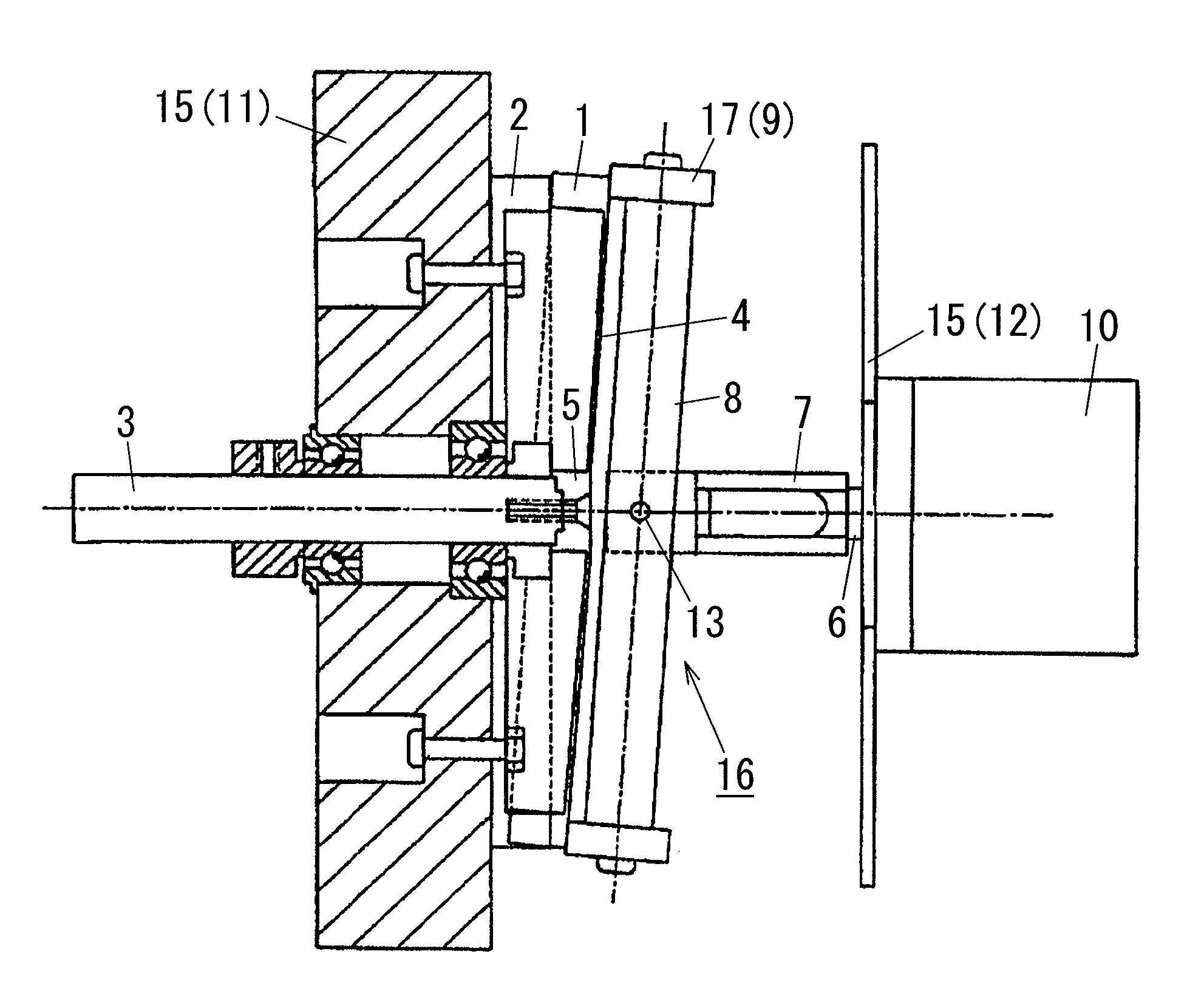

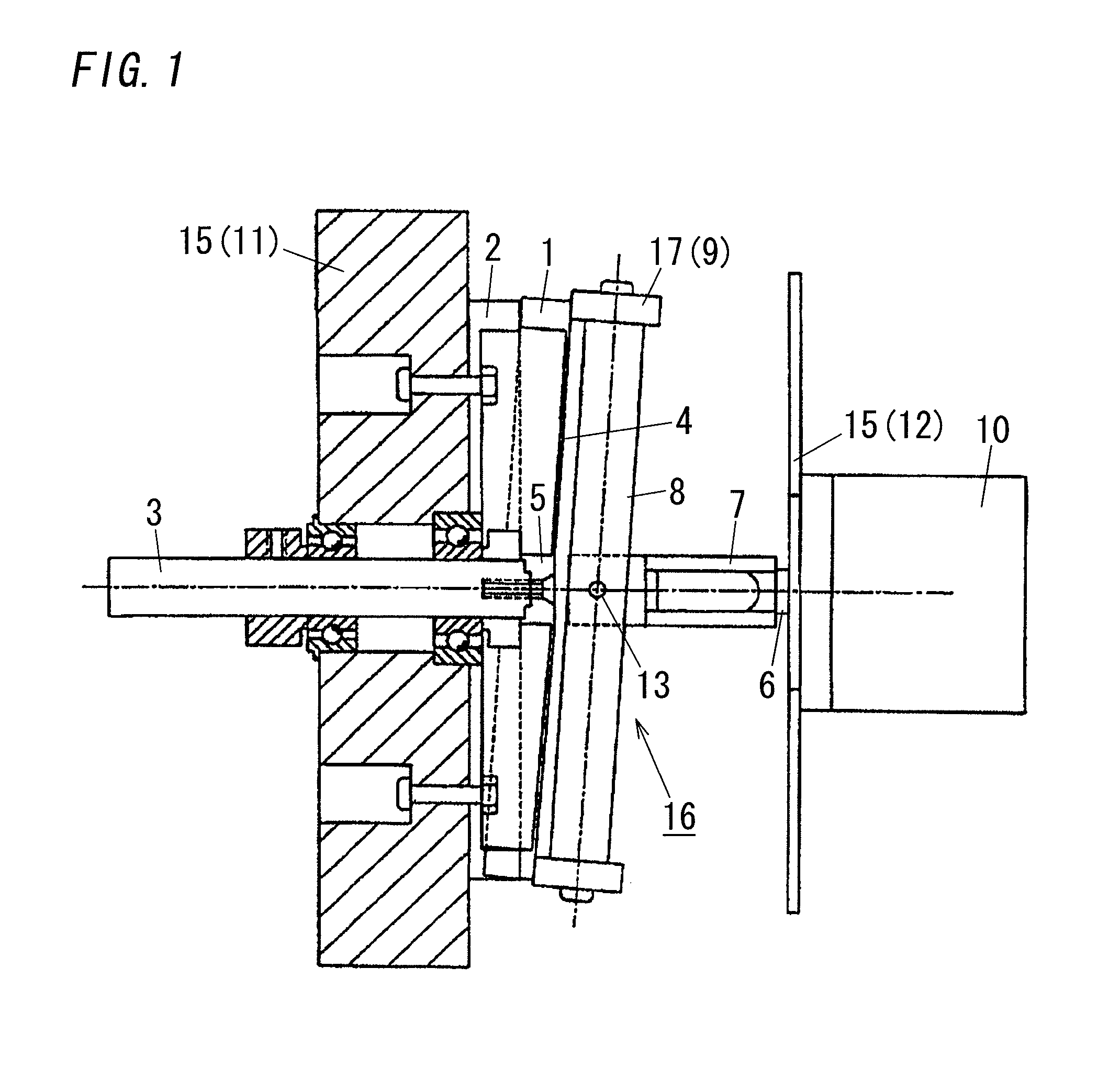

Drive unit with overload protection for driving a crown gear

ActiveCN101988566AInexpensive overload protectionSmall cross sectionGearboxesSlip couplingDrive shaftGear wheel

This invention relates to a drive unit for driving a ring gear, comprising a motor, a transmission and a drive shaft, on which a pinion is arranged for driving the ring gear, wherein the drive unit includes a mechanical overload protection. In accordance with the invention the overload protection is arranged between the transmission and the pinion.

Owner:LIEBHERR COMPONENTS BIBERACH GMBH

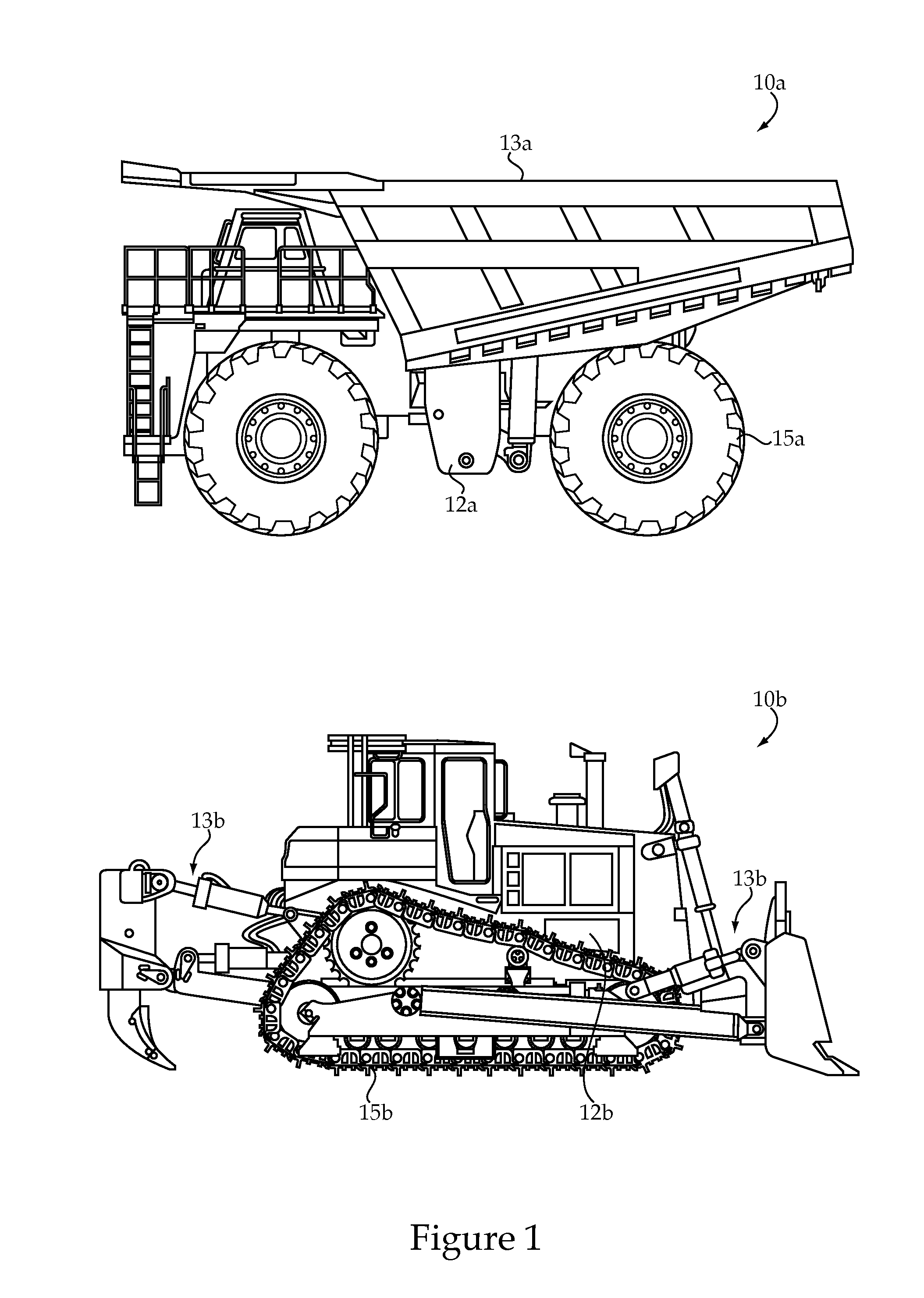

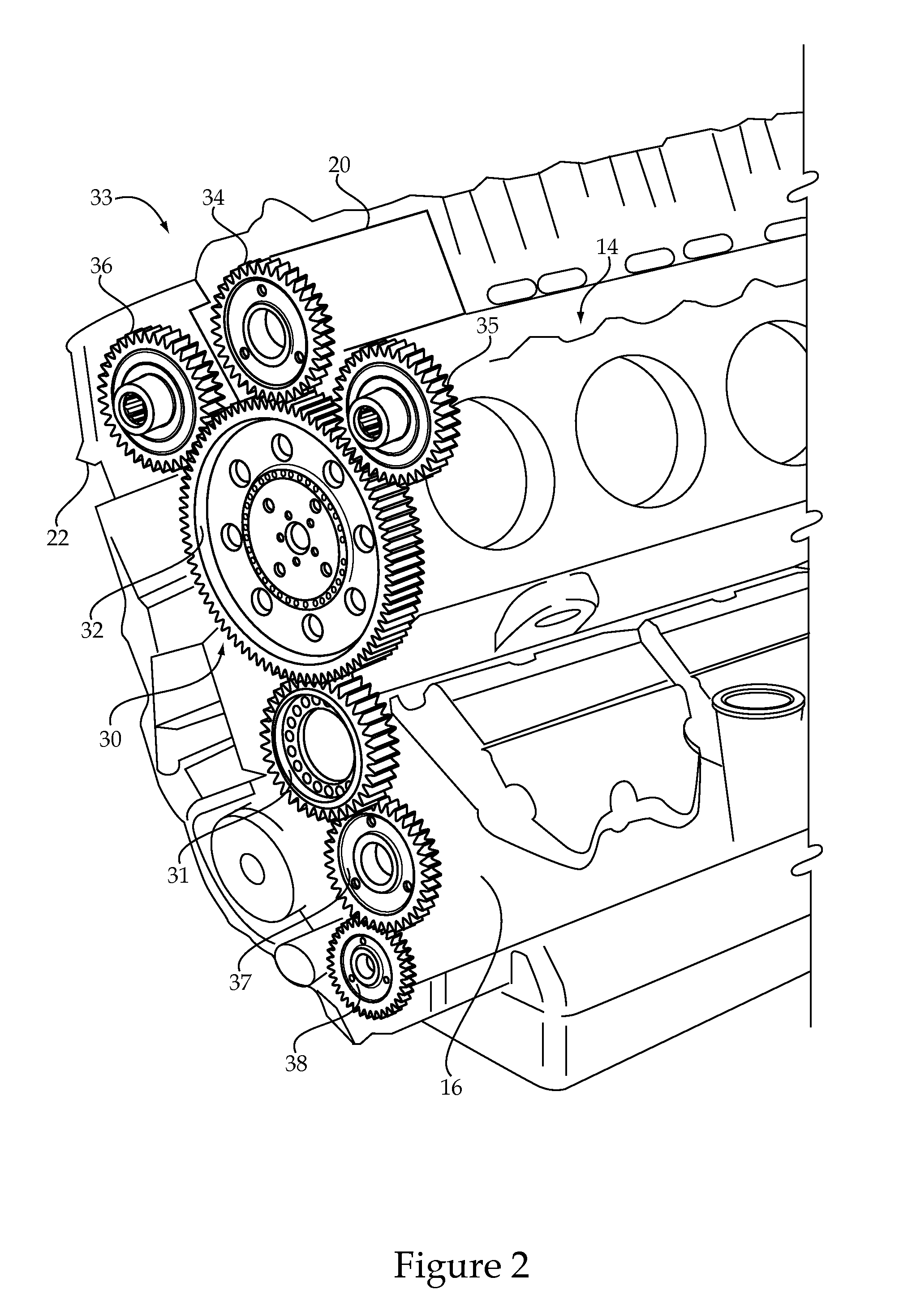

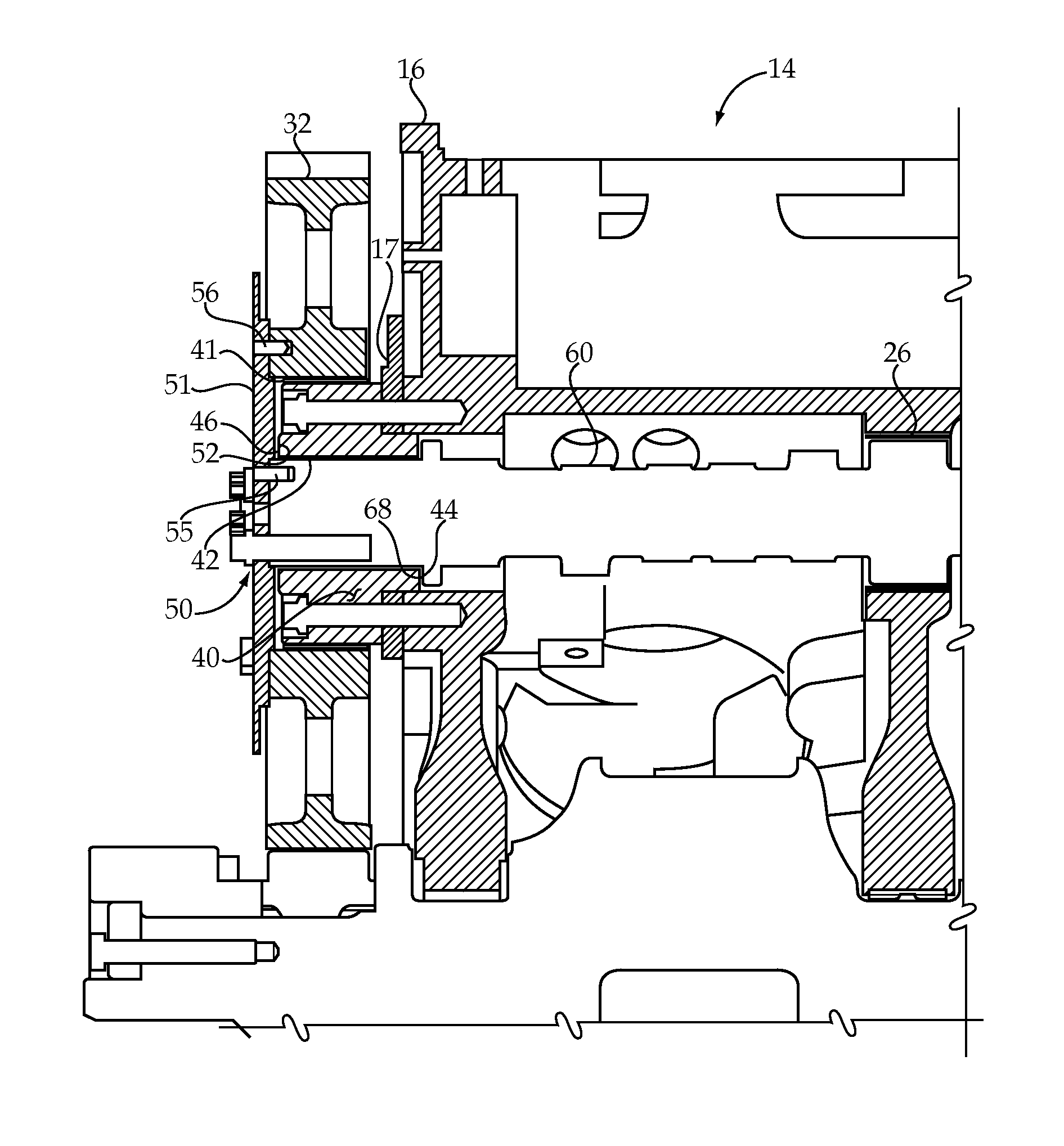

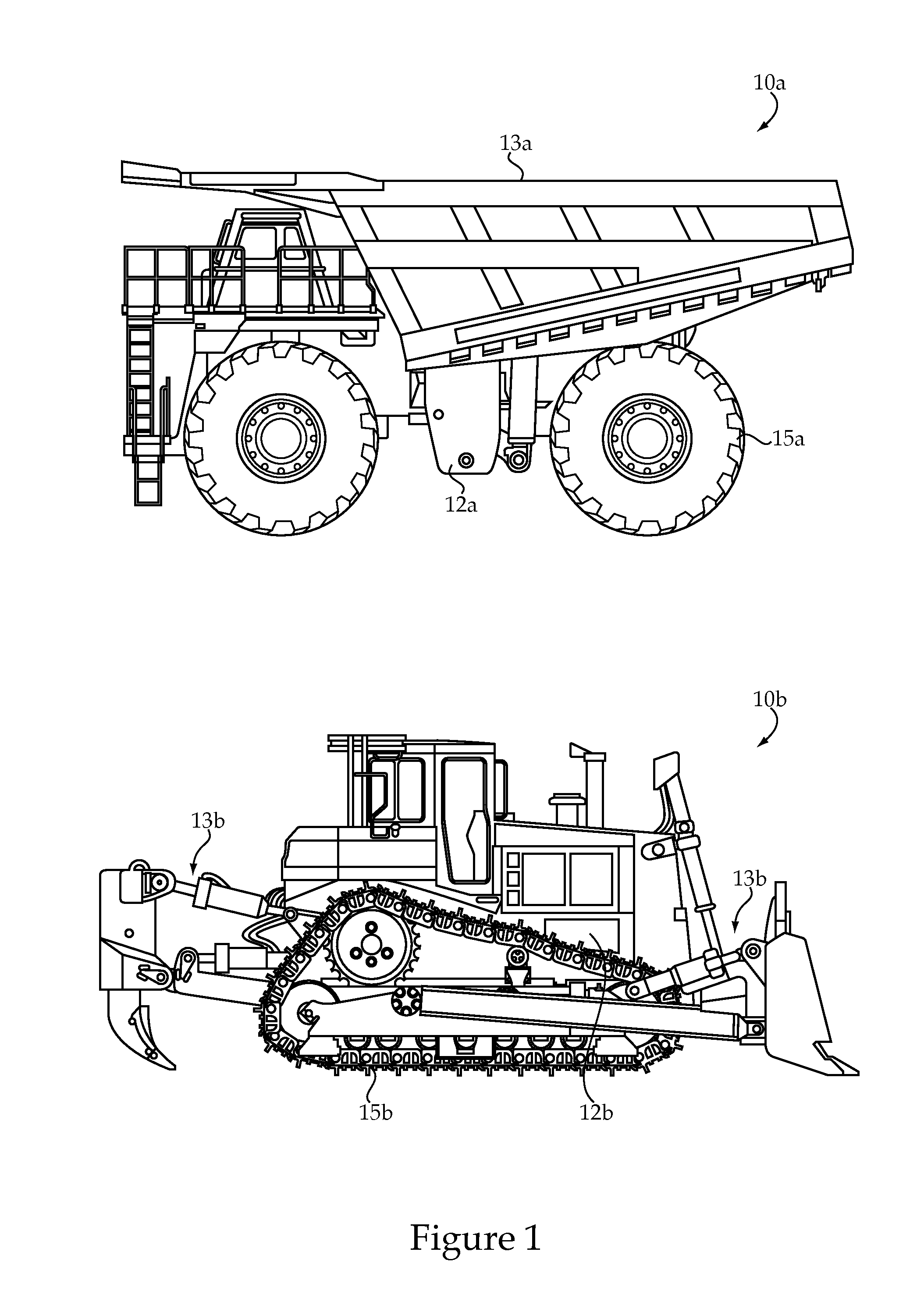

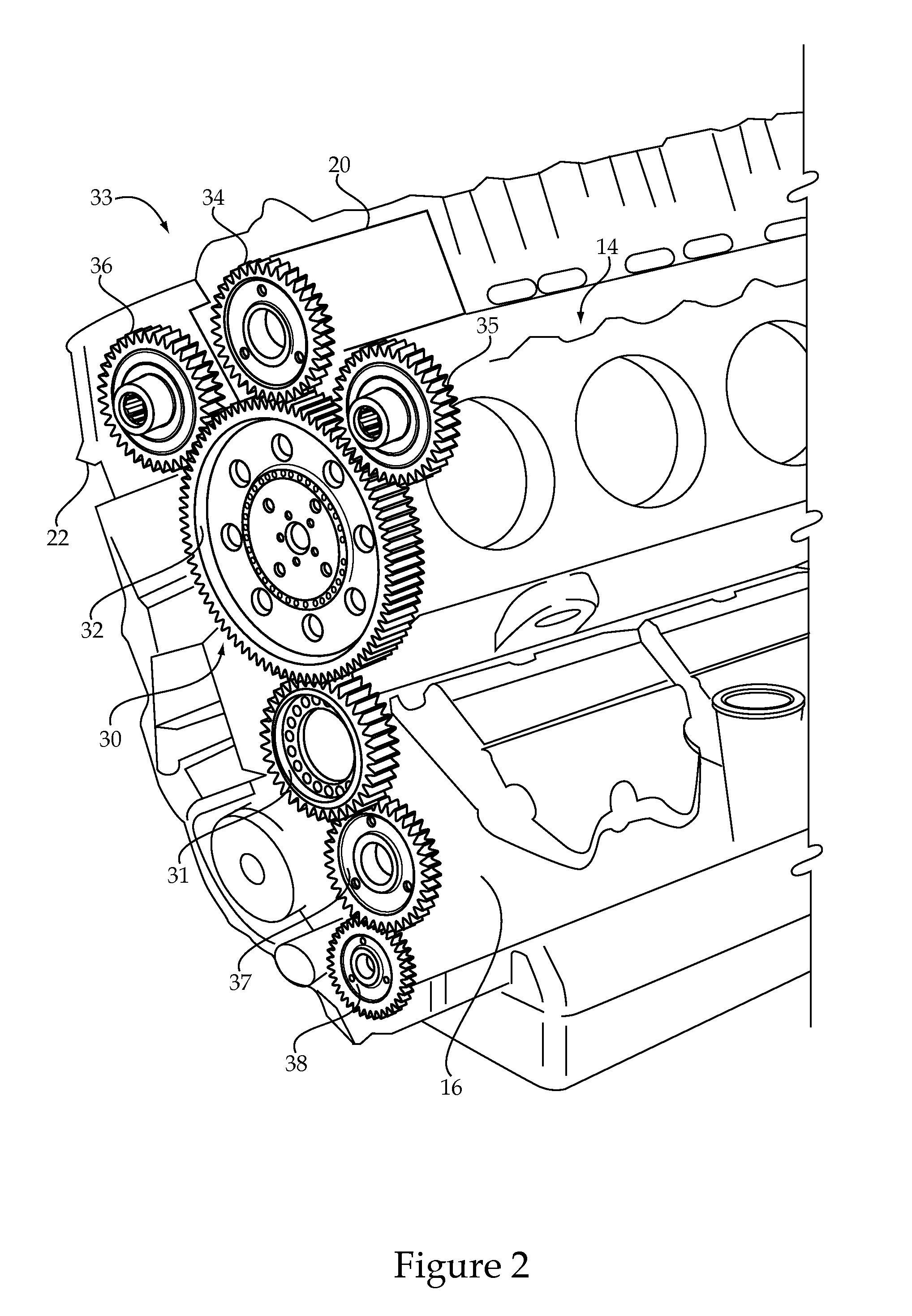

Engine With Stub Shaft Supported Cam Gear And Machine Using Same

In one aspect, a machine includes an engine supported on a machine body. The engine includes a housing and a gear train that includes a crank gear meshed with a cam gear that is meshed with at least one powered gear. The cam gear is attached to a cam shaft by a drive coupler. The cam shaft is rotationally supported in the housing on a plurality of bearings, and the cam gear is rotationally supported on a stub shaft with an inner surface that is out of contact with the cam shaft. The stub shaft is attached to the housing of the engine.

Owner:CATERPILLAR INC

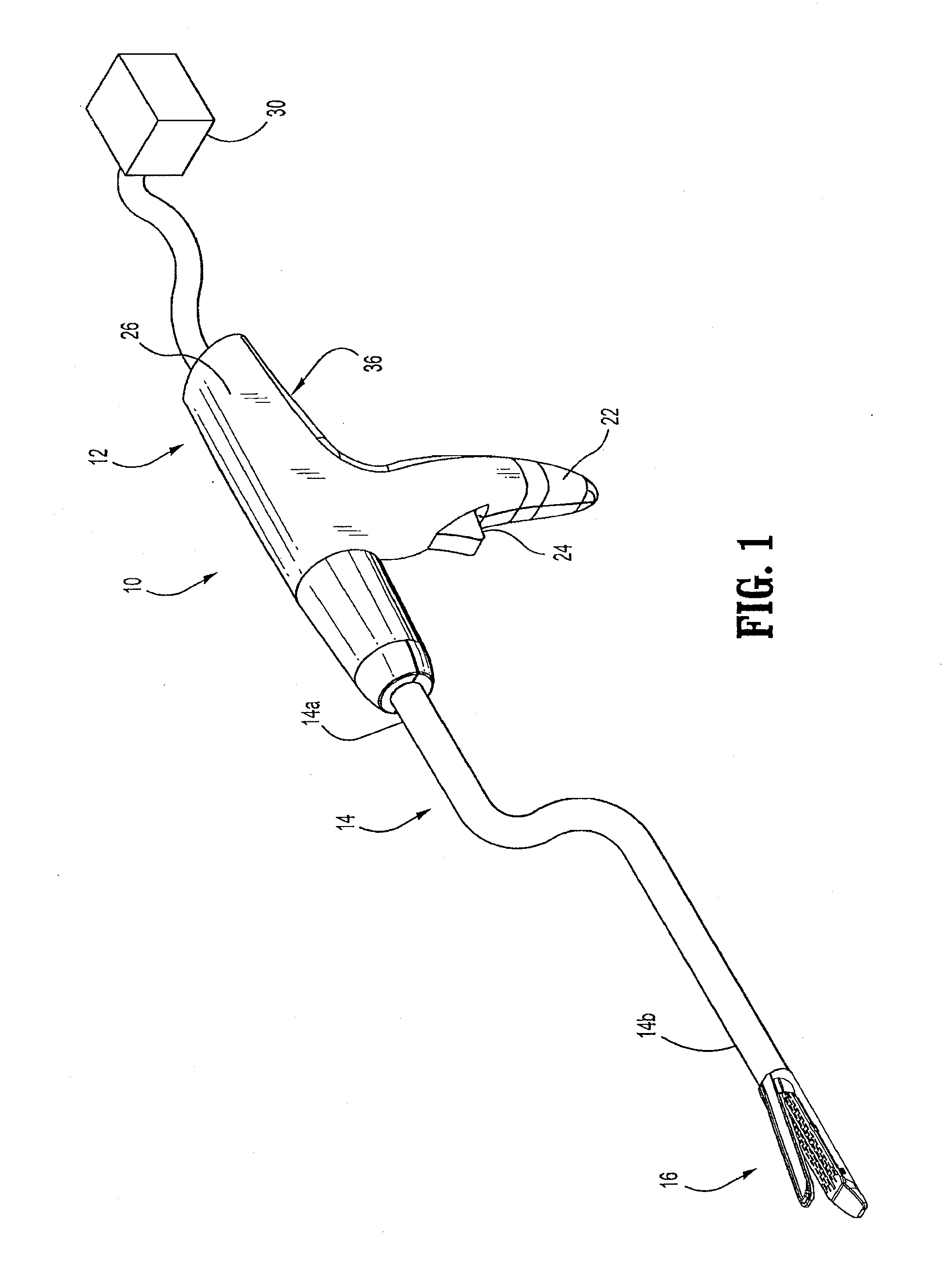

Surgical micro-shears and methods of fabrication and use

Methods and devices are provided for use in medical applications involving tissue removal. One exemplary powered scissors device includes a distal housing having a fixed cutting arm located thereon, an elongate member coupled to the distal housing and configured to introduce the distal housing to a target tissue site of the subject, a rotatable blade rotatably mounted to the distal housing, the rotatable blade having at least one cutting element configured to cooperate with the fixed arm to shear tissue therebetween, a crown gear located at a distal end of an inner drive tube, and a first spur gear configured to inter-engage with the crown gear and coupled with the rotatable blade to allow the crown gear to drive the rotatable blade.

Owner:MICROFAB

Modular transmission system

In a method of manufacturing multiple transmission units with individually selectable gear ratios that vary from unit to unit, a gear pair having a desired transmission ratio is selected from a multiplicity of interchangeable gear pairs that includes both spiroplan gears and conventional crown gear and pinion combinations. The selected gear pair is then installed into a housing having first and second bearing sections configured to support bearings in which the shafts of the selected gear pair are rotatably mounted. The bearing sections are configured such that, for every gear pair that may be selected from among the multiplicity of gear pairs, the bearing sections support the first and second shafts in such a position and orientation that teeth of the gears engage with each other and a longitudinal axis of one of the gears of the gear pair is offset by a fixed distance from a longitudinal axis of the other. The fixed distance is maintained at a constant value which does not vary with or depend on the tooth configuration of the gear pair that is selected. A modular transmission system is thus provided, which can achieve a wide range of gear ratios, by an appropriate selection of interchangeable gear pairs, without need of modification of the basic components of the apparatus.

Owner:SEW-EURODRIVE GMBH & CO KG

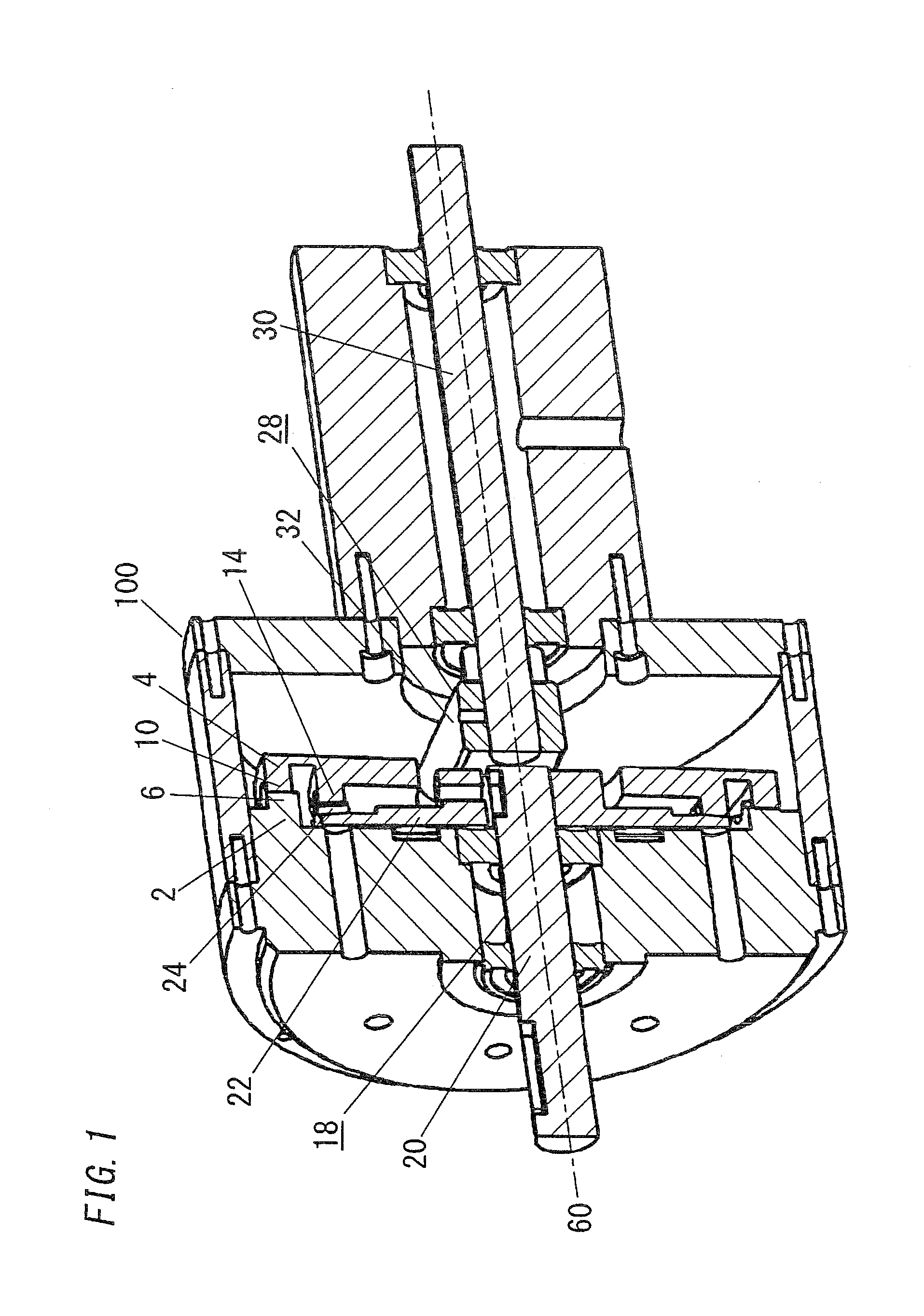

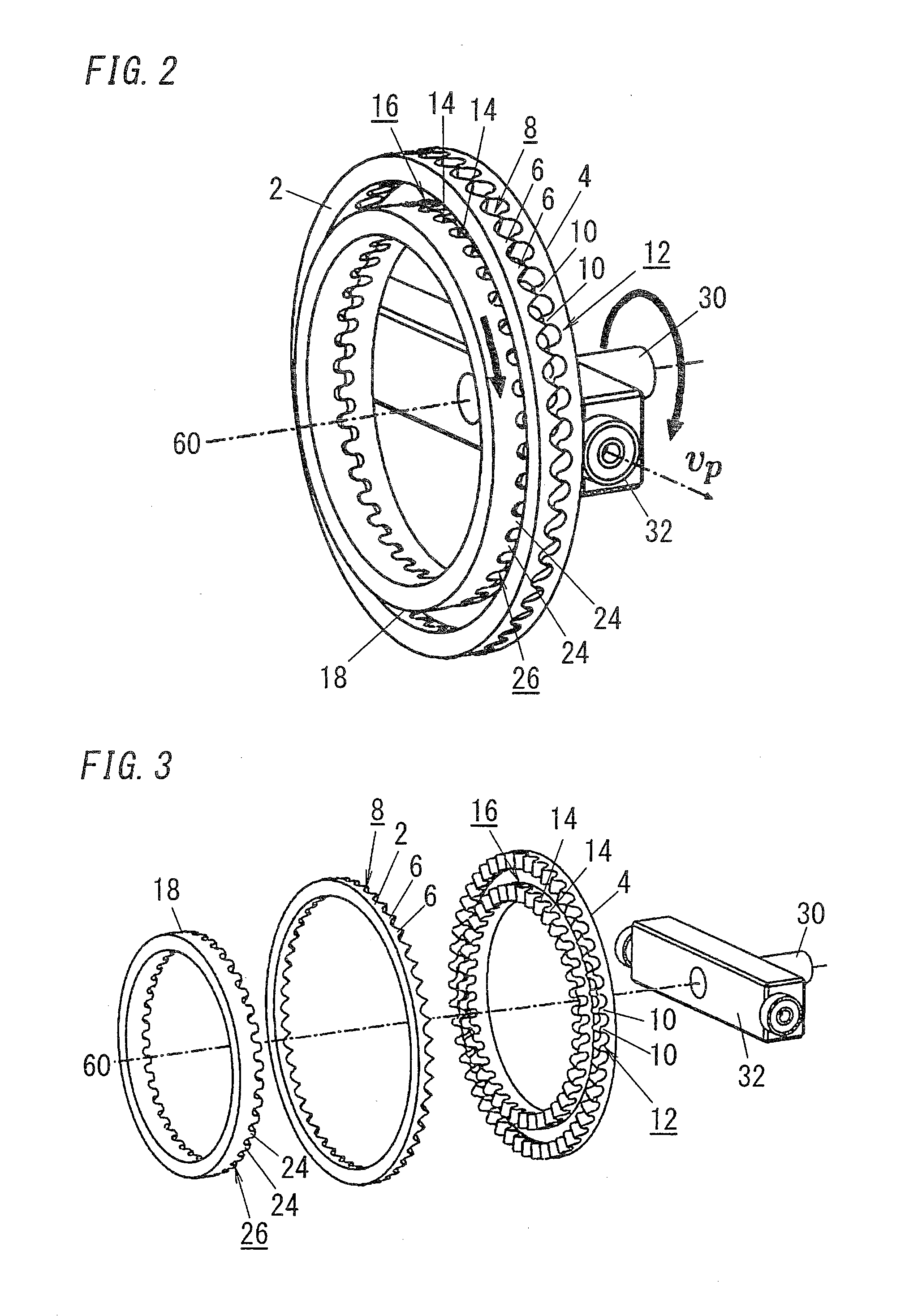

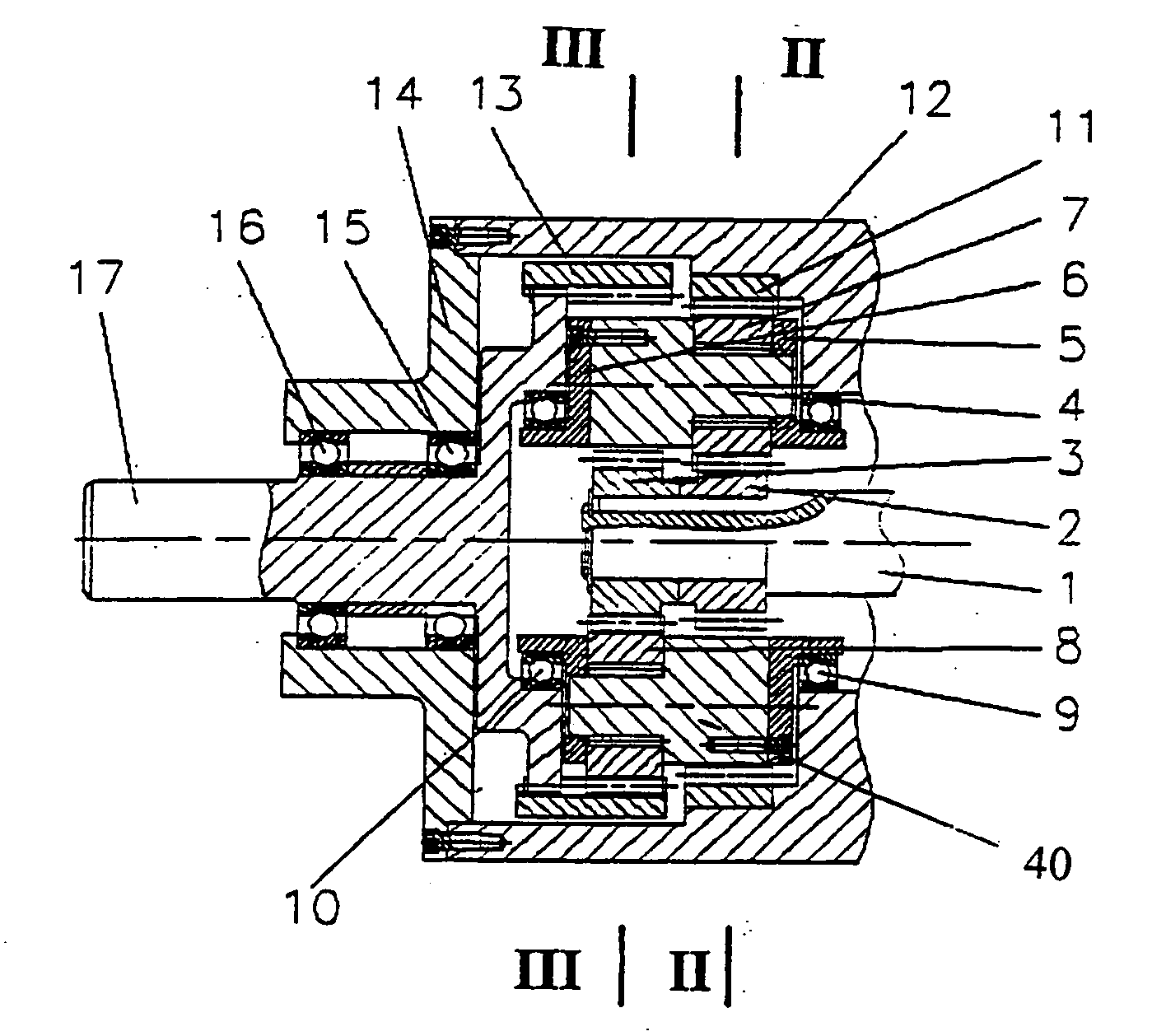

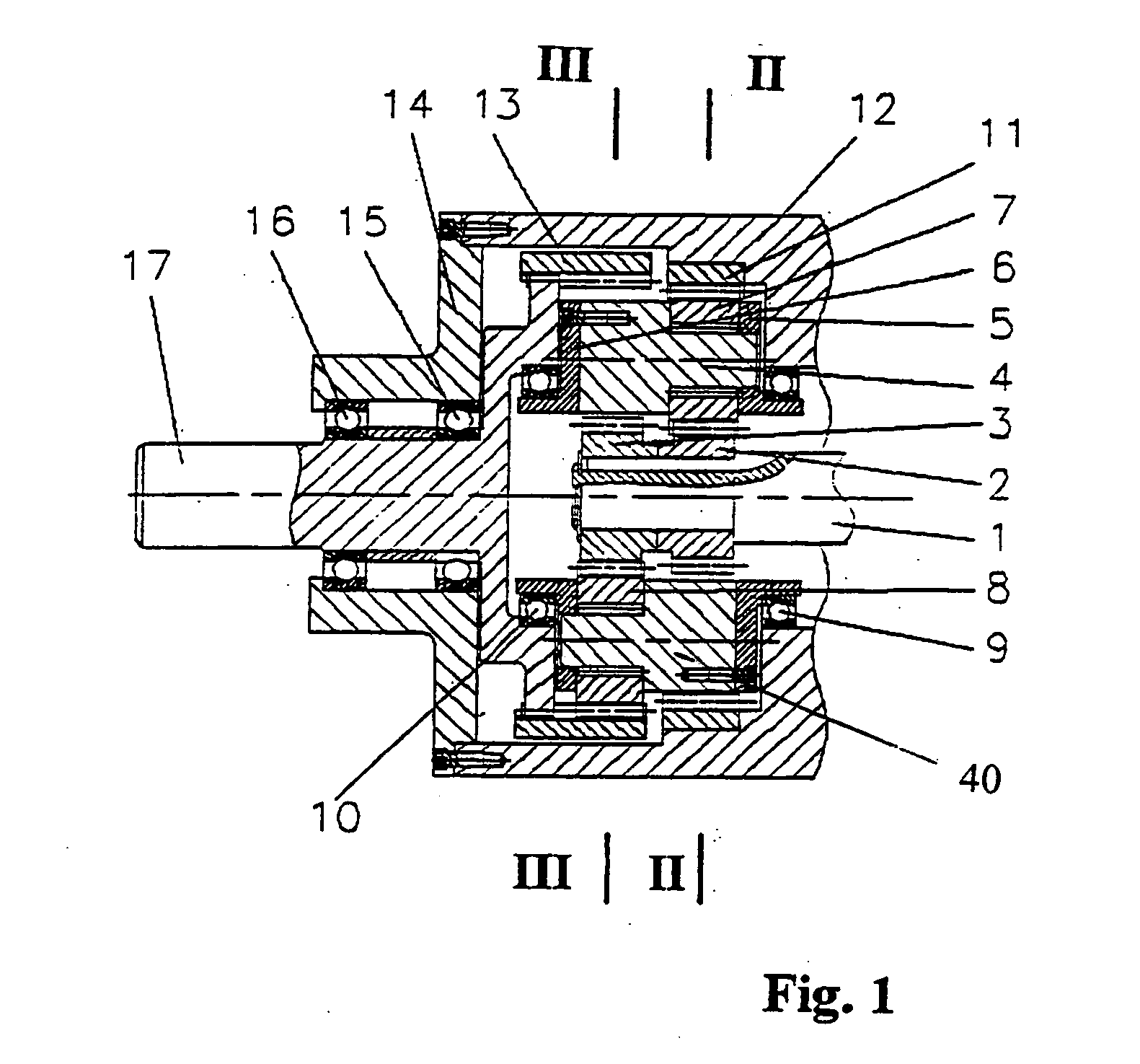

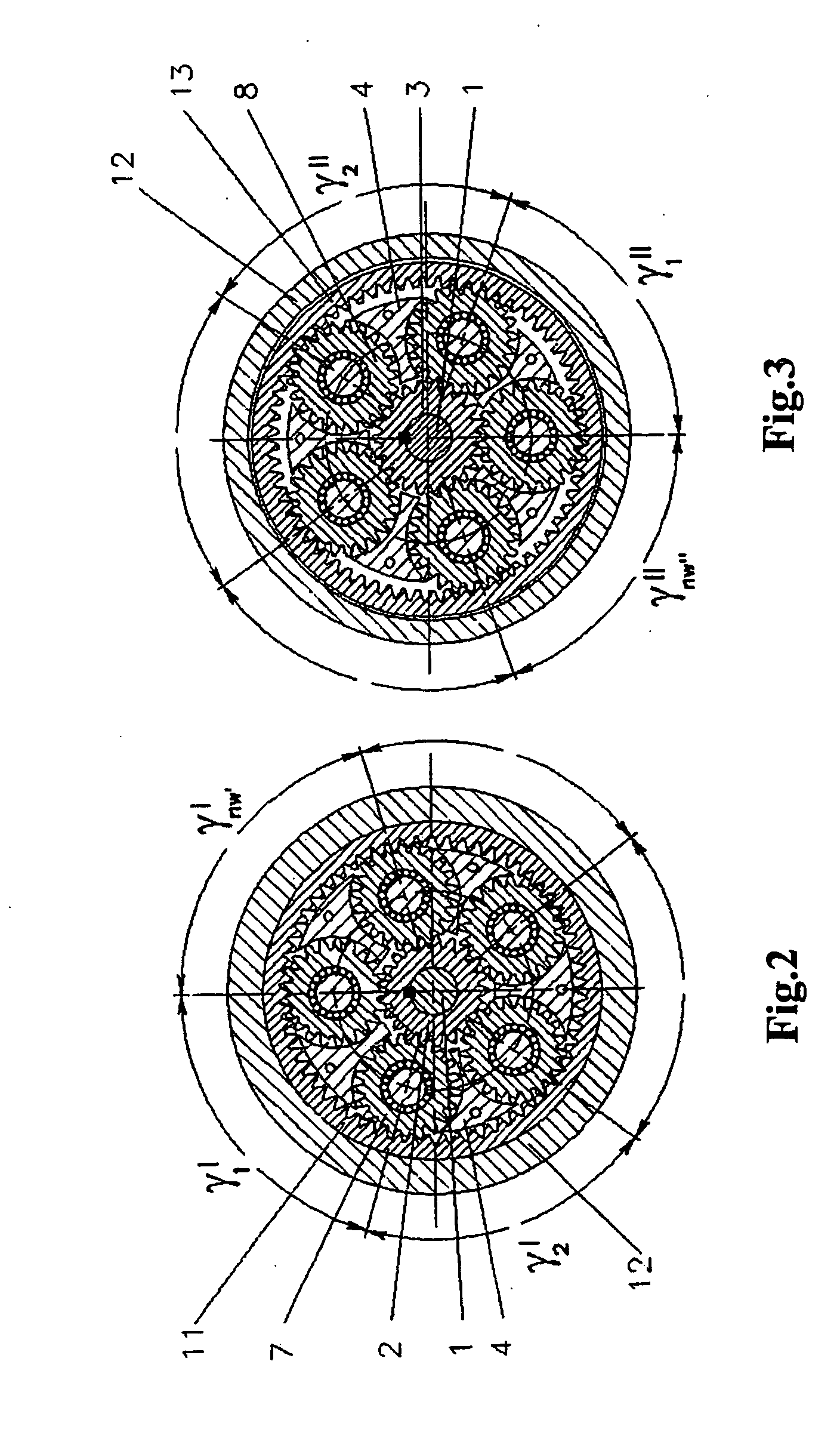

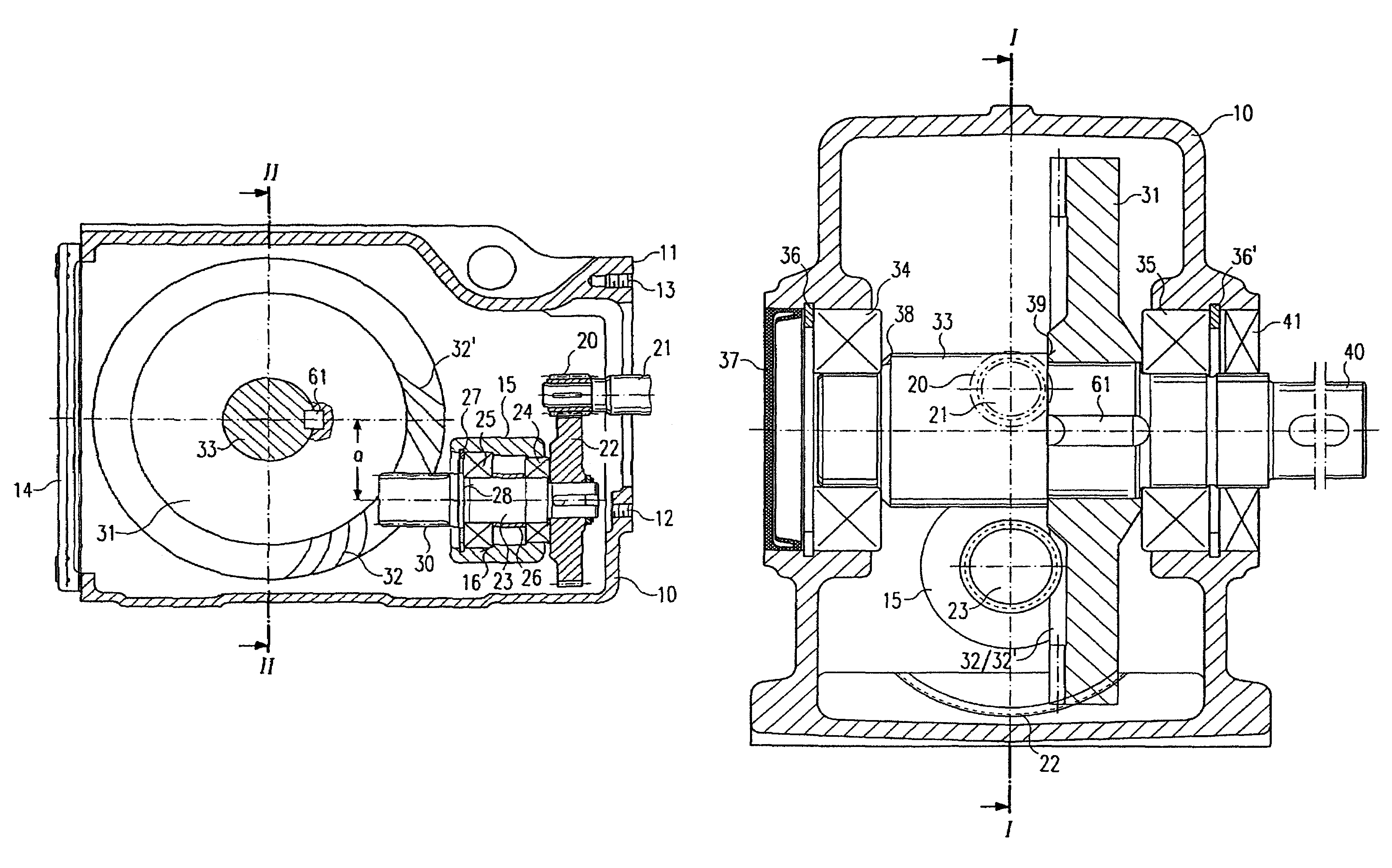

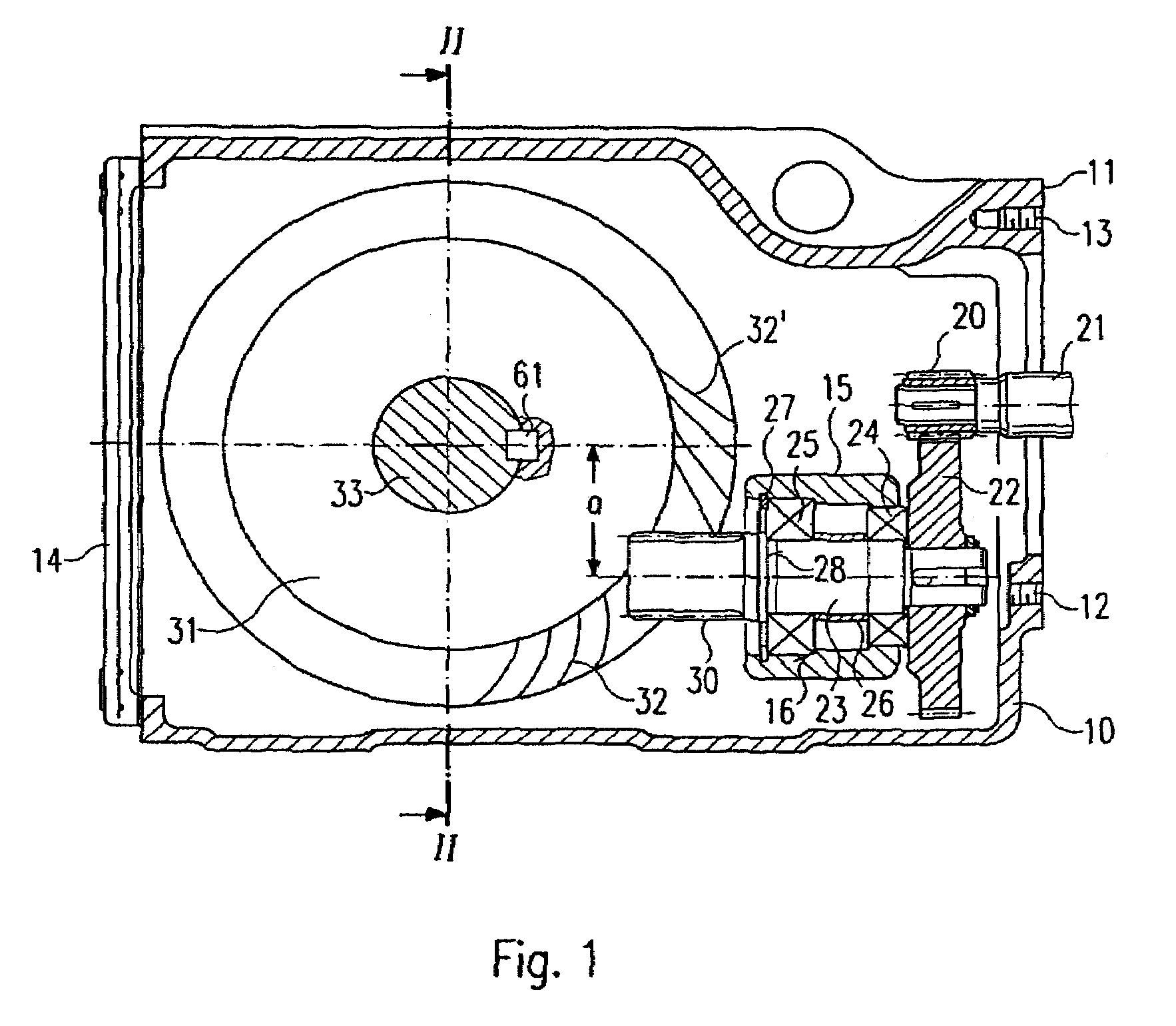

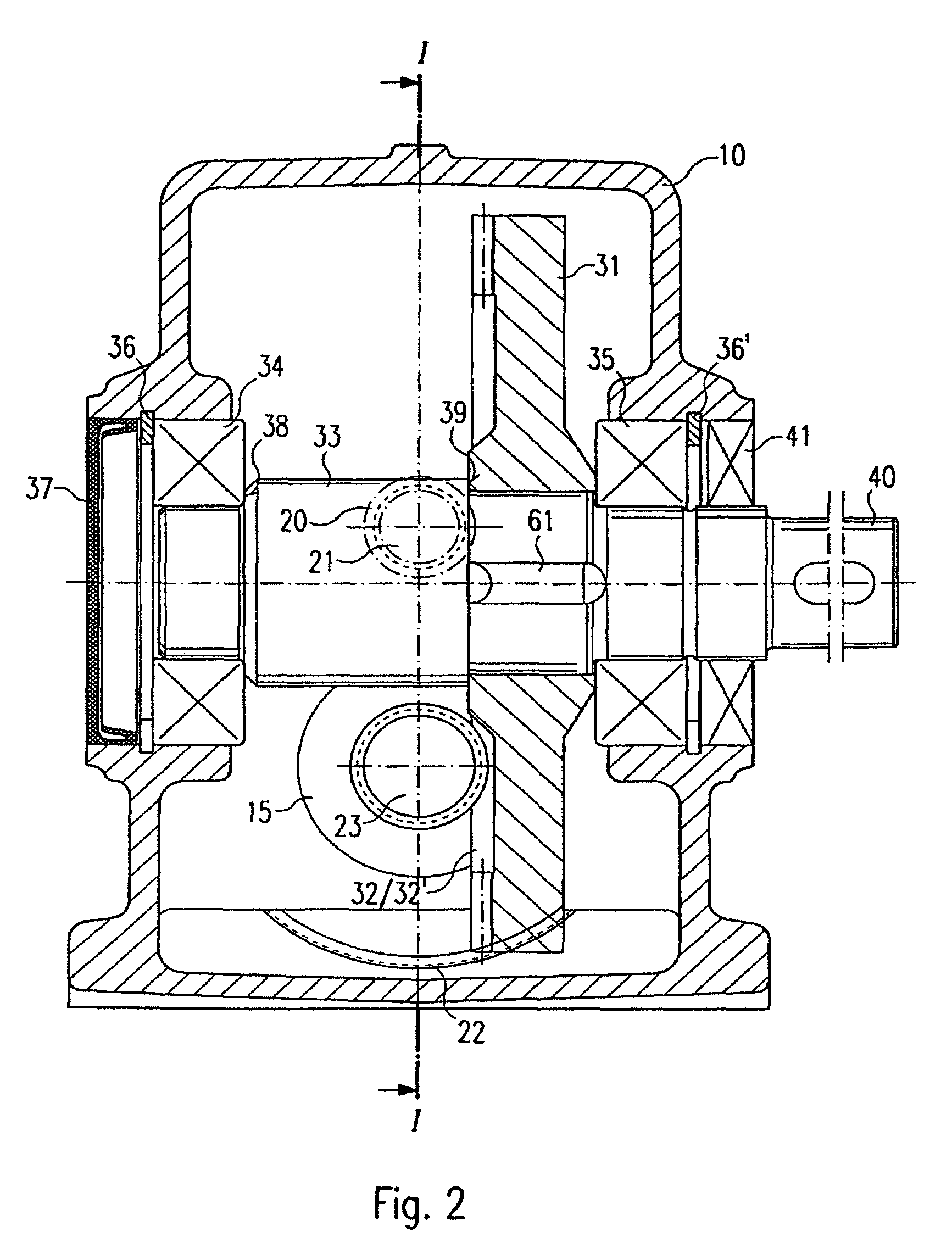

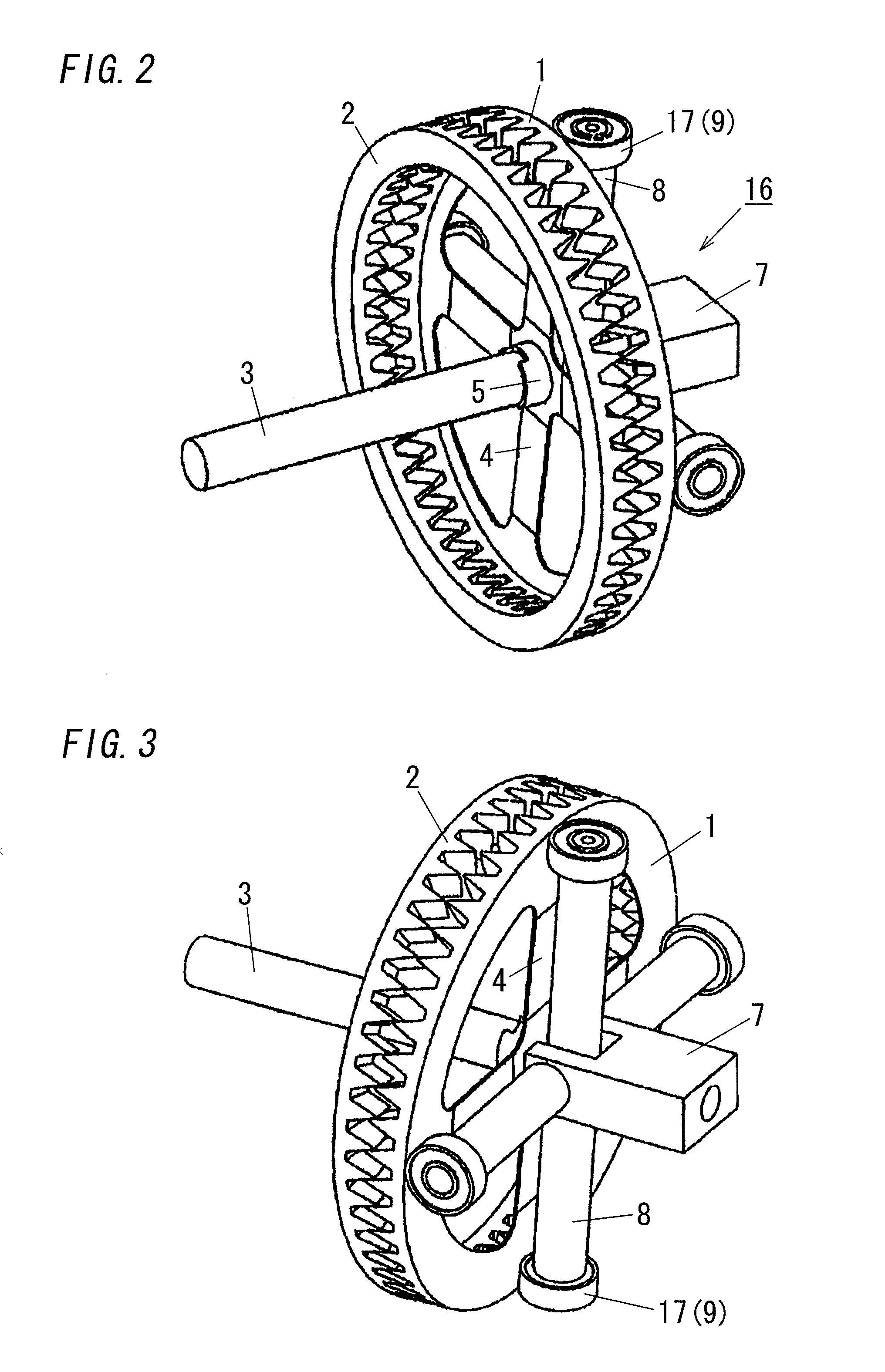

Modified crown reduction gear

ActiveUS8210070B2Reduce ratePrevent reboundToothed gearingsWobble plate gearingsGear wheelReduction ratio

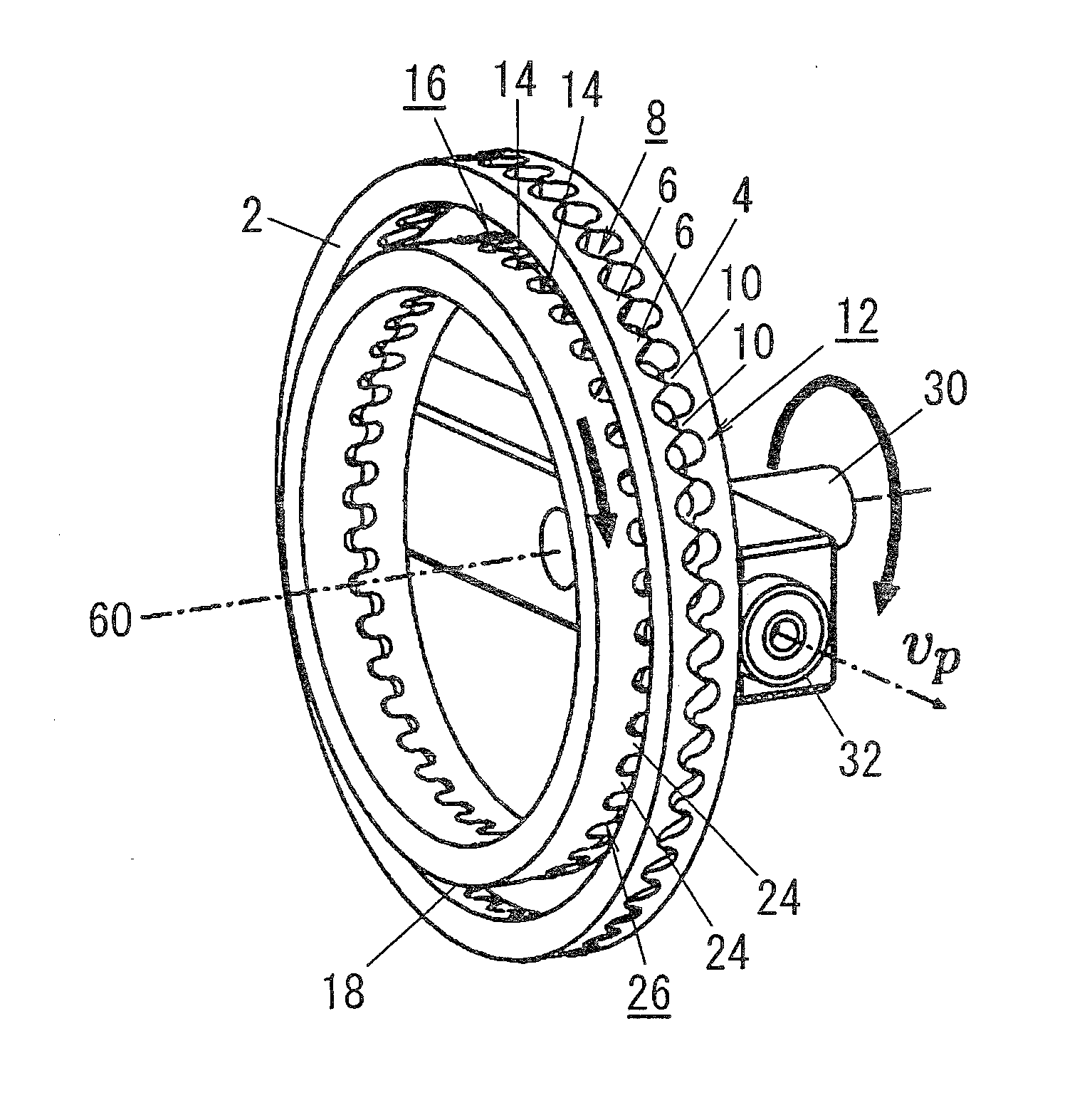

A reduction gear capable of satisfying, at high level, each of: realizing a high reduction ratio; preventing backlash by securing rotation smoothness; and carrying out compactification and weight saving of entire mechanism is provided. The reduction gear of the invention is a modified crown reduction gear, comprising: a pressing mechanism 16 operated to rotate; a fixed crown gear 2 fixed to an external member 15; a movable crown gear 1, wherein the difference in the number of teeth between the gears is one; and an output axis 3 flexibly attached to the gear 1. The gear 1 engages with the gear 2 at a slant by pressing-force provided from the mechanism 16. In this instance, contact locations of teeth of the gears 1 and 2 are dispersed at two places existing at both sides between which a gradient center line intervenes.

Owner:FUKUSHIMA UNIVERSITY

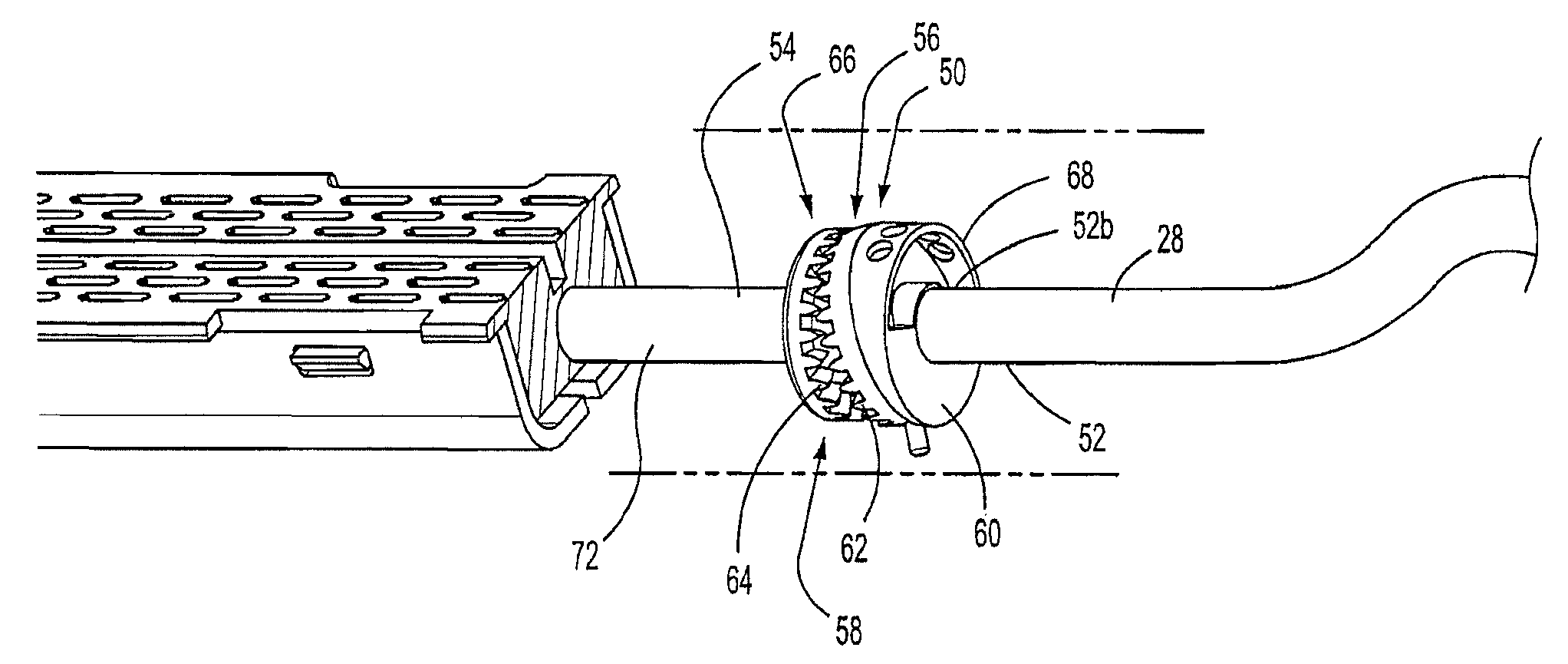

MEMS debrider drive train

A medical device such as for removing tissue from a subject is provided with a distal housing configured with a tissue cutter assembly, an elongate member coupled to the distal housing and having an outer tube and an inner drive tube with a crown gear located on a distal end thereof, first and second rotatable members each rotatably mounted to the tissue cutter assembly, a first drive gear train coupled between the crown gear and the first rotatable member, and a second drive gear train coupled between the crown gear and the second rotatable member. The first and second drive gear trains are configured to drive the first and second rotatable members, respectively, in opposite directions. Concave and convex gear tooth profiles are also disclosed for improved performance of the first and second drive gear trains.

Owner:MICROFAB

Fire extinguishing device for power distribution cabinet

ActiveCN111262139ADischarge in timeReduced service lifeFire rescueSubstation/switching arrangement casingsDrive wheelGear wheel

The invention belongs to the field of fire extinguishing equipment and relates to a fire extinguishing device for a power distribution cabinet. The cabinet comprises a cabinet body; a plurality of outer air holes which are uniformly distributed are formed in the side wall of the cabinet body; the inner side wall of the cabinet body is connected with an isolation plate in a sliding manner; a plurality of uniformly distributed inner air holes are formed in the isolation plate; the plurality of outer air holes are communicated with the plurality of inner air holes one by one; the inner top surface of the cabinet body is fixedly connected with a heat conduction box; a rotating shaft which is horizontally arranged is rotationally connected into the heat conduction box; a driving wheel and two driving gears are fixedly arranged on the rotating shaft in a sleeving mode; the two driving gears are arranged on the two sides of the driving wheel respectively; two vertically-arranged rotating rodsare arranged in the heat conduction box; and crown gears connected with the driving gears in an engaged mode are fixedly connected to the upper ends of the two rotating rods. When a fire occurs in the power distribution cabinet, an extrusion plate in a rotating box can continuously move up and down when the driving wheel rotates, so that a fire extinguishing solution in a lower cavity can be sprayed into the cabinet body to extinguish the fire.

Owner:山东华控自动化设备有限公司

Engine with stub shaft supported cam gear and machine using same

In one aspect, a machine includes an engine supported on a machine body. The engine includes a housing and a gear train that includes a crank gear meshed with a cam gear that is meshed with at least one powered gear. The cam gear is attached to a cam shaft by a drive coupler. The cam shaft is rotationally supported in the housing on a plurality of bearings, and the cam gear is rotationally supported on a stub shaft with an inner surface that is out of contact with the cam shaft. The stub shaft is attached to the housing of the engine.

Owner:CATERPILLAR INC

Transfer box with crown teeth

InactiveUS7713158B2Easy to assembleReduce the number of partsDifferential gearingsControl devicesControl theorySpur gear

A transfer box with a housing, an input shaft, a first output shaft extending coaxially relative to said input shaft, and a second output shaft extending parallel to said two shafts, as well as with a differential gear assembly arranged between said shafts, wherein the input shaft carries a cross member with a plurality of radial bearing arms for the differential gears, wherein a first side gear is connected in a rotationally fast way to the first output shaft and wherein a second side gear is rotatably supported on the input shaft and drives the second output shaft, wherein the differential gears are spur gears and the side gears crown gears and wherein the teeth of the differential gears engage the teeth of the side gears.

Owner:GKN DRIVELINE INT GMBH

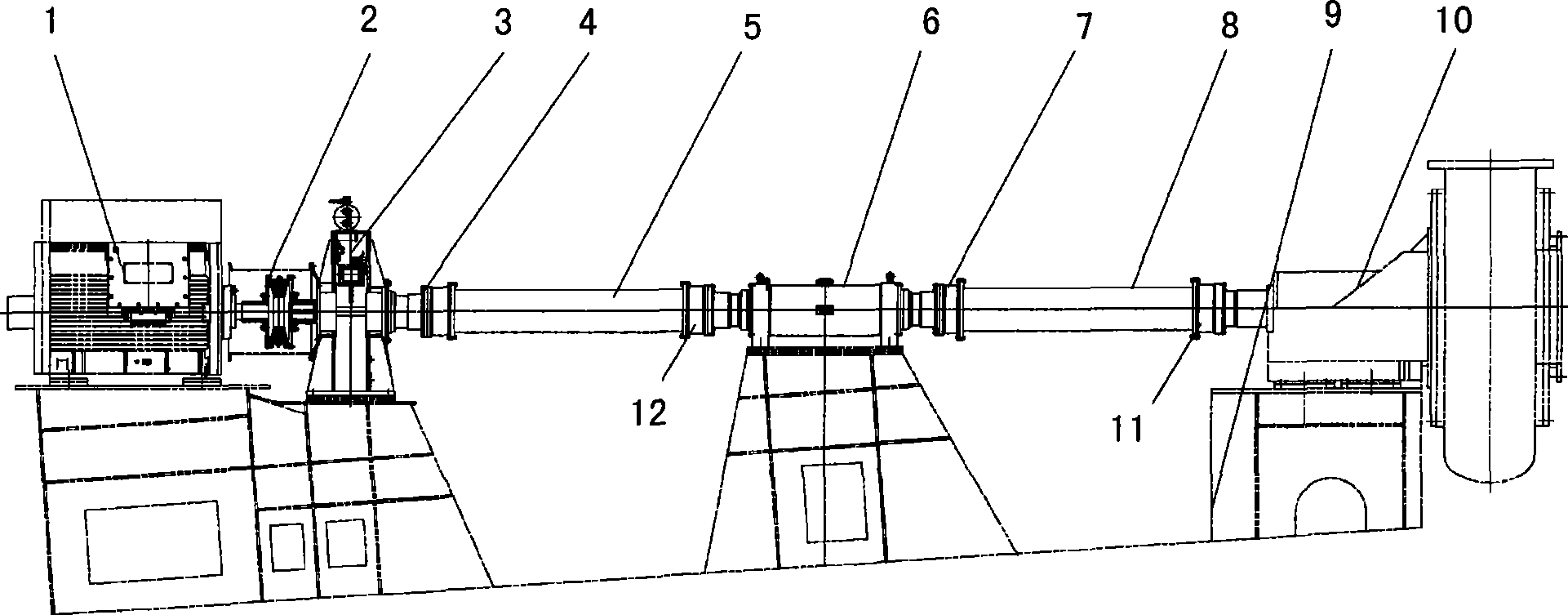

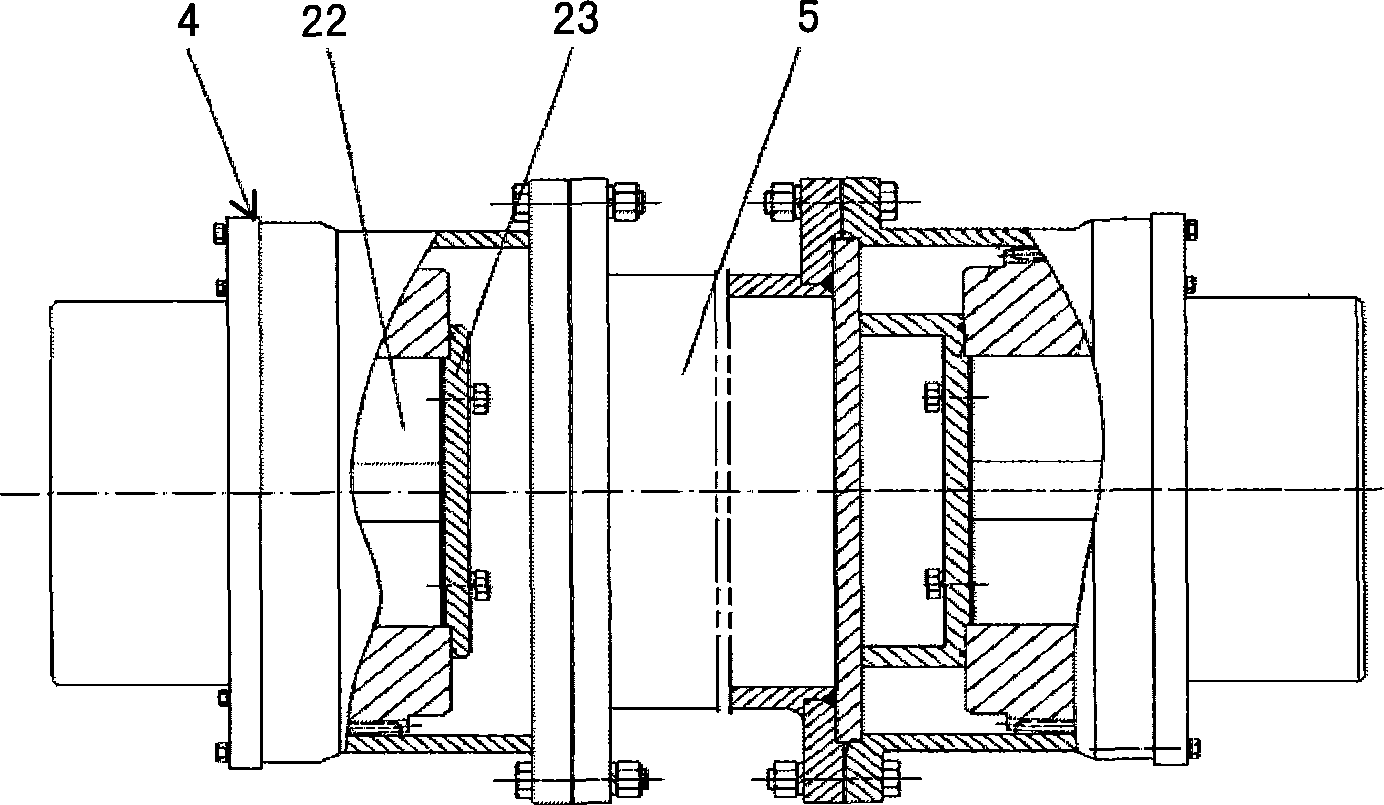

Long axis output and electric shaft driven mud pump transmission agent in water

ActiveCN101392541AAchieve long-distance power transmissionReduce alignment requirementsMechanical machines/dredgersUnderwaterDevice form

The invention provides a long-shaft output electrical shaft driven type underwater dredge pump transmission system, which is used for transmitting the power and rotating speed of a motor to an underwater dredge pump. The transmission system is characterized in that the transmission system comprises an underwater gearbox, at least two hollow shafts, an intermediate supporting device and a bridge frame; an input shaft of the underwater gearbox is connected with the motor through a high-elasticity coupling; at least two hollow shafts and at least one intermediate supporting device form a long shaft system; in the long shaft system, two ends of the intermediate supporting device are connected with the two hollow shafts through crown gear couplings respectively, and the two hollow shafts are positioned at two ends of the long shaft system respectively; an output shaft of the underwater gearbox is connected with one hollow shaft positioned at one end of the long shaft system through one crown gear coupling, and the other hollow shaft positioned at the other end of the long shaft system is connected with the underwater dredge pump through the other crown gear coupling; and the intermediate supporting device, the underwater gearbox, the motor and the underwater dredge pump are all supported by the bridge frame.

Owner:SHANGHAI QIYAO HEAVY IND CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com