Long-service-life multi-face self-lubricating antifriction plate and manufacture method thereof

A manufacturing method and technology of anti-friction plate, which are applied in the field of long-life multi-faceted self-lubricating anti-friction plate and its manufacturing field, can solve the problem of insufficiently improving the bonding performance of anti-friction material and steel substrate, and the metallographic structure of manganese steel plate Roughness, reduced service life of anti-friction plates, etc., to achieve the effect of scientific and innovative conception, high wear resistance and reduced force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] (2) Preparation of anti-friction layer dressing

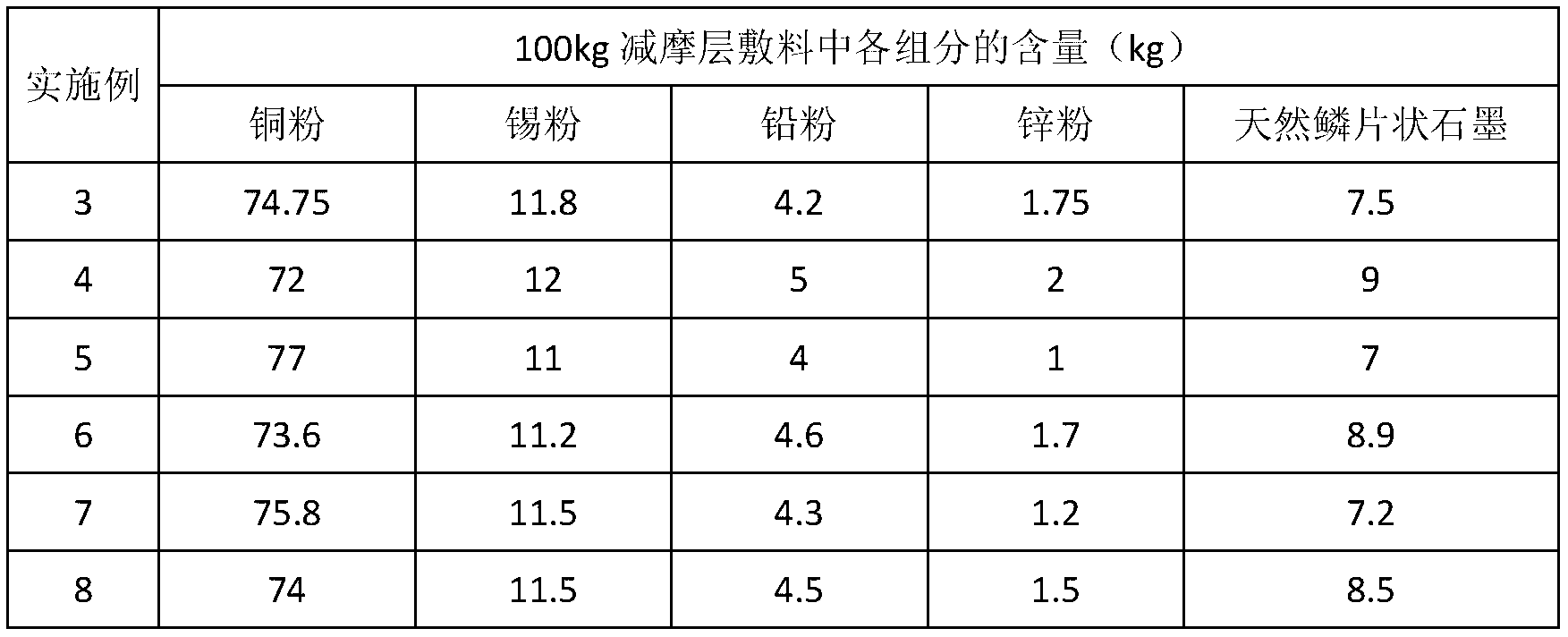

[0019] The mixture composed of copper powder, tin powder, lead powder, zinc powder, and natural flake graphite is fed into the mixing machine for full mixing. The percentages of each component to the total weight of the material are: copper powder 72% to 77%, tin powder 11%~12%, lead powder 4%~5%, zinc powder 1%~2%, natural flake graphite 7%~9%.

[0020] (3) Manufacturing method of anti-friction plate

[0021] 1) Apply anti-friction layer dressing (2) on the outer surface of the substrate (1), put it in the sintering furnace for high-temperature sintering for 20-30 minutes, at a sintering temperature of 800-900℃, use decomposed ammonia as a protective gas, and sinter it into a loose state Anti-friction plate;

[0022] 2) Roll the loose anti-friction plate into a dense plate shape by a double-roll blooming mill;

[0023] 3) Annealing treatment, the annealing temperature is 800~850℃;

[0024] 4) Send the annealed anti-friction plat...

Embodiment 1

[0027] The present invention is implemented according to the manufacturing method of the multi-faceted self-lubricating anti-friction plate.

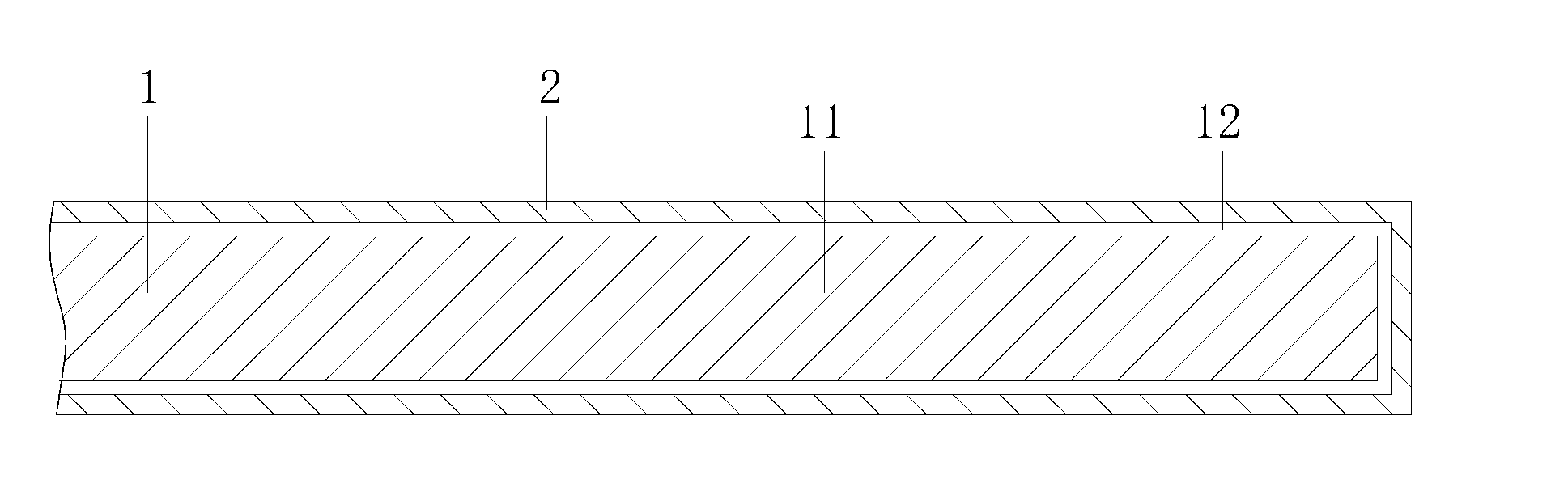

[0028] Among them, in the manufacturing method (1) of the substrate 1, the steel plate 11 is preferably Q235 steel, and the dense thickness of the copper alloy coating sprayed on the outer surface of the steel plate 11 is 0.1 mm.

[0029] According to the above-mentioned preparation method of anti-friction layer dressing, 75 kg of copper powder, 11 kg of tin powder, 5 kg of lead powder, 2 kg of zinc powder, and 7 kg of natural flake graphite are fed into the three-dimensional mixer, and mixed at room temperature for 3-6 Hours, prepare 100 kg of antifriction layer dressing.

[0030] During the processing of the anti-friction plate, the sintering temperature is set to 850°C, the sintering time is 30 minutes, the annealing temperature is 820°C, and the annealing time is 40 minutes.

Embodiment 2

[0032] The content of Example 2 is basically the same as that of Example 1, and the difference is that the dense thickness of the copper alloy coating sprayed on the outer surface of the steel plate 11 is 0.15 mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| friction coefficient | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com